Page 1

SERVICE CRANE

Mod.

5500

USE AND MAINTENANCE MANUAL

Code MD.0.176

Rev 0

Edition 07/09

Page 2

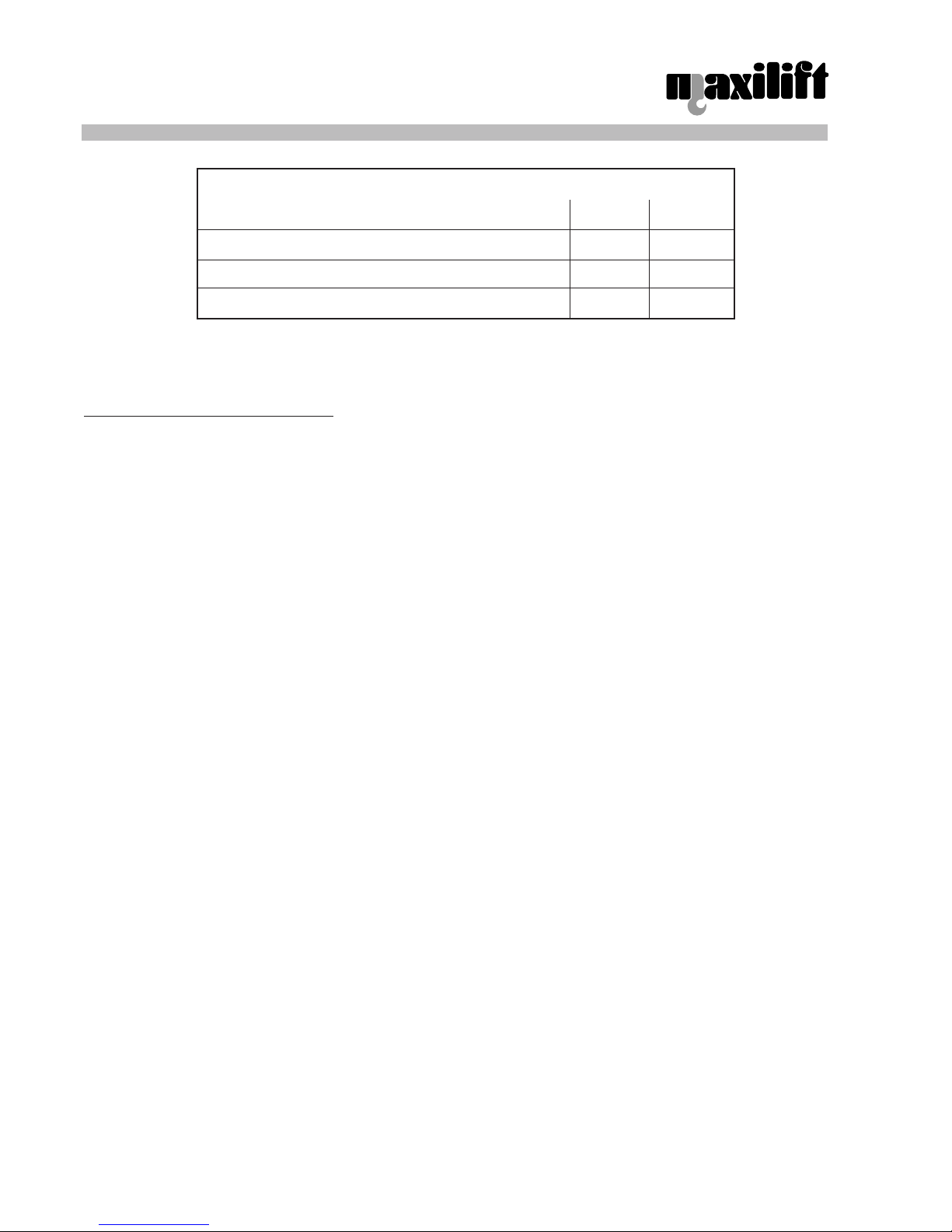

OPTIONALS SUPPLIED ALONG WITH THE CRANE

Description YES NO

Oil tank

Outrigger beam - (mechanical jack)

Outrigger beam - (hydraulic jack)

The table has to be filled carefully with the above option when purchased

PRELIMINARY INFORMATION

Operator’s and maintenance manual of MAXILIFT COBRA 5500 SERVICE CRANE

Manual code: MD.0.176

This manual is valid starting from serial no: .......

Manufacturer: NEXT HYDRAULICS S.r.l.

Via Mediterraneo 6, I 42022 BORETTO Reggio Emilia

In this booklet the word “Manufacturer” is referred to “NEXT HYDRAULICS S.r.l.”

List of documentation supplied along with the CRANE:

• Operator’s and maintenance manual (for the end user)

SERIAL NO:..............................................................

YEAR OF MANUFACTURING:.................................

ATTENTION

Always carefully read this manual before operating the crane. Most of the accidents occurred during operations are caused by the omission of elementary precautions and non fulfillment of the safety instructions.

Many accidents can be avoided when their causes are well known and the relevant adequate counter measures are previously taken.

Page 3

INDEX

1 FOREWORD ..................................................................................................PAGE 1

1.1 Summary ........................................................................................................................................................ “ 1

1.2 Remarks ......................................................................................................................................................... “ 1

1.3 Manual revision............................................................................................................................................... “ 2

2 HOW TO CONSULT THE MANUAL ...................................................................... “ 2

2.1 Instructions ..................................................................................................................................................... “ 2

3 CRANE IDENTIFICATION ..................................................................................... “ 3

3.1 Versions and optional available ..................................................................................................................... “ 3

3.2 Crane identification data ................................................................................................................................ “ 3

4 CRANE USAGE AND LIMITS OF APPLICATIONS................................................ “ 4

4.1 Crane classification and proper usage ......................................................................................................... “ 4

4.2 Improper usage .............................................................................................................................................. “ 4

4.3 Crane operator’s training ............................................................................................................................... “ 4

5 SAFETY RULES ................................................................................................... “ 6

5.1 Rules concerning people ............................................................................................................................... “ 6

5.2 Rules concerning the crane ........................................................................................................................... “ 6

5.3 Rules for the correct positioning of the crane ................................................................................................ “ 7

5.3.1 Choice of the crane operating place pressure on the ground ....................................................................... “ 7

5.3.2 Safety distance from trenches and slopes .................................................................................................... “ 7

5.3.3 Safety distance from electrical power lines ................................................................................................... “ 8

5.3.4 Crane and load ground connection ............................................................................................................... “ 8

5.3.5 Influence of the wind on the crane operation ................................................................................................. “ 10

5.4 Rules concerning safety in the traffic ............................................................................................................. “ 10

5.5 General rules on winch operations ................................................................................................................ “ 11

5.5.1 Winch system operation ................................................................................................................................. “ 11

5.5.2 Operator safety tips......................................................................................................................................... “ 11

5.5.3 General rules when operating winch ............................................................................................................. “ 11

5.6 WIRE ROPE .................................................................................................................................................... “ 12

5.6.1 General ........................................................................................................................................................... “ 12

5.6.2 Wire rope precautions .................................................................................................................................... “ 12

6 DESCRIPTION OF THE CRANE .......................................................................... “ 13

6.1 Model: 5500 H ................................................................................................................................................. “ 13

6.2 Model: 5500 E - 12/24 ..................................................................................................................................... “ 14

6.3 Safety devices ................................................................................................................................................. “ 15

6.3.1 Safety devices installed .................................................................................................................................. “ 15

6.3.2 Load limiting device ........................................................................................................................................ “ 15

6.3.3 Relief valve ...................................................................................................................................................... “ 16

6.3.4 Pilot operated holding valves ......................................................................................................................... “ 16

6.3.5 Safety devices’sealing .................................................................................................................................... “ 16

6.4 Microprocessor remote control system ......................................................................................................... “ 1 7

6.4.1 Available control version ................................................................................................................................. “ 17

6.4.2 Electronic power unit ...................................................................................................................................... “ 17

6.4.3 The radio receiver unit .................................................................................................................................... “ 18

6.4.4 The cable keyboard ........................................................................................................................................ “ 18

6.4.5 The keyboard radio trasmitter ........................................................................................................................ “ 19

6.4.5.1 Radio system protection device ..................................................................................................................... “ 20

6.4.6 Proportional mono-function regulation hydraulic unit .................................................................................... “ 20

6.4.7 Proportional dual-mode regulation hydraulic unit ......................................................................................... “ 21

6.4.8 Wiring .............................................................................................................................................................. “ 21

I

Page 4

II

6.5 Remote control use ................................................................................................................................ Page 22

6.5.1 Use of the mono-function proportional remote control .................................................................................. “ 22

6.5.2 Use of the dual-mode proportional remote control ....................................................................................... “ 22

6.6 Signal and diagnostic ..................................................................................................................................... “ 23

6.6.1 Keyboard diagnostic signal ............................................................................................................................ “ 23

6.6.2 Display messages ......................................................................................................................................... “ 24

6.6.3 Normal display menu ..................................................................................................................................... “ 24

6.6.4 Micro-switches and pressure switch display menu ...................................................................................... “ 26

6.6.5 Current display menu ..................................................................................................................................... “ 26

6.6.6 Remote control keyboard display menu ........................................................................................................ “ 27

6.6.7 Work pressure display menu ......................................................................................................................... “ 28

7 OPERATING INSTRUCTIONS .........................................................................PAGE 29

7.1 General attentions .......................................................................................................................................... “ 29

7.2 Stabilizing the truck ......................................................................................................................................... “ 3 0

7.3 Opening the crane .......................................................................................................................................... “ 32

7.4 Closing the crane ........................................................................................................................................... “ 32

7.5 Winch system operation ................................................................................................................................. “ 32

7.6 Before starting traveling on road .................................................................................................................... “ 3 2

7.7 Main errors occurring when operating the crane ........................................................................................... “ 32

7.8 Standard hand signals ................................................................................................................................... “ 33

8 PUTTING THE CRANE INTO SERVICE ................................................................ “ 34

8.1 Ten rules for the perfect crane operator ......................................................................................................... “ 34

8.2 Daily check list ................................................................................................................................................ “ 3 4

8.3 Safety tips for crane starting in cold climates ................................................................................................ “ 34

8.4 Crane protection and storage ........................................................................................................................ “ 34

8.4.1 Short shutdowns ............................................................................................................................................ “ 34

8.4.2 Long shutdowns ............................................................................................................................................. “ 35

9 MAINTENANCE .................................................................................................... “ 36

9.1 Warnings ........................................................................................................................................................ “ 36

9.2 Maintenance prescriptions ............................................................................................................................. “ 36

9.3 Maintenance schedule ................................................................................................................................... “ 3 7

9.3.1 Daily checking ................................................................................................................................................. “ 3 7

9.3.2 Monthly checking ............................................................................................................................................ “ 3 8

9.3.3 Checking every six months ............................................................................................................................. “ 3 8

9.3.4 Others ............................................................................................................................................................. “ 38

9.4 Crane servicing ............................................................................................................................................... “ 39

9.4.1 Oil level checking ............................................................................................................................................ “ 39

9.4.2 Oil change ....................................................................................................................................................... “ 3 9

9.4.3 Oil filter replacement ...................................................................................................................................... “ 39

9.4.4 Wormgear assembly control .......................................................................................................................... “ 4 0

9.4.5 Greasing the hydraulic boom sections .......................................................................................................... “ 40

9.4.6 Wear pads check and replacement ............................................................................................................... “ 40

9.5 Greases and oils reference table .................................................................................................................. “ 41

9.6 Wire rope ........................................................................................................................................................ “ 42

9.6.1 Wire rope inspection ...................................................................................................................................... “ 4 2

9.6.2 Rope replacement .......................................................................................................................................... “ 42

9.6.3 Wire rope lubrication ...................................................................................................................................... “ 4 3

9.7 Possible faults and relevant remedies .......................................................................................................... “ 44

10 TECHNICAL DATA ............................................................................................... “ 46

11 WIRING AND HYDRAULIC DIAGRAMS ................................................................ “ 48

11.1 Electrical diagram ........................................................................................................................................... “ 48

11.2 Hydraulic diagrams ........................................................................................................................................ “ 50

11.2.1 Hydraulic diagram mono-function proportional ............................................................................................. “ 50

11.2.2 Hydraulic diagram dual-mode proportional ................................................................................................... “ 5 1

Page 5

1

1 FOREWORD

1.1 SUMMARY

This manual is divided into chapters to make its consultation easier.

Chapter 1: Includes summary and a short introduction.

Chapter 2: Explains how to consult the manual.

Chapter 3: Crane identification data.

Chapter 4: Limits of crane operation and usage.

Chapter 5: Safety rules.

Chapter 6: Description of the crane, safety devices and controls.

Chapter 7: Description of operation and usage tips.

Chapter 8: Crane starting up and storage.

Chapter 9: Essential crane maintenance instructions. Additional instructions can be included in the

truck maintenance manual.

Chapter 10: Includes the crane technical data, load charts and diagrams, list of main characteristics.

Chapter 11: Wiring and hydraulic diagrams

1.2 REMARKS

Many thanks for the preference kindly given to our product. Please remember that the servicing instructions

and the load charts hereby reported and applied on the crane are an essential part of the crane supply itself.

They are mainly intended for the crane operator and include all necessary information on the admittable and

permissible field of usage for a safe operation. Anyway, these instructions are not a training manual for

beginners or unskilled operators, it must be stressed that as a fundamental presupposition only skilled and

professional crane operators are allowed to work with the crane.

The crane operator is directly responsible for the state of the crane and for every crane operation. When the

training is hurried and full of gaps, this is the origin of many accidents. This manual gives the guidelines for

a correct, safe usage of the crane and its rational maintenance. When daily and constantly applied, these

guidelines ensure long service life with minimum maintenance costs, high performance of the crane and

good commercial value after years. Moreover, most of the frequent accidents during operation and servicing

are avoided. Once this manual has been read carefully, keep it in good conditions and quickly available

close to the crane.

If a technical assistance is required please apply to the nearest authorized installer.

ATTENTION

As far as safety is concerned it is strongly recommended to carefully read the safety tips of the

chapter, SAFETY RULES.

ATTENTION

Should some or any part of this manual be not clear, please contact the Manufacturer.

IMPORTANT

When receiving this manual, check if all the data are correct. Inform the Manufacturer if something is found wrong.

Page 6

2

NOTE

The table on the back of the front page has to be filled at customer’s care. It contains all the necessary data required when calling our Technical Service.

A copy of this manual is supplied along with every crane. Data, descriptions and pictures of this manual are

not binding. The Manufacturer reserves the right to change at any time all the items, components and parts

deemed to be necessary for product improvement or commercial or production needs. This right is kept

without obligeance of quick updating of this manual. Fundamental data, performances and characteristics

of the product will be maintained.

1.3 MANUAL REVISION

Should be necessary to carry some modification on the crane, they must be authorized by the Manufacturer

which also takes the commitment of manual updating. Revised or added pages will be mailed to the Customer and shall be inserted in the manual at his care and cost.

2 HOW TO CONSULT THE MANUAL

2.1 INSTRUCTIONS

Always carefully read this manual before operating the crane. In this manual the following symbols are used:

DANGER

Referred to dangers related to the described activity, when the safety of people is concerned.

ATTENTION

Referred to dangers related to the described activity, mainly when the safety of things is concerned (for instance, damage of the load or of the crane).

IMPORTANT

Referred to information or integration on crane operation.

NOTE

Used to draw your attention on information or suggestions to make easier the crane usage for

the operator.

The symbols and marks are completed with notices stating the dangers, their nature, the avoidance actions

to be taken and tips to be followed.

DANGER

In this manual the crane is shown in many pictures with its panels or covers removed for a better evidence.

It is forbidden to use and operate the crane with panels, covers and other safety devices removed.

!

!

Page 7

3

3 CRANE IDENTIFICATION

3.1 VERSIONS AND OPTIONS AVAILABLE

The service instructions written on this manual are referred to the CRANE MAXILIFT COBRA 5500. This

model is supplied in 8 versions. When ordering, one or more of the following versions are to be specified:

Version Remote control Hydraulic supply Power supply

5500 KP - H Cable - Proportional mono-function Fed by a punp, driven by a P.T.O. truck 12 - 24V

5500 KP - E Cable - Proportional mono-function Fed by a DC electro-hydr. power pack 12 - 24V

5500 KPD - H Cable - Proportional dual-mode Fed by a punp, driven by a P.T.O. truck 12 - 24V

5500 KPD - E Cable - Proportional dual-mode Fed by a DC electro-hydr. power pack 12 - 24V

5500 RKP - H Radio - Proportional mono-function Fed by a punp, driven by a P.T.O. truck 12 - 24V

5500 RKP - E Radio - Proportional mono-function Fed by a DC electro-hydr. power pack 12 - 24V

5500 RKPD - H Radio - Proportional dual-mode Fed by a punp, driven by a P.T.O. truck 12 - 24V

5500 RKPD - E Radio - Proportional dual-mode Fed by a DC electro-hydr. power pack 12 - 24V

The following options are available for the above versions:

Type of optional Available on models

Oil tank (only for H version)

Outrigger beam - (mechanical Jack) All

Outrigger beam - (hydraulic jach) All

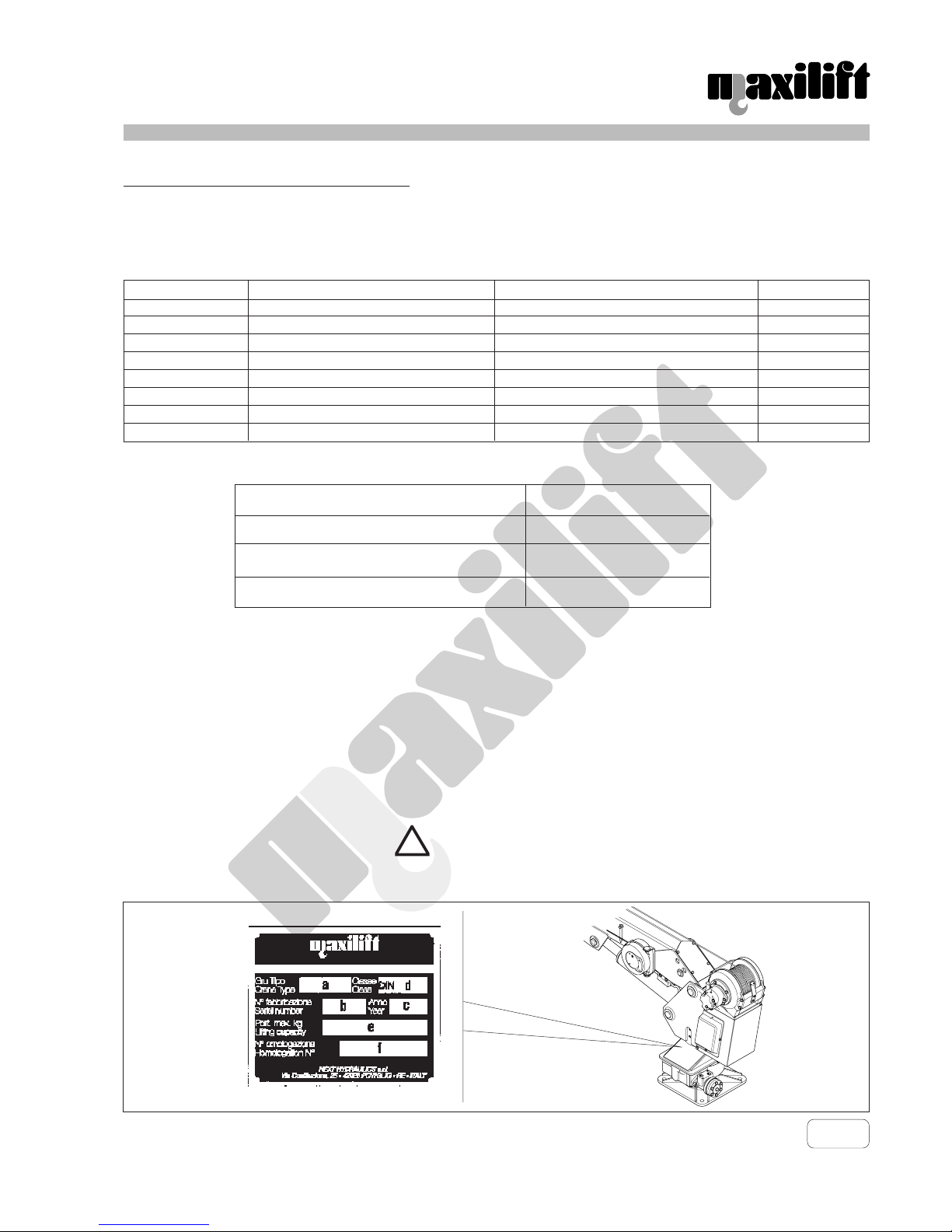

3.2 CRANE IDENTIFICATION DATA

Every crane is identified by its serial number and name of the model written on the plate riveted on the crane.

Data plate description

a) Crane model

b) Serial number

c) Year of manufacturing

d) Lifting class

e) max SWL

f) Approval number

ATTENTION

It is strictly forbidden to change, erase, modify the data written on the plate.

Pict. 1

Page 8

4

4 CRANE USAGE AND LIMITS OF APPLICATIONS

4.1 CRANE CLASSIFICATION AND PROPER USAGE

The machine is an hydraulic truck crane for hook service. It can also be used for the same purpose from a

static mounting. The lifting capacity is 3,5 ton-meter (25,000 ft. lbs.), making it especially suitable for installation on light truck.

The crane is classified in class H2-B3 according to DIN 15018 standards, and must be used accordingly,

that is: trucks loading/unloading, hook service.

4.2 IMPROPER USAGE

It is forbidden:

• To use the crane in different operations from those it has been designed and built for. (see above

point 4.1).

• To use the crane with attachment like: grabs, clamshells, magnets and so on.

• Pulling loads with crane in horizontal position.

• To operate the crane with procedures different from those described in this manual, or using componen

ts and attachments not approved when the crane was designed.

• Non observance of the established maintenance programs.

• Non observance of safety rules.

• To make modifications involving crane components or parameters related to the working cycle.

• The unauthorized use of captive spare parts and components not specifically approved by the Manufac

turer.

• To carry out modifications or structural interventions without the approval of the Manufacturer.

• To operate the crane out of the admittable range of temperatures: -30° C/ +50° C (-22 °F/ + 122 °F).

Any of the above mentioned improper usages or non observance will cause:

• immediate cancellation of the Manufacturer Warranty

• cancellation of Manufacturer liability for damage of people, animals, things.

ATTENTION

The improper usage can damage the crane and subsequently result in dangerous situations for

the staff entitled to its operation.

4.3 CRANE OPERATOR’S TRAINING

The crane must be operated only by skilled people trained for this purpose.

This people will be asked for:

• a basic technical education and a working experience in the mechanical, hydraulic and electrical field;

• a technical knowledge of cranes operation, covering all the points, especially the load charts and the

truck stability against tipping over;

• practical knowledge of slings usage and precautions when moving the loads;

• complete knowledge of all the operations and motions to be executed with the crane; competent and

qualified personnel of the authorized workshop which has installed the crane will take care of

this;

• complete reading and understanding of this manual;

• complete knowledge and understanding of safety and risk avoidance regulations;

• Vision of at least 20/30 Snellen in one eye and 20/50 in the other, with or without the aid of corrective

lenses;

Page 9

5

• normal depth perception and field of vision (peripheral);

• ability to distinguish colors if color recognition or differentiation is, required for safe operation;

• adequate hearing, with or without a hearing aid;

• sufficient strength, endurance, agility and coordination to meet equipment operation demands;

• emotionally stable;

• not subject to seizures, loss of physical control, dizziness or have physical limitations which could impair

the ability to safety operate the crane.

Page 10

6

5 SAFETY RULES

5.1 RULES CONCERNING PEOPLE

• Always wear the prescribed personal safety devices

• Always wear approved accident-prevention clothing such as: protective helmets, anti-slip shoes, protec

tive gloves, antinoise headphones, protective glasses, reflective jackets with breathing apparatus. Con

sult your employer regarding current safety regulations and accident-prevention equipment.

• Do not wear ring, wristwatches, jewelry, loose-fitting or hanging clothing such as ties, torn garments,

scarves, unbuttoned ja-ckets or unzipped overalls, which could get caught up in the moving parts of the

crane.

• Keep quickly and readily available on the truck a first-aid box and a fire extinguisher. The fire extin

guisher must always be kept charged and has to be used according to current regulations.

5.2 RULES CONCERNING THE CRANE

• The Manufacturer is not liable for accidents occurred during the usage of the crane caused by non

fulfillment from the opera tor’s side of current rules, laws and regulations.

• The crane is designed to be used within the -30°/+50° (-22 °F/ +122 °F) temperature range and has to be

operated only in this range. The manufacturer is not liable for accidents occurred during the usage of

the crane outside this temperature range.

• Carefully read the Operator’s and maintenance manual before starting up, using, servicing or doing any

thing on the crane.

• Read and follow all the safety instruction plates applied on the crane before starting up, using, servicing

or doing anything on the crane.

• Do not use controls and hoses as handholds: these parts move and cannot provide stable support.

Furthermore, a control mistakenly moving can accidentally set the crane in motion.

• The operator’s control desk must always be kept clean from oil, grease, mud, snow to avoid accidents

due to slippery surface.

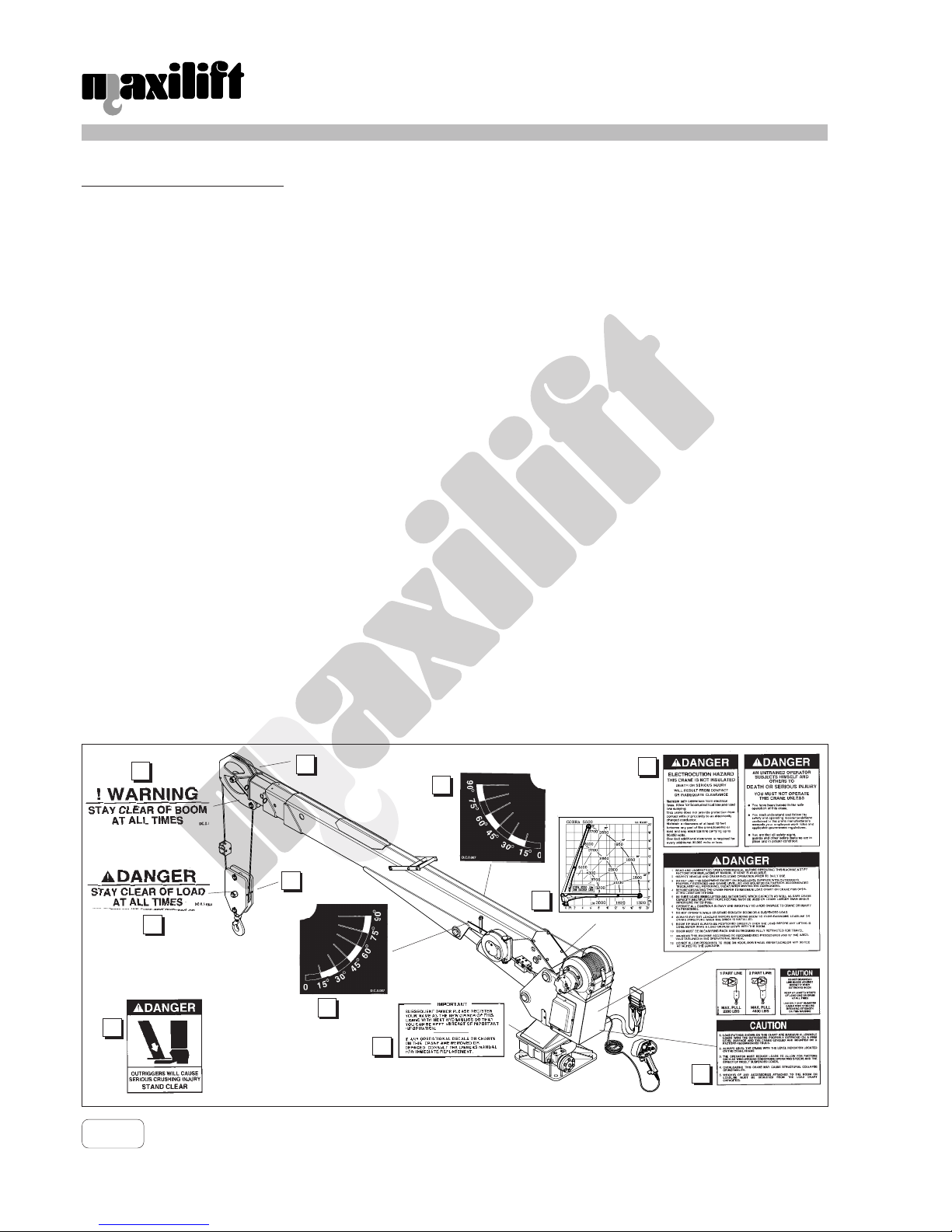

• The safety instruction plates, notices, load charts and any other sticker applied on The crane must be

kept readable and in good conditions. If necessary, replace them. The position of these plates is shown

in the following picture.

1R

1L

5

2

3

4

8

7

6

6

7

2

Pict. 2

Page 11

7

5.3 RULES FOR THE CORRECT POSITIONING OF THE CRANE

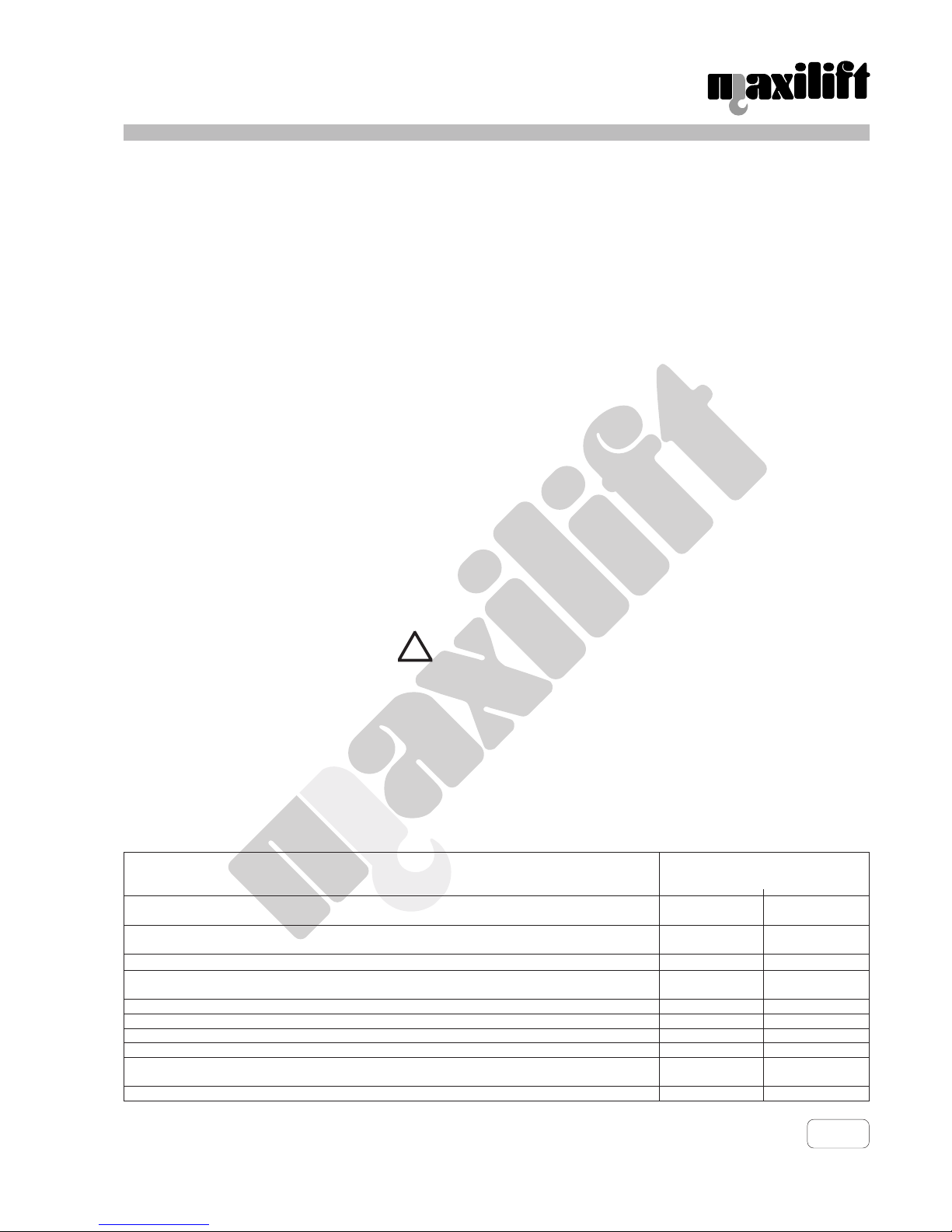

5.3.1Choice of crane operating place pressure on the ground

• Carefully choose the place where lowering and put into action the stabilizers of the crane outriggers.

The most important thing is the capacity of the ground to bear the pressure produced by the outriggers.

• Make sure that the outriggers working area is free from underground piping, tunnels, holes.

• The positioning must be carried out so as to operate the crane with the shortest outreach possible and

without any obstacle in the working area.

• Never move the crane from its rest position without stabilizing the truck.

• The outriggers reaction is transmitted to the ground by steel pads. When this pressure exceed the

maximum admittable pressure value of the ground, the surface of their bearing area must be increased

by means of additional plates of firm material (i.e. wooden plates). The outriggers pads must work in the

middle of the additional plates. The required bearing surface can be easily calculated as follows

when the outrigger’s reaction and the admittable pressure on the ground are known. Outrigger’s

reaction: look at the plate applied on the outrigger jack. Admittable pressure on various types of soils:

look at the following table for indicative values.

Bearing pressure calculation

When: Then:

t = outrigger’s reaction (tons) (US ton) p = bearing pressure on ground (daN/cm2) (lbs./Sq.in.)

A = bearing plate surface (cm2) (sq. in.)

p = (1000 • t) : A (metric)

p = (2000 • t) : A (U.S.A.)

ATTENTION

In case of doubts on the ground carrying capacity, make a hardness test of the ground.

Always level the crane acting on outriggers with reference to the level indicator fitted on the truck. Maximum

admittable angle is 3°.

5.3.2Safety distance from trencher and slopes

The crane must be positioned sufficiently far away from trenches or slopes. The safety distance depends

also on the soil, if the slopes or trenches are not sustained. Rule of the thumb: (look at the following picture)

SOIL ADMITTABLE PRESSURE

(daN/cm

2

) (lbs./sq.in.)

Dumped, non compacted soi 0.0/1.0 0,0/14

natural, virgin soil:

-mud, marshland, peat 0.0 0,0

incoherent artificially compacted soils:

-fine and medium size sand 1.5 21

-large size sand, gravel 2.0 28

natural coherent terrain:

-doughy 0.0 0,0

-soft. 0.4 6

-stiff 1.0 14

-demi-solid 2.0 28

-solid 4.0 56

rock, not altered by athmospheric agents, well stratified and slightly cracked:

-closed stratified 15.0 213

-solid stratified, pillar-like 30.0 426

Page 12

8

Pict. 3

!

• for brought-back or crumbling terrain safety distance (a) must be double of the slopes’ depth that is:

a = 2 • b

• for compacted, not crumbling terrain safety distance (a) must be equal to the slopes’ depth, that is:

a = 1 • b

Distance to be measured from point ©

Max. reaction on the ground varies according to the vehicle where the crane is installed.

IMPORTANT

The installer must calculate this max. reaction on the ground and applied the value on the outrigger jacks.

5.3.3Safety distance from electrical power lines

Always keep a sufficient safety distance when you cannot avoid having electric power lines in the working

area of the crane. Special care must be taken when the power lines have not been disconnected by experienced people, or when the lines status is unknown.

Voltage (V) minimum distance

(m) (ft)

up to 1000 v 1 4

from 1 kV to 110 kV 3 10

from 110 kV to 220 kV 4 13

from 220 kV to 380 kV 5 16

DANGER

Always keep a sufficient safety distance from electric power lines. Follow present law regulations. When the voltage of the lines is unknown keep a minimum safety distance of at least

5m (20 ft.)

5.3.4Crane and load ground connection

The crane can be electrostatically charged, especially when the additional bearing plates are made of insulating materials (wood, plastics) It has to be noted that, even when the crane has been connected to ground,

the load can be loaded electrostatically charged, because the rope pulleys or the slings and ropes used to

lift the load are made of insulating materials.

DANGER

Always connect to ground both the crane and its load before starting operations

!

Page 13

9

Grounding is especially required when:

• working close to electric power lines;

• working nearby powerful broadcasting plants such as radio, T.V., an so on

• working nearby electricity plants where high frequency is involved

• when a storm is approaching

Crane ground connection

DANGER

electrocution hazard

While grounding the crane, carefully follow the below mentioned instructions, in order to avoid

electrocution hazard

In order to avoid electrocution hazard the following tips must be followed:

• drive a metal rod, roughly 1.5 meter long, (5 ft.) in the ground, at least 1 meter (4 ft.) deep

• connect a power cable of minimum 16 mm2 (0,025 sq. in.) cross section to the former rod. This linkage

must be made with a hose clamp or a vice.

• moisten the ground all around the rod to improve conductivity.

NOTE

Arrange the linkage for ground connection and the relevant symbol

• connect the remaining end of the cable with the point of connection indicated en on the crane base.

DANGER

electrocution hazard

The ground cable must be connected only on the indicated point on the crane base. Avoid any

linkage to screwed on parts of the crane, such as valves, cover plates, gearboxes, etc.

DANGER

electrocution hazard

Always ground the crane perfectly.

Load ground connection

In order to avoid the electrostatic charging of the load it is necessary to use:

• a metal rod having a good conductivity, with a length of 1.5 meters (5 ft.) roughly, to be driven into the

ground, at least 1 meter (4 ft.) deep.

• a power cable with a minimum cross section of 16 mm2 (0,025 sq. in.).

• a second metal rod, having good conductivity and an insulating handle complying to the relevant safety

Regulations. This rod has to be used to touch the load.

• Then connect this cable to the ground rod on one side. Moinsten the ground all around the rod to

improve conductivity.

• Then connect the other side of the cable to the insulated rod. Both connections must be made using the

relevant vices or metal clamps as an alternative.

!

!

!

Page 14

10

!

!

DANGER

electrocution hazard

Always connect in a perfect way the load and the ground

Before touching the load with your hands, always ground the load by touching it with the insulated rod.

DANGER

electrocution hazard

Always hold the rod by its insulated handle.

5.3.5 Influence of the wind on the crane operation

A strong wind can overload the crane, so during operations keep under control the wind speed. When

working with full load, the maximum admittable wind speed is 45 km/h (28 mile/h).

When this value is exceeded, any crane operation must be stopped and the crane must be brought to the

rest position. Since the maximum working height of the crane is reasonable, refer to the following table to

evaluate the possible wind effect:

Force of the wind wind speed wind effects

Beaufort Denom. m/sec(ft./sec.) km/h (mile/h)

0 calm 0 - 0.2 0-0.65 1 0.6 calm,the smoke goes straight upwards

1 light 0.3 - 1.5 1-5 1-5 0.6-3 wind direction can only be seen looking at the

smoke. Wind indicators are idle

2 light 1.6 - 3.3 5-11 6-11 3-7 leaves are moving,the wind can be on the face.

3 light 3.4 - 5.4 11-18 12-19 7-12 leaves and small brances are moving breeze

4 slow 5.5 - 7.9 18-26 20-28 12-17 dust and paper sheets are lifted up, breeze

slender, rods are moved

5 strong 8 - 10.7 26-35 29-38 17-24 small waves on water surfaces breeze

6 strong 10.8 - 13.8 35-45 39-49 24-30 rods are bent,it is difficult to use wind umbrella

7 tight 13.9 - 17.1 45-56 50-61 30-38 the trees are moved it is difficult to wind walk

against wind

8 stormy 17.2 - 20.7 56-68 62 - 74 38-46 trees’branches break.it is very difficult to walk in

open areas

9 tempest 20.8 - 24.4 68-80 75 - 88 46-55 small damages to buidings (roofing tiles wind fall

down)

10 violent 24.5 - 28.4 80-93 89 - 102 55-63 big damages to the buildings, trees uprooted

tempest

5.4 RULES CONCERNING SAFETY IN THE TRAFFIC

- The machine is an hydraulic crane for lorries and light trucks.The installation on the vehicle must be made

in compliance with the relevant national laws and regulations.

- When traveling on roads and public sites always respect the relevant national laws and regulations.

DANGER

Before traveling on roads,make sure that the crane is folded in rest position. If the crane is open

or lying on vehicle’s body exceeding the overall dimensions allowwed by the highway code,it can

hit bridges,electric power lines or other obstructions.

-Before driving away,make sure that the lever of the pin securing the outrigger’s beam is fully locked.Accidental

slipping out of the outrigger during traveling can result in serious damages. Special care must be taken

when driving nearby crossroads, lever-crossing and subways.

!

Page 15

11

5.5 GENERAL RULES ON WINCH OPERATIONS

5.5.1 Winch system operation

The Winch is mounted at the rear of the first section boom.It has capacities totally indipendent of the rest of

the crane and can normally pull more than the crane itself can withstand.Therefore,care must be taken to

insure that the load being lifted is within boom rating.To lift some of the heavier loads on the capacity chart,it

will be necessary to multiple-part reeve the winch block to increase the lifting capacity of the winch (the

speed is proportionately slower) and remain in the strenght limitations of the winch and wire rope.

The winch load rating chart on each machine provides the information for pull limitations on the winch with

various applicable part reevings.These ratings are based on providing the proper operating safety factor on

the wire rope supplied with the machine.

Therefore,any replacement rope must meet the rope specifications for size,construction and stregth as

outlined in specification sections of this manual.

5.5.2Operator safety tips

• Do not pull the load block into the boom tip.

• Payout loadline before or during boom extension to avoid two-blocking.

• Do not allow personnel to ride the load-line, hook or load, or any other device attached to loadline.

• Keep at least three full wraps of wire rope on the winch drum at all times.

• Check the winch brake for proper operation before handling the load.

• Use proper multi-part reeving for the load to be lifted.

• When using multi-part reeving, be sure cable is properly routed.

• Know the lifting capacity of both the winch and boom. They will have different capacities. The weight of

the load must not ex-ceed the lesser capacity.

• Do not drag loads with winch or boom.

• Always wind loadline.under tension to assist proper spooling

5.5.3General rules when operating winch

1 - Always operate the winch control to payout the loadline while extending the boom. This will maintain

clearance between the boom tip and loading hook.

2 - Do not pull load block into boom tip.

3 - Make certain the winch cable is not twisted or kinked and that cable is properly seated on the drum

and in the sheaves.

4 - Before lifting a load, always make certain that three full wraps of rope will remain on the drum at all

times throughout the lift.

5 - When lifting a load approaching the rated winch load, raise the load a few inches and return the

control to neutral to determine if the brake is working properly.

6 - Do not drag loads in any direction with the winch.

7 - Never attempt to lift loads wich are not loose and free, i.e. frozen down material or poles out of

ground.

8 - Maintain tension on the loadline at all times to prevent the cable from becoming twisted or improperly

seated on the winch drum or sheaves.

9 - Avoid rough boom lifting and lowering manoeuvres with suspended load, in order not to cause dan-

gerous swingings of the same.

10- Avoid boom extension manoeuvre under load. When moving loads near to max. rates it is rather

advisable to extend the boom without load in order to reach the vertical line of the same, and then to

proceed with lifting by using the winch.

Page 16

12

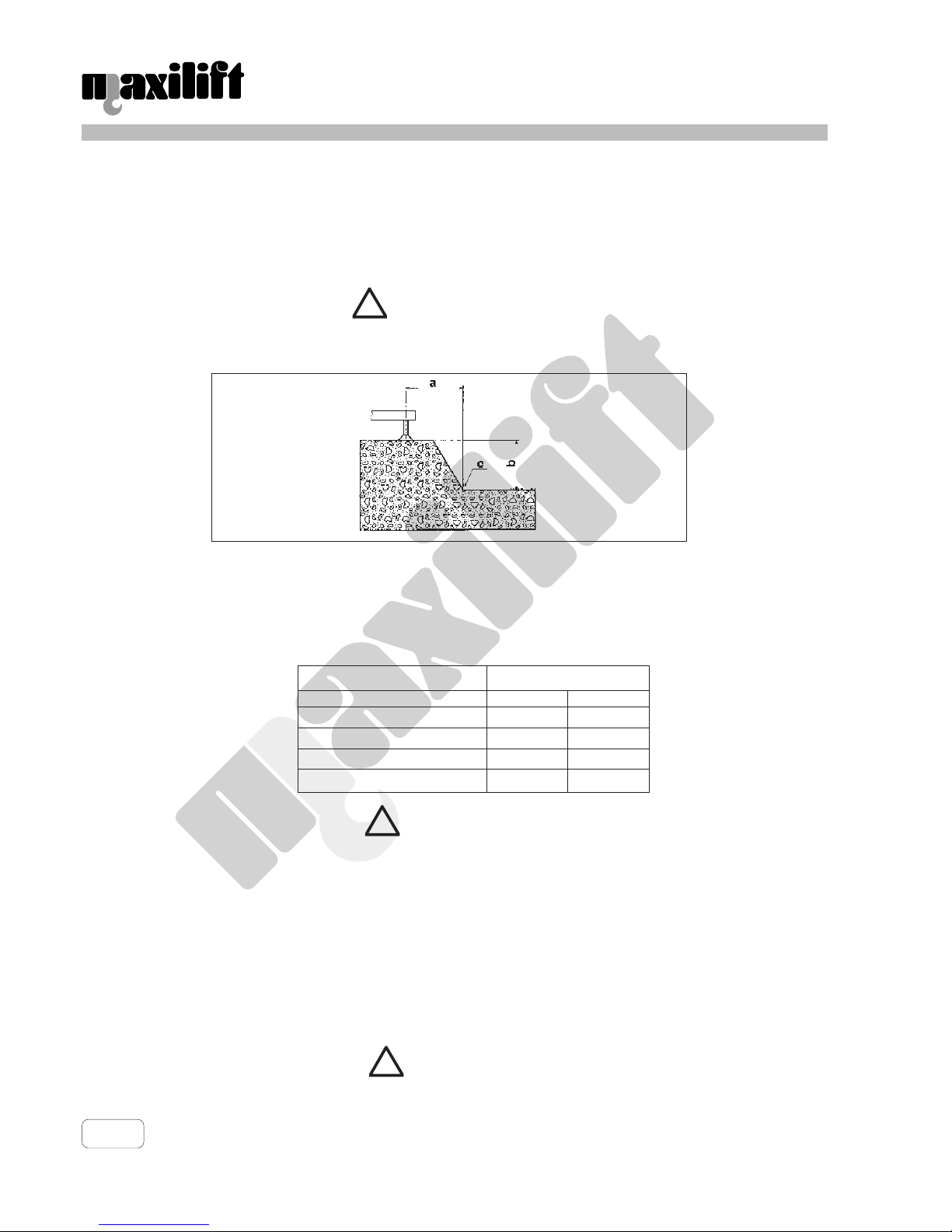

5.6 WIRE ROPE

5.6.1General

Wire rope can be the weak link in crane safety. It is subjected to heavy loads, abrasion, kinking, extreme

weather conditions, chemical attack and other forces which can reduce its reliability. The inspection and

care of wire rope is essential in the effort to provide for safe working conditions.

5.6.2Wire rope precautions

1 - Avoid the formation of kinks. Kinks will cause severe weakness in the rope. No corrections are availa

ble for kinked rope.

2 - Do not drag wire rope over a non-rotating support such as a non-functioning sheave. Severe abrasion

caused to outer wire strands will result from friction.

3 - Do not use worn sheaves or flat grooved sheaves. They do not provide support to the full radius of the

rope. Flattening and distortion will result.

4 - Do not use nicked or otherwise broken sheaves. Necks and cracks in sheaves will cut the wire rope.

5 - Evenly wrap wire rope onto the drum. Uneveness will cause crusking and/or crimping of the rope.

6 - Select replacement wire rope to match the capacity and use of the crane. The crane was originally

equipped with appropriate wire rope.

7 - Do not expose the rope to corrosive chemicals.

8 - Lubricate the rope frequently to reduce friction and help prevent corrosion.

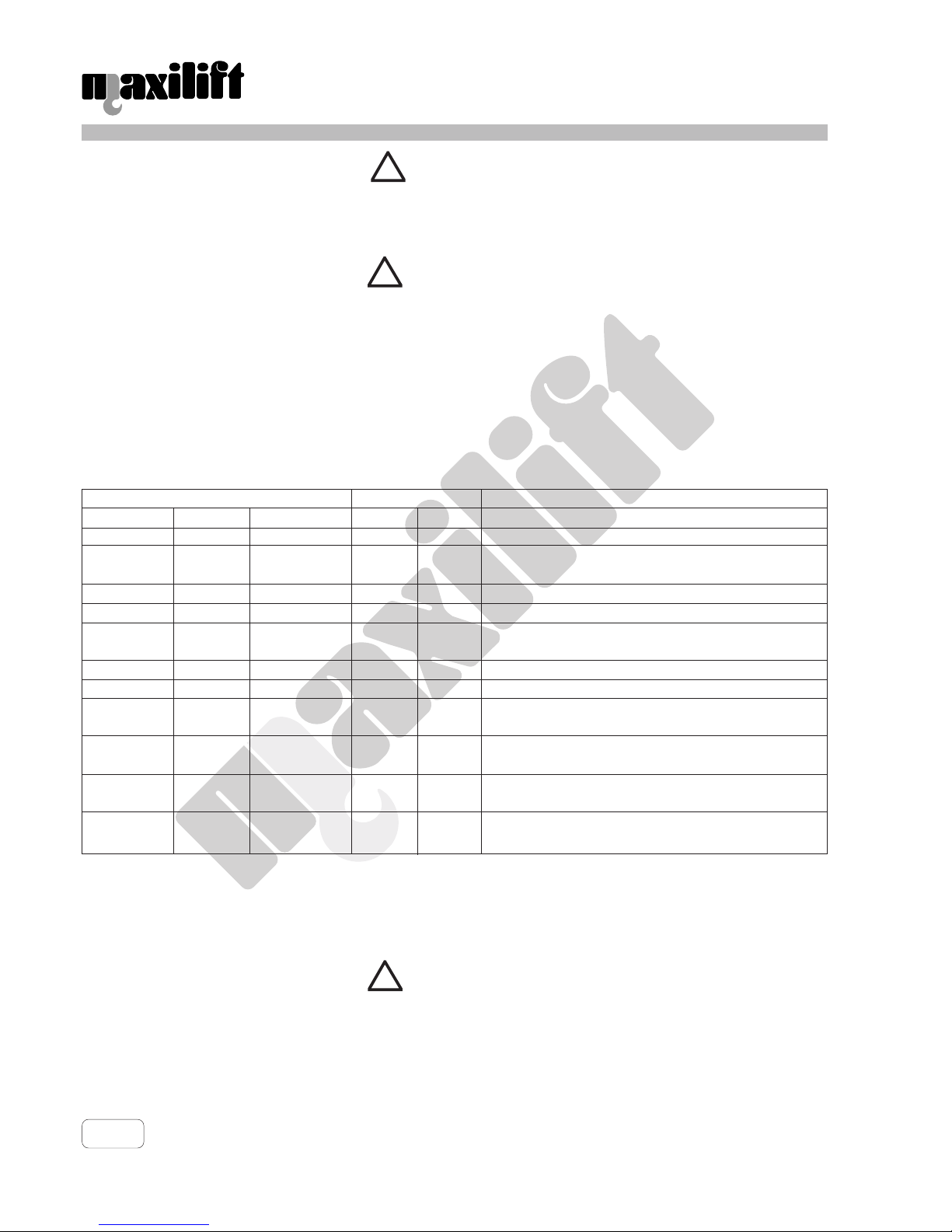

Pict. 4

Page 17

13

6 DESCRIPTION OF THE CRANE

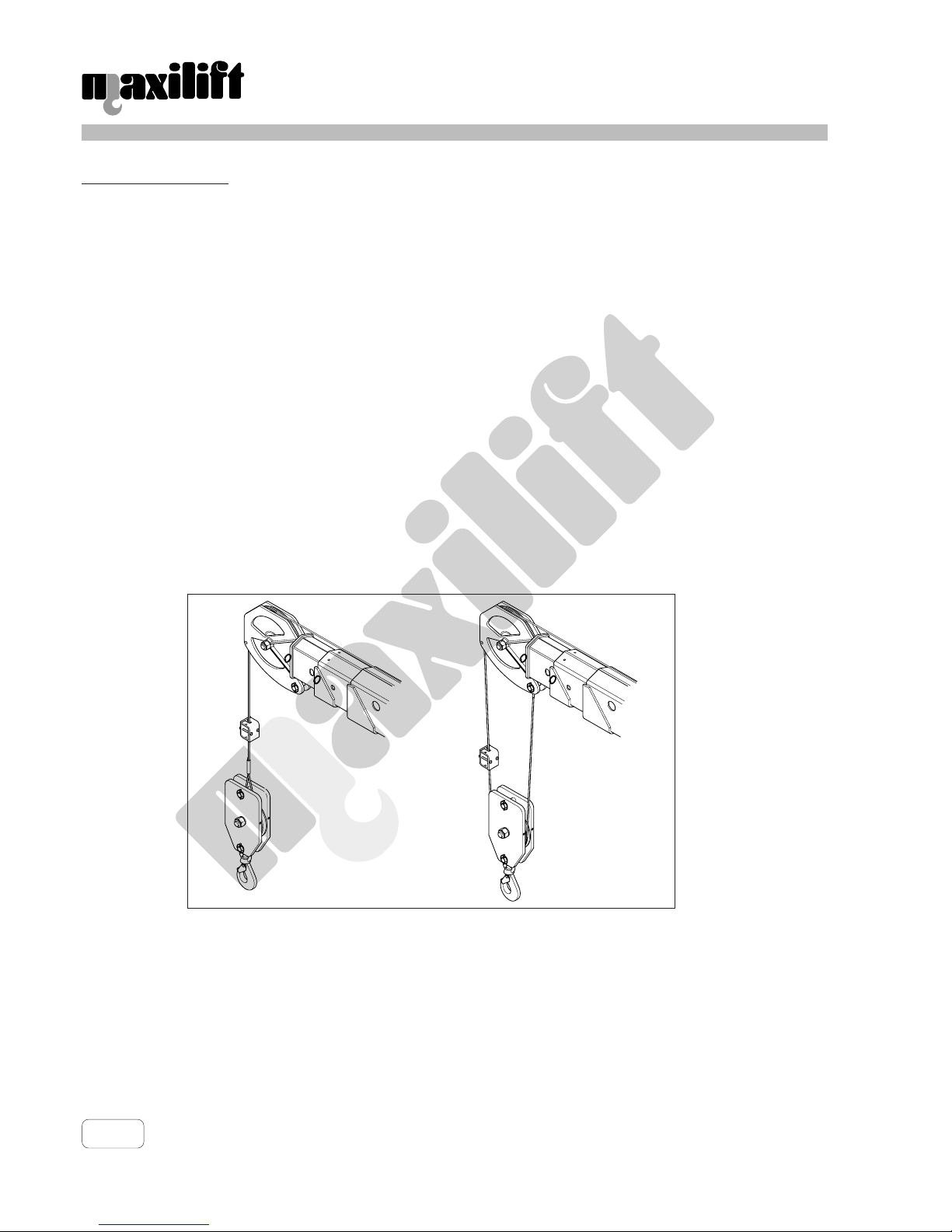

6.1 MODEL 5500 H

Item Description

1 Slewing system

2 Slewing motor

3 Column

4 Main boom

5 Boom hoist cylinder

6 First hydraulic boom section

7 Second hydraulic boom section

8 First telescope cylinder

9 Second telescope cylinder

10 Hydraulic unit

11 Electronic Power unit

12 Cable or radio remote control box

13 Winch

14 Travelling block

15 Oil tank - (only for H version ) OPTIONAL

16 Outrigger beam - (mechanical jack) OPTIONAL

17 Outrigger beam - (hydraulic jack) OPTIONAL

16

17

3

15

2

1

4

5

6

7

8

9

10

11

13

14

Pict. 5

12

Page 18

14

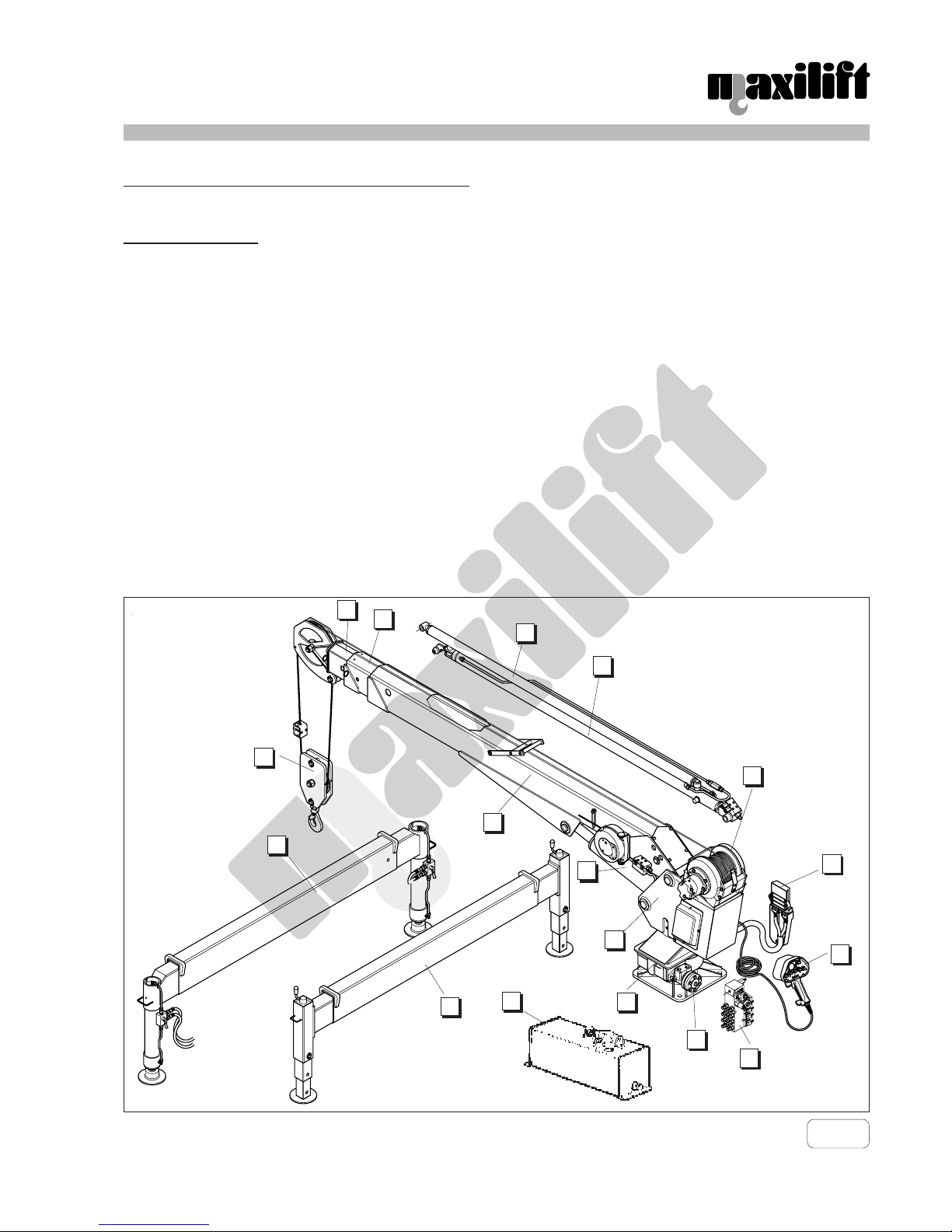

6.2 Model 5500 E 12/24

Item Description

1 Slewing system

2 Slewing motor

3 Column

4 Main boom

5 Boom hoist cylinder

6 First hydraulic boom section

7 Second hydraulic boom section

8 First telescope cylinder

9 Second telescope cylinder

10 Hydraulic unit

11 Electronic Power unit

12 Cable or radio remote control box

13 Winch

14 Travelling block

15 Elettro-hydraulic power pack

16 Outrigger beam (mechanical jack) OPTIONAL

17 Outrigger beam (hydraulic jack) OPTIONAL

16

17

3

2

1

4

5

7

10

11

14

Pict. 6

8

9

6

13

15

12

Page 19

15

6.3 SAFETY DEVICES

6.3.1Safety devices installed

All the safety devices,installed on MAXILIFT COBRA 5500 crane, are listed and described in the following

pages.

description of safety functions

The crane is fitted with 4 standard electrohydraulic safety limitations:

1) The load limiting device, which intervent each time the load mentioned on loading diagram is excee

ded and locks the crane, stopping all mouvements, except re-entry of boom extension and lowering

the load.

2) 0° working placing of the boom. The crane is fitted with a stop-end system allowing only boom lifting

manoeuvre when the position is lower than 0° (rest position)

3) Stop-end system for winch raising, which intervent in order to avoid the travelling block to hit against

the pulley. It stops the raising of the winch rope, boom lowering and boom extension.

4) Stop-end system for winch lowering, which intervent when in thr winch drum remaining only 3 wraps

of rope and locks the lowering of the winch rope.

ATTENTION

It is strictly forbidden to alter or manipulate the safety devices

Before operating the crane make sure that all the safety devices are in perfect working conditions

6.3.2Load limiting device

The load limiting device system locks crane functioning when pressure in the main cylinder reachs the

setting level, corresponding to the nominal crane moment.

The load limiting is used in order to avoid crane overload.

In lock position it is not possible to carry out any manoeuvre, except re-entry of boom extension and lowering

the load (only possible manoeuvres).

In order to unlock the crane, re-entry with the boom extension until crane moment becomes lower than that

marked on the loading diagramm, or intervent on winch lowering by putting the load on the ground.

DANGER

The load limiting device, even when in perfect working condition, cannot avoid accidents due to

operator’s maneuvering mistakes.

DANGER

It is strictly forbidden to operate the crane with its load limiting device switched off or put out of

service or faulty.

NOTE

The load limiting device can lock at the max. main boom angle even without load.

In such case, in orer to unlock the machine it is necessary to act simultaneosly both on the extension re-entry and boom lowering levers.

!

!

Page 20

16

6.3.3 Relief valve

The main relief valve is on the control valve and limits the maximum working pressure.

6.3.4 Pilot operated holding valves

These valves are installed on every cylinder and will stop and lock every motion of the cylinder should any

pressure loss occur. Before starting operations it is necessary to check that these valves are perfectly

working, as follows:

• lift a load and raise the boom up to an angle of 45° upwards, with the boom sections partially extended

• switch the truck engine off push and pull repeatedly all the control switches: the load must remain still.

6.3.5 Safety devices’ sealing

Some safety devices or crane components can be sealed after setting during testing operations.

Such sealing can be only removed by the manufacturer or by an authorized workshop who will carry out a

new sealing after repairing according to Manufacturer’s specifications.

DANGER

The removal of sealing by non authorized personnel, or a sealing not complying to manufacturer

specifications results in an improper usage of the crane.

!

Page 21

17

6.4 MICROPROCESSOR REMOTE CONTROL SYSTEM

COBRA cranes are equipped with an advanced microprocessor remote control system that correctly manages

the crane operations as well as its safety devices and provides indications to help the operator performing rapid

troubleshooting or adjustments when necessary.

6.4.1 AVAILABLE CONTROL VERSIONS

· Single function cable proportional control

· Dual-mode (multi-function) cable proportional control

· Single function radio proportional control

· Dual-mode (multi-function) radio proportional control

The system is consisting of the following

main components

(Pict. 7):

1) Control and safety devices managing con-

trol unit

2) Remote control keyboard

3) Directional and flow regulating hydraulic unit

4) Electrical connection wiring from the unit to

the solenoid valves, the micro-switches, the

power supply and the keypad.

6.4.2 ELECTRONIC POWER UNIT (Pict.8)

The electronic unit, located aside the revolving

column’s guard, is made up of a sealed plastic

compact container (ip 67), that includes a

microprocessor electronic device to manage

crane operation controls and safety systems.

A three digit display (1) used as regulation or

control interface is found on the front of the unit.

Two electrical wiring connectors (2) are found

on the unit.

Pict.8

Pict.7

1

2

3

4

1

2

Page 22

18

6.4.3 THE RADIO RECEIVER UNIT (Pict.10)

The radio control version unit (3) is externally equal to the remote control version, internally, it includes the

electronic system that manages machine logic and radio module and works as a receiver; a safety system

prevents other transmitters from entering the system since it only recognizes its matched keyboard (transmitter)

through the RFID code (radio frequency identifier).

The European version (868 MHz) includes an antenna that is applied to the electronic units through a connector,

it enhances the medium/large range reception field (considering the 868 MHz transmitter reduced power).

A supplementary unit (7 function radio) is available upon request; it is similar to the main one and it activates

two auxiliary functions (on the OPT1 – OPT2 radio button) that control the diesel engine acceleration or turns

on-off a motor-compressor (generator).

6.4.4 THE CABLE KEYBOARD (Pict.9)

The keyboard, which can be used with a single hand, has been studied to provide the operator with an

ergonomic and practical remote control device to optimize the different crane functions.

It is mainly made up of a plastic container with a protected control panel integrally connected to a supporting

ergonomic handgrip.

Five radial selectors (S) that control machine

maneuvers are found on the panel (4 for crane

movements, 1 for engine START/STOP). The

safety stop emergency button (P) is located over

the maneuver selectors; it must also be used

as keyboard on/off button.

The green indication Led (L) is found aside the

emergency button and the diesel engine START/

STOP selector, if these two functions are

activated.

The system foresees the possibility to

supply and control these two external functions.

The keyboard panel is provided with the

essential function-guiding symbols with green

background; it results pleasant and intuitive for

the operator.

The movement speed that has been preestablished through the maneuver selectors, (S)

can be controlled through the potentiometric

button that is housed on the bottom of the

handgrip.

The control unit connector is applied at the end

of the cable; such cable remains flexible and

easy to handle even if exposed to extreme

conditions.

Pict.9

S

P

start-stop

L

Page 23

19

6.4.5 THE KEYBOARD – RADIO TRANSMITTER (Pict.10)

The operator interface is identical to the

abovementioned one.

The differences are:

- The absence of the integral cable,

replaced by a connector at the base of

the handgrip to connect the battery supply

serial cable (1). This 2 m. cable is

included in the standard supply and it

charges the keyboard batteries; it can also

be used to control the crane through cable

system. A 10 m cable is available upon

request; it can be used to work on areas

where the radio control is forbidden.

- an additional selector for optional

functions (OPT1 and OPT2).

- The rechargeable batteries that are

housed on a specific compartment (2)

protected by the keyboard and that can

be easily extracted disconnecting a quick

connector. Battery recharge may last up to three hours if batteries are completely flat. For this purpose

a car battery charging cable that can be connected to the car lighter is also supplied.

- The radio transmitter module.

- A circular magnet, located on the rear that allows placing the keyboard on metallic surfaces.

WARNING

Verify the emergency button correct operation (5) before using the radio control.

The radio control must be turned off when operations are suspended by pressing the

emergency button (5).

The keyboard box must only be opened in case of repair or anomaly.

Check the emergency button operation as follows:

- Start a function (ex. boom lift), checking if it is performed by the crane.

- Press the emergency button and check if the previously performed action is immediately stopped,

otherwise stop the machine.

N.B. Never let the crane work with disabled emergency button.

WARNING

When the cable keyboard is not being used, it must be disconnected from the connector

located on the guard aside the unit where the protection cover will be screwed.

Press the mushroom button of the cable and radio keyboards after their use and before storing

them on a protected and safe place.

The radio keyboard batteries last from 12 to 24 hours depending on their use.

It is suggested to let the batteries discharge until they are completely flat before starting a new

recharge cycle.

Pict.10

1

2

3

4

5

Page 24

20

6.4.5.1 RADIO SYSTEM PROTECTION DEVICES

The radio control system is provided with some protection systems that are automatically started in case of:

- radio interference on the crane working area that influences the radio control frequency range

- transmitter capacity field exceeded (keyboard)

On these cases the system locks all the functions.

Press and release the emergency button to restore the functions

In addition, when the battery charge is too low for safety operations the system is blocked, the green LED

turns off and the radio module interrupts transmissions with the unit.

The keyboard is provided with battery energy saving system to reduce battery consumption.

When the keyboard remains unused for at least 15 minutes, the radio system is set to “energy save”, the

green led turns off and the radio module interrupts the transmission with the unit (receiver).

Press and release the emergency button to unblock.

6.4.6 PROPORTIONAL MONO-FUNCTION REGULATION HYDRAULIC UNIT (Pict.11)

The unit is consisting of two separate aluminium blocks.

The upper section includes the proportional adjusting valve (VR) and the manual bypass control valve (OM) of

the proportional regulator.

The lower section includes the main relief valve (VM), the dump valve (EV9) and the control solenoid valves

(EV…A – EV…B), two for each movement.

The solenoid valves: EV9 – EV3B – EV2B – EV1B – EV1A are equipped with a manual override, to be used

only for emergency (failure of the electronic control unit or the button strip, lack of power supply).

In such cases it is necessary to proceed as follows:

a) fully turn counter-clockwise the valve

handwheel (OM) in order to bypass the

proportional valve (VR)

b) fully turn counter-clockwise the manual

override of the valve coupled to the

desired movement (extension re-entry,

boom lowering, etc.).

c) finally fully turn counter-clockwise the

manual override of the valve (EV9), in

order to activate the desired movement

d) once the standard working conditions of

the crane are restored, always remember

to close completely the manual overrides,

by turning them clockwise.

e) finally close completely the bypass valve

(OM) by turning the handwheel

clockwise.

Pict.11

EV3A

EV9

VR

EV4B

EV3B

EV2B

EV1B

OM

VM

EV4A

EV2A

EV1A

Page 25

21

6.4.7 PROPORTIONAL DUAL-MODE REGULATION HYDRAULIC UNIT (Pict.12)

The unit is consisting of two separate aluminium blocks.

The upper section includes the proportional adjusting valve (VR), the manual bypass control valve (OM) of the

proportional regulator, the main relief valve (VM), the winch operating solenoid valves (EV4A – EV4B), the

dump valve (EV9) and the solenoid valves (EV3 – EV4) required to operate the winch and another function at

the same time.

The lower section includes the control solenoid valves (EV…A – EV…B), two for each movement.

The solenoid valves: EV9 – EV3B – EV2B – EV1B – EV1A are equipped with a manual override, to be used

only for emergency (failure of the electronic control unit or the button strip, lack of power supply).

In such cases it is necessary to proceed as follows:

a) Fully turn counter-clockwise the valve

handwheel (OM) in order to bypass the

proportional valve (VR)

b) Fully turn counter-clockwise the manual

override of the valve coupled to the

desired movement (extension re-entry,

boom lowering, etc.).

c) Finally Fully turn counter-clockwise the

manual override of the valve (EV9), in

order to activate the desired movement

d) Once the standard working conditions of

the crane are restored, always remember

to close completely the manual overrides,

by turning them clockwise.

e) Finally close completely the bypass valve

(OM) by turning the handwheel clockwise.

6.4.8 WIRING (pict.13)

Made up of a single wiring unit that is

connected to the electronic unit through two

sealed multipolar connectors (1) provided with

quick hooking system.

The wiring includes the solenoids to connect

the solenoid valves located on the hydraulic

unit, it also connects the unit to the safety limit

switches (FA – FB – FV), to the pressure

gauge or to the pressure transducer (PM), to

the diesel engine start/stop and to the power

supply. The wiring also includes the keyboard

connection female connector (3) that is

placed aside the electronic unit on the crane’s

cover.

Pict.13

1

2

3

Pict.12

EV3A

EV9

VM

1

VR

EV4B

EV3B

EV2B

EV1B

EV3

OM

EV4

EV4A

EV2A

EV1A

Page 26

22

6.5 REMOTE CONTROL USE

After the preliminary operations concerning:

- PTO engaging

- extension and lowering of stabilizer legs and their levelling

- control system supply by switching on the proper switch inside the cabin

- power supply by turning the battery-disconnecting lever in case of electro-hydraulic crane

you can go on working with the remote control.

6.5.1 USE OF THE MONO-FUNCTION PROPORTIONAL REMOTE CONTROL

First, release the emergency button (E).

It is necessary to select the desired movement

by pushing the selector (S) upwards or downwards (check carefully the symbols on the panel;

the opposite movements are carried out by inverting the movement).

While keeping the selector pushed act gradually with your forefinger on the proportional button (P), in order to get a gradual speed increase.

Proportionally to the stroke of the button, you

will get a movement of the selected function

which will be quicker and quicker until you achieve

the maximum speed.

ATTENTION

Do not operate the proportional button

before selecting the movement: it will not

work.

Do not pull immediately the proportional

button to its maximum limit: you will not get

the right gradualness and the movements

will be jerking and dangerous.

Always release first the proportional button, and then the selector of the movement

chosen.

6.5.2 USE OF THE DUAL-MODE PROPORTIONAL REMOTE CONTROL

The dual-mode remote control can be normally used as a mono-function remote control when following the

instructions of previous paragraph.

The remote control in object allows the combination of two movements at the same time by coupling the winch

function (raising or lowering) to one of the remaining movements.

You always have to select first the two functions chosen, and then to operate the proportional button metering the speed,

in order to achieve the desired speed, even allowing at the same time the winch rope raising or lowering.

By releasing one of the movements the speed of the other one does not increase until the function is stopped.

By this way of operating the two speeds are nearly halved in comparison to the use of a single function.

Pict.14

S

P

E

Page 27

23

6.6 SIGNALS AND DIAGNOSTIC

6.6.1 KEYBOARD DIAGNOSTIC SIGNALS

The following signal devices are found on the radio keyboard:

- a beeper

- a green led

Beeper signals:

Radio connection keyboard:

- a brief signal (beep) indicates that the keyboard is powered (through the emergency button)

- a long signal (beep) indicates that the RFID code (radio frequency identifier, exclusively used by

authorized workshops) self-learning procedure has been activated.

- four brief signals indicate that the keyboard has switched to energy save mode or that battery charge is

not enough.

Cable connection keyboard (serial):

- a brief signal (beep) indicates that the serial cable has been connected

Led signals:

Radio connection keyboard:

- led ON indicates that the keyboard is supplied, the emergency button is released and the battery level is

enough to work.

- slow continuous blinking led indicates that the keyboard is supplied and the battery charge level is too

low to work.

- led off indicates that the keyboard is in energy save mode or out of service due to insufficient battery

charge level or that the proportional button is switched on

- a continuous and fast blinking signal indicates that the keyboard is tuned to the auxiliary channel, for

example when the RFID code (radio frequency identifier, exclusively used by authorized workshops) selflearning function is used.

Cable connection keyboard (serial):

- led with intermittent blink (two blinks followed by a pause), indicates battery recharge mode

- led ON indicates that the keyboard is supplied (for example that the serial cable is connected) and is

ready to be used; during battery recharge it indicates that a function has been activated;

- led OFF indicates that the keyboard does not recharge the batteries and that the emergency button is

pressed.

NOTE: every time that the serial cable is connected, the keyboard performs the battery status control for

about 3 seconds, afterwards, the recharge procedure is automatically started if no errors are found.

The following signal devices are found on the remote keyboard:

- a beeper

- a green led

Beeper signals:

- a brief signal (beep) indicates that the keyboard is powered (connected cable and emergency button

switched off)

Led signals:

- led ON indicates that the keyboard is supplied, the emergency button is released

- led OFF indicates that the keyboard is out of service, the emergency button is switched

Page 28

24

6.6.2 DISPLAY MESSAGES

As previously explained, the electronic control unit is fitted with a 3 digits display showing messages which help

the operator understanding if everything is working properly, the operating state and the functioning of its

electrical components.

The operator, when led by an expert or following basic operations, can actually read on such display different

messages helping him locating possible electrical anomalies on the system. This is a great help for searching

and identifying possible faults, preventing useless and unsuitable interventions by the after-sales service.

Against possible displays of error messages, the operator is requested to contact the Technical After-Sales

Service.

6.6.3 NORMAL DISPLAY MENU

When switching on, after a sequence of messages on the display this must show:

When carrying out whichever movement by selecting the function it must appear:

When the overload condition is almost reached the display shows:

When the crane goes gets locked by the LLD (overload) the display shows:

In this case you have to carry out the manoeuvres allowing the overload reduction, i.e.: extension re-entry or

winch lowering.

The boom might be blocked on maximum lift position on some crane models, even without load.

To be able to descend with the lifting cylinder, it is necessary to select the extension insertion or the winch

descent and immediately afterwards the boom descent followed by the proportional button.

In case of pressure gauge (pressure transducer) signal absence

Moreover, the system can show the following error messages, which can be displayed when operating or trying

unsuccessfully to operate.

The messages and relevant meanings are the following:

“O”xx followed by the solenoid valve abbreviation.

It means open circuit detected on the solenoid valve in object.

Examples:

Open circuit alarm on solenoid valve EV3B.

Page 29

25

The following table shows all the displayed alarm codes.

Display Alarm Type Valve on which the alarm is detected

O1A open circuit EV on/off 1A (CLOCKWISE ROTATION)

O1b open circuit EV on/off 1b (COUNTER-CLOCKWISE ROTATION)

O2A open circuit EV on/off 2A (BOOM UP)

O2b open circuit EV on/off 2b (BOOM DOWN)

O3A open circuit EV on/off 3A (TELESCOPIC BOOM OUT)

O3b open circuit EV on/off 3b (TELESCOPIC BOOM IN)

O4A open circuit EV on/off 4A (WINCH DOWN)

O4b open circuit EV on/off 4b (WINCH UP)

O_3 open circuit E3

O_4 open circuit E4

O_r open circuit VR (proportional valve)

The system, through simple operations, allows to enter other menus, which can be helpful for the operator

or a technician from the After-Sales Service.

These menus are:

- MICRO-SWITCHES AND PRESSURE SWITCH DISPLAY MENU

- CURRENT DISPLAY MENU (for proportional valve adjustment)

- REMOTE CONTROL KEYBOARD DISPLAY MENU

- WORK PRESSURE DISPLAY MENU

The following calibration and regulation menus need specific qualification and are exclusively

used by authorized workshops:

- RAMP AND CURRENT CALIBRATION MENU

- MOMENTUM LIMITER THRESHOLD VALUE SELF-LEARNING MENU

- SYSTEM TYPE SETTING MENU (SINGLE-FUNCTION – DUAL MODE)

- MOMENTUM LIMITER TYPE SETTING MENU

- RFID (Radio Frequency Identifier) CODE LEARNING MENU

Page 30

26

6.6.4 MICRO-SWITCHES AND PRESSURE SWITCH DISPLAY MENU

This menu is accessed from the Normal Display Menu through the following procedure:

push the proportional button to its maximum level, then operate the 1A and 3B movements simultaneously for

at least 5 seconds (the maneuver can be performed in radio mode or through serial cable).

.

In this menu the state of FA, FB, FV, PM micro-switches are displayed cyclically, with a 2.5 seconds interval;

each micro-switch can be in one of the following conditions:

O open

C closed

Example: display of the state

“FB micro-switch open”

Example: display of the state

“PM micro-switch closed”

The following table shows all displayed codes:

Fa.O Fa.C micro-switch FA (micro on winch drum/cable

descent)

Fb.O Fb.C micro-switch FB (stopped boom limit switch)

Fu.O Fu.C micro-switch FV (limit switch on cable diverting pulley / cable lift)

Pr.O Pr.C micro-switch PM (digital pressure gauge or analog pressure transducer)

When no operation is activated the electronic control unit automatically switches to the Normal Display Menu

after 60 seconds; otherwise a new power-on is required in order to get out of this menu.

6.6.5 CURRENT DISPLAY MENU (proportional regulation)

This menu is accessed from the Normal Display Menu through the following procedure:

- push the proportional button to its maximum level, then operate the 1A and 4B movements simultaneously

for at least 5 seconds (the maneuver can be performed in radio mode or through serial cable).

- In this menu, when no operation is active, the indication “Cur” is displayed. When a movement is

active the value of the current (in mA) that is driving the proportional solenoid valve is displayed.

Example: indication without any active movement

Example: indication with an active movement and

with the proportional valve driven at 523 m

A

When no operation is activated the electronic control unit automatically switches to the Normal Display Menu

after 60 seconds; otherwise a new power-on is required in order to get out of this menu.

2A

3A

4A

4B

3B

2B

1B

1A

5A

5B

Pict. 14A

Page 31

27

6.6.6 REMOTE CONTROL KEYBOARD DISPLAY MENU

This menu is accessed from the Normal Display Menu through the following procedure:

push the proportional button to its maximum level, then operate the 1A and 2B movements simultaneously for

at least 5 seconds (the maneuver can be performed in radio mode or through serial cable).

In this menu, when no operation is active, the indication “_ _ _” is displayed. When a movement is active the

state of the contact that activates the movement in the remote control pendant is displayed. For each of the

contacts the following state is displayed:

C closed

In case of multiple command (two or more movements activated simultaneously) only the state of the first

received command is displayed.

Example: indication without any active movement

Example: indication when the contact 1A

is closed on the remote control uni

The following table shows all displayed codes:

Display Indication

C1A contact 1A closed (CLOCKWISE ROTATION)

C1b contact 1B closed (COUNTER-CLOCKWISE ROTATION)

C2A contact 2A closed (BOOM UP)

C2b contact 2B closed (BOOM DOWN)

C3A contact 3A closed (TELESCOPIC BOOM OUT)

C3b contact 3B closed (TELESCOPIC BOOM IN)

C4A contact 4A closed (WINCH DOWN)

C4b contact 4B closed (WINCH UP)

C5A contact 5A closed (START)

C5b contact 5B closed (STOP)

When no operation is activated the electronic control unit automatically switches to the Normal Display Menu

after 60 seconds; otherwise a new power-on is required in order to get out of this menu.

Page 32

28

6.6.7 WORK PRESSURE DISPLAY MENU

This menu is only available on the momentum limiter system with analog pressure transducer and it

displays the real time oil hydraulic pressure (in bar).

This menu can be accessed from the normal display menu through the following procedure:

Fully press the proportional button and simultaneously start maneuver 1A and the STOP selector for 5

seconds (the maneuver can be performed in radio mode or through serial cable).

80 bar work pressure display example

Turn the system off and on to exit this menu.

Page 33

29

7 OPERATING INSTRUCTIONS

7.1 GENERAL ATTENTIONS

The crane must be used exclusively by qualified and skilled operators. They must know location and function of every control, instruments, indicators, lights, plate and sticker.

DANGER

Before starting operations make sure that nobody is in the working area of the crane.

• The crane must work only on flat ground.

• Make sure that the truck is well braked and, if necessary, apply blocks to the tires.

• Pull the outrigger’s beams out of their housing till the yellow line painted on it is completely visible, and

make sure that the safety pins on the box are perfectly hooked on the beams.

• Lower the outriggers pads down to the ground. Be sure of not entirely lifting up the truck suspensions. It

is important for the truck stability that a part of the truck weight still burdens on the tires.

• When swinging outrigger jacks are supplied check that it is in vertical position and with its safety pin

inserted in its housing and well secured (see picture 18).

• When lowering the outrigger jacks stay away from them, to avoid crushing of feet and legs.

• Never operate the crane without having checked that the outriggers are well positioned on firm ground.

If necessary, their bearing area must be increased with additional pads. The truck stability relies very

much on the working conditions! When the ground under the outrigger pads is sinking, their bearing

area must be increased. The crane Manufacturer can supply additional plates with increased area.

• Be sure that the lifted loads are, for every outreach, not higher than those stated on the load chart.

• Before operating the crane be sure that all the pinned joints and the hook pin are safely locked by their

retainers.

• Lifting tackles, chains or ropes must be applied to the hook in such a way that will not damage the hook

safety latch.

• Whilst swinging the boom always keep the load suspended from the ground. Dragging of the load is

forbidden.

• Never stay or walk under hanging loads or within the operating radius of the crane.

• Do not use the crane near electric power or telephone lines.

• Never start the crane operation without signaling it in a proper way.

• The load should never be lifted or carried on areas where people are passing or working. If this cannot

be avoided in any way, hese operations must be properly signaled.

• Before leaving the controls, make sure that the control switches are in neutral position, the main switch

is turned off and the load is resting on the ground.

• When the working area of the crane cannot be clearly seen from the operator control deck, a second

operator charged with signaling is required (see pag. 31).

• Stay away from the outrigger beams when they are pulled in, to avoid crushing hazard between them

and the truck parts.

• When the work is over make sure that the outriggers beam are locked in rest position and the shut-off

valves are closed. Lack of doing this may result in serious danger if these parts come out whilst traveling

on road.

• The stickers and plates applied on the crane are necessary to enable a safe usage of the same. Should

them be no longer readable, replace them as soon as possible with new ones.

• Always disconnect the power take-off before driving away. If the truck engine turns at high revs, the PTO

would be damaged.

• The operator should be someone who is familiar with type of crane and has had some experience with it.

• If the crane is accidentally hit, it has to be checked and tested from the closest authorized installer

workshop.

!

Page 34

30

• Check every month the state and correct functioning of all the parts subject to wear: pins, valves, hoses,

sliding pads and bushings, etc. If necessary replace with genuine spare parts.

• It is absolutely forbidden to alterate the hydraulic circuit and open the safety seals. Failure to comply will