COBHAM SAILOR 900 Ka Installation Manual

SAILOR 900 Ka

Installation manual

SAILOR 900 Ka

Important

Quick guide

Configuration tasks (minimum)

This quick guide aims at experienced service personnel who have installed the SAILOR 900 Ka system and

connected power. It lists the minimum configuration tasks you have to make before the system can be

used on-air on a satellite.

1. Switch on the Antenna Control Unit only.

Do not switch on the modem at this point.

2. Connect a PC to the front LAN connector or the LAN3 connector at the rear of the Antenna Control

Unit.

3. Open an Internet Browser to access the SAILOR 900 Ka: IP address: http://192.168.0.1 (default), user

name: admin, password: 1234.

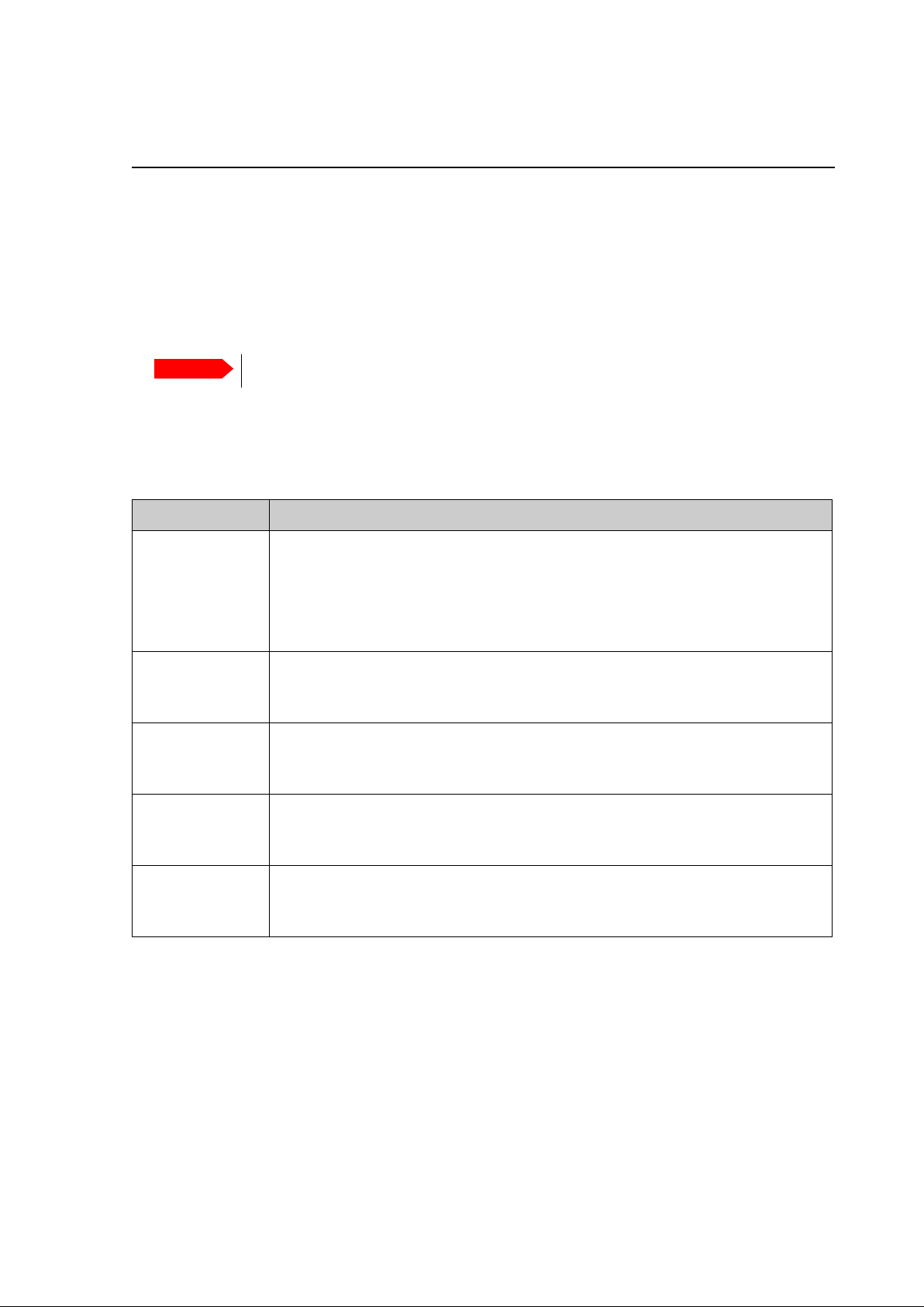

Configuration task What to do and where to find more information

Heading input

Cable calibration

Azimuth

calibration

Network settings

Satellite profile

4. Switch on the modem and wait for the modem to boot and perform the initial BUC calibration.

5. Verify that the SAILOR 900 Ka acquires the Ka satellite (ACU display shows ACQUISITION).

Configure the heading input to External under SERVICE > Calibration. For

more information see Select the desired heading input, see the following table.

on page 6-5.

Connect the ship’s heading (NMEA0183, RS-422/RS-232) to the NMEA 0183

multi-connector. For more information see NMEA 0183 connector on page 4-3.

Make a cable calibration under SERVICE > Calibration to ensure that the cable

loss is calculated properly. For more information see Cable calibration on page 6-

10.

Make an azimuth calibration under SERVICE > Calibration to ensure that the

antenna can point and receive a signal from the satellite. For more information see

Azimuth calibration on page 6-8.

Configure the network settings under SETTINGS > Network according to your

requirements. For more information see To configure the LAN network on page 6-

24.

A satellite profile with the iDirect X7 Modem is already set up at the factory. No

further profiles are needed. You must activate the satellite profile, see Satellite

profiles on page 6-19.

6. Verify that the system is operational. The status in the ACU display must show TRACKING and the

upper status line MDM: NETOK.

98-146706-A

SAILOR 900 Ka

Installation manual

Document number: 98-146706-A

Release date: 16 July 2015

Disclaimer

Any responsibility or liability for loss or damage in connection with the use of this product and the

accompanying documentation is disclaimed by Thrane & Thrane A/S. The information in this manual is

provided for information purposes only, is subject to change without notice and may contain errors or

inaccuracies. Manuals issued by Thrane & Thrane A/S are periodically revised and updated. Anyone

relying on this information should acquire the most current version e.g. from

www.cobham.com/communications-and-connectivity/satcom, Service and support, or from the

distributor. Thrane & Thrane A/S is not responsible for the content or accuracy of any translations or

reproductions, in whole or in part, of this manual from any other source. In the event of any

discrepancies, the English version shall be the governing text.

Thrane & Thrane A/S is trading as Cobham SATCOM.

Copyright

© 2015 Thrane & Thrane A/S. All rights reserved.

Trademark acknowledgements

• Some product and company names mentioned in this manual may be trademarks or trade names of

their respective owners.

GPL notification

The software included in this product contains copyrighted software that is licensed under the GPL/LGPL.

The verbatim licenses can be found online at:

http://www.gnu.org/licenses/old-licenses/gpl-2.0.html

http://www.gnu.org/licenses/old-licenses/lgpl-2.1.html

You may obtain the complete corresponding source code from us for a period of three years after our last

shipment of this product, which will be no earlier than 2021, by sending a money order or check for DKK

50 to:

SW Technology/GPL Compliance,

Cobham SATCOM (Thrane & Thrane A/S),

Lundtoftegaardsvej 93D

2800 Lyngby

DENMARK

Write "source for product SAILOR 900 Ka" in the memo line of your payment. This offer is valid to anyone

in receipt of this information.

http://www.cobham.com/about-cobham/communications-and-connectivity/about-us/satcom/free-andopen-source-software-(foss).aspx

ii 98-146706-A

Safety summary

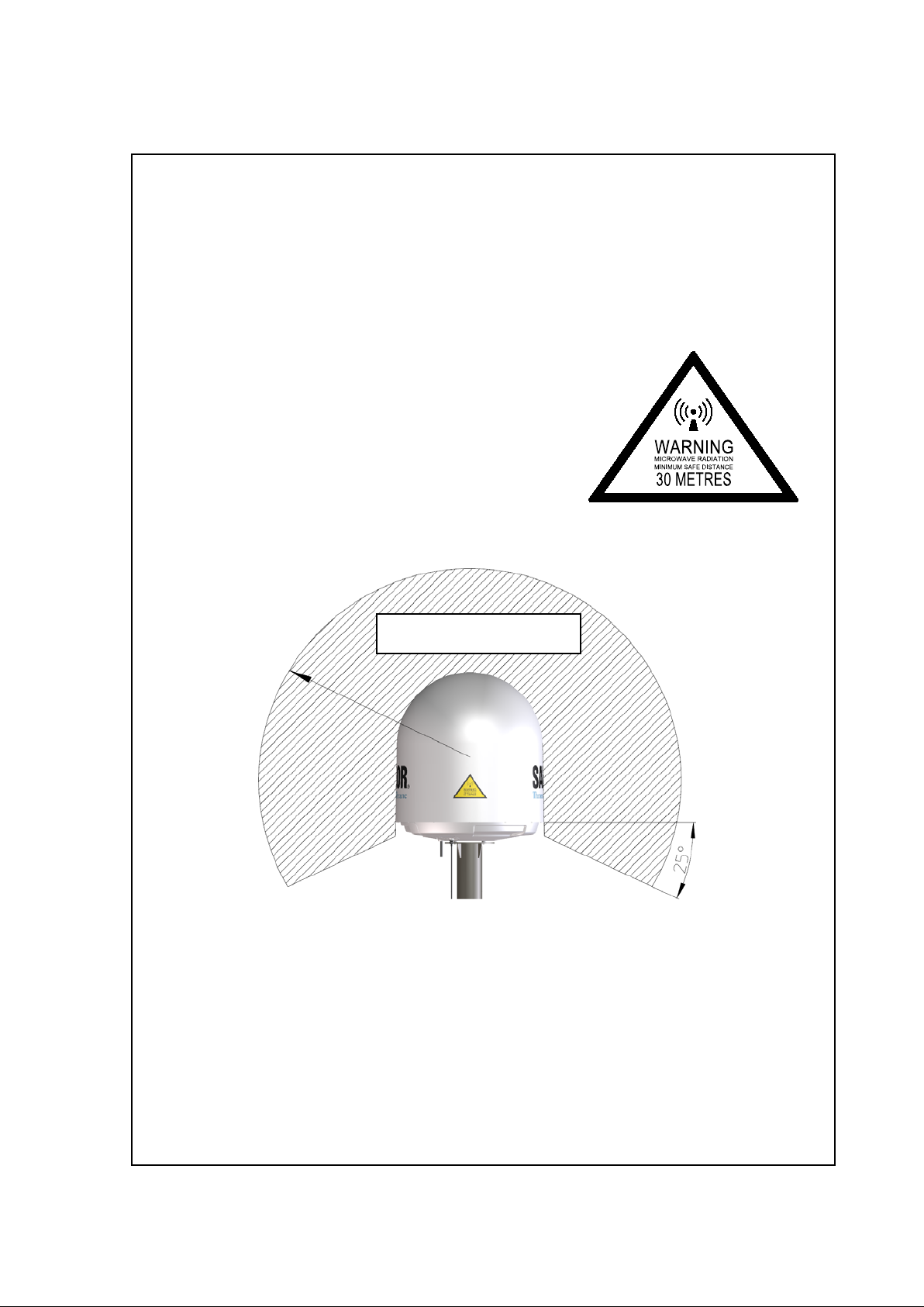

MICROWAVE RADIATION

No personnel within safety distance

Safety distance:

30 m, 10 W/m

2

The following general safety precautions must be observed during all phases of operation,

service and repair of this equipment. Failure to comply with these precautions or with specific

warnings elsewhere in this manual violates safety standards of design, manufacture and

intended use of the equipment. Thrane & Thrane A/S assumes no liability for the customer's

failure to comply with these requirements.

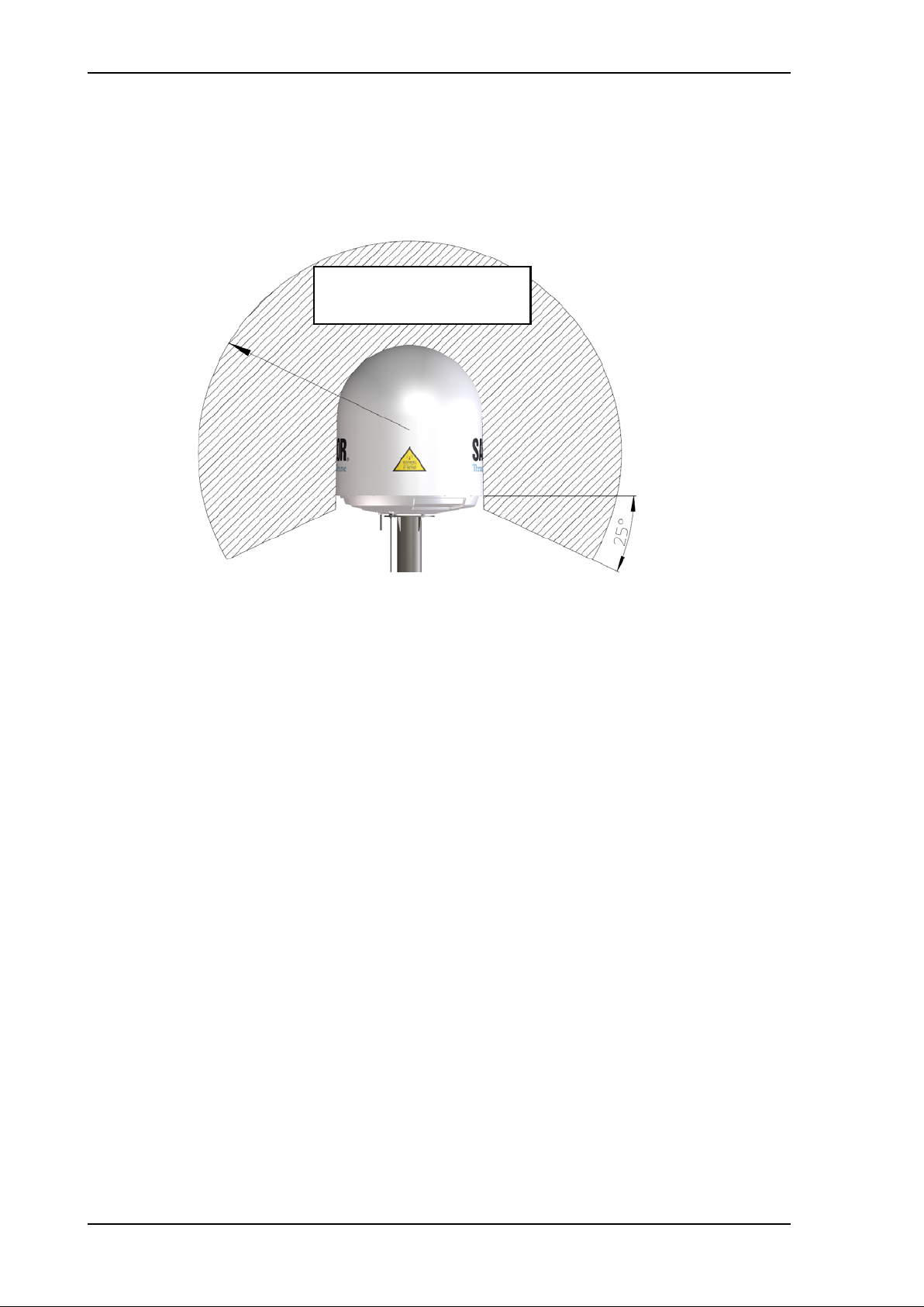

Microwave radiation hazards

During transmission the Above Deck Unit (antenna) in this

system radiates Microwave Power.This radiation may be

hazardous to humans close to the Above Deck Unit. During

transmission, make sure that nobody gets closer than the

recommended minimum safety distance.

The minimum safety distance to the Above Deck Unit

reflector on the focal line is 30 m, based on a radiation level

of 10 W/m

drawing below.

2

. No hazard exists >25° below the Above Deck Unit’s mounting plane. Refer to the

No-transmit zones

In order to protect personnel no-transmit zones can be programmed. For further information

see Blocking zones with azimuth and elevation on page 3-5.

Distance to other equipment

Do not move the Above Deck Unit closer to radars than the minimum safe distance specified in

section Interference from radar, GPS and other transmitters on page 3-13 — it may cause

damage to the Above Deck Unit.

98-146706-A iii

Compass Safe Distance:

SAILOR 900 Ka antenna or ADU (Above Deck Unit): min. 100 cm (ENC 60945).

SAILOR 900 Ka ACU (Antenna Control Unit): min. 10 cm (EN 60945)

Service

User access to the interior of the ACU is not allowed. Only a technician authorized by Cobham

SATCOM may perform service - failure to comply with this rule will void the warranty. Access to

the interior of the Above Deck Unit is allowed. Replacement of certain modules and general

service may only be performed by a technician authorized by Cobham SATCOM.

Grounding, cables and connections

To minimize shock hazard and to protect against lightning, you must connect the equipment

chassis and cabinet to an electrical ground. Ground the ACU to the ship. For further details see

Appendix B, Ground and RF protection.

Do not extend the cables beyond the lengths specified for the equipment. The cable between

the ACU and Above Deck Unit can be extended if it complies with the specified data

concerning cable losses etc.

Rx and Tx cables for the SAILOR 900 Ka system are shielded and should not be affected by

magnetic fields. However, try to avoid running cables parallel to high power and AC/RF wiring as

this might cause malfunction of the equipment.

Power supply

The voltage range for the SAILOR 900 Ka ADU and ACU is 20 – 32 VDC. The Above Deck Unit is

powered by the ACU.

If a DC power bus is not available, an external 115/230 VAC to 28 VDC power supply can be

used, for example a SAILOR 6080 Power Supply.

Do not operate in an explosive atmosphere

Do not operate the equipment in the presence of flammable gases or fumes. Operation of any

electrical equipment in such an environment constitutes a definite safety hazard.

Keep away from live circuits

Operating personnel must not remove equipment covers. Component replacement and internal

adjustment must be made by qualified maintenance personnel. Do not replace components

with the power cable connected. Under certain conditions, dangerous voltages may exist even

with the power cable removed. To avoid injuries, always disconnect power and discharge

circuits before touching them.

Failure to comply with the rules above will void the warranty!

iv 98-146706-A

Record of Revisions

Rev. Description Release Date Initials

A Original document 17 July 2015 UFO

98-146706-A v

vi 98-146706-A

Table of contents

Chapter 1 About this manual

1.1 Intended readers ..............................................................................................................1-1

1.2 Manual overview ...............................................................................................................1-1

1.3 Software version ...............................................................................................................1-1

1.4 Typography ...........................................................................................................................1-2

1.5 Precautions ............................................................................................................................1-2

Chapter 2 Introduction

2.1 SAILOR 900 Ka system .................................................................................................2-1

2.1.1 Overview ..................................................................................................................................2-1

2.1.2 Above Deck Unit (ADU) ...................................................................................................2-3

2.1.3 Antenna Control Unit (ACU) ..........................................................................................2-6

2.1.4 iDirect X7 Modem ...............................................................................................................2-7

2.1.5 Satellite type approvals ....................................................................................................2-8

2.1.6 Service activation ................................................................................................................2-8

2.2 Part numbers and options .........................................................................................2-8

2.2.1 Applicable model and part numbers ..........................................................................2-8

2.2.2 Options for SAILOR 900 Ka ............................................................................................2-8

Chapter 3 Installation

3.1 What’s in the box .............................................................................................................3-1

3.1.1 To unpack ...............................................................................................................................3-1

3.1.2 Initial inspection ..................................................................................................................3-2

3.1.3 Tools needed .........................................................................................................................3-2

3.1.4 Transport of the antenna ................................................................................................3-2

3.2 Site preparation .................................................................................................................3-3

3.2.1 General site considerations ............................................................................................3-3

3.2.2 Obstructions (ADU shadowing) ....................................................................................3-4

3.2.3 Blocking zones with azimuth and elevation ...........................................................3-5

3.2.4 Safe access to the ADU (radiation hazard) .............................................................3-6

3.2.5 Ship motion and offset from the ship’s motion centre ....................................3-7

3.2.6 Mast foundation and height ..........................................................................................3-8

3.2.7 Interference from radar, GPS and other transmitters .....................................3-13

3.2.8 Condensation, water intrusion and deposits ......................................................3-16

98-146706-A vii

Table of contents

3.3 Installation of the ADU ............................................................................................ 3-17

3.3.1 To install the ADU ............................................................................................................3-18

3.3.2 To open and remove the service hatch ................................................................ 3-21

3.3.3 To ground the ADU .........................................................................................................3-22

3.3.4 Alternative ADU cable ...................................................................................................3-23

3.4 Installation of the ACU ............................................................................................ 3-24

3.4.1 To install the ACU ............................................................................................................3-24

3.4.2 To ground the ACU .........................................................................................................3-24

3.5 Installation of the modem ..................................................................................... 3-25

3.6 To connect the ADU, ACU and modem .......................................................3-25

Chapter 4 Interfaces

4.1 Interfaces of the ACU ..................................................................................................4-1

4.1.1 LEDs, display, keypad and connectors ......................................................................4-1

4.1.2 DC Input connector ...........................................................................................................4-1

4.1.3 ADU connector ....................................................................................................................4-2

4.1.4 Rx In and Tx Out connectors .......................................................................................4-3

4.1.5 NMEA 0183 connector ....................................................................................................4-3

4.1.6 RS-232 and RS-422 connectors ...................................................................................4-4

4.1.7 LAN1 – 4 connectors .........................................................................................................4-5

Chapter 5 Power and startup

5.1 Power source .......................................................................................................................5-1

5.2 Power cable ...........................................................................................................................5-1

5.3 Power up .................................................................................................................................5-3

5.3.1 To connect the power cable to the ACU .................................................................5-3

5.3.2 Power-up procedure ..........................................................................................................5-3

5.3.3 Initialisation steps in daily use ......................................................................................5-4

5.3.4 SAILOR 900 Ka operational ............................................................................................5-4

Chapter 6 Configuration

6.1 Introduction to the built-in web interface ..................................................6-1

6.1.1 Overview ..................................................................................................................................6-1

6.1.2 Connecting to the web interface ................................................................................6-1

viii 98-146706-A

Table of contents

6.2 Calibration .............................................................................................................................6-3

6.2.1 Service profile for calibration ........................................................................................6-3

6.2.2 Heading input ........................................................................................................................6-4

6.2.3 Azimuth calibration ............................................................................................................6-8

6.2.4 Cable calibration ...............................................................................................................6-10

6.2.5 Manual One Touch Commissioning (BUC calibration) .................................. 6-11

6.2.6 About operation in gyro-free mode .............................................................6-12

6.2.7 Fixed TX IF principle .......................................................................................................6-13

6.3 Configuration with the web interface ........................................................... 6-14

6.3.1 Overview and dashboard ..............................................................................................6-14

6.4 Satellite profiles and VSAT modem profiles ............................................6-19

6.4.1 Satellite profiles ................................................................................................................6-19

6.4.2 VSAT modem profiles ....................................................................................................6-20

6.4.3 To set up blocking zones (RX and TX) ....................................................................6-22

6.4.4 To configure the LAN network ..................................................................................6-24

6.4.5 E-mail setup ........................................................................................................................6-27

6.4.6 To send statistics reports .............................................................................................6-28

6.4.7 To send a diagnostics report ......................................................................................6-31

6.4.8 Upload ................................................................................................................................... 6-32

6.4.9 Administration ................................................................................................................... 6-32

6.5 Keypad and menus of the ACU ..........................................................................6-38

6.5.1 ACU display and keypad ............................................................................................... 6-38

6.5.2 Navigating the menus .................................................................................................... 6-39

6.5.3 The menu tree ...................................................................................................................6-39

6.5.4 Brightness of the display ..............................................................................................6-43

6.5.5 Reset of the ACU and ADU .........................................................................................6-43

6.6 SNMP support .................................................................................................................. 6-44

Chapter 7 Installation check

7.1 Installation check list: Antenna ............................................................................7-2

7.2 Installation check list: ACU and modem, connectors and wiring 7-3

7.3 Installation check list: Functional test in harbor ....................................7-4

Chapter 8 Service

8.1 To get support ....................................................................................................................8-2

8.1.1 Help desk and diagnostic report ..................................................................................8-2

8.2 Software update ................................................................................................................8-5

8.2.1 Prerequisites ..........................................................................................................................8-5

8.2.2 Software update (ADU, ACU) ........................................................................................8-5

98-146706-A ix

Table of contents

8.3 Status signalling with LEDs and status messages ...................................8-8

8.3.1 LEDs of the ADU modules ...............................................................................................8-8

8.3.2 LEDs in the ACU ...................................................................................................................8-9

8.3.3 LEDs of the modem ...........................................................................................................8-9

8.4 Removal and replacement of the ACU .........................................................8-10

8.5 Removal and replacement of ADU modules ............................................8-11

8.6 Troubleshooting .............................................................................................................8-14

8.6.1 Overview ............................................................................................................................... 8-14

8.6.2 Event list for troubleshooting ....................................................................................8-14

8.6.3 Diagnostics report for troubleshooting .................................................................8-14

8.6.4 To make a line up procedure ......................................................................................8-14

8.7 To return units for repair ........................................................................................8-16

Appendix A Technical specifications

A.1 SAILOR 900 Ka system components .................................................................A-1

A.1.1 General specifications .......................................................................................................A-1

A.1.2 ADU ...........................................................................................................................................A-2

A.1.3 ACU ............................................................................................................................................A-4

A.1.4 Patents ......................................................................................................................................A-4

A.2 Outline drawings ...............................................................................................................A-5

A.2.1 ADU ...........................................................................................................................................A-5

A.2.2 ACU ............................................................................................................................................A-6

A.2.3 N-connector interface on the ADU ............................................................................A-7

A.3 X7 Modem BUC & Console to ACU cable ......................................................A-8

Appendix B Ground and RF protection

B.1 Why is a ground connection required? ............................................................B-1

B.1.1 Safety ........................................................................................................................................B-1

B.1.2 ESD Protection .....................................................................................................................B-1

B.2 Recommendations ...........................................................................................................B-2

B.2.1 To ground the ACU ............................................................................................................B-2

B.2.2 To ground the ADU ............................................................................................................B-4

B.3 Alternative ground for steel hulls ........................................................................B-4

B.3.1 To ground the ACU ............................................................................................................B-4

B.3.2 To ground the ADU ............................................................................................................B-5

B.4 Alternative ground for aluminum hulls ...........................................................B-7

B.4.1 To ground the ACU ............................................................................................................B-7

B.4.2 To ground the ADU ............................................................................................................B-7

x 98-146706-A

B.5 Alternative ground for fibre glass hulls ...........................................................B-9

B.5.1 To ground the ACU ............................................................................................................B-9

B.5.2 To ground the ADU ............................................................................................................B-9

B.6 Separate ground cable ............................................................................................... B-11

B.6.1 To construct a ground cable .......................................................................................B-11

B.6.2 Ground cable - connection ..........................................................................................B-12

B.6.3 Isolation of the ADU from the mounting base ..................................................B-12

B.7 RF interference ................................................................................................................B-13

B.8 Jumper cable for grounding ................................................................................... B-14

Appendix C System messages

C.1 Event messages – overview ......................................................................................C-1

C.2 List of ADU events ...........................................................................................................C-2

C.3 List of ACU events ...........................................................................................................C-8

Table of contents

Appendix D Command line interface

D.1 Introduction ........................................................................................................................ D-1

D.1.1 Telnet connection ............................................................................................................. D-1

D.1.2 Help ........................................................................................................................................... D-2

D.1.3 Conventions ......................................................................................................................... D-2

D.2 Supported commands ................................................................................................D-2

D.2.1 config ....................................................................................................................................... D-3

D.2.2 demo ........................................................................................................................................ D-3

D.2.3 dual_antenna ....................................................................................................................... D-3

D.2.4 exit ............................................................................................................................................ D-4

D.2.5 help ........................................................................................................................................... D-4

D.2.6 modem .................................................................................................................................... D-4

D.2.7 satellite .................................................................................................................................... D-5

D.2.8 status ........................................................................................................................................ D-8

D.2.9 system ..................................................................................................................................... D-8

D.2.10 track .......................................................................................................................................... D-9

D.2.11 zone ........................................................................................................................................D-10

Appendix E Approvals

E.1 CE (R&TTE) ............................................................................................................................. E-1

Glossary ..............................................................................................................................................................Glossary-1

Index ....................................................................................................................................................................Index-1

98-146706-A xi

Table of contents

xii 98-146706-A

Chapter 1

About this manual

About this manual 1

1.1 Intended readers

This is an installation and service manual for the SAILOR 900 Ka system, intended for

installers of the system and service personnel. Personnel installing or servicing the system

must be properly trained and authorized by Cobham SATCOM. It is important that you

observe all safety requirements listed in the beginning of this manual, and install the system

according to the guidelines in this manual.

1.2 Manual overview

This manual has the following chapters:

• Introduction

• Installation

• In terfaces

• Power and startup

• Configuration

• Installation check

• Service

This manual has the following appendices:

• Technical specifications

• Ground and RF protection

• System messages

• Command line interface

• Approvals

1.3 Software version

This manual is intended for SAILOR 900 Ka with software version 1.50 (ADU and ACU).

98-146706-A 1-1

Typography

1.4 Typography

In this manual, typography is used as indicated below:

Bold is used for the following purposes:

•To emphasize words.

Example: “Do not touch the antenna”.

• To indicate what the user should select in the user interface.

Example: “Select SETTINGS > LAN”.

Italic is used to emphasize the paragraph title in cross-references.

Example: “For further information, see To connect cables on page...”.

1.5 Precautions

Text marked with “Warning”, “Caution”, “Note” or “Important” show the following type of

data:

• Warning: A Warning is an operation or maintenance procedure that, if not obeyed, can

cause injury or death.

• Caution: A Caution is an operation or maintenance procedure that, if not obeyed, can

cause damage to the equipment.

• Note: A Note gives information to help the reader.

• Important: A text marked Important gives information that is important to the user,

e.g. to make the system work properly. This text does not concern damage on

equipment or personal safety.

All personnel who operate equipment or do maintenance as specified in this manual must

know and follow the safety precautions. The warnings and cautions that follow apply to all

parts of this manual.

WARNING! Before using any material, refer to the

manufacturers’ material safety data sheets for safety

information. Some materials can be dangerous.

CAUTION! Do not use materials that are not

equivalent to materials specified by Thrane & Thrane.

Materials that are not equivalent can cause damage to

the equipment.

CAUTION! The system contains items that are

electrostatic discharge sensitive. Use approved industry

precautions to keep the risk of damage to a minimum

when you touch, remove or insert parts or assemblies.

1-2 Chapter 1: About this manual 98-146706-A

Chapter 2

Introduction

Introduction 2

This chapter has the following sections:

• SAILOR 900 Ka system

• Part numbers and options

2.1 SAILOR 900 Ka system

2.1.1 Overview

The SAILOR 900 Ka is a unique stabilized maritime VSAT antenna system operating in the

Ka-band (26.5 to 40 GHz). It provides bi-directional IP data connections both on regional

satellite beams and quasi-global Ka-band satellite networks. The following figure shows a

coverage map of the Ka service.

Figure 2-1: Coverage map for a Ka service (example)

The SAILOR 900 Ka system consists of the following units:

•Above Deck Unit (ADU)

• Antenna Control Unit (ACU)

• SAILOR 6080 AC/DC Power Supply Unit (optional)

The system only requires a single 50 Ohm cable to provide the Above Deck Unit (ADU) with

both DC power, data and control information. The radome does not have to be removed

neither before nor after the installation. To protect the ADU the built-in motors act as

brakes during transport and when the ADU is not powered. You can access the SAILOR 900

Ka remotely and make in-depth performance analysis using the built-in web interface.

The following figure shows the SAILOR 900 Ka system.

98-146706-A 2-1

SAILOR 900 Ka system

Above Deck

Unit (ADU)

Antenna Control

Unit (ACU)

SAILOR 900 Ka features

Figure 2-2: ADU and ACU

Single 50 Ohm coax cable for the ADU.

One-Touch Commissioning.

Gyro-free operation.

SNMP support.

Secure connection, HTTPS and SSH.

Remote access using SAILOR FleetBroadband over WAN.

Remote or local simultaneous software update of ADU, ACU via PC and Internet

browser.

Full remote control and troubleshooting with built-in test equipment (BITE).

ACU with 4 x LAN, NMEA 0183, RS-232 and RS-422.

No scheduled maintenance.

2-2 Chapter 2: Introduction 98-146706-A

Introduction

2.1.2 Above Deck Unit (ADU)

The SAILOR 900 Ka ADU is a 103 cm stabilized tracking antenna, consisting of a suspended

antenna with a standard global RF configuration. It is stabilized by heavy duty vibration

dampers in 3-axis (plus skew) and can be used in environments with elevations of -25° to +

125°. The ADU weighs 126 kg and is powered by the ACU. The ADU is protected by a

radome.

All communication between the ADU and the ACU passes through a single standard

50 Ohm cable (with N connector) through the rotary joint. No cable work is required inside

the radome.

SAILOR 900 Ka system

Figure 2-3: Above Deck Unit (ADU)

98-146706-A Chapter 2: Introduction 2-3

SAILOR 900 Ka system

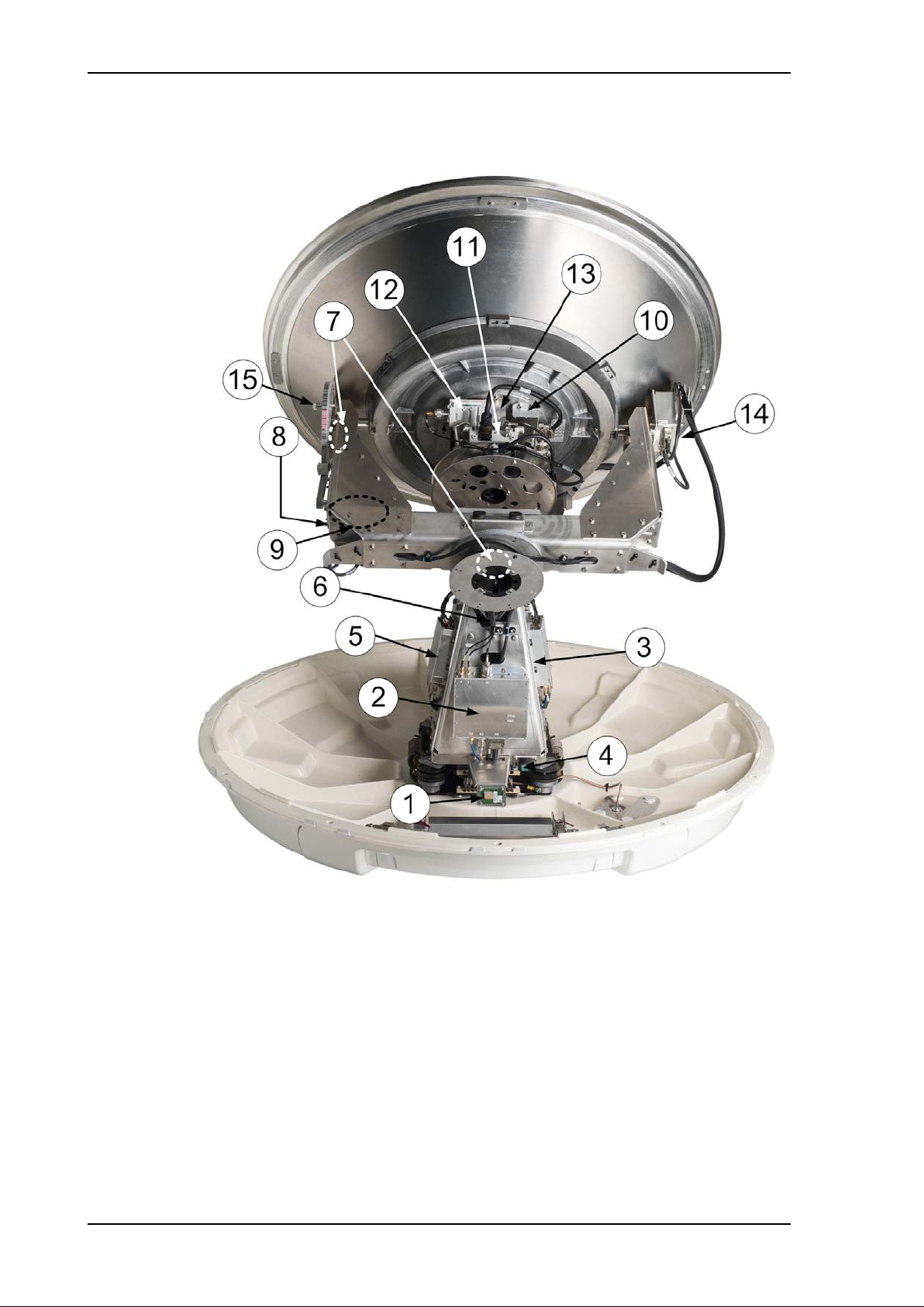

Modules in the SAILOR 900 Ka ADU

Figure 2-4: Above Deck Unit modules 1/2

1. GPS module.

2. VSAT Interface Module (VIM2).

3. Pedestal Control Module (PCM).

4. Service switch.

In switch-off position the Motor Driver modules and the BUC are turned off for safe

conditions during service and repair. The switch must be set to on for normal operation.

5. Motor Driver Module for cross elevation (DDM/SMD).

6. Cross elevation motor and encoder.

2-4 Chapter 2: Introduction 98-146706-A

SAILOR 900 Ka system

Introduction

7. Zero Reference Module (x3) (ZRM) (not visible on photo). (2 in the figure above, 1 in the

figure below)

8. Motor Driver Module for elevation (on the bottom) (DDM/SMD).

9. Elevation motor and encoder (not visible).

10. BUC Control Module (BCM).

11. Block Up Converter (BUC).

12. Low Noise Block downconverter (LNB),

13. Polariser.

14. Inertial Sensor Module (ISM).

15. Elevation locking pin to lock the antenna dish in a fixed position.

Figure 2-5: Above Deck Unit modules 2/2

16. Motor Driver Module for Azimuth (DDM/SMD).

17. Azimuth motor.

18. Azimuth encoder.

19. Rotary joint.

20. Feed horn.

98-146706-A Chapter 2: Introduction 2-5

SAILOR 900 Ka system

Four lifting brackets (included in the delivery) and reuse of packing material help getting the

ADU safely into place. Satellite profile parameters are entered in the built-in web server of

the ACU, using a PC.

The system configuration is saved in two modules, there is no loss of data at repair. The

large service hatch of the radome gives easy access to the ADU on site. The service switch

in the ADU stops the Motor Driver modules and turns the BUC off. The service tools for

replacing modules are placed on a tool holder inside the radome.

All modules have a service and power LED status indicator. Each module is encapsulated in a

metal box with self-contained mounting bolts. If necessary, belts and modules can be

exchanged through the service hatch on site.

You can do remote diagnostics and service with the ADU. Its built-in test equipment

constantly checks the modules for proper functioning, it monitors and logs information for

all modules. The ADU performs a POST (Power On Self Test) and you can request a self test

(PAST, Person Activated Self Test) and Continuous Monitoring (CM). Error codes can be

read out in the web interface and in the display of the ACU.

The ADU software is updated automatically when you make a software update of the ACU.

2.1.3 Antenna Control Unit (ACU)

The ACU is the central control unit in the system. It contains all user interfaces and

manages all communication between the ADU and the connected modem, a connected PC

and an optional FleetBroadband service communication line. The ACU has a display, status

LEDs and a keypad. It provides a DHCP client. During configuration you can configure

heading offset, save satellite setups and enter No Transmit Zones (blocking zones in which

the ADU does not transmit).

The user PC (user WAN) for Internet access etc. is connected to the ACU, not the modem.

The ACU provides DC power to the ADU through a single coaxial cable. You can use the

SAILOR 6080 AC/DC Power Supply to provide the DC power to the ACU. The ACU comes in

a 19” rack version.

Figure 2-6: Antenna Control Unit

You can do remote diagnostics and service with the ACU. Its built-in test equipment

constantly checks the device for proper functioning. It performs POST (Power On Self Test)

and you can request a PAST (Person Activated Self Test). Continuous Monitoring (CM) is

also available. BITE error codes can be read out in the web interface and in the display of

the ACU.

2-6 Chapter 2: Introduction 98-146706-A

SAILOR 900 Ka system

Introduction

/$1WRIURQW

7[,Q5[2XW*URXQG

/$1

56

10($

'&3RZHU

56

$QWHQQD

$&8

&RQWURO

YLD$&8

7[2XW

5[,Q*URXQG

56

&RQVROH

$&3RZHU

5[,Q

QRWDFWLYH

56

%8&,2

You can make a software update with a connected PC and the built-in web interface of the

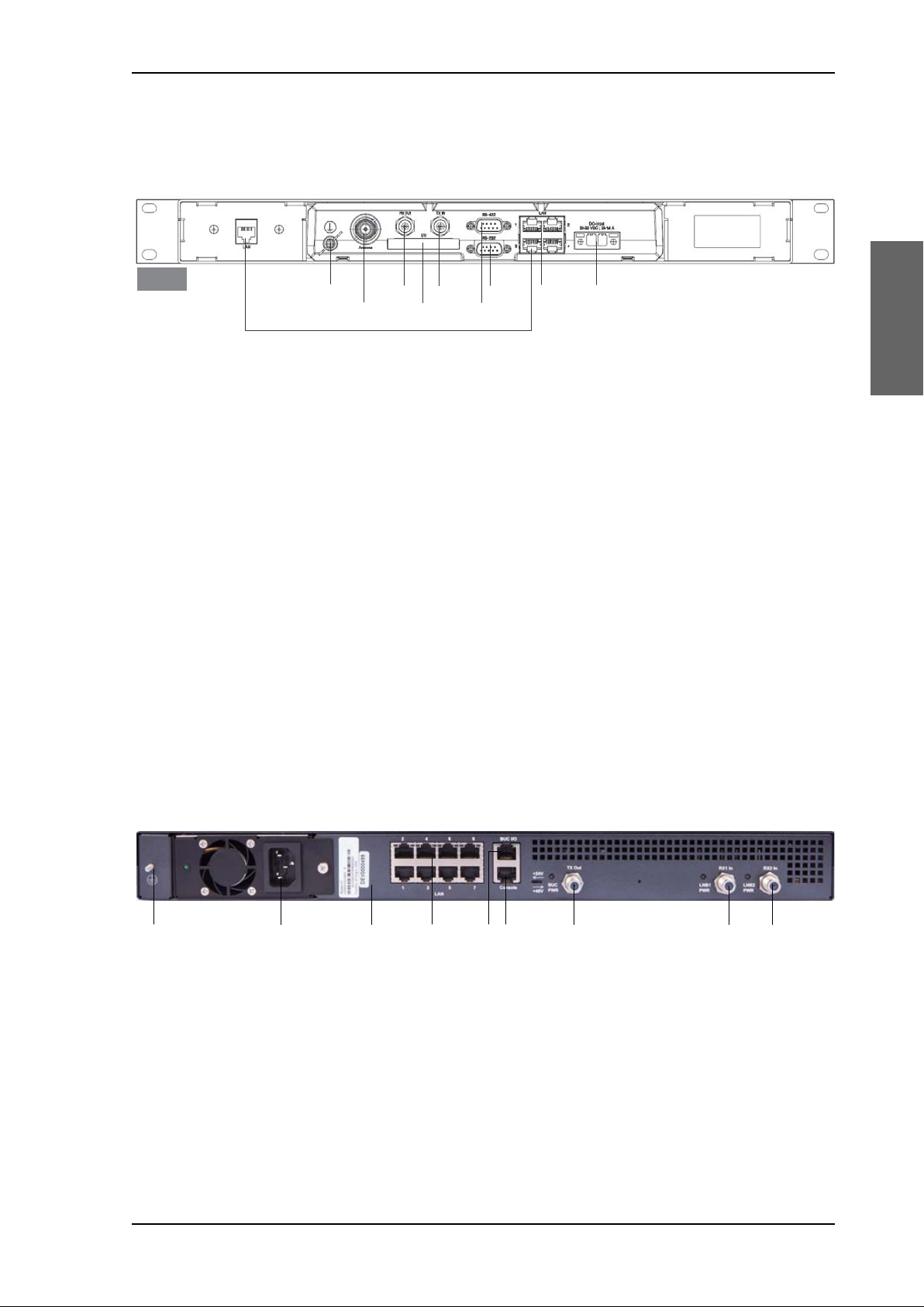

ACU. The ACU has the following interfaces and switch:

Figure 2-7: ACU (connector panel)

• N-connector for ADU cable (50 Ohm).

• 2 x F connectors for Rx and Tx cables (75 Ohm) to modem.

• Multi connector for NMEA interfaces (for input from GPS compass or Gyro compass).

• RS-422 interface for BUC I/O.

• RS-232 interface for modem control.

• 4 x LAN ports for modem control and user equipment.

• Ground wing nut

• Power connector.

• On/Off power switch (at the front).

The ACU also has a LAN connector at the front to access the service port from the ACU

front panel.

2.1.4 iDirect X7 Modem

The iDirect X7 Modem is the modem in the system. The modem has the following

interfaces and connectors:

Figure 2-8: Connector panel of the iDirect X7 modem

•GND

• 100-240 VAC power connector

• 8 LAN ports, one to ACU

• RS-422 interface BUC I/O

• RS-232 Console for modem control

• Tx Out (F-connector)

• RX1 and RX2 (RX 2 not used) (F connector)

98-146706-A Chapter 2: Introduction 2-7

Part numbers and options

2.1.5 Satellite type approvals

For a list of satellite type approvals see Appendix E, Approvals.

2.1.6 Service activation

Before you can start using the SAILOR 900 Ka, you need to activate the system for the Ka

service. Contact your service provider for activation.

2.2 Part numbers and options

2.2.1 Applicable model and part numbers

The following model and part numbers are available for the SAILOR 900 Ka system:

Part number Description

407009D-00500 Above Deck Unit (ADU)

407016B-00500 Antenna Control Unit (ACU)

Table 2-1: Part numbers for the SAILOR 900 Ka system

2.2.2 Options for SAILOR 900 Ka

The following options are available for the SAILOR 900 Ka system:

Part number Description

406080A-00500 SAILOR 6080 AC/DC Power Supply

407090A-950 Antenna cable 50 m N-Conn (not mounted),

male/male

407090A-925 Pigtail Cable 1.25 m, N-Conn, female/male

406080A-005 19” Rack mount kit for SAILOR 6080 AC/DC Power

Supply

Table 2-2: Part numbers for options of the SAILOR 900 Ka system

2-8 Chapter 2: Introduction 98-146706-A

Chapter 3

Installation

Installation 3

This chapter has the following sections:

• What’s in the box

• Site preparation

• Installation of the ADU

• Installation of the ACU

• Installation of the modem

• To connect the ADU, ACU and modem

3.1 What’s in the box

3.1.1 To unpack

Unpack the ADU and ACU and check that the following items are present:

• SAILOR 7009D ADU with 4 lifting brackets (already mounted)

• Accessory kit for SAILOR 7009D ADU:

• Package with bolts, washers and cable glands (2 sizes)

• SAILOR 7016B ACU

• Accessory kit for SAILOR 7016B ACU:

• NMEA multi-connector

• Connector 2PF pi7.62 straight

• RJ45 patch cable (0.5 m)

• Coax cable F-F, low loss, 75 Ohm (2 pcs)

•RJ45 patch cable (2m)

• X7 Modem BUC & Console to ACU cable

• Installation manual (this manual)

98-146706-A 3-1

What’s in the box

3.1.2 Initial inspection

Inspect the shipping cartons and wooden box immediately upon receipt for evidence of

damage during transport. If the shipping material is severely damaged or water stained,

request that the carrier's agent be present when opening the cartons and wooden box. Save

all box packing material for future use.

WARNING! To avoid electric shock, do not apply

power to the system if there is any sign of shipping

damage to any part of the front or rear panel or the outer

cover. Read the safety summary at the front of this

manual before installing or operating the system.

After unpacking the system, i.e. removing the top and sides of the wooden box and opening

the cartons, inspect it thoroughly for hidden damage and loose components or fittings. If

the contents are incomplete, if there is mechanical damage or defect, or if the system does

not work properly, notify your dealer.

3.1.3 Tools needed

• Unbraco key (4 mm), included, mounted on a tool holder inside the ADU radome.

• Torx TX 20 to open the locks of the service hatch

• Wrench to fasten the mounting bolts for the ADU

• Wrench to fasten the N connector at the ADU

• PC and Internet browser

•Crimping tools

3.1.4 Transport of the antenna

During transport the antenna must be able to move freely inside the radome. You must

follow the instructions below to keep a valid warranty:

CAUTION!

Do not lock the antenna dish with the elevation

locking pin during transport.

Do not strap parts of the antenna.

These actions might cause damage to the antenna.

Damage due to actions listed above will void the warranty.

3-2 Chapter 3: Installation 98-146706-A

Installation

3.2 Site preparation

Important

The following topics have to be considered when installing the ADU:

• General site considerations

• Obstructions (ADU shadowing)

• Blocking zones with azimuth and elevation

• Safe access to the ADU (radiation hazard)

• Ship motion and offset from the ship’s motion centre

• Mast foundation and height

• Interference from radar, GPS and other transmitters

• Condensation, water intrusion and deposits

3.2.1 General site considerations

For optimum system performance, you must follow some guidelines on where to install or

mount the different components of the SAILOR 900 Ka System.

Site preparation

1. Mount the ADU on stiffened structures with a minimum of exposure to vibrations.

You do not have to align the ADU with the bow-to-stern line of the ship. When configuring

the SAILOR 900 Ka system, the azimuth calibration provides the correct azimuth of the

ADU.

Painting the radome

Customers may wish to paint the radome in order to match the vessel’s colour. Cobham

SATCOM’s recommendation is that the radome should NOT be painted because it may

impact RF performance and may lead to over-heating, causing the antenna to go in safe

mode (switch off).

However, painting the radome will not void the general warranty regarding material and

workmanship etc. It is only the performance that cannot be guaranteed. Any paint used

must be non-metallic based.

It is recommended to mount the ADU in a location with as much 360° free

line of sight to the satellite as possible while making sure that the support

structure fulfills the requirements for the mast foundation.

98-146706-A Chapter 3: Installation 3-3

Site preparation

Note

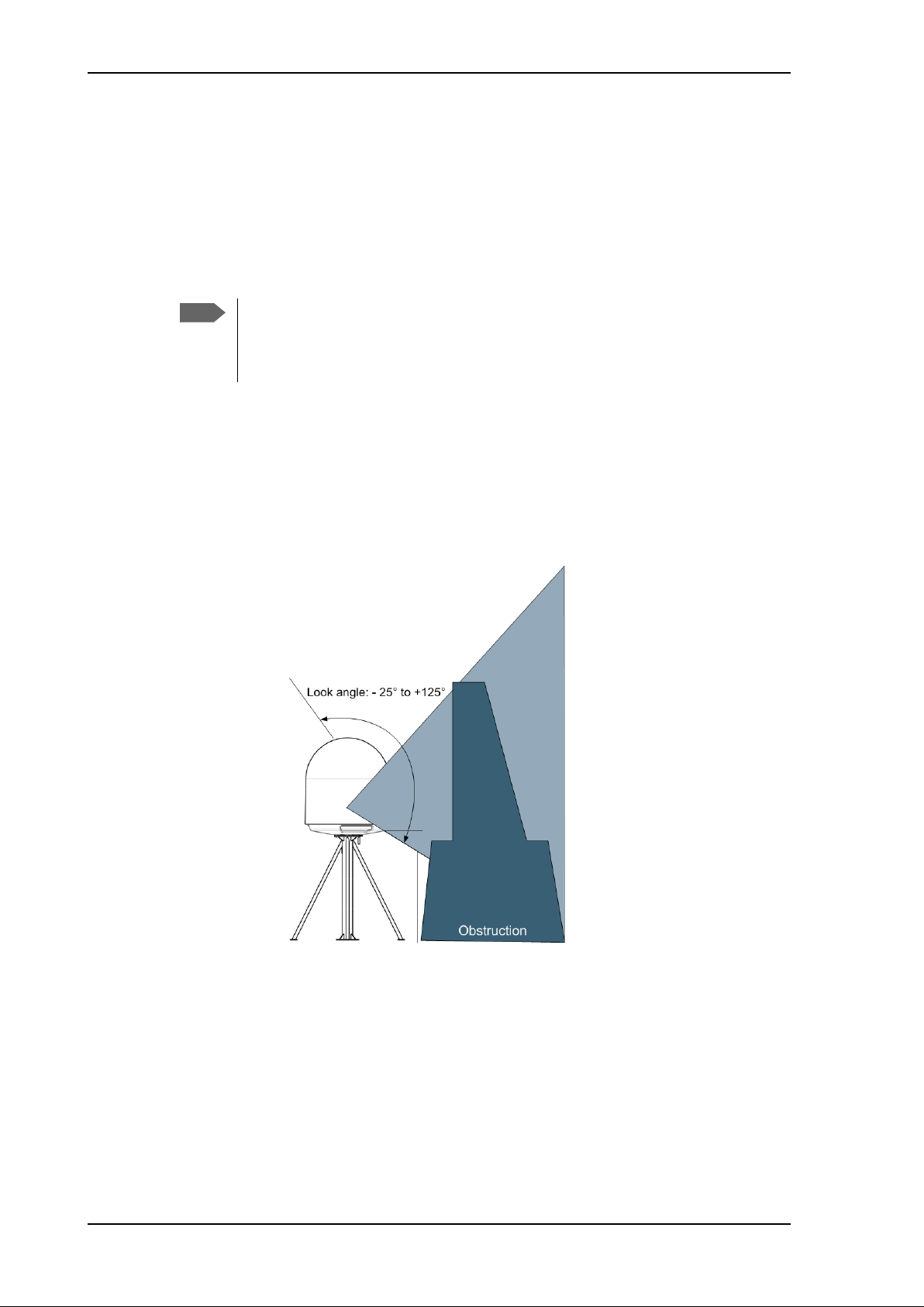

3.2.2 Obstructions (ADU shadowing)

The ADU is stabilized in 3-axis (plus skew) and can be used in environments with elevations

of -25° to + 125° to allow for continuous pointing even in heavy sea conditions. The ADU

beam is approximately 1 m in diameter for the first 30 m from the ADU. Beyond 30 m the

beam gradually widens so that it is approximately 5 m in diameter at 100 m distance. This

beam expansion continues with increasing distance. Any obstructions, such as masts,

funnels, bridge house etc. within this field can cause signal degradation or signal loss.

Note that due to the short wavelength at Ka band and the

narrow beam width of the ADU even a 6 mm steel wire

placed within 50 m inside the beam can causes signal

degradation.

For optimum performance adhere to the following guidelines:

1. Place the ADU so that it has as much free line-of-sight as possible without any

structures in the beam through one full 360 degrees turn of the vessel.

2. Do not place the ADU close to large objects that may block the signal.

3. Elevate the ADU by mounting it on a mast or on a mounting pedestal on a deck or deck

house top to avoid obstruction.

Figure 3-1: Signal degradation because of obstructing objects

3-4 Chapter 3: Installation 98-146706-A

Installation

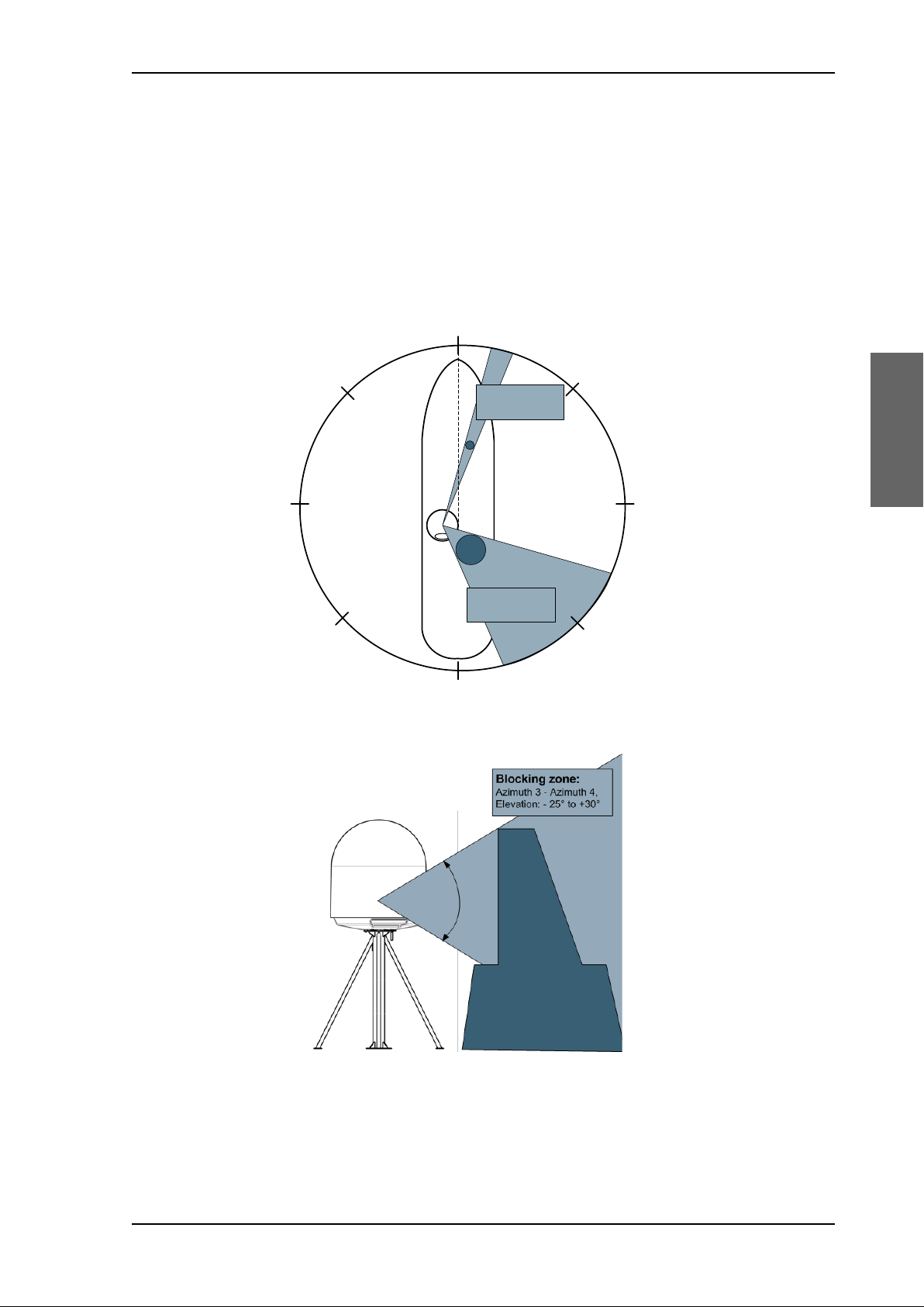

3.2.3 Blocking zones with azimuth and elevation

$QWHQQD

2EVWUXF

WLRQ

$]LPXWK

$]LPXWK

$]LPXWK

$]LPXWK

%ORFNLQJ]RQH

$]LPXWK$]LPXWK

(OHYDWLRQWR

%ORFNLQJ]RQH

$]LPXWK$]LPXWK

(OHYDWLRQWR

Your installation may require that you set up blocking zones for the ADU, i.e. areas where

the ADU will not transmit and areas where transmit power is potentially dangerous for

persons frequently being in these zones. You can set up 8 blocking zones. Each blocking

zone is set up with azimuth start and stop, and elevation angle. The blocking zones are set

up in the built-in web interface of the ACU during configuration. For further information see

To set up blocking zones (RX and TX) on page 6-22.

Site preparation

Figure 3-2: 2 blocking zones with no-transmit zones, azimuth (example)

Figure 3-3: Blocking zone with no-transmit zones, elevation angle (example)

98-146706-A Chapter 3: Installation 3-5

Site preparation

MICROWAVE RADIATION

NO PERSONNEL within safety

distance of 30 m, based on 10 W/m

2

3.2.4 Safe access to the ADU (radiation hazard)

The ADU radiates up to 54.5 dBW EIRP. This translates to a minimum safety distance of

2

30 m from the ADU while it is transmitting, based on a radiation level of 10 W/m

Figure 3-4: Radiation hazard, safety distance 30 m

.

3-6 Chapter 3: Installation 98-146706-A

Loading...

Loading...