Page 1

SAILOR 6000B MF/HF DSC

Installation manual

150W/150W FCC/250W/500W

Page 2

Page 3

Table of Contents

SAILOR 6000B MF/HF DSC

150W/150W FCC/250W/500W

Installation manual

Document number: 98-144591-D

Release date: December, 2016

Page 4

98-144591-D

ii

Disclaimer

Any responsibility or liability for loss or damage in connection with the use of this product and the accompanying

documentation is disclaimed by Thrane & Thrane A/S. The information in this manual is provided for information

purposes only, is subject to change without notice and may contain errors or inaccuracies. Manuals issued by Thrane

& Thrane A/S are periodically revised and updated. Anyone relying on this information should acquire the most

current version e.g. from www.cobham.com/satcom, Service and support, or from the distributor. Thrane & Thrane

A/S is not responsible for the content or accuracy of any translations or reproductions, in whole or in part, of this

manual from any other source. In the event of any discrepancies, the English version shall be the governing text.

Thrane & Thrane A/S is trading as Cobham SATCOM.

Copyright

© 2016 Thrane & Thrane A/S. All rights reserved.

Trademark Acknowledgements

• Thrane & Thrane is a registered trademark of Thrane & Thrane A/S in the European Union and the Unites

States of America.

• SAILOR is a registered trademarks of Thrane & Thrane A/S.

• Other product and company names mentioned in this manual may be trademarks or trade names of their

respective owners.

Page 5

iii98-144591-D

Safety summary

The following general safety precautions must be observed during all phases of operation, service and repair of this

equipment. Failure to comply with these precautions or with specifi c warnings elsewhere in this manual violates

safety standards of design, manufacture and intended use of the equipment. Thrane & Thrane assumes no liability

for the customer's failure to comply with these requirements.

GROUND THE EQUIPMENT

To minimise shock hazard, the equipment chassis and cabinet must be connected to an electrical ground and the

cable instructions must be followed.

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE

Do not operate the equipment in the presence of fl ammable gases or fumes.

Operation of any electrical equipment in such an environment constitutes a defi nite safety hazard.

KEEP AWAY FROM LIVE CIRCUITS

Operating personnel must not remove equipment covers. Component replacement and internal adjustment must be

made by qualifi ed maintenance personnel. Do not service the unit with the power cable connected. Always discon-

nect and discharge circuits before touching them.

Service

General service must be done by skilled service personnel.

Caution! Only skilled service personnel may service and repair the equipment.

Always carry out work under ESD safe conditions.

Page 6

98-144591-D

iv

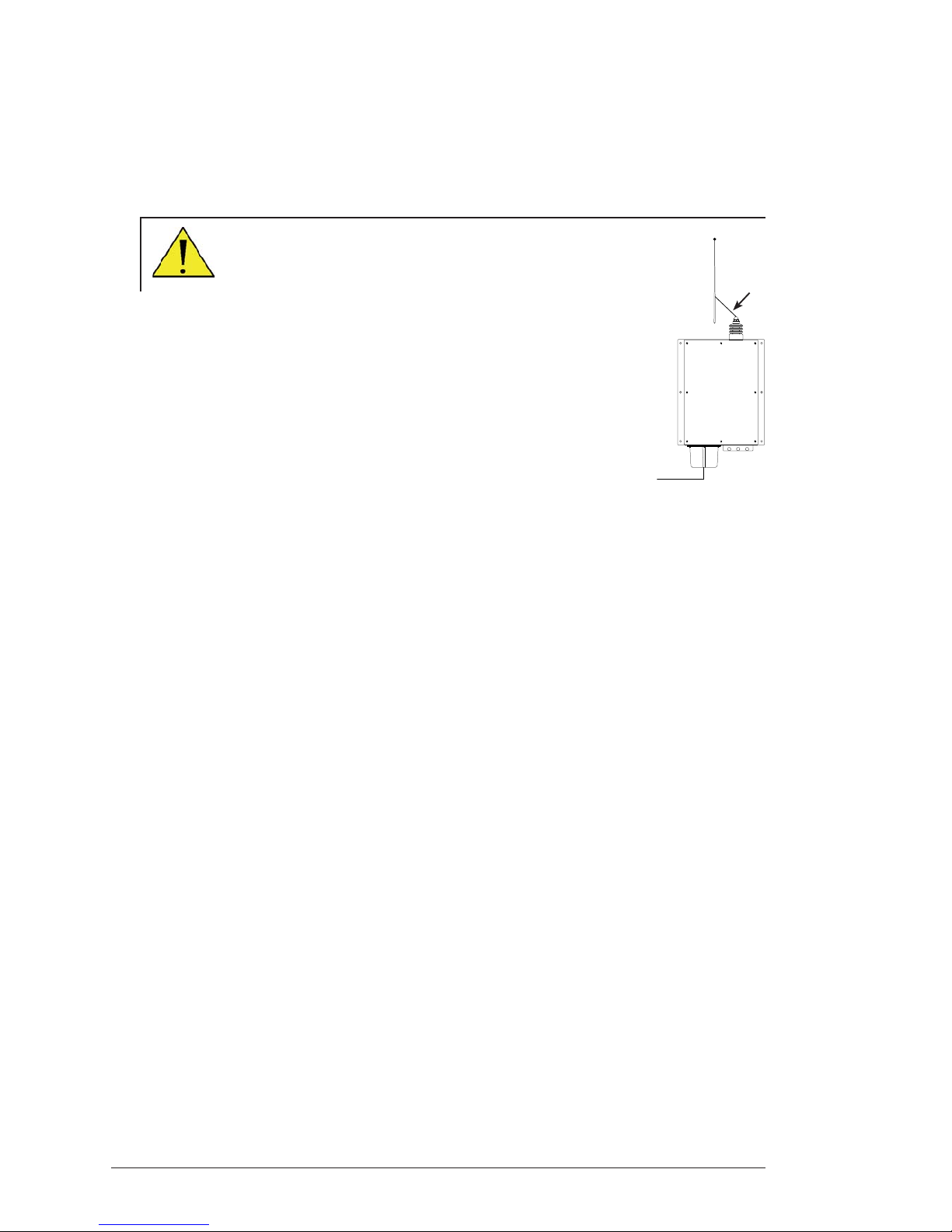

RF exposure hazards and instructions

Your Thrane & Thrane radio generates electromagnetic RF (radio frequency) energy when transmitting. To ensure

that you and those around you are not exposed to excessive amounts of energy and thus to avoid health hazards

from excessive exposure to RF energy, all persons must obey the following:

Caution! Never touch the horn of the Antenna Tuning Unit or feeder wire when

the MF/HF

radio is transmitting. High voltage which can cause death

or serious injury is present at the locations shown in the illustration

below.

Warranty limitation

The radio is not a user maintainable unit, and under no circumstances should the unit be opened except by authorized

personnel. Unauthorized opening of the unit will invalidate the warranty.

Unit

Antenna Tuning

MF/HF

SAILOR 638x

Page 7

v98-144591-D

Record of revisions

Rev. Description Relase Date Initials

A Original document October 2015 CMA

B Installation is changed - page vi

Warning is changed - page v

Drawing updated - page 2-24.

Setup menu updated - page 2-26

Cable names are changed (AUX & SYS) - pages 2-18, 2-20, 2-21

Accessory list updated - page 5-8 November 2015 CMA

C Technical data, - Antenna added - page 1-1

Input impedance 20 mA changed to 60 mA - page 1-3

Chapter 1.2.4, Input impedance, Sensitivity, Intermodulation, Spurious

rejection are removed - page 1-4

Chapter 2.4.1 Headline changed from 'Transceiver Antenna' to 'Transmitter

Antenna' - page 2-12

Chapter 2.4.3 is rewritten - page 2-15

RX Antenna & TX Antenna added confi g. drawing - page 2-18 February 2016 CMA

D Chapter 4.1 pkt. 6 added - page 4-1

Chapter 4.2 Calibrating the master oscillator added - page 4-1 December 2016 CMA

Preface

Radio for occupational use

The SAILOR 6000B MF/HF DSC fulfi ls the requirements of the SOLAS directive and is intended for use in maritime

environment.

SAILOR 6000B MF/HF DSC is designed for occupational use only and must be operated by licensed personnel only.

SAILOR 6000B MF/HF DSC is not intended for use in an uncontrolled environment by general public.

Training information

The SAILOR 6000B MF/HF DSC is designed for occupational use only and is also classifi ed as such. It must be ope-

rated by licensed personnel only. It must only be used in the course of employment by individuals aware of both

the hazards as well as the way to minimize those hazards.

The radio is thus NOT intended for use in an uncontrolled environment by general public. The SAILOR 6000 MF/HF

DSC has been tested and complies with the FCC RF exposure limits for Occupational Use Only. The radio also complies with the following guidelines and standards regarding RF energy and electromagnetic energy levels including

the recommended levels for human exposure:

• FCC OET Bulletin 65 Supplement C, evaluating compliance with FCC guidelines for human exposure to radio

frequency electromagnetic fi elds.

• American National Standards Institute (C95.1) IEEE standard for safety levels with respect to human exposure

to radio frequency electromagnetic fi elds, 3 kHz to 300 GHz

• American National Standards Institute (C95.3) IEEE recommended practice for the measurement of potentially

hazardous electromagnetic fi elds - RF and microwaves.

Below the RF exposure hazards and instructions in safe operation of the radio within the FCC RF exposure limits

established for it are described.

Page 8

98-144591-D

vi

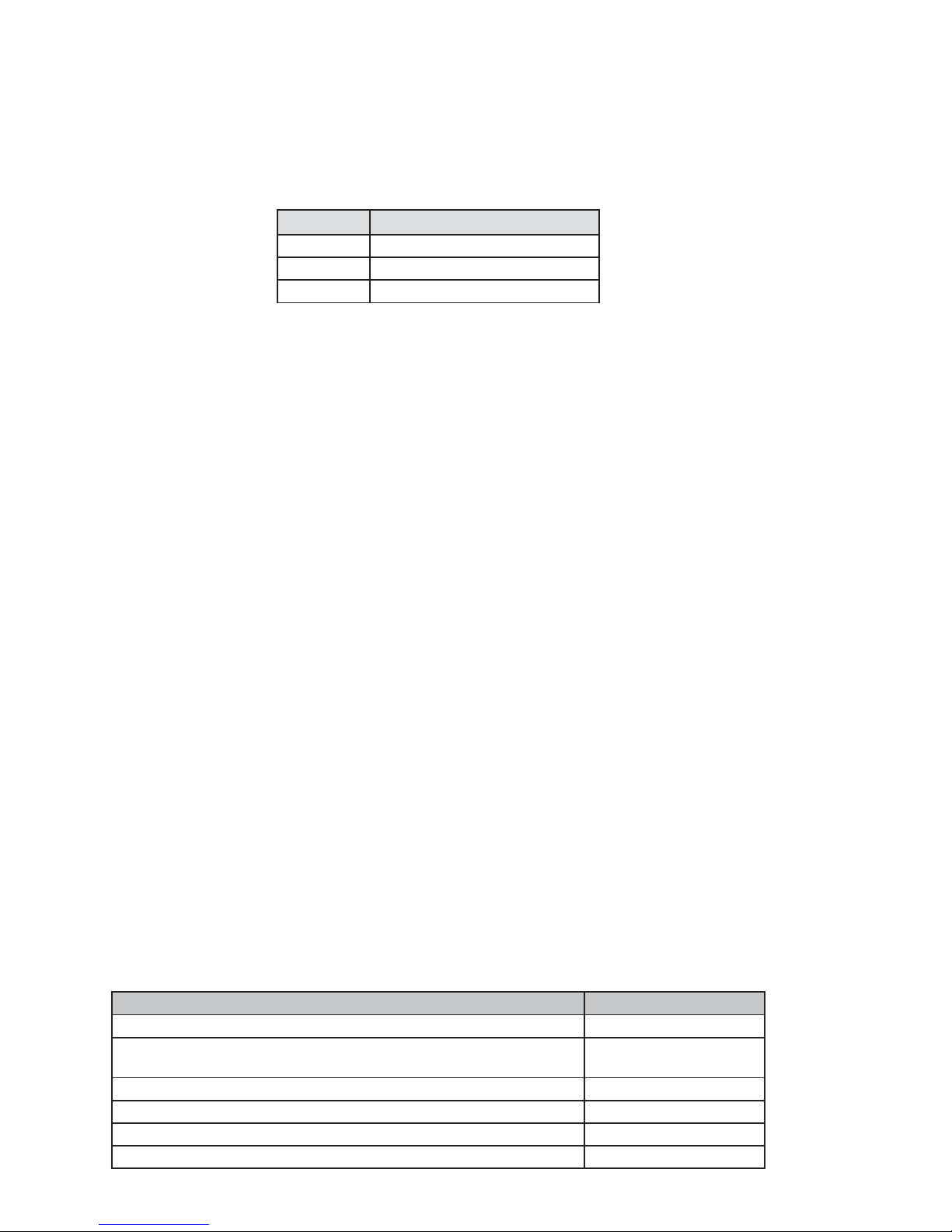

Warning

The SAILOR radio set generates electromagnetic RF (radio frequency) energy when transmitting. To ensure that no

personnel will be exposed to excessive amounts of RF-energy and to avoid health hazards from excessive exposure

to RF energy, the following safety distances must be followed:

Antenna Safety distance

150W Calculated: 1.71 m or 5.7 feet

250W Calculated: 2.21 m or 7.3 feet

500W Calculated: 3.12 m or 10.3 feet

Calculations cover a whip antenna with a maximum gain of 3dBi, worst case frequency (30 MHz), full power and

100% duty cycle (transmitter always on) considering the most conservative limits mentioned in:

FCC OET Bulletin 65 (1997)

Canada RSS102 (2010)

Canada Safety Code 6 (2015)

Installation Example for 150W

1. A whip antenna with a maximum gain of 3 dBi must be mounted at least 12.3 ft. (3.71m) above the highest

deck where people may be staying during continuous radio transmissions. The distance is to be measured

vertically from the lowest point of the antenna. This provides the minimum separation distance which is in

compliance with RF exposure requirements and is based on the MPE radius of 5.7 feet (1.71 m) plus the 6.6 ft.

(2.0 m) height of an adult.

2. On vessels that cannot fulfi ll requirements in item 1, the antenna must be mounted so that the lowest point of

the antenna is at least 5.7 feet (1.71m) vertically above the heads of people on deck and all persons must be

outside the 5.7 feet MPE radius during radio transmission.

• Always mount the antenna at least 5.7 feet from possible human accessNever touch the antenna when

transmitting.

• Never touch the antenna when transmitting.

• Use only authorized T&T accessories.

• Only allow trained and certifi ed operators knowing about RF-energy and hazards to operate the radio.

3. If the antenna has to be placed in public areas or near people with no awareness of the radio transmission, the

antenna must be placed at an even greater distance. Consult the appropriate standard for exact limits, depending

on national specifi cations.

Failure to observe any of these warnings may cause RF exposure exceeding above mentioned limits or create dangerous conditions..

Related documents

Title and description Document number

Installation guide SAILOR 630x MF/HF Control Unit 98-132396

Installation guide SAILOR 6000B MF/HF Transceiver Unit & Antenna Tuning Unit

150 W/250 W/500 W

98-144542

User Manual SAILOR 6301 MF/HF Control Unit 98-131070

User Manual SAILOR MF/HF System 6000A/6000B MF/HF Radiotelex 98-151795

Installation and user manual SAILOR 6101 and 6103 Alarm Panel 98-130981

Emergency call sheet 98-132369

Page 9

Table of Contents

vii

98-144591-D

Chapter 1 General information

1.1 Introduction .............................................................................................................................1-1

1.2 Technical data ...........................................................................................................................1-1

Chapter 2 Installation

2.1 Description .................................................................................................................................2-1

2.2 Mounting the units ................................................................................................................. 2-1

2.3 Ground connections .............................................................................................................2-9

2.4 Antennas ..................................................................................................................................... 2-12

2.5 DC Power cabling ...................................................................................................................2-17

2.6 Interconnection of units .....................................................................................................2-18

2.7 Position and time information ..........................................................................................2-25

2.8 Telex operation ........................................................................................................................2-26

2.9 ID Programming .......................................................................................................................2-27

2.10 Programming Telex ID .........................................................................................................2-29

2.11 Confi guration ........................................................................................................................... 2-31

2.12 Final installation check .........................................................................................................2-35

Chapter 3 Technical description

3.1 Control Unit ...............................................................................................................................3-1

3.2 Transceiver Unit ....................................................................................................................... 3-1

3.3 Supply Filter module 57-139985 ....................................................................................3-1

3.4 Exciter Control module (ECM) 60-139984 ...............................................................3-1

3.5 PA and Filters module 60-122881..................................................................................3-2

3.6 PA and Filters module 60-123937 (FCC) ................................................................... 3-3

3.7 SMPS module 60-122882 (150 W/250 W) ...............................................................3-3

3.8 SMPS module 60-126172 (500 W) ...............................................................................3-3

3.9 SMPS module 60-126236 (500 W) ...............................................................................3-4

3.10 Antenna Tuning Unit ............................................................................................................3-4

3.11 Power control and protection system ........................................................................... 3-6

Table of Contents

Page 10

98-144591-D

viii

Table of Contents

Chapter 4 Service

4.1 Preventive maintenance ..................................................................................................... 4-1

4.2 Calibrating the master oscillator ......................................................................................4-2

4.3 Cleaning the Air fi lter (500 W Transceiver only) ......................................................4-5

4.4 System test and verifi cation .............................................................................................. 4-5

4.5 Software update ......................................................................................................................4-5

Chapter 5 Spare part exchange

5.1 Disassembling the Transceiver Unit (150 W/250 W) ............................................5-1

5.2 Disassembling the Transceiver Unit (500 W) ............................................................5-2

5.3 Transceiver Unit module location ...................................................................................5-3

5.4 Module overview .....................................................................................................................5-5

5.5 Required service tools ........................................................................................................... 5-8

5.6 Accessory list ............................................................................................................................5-8

Glossary ................................................................................................................... Glossary-1

Page 11

Chapter 1: General information

1-1

General information

98-144591-D

Technical data

General information

1.1 Introduction

The 150 W/250 W/500 W MF/HF transceiver with integrated DSC and telex (NBDP) is designed for maritime applications in voluntary as well as compulsorily fi tted vessels. It offers simplex and semi-duplex

SSB radiotelephone communication in the maritime mobile frequency bands between 1.6 and 30 MHz.

The basic version of the transceiver includes voice, DSC and a dedicated 2187.5 KHz DSC watch receiver,

forming an ideal system for MF GMDSS installations.

The equipment consists of a compact transceiver control unit, a fully remote controlled transceiver unit

and an automatic antenna tuning unit.

The microprocessor controlled Antenna Tuning Unit automatically matches the impedance of antennas

between 8 and 18 metres in length and requires no presetting at the installation. It is designed for outdoor

installation and may be located up to 100 metres from the Transceiver Unit.

The Transceiver Unit contains all receiver and transmitter circuits. The fully protected solid state 150 W/

250 W /500 W power amplifi er matches a 50 ohm antenna system, but is normally used in connection

with the Antenna Tuning Unit. The DSC/Telex modem contains two demodulators, one connected to the

built-in watch receiver for continuous watch on the DSC distress frequencies, the other connected to

the communication receiver which may be used to keep simultaneous watch on other DSC frequencies

or telex communication.

The transceiver can be upgraded to scan 6 DSC channels, and Telex operation to comply with MF/HF

requirements in sea area A4. Codes are purchased as accessories for the system.

The Control Unit is for operation of radiotelephony as well as DSC and confi guration. Use of the equip-

ment is simple, logic and straight forward. DSC operation is based on the use of soft keys. Guiding texts

are provided and the large display is able to show the contents of a complete call in one screen.

For telex operation the Message Terminal must be connected to the system via the CAN bus.

The equipment is designed for operation from a 24 V DC supply, like e.g. a battery. With the optional AC

Power Supply unit installed the equipment may be supplied from 115/230 V AC main or emergency supplies with automatic switch-over to 24 V DC supply in the absence of AC supply voltage. Also optionally, a

battery charger for AC is available in the product line.

The built-in test facilities and easy-to-replace module design of the equipment simplifi es the service concept.

1.2 Technical data

1.2.1 General

Complies with the relevant IMO performance standards for MF, MF/HF, MSI, and NBDP GMDSS equipment,

the ITU Radio Regulations, the ITU-R recommendations and the relevant performance specifi cations of

ETSI, IEC and FCC, in the ITU marine bands.

Operating modes: Simplex and semi-duplex SSB telephony (J3E), DSC (J2B), AM broadcast

reception (H3E) and Telex (J2B)

Antennas: The Transceiver is designed to operate as a "two antenna simplex/semi-

duplex" confi guration only, meaning that separate antennas are used for

reception (RX) and transmission (TX) respectively.

Frequency stability: Better than 0.35 ppm

Warm-up time. Less than one minute

Ageing less than 0.1 ppm/year

Normal operating

temperature: from 0°C to +40°C

Extreme operating

temperature: From -15°C to +55°C

ATU From -25°C to +55°C

Chapter 1: General information

Chapter 1

Page 12

1-2

Chapter 1: General information 98-144591-D

Technical data

User-programmable

channels: 199 frequency pairs with mode (1-199)

User-programmable

stations: 40 stations with name, MMSI and station channel

Supply voltage: Nominal 24V DC (-10 +30% — 21.6 - 31.2 V DC)

With optional external AC power supply:

115/230V AC 50/60 Hz. Automatic change-over to DC in the absence of AC supply

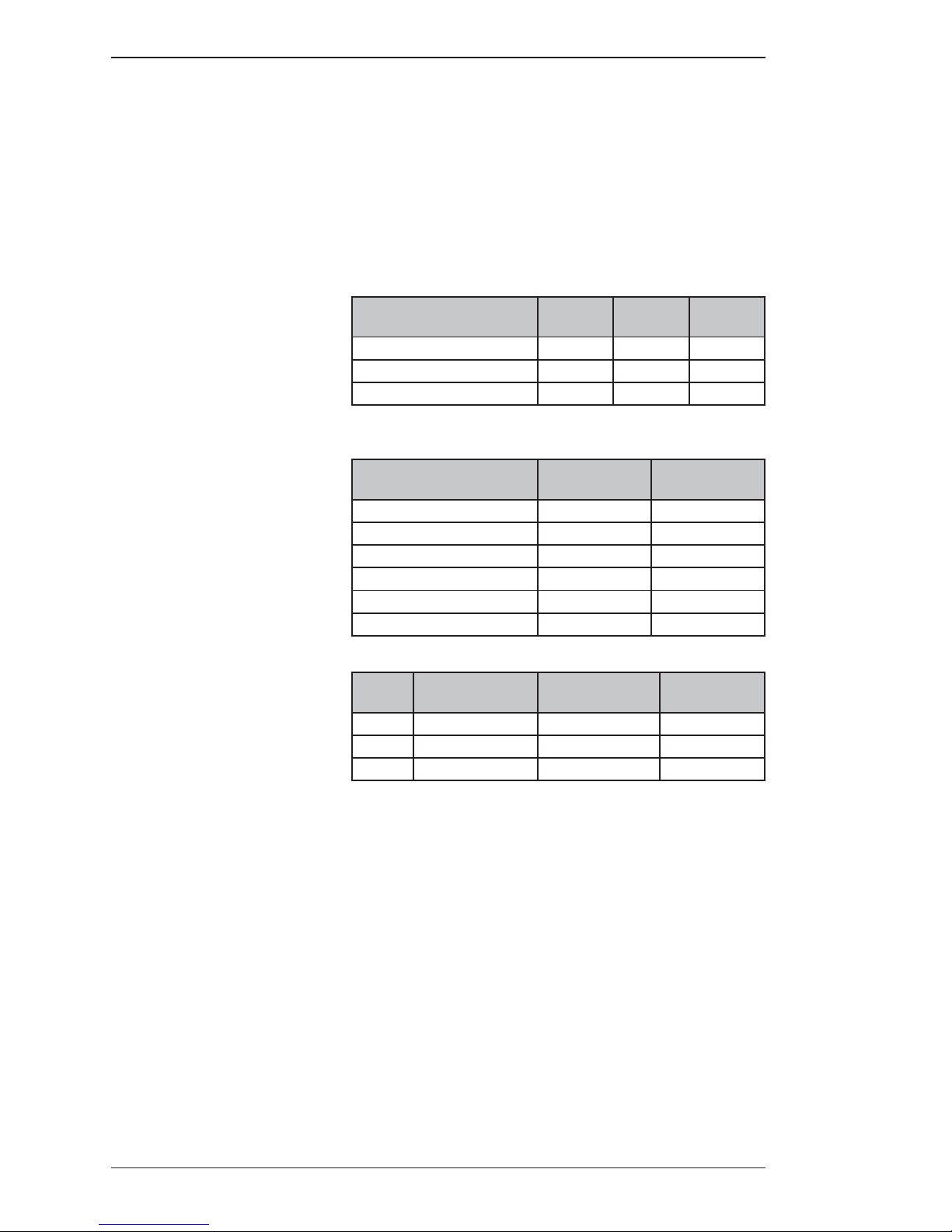

Power consumption:

Rx Mode: Approximately

45W

150 W 250 W 500 W

Tx, SSB speech 175 W 300 W 600 W

Tx, SSB two-tone 300 W 550 W 1100 W

Tx, DSC/TELEX 310 W 600 W 1000 W

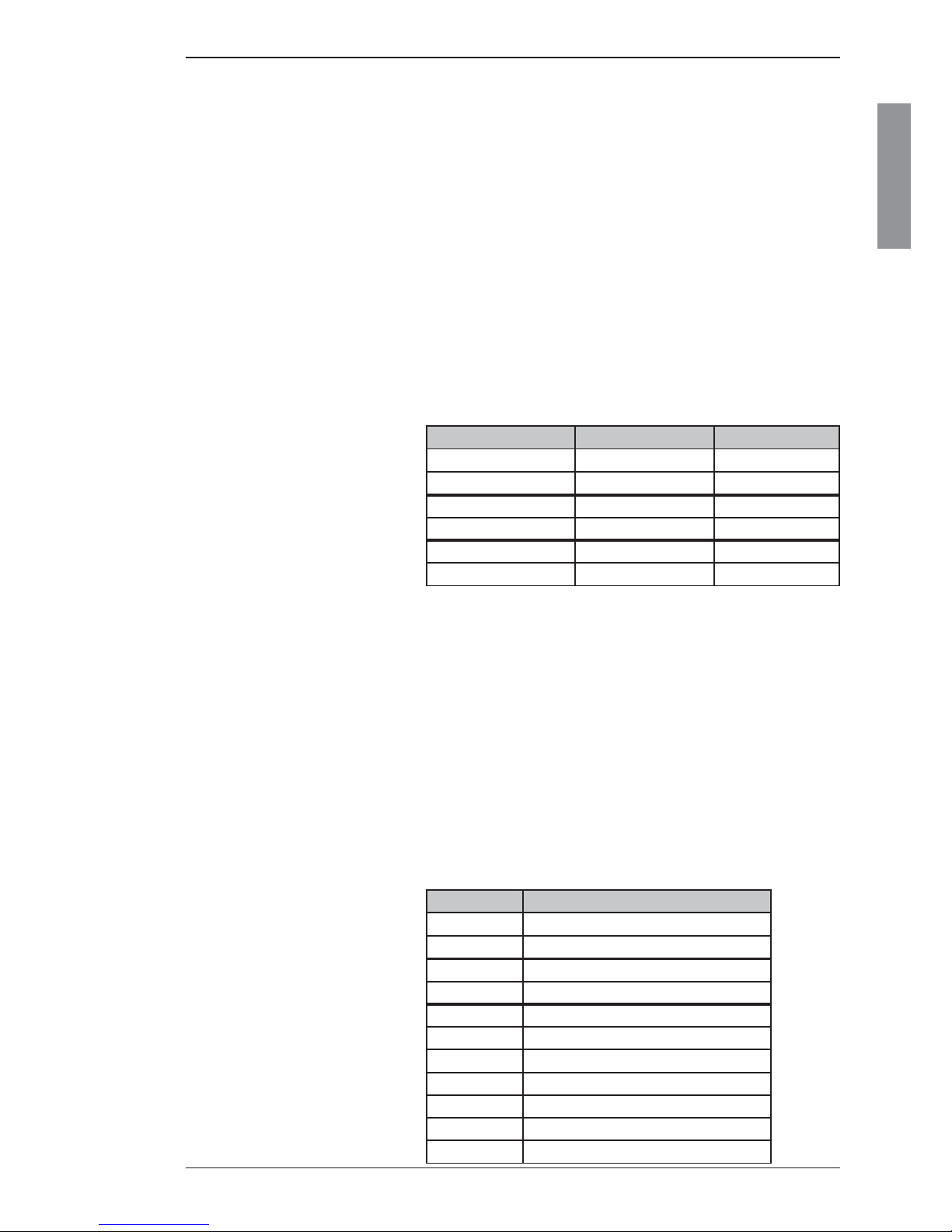

Compass safe distance:

Compass safe distance in accordance with ISO/R 694 are given below in metres

Unit

Standard

5.4°/H

Steering

18°/H

Control Unit 1.2 0.5

Transceiver Unit 0.85 0.25

Antenna Tuning Unit 0.6 0.3

Handset 0.3 0.2

Cradle 1.1 0.7

Loudspeaker 2.2 1.6

IP ratings (estimated):

System Transceiver Unit

Antenna Tuner

Unit *

Control Unit

150 W IP43 IP56 IP54

250 W IP43 IP56 IP54

500 W IP20 IP56 IP54

* Antenna cable must be carefl ly installed to obtain this IP rating

Dissipated heat: The dissipated heat in standby RX mode is typically 45 W depending on

attached ancillary equipment.

In transmit mode, use the consumption fi gures for the appropriate mode,

multiplied by 0.66.

E.g. 0.66 x 175 W = 115.5 W dissipated heat for a 150 W system in SSB

speech mode.

For a fi gure in kilocalories (kcal), multiply dissipation effect by on-time in

hours and then by 0.860.

For the 150W system, e.g. 115.5 W x 2 h + 45 W x 22 h (TX 2 hours + RX

22 hours a day) = 1221 Wh. 1221 Wh x 0.860 ~ 1050 kcal a day.

Page 13

Chapter 1: General information

1-3

General information

98-144591-D

Technical data

1.2.2 Receiver characteristics

General: Complies with ETSI 300373 in the ITU marine bands.

Frequency range: 150 KHz to 30 MHz

Frequency resolution: 100 Hz by keyboard entry

10 Hz, 100 Hz or 1 KHz search/fi ne-tune facility is provided

Input impedance: Rx : 50 ohm

12V DC / 60 mA is available for possible use of active antenna.

Sensitivity: Telephony (J3E): below 11 dBμV for 20 dB Sinad

Broadcast (A3E): below 25 dBμV for 20 dB Sinad

DSC/Telex (J2B): below 0 dBμV

Intermodulation:

Wanted signal Signal

Telephony (J3E) 30 dBμV

Intermodulation level

above 80 dBμV

Telex (J2B) 30 dBμV

Intermodulation level above 90 dBμV

DSC (J2B) 20 dBμV

Intermodulation level above 80 dBμV

Spurious rejection: Above 70 dB

Audio output power: Build-in loudspeaker 6 W typical.

Optional loudspeaker output 6 W typical with less than 10 % distortion.

Output intended for 8 ohm loudspeaker.

1.2.3 Transmitter characteristics

General: Complies with ETSI 300373 and FCC in the ITU marine bands.

The Transmitter characteristics are with the Antenna Tuning Unit included.

Frequency range: All frequencies in the range 1605 KHz to 30 MHz however by factory

default arranged in the ITU marine bands.

Factory pre-programmed:

Band Frequency

00 1.605 - 4.000 MHz

01

4.000 - 4.438 MHz

02 6.200 - 6.525 MHz

03 8.100 - 8.815 MHz

04 2.230 - 13.200 MHz

05 6.360 - 17.410 MHz

06 8.780 - 18.900 MHz

07 19.680 - 19.800 MHz

08 22.000 - 22.855 MHz

09 25.070 - 25.210 MHz

10 26.100 - 26.175 MHz

Page 14

1-4

Chapter 1: General information 98-144591-D

Technical data

Frequency resolution: 100 Hz

Output impedance: TX: 50 ohm

The Antenna is matched by the Antenna Tuning Unit

Power reduction: Low power: 20 W PEP

Intermodulation: below -31 dB/PEP

Spurious Emission: below -43 dB/PEP

below -60 dB/PEP (FCC)

Hum and noise: Less than - 40 dB/PEP

Output power 150 W SSB: ± 1.4 dB into 50 ohm Antenna.

DSC/Telex:

85 W ± 1.4 dB

Output power 250 WSSB: ± 1.4 dB into 50 ohm Antenna.

DSC/Telex:

125 W ± 1.4 dB

Output power 500W SSB: 1.6-4 MHz 400 W PEP +0/-1.4 dB

4-27 MHz 500 W PEP ±1.4 dB into 50 ohm Antenna.

DSC/Telex:

250 W ± 1.4 dB

1.2.4 DSC Watch keeping receiver characteristics

General: Complies with ETSI 300338 and ETSI 301033.

Frequency range: Default set to D1 - 2187.5 KHz.

When scanning is enabled by option code it will default be D6 - 2-4-6-8 12-16 MHz.

Can be reduced to minimum 3 frequencies via the Service Interface.

Regarding further receiver characteristics refer to section 1.2.2.

1.2.5 Antenna Tuning Unit characteristics

Frequency range: 1.6 MHz - 27.5 MHz

Antenna requirements: 8-18 m wire and/or whip antenna

Antenna tuning: Fully automatic with no presetting

Tuning speed: 0.1 - 8 sec. (typical)

Power capability

150 W/250 W: 350 W PEP into 50 ohm antenna

500 W: 600 W PEP into 50 ohm antenna

Extreme operating

temperature: from -25°C to +55°C

Page 15

Chapter 1: General information

1-5

General information

98-144591-D

Technical data

1.2.6 DSC/Telex modem characteristics

DSC: DSC Equipment class: Class A

Protocols: ITU-R M. 493-13

Ship’s identity: 9-digit identity number

NMEA interface: According to IEC 61162-1

GLL, RMC, ZDA, GGA, GNS

TELEX: Protocols: ARQ, FEC and Selective FEC

Ship’s identity: 5- and/or 9-digit identity number

1.2.7 Dimensions and weight

Control Unit

6301/02/03: Width: 241 mm (9.5")

Height: 107 mm (4.2")

Depth: 99 mm (3.9")

Weight: 0.82 kg (1.8 lbs)

Transceiver Unit 150 W/250 W

6365/66/68: Width: 390 mm (15.3")

Height: 445 mm (17.5")

Depth: 127 mm (5")

Weight: 19 kg (41.9 lbs)

Transceiver Unit 500 W

6369: Width: 392 mm (15.4")

Height: 507 mm (20")

Depth: 217 mm (8.5")

Weight: 28 kg (61.7 lbs)

Antenna Tuning Unit 150 W/250 W

6384: Width: 290 mm (11.4")

Height: 500 mm (19.7")

Depth: 80 mm (3.1")

Weight: 3.3 kg (7.3 lbs)

Antenna Tuning Unit 500 W

6383: Width: 401 mm (15.8")

Height: 617 mm (24.3")

Depth: 356 mm (14")

Weight: 17 kg (37.5 lbs)

Equipment category: Control Unit: Protected

Transceiver Unit: Protected

Antenna Tuning Unit: Exposed

(According to IEC60940)

Page 16

1-6

Chapter 1: General information 98-144591-D

Technical data

Page 17

2-1

Installation

Chapter 2: Installation

98-144591-D

Mounting the Units

Installation

2.1 Description

Correct installation of the equipment is important for maximum performance and reliability. Antennas

and ground connections must be installed with the greatest care using corrosion resistant materials.

Cable routing shall be made so that the cables are protected from physical damage. Sharp cable bends

especially on coaxial cables must be avoided and a suffi cient number of clips or straps should be used

to secure the cables.

2.2 Mounting the units

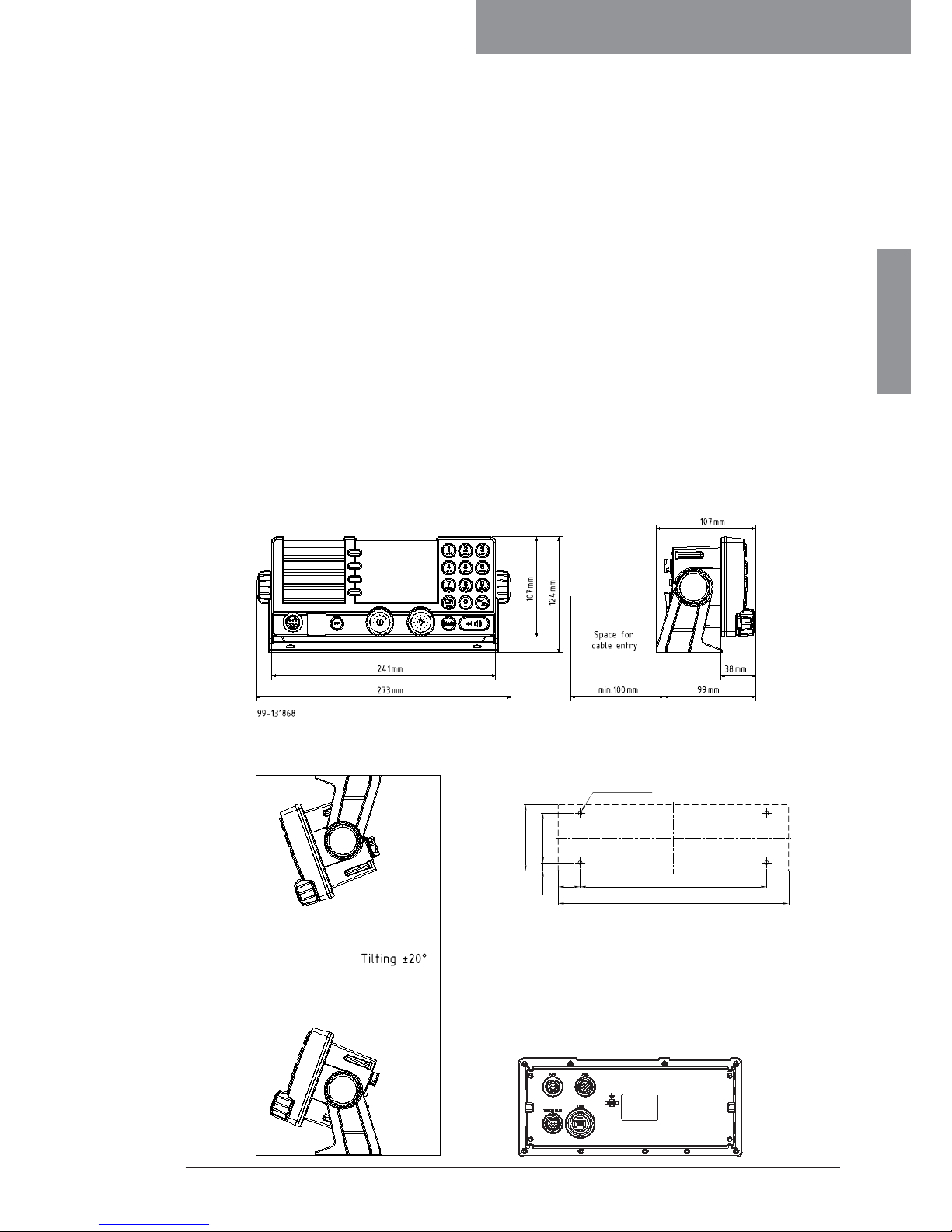

2.2.1 Mounting the Control Unit (CU)

One Control Unit can be connected to the Transceiver Unit using the cable supplied (CU-TU Bus). The CU

may be mounted up to 100 m from the Transceiver Unit using just a multicable 5 x 2 x 0.5 mm2 screened.

The Control Unit may be tabletop or bulkhead mounted.

Control Units with mounting bracket

Mounting option Drilling plan for bracket

Chapter 2

Control unit connector panel

Weight:

Control Unit 0.82 kg

Mounting Bracket 0.20 kg

200mm

53mm

71mm

247mm

9mm

4 x M4 or hole for

self-tapping ø3.9

23.5mm

Page 18

2-2

Chapter 2: Installation

98-144591-D

Mounting the Units

Control Units with fl ush mounting bracket

Drilling plan

Flush mount template

Remove material from shaded area only!

89mm

227mm

R2.5mm x 4

Weight:

Flush mount bracket 0.04 kg

WARNING:

Only use screws supplied with

mounting kit for attaching fl ush

mounting bracket to Control Unit.

Handset for Control Unit

This Handset has a hook-on/off function,

which is activated by a small magnet embedded

in the cradle.

The cradle must be installed as illustrated in

order to ensure the hook-on/off functionality

of the Handset.

75

62

226

* 120

min. 100

Space for handset access

Space for cable and handset cable

54

45

135

39655C

Drilling plan

Weight:

Handset for Control Unit 0.4 kg (0.02

lbs)

Dimensions are in mm

Page 19

2-3

Installation

Chapter 2: Installation

98-144591-D

Mounting the Units

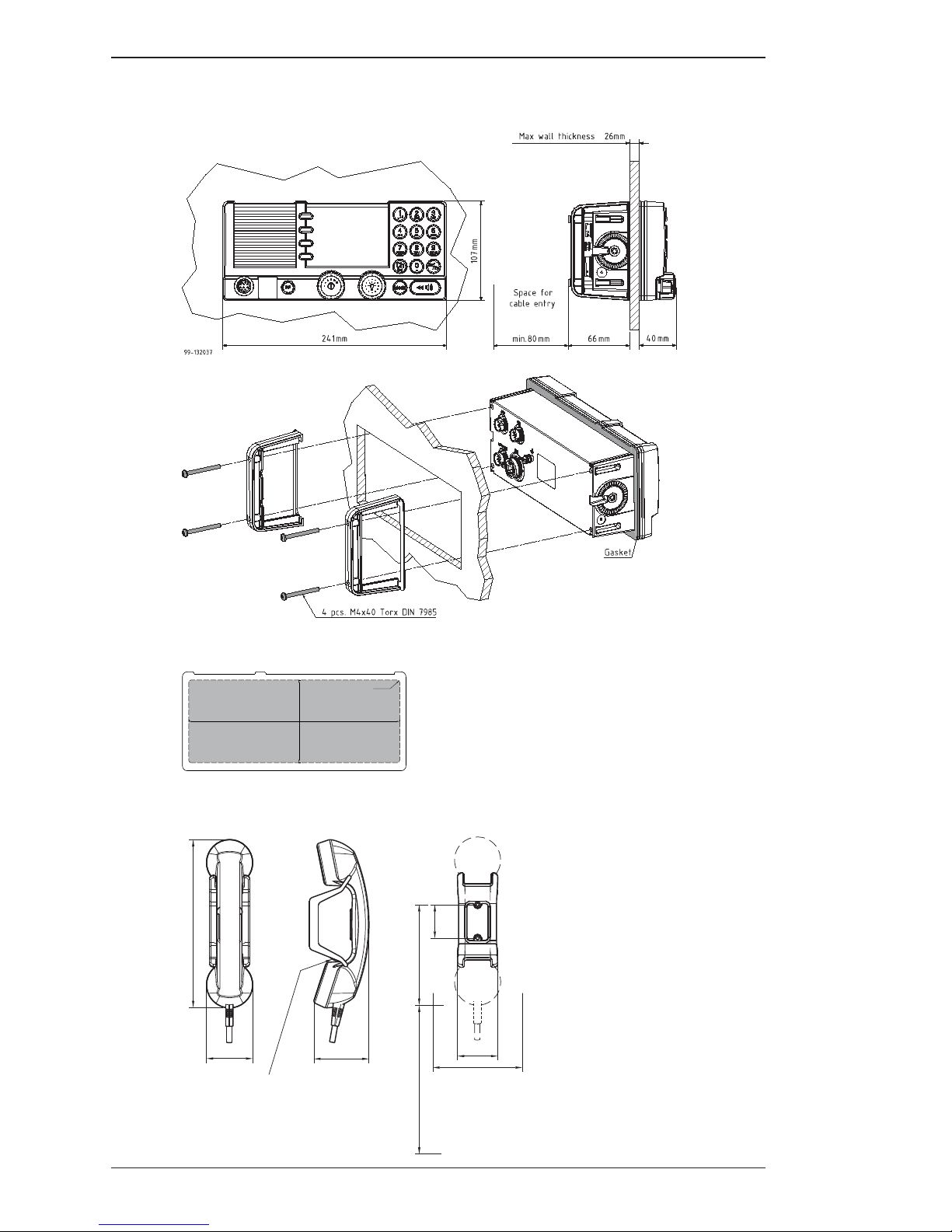

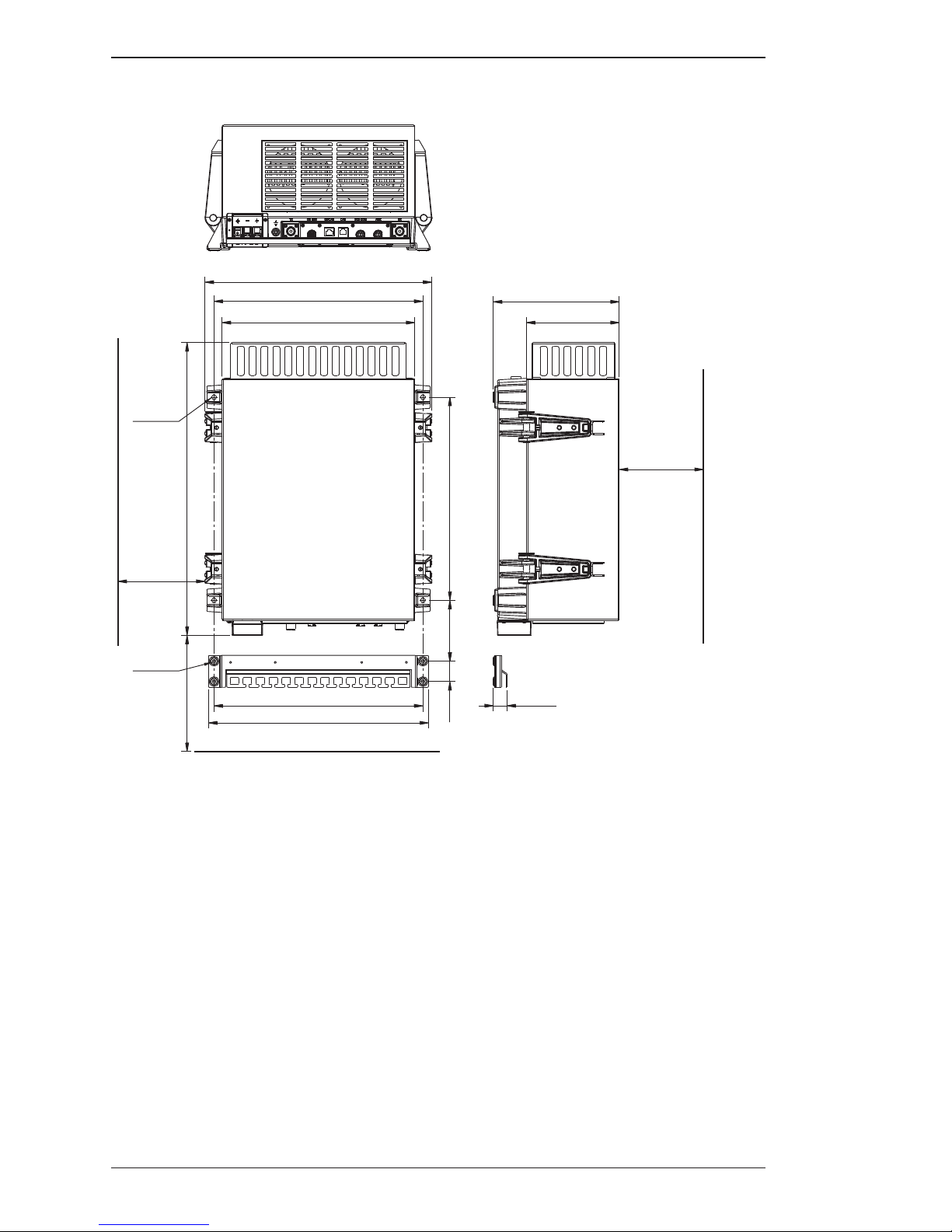

2.2.2 Mounting the Transceiver Unit (TU)

The Transceiver Unit should be installed in a dry place and consideration should be given to accessibility for servicing. It is important to provide suffi cient airspace below, above and in front of the unit

for adequate air circulation through the cooling fi ns. The drawing below shows the outer dimensions,

mounting possibilities and the minimum distance to other objects, as well as a drilling plan.

Transceiver Unit 150 W/250 W

105 mm 350mm

360 mm

391 mm

35 mm

150 mmMin.

379 mm

150 mmMin.

360 mm

Space for

cable access

Space for

service

4 x ø8mm

443 mm

4 x ø6mm

23.5 mm

88 mm

145 mm

500Min. mm

Space for airflow

and service

Page 20

2-4

Chapter 2: Installation

98-144591-D

Mounting the Units

Transceiver Unit 500 W

360 mm

379 mm

35 mm 105 mm 350 mm

150 mmMin.

200 mmMin.

360 mm

391 mm

332 mm

505 mm

Space for cable

and airflow

Space for

service access

Cable fitting

4 x ø8mm

4 x ø6mm

1000Min. mm

160 mm

217 mm

23.5 mm

Space for airflow

and service

Page 21

2-5

Installation

Chapter 2: Installation

98-144591-D

Mounting the Units

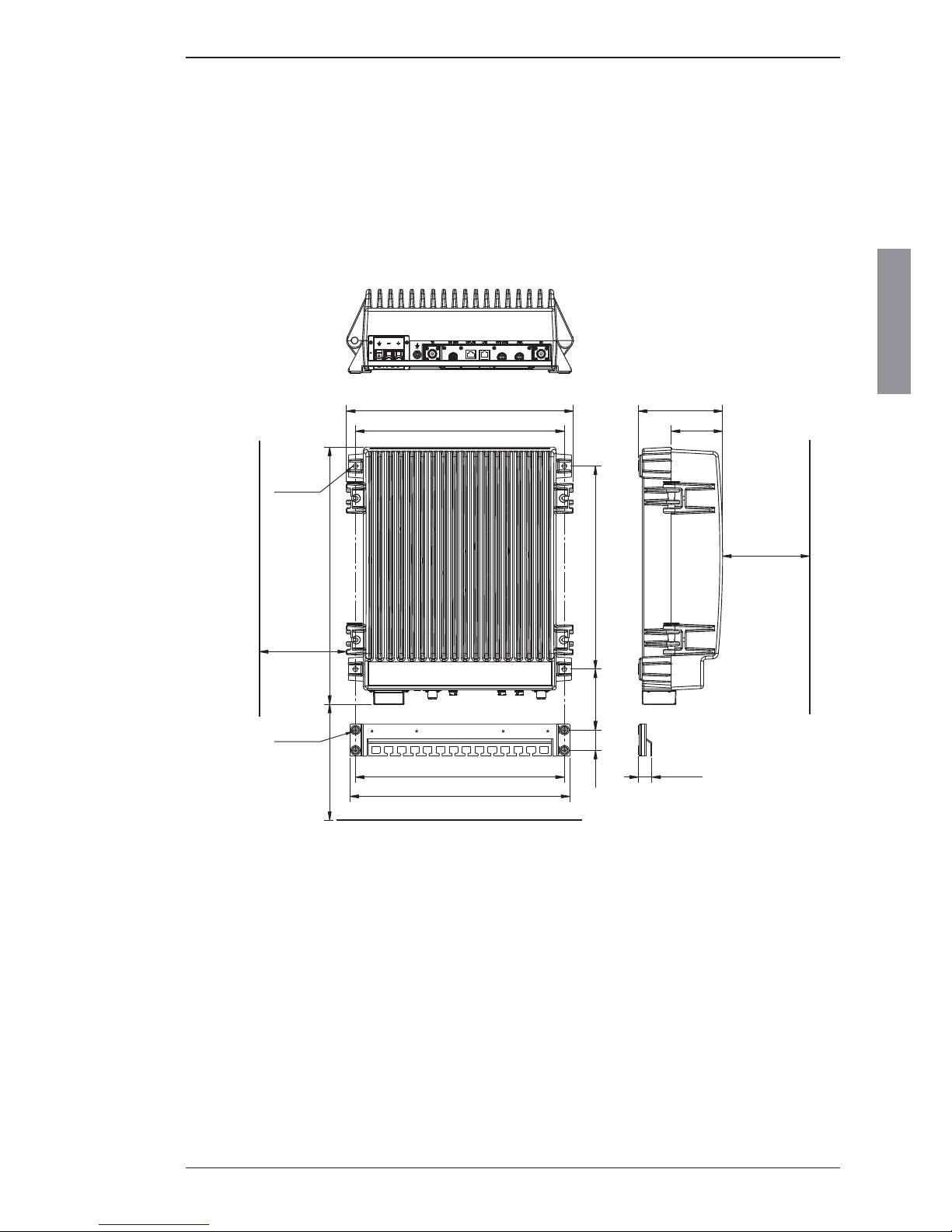

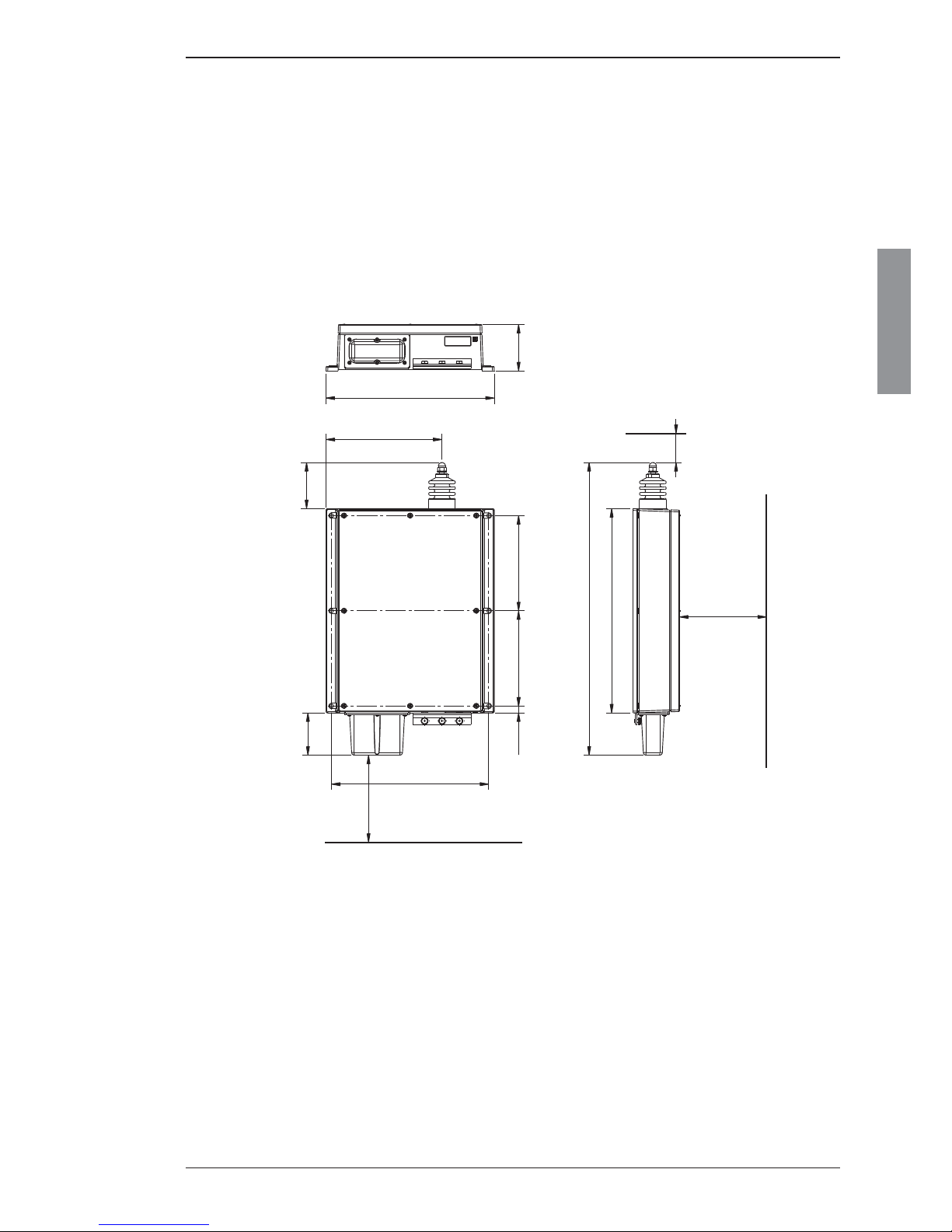

2.2.3 Mounting the Antenna Tuning Unit (ATU)

The ATU may be positioned up to 100 metres from the Transceiver Unit using just one RG-213/U or

better coaxial cable.

The ATU must be installed outside in a convenient position to have good access for suffi cient length

of feed wire to meet the antenna connection point. It is recommended that the ATU be installed vertically to allow any moist condensating inside the ATU to drain out through the rubber gasket along the

coax cable.

Antenna Tuning Unit 150 W/250 W

It is recommended to use the mounting bracket shown in section 2.2.4

Space for cable and

service access

164 mm 164mm

271 mm

150Min. mm

75 mm

12 mm

80 mm

200 mm

352 mm

504 mm

500Min. mm

50Min. mm

Space for

service access

Space to nearest overhang

80 mm

290 mm

Page 22

2-6

Chapter 2: Installation

98-144591-D

Mounting the Units

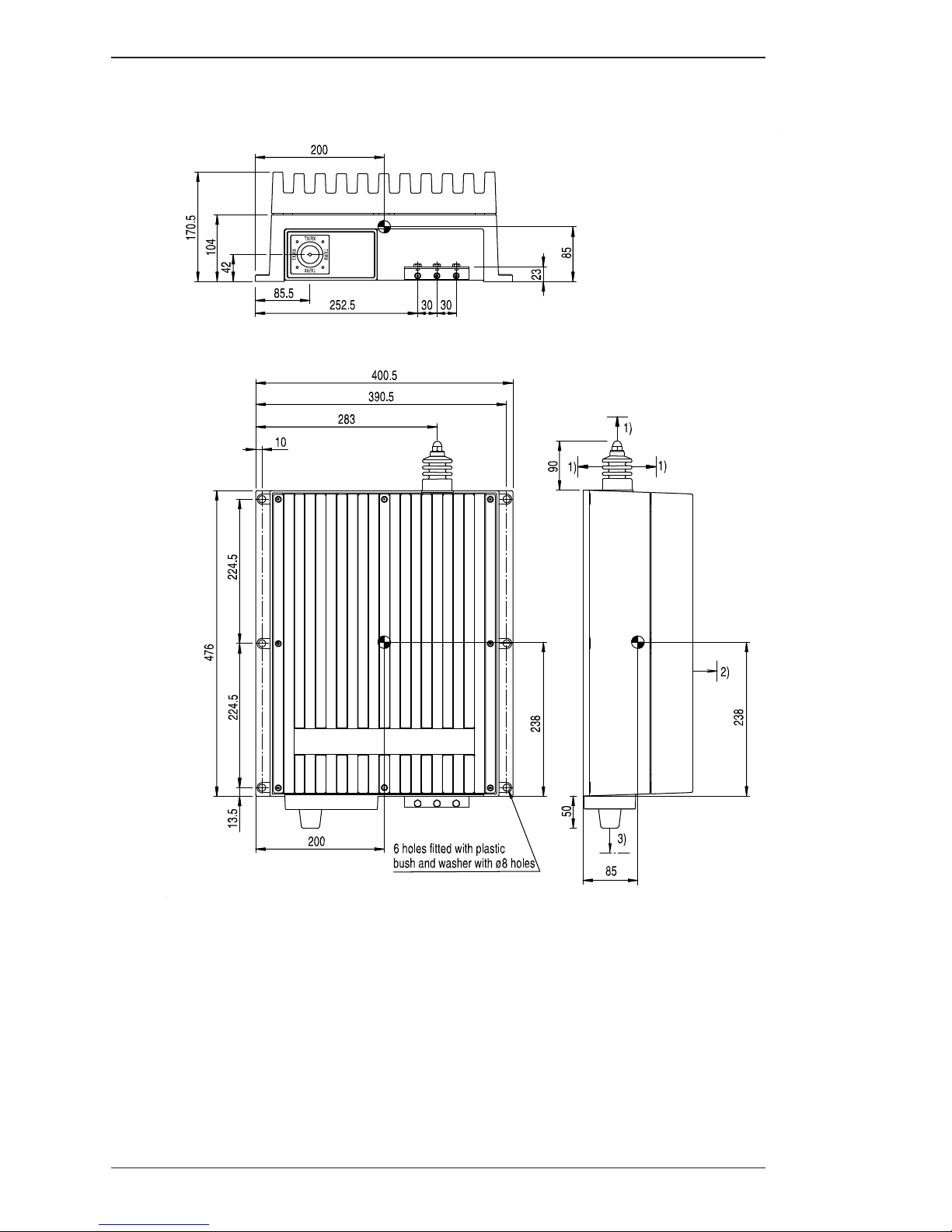

Antenna Tuning Unit 500 W

1) Distance to metal constructions: min. 150

2) Space for service access: min. 500

3) Space for cable and service access: min. 200

Dimensions are in mm

Tolerance: +/- 1 mm

Mounting hole: ø8

Weight: 17 Kg

4-0-32426

Page 23

2-7

Installation

Chapter 2: Installation

98-144591-D

Mounting the Units

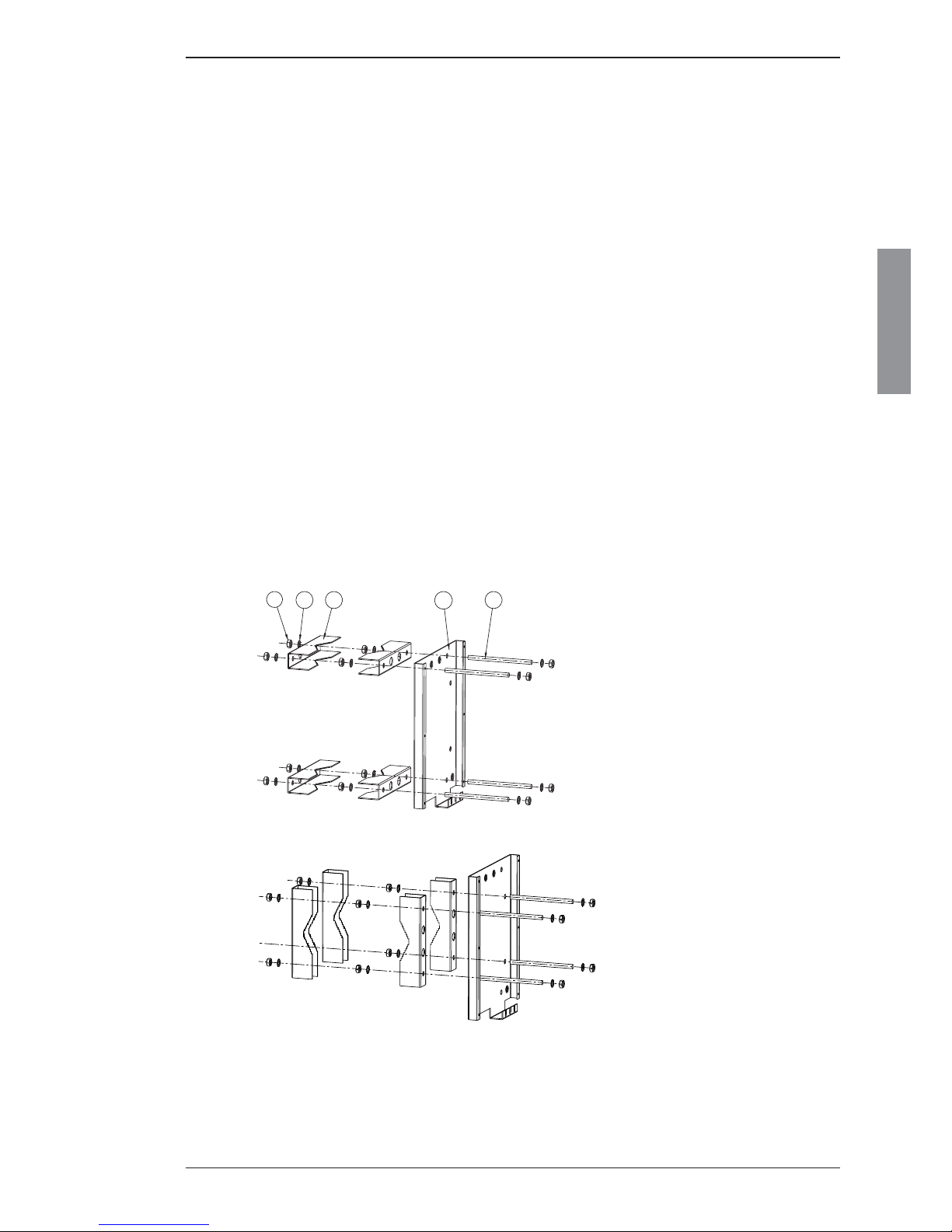

2.2.4 Recommended ATU installation

On a metal-hull vessel

Install the ATU using the ATU Mounting Kit. The kit is stainless steel which can be bolted or welded to

ship's hull to ensure good and solid connection as the radio system primary ground point.

The mounting kit will, at the same time ensure straight and fl at mounting surface for the ATU cabinet

and provide good airfl ow around the ATU for better heat dissipation.

On a wooden or fi breglass hull vessel

Install the ATU using the ATU Mounting Kit. The kit is made of stainless steel and may be bolted to ship’s

hull and serve as the ATU grounding point and the radio system’s primary ground point.

The ground-plane should preferably be provided by as wide a surface as possible with shortest possible

connection to the ATU grounding point.

The ground-plane may be establish in various ways such as e.g. through connecting all accessible metal

parts together and connecting to the ATU ground point.

ATU Mounting Kit

An optional ATU Mounting Kit as shown below is available in two versions:

1. Comprises mounting plate and fi ttings for mast - part no. 737589

For mounting the ATU directly on a mast, where the Mounting Plate and fi ttings for mast can form a

suffi cient earth connection on a steel mast welded to the superstructure.

2. Comprises the mounting plate only - part no. 737588

To get an even mounting surface on an uneven support.

1

3 5

4

2

1. Nut M10

2. Toothed lock washer M10

3. Fitting for mast

4. Mountingplate for ATU

5. Treadrod M10

Page 24

2-8

Chapter 2: Installation

98-144591-D

Mounting the Units

2.2.5 SAILOR 6208 Control Unit Connection Box

The SAILOR 6208 is used to convert the small cable dimension from preconfi gured cable plug to spring

loaded terminals with strain relief for connection to larger cable dimensions.

The box is used to connect the Transceiver Unit to Control Units and Message Terminal respectively.

The box is fi tted with optional 120 ohm CAN-BUS termination.

Weight:

SAILOR 6208 0.5 kg.

2.2.6 SAILOR 6209 Accessory Connection Box

The SAILOR 6209 is used to convert the small cable dimension from LTW plug to screw terminals with

strain relief for connection larger cable dimensions.

The box is used to connect the Transceiver Unit and /or the Control Unit to peripheral equipment e.g.

GPS, external loudspeaker etc.

4 pcs. ø5.50

100

100

26

11.00

77.70

7.50

82.70

Weight:

SAILOR 6209 0.4 kg.

Dimensions are in mm

The SAILOR 6208 and the SAILOR 6209 may be ordered as accessory. Please fi nd accessory list on the

last page of this manual.

Drilling Plan

Drilling Plan

Page 25

2-9

Installation

Chapter 2: Installation

98-144591-D

Grounding considerations

2.3 Ground connections

2.3.1 Grounding considerations

Proper system grounding is the most important installation detail for obtaining proper RF performance

of the MF/HF system.

Two areas of grounding must be considered:

a) The grounding connection between the ATU and grounding plane.

b) The grounding connection of the TU and the externally connected equipment.

Each area requires separate considerations even though they are interrelated. Ideally the Control Unit,

Transceiver Unit, Antenna Tuning Unit and the antenna ground-plane should all have the same RF

ground potential. Unfortunately this is seldomly achievable, but interference problems will be reduced

proportionately to how close to this "ideal" situation the actual grounding of the installation is achieved.

Ground loops may cause problems with heavy interference in an installation. A ground loop is caused

by more than one ground path being present for a given unit. This will introduce circulating RF currents

which may cause malfunction of other equipment onboard the ship as well as a “hot” handset.

ATU

TU

CU

'Hot' Handset

RF current loop

Ground-Plane

Not OK installation

Zg

2.3.2 RF ground loop

It is not always possible or practical to install the ATU so as to allow for a very short connection to the

actual ground-plane. In such a case the coaxial cable connecting the ATU and the TU each with a different ground potential, will cause RF loop currents to fl ow.

ATU

TU

CU

Not OK installation

coaxial cable

RF current loop

Ground-Plane

Zg

Vg = Iant x Zg

Page 26

2-10

Chapter 2: Installation

98-144591-D

Grounding connections

2.3.3 Minimizing ground loops

By routing the coax cable very close together with the ATU grounding strap (i.e. secure good RF coupling between the two) all the way down to the ground-plane, there will be no RF ground loop left to

generate any interference.

ATU

TU

CU

coaxial cable

Ground-Plane

OK installation

Zg

Vg = Iant x Zg

2.3.4 Antenna start

The vertical antenna always "starts" at its electrical ground-plane, whether or not it is physically mounted

there. First determine the antenna’s electrical ground-plane, which is where the ATU should preferrably

be installed. Where possible always take the ATU to the ground, not the ground to the ATU.

In case of a fi breglass boat, the ground-plane may well be at the hull grounding terminal. Then this will

be where the antenna actually "starts" and hence where the ATU preferrably should be installed.

ATU

TU

CU

OK installation

Not a 'Hot' Handset

Ground-Plane

The antenna starts here

2.3.5 Antenna Tuning Unit

It is of the utmost importance that the ATU grounding connection provides the lowest possible RFimpedance. Losses in the ground connection will result in a decrease in radiated power which means

that the range of the transmitter will be reduced.

For ATU grounding in steel ships a 100 x 0.5 mm copper strap is connected between the ground terminal

at the bottom of the Antenna Tuning Unit and the Antenna Mounting Kit welded to the superstructure

or, if not using the ATU Mounting Kit then to two or three ½" or M12 bolts welded to the superstructure.

The length of this copper grounding strap should be kept as short as possible within app. 0.5 m in order

to ensure that its RF impedance remains within reasonable limits.

Page 27

2-11

Installation

Chapter 2: Installation

98-144591-D

In case the described copper strap material should not be readily available, a corresponding length of

a 3-conductor cable of minimum 25mm² (AWG 3) stranded conductor cross sectional area may be

used as illustrated below. This illustration further shows how shielding of the grounding connection to

reduce RF radiation from the ground leads may be achieved, if required, by grounding the cable shield

at the ATU end only.

Shielded ground downlead

It is recommended to install the ATU by means of the ATU mounting bracket shown in section 2.2.4

as this stainless steel bracket can be welded to the super structure and will provide the best possible

none corroding ground connection.

On ships constructed of non-conductive material such as wood or fi berglass other means of establishing

a ground plane must be found, such as an external copper ground plate below the water line (e.g. a

standard Dynaplate) or utilizing existing internal steel framing or e.g. connecting all accessible metal

parts together and use this a ground-plane.

As stated in paragraph 2.3.4 it is important that ground loops be minimized by taking the ATU to the

ground rather than taking the ground to the ATU. However, it should not be attempted to install the

ATU indoors as this would result in a need to pass the antenna feed wiring through deck and/or bulkhead

feedthroughs etc. having severe impact on the RF performance, not to mention the RF fi elds generated

around the feed wiring causing problems in other installations and equipment.

Grounding connections

Copper strap 100 x 0.5mm

Dimensions are in mm.

20

50

80

6

6.6

R3.3

Copper strap cut-out at the ATU end

L <~0.5m

L <

~

0.5m

Page 28

2-12

Chapter 2: Installation

98-144591-D

In situations where the grounding connection of the ATU/antenna system cannot be kept within the

indicated length limit, fi nding workable alternative means of grounding through e.g. a longer grounding

connection between the ground-plane and the ATU, may require trial and error methods to be applied

in order to fi nd a workable solution. It is important here to keep in mind the initial statement of this

paragraph saying that the longer the grounding connection, the higher the RF impedance of this and

consequently the RF loss, resulting in less power radiated from the antenna.

It should also be noted that, as no two situations are alike, having found a workable solution for one

situation this may not necessarily prove workable for another.

2.3.6 Transceiver Unit and Control Unit

The Transceiver Unit is preferably grounded

separately to the ships metal in the shortest

possible way. A 10mm² (AWG 7) to 16mm²

(AWG 5) ground wire is connected to the

ground terminal (cable clamp) at the bottom of the unit.

Grounding connections

11mm

ø5.4mm

crimp

wire

Page 29

2-13

Installation

Chapter 2: Installation

98-144591-D

Antennas

2.4 Antennas

With the SAILOR 6000B-series MF/HF a two-antenna confi guration is introduced which

implies that SSB, DSC and Telex reception all take place using a separate RX antenna, as

opposed to previous SAILOR MF/HF systems (SAILOR 6000A-, SAILOR 5000-, SAILOR

4000- and SAILOR 2000-series) in which SSB reception takes place using a common

TX/RX antenna.

The fact that SSB reception in the SAILOR 6000B-series takes place using a separate RX antenna implies

that the same considerations that were given to selecting the proper position of the combined RX/TX

antenna in previous systems, must be given to the position of both the RX and TX antenna in a SAILOR

6000B MF/HF system installation.

2.4.1 Transmitter Antenna

The transmitter antenna should be erected in the open, away from conducting object such as derricks

etc. which may cause reduction of the radiated power. Insulators used should be of the best type having low leakage even when wet. Stays, wires, steel masts etc. should be either effectively grounded or

insulated. The antenna should also be

kept as far away as possible from electrical equipment in order to minimize

noise. Electrical installations such as

cable braiding (screens) and instruments in the vicinity of the antenna

should be grounded effectively, and

the instruments in question should be

fi tted

with noise-interference suppression

devices, effective in the range 0.1 MHz

to

30 MHz to avoid malfunction of these

instruments. The Antenna Tuning Unit

will tune on any frequency in the range

1.6 to 27 MHz to good whip and/or

wire installations of 12 to 18 m total

electrical length.

Shorter antennas, total electrical length

down to 8 m, can be used. Where possible longer antennas should be installed

to maximize the radiated power in the

lower frequency bands.

In general a recommended 12 m antenna

installation can be made up using an 8 m

whip and 4.5 m feeder or a 10 m whip

and 2.5 m feeder. In both cases the whip

should be mounted on a pole allowing for

the feeder to be erected at an angle of no

less than 45-60 degrees to create a vertical antenna system. Using horizontal

feeders or feeders mounted at an angle

below 45 degrees usually transform the

antenna radiation resistance to a lower

value reducing the radiated power. The total antenna system should be kept well away from conductive

objects such as the mast, stays, wires etc. a horizontal distance of 6-8 m should be aimed at.

The antenna is terminated at the insulator at the top of the Antenna Tuning Unit. The insulator must be

relieved from mechanical stress by using max. 1 meter fl exible wire between the insulator and a support.

To maximize the radiated power and avoid fl ash over keep distance to metal parts as long as possible.

All wire junctions in the antenna system must be made with cable lugs of correct size according to the

wire gauge. This will prevent bad connections due to corrosion. For further corrosion proofi ng grease

may be applied to the cable joints.

(illustration refers to

the KUM803-1 antenna)

>45°

>1 meter

Insulator

Strain relieving insulator

Feed wire

ATU

Page 30

2-14

Chapter 2: Installation

98-144591-D

Antennas

2.4.2 Considerations on antenna length requirements

Antenna impedance

The length of the transmitting antenna used with MF/HF equipment in general and the MF/HF equipment specifi cally for purpose of this discussion is of utmost importance for the proper performance of

the equipment, i.e. the ability to tune properly to the antenna and the effective transmission range. In

terms of transmission range, more important than increasing the transmitter RF output power from say

150 W to 250 W is in fact the use of an adequate length antenna.

Comparatively, any practical length whip antenna remains too short for the wavelength for which it is

used, especially at the lower frequencies. For the frequency range 1.6 – 30 MHz defi ning the commercial

MF/HF marine band, the wavelength spans the range 190 – 10 m approximately.

A proper ground-plane for the TX antenna is essential in order for this to effectively radiate power

into the air. An RF transmitter connected directly to a whip antenna which is in the presence of the

ground-plane, looks into an impedance between the whip antenna and the ground-plane which varies

considerably with frequency and hence would cause varying load on the transmitter power amplifi er.

As an illustration of the typical impedance variation versus frequency of a whip antenna refer to below

fi gure.

1.6

3.2 6.4 12.8 25.6

Imp. (ohm)

Freq. (MHz)

1000

500

Typical impedance variation versus frequency for an 8m whip antenna with 4 m feed wire

Function of the Antenna Tuning Unit (ATU)

The MF/HF transmitter power amplifi er (PA) provides a fi xed output impedance of 50 ohms over its

operating frequency range to which the load (the antenna) should be matched (i.e. load should preferably be 50 ohms also) in order for the transmitter to deliver its full power output to the load. However,

with the varying impedance of an antenna, as described above such conditions will not be met . On the

remaining frequencies within the transmission band the varying mismatch between the transmitter

fi xed output impedance and the different impedance of the antenna at any given frequency, will result

in reduced RF power delivered to the antenna – in worst case hardly any power at all - if the antenna

was connected directly to the transmitter.

To overcome the frequency dependant mismatch between the transmitter output impedance and the

antenna (load) impedance, the ATU is put into the antenna circuit to provide variable compensation

counteracting the varying impedance of the antenna, the end result of which is the “transformation” of

this into a “fi xed” app. 50ohms load, as seen from the transmitter.

Ground-plane

Capacity C

Whip antenna

Page 31

2-15

Installation

Chapter 2: Installation

98-144591-D

The required compensation is achieved through insertion of the correct combination of inductors

and capacitors in series with the antenna to form a resonance circuit at the given frequency. Hence,

depending on the impedance of the antenna (i.e. the transmission frequency) a suitable combination

of inductors and capacitors are put in-circuit through a number of relays, all controlled by the ATU

processor during the tuning process.

C1 C2

L

Rg = 50ohm

TX out

Antenna tuning

unit

Transmitter

Antenna

Schematic illustration of the insertion of ATU compensation circuitry

MF/HF ATU

The 6000-series ATUs will easily tune to the varying impedance of an 8 m whip antenna with a properly

installed 4 m feed wire, over the operating frequency range 0.15 – 30 MHz. A slightly shorter antenna

system might be used at the possible sacrifi ce of the ability to tune at the extreme low end of the

frequency band below 2 MHz.

However, the impedance of the antenna system is infl uenced by any nearby metallic objects such as

the vessel's superstructure and/or nearby metal poles/masts or stays/wires. Consequently, in order not

to alter the impedance of the antenna system which may eventually cause diffi culties for the ATU to

match the resulting impedance, the transmitting antenna should be kept at a distance of no less than

6-8 m from any such objects. Similarly goes for the feed wire connecting the ATU to the antenna which

should be kept at a minimum of 1 m from metallic objects.

It should be noted that even though the ATU will tune to the mentioned antenna system length, the

effective radiated power (i.e. the effi ciency of the antenna) in the low frequency end may suffer com-

pared to longer antenna systems of recommended electrical length 10-18 m.

Electrical connection of transmitting antennas

The connection to the transmitting antenna is by a single ended wire - the feed wire - connecting from

the ATU insulator (see fi gure on page 2-12). This feed wire adds to the electrical length of the antenna

(when correctly installed), thus in effect increasing the effi ciency of the antenna. The longer the feed wire

the better the effi ciency of the antenna system consisting of transmitting antenna and the feed wire.

For direct addition of feed wire length to antenna electrical length, the feed wire should be vertically

installed as an extension downwards of the transmitting antenna. In practice, where the ATU is placed

between the feed wire and the ground-plane (steel deck), the direct vertical installation of the feed wire

may be diffi cult in terms of total height. This may partly be accounted for by allowing the feed wire

installed at an angle of at least 45 degrees with the horizontal plane. Installing the feed wire at lower

angles will create capacitance to the ground-plane in turn decreasing the effi ciency of the antenna.

Antennas

Page 32

2-16

Chapter 2: Installation

98-144591-D

2.4.3 Receiver antenna

A passive type antenna is recommended as receiver

antenna. The antenna should be erected well in the

clear and kept away as far as possible from electrical

equipment to minimize noise interference. Electrical

installations such as cable braiding and instruments in the

vicinity of the antenna should be grounded effectively

and the instruments in question should be fi tted with

noise interference suppression devices effective in the

frequency range 0.1 to 30 MHz. The antenna feed-in

shall be by coaxial cable.

It is recommended to provide the installation with an

impedance matching transformer inserted at the antenna.

The matching transformer grounding cable should be

as short as possible and connected to ground through

welded bolt.

Recommended type of antenna is a 6 to 10 meter whip

antenna.

Passive RX antenna

TX antenna

Example of possible MF/HF antenna placements with a passive RX antenna.

Antennas

50-60 cm

Coaxial feed

Ground wire

Welded bolt

(illustration refers to

the KUM600-2 antenna)

Page 33

2-17

Installation

Chapter 2: Installation

98-144591-D

Antennas

In case a passive antenna for practical reasons cannot be installed, an active antenna may be used. It

is however, important to emphasize that an active antenna may decrease the receiving capabilities

through reduction in received signal level and receiver dynamic range.

It is of utmost importance for an active receiver antenna to work properly with the MF/HF system

that it be installed as high as at all possible with unobstructed horizontal view.

TX antanna

Active RX antenna

Example of possible MF/HF antenna placements with an active RX antenna.

Installation of any type of receiver antenna should be completed by verifying that the

receiving capability is adequate in applicable receiving modes (SSB, DSC, Telex).

In order to avoid any unnecessary decrease in receiving capabilities an active antenna used with the

SAILOR 6000B MF/HF systems should meet the following main requirements:

Electrical requirements

Operating frequency: 0.15 – 30 MHz

Output impedance: 50 Ω Ω

Noise fi gure: below 12 dB

Intermodulation: Reference signal 30 dBμV/m

Intermodulation level above 80 dBμV/m

Mechanical requirements

Length of the antenna element: 1.0 to 1.5m

Cobham have tested and recommends the AC Antennas KUM121 as a suitable choice.

Page 34

2-18

Chapter 2: Installation

98-144591-D

DC Power cabling

2.5 DC Power cabling

The supply leads are connected to the supply terminal of the Transceiver Unit. The supply terminal is

designed for 3 wire shielded power supply cable to meet international installation and EMC requirements.

The safety ground wire is connected to the terminal showing ground symbol and shielding connected

to the cable fi tting shown in page 2-3 must be well grounded to ships hull.

The earth connection of the equipment will not cause the battery to be earthed. Maximum permissible

peak voltage between the battery terminals and earth is 100 V.

Fusing must be provided in the supply leads for cable protection.

Cable lengths stated in tables are the total cable length from battery terminals via charger, shunt box,

DC distribution to TU DC-terminals.

Table below shows the necessary cable cross sections and external fuse ratings.

150 W/250 W

Max. cable length to

battery*

Recommended Cable

Sceened multiwire

External fuses

5 m 3 x 10 mm² (7 AWG) 40 A

8 m 3 x 16 mm² (5 AWG) 50 A

12 m 3 x 25 mm² (3 AWG) 63 A

500 W

Max. cable length to

battery*

Recommended cable

Sceened multiwire

External fuses

4 m 3 x 16 mm² (5 AWG) 100 A

6 m 3 x 25 mm² (3 AWG) 100 A

Page 35

2-19

Installation

Chapter 2: Installation

98-144591-D

Interconnection of units

2.6 Interconnection of units

Transceiver Unit connector panel

TX

CU BUS

CU LAN

LAN

SYS COM

AUX

RX

24V DC

Control Unit connector panel

TU-CU BUS

AUX

LAN

ACC

150 W/250 W Antenna Tuning Unit connector pane

500 W Antenna Tuning Unit connector panel

TX/RX

TX/RX

TX/RX

TX/RX

Page 36

2-20

Chapter 2: Installation

98-144591-D

Interconnection of units

99-130929_6300B

Control Unit

Transceiver Unit

Antenna

Tuning

Unit

Handset

ACC

AUX

TU-CU BUS

LAN

24VDC

RX TX

Loud

speaker

2182 Selc

(optional)

External

DSC

Alarms

(optional)

AC

Power Supply/

Battery

Charger

LTW

12

Female

RG-213/U

3

4

6

TX

inhibit

(optional)

1

10

13

2

5

7

13

Please check the accessory list to find recommended power products

)

*

**

Please check the accessory list to find recommended loudspeaker

Please note that for distance less than 25 m the system will work with 0.25 mm² instead of 0.5 mm²

)

TU-CU

GNDLAN

Message

Terminal

LTW

12

Female

LTW

10

Female

Keyboard

Printer

12

RJ45

8

GPS

(optional)

406209A

Handset/

Hand-

microphone

(Back)

Handset/

Hand-

microphone

(Front)

LTW

10

Female

14

GND

SYS COM

TX

RJ45

LTW

12

Female

LTW

10

Female

LTW

10

Female

PL259 PL259

Ethernet

Switch

Alarm

Panel

Data

Modem

(Remote

24V

Battery

GPS

RG-213/U

12

**

)

)

*

"Optional"

(optional)

(optional)

"Optional/Service"

406208A

Control Unit

Conn. Box

11

406208A

Control Unit

Conn. Box

406209A

Accessory

Conn. Box

8

***

)

optional)

12

12

***

)

***

)

406208A

Control Unit

Conn. Box

15

12

3a 3a

Please note power separately

Option

3a

Control Unit

AUX

406209A

Accessory

Conn. Box

9

RX Antenna TX Antenna

Page 37

2-21

Installation

Chapter 2: Installation

98-144591-D

Interconnection of units

Cable 1: Control Unit - ACC

Cable: 10 x LTW-UL2464 26AWG

Cable-connector: 10 way (ex. LTW)

5 m cable with connector supplied

Control

Unit

Designation Remarks Color

'ACC'

10 way

LTW

1 NMEA+ NMEA position input Brown

2 NMEA- NMEA position input Blue

3 2182 Select OC output. Low when 2182 kHz is selected White

4 NC No Connection Green

5 MIC Handset microphone Yellow

6 EAR Handset earpiece Grey

7 HOOK PTT Hook and PTT Pink

8 +12 V DC 12 V supply to handset Red

9 GND System ground Black

10 GND System ground Orange

Cable 2: Control Unit - Ground

Recommended wire dimension: min. 2.5 mm

2

(AWG 13) - Maximum length 0.2 m

Cable 3: Control Unit - Transceiver Unit

Cable: 12 x LTW-UL2464 20AWG

Cable-connector: 12 way (ex. LTW)

6 m cable with connectors supplied with equipment

Control

Unit

Transceiver

Unit

Tvisted

pair

Designation Remarks Color

'TU-CU

BUS'

12 way

LTW

'TU-CU

BUS'

12 way

LTW

1 1 a SHIELD Screen connected to system ground Brown

2 2 b GND System ground Blue

3 3 b +24 V Supply voltage for the Control Unit White

4 4 c CAN Vcc CAN supply (15 V DC) Green

5 5 d CAN H CAN data H Yellow

6 6 d CAN L CAN data L Grey

7 7 c CAN GND CAN ground Pink

8 8 a SUPPLY_ON

Supply on signal to the Transceiver Unit

Active when connected to GND

Red

9 9 e AUDIO IN+

Balanced Audio IN

Black

10 10 e AUDIO IN- Orange

11 11 f AUDIO OUT+

Balanced Audio OUT

Violet

12 12 f AUDIO OUT- Cyan

Page 38

2-22

Chapter 2: Installation

98-144591-D

Interconnection of units

Cable 3a: 2nd Control Unit - Transceiver Unit

If a 2nd control unit is installed, this can be done by splitting and extending the CAN bus, using e.g.

the 406208A control unit box.

Note that the CAN bus must be terminated with 120 Ohm in each end of the bus (not in the middle!).

The transceiver unit is terminated per default. Move Jumper W402 placed just inside the transceiver

unit, if termination is not needed in the place the transceiver is installed. In this case, termination

must added at both control units.

Cable 4: Transceiver Unit - TX Antenna

Cable: 50 ohm coaxial cable RG213/U (or better)

Maximum cable length 100 m

Cable-connector: UHF connector PL259, Crimp type connector should be used.

Cable 5: Transceiver Unit - Ground

Recommended wire dimension: min. 10 mm2 (AWG 7)

Maximum length 0.2 m

Cable 6: Transceiver Unit - RX Antenna

Type: 50 ohm coaxial cable RG213/U (or better)

Maximum cable length 100 m

Cable-connector: UHF connector PL259, Crimp type connector should be used.

Cable 7: Antenna Tuning Unit - Ground

Copper strap 100 x 0.5 mm or 3 x 25mm2 (AWG 3) shielded cable with wires and shielding connected

to ATU GND and shielding left open at the other end.

Refer to section ‘Ground Connections’

Cable 8: Control Unit – AUX

Cable: 12 x LTW-UL2464 20AWG

Cable-connector: 12 way (ex. LTW)

6 m cable with connector, available from eShop

Control

Unit

Designation

Cable

no.

Remarks Color

'AUX'

12 way

LTW

1 NC 10 No Connection Brown

2 NC 11 No Connection Blue

3 NC 11 No Connection White

4 NC 9 No Connection Green

5

OTHER DSC

ALARM

8 + 5 V Logic Level output, when active Yellow

6 NC 10 No Connection Grey

7 DISTRESS

ALARM

10 + 5 V Logic Level output, when active Pink

8 GND 9 System ground Red

9 SPEAKER OUT 8

External speaker (max. 6W in 8 ohm)

Black

10 NC 10

No Connection

Orange

11 NC 11

No Connection

Violet

12 NC 12

No Connection

Cyan

Page 39

2-23

Installation

Chapter 2: Installation

98-144591-D

Interconnection of units

Cable 9: Transceiver Unit - SYS COM

Cable: 10 x LTW-UL2464 26AWG

Cable-connector: 10 way (ex. LTW)

6 m cable with connector, available from eShop

Transceiver

Unit

Designation Remarks Color

'SYS CON'

10 way LTW

1 NMEA_IN+ NMEA position input Brown

2 NMEA_IN- NMEA position input Blue

3 GND System ground White

4 LINE_OUT

Single ended 600 ohms AF output

Nominal 0 dBm in 600 ohm

Refers to system ground (GND)

Green

5 LINE_IN

Single ended 600 ohms AF input

Nominal level 0 dBm

Refers to system ground (GND)

Yellow

6 TX_INHIBIT

Transmitter inhibit/RX mute input Pulled up to +15 V

Active when connected to GND

Grey

7 TX_KEYED

Low when TX keyed

OC output, max. 50 mA, 12 V

Pink

8 12V_OUT

+12 V output

Max. 50 mA

Red

9 EXT KEY

Transmitter key input. Pulled up to +15 V

Active when connected to GND

Black

10 GND System ground Orange

Cable 10: Transceiver Unit - AUX

Cable: 10 x LTW-UL2464 26AWG

Cable-connector: 10 way (ex. LTW)

6 m cable with connector, available from eShop

Transceiver

Unit

Designation Remarks Color

'AUX'

10 way LTW

1 NMEA_IN+ NMEA input Brown

2 NMEA_IN- NMEA input Blue

3 NMEA_OUT+

NMEA out

White

4 NMEA_OUT- NMEA out Green

5 Test_TX Reserved for factory test

Yellow

6 Test_RX Reserved for factory test

Grey

7 PPS+ 1 Hz Puls input for M.O. calibration

Pink

8 PPS- 1 Hz Puls input for M.O. calibration

Red

9 AC_ALR Supply Alarm input, active low

Black

10 GND GND

Orange

Page 40

2-24

Chapter 2: Installation

98-144591-D

Interconnection of units

Cable 11: Message Terminal

Cable: Shielded high quality USB-cable

Maximum cable length 1 m

Cable 12: Ethernet

Cable: STP/FTP CAT-5E or better

Maximum cable length 100 m

Cable 13: Transceiver Unit – 24 V Battery

For power cable information see section 2.6 DC Power Cabling

Cable 14: Message terminal

Cable: 5 x LTW-UL2464 24AWG

5 m cable supplied with Telex option kit

Message

terminal

Designation Remarks Color

SAILOR 6208

Control Unit

Connecton Box

'NMEA'

5 way LTW

Pin number

1 System GND GND 1

2 CAN S CAN Vcc Red 4

3 CAN C

CAN GND

Black 7

4 CAN H CAN H White 5

5 CAN L CAN L Blue 6

Cable 15: Control Unit - Transceiver Unit

Maximum cable length 100 m

For extended cable length, use shielded twisted pair cable 6x2x0.5mm2 (AWG 20) or better

For connection details refer to wiring table for cable 3.

Page 41

2-25

Installation

Chapter 2: Installation

98-144591-D

Position and time information

2.7 Position and time information

2.7.1 Connection of Navigation Equipment

Navigation equipment complying with the NMEA 0183/IEC 61162-1 standard may be connected for

automatic position and time updating. Connection is made to the NMEA+/NMEA- connections in the

Control Unit ACC connector or the NMEA+/NMEA- connections in the Transceiver Unit AUX or SYSCON

connector.

The NMEA receive circuit consists of an optoisolator with a 470 ohms series resistor to insure current

mode operation and a shunt diode to limit reverse bias as shown below. The circuit is isolated from ground.

NMEA IN -

NMEA IN +

A

B

The circuit operates with a minimum

differential input voltage of 2 volts

and draws less than 2 mA from the

line at that voltage. The maximum

voltage is 15 volts.

Interconnection between devices may be by means of two-conductor shielded twisted-pair cable.

Multiple listeners may be connected to a single talker. The receivers are connected in parallel. The shield

should be connected to the navigator chassis and should not be connected at any listener. However the

shield should be continuous (unbroken) between all listeners.

Supported sentences:

GLL (longitude, lattitude, utc, status, mode)

GGA (longitide, lattitude, utc, quality )

RMC (longitude, lattitude, utc, status, mode)

GNS (longitude, lattitude, utc, mode)

ZDA (utc, day, month, year)

Only the mentioned fi elds are used - the rest are discarded.

NMEA data on the LAN-connection is also accepted. This data should comply with IEC 61162-450.

Page 42

2-26

Chapter 2: Installation

98-144591-D

Telex operation

2.8 Telex operation

The GMDSS Radiotelex Terminal is designed in accordance with relevant IMO, ITU and ETSI recommendation/specifi cations and has been approved for shipboard installations to be operating within the

Global Maritime Distress and Safety System.

It supports world-wide ship-to-ship, shore-to-ship and ship-to-shore communication by utilizing the

radiotelex protocols described in ITU-R M.625. In case of two-way communication an ARQ (Automatic

Repetition reQuest) algorithm is used, and when broadcasting FEC (Forward Error Correction) is used.

TT-6209A

Accessory

Connection Box

TT-6209A

Accessory

Connection Box

DGNSS Receiver

TT-6588A

DGNSS Receiver

TT-6588A

Unit

Antenna Tuning

Transmitter Antenna

Handset

TT-638xB

Message Terminal

DSC Watch receiver

250W MF/HF with 6 ch. Scanning

TT-636xB

(Optional)

Keyboard

MF/HF Control Unit

TT-6301A

Alarm Panel

TT- 6103A

Ethernet Switch

TT-6197A

Handset

GPS option

2182 select option

TT-6270A

Power Supply

TT-608xA

Connection Box

Control Unit

Distress Alarm

Other Alarm

TT-6201A

Transceiver Unit

TT-6201A

TT-6208A

TT-6001A

TT-6018A / TT- 6006A

(Optional)

Receiver Antenna

GPS on LAN option

Optional connection

TT-6286A

DGNSS Antenna - Active

TT-6286A

DGNSS Antenna - Active

Telex option

Printer

H1252B

Page 43

2-27

Installation

Chapter 2: Installation

98-144591-D

ID programming

2.9 ID programming

2.9.1 Front Panel

1. Loudspeaker.

2. Four soft keys with function title in the display.

3. Large TFT color display.

4. Alphanumerical keys to enter Rx or Tx frequency or text strings.

5. CH button for channel selection.

6. Rx/Tx Key to enter Tx or RX frequency.

7. Connector for handset or handmicrophone.

8. Distress button for sending a Distress alert.

9. RF gain control (IF).

10. Volume knob with key-press function for power on/off.

11. Selector and dim knob with key-press function for radio operation and setup.

12. Mode key to select the work mode: SSB, AM Broadcast, DSC, Telex.

13. Replay button to play back up to 240 s voice messages.

Page 44

2-28

Chapter 2: Installation

98-144591-D

ID programming

2.9.2 Setup Menu

Menu items shown in bold is only available in the menu structure when it is extended by access password

>1-2-3-4-5< in the System Setup menu.

Setup Menu

Soft keys (2) Radio setup Scan Hang Time

Scan Resume

Scan Mode

External PTT

LSB Mode: OFF

ATU: Enabled

TX AM 2182: Disabled

1 x > Channel Setup Watch Receiver

Privat Channels

DSC Watch

TX Band

2 x > Power Supply Monitor: OFF

3 x > DSC Setup Position & MMSI

DSC Groups

Auto- Ack Test

Auto-Ack Polling

Auto-Ack Position

Auto-Ack Individual

Non-Distr. Inactivity

Distress Inactivity

Comm. Inactivity

Non-Distr. Alarms

Self-Term. Distr. Alarms

Medical Transport

Neutral Crafts

Print DSC

DSC self-test

4 x > DSC Call Logs Received Distress

Transmitted Calls

Received Calls

5 x > System Setup Printer Confi guration

System Time & Date

Inactivity Timeout

Language

Theme

GPS Input

NMEA in

LWE Talkers

LWE Identity

Factory Defaults

Password

Reset MMSI no

Radio Info

6 x > Controller Setup Handset 1 Vol

Handset 2 Vol

Wheel Lock

High Priority

Controller info

Page 45

2-29

Installation

Chapter 2: Installation

98-144591-D

ID programming

Setup Menu

7 x > Diagnostics Log

Self Test

ATU Status

8 x > System Confi g 6 Ch WR: Disabled

Telex: Disabled

2.9.3 Change / reset MMSI

MMSI no is requested at ‘fi rst time power up’ and directly programmed via the numeric keyboard (4)

If a MMSI reset or change of registration is needed it is accessed via the Setup Menu:

Operation Key Operation Function

Press 2 2 x More

2 Setup

2 5 x > System Setup

Scroll down to 11 Rotate Password

Select (press) 11

Key in 4 1-2-3-4-5

Scroll down to 11 Reset MMSI Number

Select (press) 11 Yes

Key in MMSI 4 9 digits 123456789

Page 46

2-30

Chapter 2: Installation

98-144591-D

Programming Telex ID

2.10 Programming Telex ID

Programming Telex ID is done via the in SAILOR 6018/6006 Message Terminal.

Requires that the Telex option has been enabled in the radio (see ‘Option Code Activation’) and TLX

mode selected on the Control Unit (12).

The MMSI (9 digits) is automatically transferred from radio to SAILOR 6018/6006 Message Terminal

when TLX mode is selected.

5 digit TLX call code and answerback is programmed on screen via the SAILOR 6018/6006 Message

terminal.

Operation Key Action

Press Settings

Identifi cation

Key in Pswd 1-2-3-4

Key in 5 digit call code (1-2-3-4-5)

Press Answer back

Key in* Answer back max 20 characters

Press OK

If a 5 digit TLX call code has not been issued or otherwise is not available, insert 5 x 2 (22222) to indicate invalid call code.

*

Step Action

1 Figure shift (FS)

2 Carriage return (CR)

3 Line feed (LF)

4 5 or 9 digit call ID

5 letter shift (LS)

Step Action

6 Space

7 Abbreviated ID

8 Space

9X

10 Letter shifts to obtain 20 characters

Page 47

2-31

Installation

Chapter 2: Installation

98-144591-D

Programming Telex ID

Figure Shift (FS), Letter Shift (LS), Carriage Return (CR) and Line Feed (LF) are normally not required

inserted in the answerback.

Page 48

2-32

Chapter 2: Installation

98-144591-D

Confi guration

2.11 Confi guration

The GMDSS approved radio is by default confi gured to meet the legislative requirements and restrictions.

Optional functionality may be confi gured and will normally require national exemptions to be utilized.

Confi guration and test facilities, which are considered ‘user facilities and basic settings’, are available

via the menu structure.

Further confi guration possibilities are available behind the access password >1-2-3-4-5< indicating that

any changes in this area will affect the system operation and therefore should be done with caution.

Other confi gurations considered installation features are accessed via the Service Interface.

Please refer to the '97-147768 – User manual SAILOR 6000B MF/HF Service Interface', available for

download at Cobham extranet.

2.11.1 CU confi guration

Priority setting is via the menu and Main CU is High Priority = ON and Slave CU is High Priority = OFF.

Operation Key Operation Function

Press 2 2 x More

2 Setup

2 3 x > Controller Setup

Scroll down to 11 Rotate High Priority

Select 11 Press

Select 11 Rotate High Priority = ON/OFF

Press 2 Exit To store

2.11.2 ATU confi guration

ATU is default enabled.

ATU enable/disable is confi gured via the Service Interface.

Only disable ATU when testing on 50 load or using a dedicated antenna matched for a certain frequency.

2.11.3 DSC printing ON/OFF

Operation Key Operation Function

Press 2 2 x More

2 Setup

2 3 x > DSC Setup

Scroll down to 11 Rotate Print DSC: OFF

Select 11 Press

Select 11 Select ON/OFF

LAN connected printer can now be selected to print DSC messages from the log. A SAILOR 6004 Control

Panel with printer is also accepted. Please check ‘2.12.4 DSC Printer Confi guration’ for setup.

Page 49

2-33

Installation

Chapter 2: Installation

98-144591-D

Confi guration

2.11.4 DSC Printer confi guration

Operation Key Operation Function

Press 2 2 x More

2 Setup

2 5 x > System Setup

Scroll down to 11 Rotate Printer confi guration

Select 11 Press

2.11.5 DSC self test

Menu Key Operation Function

3 x > 2 DSC setup

Scroll 11 DSC Self Test

Press 11 Select RUN

Press 11 To Activate

System start TX test With DSC call on 2187.5 kHz to own WR.

2.11.6 Factory default/reset

Factory default is a ‘User defi ned’ reset of settings and address books etc.

Operation Key Operation Function

Press 2 2 x More

2 Setup

2 5 x > System Setup

Scroll down to 11 Rotate Factory Default

Press 11 Select Continue Factory Reset

Select 2 Yes / No Factory Resetting

Please wait up to 30 sec.

System reboot and Control Unit connecting to radio.

2.11.7 Factory reset via service tool

Factory reset will bring all ID and confi guration settings in the radio system back to factory level as a

new system and is performed via the Service Interface or in the protected menu on the Control Unit.

Options already enabled in the system will remain activated. Resetting of options require separate

operation via the Service Interface.

2.11.8 LSB mode confi guration

LSB (Lower Side Band) mode is confi gured via the Service Interface or in the protected menu.

GMDSS radios require SSB operation in USB (Upper Side Band) mode and may only have LSB mode

enabled on a special exemption depending on national requirements where the ship is registered.

Radios installed and operated as ‘non-GMDSS radios’ can have LSB enabled.

Page 50

2-34

Chapter 2: Installation

98-144591-D

Confi guration

2.11.9 Option code activation

6-channel Watch Receiver and Telex functions are optional features and are thus disabled in the radio

as supplied from factory.

Both functions are enabled by inserting a unique 10 digit option code for each via the System Confi -

guration in the Setup menu:

Operation Key Operation Function

Press 2 2 x More

2 Setup

2 6 x > System confi guration

Select 11 6 CH WR Option Code

Key in DSC6 option code 2 xxxxxxxxxx Enabled

Scroll down to 11 TLX mode Option Code

Key in TLX option code 4 xxxxxxxxxx Enabled

The 10 digit option codes for 500 W systems are foc and supplied with equipment (not programmed).

The 10 digit option codes for 150 W/250 W systems may be ordered with the system or any time later.

DSC6 option code part number: 406300-006

TLX option code part number: 406300-001

DSC6 and TLX option codes are unique to each radio and generated on basis of the TU serial number

and locked to this.

Option codes already generated either through purchase or as factory supplied for the 500 W systems

may be looked up in the ‘Confi guration Key Search’ at www.cobham.com/satcom.

Options already enabled in a system will remain activated even after ‘Factory default’ and ‘Factory Reset’

operation. To disable these optional functions requires reset of the respective option code using the

Service Interface.

2.11.10 Power Supply monitoring

This item requires a SAILOR 6081A located on same LAN network segment as the TU.

Power Supply monitoring is by default set ‘OFF’ from factory.

When the Power Supply monitoring is set ‘ON’ the TU ‘Supply Alarm’ connector becomes active and

ready for interconnection to the Power Supply/Charger in order to monitor ‘AC Alarm’ and ‘Battery

High/Low Voltage Alarm’ states.

The Power Supply monitoring function meets the GMDSS requirements for AC fail and Battery voltage

alarms with acoustic and visual indication on the Control Unit.

Operation Key Operation Function

Press 2 2 x More

2 Setup

2 2 x > Power Supply

Select 11 Press Monitor

Scroll 11 Select Enabled/Disabled