Page 1

GR716-BOARD

Development Board

2019 User's Manual

The most important thing we build is trust

GR716-BOARD

Development Board

User's Manual

GR716-BOARD-UM, 2019, Version 0.1 www.cobham.com/gaisler

Page 2

GR716-BOARD

Intentionally Blank

GR716-BOARD-UM, May 2019, Version 0.1 2 www.cobham.com/gaisler

Page 3

GR716-BOARD

Table of Contents

1 Introduction......................................................................................................................5

1.1 Scope of the Document.......................................................................................5

1.2 Reference Documents..........................................................................................5

2 Abbreviations...................................................................................................................6

3 Introduction......................................................................................................................7

3.1 Overview.............................................................................................................7

3.2 Handling..............................................................................................................8

4 Board Design....................................................................................................................9

4.1 Board Block Diagram..........................................................................................9

4.2 Board Mechanical Configuration......................................................................10

4.3 GR716 Microcontroller.....................................................................................13

4.4 Memory.............................................................................................................14

4.5 LVDS Interfaces................................................................................................14

4.6 GPIO..................................................................................................................15

4.7 Bootstrap Signals...............................................................................................15

4.8 Debug Support Unit Interfaces..........................................................................16

4.9 Oscillators and Clock Inputs.............................................................................17

4.10 Power Supply and Voltage Regulation..............................................................18

4.11 Reset Circuit and Button...................................................................................21

4.12 Watchdog...........................................................................................................21

5 Setting Up and Using the Board...................................................................................22

6 Interfaces and Configuration.......................................................................................23

6.1 List of Connectors.............................................................................................23

6.2 List of Oscillators, Switches and LED's............................................................25

7 Change Record...............................................................................................................30

GR716-BOARD-UM, May 2019, Version 0.1 3 www.cobham.com/gaisler

Page 4

GR716-BOARD

List of Figures

Figure 3-1: GR716-BOARD Development Board...............................................................................7

Figure 4-1: GR716-BOARD Board Block Diagram............................................................................9

Figure .4-2: GR716-BOARD Board Dimensions..............................................................................10

Figure 4-3: GR716-BOARD mounted on a GR716-CPCI-DEV Carrier board.................................11

Figure 4-4: GR716-TEST-MEMORY BOARD.................................................................................12

Figure 4-5: GR716-TEST-ADCDAC BOARD..................................................................................12

Figure 4-6: GR716 Microcontroller Block Diagram..........................................................................13

Figure 4-7: GR716 Package...............................................................................................................13

Figure 4-8: SPI Boot Memory Connections.......................................................................................14

Figure 4-9: Debug Support Unit connections.....................................................................................16

Figure 4-10: GR716-DSU-USB Adapter............................................................................................16

Figure 4-11: Board level Clock Distribution Scheme........................................................................17

Figure 4-12: Power Regulation Scheme.............................................................................................19

Figure 4-13: Power Supply Configuration Jumpers...........................................................................20

Figure 6-1: PCB Top View.................................................................................................................26

Figure 6-2: PCB Bottom View...........................................................................................................27

Figure 6-3: PCB Top View (Photo)....................................................................................................28

Figure 7-1: PCB Bottom View (Photo)..............................................................................................29

List of Tables

Table 1: Bootstrap Resistor Settings...................................................................................................15

Table 2: List of Connectors................................................................................................................23

Table 3: J1 Screw Terminal Connector for Input Voltages.................................................................23

Table 4: J2 POWER – External Power Connector.............................................................................23

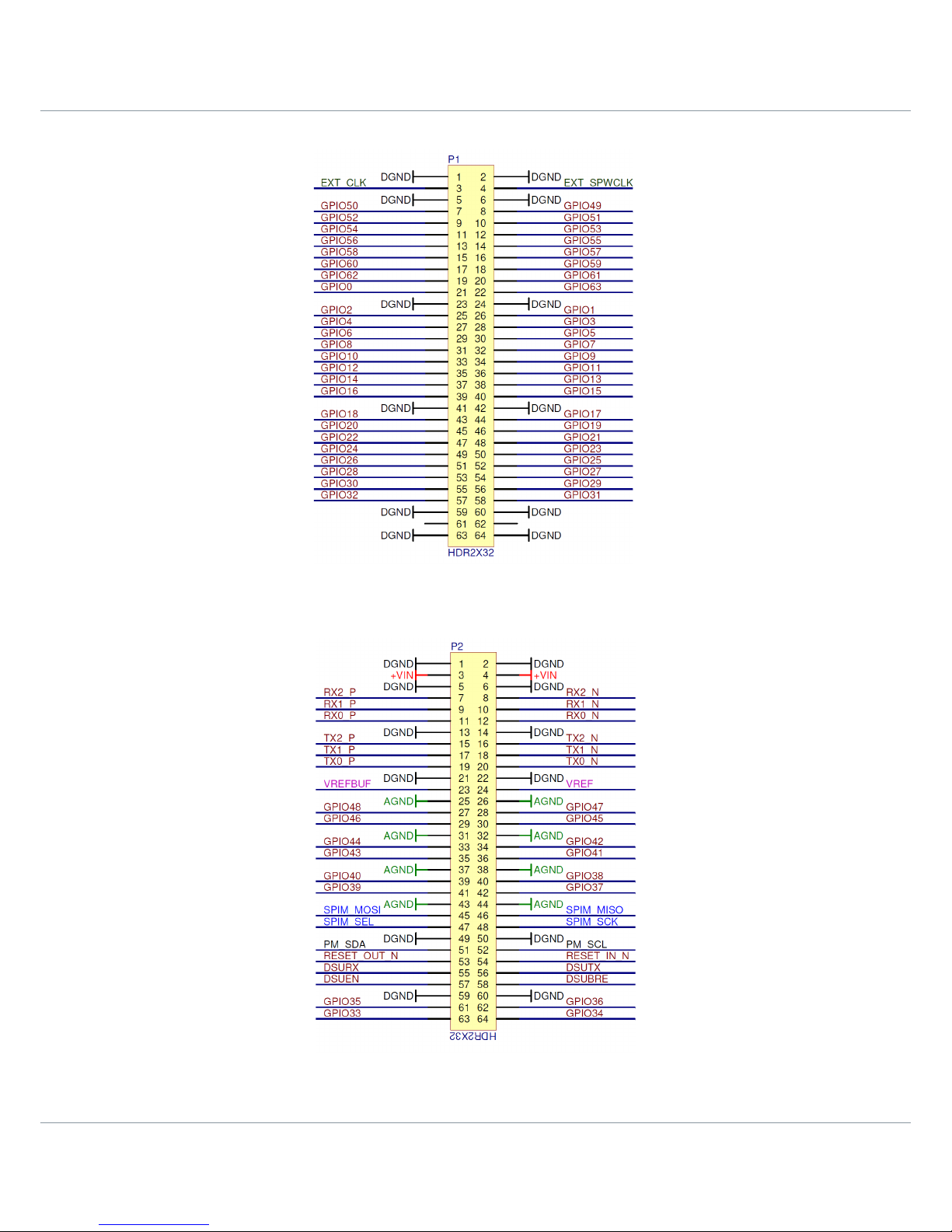

Table 5: Expansion connector P1 Pin-out...........................................................................................24

Table 6: Expansion connector P2Pin-out............................................................................................24

Table 7: List and definition of Oscillators and Crystals.....................................................................25

Table 8: List and definition of PCB mounted LED's..........................................................................25

Table 9: List and definition of Switches.............................................................................................25

Table 10: Definition of Switch S1 functions......................................................................................25

GR716-BOARD-UM, May 2019, Version 0.1 4 www.cobham.com/gaisler

Page 5

GR716-BOARD

1 Introduction

1.1 Scope of the Document

This document provides a User's Manual and Interface document for the “GR716BOARD” Development and Demonstration board.

The work has been performed by Cobham Gaisler AB, Göteborg, Sweden.

1.2 Reference Documents

[RD1] GR716, Data Sheet and User's Manual",Cobham Gaisler, GR716-UM-DS, available

from http://www.gaisler.com/index.php/products/components/GR716

[RD2] GR716-BOARD_schematic.pdf, Schematic

[RD3] GR716-BOARD_assy_drawing.pdf, Assembly Drawing

[RD4] GRMON3 User's Manual, available from:

https://www.gaisler.com/index.php/products/debug-tools/grmon3

GR716-BOARD-UM, May 2019, Version 0.1 5 www.cobham.com/gaisler

Page 6

GR716-BOARD

2 Abbreviations

ASIC Application Specific Integrated Circuit.

DSU Debug Support Unit

EDAC Error Detection and Correction

ESA European Space Agency

ESD Electro-Static Discharge

ESTEC European Space Research and Technology Center

GPIO General Purpose Input / Output

IC Integrated Circuit

I/O Input/Output

IP Intellectual Property

LDO Low Drop-Out

PCB Printed Circuit Board

POL Point of Load

SOC System On a Chip

SPW Spacewire

TBC To Be Confirmed

TBD To Be Defined

GR716-BOARD-UM, May 2019, Version 0.1 6 www.cobham.com/gaisler

Page 7

GR716-BOARD

3 Introduction

3.1 Overview

This document describes the GR716-BOARD Development Board.

This equipment is intended to be used as a platform for the demonstration of the

Cobham Gaisler GR716 RAD Hard Microcontroller.

Furthermore, this board provides developers with a convenient hardware platform for

the evaluation and development of software for the GR716 microcontroller.

The GR716 Microcontroller features a fault-tolerant LEON3 SPARC V8 processor,

communication interfaces and on-chip ADC, DAC, Power-on-Reset, Oscillator, Brownout detection, LVDS transceivers, regulators to support for single 3.3V supply, ideally

suited for space and other high-rel applications.

The GR716 Microcontroller is a complex device with multifunctional pins whose

function depend on the mode of operation and programming of internal registers of the

device. This board treats the pins in a generic manner to allow easy access to all the pins

and features of the GR716 microcontroller

GR716-BOARD-UM, May 2019, Version 0.1 7 www.cobham.com/gaisler

Figure 3-1: GR716-BOARD Development Board

Page 8

GR716-BOARD

The board contains the following main items as detailed in section 4 of this document:

• size 80 x 100mm

• two 2x32 pin stackable 0.1” headers allowing access to all I/O pins

• connector for single VIN power input (+5V to +12V)

• alternative connector for connections to individual device power supplies

• jumpers for power supply configuration

• on-board regulators converting from VIN to 3.3V & 1.8V

• 256 Mbit SPI memory (Cypress, S25FL256SAGN in 8 pin WSON package)

• socket for crystal (25MHz TBC)

• DIP switch for bootstrap settings

• on-board I2C voltage/current measurement

3.2 Handling

ATTENTION: OBSERVE PRECAUTIONS FOR

HANDLING ELECTROSTATIC SENSITIVE DEVICES

This unit contains sensitive electronic components which can be damaged by

Electrostatic Discharges (ESD). When handling or installing the unit observe

appropriate precautions and ESD safe practices.

When not in use, store the unit in an electrostatic protective container or bag.

When configuring the jumpers on the board, or connecting/disconnecting cables, ensure

that the unit is in an un-powered state.

When operating the board in a 'stand-alone' configuration, the power supply should be

current limited to prevent damage to the board or power supply in the event of an overcurrent situation.

This board is intended for commercial use and evaluation in a standard laboratory

environment, nominally, 20°C. All devices are standard commercial types, intended for

use over the standard commercial operating temperature range (0 to 70ºC).

GR716-BOARD-UM, May 2019, Version 0.1 8 www.cobham.com/gaisler

Page 9

GR716-BOARD

4 Board Design

4.1 Board Block Diagram

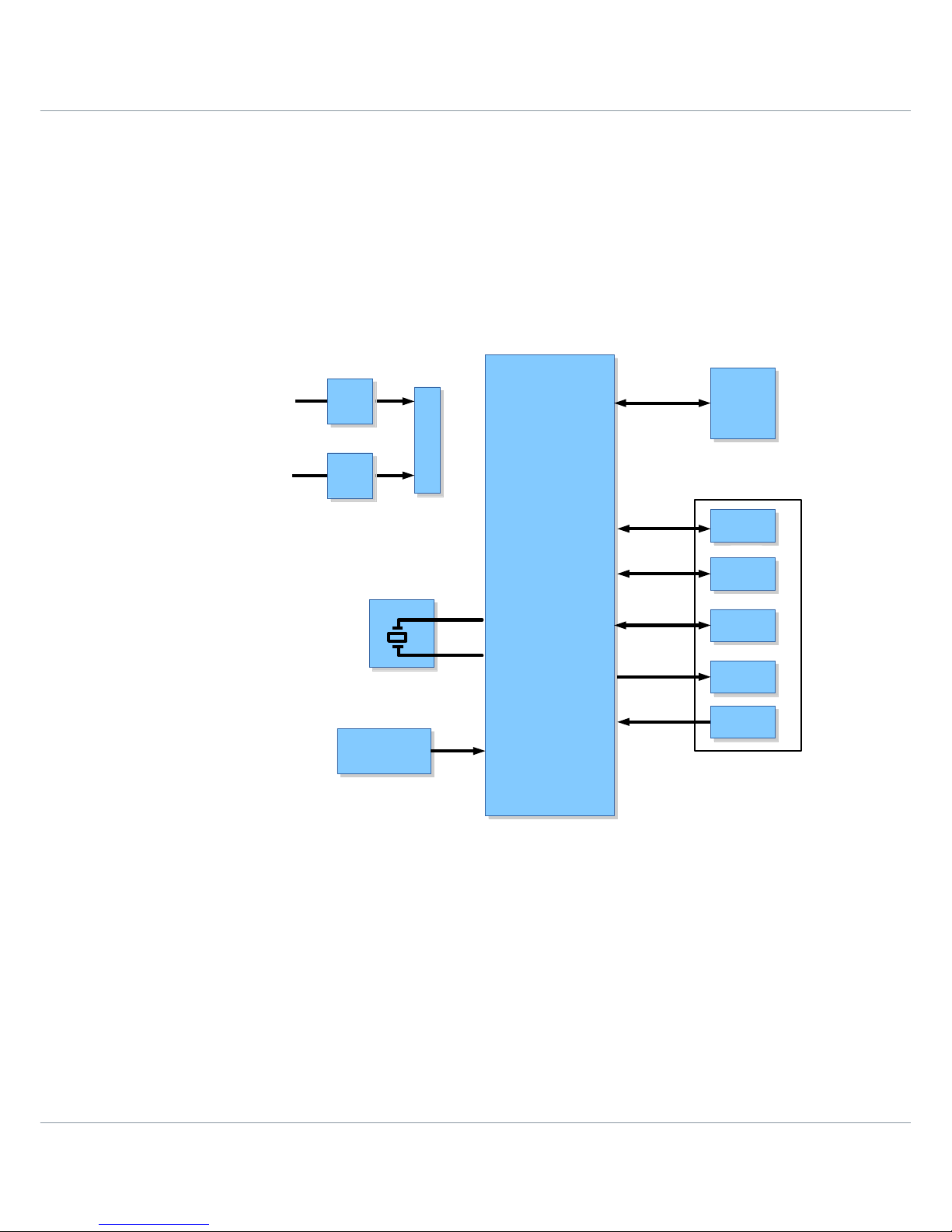

The GR716-BOARD Board provides the electrical functions and interfaces as represented

in the block diagram, Figure .4-2.

Note that not all features and interfaces are available at the same time, and the

configuration of on-board resistors plus programming of registers is required to access

some of the features.

GR716-BOARD-UM, May 2019, Version 0.1 9 www.cobham.com/gaisler

Figure 4-1: GR716-BOARD Board Block Diagram

CRYSTAL

CRYSTAL

GR716

MICRO-

CONTROLLER

GR716

MICRO-

CONTROLLER

RESET_OUT

RESET_OUT

EXPANSION CONNECTOR

DCDC

DCDC SPI

FLASH

SPI

FLASH

GPIO

GPIO

DSU

DSU

BOOTSTRAP/

CONFIGURATION

BOOTSTRAP/

CONFIGURATION

3.3V

RESET_IN

RESET_IN

DCDC

DCDC

1.8V

VIN

VIN

LVDS

LVDS

CONFIGURATION

JUMPERS

CONFIGURATION

JUMPERS

Page 10

GR716-BOARD

4.2 Board Mechanical Configuration

The board (80 x 100mm) and can be used 'stand-alone' on the bench-top simply an

external +5V power supply connected to connector J2.For mounting of the board on a

carrier or expansion board, four M2.5 mounting holes are provided in the corners of the

board, as shown in the figure below.

The expansion connectors P1 and P2 of the GR716-BOARD are stacking style

connectors having a socket on the bottom side and an extended pin on the top side. In a

stand-alone configuration the pins on the top side allow easy access for Logic Analyser

or Oscilloscope probing for all the functional microcontroller pins.

GR716-BOARD-UM, May 2019, Version 0.1 10 www.cobham.com/gaisler

Figure .4-2: GR716-BOARD Board Dimensions

Page 11

GR716-BOARD

The sockets on the bottom side allow the board to be plugged on to a carrier board to

conveniently enable further development testing.

The CPCI format board providing GPIO, SPW, Serial (via FTDI-USB) and analog

coaxial connector which has been developed for this purpose is shown in Figure 4-3.

Alternatively, the stacking connector concept allows the interface functions to be

expanded by stacking the GR716-BOARD to other boards in a concept similar to

PC104.

A test board for adding memory (SPI serial, 8 bit parallel FLASH and 8 bit SRAM) is

shown in Figure 4-4, and a test board for exercising the Analog features of the GR716

microcontroller is shown in Figure 4-5.

This concept also provides a convenient way for User Defined interface boards to be

developed and connected to the GR716-BOARD, if other functions or features are to be

demonstrated.

GR716-BOARD-UM, May 2019, Version 0.1 11 www.cobham.com/gaisler

Figure 4-3: GR716-BOARD mounted on a GR716-CPCI-DEV Carrier board

Page 12

GR716-BOARD

GR716-BOARD-UM, May 2019, Version 0.1 12 www.cobham.com/gaisler

Figure 4-4: GR716-TEST-MEMORY BOARD

Figure 4-5: GR716-TEST-ADCDAC BOARD

Page 13

GR716-BOARD

4.3 GR716 Microcontroller

The Cobham Gaisler GR716 Microcontroller features a fault-tolerant LEON3 SPARC

V8 processor, communication interfaces and on-chip ADC, DAC, Power-on-Reset,

Oscillator, Brown-out detection, LVDS transceivers, regulators to support for single

3.3V supply, ideally suited for space and other high-rel applications.

The GR716 Microcontroller is a complex device with many modes of operation. For the

details of the interfaces, operation and programming, refer to[RD1].

The GR716 microcontroller is packaged in a 132-pin, 0.635mm pitch Ceramic Quad

Flat Pack package (housing: 24 x 24 mm).

GR716-BOARD-UM, May 2019, Version 0.1 13 www.cobham.com/gaisler

Figure 4-6: GR716 Microcontroller Block Diagram

Figure 4-7: GR716 Package

Page 14

GR716-BOARD

4.4 Memory

The memory configuration installed on the board comprises:

• 256 Mbit SPI serial boot prom (Cypress, S25FL256SAGN)

The SPI boot memory is connected directly to the SPIM interface of the GR716 Microcontroller. Although the SPI memory chip can operate in a x4 data mode, only a x1 data

mode is usable with the GR716.

4.5 LVDS Interfaces

The GR716 microcontroller provides a set of three LVDS input pairs and three LVDS

output pairs which are configurable from software via configuration registers to provide

SpaceWire or SPI4SPACE interfaces.

These signals are connected from the GR716 microcontroller to the Expansion

connector, P2.

100 Ohm Termination resistors and fail-safe resistors for the LVDS receiver signals are

mounted on the board close to the receiver.

GR716-BOARD-UM, May 2019, Version 0.1 14 www.cobham.com/gaisler

Figure 4-8: SPI Boot Memory Connections

Page 15

GR716-BOARD

4.6 GPIO

All 64 GPIO pins are connected from the GR716 Microcontroller to the Expansion

connector.

These General purpose I/O pins are 3.3V LVCMOS voltage levels.

Note though that most pins have multiple functions and in certain configurations may

have different input/output voltage requirements (e.g. ADC and DAC signals). Care

must be taken to account for this.

No current limiting or overvoltage protection components are

included on the GPIO signals of the GR716-BOARD board. The

signals are connected directly from the microcontroller to the

expansion connector. Care must therefore be taken to ensure that

any external circuitry connected does not exceed the allowable

voltage limits for the input/output pins.

4.7 Bootstrap Signals

A number of features of the GR716 microcontroller are required to be set at power-on of

the processor, by means of bootstrap pins. A number of GPIO and function pins are predefined for this purpose, according the definition Table 22 of [RD1].

To define the desired setting, an 8 pole, Double-Throw DIP switch (S1), is provided on

the board to connect these signals to either a pull-up or a pull-down resistor, or to allow

the pin to float.

Pin Function Default

GPIO0 Disable EDAC Up

GPIO17 Bypass Internal Boot Prom Down

GPIO62 Enable Memory Test Down

GPIO63 Redundant Memory Available Down

DSUTX Copy ASW image/SPW default frequency Down

SPIM_MOSI Remote Access/Boot from Memory Down

SPIM_SCK Boot Source 0 Down

SPIM-SEL Boot Source 1 Down

Table 1: Bootstrap Resistor Settings

GR716-BOARD-UM, May 2019, Version 0.1 15 www.cobham.com/gaisler

Page 16

GR716-BOARD

4.8 Debug Support Unit Interfaces

Program download and debugging to the processor is performed using the GRMON

Debug Monitor tool from Cobham Gaisler ([RD4]). The GR716 microcontroller

provides a UART based DSU interface for Debug and control of the processor by means

of a host terminal, as represented in Figure 4-9.

Four control signals from the Debug Support Unit interface to the processor are

implemented:

DSUTX Debug UART Transmit

DSURX Debug UART Receive

DSUEN This signal is pulled high on the board to enable Debugging

DSUBRE This signal is pulled low on the board

To connect to a host computer, a small adapter can be used as shown in Figure 4-10.

GR716-BOARD-UM, May 2019, Version 0.1 16 www.cobham.com/gaisler

Figure 4-9: Debug Support Unit connections

GR716

DSUBRE→

HOST

TERMINAL/COMPUTER

USB

DSUEN

→

FTDI

DSUR

X

→

DSUTX

←

EXPANSION

CONNECTOR

GR716-DSU-USB

Figure 4-10: GR716-DSU-USB Adapter

Page 17

GR716-BOARD

4.9 Oscillators and Clock Inputs

The oscillator and clock scheme for the GR716-BOARD Board is shown in Figure 4-11.

Two oscillator inputs are required: CLK for the main system clock, and SPW_CLK for

the SpaceWire clock of the microcontroller

To allow the GR716 Microcontroller to operate in a stand alone manner a crystal is

required on the board which is connected to the Crystal oscillator interface for the

GR716. On this board the crystal is mounted on a DIL8 socket adapter in order to allow

various crystal frequencies to be tested.

This generates an output clock, XO_OUT, which is connected to the CLK and

SPW_CLK inputs with jumpers.

In an alternative scenario, it may be preferred to have a separate CLK or SYS_CLK to

allow different frequencies to be used. In this case the jumpers can be moved and

instead an external 3.3V LVCMOS clock signal provided via the expansion connector.

For more details of the internal Crystal Oscillator, PLL structure and clock gating

features of the GR716, please refer to sections 9 and 10 of [RD1].

GR716-BOARD-UM, May 2019, Version 0.1 17 www.cobham.com/gaisler

Figure 4-11: Board level Clock Distribution Scheme

GR716

microcontroller

GR716

microcontroller

SPW_CLK

CLK

XO_1

XTAL

25 MHz

Y1

XO_2

XO_OUT

EXPANSION

CONNECTOR

EXPANSION

CONNECTOR

Page 18

GR716-BOARD

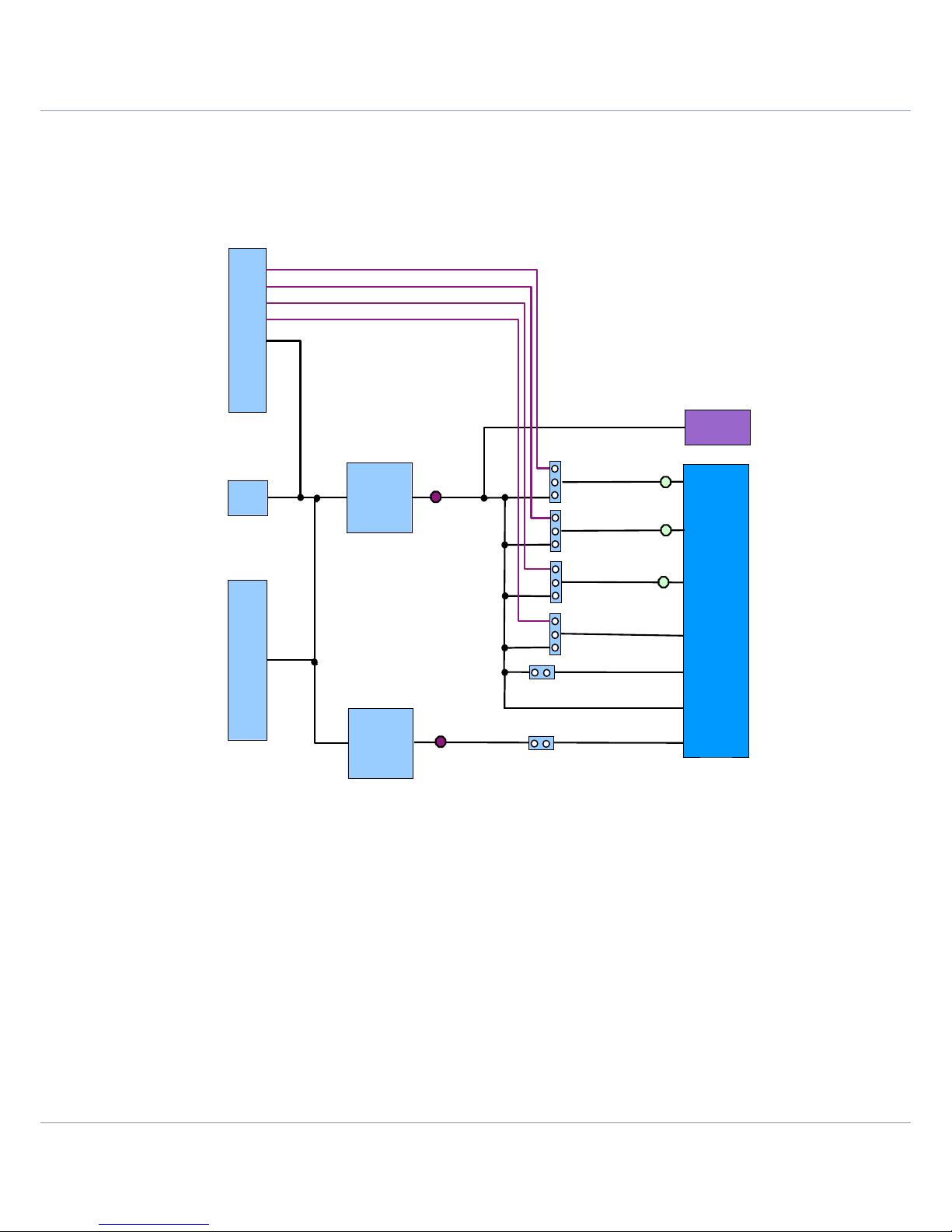

4.10 Power Supply and Voltage Regulation

The power configuration is represented in Figure 4-12.

By means of configuration jumpers, several configurations can be tested:

1. Individual voltages from external bench supplies connected to the screw

terminal connector J1 to provide

+VADC (+3V3 nominal)

+VREF (+3V3 nominal)

+VDAC (+3V3 nominal)

+VLVDS (+3V3 nominal)

This allows individual power supplies to be tested over min/nom/max by

varying the supply voltages

In this case

2. Single VIN (+12V nominal) input supply connector to J1.

3. Single VIN (+12V nominal) input supply connector to J2.

4. VIN provided from external circuitry connected to Expansion connector P2.

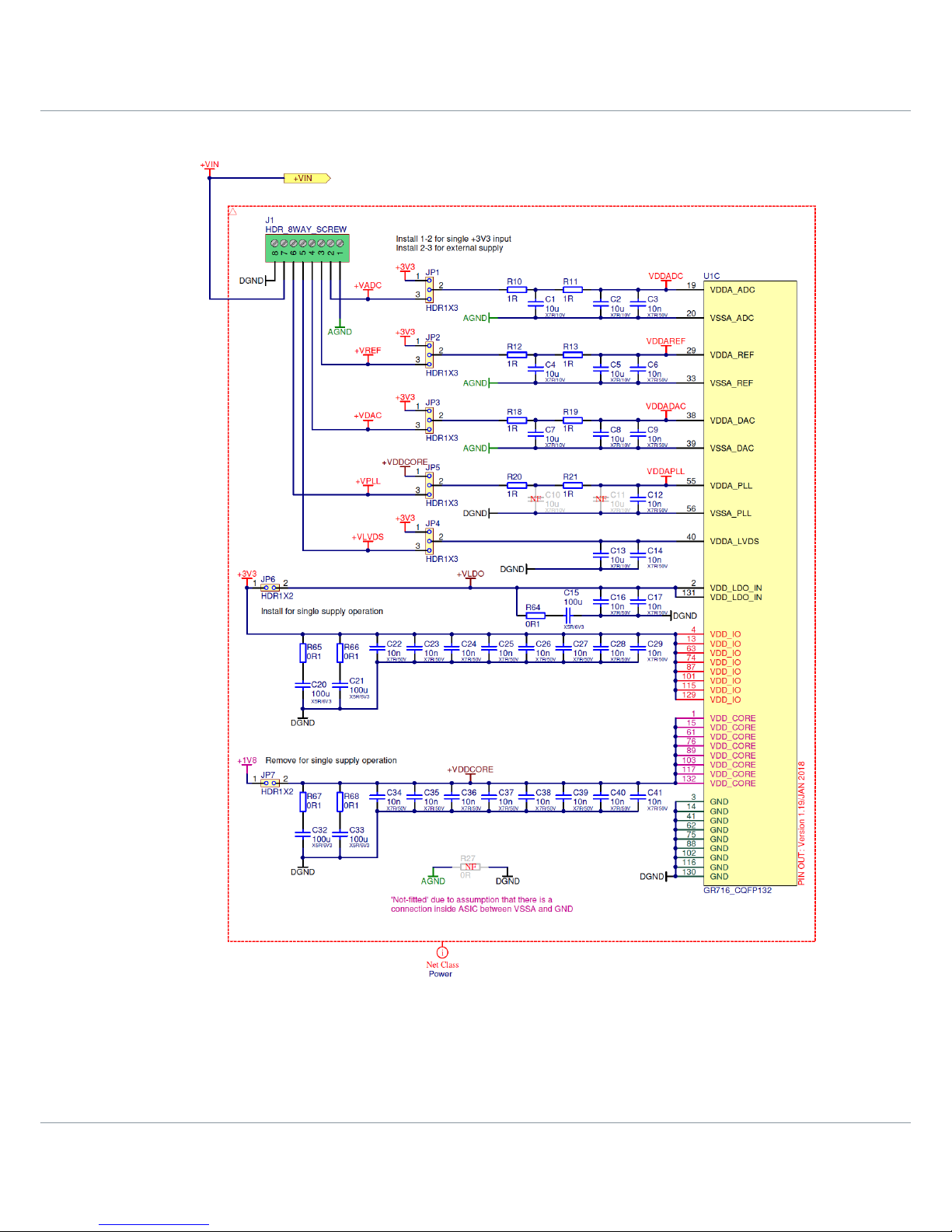

With reference to the setting of the jumpers shown in Figure 4-13:

• In case 1, jumpers JP1, JP2, JP3 and JP4 should be set to position 1-2.

• In cases 2,3,4 VIN is regulated with two LMZ21701 micro Point-of-Load

regulators to generate a regulated VDDIO (+3.3V) and VDD_CORE (+1.8V). In

these cases, jumpers JP1, JP2, JP3 and JP4 should be set to position 2-3.

• Jumper JP5 (VPLL) should not be installed. VPLL is provided from the 1V8

voltage generated by the LDO regulator inside the GR716.

• If the GR716 is to be operated from a single 3.3V, and the internal LDO is to be

used to generate the VDDCORE voltage of 1.8V then JP6 should be installed

and JP7 removed.

• If the GR716 is to be operated from both the POL generated 3.3V and 1.8V

supplies, then JP6 should be removed and JP7 installed. In this situation, the

internal LDO is disabled and VDDCORE voltage of 1.8V is provided form the

POL regulator.

At the output of the 3.3V and 1.8V POL regulators, 20 mOhm sense resistors and

INA219 Current/Power Monitor circuits with an I2C interface are incorporated on the

board. The I2C signals (SDA, SCL) are connected to the Expansion connector P2 to

allow the current/voltage to be measured using an I2C master circuit.

GR716-BOARD-UM, May 2019, Version 0.1 18 www.cobham.com/gaisler

Page 19

GR716-BOARD

GR716-BOARD-UM, May 2019, Version 0.1 19 www.cobham.com/gaisler

Figure 4-12: Power Regulation Scheme

J2

+3V3

DCDC

GR716

5V min

12V nom

14.5V max

LMZ21701

1A max

VDDA_ADC

VDDA_DAC

+3V3

VDDA_REF

VDDA_LVDS

VDD_LDO_IN

VDD_IO

VDD_CORE

FILTER

FILTER

FILTER

FLASH

EXPANSION

CONNECTOR

+1V8

+1V8

DCDC

J1

I2C measure

I2C measure

LMZ21701

1A max

+VIN

+VLVDS

+VREF

+VDAC

+VADC

Page 20

GR716-BOARD

GR716-BOARD-UM, May 2019, Version 0.1 20 www.cobham.com/gaisler

Figure 4-13: Power Supply Configuration Jumpers

Page 21

GR716-BOARD

4.11 Reset Circuit and Button

The GR716 microcontroller includes an internal RESET circuit with Brown-out detector

to reset the processor and its peripherals (see section 8 of [RD1]).

The resulting low reset signal is present on the microcontroller pin RESET_OUT_N.

This signal is connected to the expansion connector, P2.

A manual reset of the microcontroller can be generated using the RESET_IN_N signal.

This signal is present on the expansion connector P2, and can be driven from an

external circuity if required. A miniature push button switch is provided on the GR716DSU-USB (Figure 4-10) to pull this signal low, when the button is pressed.

4.12 Watchdog

The GR716 microcontroller includes an internal Watchdog timer function which can be

used for the purpose of generating a system reset in the event of a software malfunction

or crash. Please refer to [RD1].

GR716-BOARD-UM, May 2019, Version 0.1 21 www.cobham.com/gaisler

Page 22

GR716-BOARD

5 Setting Up and Using the Board

The board is provided with a default configuration set by bootstrap settings.

For additional information, refer to [RD2] and for information about the Bootstrap

signals, refer to section 4.7.

To operate the board stand alone on the bench top, install the power configuration

jumpers appropriately, and +12V supply to the board connector J2.

ATTENTION! To prevent damage to board, please ensure that the

correct power supply voltage and polarity is used with the board.

Do not exceed +14.5V at the power supply input, as this may

damage the board.

he POWER_3V3 and POWER_1V8 power good LED’s should be

illuminated indicating that the power supply is present and the

board is generating the supply voltages that it requires.

Upon power on, using default bootstrap the processor will start executing instructions

beginning at the memory location 0x02000000, which is the start of the PROM. If the

PROM is 'empty' or no valid program is installed, the first executed instruction will be

invalid, and the processor will halt with an ERROR condition.

To perform program download and software debugging on the hardware it is necessary

to use the Cobham Gaisler GRMON3 debugging software, installed on a host PC (as

represented in Figure 4-9). Please refer to the GRMON3 documentation for the

installation of the software on the host PC (Linux or Windows), and for the installation

of the associated hardware dongle.

To perform software download and debugging on the processor, a link from the Host

computer to the DSU interface of the board is necessary. As described in section 4.8 this

is achieved via the FTDI USB interface.

Program download and debugging can be performed in the usual manner with

GRMON3. More information on the usage, commands and debugging features of

GRMON3, is given in the GRMON3 Users Manuals and associated documentation,

[RD4].

GR716-BOARD-UM, May 2019, Version 0.1 22 www.cobham.com/gaisler

Page 23

GR716-BOARD

6 Interfaces and Configuration

6.1 List of Connectors

Name Function Type Description

J1 POWER HDR_8_SCREW Screw terminals for individual external power

J2 POWER_5V 2.1mm centre +ve DC power input connector

PI EXPANSION-1 2x32 pin 0.1” Header Expansion connector-1

P2 EXPANSION-2 2x32 pin 0.1” Header Expansion connector-2

Table 2: List of Connectors

Pin Name Comment

1 AGND Analog Ground

2 +VADC +3V3

3 +VREF +3V3

4 +VDAC +3V3

5 +VLVDS +3V3

6 +VPLL Do not apply voltage here

7 +VIN +5V to +12V

8 DGND Digital Ground

Table 3: J1 Screw Terminal Connector for Input Voltages

Pin Name Comment

+VE +VIN Inner Pin, +5V to +12V, typically 1 A

-VE DGND Outer Pin Return

Table 4: J2 POWER – External Power Connector

GR716-BOARD-UM, May 2019, Version 0.1 23 www.cobham.com/gaisler

Page 24

GR716-BOARD

Table 5: Expansion connector P1 Pin-out

Table 6: Expansion connector P2Pin-out

GR716-BOARD-UM, May 2019, Version 0.1 24 www.cobham.com/gaisler

Page 25

GR716-BOARD

6.2 List of Oscillators, Switches and LED's

Name Function Description

Y1 XTAL 8 pin DIL socket for 5-25 MHz crystal

Table 7: List and definition of Oscillators and Crystals

Name Function Description

D1 RESET_OUT Processor RESET_OUT signal

D2 POWER_3V3 3.3V power good

D3 POWER_1V8 1.8V power good

Table 8: List and definition of PCB mounted LED's

Name Function Description

S1 8 pole SPDT DIP switch Pull-up/Float/Pull-Down Bootstrap settings – see Table 10

Table 9: List and definition of Switches

Name Function Description

S1-1 GPIO0 Disable EDAC

S1-2 GPIO17 Bypass Internal Boot Prom

S1-3 GPIO62 Enable Memory Test

S1-4 GPIO63 Redundant Memory Available

S1-5 DSUTX Copy ASW image

S1-6 SPIM_SEL Boot Source 0

S1-7 SPIM-SCK Boot Source 1

S1-8 SPIM-MOSI Remote access/Boot from memory

Table 10: Definition of Switch S1 functions

(refer to [RD1])

GR716-BOARD-UM, May 2019, Version 0.1 25 www.cobham.com/gaisler

Page 26

GR716-BOARD

GR716-BOARD-UM, May 2019, Version 0.1 26 www.cobham.com/gaisler

Figure 6-1: PCB Top View

Page 27

GR716-BOARD

GR716-BOARD-UM, May 2019, Version 0.1 27 www.cobham.com/gaisler

Figure 6-2: PCB Bottom View

Page 28

GR716-BOARD

GR716-BOARD-UM, May 2019, Version 0.1 28 www.cobham.com/gaisler

Figure 6-3: PCB Top View (Photo)

Page 29

GR716-BOARD

GR716-BOARD-UM, May 2019, Version 0.1 29 www.cobham.com/gaisler

Figure 7-1: PCB Bottom View (Photo)

Page 30

GR716-BOARD

7 Change Record

Issue Date Section / Page Description

0.0 2019-05-02 All Draft Issue

0.1 2019-05-02 All Corrected bootstrap signals and start-up behaviour for default

configuration

GR716-BOARD-UM, May 2019, Version 0.1 30 www.cobham.com/gaisler

Page 31

GR716-BOARD

Cobham Gaisler AB

Kungsgatan 12

411 19 Göteborg

Sweden

www.cobham.com/gaisler

sales@gaisler.com

T: +46 31 7758650

F: +46 31 421407

Cobham Gaisler AB, reserves the right to make changes to any products and services described herein at any

time without notice. Consult Cobham or an authorized sales representative to verify that the information in

this document is current before using this product. Cobham does not assume any responsibility or liability

arising out of the application or use of any product or service described herein, except as expressly agreed

to in writing by Cobham; nor does the purchase, lease, or use of a product or service from Cobham convey a

license under any patent rights, copyrights, trademark rights, or any other of the intellectual rights of

Cobham or of third parties. All information is provided as is. There is no warranty that it is correct or suitable

for any purpose, neither implicit nor explicit.

Copyright © 2019 Cobham Gaisler AB

GR716-BOARD-UM, May 2019, Version 0.1 31 www.cobham.com/gaisler

Loading...

Loading...