Page 1

INVERTER GENERATOR

USER MANUAL

Model:IG20SI

4-Stroke Engine

Page 2

Thank you for purchasing a Cobra Inverter Generator

● Cobra reserves the right of modification of product and revision of the manual without any notice.

● Take this manual as a part of the generator. If the generator is resold, it is required to take the manual along

with the generator.

● This manual contains how to correctly operate the generator, please read carefully before using the generator.

Correct and safe operation will guarantee your safety and extend the working life of generator.

● Cobra will continuously innovate and develop its products both in design and quality. The content of this

manual may have minor difference from the updated product. Please contact your supplier for further support.

IMPORTANT SAFETY NOTICE:

The emission of engines contains poisonous carbon monoxide. Use the generator

only outdoors and away from people.

NEVER use petrol powered equipment in a home, garage, tent, camper-van,

caravan, motor-home or boat. Even if doors, windows or vents are open. Only use

outdoors, well away from doors, widows and openings. Prevent inhaling exhaust

fumes.

Page 3

CONTENT

Hourm eter

04

06

07

08

08

09

10

10

11

12

13

15

17

18

19

20

20

22

22

23

25

26

28

30

31

32

33

33

34

36

Page 4

1.SAFETY INFORMATION

To ensure personal and property safety, please

carefully read the following information.

WARNING

distance with constructions and other

electrical appliances at least.

• Place the generator on the leveled surface, in

order to avoid overturning or spilling fuel.

• Children and pets should be keep away the

operation area.

• Do not operate with wet hand.

• Read and understand the user manual before

using the generator.

• The emission of engine contains poisonous

carbon monoxide. Use the generator in the

ventilated condition.

• Do not touch the hot muffler, when the generator

is running, or before cooling.

• Petrol is explosive and flammable in the

specified conditions when refueling, the

generator needs to be stopped and be kept

cigarette and fire source away.

• Do not connect to the building’s electrical system

or other generator, in order to avoid the electric

shocks and fires.

• The running generator must keep one meter

• Do not expose the generator to rain, moisture

or snow.

• Place the generator at least 1 m away from

buildings or other equipments during

operation.

• The major repair work should be carried out

only by professionally trained person.

• Do not use the generator in underground

working

• Do not use the generator in potentially

explosive atmospheres

• Use personal protective equipment: glove,

mask, earplugs, when you operate or maintain

the generator

<<04>>

Page 5

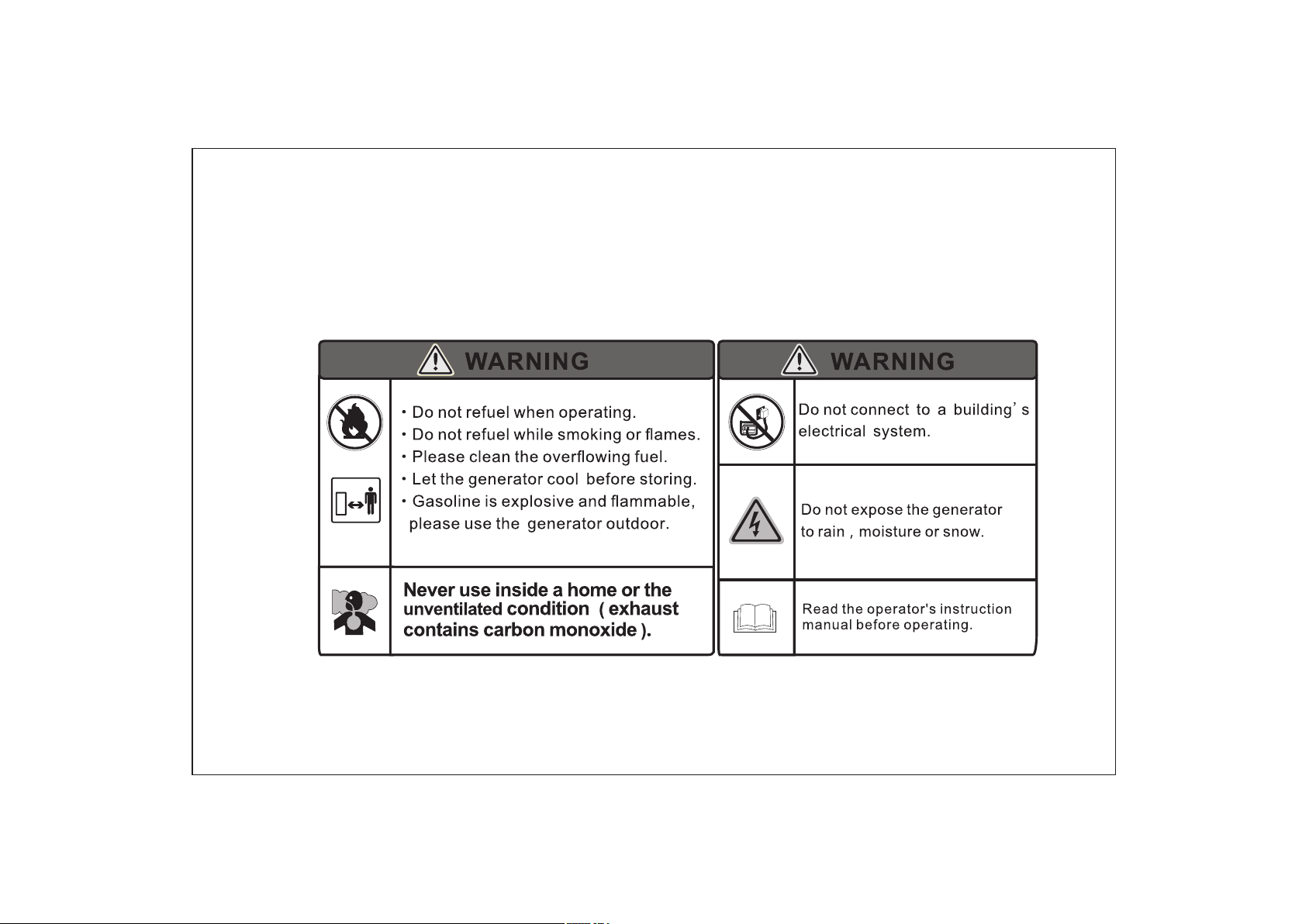

SAFETY LABEL:

<<05>>

Page 6

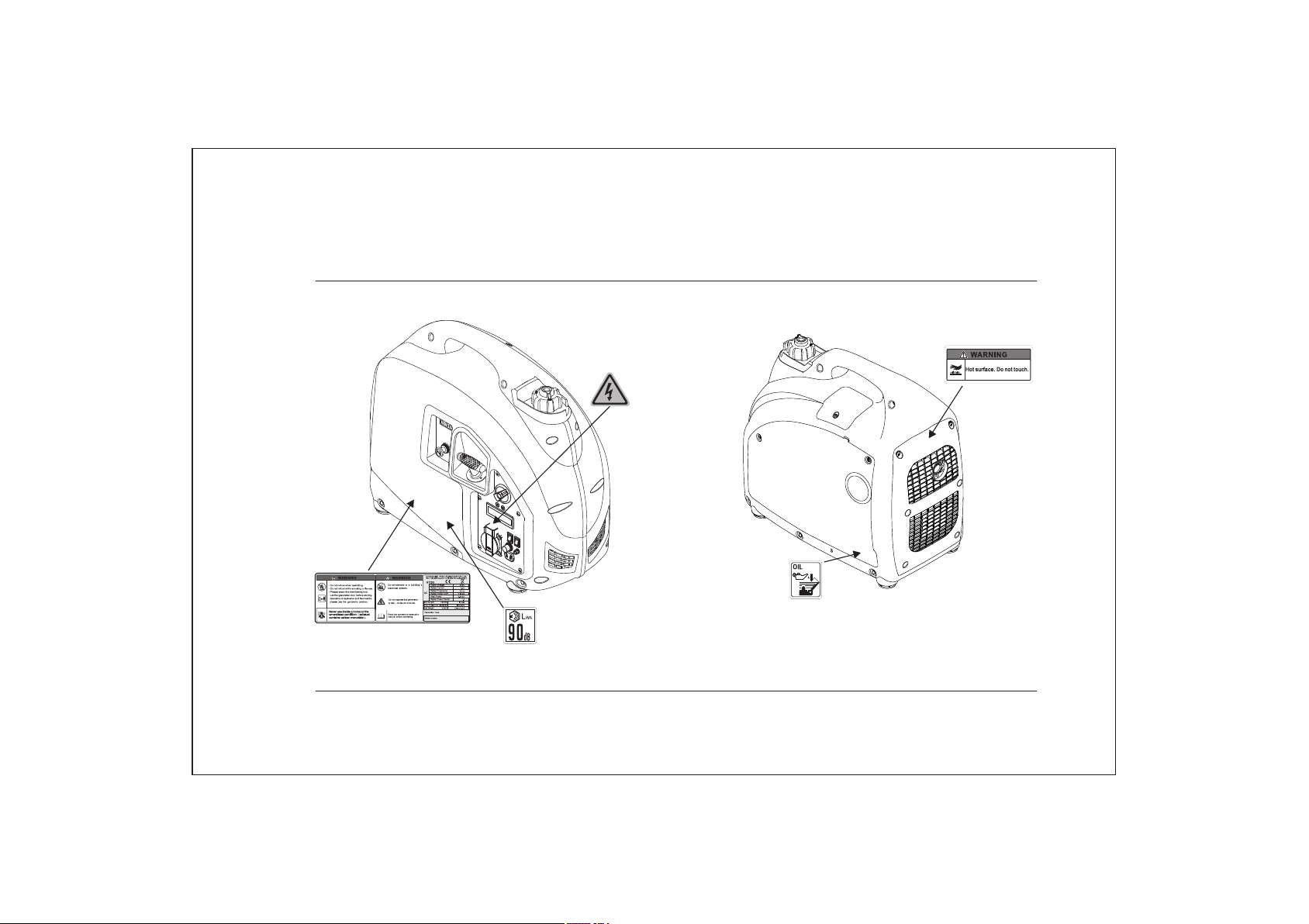

2. SAFETY LABLE LOCATIONS

<<06>>

Page 7

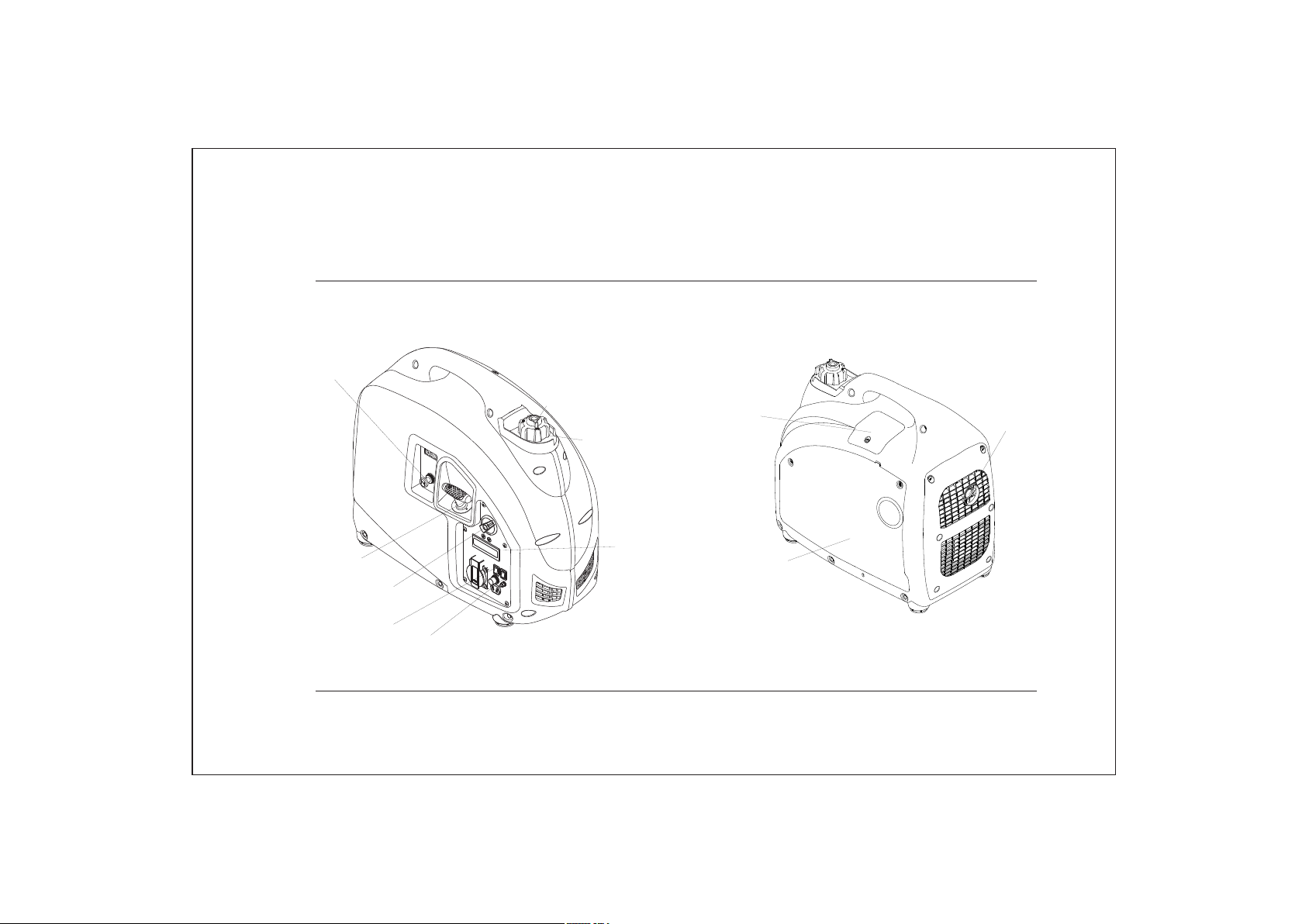

3. C IDENTIFICATIONOMPONENTS

CHOKE

KNOB

STARTER GRI P

FUEL SWIT CH

FUEL CAP

VENT LEVE R

FUEL C AP

CONTROL

PANE L

SPAR K P LUG

MAINTENA NCE

COV ER

AIR CLE ANE R

MAINTENA NCE COVER

MUFFLER

ECON. SW

ENGINE SWI TCH

<<07>>

Page 8

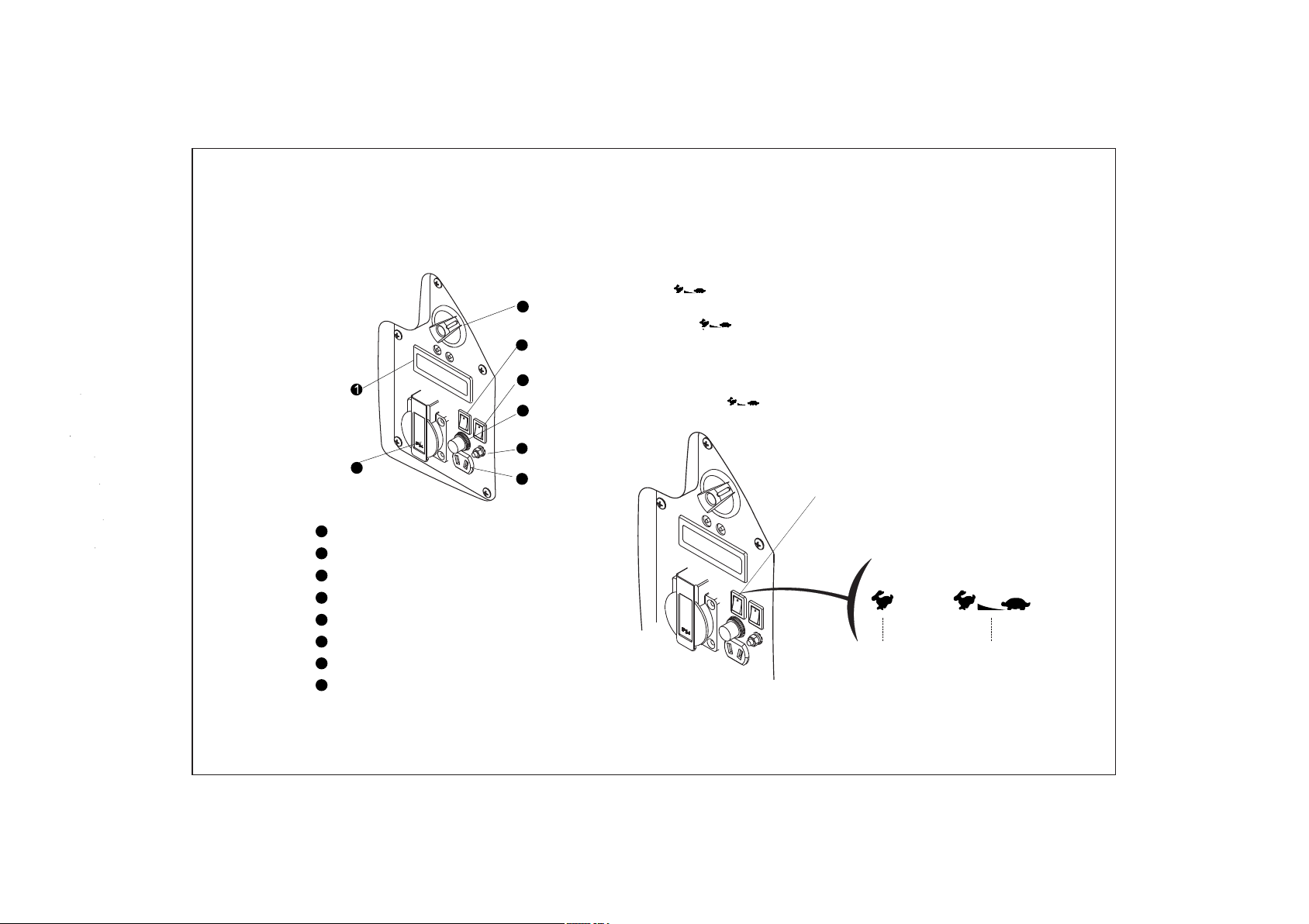

3.1) Control Panel

2

1

Hourmeter

AC Receptacle

2

3

Ground Terminal

4

DC Receptac le

5

DC Circuit Protector

Engine Swit ch

6

7

ECON. SW

8

Fuel Switc h

3.2) ECON. SW (Economy control switch):

“ON”( )

8

7

6

5

3

4

• When the economy control switch is turned to

“ON”( )

,the engine keeps running at idle state

automatically when the electrical appliance is

disconnected,and it will return to the proper speed

with the requirement of electrical load.

● The “ON”( ) is recommen ded to minimize the fuel

ECON. SW

ONOFF

<<08>>

Page 9

NOTE

• When a high load electrical appliance is

connected instantaneously, in order to reduce

voltage change, turn the economy control switch

to the“OFF”( )position.

• In

DC operation, turn the economy control switch

to the “OFF”( )position.

• Connect both AC load and DC load, turn the

economy control switch to the “OFF”( ) position.

will be off, and output indicator light (green)

will be on.

• Under the non-overloading condition, the

"RESET" is supposed to be ineffective.

• Press DISP; then lighten the backlight.

• Display voltage/frequency, engine speed,

cumulative working time in turn.

NOTE

• No button in 10S, the backlight shut off.

“OFF” ( )

When the econ omy control switch turns to th e “OFF”

( ) position en gine runs at high s peed.

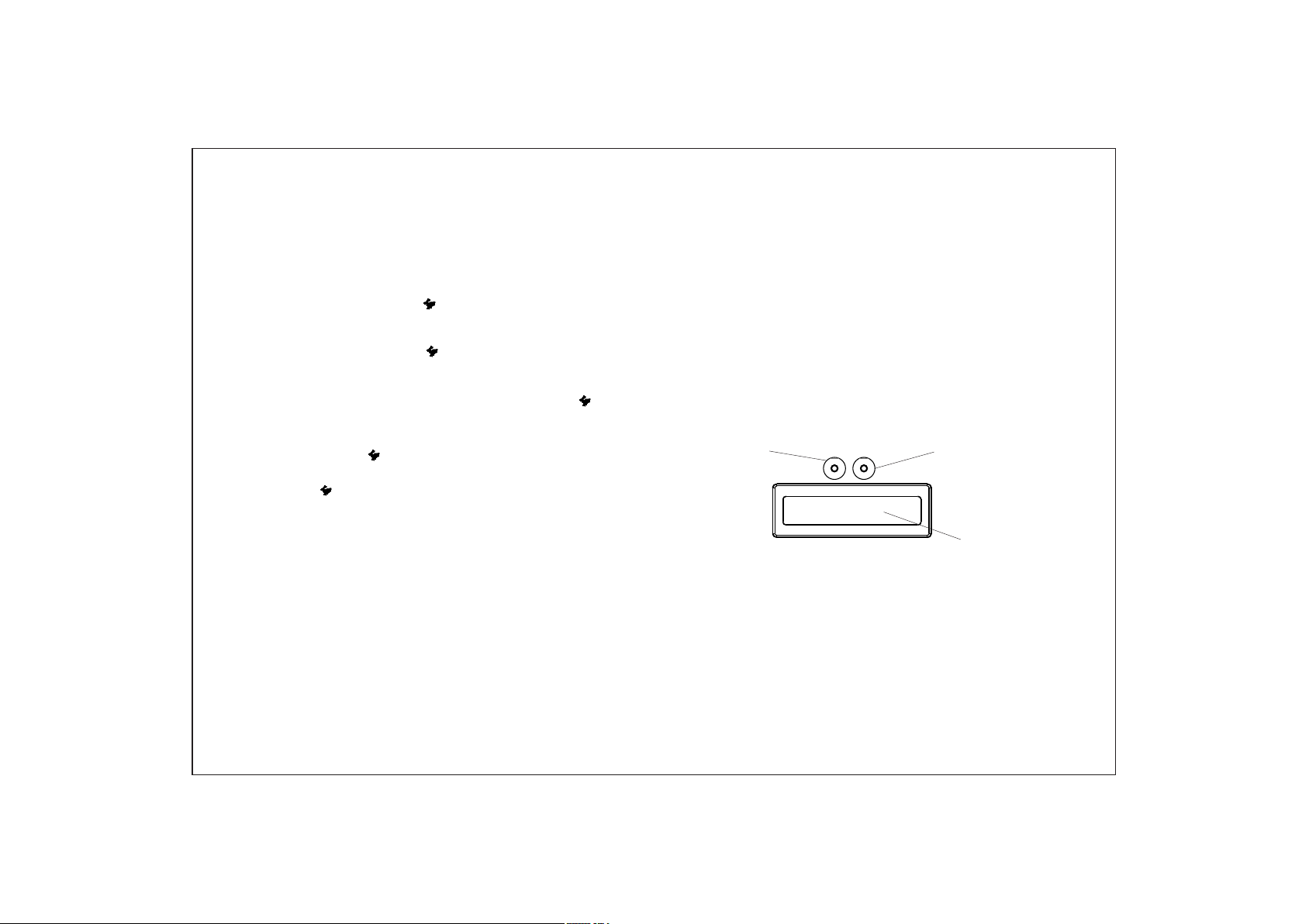

3.3) Hourmeter

• Under the condition of protection, the overload

indicator

recover the output of the generator, and

unnecessary to restart engine overall.

• Press and hold the “RESET” button for one second,

until the overload indicator light (red)

light(red) is on, the "RESET" button can

RESET

NOTE

• For protection condition, the output indicator

light (green) is off, and the overload indicator

light (red) is on.

• Every starting the engine the "RESET" button is

available within 5 times. Otherwise, you need

restart the engine.

DISP

backlight

<<09>>

Page 10

4. PRE- OPERATION CHECK

WARNING

Be sure the gen erator is on the le veled surfa ce and

the generat or is stopped.

4.1) Check Oil Level

NOTE

• Using non-detergent or 2-stroke oil could

shorten the engine’s working life.

• Using the high quality engine oil with strong

detergents

• Using 4-stroke engine oil, certified to meet or

exceed API standards: SG, SF ,SAE stickiness

rating:

Remove the oil filler cap, fill the specified amount of

t

he recommended oil and then tighten the oil filler

cap .

NOTE

• Do not tilt the generator when adding engine

oil. This could result in overfilling and

damage to the engine.

OIL FILLER

CAP

UPPER LEVE L

OIL FILLER H OLE

OIL POT

Oil Cap acity:0.41L

15W -40

10W -40

10W -30

5W- 30

-30 -20 -10 0 10 20 3 0

-20

20 40 60 8 0

0

40℃

100 F

NOTE

Carefully u se and store the en gine oil, avo id

getting dir t or dust into the en gine oil.

Mixing diff erent kinds of engine oil is pro hibited.

<<10>>

Page 11

NOTE

• Before the engine oil reduces below the safety

margin, low oil alert system will close the engine

automatically. The oil alert

indicator light red

will be on.

• To avoid the inconvenience caused by

unexpected stopping,

it is still advisable to

check the engine oil level regularly.

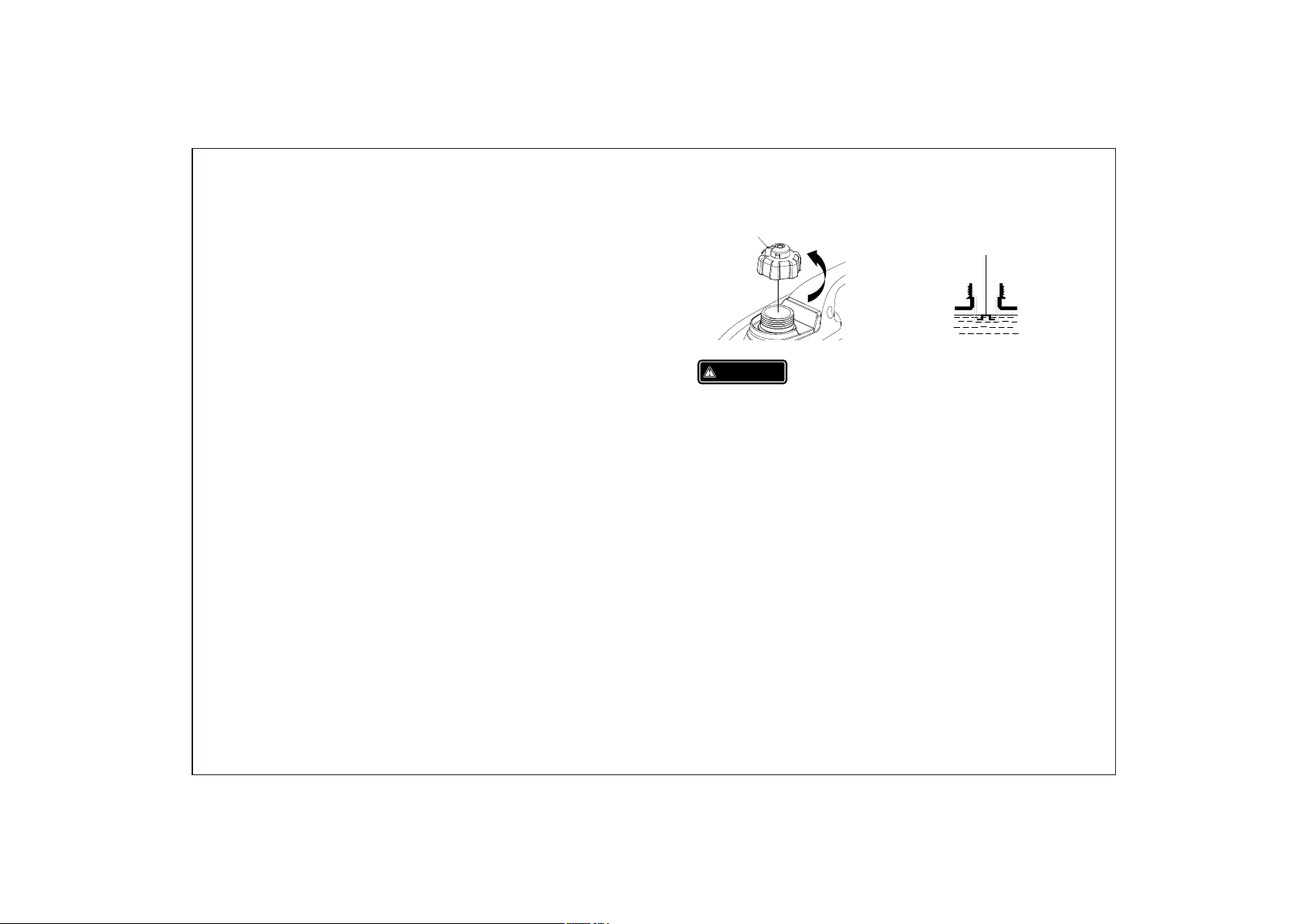

FUEL CAP

WARNING

OPEN

UPPER LIMI T MAR K

Fuel C apaci ty: 3.6 L

4.2) Check Fuel Level

Fuel recommend: use unleaded Petrol

(Research O ctane Number of 9 1 or higher, Pump

Octane Number of 86 or higher)

Never use stale or contaminated Petrol or an oil/

Petrol mixture,

Avoid getting dirt or water into the fuel tank.

Do not use a mixture Petrol containing ethanol or

methanol; otherwise, it will seriously damage the

engine.

• Petrol is extremely explosive and flammable.

• Around the refueling area and fuel storage

area, prohibit smoking and firing.

• Do not overfill the fuel tank (no fuel above the

red upper limit mark). After refueling, make sure

the fuel cap is closed properly and securely.

• Do not make fuel spill from fuel tank. (No

residual fuel around the neck of tank, before

starting engine)

• Avoid contacting with skin or breathing the fuel

vapor.

• KEEP OUT OF REACH OF CHILDREN.

<<11>>

Page 12

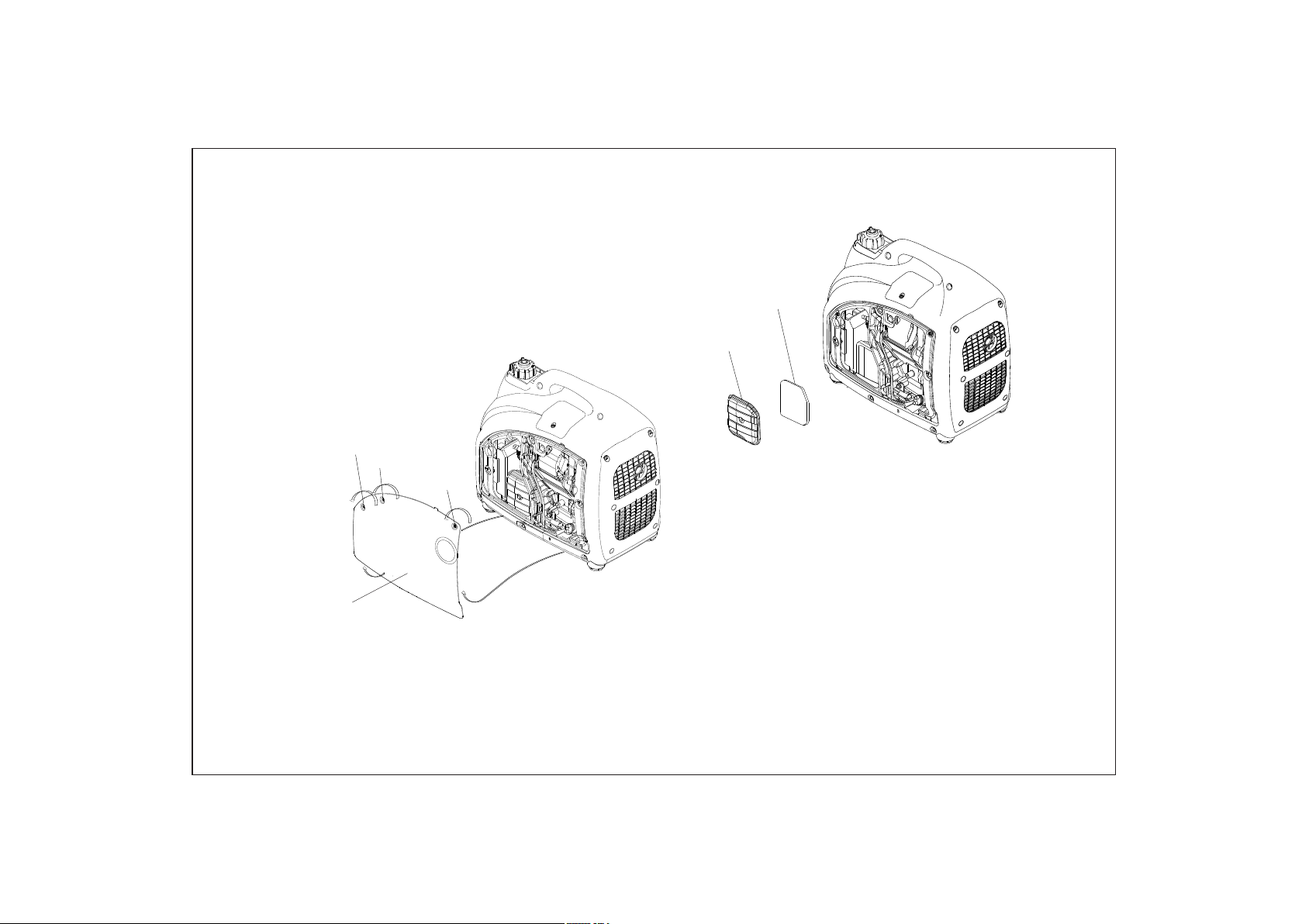

4.3) Check Air Cleaner

Check the air c leaner element to be sure it is cl ean

and in good con dition.

a.Loosen th ree screws of the a ir cleaner

maintenan ce cover, and re move the cove r.

COVER SCREW

COVER SCREW

COVER SCREW

AIR CL EANE R

MAI NTENA NCE COVER

b. Loosen the ai r cleaner cover s crew, and re move

the cover

AIR CLEANER ELEMENT

AIR CLEANER

COVER

c. Check the element, clean or replace it,if necessary.

NOTE

Do not run engine without the air cleaner element.

Operating the generator without the filter will damage

the engine.

<<12>>

Page 13

5. STARTING THE ENGINE

NOTE

Before starting engine, disconnect load with AC

receptacle.

5.1) Turn the fuel ca p vent lever to t he “ ON”

sition.

po

FUEL CAP VEN T LEV ER

OFF

NOTE

When transporting generator, turn the fuel cap vent

lever to the “OFF”

position.

5.2) Turn fuel switch to the “ON ” position.

FUEL SWITC H

ON

5.3) Turn the

ON

ON

engine swit ch to “ON” position.

<<13>>

Page 14

5.4) Pull t he choke knob f ully

CHOKE KNOB

out.

STARTER G RIP

NOTE

Do not pull out the choke knob, when engine is hot or

ambient temperature is high.

5.5) Pull t he starter gr ip slowly

until it is eng aged,

then pull it qu ickly.

NOTE

Return the starter grip slowly by hand. Do not make

the starter grip spring back quickly.

5.6) Push t he choke knob t o the original po sition,

when the engi ne warms up.

<<14>>

Page 15

CHOKE KNOB

NOTE

If the generator stops and can not restart, check

the oil level firstly.

Carbure tor Modificat ion for High Alti tude

Operation

At high altitude, the st andard carburetor air-fuel

mixture wil l be too rich. Perform ance will

decrease, a nd fuel consump tion will inc rease. A

very rich mixture will also foul t he spark plug and

cause hard st arting.

If the generator operates at high altitude, change the

main nozzle or adjust the idling screw of carburetor

If the generator always operates at altitude above

1000 meters contact an authorized Cobra service

dealer to modify the carburetor.

Generator output power should be modified

according to the altitude and ambient temperature.

The correction factor refers to 13.2

WARNING

If the carburetor has been modified for high altitude

operation, the air-fuel mixture will be too lean for low

altitude use. Operation at low altitude may cause the

engine to overheat and result in serious engine

damage. The carburetor needs return to original

specifications.

<<15>>

Page 16

6. GENERATOR USE

WARNING

• Be sure to ground the generator when the

connected electrical appliance is grounded.

• Do not connect to the building’s electrical

system, in order to avoid the electric shocks

and fires.

GROUND TER MIN AL

WARNING

• For continuous operation, do not exceed the

rated out-put power of generator.

• Do not make parallel connection with other

generators.

• Do not connect an extension to the exhaust pipe.

• When an extension cable is required, be sure to

use a tough rubber sheathed flexible cable

(according to IEC245 or equivalent standards).

The maxmin length of the

extension cable: 60m for cable of 1.5mm ;

100m for cable of 2.5mm .

• Keep away from other electric cables or wires.

NOTE

• The DC receptacle can be used while the AC

power is in use. If use both at same time, be

sure not to exceed the total power for AC and

• (AC:1.6kVA, DC:5A)

EARTH

MARK

• Most of motor appliances require more than

their rated wattage, when starting.

<<16>>

Page 17

6.1) DC Application

The DC receptacle, 15-30V under no load condition,

may be used for charging 12V battery only.

NOTE

In DC operation, turn the ECON SW to the

“OFF” ( ) position.

Disconnect the vehicle battery ground cable

6.1.1)

from the negative battery terminals.

6.1.2) Connect the DC receptacle to battery

terminals with the charging cable

CAUTION

Connect

black lead to negative battery terminal.

6.1.3) Turn ECON SW to “OFF” ( ) position and

red lead to positive battery terminal and

then start engine

CHARGING C ABL E

NOTE

Do not start the automobile engine when the

generator is still connected to the battery, otherwise

the generator will be damaged.

Disconnecting the charging cable

1)Stop the engine.

2)Disconnect the black lead from the negative

battery terminal.

3)Disconnect the red lead from the positive battery

terminal.

<<17>>

Page 18

4)Reconnect the vehicle battery ground cable.

WARNING

• The battery can release the explosive gases

• Keep the battery away from spark/fire. Charge

the battery in ventilated condition.

• Battery electrolyte contains sulfuric acid that will

cause severe burn of skin and eyes. Therefore it is

necessary to wear the protective clothing and

mask.

circuit pro tector, remo ve load first ly, and

then reset th e protector aft er a few minute s.

DC

RECEPTACLE

DC CIRCUIT

PROTECTO R

• If battery electrolyte gets into eyes flush

thoroughly with warm water for 15min at least

and call a doctor immediately

• If you swallow a little of battery electrolyte

accidentally flush thoroughly with water your

mouth and then drink large quantities of water or

milk with magnesia or vegetable oil and call a

doctor immediately

NOTE

• The DC receptacle can be used while the AC

power is in use .

• When DC circuit overload will trip the DC

6.2) AC applications

ON OFF

6.2.1) Start engine and make sure the output

indicator light (green) is on.

6.2.2) Confirm all electrical appliances are switched

off, and connect the appliance plugs to the

generator receptacle.

NOTE

To obtain the best working and longest working life of

the generator, a new generator is supposed to run for

20 hours at 50% rated load.

<<18>>

Page 19

OUTPUT IND ICATOR

LIGHT (GRE EN)

PLU G

NOTE

Confirm all electrical appliances are in good working

condition before connecting them to the generator. If

an electrical appliance becomes abnormal, sluggish,

or stops suddenly, shut off the generator engine

immediately, and disconnect the appliance.

6.3) Output and Overload Indicator

In normal ope rating, outpu t indicator l ight (green)

will remain o n.

If the genera tor is overload ( over 1.6 kVA), or the

connected a ppliance is sho rt-circui t, the output

indicator l ight (green) is off, and overl oad

indicator l ight (red) is on. The AC power will be

switched of f, but engi ne is still runni ng.

If the overlo ad indicator light (red) is on ,

disconnec t the electrica l appliance s firstly, press

and hold the re st button 1s. If th e overload

indicator l ight (red) is OFF and the output

indicator l ight (green) is on, reconnec t the

electrica l appliances. O therwise stop the e ngine

and check the g enerator.

OVE RLOAD INDICATOR

LIGHT(RE D)

OUTPUT IND ICATOR

LIGHT (GRE EN)

<<19>>

Page 20

6.4) Oil alert system

7. STOPPING THE ENGINE

The oil alert s ystem is design ed to prevent e ngine

damage caus ed by an insuffic ient amount o f oil

in the crankc ase. Before the o il level in the

crankcase f alls below a safe l imit, the oil a lert

system will a utomaticall y shut down the e ngine

(the engine s witch remains in the “ON“pos ition).

If the oil aler t system shuts do wn the engine , the

oil alert ind icator light (red ) will be on. Che ck

the engine oi l level.

OIL ALERT IND ICATOR

LIGHT ( RED)

To stop the eng ine in an

emergency, turn the en gine

switch to the “ OFF”position.

7. 1) Switch off t he connected

electrica l appliances,

and pull out th eir plugs.

PLU G

7.2) Turn the engine switch to the “ OFF” p osition.

<<20>>

Page 21

7.3) Turn the fuel switch to the “OF F” position .

FUEL SWITC H

OFF

7.4) Turn the fuel cap vent lever to the “OFF”

position.

FUEL CAP VEN T LEV ER

OFF

OFF

NOTE

Be sure the fuel cap vent lever and engine switch

locate the “OFF” position, when stopping,

transporting and storing the generator.

ON

<<21>>

Page 22

8.

AINTENANCE

M

The purpose of the maintenance and adjustment

schedule is to keep the generator in the best

operating c ondition.

Spa rk plug

Spark arre ste r

Valve Clearance

Combustion Chamber

Fuel tank& filter

Fuel l ine

Rep lace

Check-adjust

Cle an

Cle an

Che ck

⊙

+(2)

Aft er ever y 300 hr s(2)

Eve ry yea r(2)

Eve ry 2 yea rs ( Rep lace if n ecess ary) (2)

WARNING

Stop the engi ne before performing any

maintenan ce. If the engine m ust run, be sur e the

area is well ve ntilated. The exhaust cont ains

poisonous carbon monoxide gas.

Use genuine Cobra or equivalent quality

components to replace the wear components.

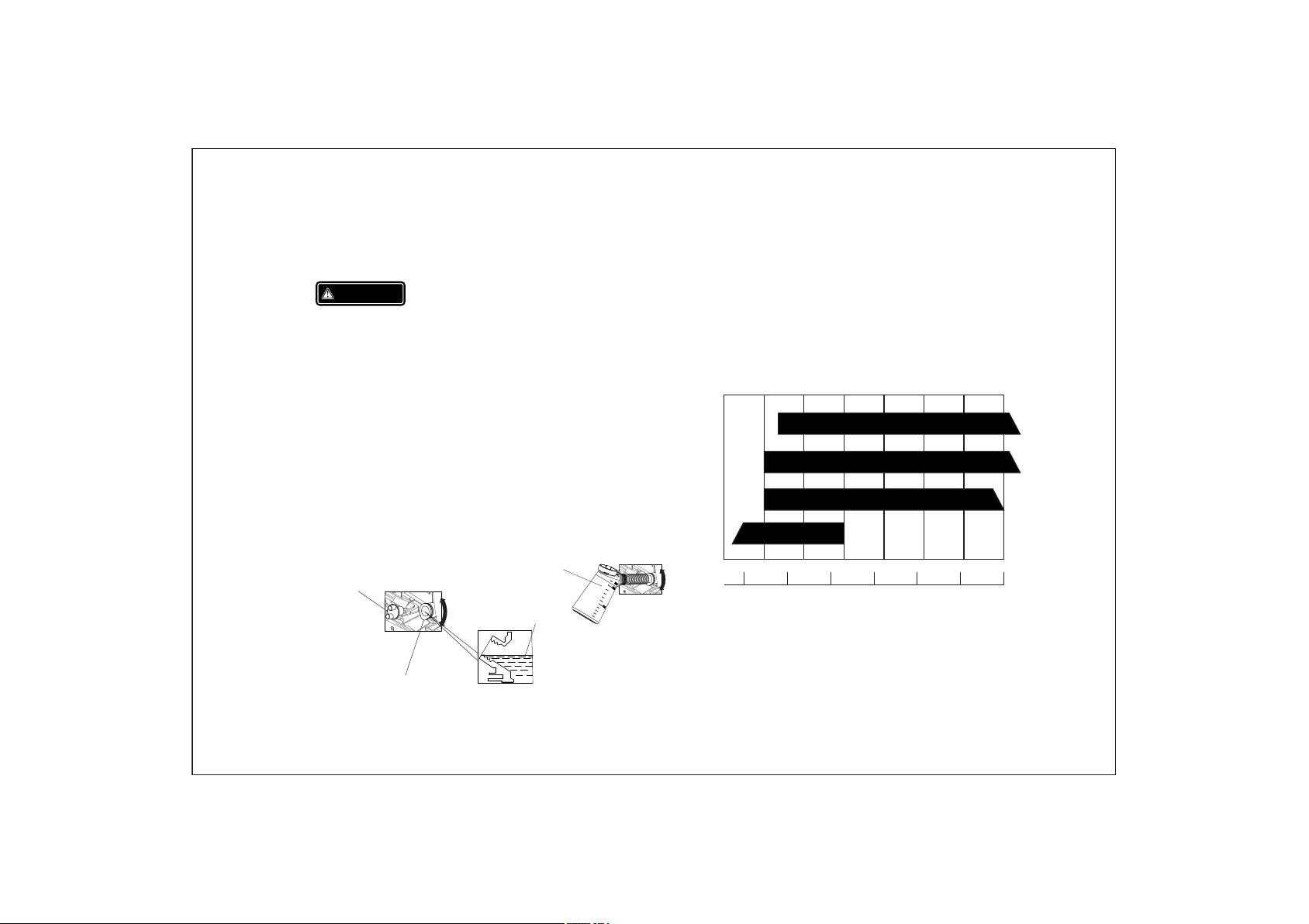

Maint enanc e Sched ule

Reg ular Se rvic e

Per iod (3 )

Ite m

Eng ine

oil

Air

cle aner

Spa rk plug

Check level

Cha nge

Che ck

Cle an

Check-adjust

Eac h

use

Fir st

mon th

or

10 hr s.

Eve ry 3

mon ths

or

50 hr s.

+(1)

Eve ry 6

mon ths

or

100 h rs.

Eve ry

2 yea rs

or

300 h rs.

NOTE

(1) Service more frequently when used in dusty areas.

(2) These items should be serviced by your servicing

dealer, unless you have the proper tools and are

mechanically proficient. Refer to Cobra manual for

service procedures.

(3) For commercial use, long hours of operation to

determine proper maintenance intervals.

8.1) Change Oil

Drain the oil r apidly and completely whil e the

engine is sti ll warm.

8.1.1) Loos en three screws o f the air clean er

maintenan ce cover, and re move the cove r.

8.1.2) Remo ve the

oil filler ca p.

<<22>>

Page 23

8.1.3) Drai n dirty oil into a container tho roughly.

OIL P OT

8.1.4) Refi ll the recommended oil and che ck the oil

level.

8.1.5) Rein stall the oil filler cap.

8.1.6) Rein stall the maint enance cove r and tighten

the cover scr ews.

COVER SCREW

COVER SCREW

AIR CL EANE R

MAI NTENA NCE COVER

COVER SCREW

OIL F ILLER

CAP

UPP ER LEVE L

Oil Cap acity: 0.41L

OIL F ILLER H OLE

After oil change, wash your han ds with soap.

NOTE

For conforming to the environment requir ement,

the used oil will be put into a sealed container and

then be transport ed to the service station fo r

recycler. Do not throw it into the trash or po ur it on

the ground.

8.2) Air Cleaner Service

A dirty air cle aner will restrict air flow in to the

carbureto r.Clean and maintain the air c leaner

regularly, especi ally in the ext remely dusty ar eas.

<<23>>

Page 24

WARNING

Do not use Petrol or low ignition point solvents for

cleaning. They are flammable and explosive under

certain conditions.

NOTE

Never run the generator without the air cleaner, rapid

damage to the engine will occur.

8.2.1) Loosen three screws of the air cleaner

maintenan ce cover, and re move the cove r.

COVER SCREW

COVER SCREW

AIR CL EANE R

MAI NTENA NCE COVER

COVER SCREW

8.2.2) Loosen the air cleaner cover screw and

remove the c

over.

AIR CLEANER ELEMENT

AIR CLEANER

COVER

8.2.3) Take out the air cleaner element, and clean

it with non- flammable or high flash point

solvent, then dr y it.

8.2.4) Soak the air cleaner element in the clean

engine oil, and squeeze out the redundant

oil.

ELE MENT

<<24>>

Page 25

8.2.5)Reinstall the air cleaner element and cover.

8.2.6)Reinstall the maintenance cover, and tighten

the screws.

8.3) Spark Plug Service

Recommendation spark plug: E6RTC

Check the spark plug gap and clean th e carbon

deposition at the bottom o f the spark plug.

HANDLE BAR

SPARK PLUG CAP

8.3.1) Remove the spark plug maint enance cover

SPARK PLUG

MAINTENANCE COVER

8.3.2) Take off the spark plu g cap

8.3.3) Clean the carbon deposition at th e bottom of

the spark plug.

8.3.4) Take off the spark plug with the spark plug

spanner.

8.3.5) Visual inspection the spark plug. Change a

new one if its insulator cracked or chipped.

Clean it with a wire brush if the spark plug is

reused.

0. 60- 0.70mm

(0.024-0.028in)

<<25>>

Page 26

8.4) Spark Arrester Maintenance

8.3.6) Meas ure the spark plu g gap with a feel er

gauge. The no rmal value:0. 6-0.7mm(0 .024-

0.028in). A djust the gap by be nd one of the

electrode c arefully.

8.3.7) Rein stall the spark p lug careful ly, by han d,

to avoid cros s-threading. A new spark plu g

should be tig htened 1/2 turn with a spanner.

A used Spark pl ug should be tigh tened 1/8 to

1/4 turn with s panner.

8.3.8) Rein stall the spark p lug cap

8.3.9) Rein stall the spark p lug mainten ance cover.

NOTE

• The spark plug must be securely tightened.

Tightening in wrong way will cause spark plug

hot, even damage the engine.

• Never use a spark plug with an improper heat

range.

WARNING

The spark arr ester must be mai ntained eve ry

100h service.

8.4.1)Remov e the six screws, a nd remove the

muffler gua rd.

<<26>>

Page 27

8.4.2)Take off the spark ar rester from t he muffle

after the eng ine cool down.

8.4.3)Use a b rush to remove ca rbon deposi ts from

the spark arr ester . If the spar k arrester is

wear, repla ce it.

8.4.4)Rei nstall the spar k arrester an d muffle

guard.

<<27>>

Page 28

9.TRANSPORTING/STORING

Avoid fuel sp illing during transporti ng or

temporary stori ng, both the en gine switch and t he

fuel cap vent l ever should tur n to “OFF’ posi tion,

and the gener ator should pla ce in normal

operating p osition.

WARNING

Tran sporting Gene rator:

• Do not overfill the fuel tank. (No residual fuel on

the neck of tank) It is recommended not to

transport the generator with fuel in the tank.

• Do not use the generator on the transport vehicle.

The generator should be used under a good

ventilated condition.

• Avoid exposing directly in the sunshine when the

generator place in the enclosed transport vehicle

for a long time. The high temperature inside the

vehicle could cause fuel to vaporize resulting in a

possible explosion.

• Drain off the fuel, when the generator is

transported on rough roads.

Storing for a long period:

9.1) Make sure the storage area without

excessive humidity and dust.

9.2) Drain off the fuel.

WARNING

Keep away from smoking, flames and spark, Petrol is

explosive and flammable in the specified condition.

a. Drain off the Petrol in the fuel tank,storing

into the suit able containe r.

<<28>>

Page 29

b. Turn the engine switch to “ON” position, and

loosen the carburetor drain screw to discharge

Petrol inside of carburetor.

c. Take off the spark plug cap, pull the starter grip

three or four times, discharge the Petrol from the

fuel lines.

d. Turn the engine switch to “OFF” position, and

tighten the drain screw of carburetor.

e. Reinstall the spark plug cap.

STARTER G RIP

9.3) Change t he engine oil.

9.4) Remove t he spark plug, an d pour a

tablespoo n of clean engine o il(10~20ml)into

the cylinde r. Revolve the e ngine sever al

times to dist ribute the oil,and reinsta ll the

spark plug.

9.5) Pull the starter gr ip slowly until f eel

resistanc e. At this po int, the piston i s coming

up on its compr ession stroke a nd both the

intake and ex haust valves ar e closed. In th is

position, i t helps to protec t the engine fr om

internal co rrosion.

<<29>>

Page 30

10.TROUBLESHOOTING

Appliance d oes not operate:

When the engi ne can not be start ed:

Is there fue l in th e tan k?

YES

Are the engine switch and fuel switch ON?

YES

Is the fuel ca p ven t lev er ON ?

YES

Is the choke k nob p ull o ut?

YES

Is there eno ugh o il in t he

engine?

YES

Is the spark p lug i n goo d

conditio n?

YES

If the engin e sti ll do es no t

start, contact with an

authorized Cobra dealer

Refill the f uel t ank

NO

Turn the tw o swi tch s on

NO

Turn the fuel cap vent lever on

NO

Pull out the choke knob completely

NO

Add the recommended oil

NO

Clean, rea dju st ga p

and dry t he sp ark p lug.

NO

Replace it i f nec ess ary

Is the outpu t ind ica tor

light ON?

Is the overload indicator

YES

light ON?

YES

Check the electrical

appliance for any fault.

YES

NO

NO

Contact wi th an

authorized Cobra

NO

dealer

Contact wi th an

authorized Cobra

dealer

Stop engine and then replace or repair the appliance

Restart th e eng ine

DC rece ptacl e witho ut any el ectri city:

Check the electrical appliance

for any fault

NO

Is the DC circ uit

protecto r OFF ?

Change or replace the appliance

YES

YES

Pus h the DC circuit

protecto r ON.

NO

Contact with an

authorized Cobra dealer

<<30>>

Page 31

11. TECHNICAL SPECIFICATIONS

Speci fications

Model

Type

Engine Displacement

Bore*Stroke

ENGIN E

Compression Ratio

Rated Speed

Ignition Syst em

Start Syst em

Fuel Ty pe

Oil Capacity 0.41L

Oil Model

Model

GENER ATOR

Rated Frequency

Rat ed Vol tag e

Rat ed Cu rrent

Rated Speed

Rated Output Power

Max. Output Power

Par ame ter s

DJ148F

4-st roke, ove rhead val ve,

single cylinder, fo rced- air coo ling

3

79cm

48.6mm*43.0mm

9:1

2.2/5000min

Full t ransistor

Recoil starte r

Petrol without lead

SE 15W-30

IG

20SI

50Hz

230V

7.0A

4500min

1

.6kVA

.0kVA

2

-1

-1

OTHER SPECIFICATIONS

Fuel Tank Volume

Continuous Running Time

Fuel Consumption

Working Ambient Temperature

Max. Altitude

﹡Noise L

﹡﹡ Noise L

Dimensions (L*W*H )

Net Weigh t

wA

pA

12V/5ADC Output

3.6L

3.9h

550g/kW.h

-20 ~40

1000m

90dB/4m

54~59dB/7m

507mm*451mm*285m m

20kg

Noise level is measured when the ECON.SW is

turned to ‘’ ON‘’( )

L shows the guaranteed sound power

wA

tested by 2000/14/EC.

The noise level in “dB/7m” is the

arithmetic mean value of sound press level (L ) in

pA

four directions measured 7 meters away from the

generator.

The noise level may vary in different environments.

<<31>>

Page 32

12

WIRING DIAGRAMS

Hour meter

.

Aux .

Win ding

DC Rec eptac le

Mai n

Win ding

ECO N.SW

Res et

To Rese t

AC

Rece ptacl e

Step ter

Moto r

CDI

Gen erato r

Oil

Sen sor

Spar k plug

CDI

Igni tion

Engi ne

Swit ch

Ign iter

<<32>>

Page 33

13. APPENDIX

13.1) Environment Correction

The standar d condition of ra ted power out put:

Altitude: 0m

Ambient tem perature:25 C

Relative hu midity:30%

Factor of en vironment cor rection:

Altitude (m)

0

500

1000

2000

3000

4000

25 30 35 40

1

0.93

0.87 0.85 0.82 0.80 0.78

0.75 0.73

0.64 0.62 0.60 0.58 0.56

0.54 0.52 0.50 0.48 0.46

o

Ambient te mpe rat ure℃

0.98 0.96 0.93 0.90

0.91

0.89 0.87 0.84

0.71

0.69 0.66

NOTE: Relat ive humidity 60 % correctio n factorC-

0.01;

Relative hu midity 80% correction fact orC -

0.02;

Relative hu midity 90% correction fact orC-

0.03;

Relative hu midity 100% correctionfa ctorC-

0.04;

45

<<33>>

Page 34

Example:

Rated power(P )1.6kVA generator( Altitude:

N

1000m) Ambient temperature: 35,Relative

humidity: 80%

P=Pn*(C -0.02)= 1.6*( 0. 82-0. 02)=1.28kVA

13.2) Noise and Access

Noise emission measure according to ISO 8528-10,

EN ISO 3744, European Directive 2000/14/EC with

amendment 2005/88/EC

Model of generator set: IG20SI

Sound Pressure Level: 68 dB(A)

Guaranteed Sound Power Lever 90dB(A)

Measurement Uncertainty K: 1.7 dB(A)

The quoted figures are emission levels and are not

necessarily safe working levels. Whilst there is a

correlation between the emission and exposure

levels, this cannot be used reliably to determine

whether or not further precautions are required.

Factors that influence the ac tual level of exposure

of work-force include the characteris tics of the

work room, the other sources of noise, etc, i.e. the

number of machines and other adjacent

processes, and the length of t

ime for which an

operator is exposed to the noise. Also the

permissible exposure level can vary from county.

This information, however, will enable the user of

the machine to make a better evaluation of t he

hazard and risk.

<<34>>

Page 35

EC DECLARATION OF CONFORMITY

We herewith declare, Cobra Garden Machinery

Henton & Chattell Ltd, London Road, Nottingham NG2 3HW United Kingdom

that the following machine complies with the appropriate basic safety and health requirements of the EC

Directive based on its design and type, as brought into circulation by us.

In case of alteration of the machine, not agreed upon by us, this declaration will lose its validity

Machine Description: Inverter Generator

Machine Type: IG20SI (HY20i)

Engine Displacement: 79 cm

3

Rated Output Power 1.6 kVA Max 2.0 kVA

Measured sound power level 68 dB(A)

Guaranteed sound power

level:

90 dB(A)

Notified Body for EC Directive 2000/14/EC:0499

TÜV Rheinland LGA Products GmbH

Tillystrasse 2, 90431 Nürnberg, Germany 0197

Applicable EC Directives: 2006/42/EC

2006/95/EC

2004/108/EC

2000/14/EC amended 2005/88/EC

Applicable Harmonized

Standards:

EN 12601:2010

EN 61000-6-2:2005

EN 61000-6-4:2007

Authorized Signature/Date/

Place:

Peter J. Chaloner 10/1/2019

Title of Signatory: Managing Director

Name and address of the

person authorized to

compile the technical file

Cobra Garden Machinery

Henton & Chattell Ltd, London Road, Nottingham NG2 3HW United Kingdom

Page 36

14. CONSUMER INFORMATION

Consumer Service Information

Please contact your retailer for any service related issues in the first instance.

As appropriate you may be referred to another Cobra dealer who is professionally trained to complete service

work as necessary. The Cobra dealer list is available at cobragarden.co.uk or contact 0115 986 2161 for

assistance.

When contacting your dealer, please have the following information to hand:

Model and ser ial number

Date of purch ase

Detailed description of the problems

Dealer contact information and your: name,

address, and telephone number

<<36>>

Page 37

Cobra Garden Machinery

Henton and Chattell Ltd, London Road, Nottingham

NG2 3HW UK

Loading...

Loading...