Page 1

Page 2

CONTENTS

ENGINE PART.....................1-16

BRUSH CUTTER................17-27

POLE PRUNER..................28-39

HEDGE TRIMMER..............40-49

Attention Statements

Throu ghout t his man ual are s pecial

atten tion st ateme nts.

DANGER!

DANGER!

A statem ent pre ceded b y the trian gular

atten tion sy mbol an d the wor d

"WA RNING "indi cates a p otent ially

hazar dous si tuati on whic h, if not

avoid ed, COU LD resu lt in dea th or

serio us inju ry!

CAUTION!

A statem ent pre ceded b y the word

"CAUT ION" co ntain s infor mation

that sh ould be a cted up on to avo id

damag e to the ma chine .

IMPORTANT!

NOTE:

A statem ent pre ceded b y the word

"IMPO RTAN T" is one t hat pos sesse s

speci al sign ifica nce.

A statem ent pre ceded b y the word

"ONTE " conta ins inf ormat ion that is

handy t o know an d may mak e your jo b

easie r.

A statem ent pre ceded b y the triangular

atten tion sy mbol an d the wor d

"DANG ER"in dicat es an imm inently

hazar dous si tuati on whic h, if not

avoid ed, wil l resul t in deat h or

serio us inju ry!

1

Page 3

DANGER!

Appro achin g or cont actin g electri cal

lines w ith the t rimme r could c ause

death o r serio us inju ry. Keep t he

trimm er at lea st 10me ters aw ay from

elect rical l ines or b ranch es that

conta ct elec trica l lines .

Introduction

Long re ach hed ge trim mer 260 0 is

desig ned and b uilt to d elive r superio r

perfo rmanc e and rel iabil ity witho ut

compr omise t o quali ty, comf ort, sa fety or

durab ility.

IMPORTANT!

The information contained in these

instrucitions describes components

available at the time of publication.

While every attempt has been made to

provide the latest information about your

product, there may be some differences

between your attachment and

what is described here. We reserves

the right to make changes to products without

prior notice and without obligation to make

alterations to components

previously manufactured.

The procedures described in this manual

are intenaded to help you get the most

from your machine as well as to protect

you and others from harm.

these procedures are guidelines for safe

operation under most conditions, and are

not intended to replace any safety rules

and/or laws that may be in force in your

area.

If you have questions regarding your

power tool, or if you do not understand

someting in this manual, your local

dealer will be glad to assist you.

Safety Precautions

NOTE!

THE ARTICUL ATED HEDGE

TRIMMER IS NOT INSULATED

AGAINST ELECTRICA L SHOCK1

An arti culat ed hedg e trimm er has the po tenti al

to do ser ious da mage if m isuse d, abused o r

misha ndled . To reduce t he risk o f injur y, you

must ma intai n contr ol at all t imes, and o bserv e

all saf ety pre cauti ons dur ing opera tion.

Never p ermit a p erson w ithou t trainin g or

instr uctio n to oper ate thi s machine !

For spe cific m ainte nance a nd safety

infor matio n about y ou long reach Hedg e

trimm er T260 0 Multi purpo se Engi ne or

long re ach pru ner P26 00 power head,

consu lt the ow ner's m anual p rovided

with it . If it has b een los t or misp lace,

conta ct us for a r eplac ement .

2

Page 4

Operating Precautions

Never o perat e this to ol or any

other p ower eq uipme nt if you a re

tired , ill, or u nder th e influ ence of

alcoh ol, dru gs, or an y subst ance

that co uld aff ect you r abili ty or

judge ment.

Keep by stand ers at le ast 15 me ters

(50 fee t) away f rom the o perat ing

trimm er to red uce the r isk of be ing

struc k by fall ing obj ects or thrown

debri s.

Never c ut off br anche s over yo ur

head. T he cut- off b ranch es may

hit you a nd caus e serio us inju ry.

read an d follo w this ma nual,

make su re anyo ne usin g the

trimm er dose l ikewi se. Fai lure

to do so co uld res ult in se rious

perso nal inj ury or ma chine

failu re. Kee p this ma nual fo r

futur e refer ence.

Alway s wear a ha rd hat to r educe

the ris k of head i njuri es during

opera tion of t his mac hine. In

addit ion, al ways we ar eye an d

heari ng prot ectio n. We

recom mends w earin g a face

shiel d as addi tiona l face an d eye

prote ction .

Wear no n-sli p heavy -duty g loves

to impr ove you r grip on t he

trimm er hand le. Wea r sturd y

footw ear wit h nonsh ip sole s to

proiv ide goo d footi ng. Ste el-toes

safet y boots a re reco mmend ed.

Were sn ug-fi tting c lothe s that al so

permi ts free dom of mo vemen t.

3

Page 5

Operating Precautions

Never p ermit a p erson w ithou t trainin g

or inst ructi on to ope rate this machin e.

WARNING!

Alway s make su re the cu tter

attac hment i s prope rly installed an d

firml y tight ened be fore operation .

Never u se a crac ked or wa rped cu tter

or cutt er bar: r eplac e or repa ir before

use.

Befor e start ing the e ngine , make sure

the cut ter is cl ear of al l objects.

Alway s stop th e engin e immed i-ately

and che ck for da mage if y ou strike a

forei gn obje ct or if th e machi ne

becom es tang led. do n ot operate with

broke n or dama -ged eq uipme nt.

When cu tting a b ranch t hat is un der

tensi on, be al ert for s pring -back so th at

you wil l not be st ruck by t he movi ng

branc h.

Stop th e machi ne imme diate ly if it

sudde nly beg ins to vi brate o r shake.

Inspe ct for br oken, m issing or

impro perly i nstal led par ts or

attac hment s.

Never s moke or l ight fi res nea r the

hedge t rimme r. Keep th e trimmer a way

from ex cessi ve heat . Engin e fuel is

very fl ammab le and fi re could lead to

serio us pers onal in jury or p roperty

damag e.-

Never o perat e this ma chine o r other

power e quime nt if you a re tire d, ill, or

under t he infl uence o f alcohol, drugs ,

or any ot her sub stanc e that co uld

affec t your ab ility o f judge ment.

Do not op erate t he arti culated hedge

trimm er with t he muff ler rem oved.

Make su re ther e is alwa ys good

venti latio n when op erati ng the

artic ulate d hedge t rimme r. Fumes fro m

engin e exhau st can ca use ser ious

injur y or deat h. Neve r run the e ngine

indoo rs!

Make su re ther e are no mi ssing o r

loose f asten ers, an d that th e stop

switc h and thr ottle c ontro ls are work ing

prope rly

If a cutt er shou ld bind f ast in a cu t,

shut of f the eng ine imm ediat ely. Push

the bra nch or tr ee to eas e the bin d and

free th e cutte r.

Make su re the cu tters a re corr ectly

adjus ted bef ore ope rating the

artic ulate d hedge t rimme r (see page

17 for cu tter ad justm ent pro cedures ).

Never a ttemp t cutte r adjus tment wit h

the eng ine run ning!

Make su re of no fu el leak ing fro m Fuel

tank, f uel cap , Fuel pi pe and

carbu retor a nd othe r parts which fuel

may lea k. Repa ir the ma chine if fuel

leaki ng, mak e sure no l eakin g again.

4

Page 6

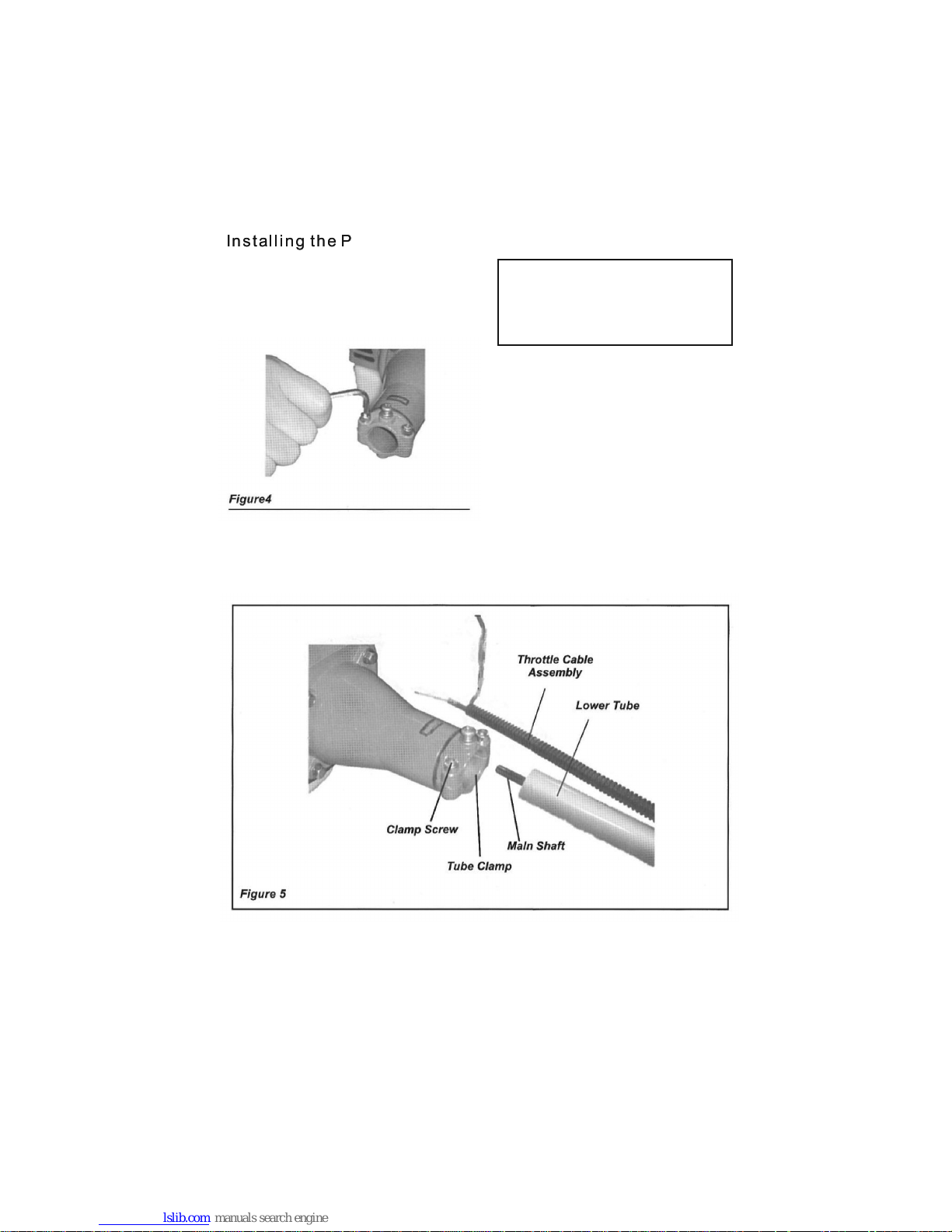

Installing the Powerhead

CAUTION!

1.Pla ce the po werhe ad on a cle an, flat

surfa ce, spa rk plug f acing up.

2.Use t he 4mm al len wre nch to lo osen

the tub e clamp a s shown i n figure 4.

3.Sli p off the p rotec tive co vers fr om

two end s of bube .

Do not fo rce the l ower tu be info

the pow erhea d! Exce ssive f orce

can dam age the c ompon ents.

4.Pus h the low er tube t oward s the tube

clamp a nd rota te it by ha nd to che ck

that th e mains haft sp lines e ngage the

power head, S ee Figu re 5

5.Ins ert the l ower tu be into t he tube

clamp u ntil it b ottom s and ali gn the

posit ionin g holes o n the tub e and

clamp , then in stall t he scre w.

6.Fas ten the c lamp se curel y with 2

clamp s crews .

5

Page 7

Connecting the Throttle Cable

1.Rem ove the a ir clea ner cov er.

2.Con nect th e end of th e throt tle cable t o

the joi nt on the t op of the c arbur etor.

See Fig ure 6, fi gure 7.

Conne cting s witch w ires

conne ct the sw itch wi res bet ween the

engin e

and the m ain uni t. Pair t he wire s

of the sa me colo r. See fig ure 8.

6

Page 8

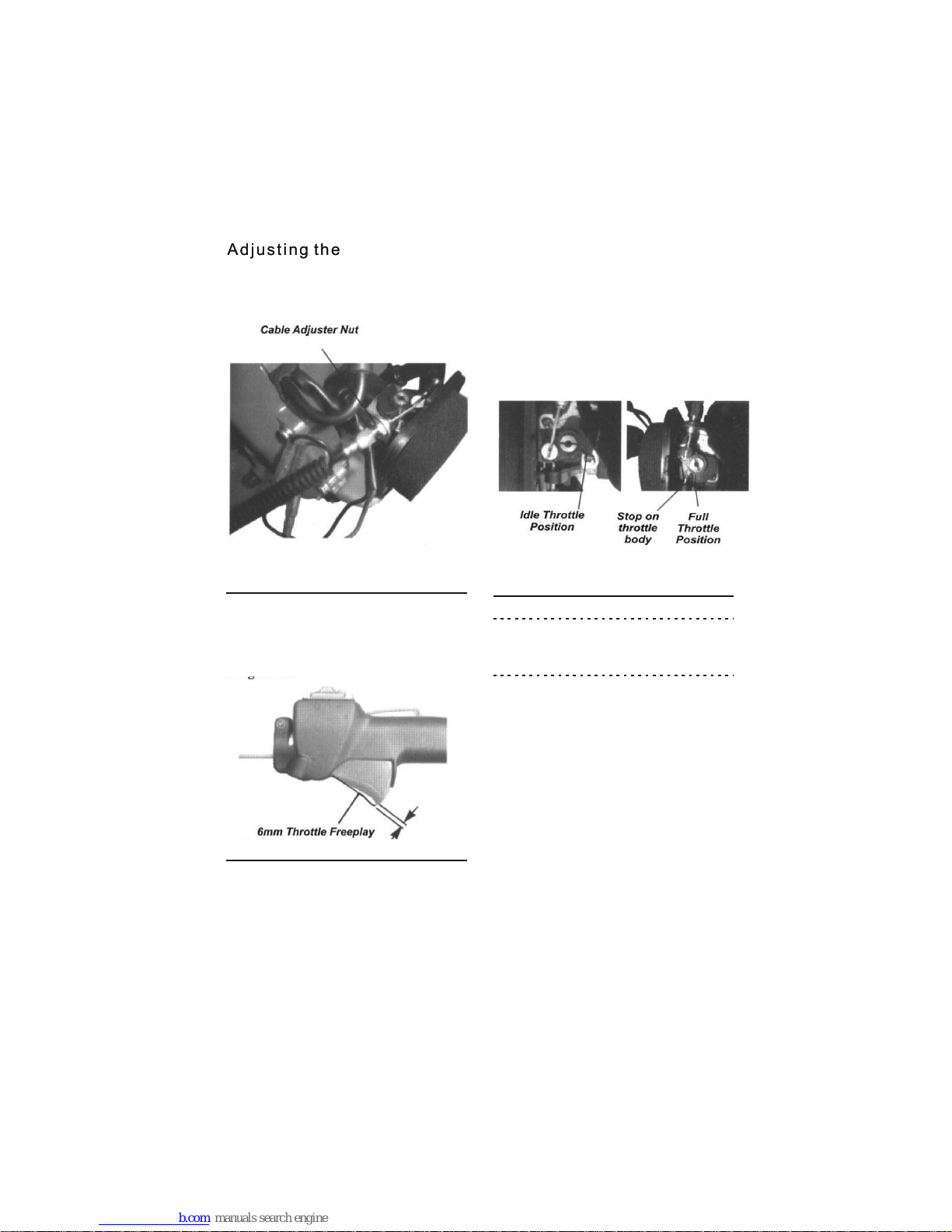

Adjusting the Throttle cable

1.Loo sen the t hrott le cabl e nut at fan

cover a s shown i n figur e 9.

figure

9

figure

10

figure

11

2.Adj ust the t hrott le cabl e adjuste r

nuts un til you a chiev e a free play on

the thr ottle t rigge r of abou t 6mm.

See Fig ure 10.

When 6m m free pl ay is ach ieved ,

tight en the tw o 10mm th rottle cable

nuts. W hen the t hrott le cable is

corre ctly ad juste d, and th e throttl e

trigg er is ful ly depr essed ( full

throt tle), t he thro ttle wi ll contac t the

stop on t he thro ttle bo dy. See Fi gure

11.

A dab of Nev er-Se ez TM or eq uival ent

eases r emova l.

4.Rep lace th e air cle aner co ver.

7

Page 9

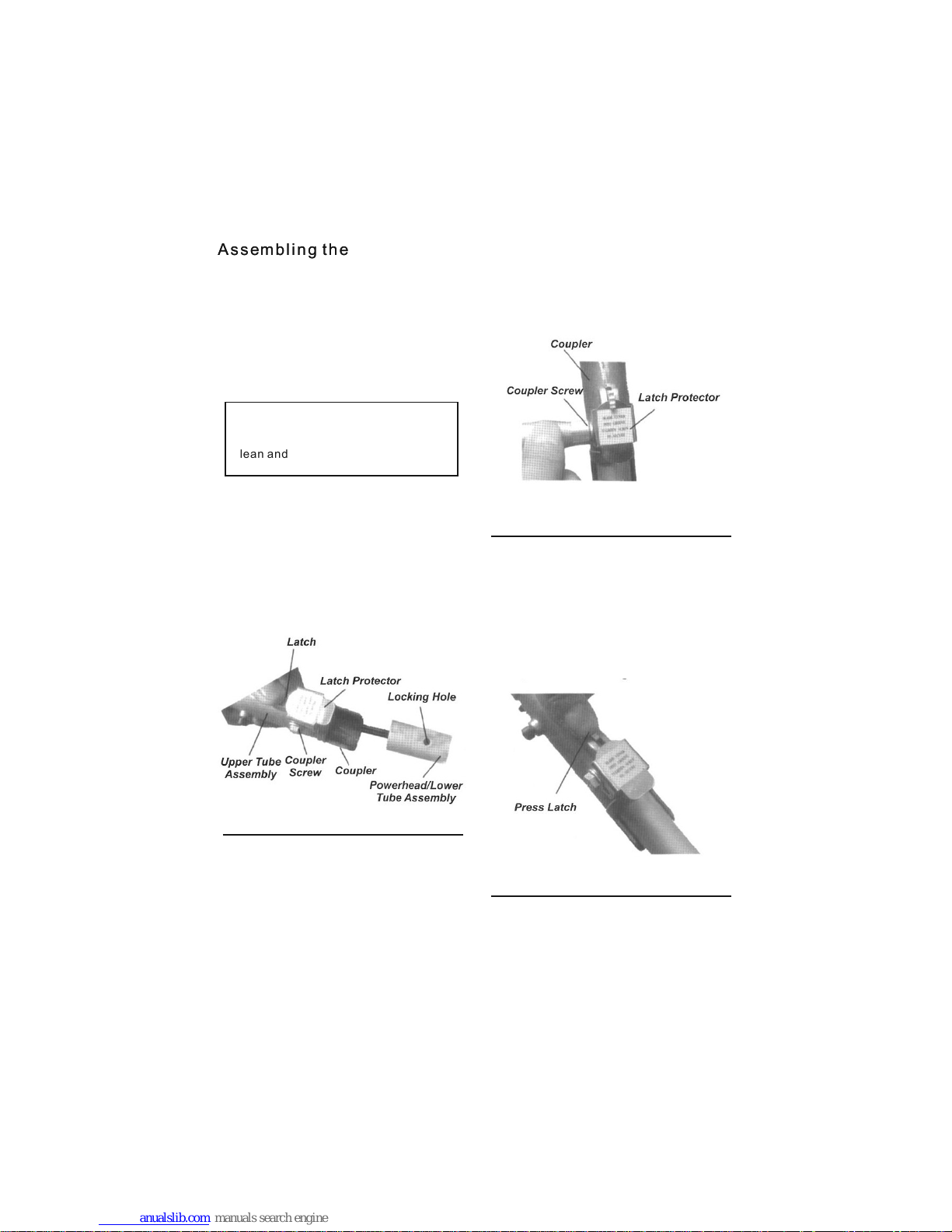

Assembling the Tube Sections

1.Pla ce the po werhe ad/lower tube

assem bly and t he uppe r tube

assem bly on a cl ean, fl at surf aceso

that bo th asse mblis e fit end t o end.

The pow erhea d/low er tube a ssembly

shoul d be faci ng up, an d the upp er

tube as sembl y shoul d be posi tioned

with th e latch P rotec tor fac ing up.

Figure

12

Keep th e open en d of the tu bes

clean a nd free o f impur ities !

CAUTION!

Figure

13

Figure

14

2.Loo sen the c ouple rscre w.

3.Dep ress th e latch a nd insert the

power head/ lower t ube ass embly int o

the cou pler un til it bo ttoms . Release

the lat ch. Roc k the upp er tube

assem bly bac k and for th unti l you

are sur e it snap s in plac e by the

coupl er lock . See Fig ure 12.

4.Whe n the two t ube hal ves are l ocked

toget her, sli de the la tch prote ctor

into gr oove of l atch, t hen tig hten the

coupl er scre w. See Fig ure 13.

Disas sembl ing The P ole sec tions

1.Wit h the pol e prune r on a clea n, flat

surfa ce, loo sen the c ouple r screw.

slide t he latc h prote ctor ou t of groove

of latc h.

2.Dep ress th e latch . This re lease t he

coupl er lock . See Fig ure 14.

3.Pul l the upp er tube a ssemb ly out of

the cou pler

8

Page 10

WARNING!

This en gine is t o be oper ated on a 25:1

mixtu re cons istin g of unleaded

gasol ine and 2 -cycl e mixin g oil only.

Some ga solin es cont ain alc ohol as an

oxyge natel O xygen ated fu els may

cause i ncrea sed ope ratin g

tempe ratur es. Und er cert ain condi tions

alcoh ol-ba sed fue ls may al so reduce

the lub ricat ing qua lities of some mix ing

oils. N ever us e any fue l conta ining

more th an 10% al cohol b y volume!

When an o xygen ated fu el must be

used, f uel con taini ng an oxy genate

such as M TBE is to p refer red ove r an

alcoh ol base d fuel.

Gener ic oils a nd some o utboa rd motor

oils ma y not be in tende d for use i n

high- perfo rmanc e air coo led 2-cyc le

engin es, and s hould n ever be used in a

this en gine!

Mixing Fuel

CAUTION!

Alway s minim ize the r isk of fi re when

handl ing fue l!

Alway s allow t he prun er to cool

befor e refue ling!

Wipe al l spill ed fuel a nd move t he

prune r at leas e 3 meter s (10 feet)

from th e fueli ng poin t befor e

resta rting !

Never s moke or l ight an y fires near

the pru ner or fu els!

Never p lace an y flamm able ma terial

near th e engin e muffl er!

Never o perat e the eng ine wit hout

the muf fler an d spark a rrest or in

place a nd prop erly fu nctio ning!

Never o perat e this ma chine if fuel

syste m compo nents a re dama ged

or are le aking .

Use onl y fresh , clean u nlead ed galoli ne

with an o ctane r ating o f 87 or abo ve.

Mix all f uel wit h 2-cyc le Engi ne Oil at a

gasol ine/o il rati o of 25:1 .

Mix onl y enoug h fuel fo r your im mediate

needs ! If fuel m ust be st ored lo nger than

30day s, it sho uld fir st be tre ated with a

TM

stabi lizer s uch as St aBil

1.Pla ce the pr uner on a f lat, le vel surfa ce.

2.Cle ar any di rt or oth er debr is from

aroun d the fue l fille r cap.

3.Rem ove the f uel cap , and fil l the fuel

tank wi th clea n, fres h fuel mi xture.

4.Ins tall an d firml y tight en the fuel c ap.

5.Wip e up any sp illed f uel from the

power head be fore re start ing.

IMPORTANT

9

Page 11

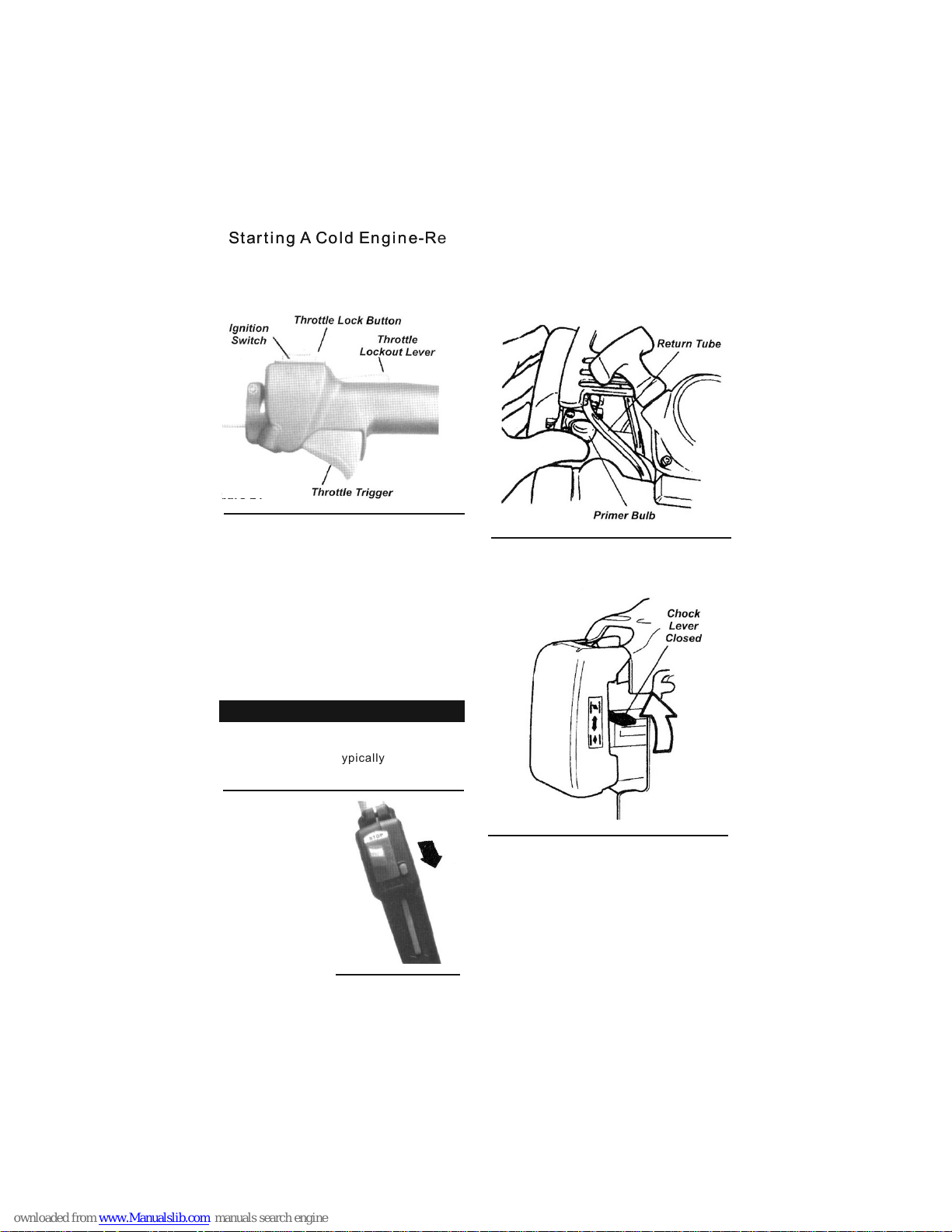

Starting A Cold Engine-Restarting After Refueling

Contr ol Posi tions ( cold en gine)

1.Set t he thro ttle tr igger to "Fast idl e"

as foll ows (Fi gure 24 ):

figure 26

figure 27

figure 25

Engin e ignit ion is co ntrolled by a

twopo sitio n START-STOP swit ch moun ted

on the th rottl e body, ty pical ly labe led "I"

for START and "O" fo r STOP.

IMPORTANT

●Depre ss and ho ld the th rottl e

locko ut leve r.

●squee ze and ho ld the th rottl e

trigg er.

●Depre ss the th rottl e lock bu tton.

●While h oldin g down th e throt tle

lock bu tton, r eleas e the thr ottle

trigg er and th rottl e locko ut lever.

●Relea se the th rottl e lock bu tton.

2.Sli de the

ignit ion

switc h to the

"I" (st art)

Posit ion. Se e

Figur e 25.

3.Pri me the en gine by d epressing the

carbu retor p rimer b ulb fou r or five

times , See Fig ure 26. You s hould be

able to s ee fuel i nside t he bulb .

4.Cho ke the en gine by m oving t he

choke l ever up t o the "cl osed"

posit ion. Se e Figur e 27.

Contr ol Posi tions ( warm en gine)

1.Set t he thro ttle tr igger t o "fast idl e"

(see St ep 1 abov e).

2.Sli de the ig nitio n switc h to the "I"

(START) posit ion.

3.Mov ing the c hoke le ver dow n to the

"open " posit ion.

figure 24

10

Page 12

Figure 28

Figure 29

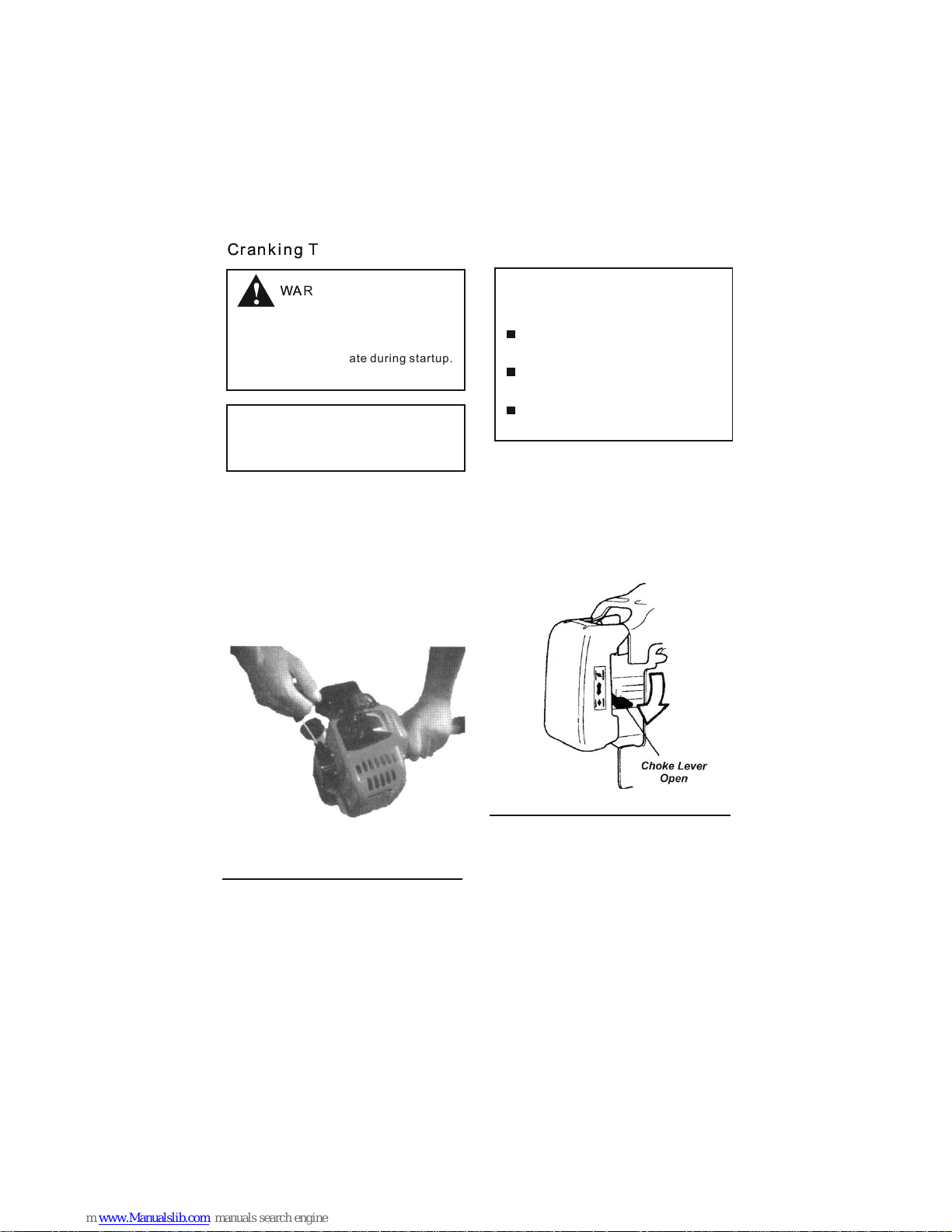

Cranking The Engine

When st artin g the eng ine, ma ke sure

the cut ting at tachm ent is we ll clear

of byst ander s, pets o r objec ts. The

attac hment m ay rota te duri ng startu p.

WARNING!

CAUTION!

CAUTION!

Never o perat e the pol e prune r unless

a cutti ng atta chmen ts is ins talled.

The rec oil sta rter ca n be dama ged

by abus e.

Alway s engag e the sta rter be fore

attem pting t o crank t he engi ne.

Never p ull the s tarte r cord to i ts

full le ngth.

Alway s rewin d the sta rter co rd

slowl y.

1.Pla ce the un it firm ly on the ground,

makin g sure it i s stabl e and tha t the

cutti ng atta chmen t is free a nd clear

of any by stand ers or ob jects , Hold

onto th e hand gr ip on the o uter tu be

with yo ur left h and gra sp the starter

rope ha ndle wi th your r ight ha nd.

See Fig ure 28.

2.Pul l the sta rter ha ndle sl owly unti l

you fee l the sta rter en gage.

3.Pul l the sta rter ha ndle qu ickly to

start t he engi ne.

When Th e Engin e Start s Or Fire s

Open th e choke b y movin g the cho ke

lever d own. Se e Figur e 29.

11

Page 13

The cut ting at tachm ent wil l engage

and rot ate as th e engin e start s and

accel erate s.

WARNING!

If the en gine di d not con tinue t o run,

repea t the app ropri ate cra nking

proce dure (w arm or co ld engi ne).

When th e engin e start s clear e xcess

fuel fr om the co mbust ion cha mber ty

revvi ng the en gine se veral t imes with

the thr ottle t rigge r (oper ating the

trigg er will a utoma tically diseng age

the "fa st idle " setti ng).

If The en gine Fa ils To Start

Repea t the app ropri ate cra nking

proce dure (w arm or co ld engi ne). If

the eng ine fai ls to sta rt afte r repeate d

attem pts, th e engin e is like ly floode d.

Proce ed to the f ollow ing pro cedure.

Start ing A Flo oded En gine

1.Dis conne ct the sp ark plu g lead, and

then us e the spa rk plug w rench t o

remov e the spa rk lug (t urn

count erclo ckwis e to remo ve).See

Figur e 30.

If the sp ark plu g is foul ed or soa ked

with fu el, cle an the lu g as nece ssary.

Figure 30

Figure 31

2.Ope n the cho ke (Fig ure 31) a nd fully

depre ss the th rottl e trigg er with you r

left ha nd, the n pull th e start er handle

rapid ly with y our rig ht hand t o clear

exces s fuel fr om the co mbust ion

chamb er.

CAUTION!

The cut ting at tachm ent can c ontinue

rotat ing aft er the en gine is switched

off!

WARNING!

Incor rect sp ark plu g insta llation c an

resul t in seri ous eng ine dam age.

3.Rei nstal l the spa rk plug a nd tighte n it

firml y. If a torq ue wren ch is ava ilabl e,

torqu e the spa rk plug t o 16.7- 18.6

N.m.

4.Rep eat the s tarti ng proc edure for a

warm en gine.

5.If th e engin e still f ails to s tart, ref er

to the tr ouble s shoot ing sec tion near

the end o f the man ual.

Stopping The Engine

1.Coo l the

engin e by

allow ing it to

idle fo r two

or thre e

minut es.

2.Sli de the

ignit ion

switc h to the

"O" or ST OP

posit ion. Se e

Figur e 31.

12

Page 14

The cut ting at tachm ent mus t never

rotat e at engi ne idle s peed.

WARNING!

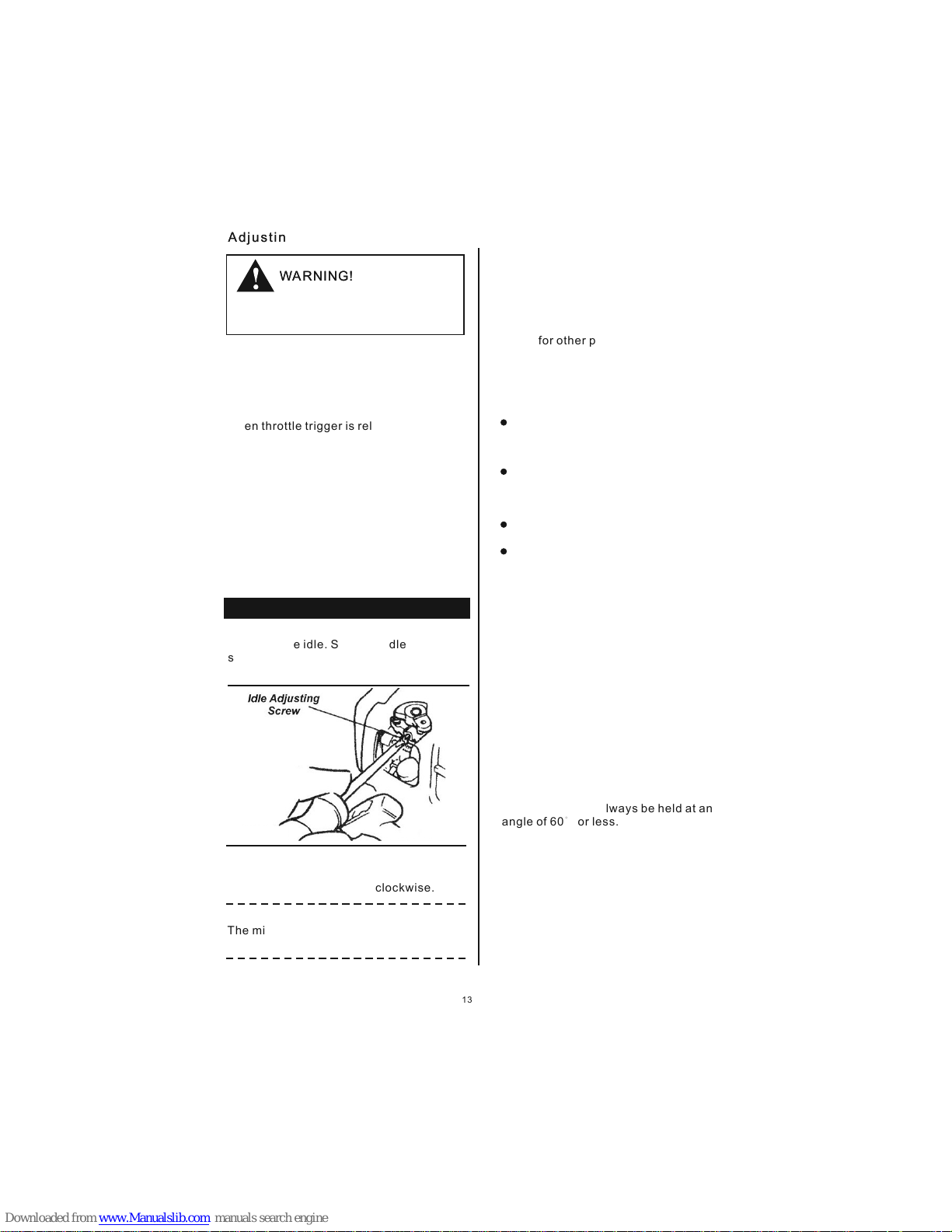

Adjusting The Carburetor

The eng ine mus t retur n to idle s peed

whene ver the t hrott le trig ger is rele ased.

Idle sp eed is ad justa ble and m ust be

set low e nough t o permi t the eng ine

clutc h to dise ngage t he chai n saw

when th rottl e trigg er is rel eased.

Check and Adjust Idle Speed

1.Sta rt the en gine an d allow i t to idle

two or th ree min utes, o r until i t

warms u p.

If the cu tting a ttach ment ro tates at

engin e idle, r educe i dle spe ed by

turni ng the id le adju sting s crew

count er cloc kwise a s neces sary. Se e

Figur e 32.

Use a tac homet er, if one i s available,

to set en gine id le. Sta ndard i dle

speed i s:

300±200 rpm

IMPORTANT

Figure 32

NOTE

3.If th e engin e is stal ling an d won't

idle, i ncrea se idle s peed by turning

the idl e adjus tment s crew cl ockwise .

The mix ture of t he carb ureto r on this

unit ca nnot be a djust ed.

Safety Operation

This ma chine i s desig ned esp ecially

for cut ting br anche s.

Never u se this m achin e for any o ther

purpo ses. Ne ver try t o cut sto nes,

metal s, plas tics or a ny othe r hard

objec ts.

Using f or othe r purpo ses tha n cutting

branc hes may d amage t he mach ine or

cause s eriou s injur y.

Preparations

Wear su itabl e prote ctive c lothi ng

and equ ipmen t-see s ectio n "safety

Preca ution s".

Choos e the bes t work po sitio n for

safet y again st the fa lling o bject

(Bran ch etc)

Start t he engi ne.

Put on th e strap .

Never s tand di rectl y under neath the

branc h you are c uttin g-be wa ry of

falli ng bran ches. N ote tha t a branch

may spr ing bac k at you af ter it hi ts the

groun d.

Cutti ng sequ ence:

To allow br anche s a free fa ll, always

cut the l ower br anche s first . Prune

heavy b ranch es (Lar ge diam eter) in

sever al cont rolla ble pie ces.

Worki ng posi tion:

Hold th e contr ol hand le with y our right

hand, a nd the sh aft wit h your le ft hand.

Your l eft arm s hould b e exten ded to

the mos t comfo rtabl e posit ion.

The sha ft shou ld alwa ys be hel d at an

angle o f 60° or les s.

13

Page 15

WARNING!

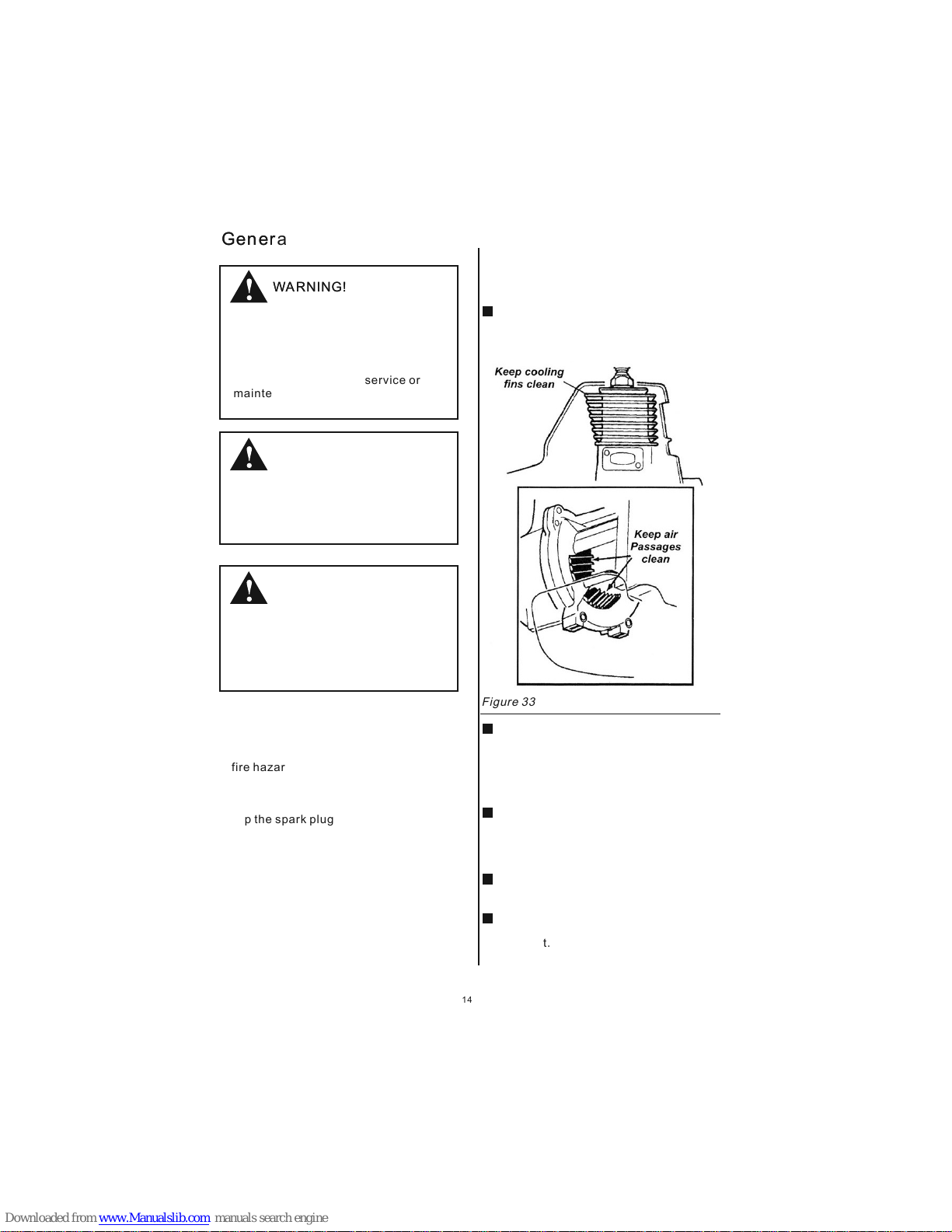

General maintenance

Befor e perfo rming a ny main tenance ,

repai r, or clea ning wo rk on the

machi ne, mak e sure th e engin e and

cutti ng atta chmen t are com pletely

stopp ed. Dis conne ct the spark plug

wire be fore pe rform ing service or

maint enanc e work.

WARNING!

WARNING!

Muffler

Non-s tanda rd part s may not operate

prope rly wit h your un it and ma y cause

damag e and lea d to pers onal in jury.

Opera ting th e engin e witho ut a

muffl er or wit h a muffler th at is

damag ed or imp roper ly suff icien tly to

lead to h earin g loss.

This ma chine m ust nev er be ope rated

with a fa ulty or m issin g spark arrestor o r

muffl er is wel l secur ed and in g ood

condi tion, A wor n or dama ged muffler is

a fire ha zard an d may als o cause

heari ng loss .

SPARK PLUG

Keep th e spark p lug and w ire

conne ction s tight a nd clea n.

Daily maintenance

Prior t o each wo rk day, pe rform t he

follo wing:

Remov e all dir t and deb ris from the

engin e, chec k the coo ling fi ns and air

clean er for cl oggin g, and cl ean as

neces sary. se e Figure 33 .

Caref ully re move an y accum ulating o f

dirt or d ebris f rom the muffler an d fu el

tank firs t bu ild-up in these are as c an

lead to engin e ov erhea ting , fire or

prema ture wear .

Check f or loos e or miss ing scr ews or

compo nents . Make su re the cu tting

attac hment i s free of d ebris and

secur ely fas tened .

Check t he enti re mach ine for leaking

fuel or g rease .

Make su re nuts , bolts a nd scre ws

(expe ct carb ureto r adjus ting scre ws)

and tig ht.

Figure 33

14

Page 16

Figure 34

Figure 35

Every 1 0 hours o f opera tion:

(more f reque ntly in d usty or dirty

condi tions ):

remov e the air c leane r eleme nt from the

air cle aner ho using a nd clea n it

thoro ughly w ith soa p and wat er. Rinse

and dry t horou ghly. Add a f ew drop s of

oil and w ork it in , then re assem ble the

eleme nt. See F igure 3 4.

CAUTION!

10-Hour Maintenance

Do not op erate t he mach ine if th e air

clean er or ele ment is d amaged, or if

the ele ment is w et or wat er soak ed.

CAUTION!

10/15-Hour Maintenance

Befor e remov ing the s park pl ug, clean

the are a aroun d the plu g to prev ent dirt

and dus t from ge tting i nto the e ngine's

inter nal par ts.

Every 1 0 to 15 hou rs of ope ratio n:

remov e and cle an the sp ark plu g. See

Figur e 35. Adju st the sp ark plug

elect rode ga p to 0.6~ 0.7mm

Repla ce the sp ark plu g as necessary.

15

Page 17

Specifications

Dry Wei ght

(With out Bar /Chai n).......... ..... ..... ...5. 9kg

Engin e Type.. ..... ..... ..... .2-cy cle, ai r-coo led,

verti cal-c ylind er

Borex Strok e.... ..... ....... ..... ..... ..... .34x2 8 mm

3

Displ aceme nt... ..... ....... ..... ..... ..... ..25. 4cm

-1

Engin e speed a t Idle. ..... ....... ..... ....3 000mi n

-1

Maxim um engi ne spee d.... ....... ....7 500mi n

-1

Maxim um Outp ut... ..... ....0.7 kW@85 00min

Fuel/ Oil Rat io... ..... ....... ..... 25:1 wi th 2-cy cle

Engin e Oil

Fuel Tank C apaci ty.. ..... ..... ..... ..... ..... 600ml

Carbu retor Ty pe... ..... ..... ..... Diaph ragm ty pe

Ignit ion.. ..... ...Flywheel ma gneto C DI syst em

Spark p lug.. ..... ..... ....... ..... ..... ..... ..... ...NG K

Air Fil ter... ..... ....... ..... ..... ..... ..... ..... Semi- wet,

quick -remo ve/in stall

Start ing Met hod.. ............ ..... ..... ..... ..... Recoi l

Cooli ng Syst em... ..... ....... ..... ..... ...Fo rced ai r

Stopp ing Met hod.. ..... ....... ..... ....S lide sw ich

Tra nsmis sion Type.. ............ ..... ..Aut omati c,

centr ifuga l clutc h with be vel gear

Oil Tank Cap acity. ..... ..... ..... ..... ..... ..400 ml

Gearc ase Rat io... ..... ....... ..... ..... ..... 1.06: 1

Stand ard Equ ipmen t.... ....... ..... ..... ..too l kit

conta ining a s park pl ug wren ch,

4mm all en wren ch and 8m m x

10mm sp anner, s trap, c hain cover

phill ips scr ewdri ver

Sound P ressu re Leve l*

Sound P ower Le vel*

Vibra tion Le vel*

91 dB (A)

106 dB (A )

2

2.32/ 2.78 m/ s

2

3.64/ 3.89 m/ s

Idlin g (Fron t/Rea r)

Racin g (Fron t/Rea r)

*Soun d Press ure Lev el: in accordanc e with IS O 1168 0-1 (An nex B)

*Soun d Power L evel: in accordance wit h ISO 11680-1 ( Annex B )

*Vibr ation L evel: i n accor dance w ith ISO 11680 -1 (Ann ex C)

16

Page 18

17

BRUSH CUTTER

1.PARTS LOCATION

See figure 1

1.Air cleaner

2.Fuel tank

3.Clutch coupler system

4.Ignition switch

5.Throttle trigger

6.Hanger

7.handle A

8.Handle B

9.Handle C

10.Outer pipe

11Debris shield

12.Gearcase

13.Blade

Page 19

2. Warning labels on the machine

(1) Rea d owner 's manu al befo re operat ion thi s machi ne

(2) Wea r head, e ye and ea r prote ction

(3) Warnin g/att entio n

(4) Kee p all chi ldren , bysta nders and h elper s 15 mete rs away f rom the b rush cu tter.

If warn ing sea ls peel o ff or bec ome soi led and i mposs ible to r ead, yo u shoul d conta ct the

deale r from wh ich you p urcha sed the pro duct to o rder ne w seals a nd offer the n ew seal i n

the req uired l ocati on.

Never r emode l your br ush cut ter.

We won' t warra nt the ma chine . If you us e the rem odele d brush c utter o r you don 't obse rve

the pro per usa ge writ ten in th e manual.

3. Symbols on the machine

IMPORTANT

WARING

18

Page 20

For saf e opera tion an d maintenance, s ymbol s are car ved in re lief on

the mac hine. Ac cordi ng to these indica tions p lease b e carfu l not to t

ake mis take

(a)Th e port to r efuel t he "mix gasoline "

Posit ion: fu el tank c ap

(b)Th e direc tion to c lose th e choke

Posit ion:a ir clea ner cover

(c)Th e direc tion to o pen the c hoke

Posit ion:a ir clea ner cov er

4. Safety precautions

Before using the machine

A. Read t he owne r's man ual carefully to u nders tand ho w to oper ation

this un it prop erly.

B. This p roduc t has bee n desig ned for u se in cut ting gr ass, an d it

shoul d never b e used fo r any oth er purpos e.

C. You shou ld neve r use the m achine wh en unde r the inf luenc e of

alcoh ol, whe n suffe ring fr om exha ustio n or lack o f sleep w hen suf ferin g

from dr owsin ess as a re sult of having tak en cold m edici ne, or at a ny

other t ime whe n a a possi bility exists th at your j udgme nt migh t be

impai red or th at you mi ght not be able to ope rate th e brush c utter

prope rly and i n a safe ma nner.

D. Avoid r unnin g the eng ine ind oors. The ex haust g ases contain

harmf ul carb on mono xide.

E. Neve r use you r brush c utter under circ umsta nce lik e those

descr ibed be low.

1. When t he grou nd is sli ppery or when othe r condi tions e xist wh ich

might m ake it im possi ble to ma intain a st eady po sture w hile us ing the

brush c utter.

2. At nigh t at time s of heav y fog. Or at any other t ime tim es when y our

field o r visio n might b e limit ed and it wou ld be diffic ult to ga in a clea r

view of a rea.

3. Duri ng rain s torms , during lightni ng stor ms at tim es of str ong or ga leforce w inds, or at any o ther ti mes when we ather c ondit ion mig ht make i t

unsaf e to use th is mach ine.

F. When usi ng this m achin e fo the first time, b efore b eginn ing act ual

work le arn to ha ndle br ush cut ter from sk illed w orker s.

G. Lack o f sleep t iredn ess, or physical e xhaus tion re sult in l ower at tenti on span s.and

this in f act can l ead to ac cident and injur y.li mit the a mount o f time wh ich the b ush cut ter

is to be us ed cont inuou sly to so mewhere a round 3 0-40 mi nutes p er sess ion, an d take

10-20 m inute s of rest b etwee n work sess ion. Als o try to ke ep the to tal amo unt of wo rk

perfo rmed in a s ingle d ay unde r 2 hours or le ss.

H. Be sur e to keep t his man ual han dy so you mig ht refe r to it lat er or whe never t he

quest ions ar ise.

19

Page 21

20

I. Alway s be sure t o inclu de this manual whe n selli ng lend ing, or o therw ise tra nsfer ring

the own ershi p of this p roduc t.

J. Neve r allow c hildr en or anyone unabl e to full y under stand t he dire ction s given i n

this ma nual to u se this b rush cu tter.

WORK ING GEAR AND CLOTHING

A. When u sing yo u brush c utter, you should w ear pro per

cloth ing and p rotec tive eq uipment a s follo ws.

1. Helm et

2. Prot ectio n goggl es or fac e protect or

3. Thic k work gl oves

4. Non- slip- sole wo rking b oots

5. Ear pr otect or

B. And you s hould c arry wi th things as follo ws

1. Attac hed too ls and fi les

2. Prop erly re serve d fuel

3. Spar e blade

4. Thin gs to not ify you r worki ng area (tape , warni ng sign s)

5. Whis tle(f or coll abora tion oe eme rgenc y)

6. Hatc het or sa w(for r emova l of obstac les)

A. Befo re begi nning w ork, lo ok around c arefu lly to ge t a feel fo r the sha pe of lan d, or

grass t o be trim med and w hethe r or not ther e are any o bstac le whic h might g et in the

way whi le work ing, an d remov e any

C. Neve r use you r brush c utter when you wea ring pa nts wit h loose c uff s, when w earin g

sanda ls, or ev en bare foot.

WARNING CONSIDERING HANDLING OF FUEL

A. The en gine of t his pro duct is d esign ed to run o n a mixed

fuel, which c ontai ns high ly flamma ble gas oline . You shoul d never

store c ams of fu el or ref ill the f uel tank in a ny plac e where t here is a

boile r, stove , wood fi re, elect rical s parks , weldi ng spar ks, or an y

other s ource o f heat or f ire whi ch might ig nite th e fuel.

B. Smok ing whi le oper ating t he brush cu tter or r efill ing its f uel tan k is extr emely

dange rous. Al ways be s ure to keep lit ciga rette a way fro m brush c utter a t all tim es.

C. When r efill ing the t ank alw ays turn off the e ngine f irst an d take a ca reful ly look

aroun d to make s ure tha t there a re no spark s or open f lames a nywhe re near b y befor e

refue ling.

D. If any f uel spi llage o ccurs during ref uelin g, use a dr y rug to wi pe up spi lls bef ore

turni ng the en gine ba ck on aga in.

E. After r efuel ing scr ew the fuel cap back t ightl y onto th e fuel ta nk and th en carr y the

brush c utter t o a spot 3m eter mo re away fro m where i t refue ling be fore tu rn on the

THINGS TO CHECK BEFORE USING YOUR BRUSH CUTTER

Page 22

Obsta cles, w hich ca n be clea red away.

B. The ar ea with in a peri meter o f 15m of th e perso n using t he brus h cutte r shoul d be

consi dered a h azard ous are a into whic h no one sh ould en ter whi le the br ush cut ter is in

use, an d when ne cessa ry yell ow waning r ope, wa rning s igns sh ould be p laced a round

work ar ea. Whe n work is t o be perf ormed sim ultan eousl y by

two or mo re pers ons, al ways check the pre sence a nd

locat ions of o thers s o as to maintain a dis tance e ach per son

suffi cient t o ensur e safet y.

C. Make s ure tha t there a re no loose screws o r bolt, f uel

leaks , ruptu res, de nts, or any other pr oblem s, whic h might

inter fere wi th safe ty oper ation.B e espec ially c arefu l to chec k

that th ere is no thing w rong wi th the blad es or wit h the joi nts

by whic h the bla des are a ttach ed to the bru sh cutt er.

D. Neve r use bla des tha t are bent, warped c racke d, brok en or

damag ed in any w ay.

E. Keep t he blad e alway s sharp .

F. Fillin g the cut ting ed ge, keep the end cor ner sha rp and

round t he root o f the edg e.

G. Chec k the bol t to fast en the bl ade and be su re the bl ade

turn sm oothl y witho ut abno rmal nois e.

NOTES O N STARTING THE ENG INE

1. Take a car eful lo ok arou nd to mak e sure th at obst acles e xist wi thin a pe rimet er of

15m or le ss arou nd brus h cutte r.

2. Plac e the bru sh cutt er onto t he ground i n a flat cl ear are a and hol d it firm ly in pla ce

so as to en sure th at neit her the b lades nor t he thro ttle ca me

into co ntact w ith any o bstac les when th e engin e start u p.

3. Plac e the thr ottle i nto the i dling pos ition w hen sta rting

the eng ine.

4. After s tarti ng the en gine. Of the blade s conti nue to ro tate

even af ter thr ottle h as been m ove fully b ack ful ly turn o ff

the eng ine and c heck th e throt tle wire an d other p arts.

KICKB ACK SAFETY PRECAUTIONS

A danger ous rea ction m ay occur when the sp innin g blade c ontac t a solid o bject i n the

criti cal are a. It is ca lled ki ck back, as a r esult , the ope rator c an lose c ontro l of the un it

which c an caus e serio us or tot al injury.

Avoid k ickba ck; obs erve th e safet y preca ution s below s trict ly.

1.Bef ore beg innin g work, clear your w orkin g area an d remov e grass a round t he

obsta cles.

2.Whe n using y our bru sh cutt er, d o not gri p other p arts ex cept th e handl es.

21

Page 23

1. Perf orm the m ainte nance a nd checki ng oper ation s descr ibed in t his man ual at re gular

inter vals. I f any par ts must be replace d or any ma inten ance or r epair w ork not d escri bed

in this m anual m ust be pe rform ed. Pleas e conta ct a repr esent ative f rom the n eares t

store a uthor ized se rvici ng dealer f or assi stanc e.

2. Unde r no circ umsta nces sh ould you ev er take a part th e brush c utter o r after i t in any

way. Doi ng so mig ht resu lt in the b rush cu tter be comin g damag ed duri ng oper ation o r the

brush c utter b ecomi ng unab le to opera te prop erly

3. When u sing yo ur brus h cutte r, ne ver tak e you eye s off . If you ne ed to, pl ace you

throt tle int o idlin g posit ion.

4. When u sing yo ur brus h cutte r. Do not let th e unit ge t close r to your f eet nor r aise th e

unit ab ove you r waist .

1. Make s ure the a pprop riate b lade is in pl aced.

2. When t ransp ortat ion by ca r, fix the uni t firml y using a r ope. Do n ot tran sport b y bicyc le

or moto rcycl e becau se it is da ngerous .

3. Neve r trans port br ush cutter in a roug h road ov er long d istan ce with out fir st remo ving

all fue l from fu el tank , as doin g s might cau se fuel t o leak fr om tank .

NOTES ON TRANSPORTATION

OPERATION SAFETY PRECAUTIONS

1. Grip t he hand le on the b rush cu tter firm ly with b oth han ds. If yo u suspe nd the wo rk,

place t he thro ttle in to the id ling posi tion.

2. Alway s be sure t o maint ain a steady,ev en post ure whi le work ing.

3. Main tain th e speed o f the eng ine at the le vel req uired t o perfo rm

cutti ng work , and nev er rais e speed of th e engin e above t he leve l

neces sary.

4. If the g rass ge t caugh t in the bl ade durin g opera tion, o r if you ne e to

check t he unit o r refue l the tan k, always b e sure to t urn off the en gine.

5. If the b lade to uches a h ard object like a st one, st op the en gine

immed iatel y and che ck if som ething wr ong wit h the bla de, if so , repla ce

the bla de by new o ne.

6. If som eone ca lls out w hile wo rking, al ways be s ure to tu rn off the

engin e befor e turni ng arou nd.

7. Neve r touch t he spar k plug or plug cord wh ile the e ngine i s in

opera tion. doing s o may res ult in bein g subje cted to a n elect rical s hock.

8. Neve r touch t he muff ler, spa rk plug o r other m etall ic part s of the

engin e while t he engi ne is in operation o r immed iatel y after

shutt ing dow n the eng ine. Do ing so may re sult i se rious b urns.

9. When y ou fini s cutti ng in one l ocation a nd wish t o conti nue wor k

in anot her spo t, turn o ff the en gine an d turn th e unit as t he blad e

faces a way fro m your bo dy.

MAINTENANCE SAFETY PRECAUTION

22

Page 24

3.Alw ays be su re to tur n off eng ine bef ore per formi ng any ma inten ance or c hecki ng

proce dures

4.Whe n sharp ening , remov ing, or rea ttach ing the b lode pr oper to ols and e quipm ent to

preve nt inju ry.

5.Whe n repla cing bl ade or any other par ts or whe n repla cing th e oil or an y lubri cants ,

alway s be sure t o use

only pr oduct s or prod ucts wh ich have be en cert ified b y for use w ith the b rush cu tter.

5.SET UP

HANDLE

Fix Han dle wit h four bo lts

see fig ure 9

INSTAL L GEARCA SE

1. Loos en two cl amp scr ews and r emove one i ndex sc rew

2.Pus h the pip e towar ds gear case and ro tate it b y hand to

check t hat the m ainsh aft spl ines enga ge the po werhe ad.

3.Ins ert the p ipe int o gear ca se until it b ottom s and ali gn

the pos ition ing hol es on the pipe and gea rcase . then

repla ce the in dex scr ew and ti ghten.

5. Fast en the pi pe clam p secur ely with tw o clamp s crews

see fig ure 10

23

Page 25

SAFETY GUARD

Attac h the saf ety gua rd to the gear case an d fix it wi th the

clamp and 2bo lls (M5 *25) se curely. (Figu re 11)

(1) Bol t

(2) Cla mp

(3) Mai n pipe

(4) Saf ety gua rd

INSTALLING THE METAL BLADE

(Figu re 12)

1.Set t he inne r holde r to the gear shaft , an d turn to f ix with t he atta ched L- shape d bar.

2.Put t he blad e on the in ner hol der with le tters t o the gea r case, a nd matc h corre ctly th e

hole of t he blad e to the pr oject ion of the in ner hol der.

3.Set t he oute r holde r to the gear shaft wi th the ho llowe d face to t he blad e.

4.Put t he atta ched bo lt cove r on the oute r holde r and sec ure

it with the bol t (left s crew) together w ith the s pring w asher

and the washe r.

(1) Nut

(2) Outer holder 1

(3) Outer holder 2

(4) Bl ade

(5) Gear shaft

(6) Bar

(7) Inner holder

(8) Gear case

INSTALLING THE NYLON CUTTER(OPTION)

(Figu re 13)

1.Set c orrec tly the i nner holder and th e outer h older t h the

gear sh aft.

2.Scr ew the at tache d bold (M 8 Left) int o the gea r shaft a nd

secur e it with t he span ner.

3. Scre w the nyl on cutt er into t he bolt by fi xing th e inner

holde r with th e L-sha ped bar and tighte n it manu ally.

Keep bo lls and w asher s to install the bla de care fully s o as

not to lo se them .

NOTE

(1) Gear Case

(2) Bolt

(3) Nylon cutter

(4) Nylon cord

24

Page 26

Stopping The engine

WARNING!

The cut ting at tachm ent can c ontinue r otati ng afte r the eng ine is sw itche d off !

1.Coo ling th e engin e by allo wing it to id le for tw o or thre e minut es.

2.Sli de the ig nitio n switc h to the "O" or S TOP posi tion. S ee Figu re 21

To Wear the Str ap

See

Figur e 22

Emerg ency Release

See Fig ure 2 3

1.Hoo k the s tra p hoo k to ha nger on the ou ter p ipe .

2.Wear the stra p so th at th e hoo k sta ys at your rig ht ha nd si de.

3.Adj ust t he le ngt h of th e strap so tha t you c an ho ld an d operate

machi ne wi ll be r ele ase d from the str ap.

In case o f eme rge ncy s tro ngly pull he w hit e tab a t the h ook. The

machi ne wi ll be r ele ase d from the str ap.

CUTTING OPERATION

METAL BLADE USAGE

Alway s cut b y gui din g the h ead from you r rig ht to l eft .

A metal bl ade c ut be st up t o the p oint 1/ 3 fro m the e dge . Use

that ar ea fo r cut tin g shr ubs. tough a nd th ick w eed s. For cutti ng

young g ras s, yo u can u se up t o 2/3 from the t ip of b lad e.

Adjus t the e ngi ne sp eed a ccording t o the c utt ing o bjects. Cu t

the you ng gr ass a t mid dle s peed. and cu t shr ubs o r tou gh and

thick w eed s at hi gh sp eed .

☆

☆

☆

(1) For branches and trees

(2) For grass an d weeds

(3) Direction of cuttin g

(4) Direction of rotation

IMPORTANT

Opera tin g at lo w spe ed ma kes it easie r for g ras s, we eds, or

twigs t o bec ome c aug ht up i n the blades , and a lso i t mak es

the sha ft an d clu tch w ear d own more qui ckl y.

Nylon c ord c ons ume s lar ge power. Ple ase n ote t hat t he engine speed i n ope rat ion s hou ld be

50% as la rge a s whe n usi ng me tal blade.

Nylon c utt er cu ts gr ass w ith the powe r of co rd ro tat ion . If you try t o cut g ras s for t he length of c ord a t

one tim e, ro tat ion s pee d becomes lo wer d ue to r esi stance and y ou ca nno t cut w ell. In case o f lar ge

resis tc nc e. ge t the n ylo n cutter awa y fro m gra ss on ce , make the ro tat ion s pee d higher, and c ut a

small a mou nt of g ras s at on e time.

If you tr y to cu t gra ss by s win ging the bru sh cu tte r in th e reverse wa y (fr om le ft to r ight). scr aps f ly

in the di rec tio n awa y fro m the body. You can av oid g ett ing y our clothe s dir ty.

rotat ion

NYLON CUTTER USA GE

☆

☆

☆

25

Page 27

1. Brush ing off d irt for m the mac hine, c heck da mage or s lack of e ach par t. If you

find ou t abnor malit ies, re pair them f or the ne xt use.

2. Extra ct fuel f rom the t ank, and loose the d rain sc rew of th e float c abin to e xtrac t

fuel, t urn on th e engin e, and leave it runn ing unt il it sto ps natu rally.

3. Remov e the spa rk plug a nd put in 1 -2cc of 2-c ycle oi l in the en gine. D raw the

start er rope 2 -3 time s, set th e plug back , and sto p it at the c ontra ction p ositi on.

4. Apply s nti-r ust oil t o the met al parts su ch as the t hrott le wire , put the c over on

the bla de, and k eep it in door av oiding da mpnes s.

8. MAINTENANCE

BLADE

Sharp en each c ultin g edge an d make sure t he bott om

comer i s round ed. (fi gure 24 )

Do not co ol the bl ade wit h water in case of usi ng

grind er. It may c ause cr acks on blade.

GEAR CA SE

Suppl y multi -purp ose gre ase of ever y 25 hour s of use.

Remov e the cut ter hol ders to arrange fo r old gre ase to

exit. ( figur e 27)

MAINTENANCE BEFORE STORAGE

26

Page 28

9. SPECIFICATION

Han dle typ e

Pow er tran smiss ion met hod

App lied bl ade

Bla de rota tion di recti on

Out ward si ze(L* W*H)( mm)

Wei ght (kg)

Loo p

Aut omati c centr ifuga l clutc h, spir al beve l gear

Met al blad e

Cou nterc lockw ise(f rom ope rator ’s vie w)

204 0^380 ^330

6.5

Loo p

Nyl on cutt er

Cou nterc lockw ise(f rom ope rator ’s vie w)

204 0^380 ^330

6.5

Type

Dis place ment

Max . outpu t

Max . engin e speed

Eng ine spe ed at idl e

Car buret or

Sta rting m ethod

Fue l

Sto pping m ethod

Fue l tank ca pacit y

Sin gle cyl inder a ir cool ing 2-c ycle ga solin e engin e

25. 4CC

0.8 5kw at 80 00rpm

1100 0rp m

300 0rpm± 200rp m

Dia phrag m type

Rec oil

Mix ture( gasol ine:2 -cycl e engin e oil) 25 :1

Sli de swit ch

700 CC

Eng ine

Nam e

Spe cific ation

Br ush cutter B250 Grass tr im mer G250

27

Page 29

POLE PRUNER

CAUTION!

Alway s maint ain thi s pole pr uner

accor ding to t he this o wner' s manual an d

follo w the rec ommen ded sch eduled

maint enanc e.

Never m odify o r disab le any of the pole

prune r's saf ety dev ices.

Alway s use gen uine pa rts and

acces sorie s when re pairing or

maint ainin g this ma chine .

Do not ma ke unau thori zed mod ificati ons

or subs titut ions to t he guid e bar or chai n

.

Never a llow th e engin e to run at high

RPM wit hout a lo ad , Doin g so could

damag e the eng ine.

When tr anspo rting t he pruner in a

vehic le , tie it d own sec urely t o prevent

damag e and fue l spill age.

Alway s stop th e engin e and allow it to

cool be fore re fueli ng. Avoi d overf illin g

and wip e off any f uel tha t may hav e

spill ed .

Never p lace fl ammab le mate rial clos e to

the eng ine muf fler an d never r un the

engin e witho ut the sp ark arrestor

scree n in plac e.

Alway s clear y our wor k area of trash or

hidde n debri s to help e nsure good

footi ng .

Keep th e saw cha in shar p and pro perly

adjus ted.

Keep th e prune r as clea n as poss ible .

Keep it f ree of lo ose veg etati on , mud,

etc .

28

Page 30

Operating the Pruner

To Wear the s trap

1.Hoo k the str ap hook t o the han ger on

the out er pipe .

2.Wea r the str ap so tha t the hoo k stays

at your r ight ha nd side

3.Adj ust the l ength o f the strap so that

you can h old and o perat e the mac hine

comfo rtabl y.

Emerg ency Re lease

In case o f emerg ency , st rongly pull the

white t ab at the h ook . The m achin e will

be rele ased fr om the st rap.

Figure 2

Always wear eye and

Hearing protection .

manufacturer

recommends wearing

a face shield as

additional face and

eye protection .

Always wear a hard hat to reduce the

risk of head injuries during oper ati on

of this machine.

Wea r non sli p hea vy- dut y wor k

gloves to improve your grip on the

pole pruner handle. Wear s nug fitting clothes that. Al so pe rmi ts

freedom of movement. NEVER wear

shorts!

Wea r stu rdy f oot wea r wit h non sli p

soles to provide good footing . Ste eltoes safety boots are recommend ed.

Never operate the

pruner at an angle

greater than 60.c in

order to reduce the risk

of being struck by

falling objects during

operation.

Always operate with both

hands firmly gripping the

machines.

Keep a proper footing and do not

overreach-Maintain your bal anc e at al l

times during operation .

Keep bystanders at least 15 meter s(5 0fe et) a way f rom t he

operating pruner to reduce the ri sk of b ein g str uck b y fal lin g

objects or thrown debris,

29

Page 31

Prior To Assembly

Product Description

Using F igure 3 a s a guide ,fami liarize

yours elf wit h the 260 0 pole pr uner and

its var ious co mpone ts Unde rstandi ng

your ma chine h elps en sure to p

perfo rmanc e,lon ger service life ,and

safer o perat ion.

Befor e assem bling ,make s ure you hav e

all the c ompon ents re quire d for a

compl ete uni t:

Power head as sembl y

Lower t ube ass embly

Upper t ube/s aw asse mbly,c hain

and gui de bar

Kit wit h this ma nual an d tool kit for

routi ne main tenan ce

Chain c over

Caref ully in spect a ll comp onents fo r damag e.

IMPORTANT

The ter ms”left -hand”, and

“LH”; ”righ t”,”r ight- hand”,a nd “RH” ,”fro nt”

and “re ar” ref er to dir ectio ns as viewe d by

the ope rator d uring n ormal operatio n

WARNING!

Do not ma ke unau thori zed

modif icati ons or al terations to you r

prune r or its co mpone nts.

30

Page 32

Cutte r attac hment w eight ……..….1 .8kg

Blade l ength

Long Mo del…… ….... ..... .…560mm /22in

Short M odel… ……... ..... .…460mm /22in

Cutte r drive ……... ..... ....... ..…Sp ur gear

Gear lu brica nt……L ithiu m based gre ase

Tool kit co ntent s………… .. Combination

Wrenc h with 13 mm+19 mm

Socke ts/fl at blad e screwdriver 4m m-hex

Wrenc h,and 8 mm+10 mm span ner

Use unit without upper tube

If the lo wer tub e assem bly is lo ng enough ,you ca n use it on ly with out upp er tube

accor ding to t he work ing con dition.

Opera te as fol lows:

1.Foll ow “disa ssemb lying the p ole sec tions” s ectio n to remo ve the up per tub e/cou pler

assem bly fro m gearc ase.

2.Foll ow”as sembl ing the pole secti ons” se ction t o assem ble the g earca se onto t he

lower t ube ass embly. See fig ure 15.

Specifications

31

Page 33

Installing and Adjusting the Bar and China

Insta lling T he Chin a

NOTE

WARNING!

WARNING!

Never a ttemp t to inst all, re place,

or adju st the ch ain wit h the

engin e runni ng.

The saw c hain is v ery sha rp. Wea r

glove s to prot ect you r hands when

handl ing.

For lon gest ch ain lif e, let ne w or

repla cemen t chain l oops soak in oil

overn ight be fore in stall ation.

1. Usin g the sma ll end of t he plug wrench,

remov e the spr ocket c over nu t (turn

count erclo ckwis e to remo ve) and rem ove

the spr ocket c over. See F igure 1 6.

2. Plac e the gui de bar ov er the gu ide bar

adjus tment s tud on th e cutti ng head

assem bly. Alig n the cha in tens ionin g pin

with th e hole in t he guid e bar. See Figure

17.

3. Inst all the c hain lo op over the drive

links w ithin t he guid e bar gro ove , and

then al ign the c hain ov er the dr ive

sproc ket . Mak e sure

the cut ter are p roper ly

orien ted as sh own in

Figur e 18. If ch ain

insta llati on is dif ficul t

or if the c hain ap pears

too tig ht, ref er to the

secti on “Adj ustin g the

China ” on the ne xt

page.

4. Inst all the s prock et cover over the ba r

stud. U sing fi nger- press ure only, insta ll

the spr ocket c over nu t.

5. Refe r to the ne xt page f or chain

adjus ting pr ocedu res.

CAUTION!

Failu re to ali gn the gu ide bar and chain

tensi oning p in can ca use serious

damag e to the sp rocke t cover, gui de

bar, cha in tens ionin g pin and cut ting

head as sembl y.

WARNING!

Never o perat e the pol e pruner Without

the spr ocket c over in stall ed.

32

Page 34

WARNING!

Never a ttemp t to inst all, re place,

or adju st the ch ain wit h the eingine

runni ng.

WARNING!

The saw c hain is v ery sha rp. Wea r

glove s to prot ect you r hands when

handl ing.

CAUTION!

Adjusting the Chain

A loose ch ain can j ump off t he guid e

bar cau sing da mage to t he chai n

and ass ociat ed equi pment. Always

make su re the ch ains is p roper ly

adjus ted; ch eck mor e often when

you are b reaki ng in a new c hain.

1. Place t he pole p runer o n a clean , flat

Surfa ce. (Fo r readj ustment during

opera tion, s hut dow n the engine, then

allow t he guid e bar and c hain to cool

befor e proce eding w ith the adjustme nt

proce dure.

2. Loose n the spr ocket c over nu t with a

Plug wr ench (F igure 1 9).

IMPORTANT

Prope r chain a djust ment is essentia l

for max imum pe rform ance, long

chain l ife, an d opera tor safety.

Alway s inspe ct chai n tensi on before

opera ting th e pole pr uner.

3. Lift th e nose of t he guid e bar whi le

turni ng the ch ain ten sioni ng screw. Se e

Figur e 20.

4. Pull th e chain b y hand al ong the t op

of the gu ide bar s evera l times from the

engin e to the ba r's tip . The cha in shou ld

feel su ng but st ill pul l freel y. See Fig ure

21.

5. Tig hten th e sproc ket cov er nut

secur ely whi le lift ing the t ip of the gui de

bar.

6. Inspe ct the ch ain for c orrec t

adjus tment ( more fr equen tly with a ne w

chain ).The c hain sh ould fe el snug but s till

pull fr eely.

Clock wise to t ighte n the chain

Count erclo ckwis e to loos en the

chain .

33

Page 35

Chain Oiler

IMPORTANT!

Never f ill the o il rese rvoir nor adjust

the oil er with t he engi ne runn ing.

The ser vice li fe of the c hain and guide bar

is affe cted by t he chai n and gui de

lubri cant. U sing su perio r lubrica nt such a s

genui ne Bar an d Chain O il will h elp ensur e

a long se rvice l ife, Fo r cold weather

opera tion, m ix bar an d chain o il with an

equal p art of ke rosen e.

Filing Th e Oil Reservo ir

The oil r eserv oir has a c apaci ty suff icien t

to prov ide abo ut 40 min utes of cutting

time (w hen set t o deliv er the minimum

flow ra te).

1.Pla ce the po le prun er on a cle an, flat

surfa ce with t he oil fi ller ca p facing up . See

figur e 22. Wip e off any d ebris f rom the o il

cap and f rom aro und the o il filler neck.

2.Rem ove the o il fill er cap an d fill the

reser voir wi th bar an d chain o il, then

repla ce the ca p.

3.Wip e up spil led oil f rom the u nit befor e

resta rting t he pole p runer.

Adjusting Oil Flow Rate

WARNING!

CAUTION!

An incr ease in b ar oil fl ow rate will

speed o il cons umpti on, req uiring

more fr equen t check s on the oi l

reser voir. To ens ure suffic ient

lubri catio n, it may b e neces sary to

check t he oil le vel mor e frequ ently

than at f uel tan k refil ls.

The gui de bar an d chain a re lubr icated

autom atica lly by a pu mp that operates

whene ver the c hain ro tates . The pum p is

set at th e facto ry to del ivery a medium

flow ra te, but i t can be ad justed in the

field A tem porar y incre ase in oil flow is

often d esira ble whe n cutti ng things l ike

hardw ood or wo od with a l ot of pit ch.

Adjus t the pum p as foll ows:

1.Sto p the eng ine and m ake sur e the stop

switc h is in the S TOP positi on.

2.Pla ce the un it in its s ide wit h the oil

Reser voir up . See Fig ure 23.

CAUTION!

The oil f low adj ustin g screw m ust be

press ed in sli ghtly i n order to yurn.

Failu re to do so c ould da mage th e

Pump an d screw.

3.Wit h a screw drive r, push in on the oil

flow ra te adju sting s crew an d turn in the

desir ed dire ction ( there a re three

incre menta l setti ngs):

Clock wise- decre ase lub ricatio n.

Count erclo ckwis e-inc rease

lubri catio n

34

Page 36

Cutti ng on a wor k platf orm:

The uni t's lon g reach e nables cutting t o be perf ormed n ext to th e trunk w ithou t the ris k of

the wor k platf orm dam aging other bran ches.

The too l angle i n this ca se depe nds on the po sitio n of the br anch.

Typica l appli catio ns

Stand ard cut :

The mos t conve nient w orking positio n is a

tool an gle of 60 °, but an y other angle may

be used t o suit th e situa tion co ncerned .

Cutti ng abov e obsta cles:

Thank s to the un it's lo ng reac h it is

possi ble to pr une bra nches that are

overh angin g obsta cles, such as rive rs or

lakes .

The too l angle i n this ca se depe nds on the

posit ion of th e branc h.

35

Page 37

Worki ng tech nique s

Relie ving cu t:

To avoid te aring t he bark , kickback or

pinch ing the b ar when p runing thick

branc hes the b ar when p runin g t hick

branc hes, al ways st art by per formi ng a

relie ving cu t (1) o n the unders ide of the

branc h.

To do this ap ply the c uttin g attachment and

pull it a cross t he bott om of the branch as

far as th e bar nos e. Perf orm the c rosscut(2 ).

Flush -cutt ing thi ck bran ches:

If bran ch diam eter is m ore than 10cm (4 ”) ,

first p erfor m und ercut (3) and cros s-cut at a

dista nce(A ) of abou t 25cm (1 0”) f rom the

final c ut. The n car ry ou t the flush-

cut(4 ),sta rting with a reli eving cut and

finis hing wi th a cross -cut.

36

Page 38

50-hour Maintenance

Every 5 0 hours o f opera tion

(more f reque ntly in d usty or d irty

condi tions ):

Remov e and cle an the cy linde r cover

and cle an dirt a nd debr is from the

cylin der coo ling fi ns.

Remov e the spr ocket c over an d

inspe ct the sp rocke t for exc essive

dirt, debri s,or we ar, Remove the

guide b ar and cl ean out t he guide bar

groov e.If th e sproc ket is excessive ly

worn, r eplac e it with a n ew one.See

Figur e 36.

Figur e 36

Lubri cate th e gearc ase. To per form

this op erati on,fi rst rem ove the

gearc ase fro m the upp er oute r tube

as foll ows(F igure 3 7):

1.Fol low “Dis assem bling the p ole

secti ons” sec tion to r emove the upper

tube fr om the ge arcas e.

2.Usi ng a leve r-typ e greas e gun,pum p

lithi um-ba se grea se(ab out 10 gram s)

into th e greas e fitti ng until you see old

greas e being p urged f rom the g earcase ,

which c an be see n in the ou ter tub e

cavit y. Clean u p exces s greas e, then

reass emble t he gear case on to the oute r

tube.

Old gre ase bei ng purg ed from the

gearc ase, wh ich can b e seen in t he

outer t ube cav ity. Cle an up exc ess

greas e, then r easse mble the

gearc ase ont o the out er tube.

CAUTION!

Use a wir e hook to e xtrac t the fuel

filte r from in side th e fuel ta nk(Figu re

38).I nspec t the fue l filte r element f or

signs o f conta minat ion. Re place it

with a ne w one of re quire d.Bef ore

reins talli ng the fi lter, inspect the f uel

line. If you fi nd dama ge or

deter iorat ion,r emove t he unit fro m

servi ce unti l it can be i nspec ted by a

train ed serv ice tec hnici an.

Make su re you do n ot pier ce the fu el

line wi th the en d of the ho oked wi re.

The lin e is deli cate an d can be

damag ed easi ly.

37

Page 39

IMPORTANT!

Sharpening the Chain

When th e cutti ng edge s of the blade

becom e dull, t hey can b e re-sh arpened

with a fe w strok es of a fil e.

In orde r to keep t he blad e in bala nce, all

cutti ng edge s must be s harpe ned equal ly.

In addi tion, i nspec t the cha in for corr ect

adjus tment ( more fr equen tly with a ne w

chain ). The ch ain sho uld fee l snug bu t still

pull fr eely. Se e Figur e 40.

Sharp ening I nstru ction s (Fig.41 )

File al l cutte rs to the s ame ang le and

depth ! Unequ al fili ng may cause the saw

to vibr ate or cu t errat icall y!

1.Usi ng a 4.5m m round f ile, sharpen all

cutte rs to a 30°an gle. Ma ke sure t hat one

fifth ( 20%) of t he file 's diam eter is alw ays

held ab ove the c utter 's top pl ate.

For con siste nt fili ng angl es, use a fil ing

guide s uch as Or egon p/ n 31692 o r

equiv alent .

R

2.Aft er all cu tters a re shar pened, us e a

depth g auge jo iner (O regon p/n 106738

or equi valen t) to mea sure th e height of

each de pth gau ge.

3.As re quire d, lowe r the dep th gauges t o a

heigh t of 0.5m m. Use a fl at file ; Oregon

p/n 122 11 or equi valen t.

4.Aft er all de pth gau ges have been

adjus ted, us e a flat fi le to rou nd each

depth g auge le ading e dge to it s orginal

curva ture an d angle .

NOTE

38

Page 40

Correct Filing Technique

Filling Problems

Correct angle on

top plate

Silghtly protruding hook or poi nt

(curve on non-chisel chain)

Top of d ept h

gauge at correct

height below top

plate

Front of depth

gauge rounded

Top plat e angle

less than

recommended

Cause

File he ld at l ess t han

recom men ded a ngle.

Resul t

slow cu tti ng. R equir es

extra e ffo rt to c ut.

Remed y

File cu tte rs to

recom men ded a ngle.

Top plat e angle

mo re than

recommended

Cause

File he ld at m ore t han

recom men ded a ngle.

Resul t

Cutti ng an gle i s very sh arp

but wil l dul l fas t. Cutt ing

actio n rou gh an d errat ic.

Remed y

File cu tte rs to

recom men ded a ngle.

Hook in side

pl ate cutting

edge

Cause

File he ld to o low o r the

file wa s too s mal l.

Resul t

Rough c utt ing . Chain

grabs . cut ter s dull

quick ly or w on' t hold a

cutti ng ed ge.

Remed y

File cu tte rs at

recom men ded a ngle.

Check f ile s ize .

Back slope on

si de plate

cu tting edge

Cause

File he ld to o hig h or the

file wa s too l arg e.

Resul t

Cutte rs wo n't f eed int o

wood. S low c utt ing. Mu st

force c hai n to cu t. caus es

exces siv e bot tom wea r.

Remed y

File cu tte rs at

recom men ded

angle C hec k fil e size.

High depth

gauge

Cause

Depth g aug e nev er file d.

Resul t

Slow cu tti ng. M ust for ce

chain t o cut . Wil l cau se

exces siv e wea r on the

cutte r hee l.

Remed y

File cu tte rs at

Lower g aug es to

recom men ded s ettin g.

Lo w depth

gauge

Cause

Wrong g aug e set ting or

no gaug e use d.

Resul t

Rough c utt ing . Chain

grabs . Saw w on' t pull ch ain

throu gh wo od. E xcess ive

wear on t he cu tte r heel.

Remed y

If dept h gan ges a re too

low, the c hai n is no l onger

servi cea ble .

39

Page 41

HEDGE TRIMMER

WARNING!

Never t ransp ort the a rticu lated hed ge

trimm er or set i t down wi th the en gine

runni ng coul d be acci dentl y

accel erate d causi ng the bl ades to

oscil late.

Mark su re the bl ade cov er is in th e

place w hen tra nspor ting an d storing

the art icula ted hed ge trim mer

When ca rryin g an arti culat ing hedge

trimm er, the bl ade of th e cutting

attac hment m ust be in t he tran sport

posit ion see F igure 1 .

CAUTION!

Alway s maint ain the a rticu lated hed ge

trimm er acco rding t o this ow ner's

manua l and fol low the r ecommended

sched uled ma inten ance

Never m odify o r disab le any of the

hedge t rimme r's saf ety dev ices.

Alway s use gen uine pa rts and

acces sorie s when re pairi ng or

maint ainin g this ma chine

Do not ma ke unau thori zed

modif icati ons to th e artic ulated he dge

trimm er

When tr anspo rting t he hedg e trimmer

in a vehi cle, ti e it down s ecure ly to

preve nt fuel s pilla ge or dam age to the

machi ne.

Alway s clear y our wor k area of trash

or hidd en debr is to hel p ensur e good

footi ng

Keep th e cutte rs shar p and pro perly

adjus ted

Keep th e artic ulate d hedge trimmer as

clean a s possi ble. ke ep it fre e of loose

veget ation , mud, de bris, etc.

40

Page 42

Product description

Prior to assembly

Using f igure 3 a s a guide , famil iarize

yours elf wit h the att achme nt of long reach

hedge t rimme r and its v ariou s

compo nents .

Under stand ing you r machi ne helps en sure

top per forma nce ,lo nger se rvice lif e and

safer o perat ion.

Befor e assem bling , make su re you have

all the c ompon ents re quire d for a

compl ete uni t:

Cutte r assem bly

Cutte r blade c over

Hand pr otect or clam p screw n ut

Cauti on labe ls

Owner 's manu al

Tool kit fo r routi ne main tenan ce

IMPORTANT

Caref ully in spect a ll comp onents,

Makin g sure th ey are no t damag ed

The ter ms” left ”, ”lef t-han d”, and “LH ”

“righ t” ,rig ht-ha nd” ,an d “RH”, “fr ont” an d

“rear “ refer t o direc tions a s viewed by t he

opera tor dur ing nor mal ope ration.

Do not ma ke unau thori zed

modif icati ons or al terat ions to you r

artic ulate d hedge t rimme r or its

compo nents .

WARNING!

41

Page 43

Installing the Hedge Trimmer Cutter Assembly

The cut ter bla des are v ery sha rp. Do

not han dle the c utter a ssemb ly unless

the pro tecti ve blad e cover i s in place.

IMPORTANT

WARNING!

Alway s wear gl oves wh en work ing with or

near th e cutte r assem bly.

1.

Remove the output shaft from the rubber

sleeve.

2.Insert the output shaft into the gearbox, align

the hexagonal screws and then tighten on

both sides, as shown in the illustration.

3.

Working head rotation:

Only change the position of the head when

the engine is not operating.

1. Pull back the lock collar as shown in the

illustration.

2. Select the required working angle for the

hedge trimmer head, rotating the side

lever.

42

4.

Gearbox Grease

1. After 25 hours run time, grease the

gearbox.

2. Use an injection pump at the designated

gearbox nozzle points, as shown.

3. Gearbox grease recommended:

OEST LT200EP

Page 44

Safety Operation

Applications

Preparations

Cutting sequence

Cutting techniques

This ma chine i s desig ned esp ecially f or

trimi ng hedg e.

Never u se this m achin e for any o ther

purpo ses. Ne ver try t o cut sto nes, metals,

plast ics or an y other h ard obj ects.

Using f or othe r purpo ses tha n trimmin g

hedge m ay dama ge the ma chine o r cause

serio us inju ry.

Prepa ratio ns

●Wear su itabl e prote ctive c lothi ng and

equip ment- see sec tion "S afety Pre cauti ons."

●Choos e the bes t work po sitio n for safet y

again st the fa lling o bject

(bran ch etc)

●Start t he engi ne.

●Put on th e strap .

Never s tand di rectl y under neath the b ranch

you are c uttin g-be wa ry of fal ling bran ches.

Note th at a bran ch may sp ring ba ck at you

after i t hits th e groun d.

Worki ng posi tion:

Hold th e contr ol hand le with y our right h and,

and the s haft wi th your l eft han d. Your left

arm sho uld be ex tende d to the mo st comfor table

posit ion.

Use lop ping sh ears to c ut out th ick

branc hes fir st.

If a radi al cut is n ecess ary, cut a l ittle a t

a time in s evera l passe s.

Vertic al cut:

Swing t he cutt ing bla de up and d own in

an arc as y ou move a long th e hedge use

both si des of th e cotti ng blad e.

Horiz ontal c ut:

Hold th e cutti ng blad e at an ang le of 0°

to 10° as yo u swing t he hedg e trimm er

horiz ontal ly.

Swing t he blad e in an arc t oward s the

outsi de of the t edge so t hat the c uttings

are swe pt on to th e groun d.

45

Page 45

46

Horizontal cut

Cutti ng clos e to grou nd from a standing

posit ion, e. g.low s hrubs .

Overhead cut

Hold th e shaft u prigh t with a 90 ° blade

angle t o cut an up per sur face of a hedge.

Vertical cut

Cutti ng with out sta nding d irectly n ext to

hedge , e.g. fl owerb ed betw een opera tor

and hed ge.

Horizontal cut

Cutti ng with out sta nding d irectly i n front

of the he dge, e. g. reac hing over a

flowe rbed.

Page 46

47

Operating the Articulated Hedge Trimmer

Always we ar a hard h at to red uce

the risk of h ead inj uries d uring

operati on of thi s machi ne.

Always we ar eye an d heari ng

protect ion. We reco mm ends

wearing a f ace shi eld as ad ditiona l

face and ey e prote ction .

Secure lo ng hair

so it is abov e

shoulde r level .

Wear no n-sli p heavy -d uty

gloves to i mprov e your gr ip

on the trim mer han dle.

Wear sn ug-fi tting c lo thes

that also p ermit f reedo m of

movemen t. NEVE R wear

shorts!

Always op erate w ith

both hand s firml y

grippin g the mac hine.

Keep a prop er foot ing and d o not

overrea ch-ma intai n your bala nce

at all time s durin g opera tion.

Keep byst ander s at leas t 50feet

15meter s away fr om the

operati ng trim mer to re duce the

risk of bei ng cut by t he movi ng

blades or s truck b y falli ng

objects o r throw n debri s.

Wear st urdy fo otwea r wi th

nonslip s oles to p rovid e good

footing . Steel -toed s afety boo ts

are recom mende d

Figure 1

Page 47

EC-DECLARATION OF CONFORMITY

EC Declaration of Conformity

We herewith declare, Cobra Garden Machinery

Henton & Chattell Ltd, London Road, Nottingham NG2 3HW United Kingdom

That the following machine complies with the appropriate basic safety and health requirements of the EC Directive

based on its design and type, as brought into circulation by us.

In case of alteration of the machine, not agreed upon by us, this declaration will lose its validity

Machine Description: 26.3 cm3 Multi-cutter

Machine Type: MT270K (PNM270K)

Displacement 26.3 cm

3

Max, Cutting width Brush cutter 255mm, Grass trimmer 420mm, Pruner 295mm,

Hedge trimmer 620mm

Measured sound power level: 98dB(A)

Guaranteed sound power level: 110dB(A)

Notified Body for EC Directive:

Intertek Testing Services Shanghai

Building No. 86, 1198 Qinzhou Road(North), Shanghai 200233 China

Applicable EC Directives 2006/42/EC 2004/108/EC

2000/14/EC 97/68/EC

Applicable Harmonized

Standards

EN ISO 11680-1:2011 EN ISO 11806-1:2011

EN ISO 10517:2009 +A1:2013

The conformity assessment procedure followed was in accordance with Annex

III of the Directive 2000/14/EC

Authorized Signature/Date

P

eter J. Chaloner 12-06-2014

Title of Signatory Managing Director

Name and address of the

person authorised to compile

the technical file

Cobra Garden Machinery

Henton & Chattell Ltd, London Road, Nottingham NG2 3HW United Kingdom

- 1 -

Loading...

Loading...