Page 1

INVERTER GENERATOR

USER MANUAL

Model:IG10SI

4-Stroke Engine

Page 2

Page 3

Thank you for purchasing Cobra Inverter Generator

● Cobra reserves the right of modification of product and revision of the manual without any notice.

● Take this manual as a part of the generator. If the generator is resold, it is required to take the manual along

with the generator.

● This manual contains how to correctly operate the generator, please read carefully before using the generator.

Correct and safe operation will guarantee your safety and extend the working life of generator.

● Cobra will continuously innovate and develop its products both in design and quality. The content of this

manual may have minor difference from the updated product. Please contact your supplier for further support.

IMPORTANT SAFETY NOTICE:

The emission of engines contains poisonous carbon monoxide. Use the generator

only outdoors and away from people.

NEVER use petrol powered equipment in a home, garage, tent, camper-van,

caravan, motor-home or boat. Even if doors, windows or vents are open. Only use

outdoors, well away from doors, widows and openings. Prevent inhaling exhaust

fumes.

Page 4

Page 5

CONTENTS

01.Safety information

02.Safety label locations

03.Components identification

1)Con trol Panel

2)ECO N.SW

3)Res et

4)Hou rmete r

04.Pre-operation check

1)Che ck oil le vel

2)Che ck fuel l evel

3)Che ck air cl eaner

05.Starting the engine

06.Generator use

1)DC ap plica tion

2)AC appli catio n

3)Out put and o verlo ad indi cator

4)Oil a lert sy stem

04

06

07

08

08

09

09

10

10

11

12

13

15

16

18

18

19

07.Stopping the engine

08.Maintenance

1)Cha nge oil

2)Air c leane r service

3)Spa rk plug s er vice

4)Spa rk arre ster ma inten ance

09.Transporting/Storing

10.Troubleshooting

11.Technical specifications

12.Wiring diagrams

13.Appendix

1)Env ironm ent cor recti on

2)Noi se and ac cess

14.Consumer information

20

21

21

22

24

25

27

29

30

31

32

32

33

34

Page 6

Page 7

1.SAFETY INFORMATION

To ensure personal and property safety, please

carefully read the following information.

distance wi th constructi ons and other

electrica l appliances at l east.

● Place the generator on the leveled surface, in

order to avoid overturning or spilling fuel.

WARNING

● Read and understand the user manual before

using the generator.

● The emission of engine contains poisonous

carbon monoxide. Use the generator in well

ventilated conditions.

● Do not touch the hot muffler, when the generator

is running, or before cooling.

● Petrol is explosive and flammable in the specified

conditions when refueling, the generator needs to

be stopped and be kept cigarette and fire source

away.

● Do not connect to the building’s electrical system

or other generator, in order to avoid the electric

shocks and fires.

● The running generator must keep one meter

● Children and pets should be

operation area.

● Do not operate with wet hands.

● Do not expose the generator to rain, moisture or

snow.

● Place the generator at least 1m away from

buildings or other equipments during

operation.

● The major repair work should be carried out

only by professionally trained person.

● Do not use the generator in underground

working

● Do not use the generator in potentially

explosive atmospheres

● Use personal protective equipment: glove,

mask, earplugs, when you operate

keep away the

<<04>>

Page 8

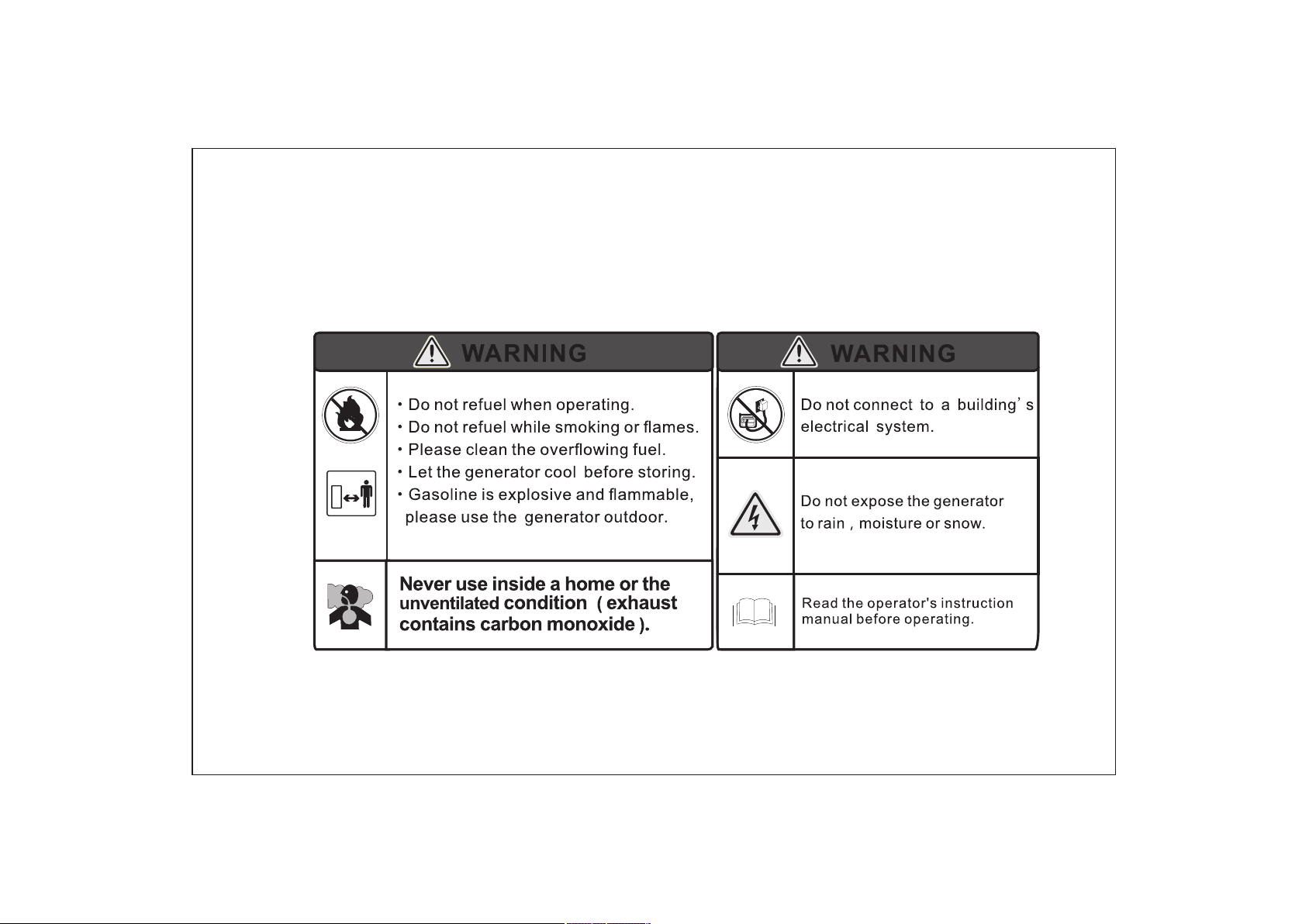

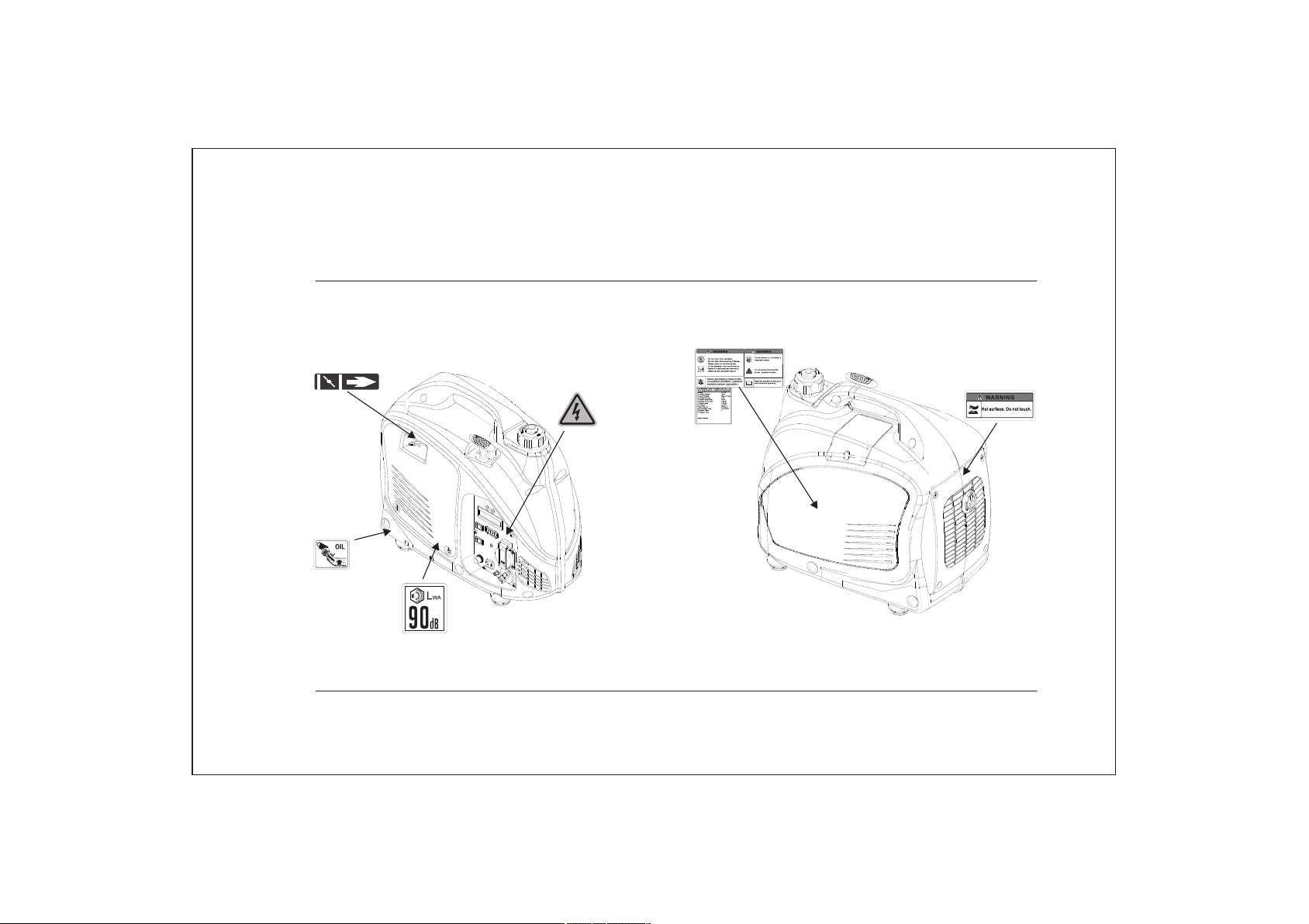

SAFETY LABEL:

<<05>>

Page 9

2. SAFETY LABEL LOCATIONS

<<06>>

Page 10

3. C IDENTIFICATIONOMPONENTS

CHOKE LEVER

AIR CL EAN ER

MAINTENA NCE

COV ER

STARTER GRI P

ENGINE SW ITC H

FUEL C AP VENT LEV ER

FUEL C AP

CONTROL

PANE L

SPAR K P LUG

MAINTENA NCE

COV ER

MUFFLER

<<07>>

Page 11

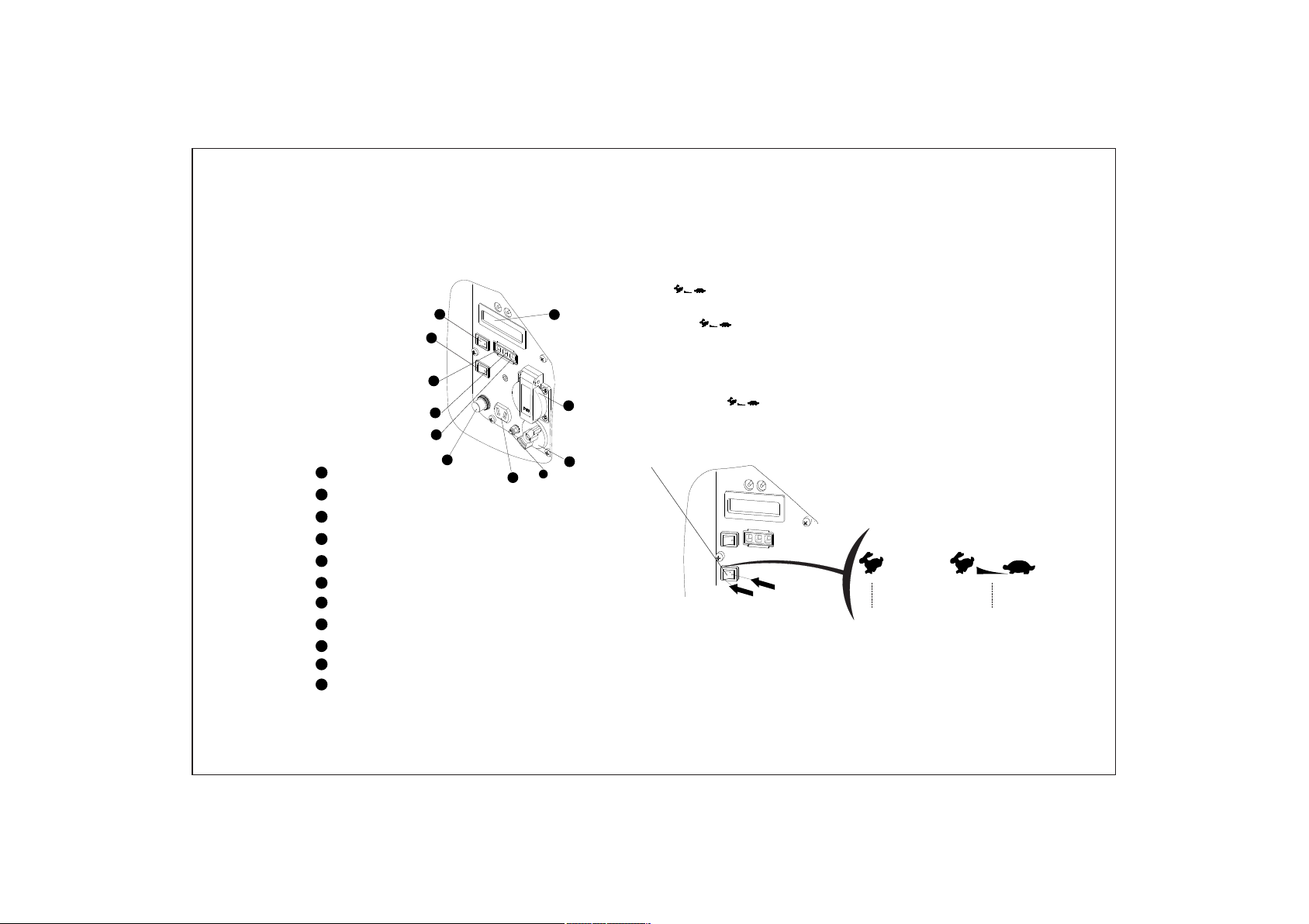

3.1) Control Panel

11

1

2

3

4

1

ECON. SW

Oil Alert Indicato r L ight(red)

2

Overload Indicato r Light(red)

3

Output Indicator Light( green)

4

5

DC Cir cuit Protector

DC Rec eptacle

6

7

Ground Terminal

8

Fuel Switch

9

AC Rec eptacle

10

Hourmeter

11

Engine Switch

5

3.2) ECON. SW (Economy control switch):

“ON”( )

10

9

8

7

6

● When the econo my control swi tch is turned to

“ON”( ), the engine keep s running at idle state

automatic ally whe n the ele ctrical appl iance is

disconnec ted,and it will retur n t o the pro per speed

with the requi rement of electrical load.

● The “ON ”( ) is recommen ded to minimize the fuel

ECON. SW

ON

OFF

ONOFF

<<08>>

Page 12

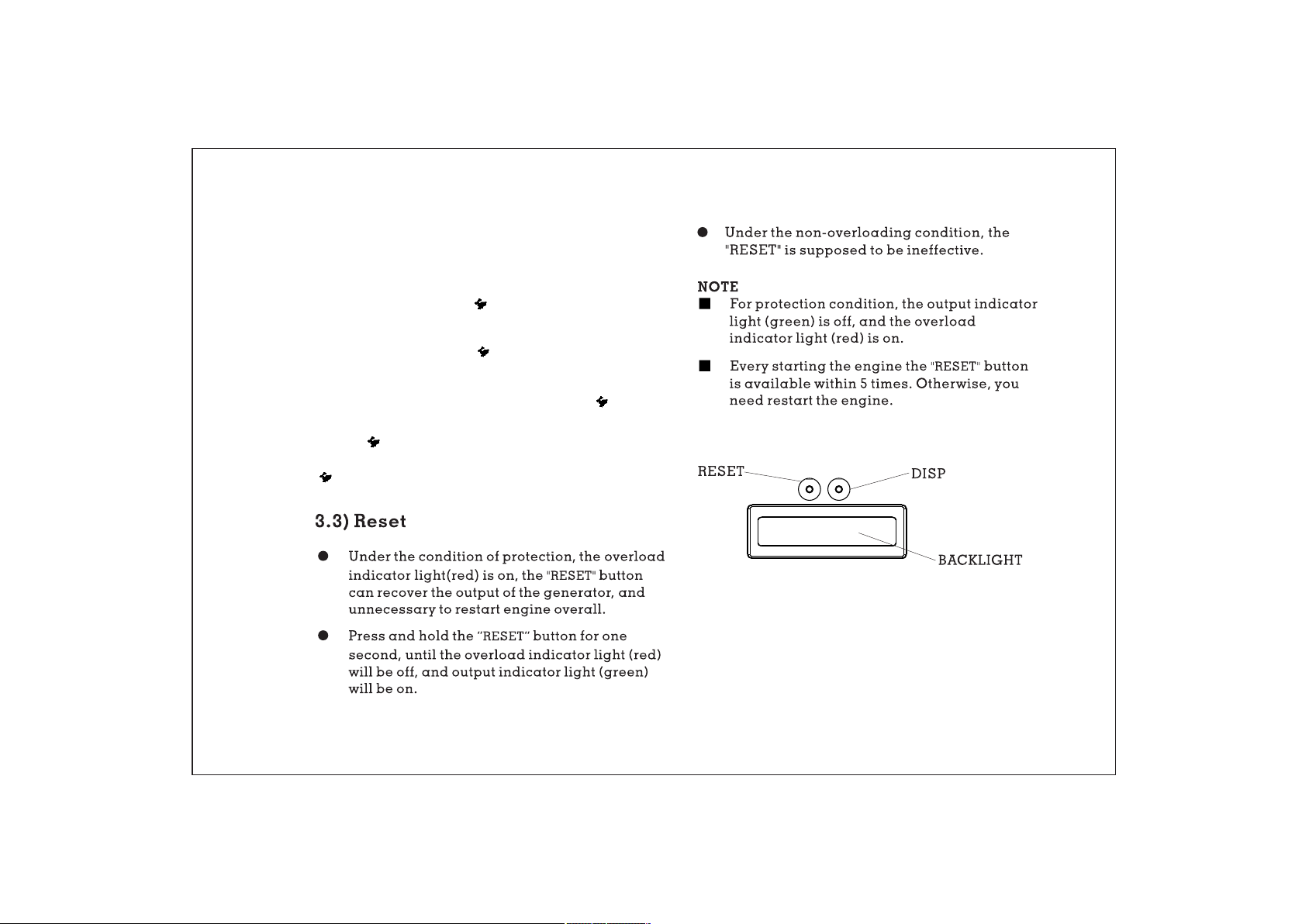

NOTE

■ When a high loa d electrical appliance is

connected i nstantaneou sly, in order to reduce

voltage cha nge, turn the eco nomy contro l

switch to the “OFF”( )position .

■ In DC operation, turn the ec onomy control

switch to the “ OFF”( )position.

■ Connect bot h AC load a nd DC load, tur n the

economy con trol switch to th e “OFF” ( )

position.

“OFF” ( )

When the econ omy control switch turns to th e “OFF”

( ) engine runs at high speed.

3.4) Hour-meter

● Pre ss the “DISP ” button to display the

voltage/frequency of output, the engine speed

and cumulative working time in turn.

● Pre ss the “DISP ” button, the back-light of hour-

meter will be on, and it will be off wit hout

operating the button for 10S.

<<09>>

Page 13

4. PRE- OPERATION CHECK

WARNING

Be sure the gen erator is on the le veled surfa ce and

the generat or is stopped.

4.1) Check Oil Level

Remove the oi l filler cap, and t hen clean it wi th

cloths. Rei nsert it into the c rankcase, a nd take out

to check oil le vel:

If the oil leve l reduces at the bo ttom of the oil f iller

cap, add the en gine oil.

Oil Cap acity:0.25L

NOTE

■ Using non-d etergen t or 2-stroke oil could

shorten the e ngine’s working life.

■ Using the hig h quality engine oil with stro ng

detergents

■ Using 4-str oke engine oil, certified to m eet or

exceed API st andards: SG, SF , SE stickine ss

rating:

15W -40

10W -40

10W -30

5W- 30

OIL FILLER

CAP

DIPSTICK

OIL FILLER H OLE

UPPER LEVE L

-30 -20 - 10 0 10 20 3 0

-20

20 40 60 80

0

40℃

100 F

NOTE

Carefully u se and store the en gine oil, avo id

getting dir t or dust into the en gine oil.

Mixing diff erent kinds of engine oil is pro hibited.

<<10>>

Page 14

NOTE

■ Before the en gine oil reduces below the saf ety

margin, low oil alert sy stem will close the

engine auto matically. The oil alert ind icator

light (red) will be on.

■ To avoid t he inconvenience caused by

unexpecte d stopping, it is still advisa ble to

check the eng ine oil level regularly.

FUEL CAP

WARNING

OPEN

UPPER LIMI T MAR K

Fuel c apa cit y: 3.8L

4.2) Check Fuel Level

Fuel recommend: use unleaded petrol

(Research Octane Number of 91 or higher, Pump

Octane Number of 86 or higher).

Never use sta le or contamina ted gasolin e or an

oil/gasol ine mixture.

Avoid getting dirt or water into the fuel tank.

Do not use a mixture petrol containing ethanol or

methanol; otherwise, it will seriously damage the

engine.

● Petrol is extremely explosive and flammable.

● Around the refueling area and fuel storage

area, prohibit smoking and firing.

● Do not overfill the fuel tank (no fuel above the

red upper limit mark). After refueling, make sure

the fuel cap is closed properly and securely.

● Do not spill fuel from fuel tank. (No residual fuel

around the neck of tank, before starting engine)

● Avoid contacting with skin or breathing the fuel

vapor.

● KEEP OUT OF REACH OF CHILDREN.

<<11>>

Page 15

4.3) Check Air Cleaner

Check the air c leaner element to be sure it is cl ean

and in good con dition.

a. Loosen the a ir cleaner maintenance cov er

screws, and r emove the cover.

AIR CLEANER ELEMENT

AIR CLEANER MAINTENANCE

COVER

COVER SCREW

b.P ress the latch t ab on the top of the ai r cleaner.

AIR CLEANER

COVER

c.R emo ve the air cleane r cover.

d. Check the ele ment, clean or re place it, if ne cessary.

NOTE

■ Do not run engi ne without air Cleaner

element, ot herw ise that make s engine

<<12>>

Page 16

5. STARTING THE ENGINE

NOTE

■ Before st arting engine , disconnec t load with

AC re ceptacle.

NOTE

■ When transp orting generator, turn th e fuel

cap vent leve r to the “OFF ” po sition.

■ Fuelin g at the first time , refueling , or storing

for a long time , the engine swit ch should

firstly be op ened for ten or twe nty seconds

and then requ ire additional pull 10-20 ti mes,

in order to the e nough fuel ente r into

carbureto r.

5.1) Turn the fuel ca p vent lever to t he “ ON”

position.

FUEL CAP VEN T LEV ER

OFF

O

N

ON

OFF

ON

ENGINE SWI TCH

5.3) Move the c hoke lever to “CLOSED” position .

CHOKE LEVE R

CLOSED CLOSED

<<13>>

Page 17

NOTE

■ Do not move the c hoke lever to “CLOSED”

position, w hen engine is hot or ambient

temperatu re is high.

5.4) Pull t he starter gr ip lightly unti l you feel

resistanc e, then pull quic kly toward ar row as

shown below.

STARTER G RIP

5.5) After st arting and warm ing up the engi ne,

turn the chok e lever to “OPE N” positi on.

CHOKE LEVE R

NOTE

■ Return the st arter grip slow ly by hand. Do no t

make the star ter grip spring b ack quickly.

OPEN

OPEN

NOTE

■ If the gene rator stops and c an not restart,

check the oil l evel firstly.

Carbure tor Modificat ion for High Alti tude

Operation

At high altitude, the st andard carburetor airfuel mixtur e will be too rich. Perf ormance will

decrease, a nd fuel consump tion will inc rease. A

very rich mixture will also foul t he spark plug

and cause har d starting.

If the genera tor operates at h igh altitud e,

change the ma in-nozzle or ad just the idling-

<<14>>

Page 18

screw

of carburet or.

the generator always operates at altitude

If

above 1,000 meters, contact with an authorized

Cobra servicing to modify the carburetor.

Generator output power should be modified

according to the altitude and ambient

temperature. The correction factor refers to

13-1.

6. GENERATOR USE

WARNING

● Be sure to grou nd the generato r when the

connected e lectrical app liance is gro unded.

● Do not conn ect to the buildi ng’s electrical

system, in or der to avoid the el ectric shoc ks

WARNING

● If the carburetor has been modified for high

altitude operation, the air-fuel mixture will be too

lean for low altitude use. Operation at low

altitude may cause the engine to overheat and

result in serious engine damage. The carburetor

needs return to original settings

GROUND TER MIN AL

<<15>>

Page 19

WARNING

6.1) DC Application

● For contin uous operatio n, do not excee d the

rated out-p ut power of gener ator.

● Do not make par allel connect ion with othe r

generator s.

● Do not connec t an extension to t he exhaust

pipe.

● When an exten sion cable is req uired, be sur e

to use a tough ru bber sheathed f lexible cab le

(accordin g to IEC245 or equivalent

standards ). The length of th e extension c able:

60m for cable o f 1.5mm ; 100m for cable of

2.5mm .

2

2

● Kee p away from other electric cab les or wires.

NOTE

■ The AC recept acle can be use d while the DC

power is in use . If use both at same t ime, be

sure not to exc eed the total pow er for AC and

DC. (AC:0. 9kVA,DC:5 A)

■ Most of motor a ppliances req uire more tha n

their rated w attage, when st arting.

The DC receptacle, 15-30V under no-load condition,

may be used for charging 12V battery only.

NOTE

■ In DC operati on, turn the EC ON.SW t o the

"OFF” ( ) position.

6.1.1) Conn ect the DC rece ptacle to batte ry

CHARGING C ABL E

<<16>>

Page 20

WARNING

WARNING

● In order to avo id producing the spark at the

terminals o f battery, connect the charging

cable first ly to the battery ter minals, and the n

to the genera tor. Disconn ect the cable f irstly

at the genera tor .

● Before conn ecting the charging cable to a

battery that is ins talled in veh icle,the

grounded ca ble of battery will b e

disconnec ted firstly. Th is sequence w ill

prevent spa rks or short-ci rcuit. When t he

cable accid entally conta ct the vehicl e’s frame

NOTE

■ Do not start the automobile engine when the

generator is still connected to the battery,

otherwise the generator will be damaged.

■ Connect the positive battery terminal to the

positive charging cable. Do not

reverse the

charging cable.

● The battery can rel ease the expl osive gases.

Kee p the battery away fr om spark/fire .

Charge the battery in ventil ated condit ion.

● Battery electro lyte contai ns sulfuric aci d

that will cau se severe burn of s kin and eyes.

Therefore i t is necessary to wea r the

protectiv e clothing and mask.

● If battery electr olyte gets in to eyes, flush

thoroughl y with warm water for 15min at

least, and ca ll a doctor immed iately.

● If you swallo w a little of batte ry e lectrolyte

accidenta lly, flush thor oughly with w ater

your mouth, a nd then drink large quanti ties

of water or mil k (with magnesia or vegetabl e

oil), and cal l a doctor immediately.

NOTE

■ The DC recept acle can be used wh ile the AC

power is in use

■ When DC circu it overload will trip the DC

<<17>>

Page 21

circuit pro tector, remo ve load first ly, and

then reset th e protector aft er a few minute s.

OVE RLOAD

INDICATOR

LIGHT(RE D)

OUTPUT

INDICATOR

LIGHT (GRE EN)

ON OFF

DC protect or

6.2) AC applications

6.2.1) Start engine and make sure the output

indicator light (green) is on.

6.2.2) Confirm all electrical appliances are switched

off, and connect the appliance plugs to the

generator receptacle.

NOTE

■ To obtain the best working and longest working

life of the generator, a new generator is run for 20

hours at 50% rated load.

NOTE

PLU G

■ Confirm all e lectrical appliances are i n

good workin g condition before connect ing

them to the gen erator. If an el ectrical

appliance b ecomes abnormal, sluggis h, or

stops sudde nly, shu t off the gener ator

engine imme diately, and discon nect the

6.3) Output and Overload Indicator

In normal ope rating, outpu t indicator l ight

(green) wil l remain on.

If the genera tor is overload ( over 0.9 kVA), or the

connected a ppliance is sho rt-circui t, the output

indicator l ight (green) is off, and overl oad

<<18>>

Page 22

indicator l ight (red) is on. The AC power will be

switched of f, but engi ne is still runni ng.

If the overlo ad indicator light (red) is on , disconnect

the electri cal appliance s firstly, press and ho ld the

rest button 1 s. If the overloa d indicator l ight (red) is

OFF and the out put indicator l ight (green ) is on,

reconnect t he electrical a ppliances . Otherwise stop

the engine an d check the generator.

6.4) Oil alert system

The oil alert s ystem is designed to prevent e ngine

damage caus ed by an insuffic ient amount o f oil

in the crankc ase. Before the o il level in the

crankcase f alls below a safe l imit, the oil a lert

system will a utomatically shut down the e ngine

(the engine s witch remains in the “ON“position).

OVE RLOAD

INDICATOR

LIGHT(RE D)

OUTPUT

INDICATOR

LIGHT (GRE EN)

If the oil aler t system shuts do wn the engine , the

oil alert ind icator light (red) will be on. C heck the

engine oil le vel.

OIL ALERT IND ICATOR

LIGHT ( RED)

<<19>>

Page 23

7. STOPPING THE ENGINE

7.3) Turn the fuel cap vent lever to the“OFF”

position.

To stop the eng ine in an

emergency, turn the en gine

switch to the “ OFF”position.

7. 1) Switch off t he connected

electrica l appliances,

and pull out th eir plugs.

PLUG

7.2) Turn the engine switch to the “ OFF” positi on.

FUEL CAP VEN T LEV ER

OFF

OFF

NOTE

■ Be sure the fuel cap vent lever and engine

switch locate the “OFF” position,

when

stopping, transporting and storing the

generator.

■ Avoid transporting the generator with fuel

still in the tank.

ON

<<20>>

Page 24

8.

MAINTENANCE

The purpose of the maintenance and adjustment

schedule is to keep the generator in the best

operating c ondition.

WARNING

Stop the engi ne before performing any

maintenan ce. If the engine m ust run, be sur e the

area is well ve ntilated. The exhaust cont ains

poisonous carbon monoxide gas.

Use genuine Cobra or equivalent quality

components to replace the wear components.

Maint enanc e Sched ule

Reg ular Se rvic e

Per iod (3 )

Ite m

Eng ine

oil

Air

cle aner

Spa rk plug

Check level

Cha nge

Che ck

Cle an

Check-adjust

Eac h

use

Fir st

mon th

or

10 hr s.

Eve ry 3

mon ths

or

50 hr s.

+(1)

Eve ry 6

mon ths

or

100 h rs.

Eve ry

2 yea rs

or

300 h rs.

Spa rk plug

Spark arre ste r

Valve Clearance

Combustion Chamber

Fuel tank& filter

Fuel l ine

Rep lace

Check-adjust

Cle an

Cle an

Che ck

⊙

+(2)

Aft er ever y 300 hr s(2)

Eve ry yea r(2)

Eve ry 2 yea rs ( Rep lace if n ecess ary) (2)

NOTE

(1) Service more frequently when used in dusty areas.

(2) These items should be serviced by your servicing

dealer, unless you have the proper tools and are

mechanically proficient. Refer to Cobra manual for

service procedures.

(3) For commercial use, long hours of operation to

determine proper maintenance intervals.

8.1) Change Oil

Drain the oil r apidly and completely whil e the

engine is sti ll warm.

8.1.1) Loos en the air cleane r maintenan ce cover

screw, and remove the cov er.

8.1.2) Remo ve the oil filler cap.

<<21>>

Page 25

8.1.3) Drai n dirty oil into a container tho roughly.

8.1.4) Refi ll the recommended oil and che ck the oil level.

8.1.5) Rein stall the oil filler cap.

8.1.6) Rein stall the maint enance cove r and tighten the

cover screw.

OIL FILLER H OLE

UPPER LEVE L

AIR CLEANER MAINTENANCE

COVER

COVER SCREW

OIL FILLER

CAP

NOTE

After oil change, wash your han ds with soap.

NOTE

For conforming to the environment requir ement,

the used oil will be put into a sealed container and

then be transport ed to the service station fo r

recycler. Do not throw it into the trash or po ur it on

the ground.

Oil Capacity: 0 .25L

8.2) Air Cleaner Service

A dirty air cle aner will restrict air flow in to the

carbureto r.Clean and maintain the air c leaner

regularly, especi ally in the ext remely dusty ar eas.

<<22>>

Page 26

WARNING

Do not use petrol or low ignition point solvents for

cleaning. They are flammable and explosive under

certain conditions.

NOTE

Never run the g enerator

without air c leaner,

otherwise that re sult in engin e abrasion rapi dly.

8.2.1) Loos en the air cleaner maintenan ce cover

screws, and r emove the cover.

AIR CLEANER MAINTENANCE

COVER

COVER SCREW

8.2.2) Press down the latch tab on the top of the air

cleaner, and open the air cleaner cover.

AIR CLEANER ELEMENT

AIR CLEANER

COVER

8.2.3) Take out the air cleaner element, and clean

it with non- flammable or high flash point

solvent, then dr y it.

8.2.4) Soak the air cleaner element in the clean

engine oil, and squeeze out the redundant

oil.

ELEMENT

<<23>>

Page 27

8.2.5)Reinstall the air cleaner element and cover.

8.2.6)Reinstall the maintenance cover, and tighten

the screws.

8.3) Spark Plug Service

Recommendation spark plug: CR7HSA, A5RTC

Check the spa rk plug gap and c lean the carbon

depositio n at the bottom o f the spark plu g.

8.3.1) Loos en the spark pl ug maintenance cover

screws, and remove the c over.

SPAR K PLUG

MAINTENANCE COV ER

8.3.2) Take off the spa rk plug cap.

8.3.3) Clean th e carbon depositi on at the botto m of

the spark plug.

HANDLE BAR

SPAR K PLUG CAP

8.3.4) Take off the spark plug with the spark plug

spanner.

8.3.5) Visual inspection the spark plug. Change a

new one if its insu

lator cracked or chipped.

Clean it with a wire brush if the spark plug

is reused.

0. 60- 0.70m m

(0.024-0.028in)

<<24>>

Page 28

8.3.6) Meas ure the spark plu g gap with a feel er

gauge. The no rmal value:0. 6-0.7mm(0 .024-

0.028in). A djust the gap by be nd one of the

electrode c arefully.

8.3.7) Rein stall the spark p lug careful ly, by han d,

to avoid cros s-threading. A new spark plu g

should be tig htened 1/2 turn with a spanner.

A used Spark pl ug should be tigh tened 1/8 to

1/4 turn with s panner.

8.3.8) Rein stall the spark p lug cap

8.3.9) Rein stall the spark p lug mainten ance cover.

NOTE

■ The spark plug must be securely tightened.

Tightening in wrong way will cause spark plug

hot, even damage the engine.

■ Never use a spark plug with an improper heat

range.

8.4) Spark Arrester Maintenance

WARNING

The spark arr ester must be mai ntained eve ry

100h service.

8.4.1)Rem ove the four scre ws, and remov e the

muffler gua rd.

<<25>>

Page 29

8.4.2)Tak e off the spark arr ester from th e muffle after

the engine co ol down.

8.4.3)Rem ove carbon deposits of the spa rk arrester

using a brush . If the spark arre ster is wear,

replace it.

8.4.4)Rei nstall the spar k arrester an d muffle

guard.

<<26>>

Page 30

9.TRANSPORTING/STORING

Avoid fuel sp illing during transporti ng or

temporary stori ng, both the en gine switch and t he

fuel cap vent l ever should tur n to “OFF’ posi tion,

and the gener ator should pla ce in normal

operating p osition.

WARNING

Tran sporting Gene rator:

● Do not overfill the fuel tank. (No residual fuel on

the neck of tank) It is recommended to drain the

generator of fuel before transporting.

● Do not use the generator on the transport vehicle.

The generator should be used under a good

ventilated condition.

● Avoid exposing directly in the sunshine when the

generator place in the enclosed transport vehicle

for a long time.

vehicle could cause fuel to vaporize resulting in a

possible explosion.

● Drain off the fuel, when the generator is

transported on rough road.

The high temperature inside the

Storing for a long period:

9.1) Make sure the storage area without excessive

humidity and dust.

9.2) Drain off the fuel.

WARNING

● Kee p away from smoking, flames an d spark,

gasoline is e xplosive and flammable in th e

specified c ondition.

a.

Drain off the petrol in the fuel tank,storing

into the suit able containe r.

<<27>>

Page 31

b. Turn the engine switch to “ON” po sition, and

loosen the ca rburetor drain screw to disc harge

c. Take off the s park plug cap, pu ll the starter grip

three or four t imes, discharge the gaso line from

the fuel pump a nd fuel lines.

d. Turn the engine switch to “OF F” position, an d

tighten the d rain screw of car buretor.

e. Reinstal l the spark plug ca p.

STARTER G RIP

9.3) Change t he engine oil.

9.4) Remove t he spark plug, an d pour a

tablespoo n of clean engine o il(10~20ml)into

the cylinde r. Revolve the e ngine sever al

times to dist ribute the oil,and reinsta ll the

spark plug.

9.5) Pull the starter gr ip slowly until f eel

resistanc e. At this po int, the piston i s coming

up on its compr ession stroke a nd both the

intake and ex haust valves ar e closed. In th is

position, i t helps to protec t the engine fr om

internal co rrosion.

<<28>>

Page 32

10.TROUBLESHOOTING

Appliance does not operate:

When the engine can not be started:

Is there fuel in the tank?

YES

Is the engine switch O N?

YES

Is the fuel cap vent lever ON?

YES

Is the choke lever OPEN?

YES

Is there enough oil in the

engine?

YES

Is the spark plug in good

condition?

YES

Refill the fuel tank

NO

Turn the engine switch on

NO

Turn the fuel cap vent lever on

NO

Turn thechoke lever to OPEN

NO

Add the recommended oil

NO

Clean, readjust gap

and dr y the s par k plug.

NO

Replace it if necessary

Is the output indicator

light ON?

Is the overload indicator

YES

light ON?

YES

Check the electrical

appliance for any fault.

YES

NO

NO

Contact with an

authorized Cobra

NO

dealer

Contact with an

authorized Cobra

dealer

Stop engine and then replace or repair the appliance

Restart the engine

DC receptacle without any electricity:

Check the electrical appliance

for any fault

NO

Is the DC circuit

protector ON?

Change or replace the appliance

YES

YES

Pus h the D C circuit

protector ON.

NO

Contact with an

authorized Cobra

dealer

<<29>>

Page 33

11. TECHNICAL SPECIFICATIONS

Speci ficatio ns

Model

Type

Engine Displacement

Bore*Stroke

ENGIN E

Compression Ratio

Rated Speed

Ignition Syst em

Start Syst em

Fuel Ty pe

Oil Capacity

Model

GENERATOR

Rated Frequency

Rat ed Vol tag e

Rat ed Cu rrent

Rated Speed

Rated Output Power

Max. Output Power

Par ameters

IG10SI - HS1200i.1

4-str oke, ov erhea d valve ,

single cylinder, forc ed-ai r cooling

3

53.2cm

43.5mm*35.8mm

7.6:1

-1

5500min

Recoil starte r

Gasoline withou t lea d

0.25L

SE 15W-30Oil Model

IG

10si

50Hz

230V

3.9A

-1

5300min

0.9kVA

1.0kVA

DC Output

Fuel Tank Volume (L)

Continuous Running Time(h)

GENERATOR SE T

Fuel Consumption (g/(kW.h)

Working Ambient Temperature( )

Max. Altitude (m)

﹡Noise (dB/4m) L

﹡﹡ Noise (dB /7m ) L

Dimensions (L*W*H )(mm)

Net Weight(kg)

12V/5A

3.8

5h (rated power)

550

-20~4 0

1000

90

wA

54~59

pA

279*425*443

14

12V/5A

Noise level is measured when the ECON.SW is turned

to ‘’ ON‘’( )

L shows the guaranteed sound power tested

wA

by 2000/14/EC.

The noise level in “dB/7m” is the

arithmetic mean value of sound press level (L ) in

pA

four directions measured 7 meters away from the

generator.

The noise level may vary in different environments.

<<30>>

Page 34

12.WIRING DIAGRAMS

<<31>>

Page 35

13. APPENDIX

13.1) Environment Correction

The standar d condition of ra ted power out put:

Altitude: 0m

Ambient tem perature:25 C

Relative hu midity:30%

Factor of en vironment correction:

Altitude (m)

0

500

1000

2000

3000

4000

25 30 35 40

1

0.93

0.87 0.85 0.82 0.80 0.78

0.75 0.73

0.64 0.62 0.60 0.58 0.56

0.54 0.52 0.50 0.48 0.46

o

Ambient te mpe rat ure℃

0.98 0.96 0.93 0.90

0.91

0.89 0.87 0.84

0.71

0.69 0.66

NOTE:

Relative hu midity 60% corr ection fact orC-

0.01;

Relative hu midity 80% correction

factorC -0. 02;

Relative hu midity 90% correction fact orC-

0.03;

Relative hu midity 100% correctionfa ctorC-

0.04;

Example:

45

1000m) Ambi ent temperature: 35℃,Relative

Rated power(P )0.9kVA ge nerator(Alt itude:

N

humidity: 8 0%

P=P *(C-0.02)=0. 9* (0.82-0.02) =0.72kVA

N

<<32>>

Page 36

13.2) Noise and Access

Noise emission measure according to ISO 8528-10,

EN ISO 3744, European Directive 2000/14/EC with

amendment 2005/88/EC

Model of generator set:

Sound Pressure Level: 68 dB(A)

Guaranteed Sound Power Lever:90dB(A)

Measurement Uncertainty K: 1.7 dB(A)

The quoted figures are emission levels and are not

necessarily safe working levels. Whilst there is a

correlation between the emission and exposure

levels, this cannot be used reliably to determine

whether or not further precautions are required.

Factors that influence the actual level of e xposure

of work-force include the characteristics of th e

work room, the other sources of noise, etc, i.e. the

number of machines and other adjacent

processes, and the length of time fo r which an

operator is exposed to the noise. Also the

permissible exposure level can vary from county.

This information, however, will enable the user of

the machine to make a better evaluation of t he

hazard and risk.

<<33>>

Page 37

14. CONSUMER INFORMATION

Consumer Service Information

Please contact your retailer for any service related issues in the first instance.

As appropriate you may be referred to another Cobra dealer who is professionally trained to complete service

work as necessary. The Cobra dealer list is available at cobragarden.co.uk or contact 0115 986 2161 for

assistance.

When contacting your dealer, please have the following

Model and ser ial number

Date of purch ase

Detailed description of the problems

Dealer contact information and your

: name, address, and telephone number

information to hand:

<<34>>

Page 38

We herewith declare, Cobra Garden Machinery

Henton & Chattell Ltd, London Road, Nottingham NG2 3HW United Kingdom

that the following machine complies with the appropriate basic safety and health requirements of the EC

Directive based on its design and type, as brought into circulation by us.

In case of alteration of the machine, not agreed upon by us, this declaration will lose its validity

Machine Description: Inverter Generator

Machine Type: IG10SI (HY10i)

Engine Displacement: 53.2 cm

3

Rated Output Power 0.9kVA Max 1.0kVA

Measured sound power level 68 dB(A)

Guaranteed sound power

level:

90 dB(A)

Notified Body for EC Directive 2000/14/EC:0499

TÜV Rheinland LGA Products GmbH

Tillystrasse 2, 90431 Nürnberg, Germany 0197

Applicable EC Directives: 2006/42/EC

2006/95/EC

2004/108/EC

2000/14/EC amended 2005/88/EC

Applicable Harmonized

Standards:

EN 12601:2010

EN 61000-6-2:2005

EN 61000-6-4:2007

Authorized Signature/Date/

Place:

Peter J. Chaloner 10/1/2019

EC DECLARATION OF CONFORMITY

Title of Signatory: Managing Director

Name and address of the

person authorized to

compile the technical file

Cobra Garden Machinery

Henton & Chattell Ltd, London Road, Nottingham NG2 3HW United Kingdom

Page 39

Cobra Garden Machinery

Henton and Chattell Ltd, London Road, Nottingham

NG2 3HW UK

Loading...

Loading...