cobia 217cc Owner's Manual

May 30, 2012

COBIA 217 CC

O w n e r ’ s M a n u a l

WELCOME

Dear New Cobia Owner,

On behalf of Cobia Boats, I would like to congratulate

you on your purchase. We at Cobia strive to build the

best products possible and wish you years of trouble

free enjoyment. There are many things to know about

the operation, care and maintenance of our products

and the systems we install in them. Please review all

the applicable information for your new boat. The more

you know, the more you will enjoy your new Cobia.

Again, a heartfelt Thank You from myself and the whole

Cobia Family.

Scott Deal, President and CEO

Maverick Boat Company, Inc. • 3207 Industrial 29th St. • Fort Pierce,

Florida 34946 • (772)-465-0631 or (888)-shallow • Fax: (772) 489-2168

May 30, 2012

TABLE OF CONTENTS

Yamaha Engine Break-In Periods...........................................3

Engine Stop Switch.................................................................3

Fuel / Water Separators..........................................................4

Garboard Drain Plug...............................................................4

Instrument Panel with Yamaha Multi-Function

Gauges....................................................................................5

Switch Panels..........................................................................5

Switch Panels & Helm.............................................................5

216 Boat Layout......................................................................6

Cobia Duffel Bag.....................................................................6

Bilge System...........................................................................7

Ball Valves, Thru Hull Fittings, & Scuppers.............................8

Stainless Boarding Ladder....................................................10

Cockpit Courtesy Lights..........................................................9

Props.....................................................................................10

Head & Waste System..........................................................19

Fuel System..........................................................................11

Self Bailing Cockpit...............................................................12

Livewell System....................................................................12

Optional Bow Cushion Set.................................................17

Dual Battery System..........................................................15

Optional Salt Water Washdown.........................................20

Optional Fresh Water Shower............................................18

Optional Trim Tabs.............................................................19

Optional Command Link Gauges.......................................18

Warranty.............................................................................24

217 SPECIFICATIONS

L.O.A.....................................................................21’ 7”

BEAM......................................................................8’ 6”

DRAFT......................................................................14”

WEIGHT W/O ENGINE......................................2950

LBS.

FUEL CAPACITY...........................................100 GAL.

DEADRISE @ TRANSOM.......................................20

DEG MAXIMUM

H.P.............................................................................200

TRANSOM HEIGHT……………………………..25”

MAXIMUM CAPACITIES…………………..…........8

PERSONS OR 1600 LBS

Rod Lockers..........................................................................13

Forward Storage...................................................................14

Anchor Locker / Rode Storage..............................................14

217 Aluminum Plate Location................................................14

Specifications..........................................................................2

Wiring Color Codes...............................................................16

Optional Cockpit Bolsters......................................................18

Maverick Boat Company, Inc. • 3207 Industrial 29th St. • Fort Pierce,

Florida 34946 • (772)-465-0631 or (888)-shallow • Fax: (772) 489-2168

May 30, 2012

ENGINE BREAK-IN PERIOD

Engine Break-In Period

New engines require a period of break-in to allow the

surfaces of the moving parts to mate evenly. Different

engines require different break-in periods and methods.

For instructions on break in methods, refer to your

Yamaha Engine Owner’s Manual for the correct break-in

procedures and times for your model engines

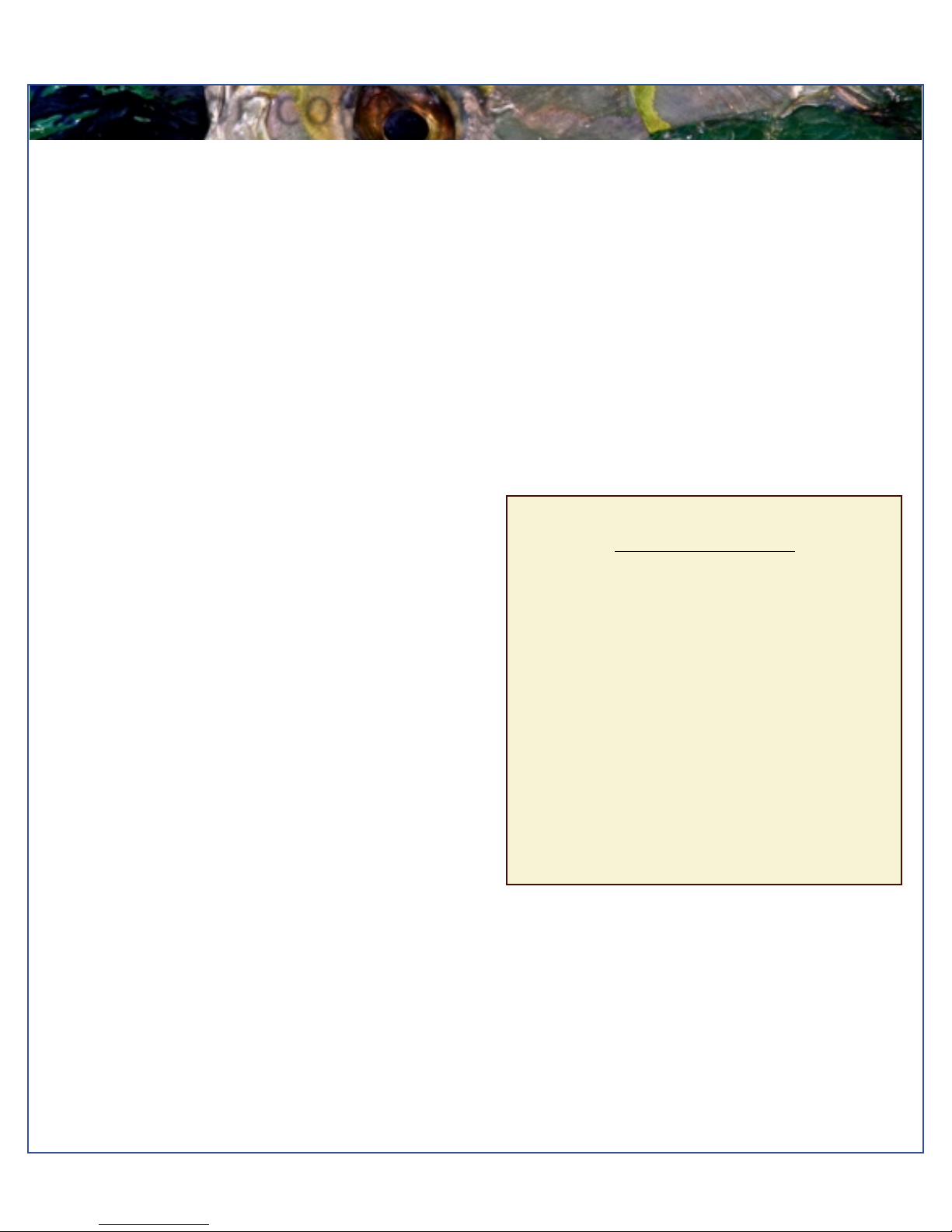

Engine Stop Switch

If activated, the spring loaded engine stop switch will

automatically shut down the engine during emergency

situations to prevent uncontrolled or unattended

operation. Certain emergency conditions (e.g., turbulent

water, wakes, accidental shove) may impair a person’s

ability to operate the craft safely. The switch, located on

the helm, must have the safety lanyard attached at its

base. This activates the protective shutdown circuitry.

Securely attach the other end of the lanyard to the

operator of the boat. If the operator moves, falls or is at

an unsafe distance from the steering wheel, tension on

the lanyard will pull it from the switch. When the lanyard is

removed, the engine stop switch is released and

automatic engine shutdown occurs.

Engine stop switch (above)

Engine Stop Switch

An engine stop switch system that is not used or does not function properly can cause death or serious injury.

DO NOT operate the boat if the engine stop switch system does not function properly. Go to a Cobia Dealer to

have this resolved immediately

The lanyard should be securely attached to the boat operator at all times that the

engine is on.

Maverick Boat Company, Inc. • 3207 Industrial 29th St. • Fort Pierce,

Florida 34946 • (772)-465-0631 or (888)-shallow • Fax: (772) 489-2168

May 30, 2012

FUEL-WATER SEPARATOR & DRAIN PLUG

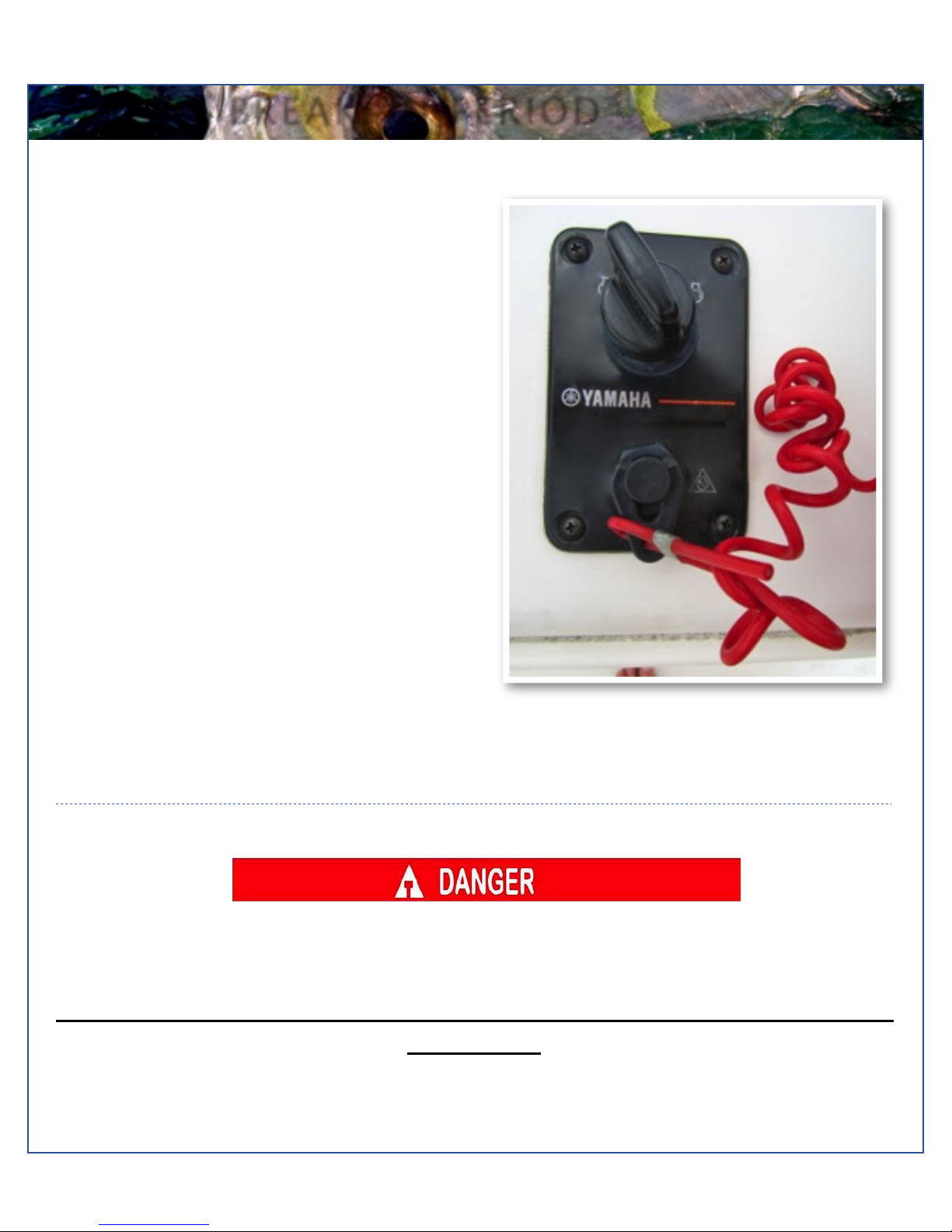

Fuel-Water Separator

A Yamaha Fuel - Water Separator is installed

between the fuel tank and engine on your 217

model. The new, improved 10-micron filter

provides superior filtration ahead of the engine's

on- board filters and injectors. Large filtering

and water capture areas maximize filtration

while maintaining adequate flow rate for larger

engines. The fuel separator can be checked by

removing it from the mounting bracket and

dumping it into an approved waste collection

device. If there appears to be an excessive

amount of water, the filter component should be

replaced. See your authorized Cobia Dealer for

replacement parts.

Maintenance Note

Yamaha recommends replacing the 10- micron fuel filter on new boats after the first 10 hours or 1 month of

operation and every 50 hours or every 6 months thereafter. In areas of hight humidity where water in fuel supplies is a

problem or extensive engine operation occurs, more frequent replacement may be necessary.

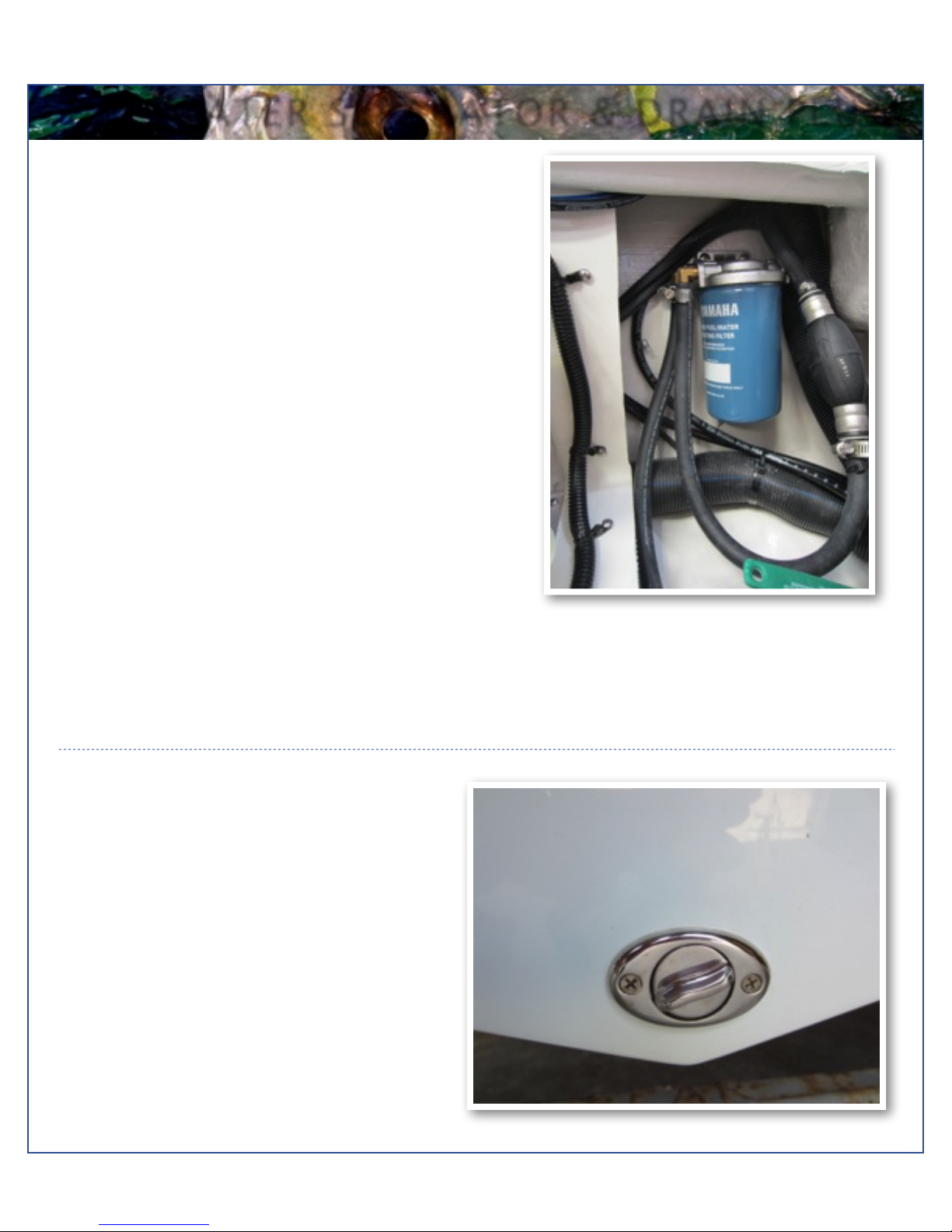

Garboard Drain Plug

The garboard drain plug is the small metal plug located at

the lowest point on the hull, at the bottom of the transom

right above the keel. The drain has been designed to so

that it can be loosened by hand while the hull is out of the

water for draining. This allows the plug to stay in contact

with the surrounding frame so you’ll never misplace or

lose it. You can completely remove the insert by pulling

back and continue turning in a counter clockwise motion.

It is manufactured with a rubber seal in place to ensure

you bilge is watertight. Always make sure before putting

the boat in the water that this plug is hand tightened

firmly. Excess water in the bilge may be an indication of a

problem with this plug or the automatic bilge pump. Refer

to page 7 of this Owner’s Manual for information on your

boats bilge system.

Maverick Boat Company, Inc. • 3207 Industrial 29th St. • Fort Pierce,

Florida 34946 • (772)-465-0631 or (888)-shallow • Fax: (772) 489-2168

May 30, 2012

SWITCH AND INSTRUMENT PANEL

Switch Panel & Helm

At the helm of the 217 CC, you have a main switch

panel, which is located to the left of the steering

wheel. This panel controls your lights, horn,

accessories, livewell, and your bilge. When a

switch is in the “on” position, its tip is illuminated.

This alerts you that the associated accessory

should be functioning and also reminds you to turn

it off during boat shutdown. When the “NAV” light

switch is in the “on” position, the labels for the

switches will be illuminated. To the right of the

steering wheel you may have your two trim tab

switches, which are optional on the 217. (Refer to

page 23 for trim tab operation.) The 217 also

comes standard with a compass mounted on top

of the console.

Switch Panel

Compass

Instrument Panel

The instrument panel on your 217 CC is composed of two Yamaha Multifunction Digital Gauges. The standard

digital gauges include a tachometer. The tachometer has several built in features including an oil level monitor,

an engine temperature monitor and engine trim indicator. Yamaha speedometer includes a digital readout of the

speed, an hour meter, trip meter, and clock.

Maverick Boat Company, Inc. • 3207 Industrial 29th St. • Fort Pierce,

Florida 34946 • (772)-465-0631 or (888)-shallow • Fax: (772) 489-2168

May 30, 2012

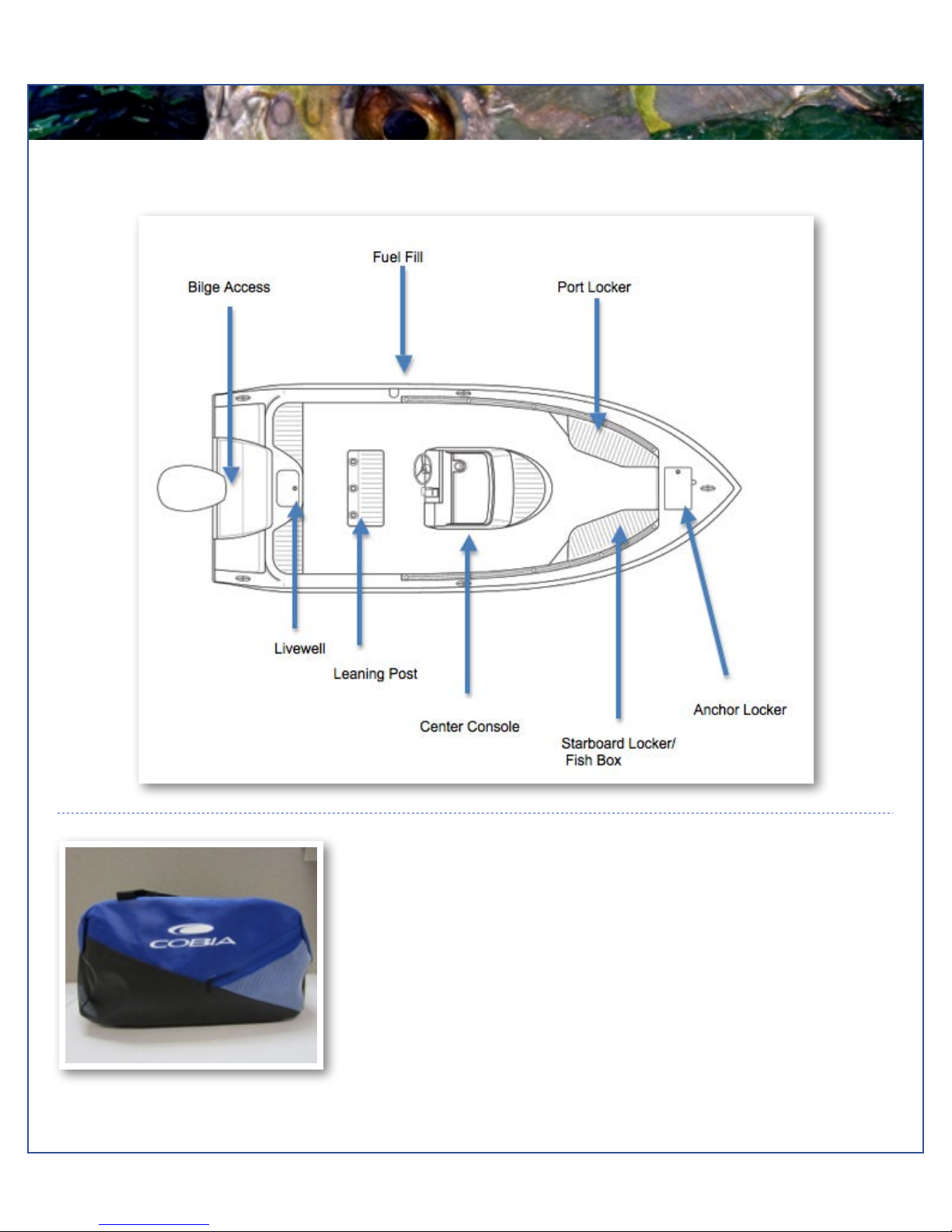

BOAT LAYOUT

217 Boat Layout

Cobia Duffel Bag

Along with your boat, you received a Black Duffel Bag with your new Cobia 217

CC. Inside the Duffel Bag are the following items:

•

Large Livewell Standpipe

•

Short Livewell Standpipe

•

1.5” Livewell Pacifier Plug

•

2 ignition Keys and Emergency Kill Cord /Engine Stop Lanyard

•

Yamaha Engine Owner’s Manuals

•

Engine Start Cord

•

Various Appliance and Accessories Manuals

Cobia 217 Duffel Bag

Maverick Boat Company, Inc. • 3207 Industrial 29th St. • Fort Pierce,

Florida 34946 • (772)-465-0631 or (888)-shallow • Fax: (772) 489-2168

May 30, 2012

BILGE

Bilge

The bilge of the Cobia 217 should always be checked

before and after a launch. While checking the bilge, note

that a small amount of water in the bilge is normal.

However, a large amount of water or any signs of fuel or

oil requires immediate attention. If such a situation

exists, the boat should be taken to a certified marine

technician immediately. Never pump fuel or oil

overboard while your boat is in the water.

Large quantities of water in the bilge may be an

indication of a leak or that the bilge pump and/or

automatic float switch is not functioning properly due to a

jam, clog or electrical issue. The automatic float switch is

wired to the hot side of the battery switch through the

“BILGE” fuse at the battery switch panel. When

functioning properly, the float switch activates the bilge

pump to pump water overboard once water in the bilge

reaches a level that submerges the switch.

If your bilge pump does not come on when the float

switch is submerged, attempt to manually turn on the

bilge pump on your switch panel. If the bilge pump

comes on and evacuates the water, it is clear that the

float switch is not functioning properly. If the bilge pump

does not come on via the switch panel, check the

breaker panel inside the console to see if a breaker has

been tripped. If the breaker has been tripped, reset it,

and turn the switch on again, listening for the bilge pump

to turn on.

If the bilge pump fails to turn on, turn the battery switch to the OFF position, then unhook the bilge pump from its cradle

by pressing down on the blue tabs on the cradle and gently turning the top of the pump. You will feel the pump release

from the cradle. The entire bilge pump and wiring should release from the cradle. After removing the pump, check the

underside and impeller areas for miscellaneous items that might clog the pump. If any obstructions are present remove

the debris and set the pump back into the cradle. Once set back in the cradle, press the blue tab down and rotate the

pump until you feel it snap back in place. Once this is completed you can try to turn the pump on again.

If the bilge pump still does not turn on, it likely needs to be replaced. It is not recommended to use your boat if the bilge

pump and/or float switch are not functioning properly.

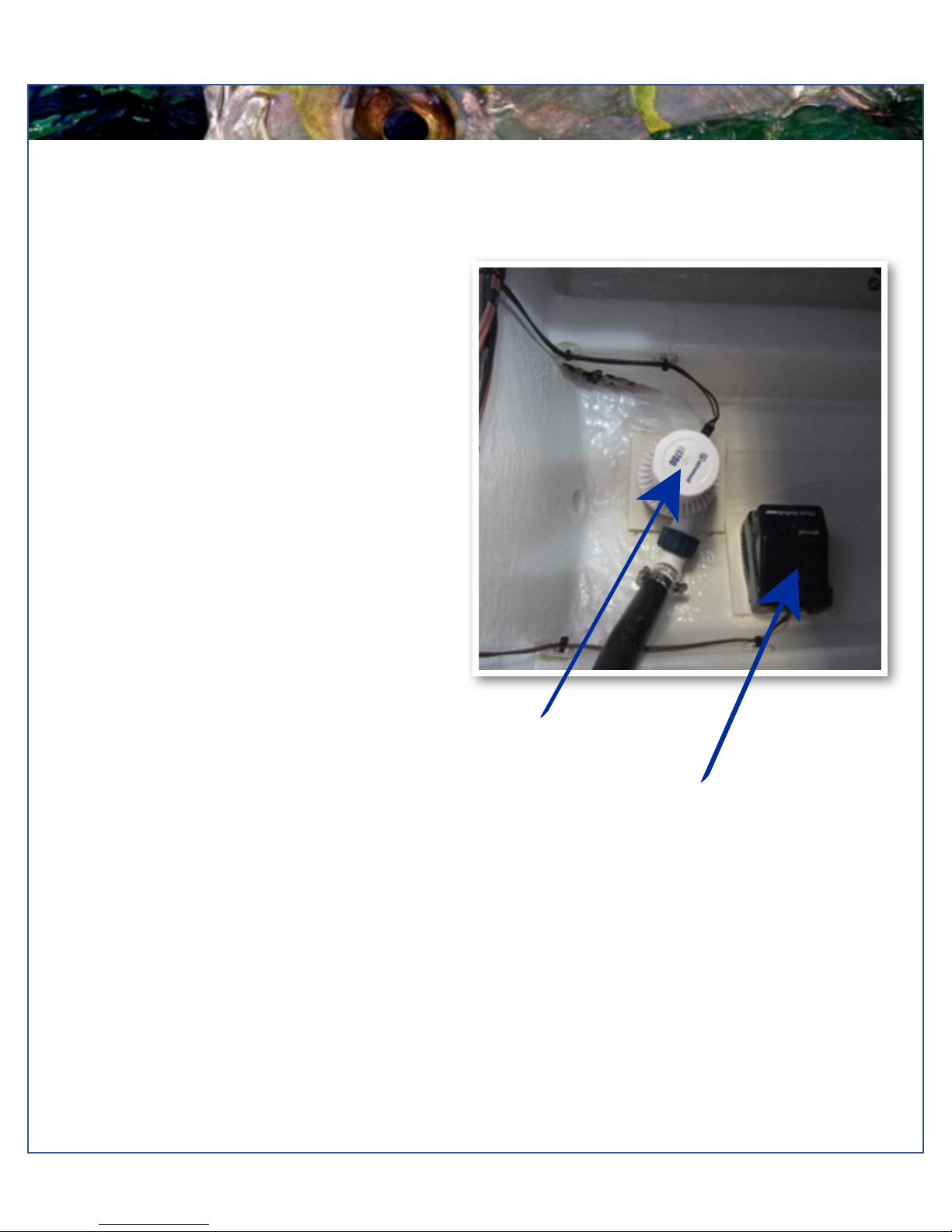

Bilge Pump

Automatic Float Switch

Maverick Boat Company, Inc. • 3207 Industrial 29th St. • Fort Pierce,

Florida 34946 • (772)-465-0631 or (888)-shallow • Fax: (772) 489-2168

May 30, 2012

SYSTEMS

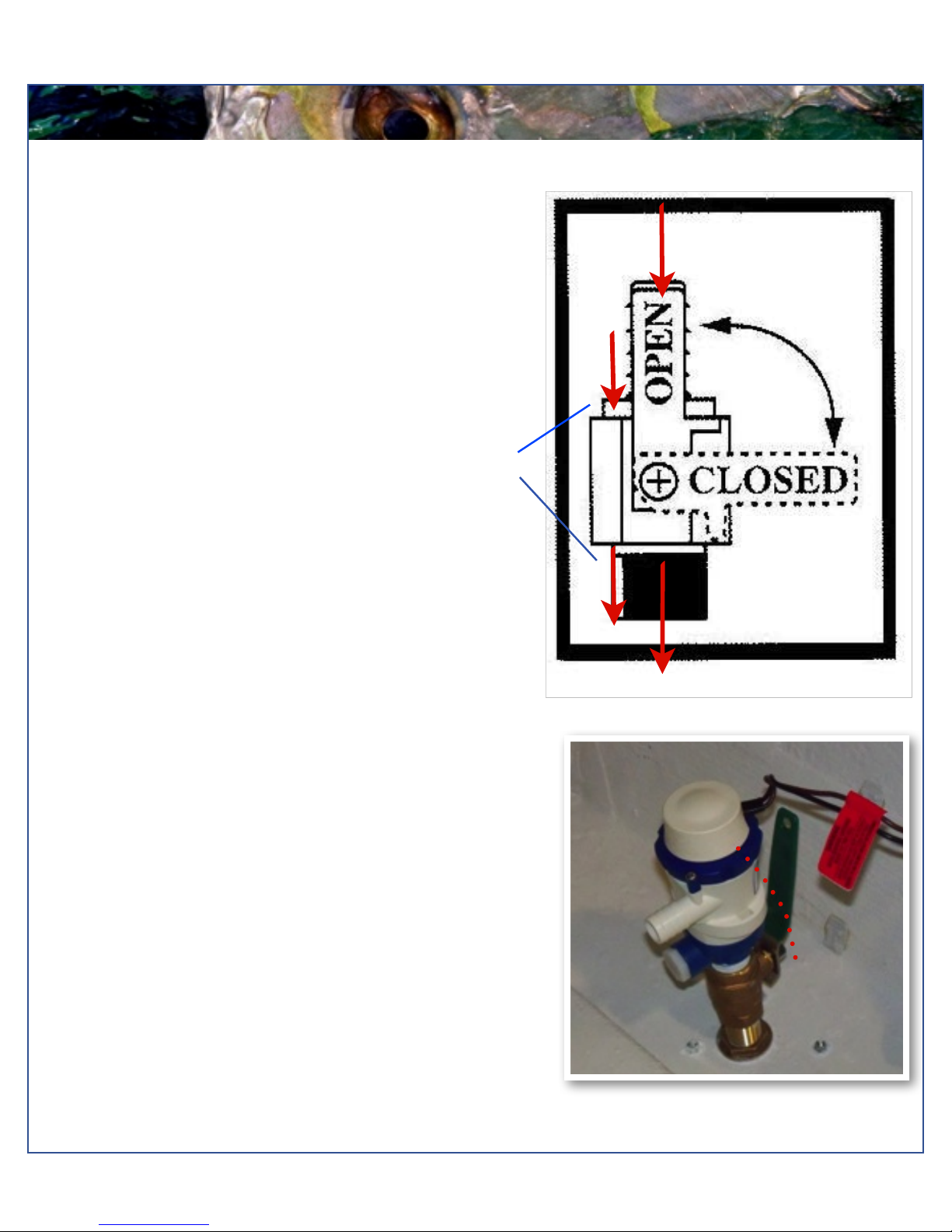

Ball Valves

Ball valves can be used to serve several purposes. They

allow seawater to enter the boat, in the case of livewells,

and they also act as a safeguard to stop water from

entering. To tell which position a ball valve is in, open or

closed, look at the valve and determine the direction of

flow. When the ball valve handle is in the same position

as the direction of flow, the valve is in the “OPEN”

position. When the ball valve handle appears to cross the

direction of flow, the valve is in the “CLOSED” position.

217 Deckdrain System

The deckdrain system is equipped with 1 1/2” thru hull

fittings through the aft port and starboard hull sides.

These fittings have to be installed lower than the drains in

the cockpit floor so that gravity will allow the cockpit to

drain free of water. This puts these fittings very close to

the water line of the hull. These drains are rigged with ball

valves that can be opened and closed to control the flow

of water. In the open position, these ball valves will allow

water to flow freely from the cockpit, thus making the boat

“self-bailing”. When closed, no water will be allowed to

travel to or from the cockpit.

Water Flow

217 Livewell Pump Assembly

The livewell pump assembly is composed of a scoop

strainer mounted to the bottom of the hull, a thru hull

fitting, ball valve assembly, and the pump. As you can

see, the ball valve assembly is in the “OPEN” position.

This is the correct position for the operation of the livewell

system.

THE LIVEWELL PUMP

ASSEMBLY IN THE “OPEN

POSITION

Maverick Boat Company, Inc. • 3207 Industrial 29th St. • Fort Pierce,

Florida 34946 • (772)-465-0631 or (888)-shallow • Fax: (772) 489-2168

CLOSED

Loading...

Loading...