Page 1

SAILOR 619 4

Terminal Control Unit

Installation and user manual

Page 2

Page 3

SAILOR 6194 Terminal Control Unit

Installation and user manual

Document number: 98-131593-D

Release date: November 18, 2013

i

Page 4

Disclaimer

Any responsibility or liability for loss or damage in connection with the use of this

product and the accompanying documentation is disclaimed by Thrane & Thrane

A/S. The information in this manual is provided for information purposes only, is

subject to change without notice and may contain errors or inaccuracies. Manuals

issued by Thrane & Thrane A/S are periodically revised and updated. Anyone relying

on this information should acquire the most current version e.g. from

www.cobham.com/satcom or from the distributor. Thrane & Thrane A/S is not

responsible for the content or accuracy of any translations or reproductions, in whole

or in part, of this manual from any other source.

Thrane & Thrane A/S is trading as Cobham SATCOM.

Copyright

© 2013 Thrane & Thrane A/S. All rights reserved.

Trademark acknowledgements

• Inmarsat is a registered trademark of the International Maritime Satellite

Organisation (IMSO) and is licensed by IMSO to Inmarsat Limited and Inmarsat

Ventures plc.

• SAILOR is a registered trademark of Thrane & Thrane A/S in the European Union,

the United States and other countries.

• Other product and company names mentioned in this manual may be trademarks

or trade names of their respective owners.

ii

Page 5

Safety summary

The following general safety precautions must be observed during all

phases of operation, service and repair of this equipment. Failure to

comply with these precautions or with specific warnings elsewhere in this

manual violates safety standards of design, manufacture and intended

use of the equipment. Thrane & Thrane A/S assumes no liability for the

customer's failure to comply with these requirements.

GROUND THE EQUIPMENT

To minimise shock hazard, the equipment chassis and cabinet must be

connected to an electrical ground and the cable instructions must be

followed.

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE

Do not operate the equipment in the presence of flammable gases or

fumes. Operation of any electrical equipment in such an environment

constitutes a definite safety hazard.

KEEP AWAY FROM LIVE CIRCUITS

Operating personnel must not remove equipment covers. Component

replacement and internal adjustment must be made by qualified

maintenance personnel. Do not service the unit with the power cable

connected. Always disconnect and discharge circuits before touching

them.

DO NOT SUBSTITUTE PARTS OR MODIFY EQUIPMENT

Because of the danger of introducing additional hazards, do not

substitute parts or perform any unauthorised modification to the

equipment.

COMPASS SAFE DISTANCE

20 cm

iii

Page 6

About the manual

Intended readers

This manual is primarily an installation manual for the Terminal

Control Unit Terminal Control Unit. The manual is intended for

installers of the system and service personnel. Personnel

installing or servicing the system must be properly trained and

authorised by Cobham SATCOM. It is important that you

observe all safety requirements listed in the beginning of this

manual, and install the system according to the guidelines in this

manual.

The manual also describes some basic configuration of the

system, the use of SSA buttons and scripting.

See also the user manual for the system in which the Terminal

Control Unit is installed, e.g. SAILOR 6120 SSA System. Related

manuals are listed on the next page under Related documents.

iv

Page 7

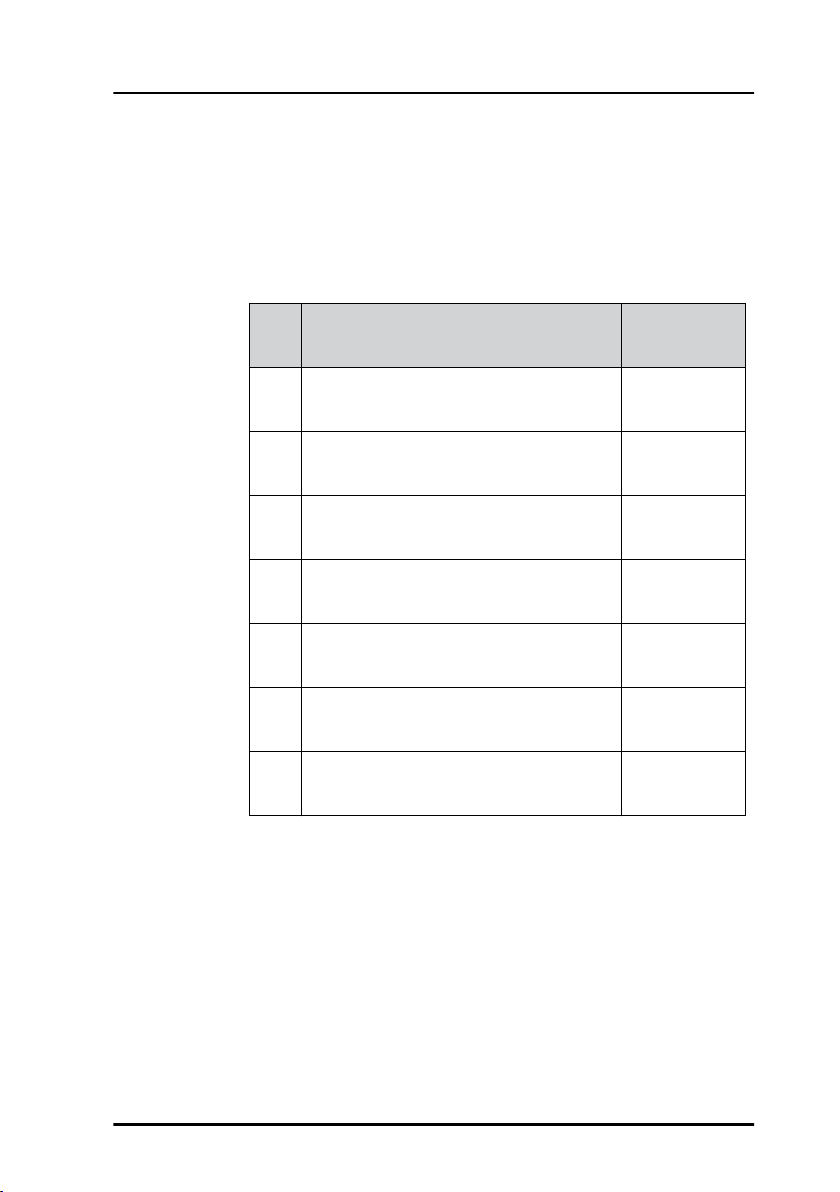

Related documents

The below list shows the documents related to this manual and

to this product.

The manuals can be found in the Self Service Center at

cobham.com/satcom under Service and Support.

Ref. Title and description

[1] SAILOR 6006 and SAILOR 6007,

Message Terminal, Installation manual

[2] SAILOR 6110 GMDSS System,

Installation manual

[3] SAILOR 6110 GMDSS System, User

manual

[4] SAILOR 6120/6130/6140/6150

System, Installation manual

[5] SAILOR 6120/6130/6140/6150

System, User manual

[6] SAILOR 6081 Power Supply and

Charger, Installation and user manual

[7] System 6000 GMDSS Console,

Installation manual

Table 1: Related documents

Document

number

98-130088

98-130752

98-130753

98-131589

98-131590

98-130980

98-131571

v

Page 8

vi

Page 9

Table of Contents

Chapter 1 Introduction

The Terminal Control Unit ...............................................................1

Chapter 2 Installation

Unpacking ................................................................................................3

Installing the Terminal Control Unit ............................................4

Outline drawing .....................................................................................6

Installing Ship Security Alert (SSA) buttons ............................7

Installing Non-SOLAS Alarm Panels .............................................9

Installing the Glonass option ....................................................... 10

Chapter 3 Connecting cables

Connector overview .........................................................................14

Power control (X1) ............................................................................15

CAN interface (X2) ............................................................................16

RS-232 interface (X5) ......................................................................19

LAN interface (X6) ............................................................................. 20

SSA and Alarm Panel (X7 to X14) ..............................................21

Grounding the Terminal Control Unit ...................................... 26

Cable requirements ...........................................................................27

Chapter 4 Using the Terminal Control Unit

Status indicators ................................................................................30

Configuration ......................................................................................35

Use of SSA buttons ........................................................................... 44

vii

Page 10

Table of Contents

Use of Non-SOLAS Alarm Panels ................................................46

Chapter 5 Scripting

Introduction to scripting ................................................................47

What can scripts do .......................................................................... 48

Complete example of a Lua script ............................................. 52

Chapter 6 Service

Updating software ............................................................................ 59

Status signalling .................................................................................. 62

Setting a temporary fixed IP address ......................................63

Returning units for repair ...............................................................64

Repacking for shipment .................................................................. 64

App. A Specifications

General specifications for the TCU ........................................... 65

Specifications for I/O pins ............................................................. 66

App. B Lua extensions

GPIO functions ....................................................................................69

Miscellaneous functions .................................................................74

Glossary .....................................................................................................................81

Index .....................................................................................................................85

viii

Page 11

Chapter 1

Introduction 1

The Terminal Control Unit

The Terminal Control Unit is used for the following purposes:

• For connecting covert alert buttons for use in Ship Security Alert (SSA)

systems or SAILOR 3042E Alarm Panels in Non-SOLAS Distress systems.

• For connecting a SAILOR 3027 terminal, which has a CAN interface,

with other equipment that has Ethernet or RS-232 interface.

• For executing custom scripts that can react on events registered by the

Terminal Control Unit, e.g. in SCADA applications and for vessel

monitoring.

You can also connect a switch for power control of the Terminal Control

Unit, and with the optional Glonass module you can connect to a Glonass

antenna.

The power for the Terminal Control Unit is supplied through the CAN

connector (extended input range 10.5-32 V DC).

Introduction

The Terminal Control

Unit is supported by

the ThraneLINK

Management

Application, a

Windows program

that provides easy

monitoring and

software update of

connected Cobham

SATCOM devices with

ThraneLINK support.

1

Page 12

Chapter 1: Introduction

2 The Terminal Control Unit

Page 13

Chapter 2

Installation 2

This chapter describes how to unpack, store and install the

SAILOR 6194 Terminal Control Unit. It contains the following sections:

• Unpacking

• What’s in the delivery

• Installing the Terminal Control Unit

• Outline drawing

• Installing Ship Security Alert (SSA) buttons

• Installing Non-SOLAS Alarm Panels

• Installing the Glonass option

For information on cable connections, see Connecting cables on page 13.

Unpacking

Installation

Initial inspection

Inspect the shipping carton immediately upon receipt for evidence of

damage during transport. If the shipping carton is severely damaged or

water stained, request that the carrier's agent be present when opening the

carton. Save the carton packing material for future use.

Warning! To avoid electric shock, do not apply power to the

system if there is any sign of shipping damage to any

part of the front or rear panel or the outer cover.

Read the safety summary at the front of this manual

before installing or operating the system.

After unpacking the system, inspect it thoroughly for hidden damage and

loose components or fittings. If the contents are incomplete, if there is

mechanical damage or defect, or if the system does not work properly,

notify your dealer.

3

Page 14

Chapter 2: Installation

What’s in the delivery

The following items are included in the delivery of the Terminal Control

Unit:

• Terminal Control Unit Terminal Control Unit

• NMEA2000 Micro Device Cable, 6 m

• Mounting tool for spring-loaded terminals

• Installation and user manual (this manual)

Installing the Terminal Control Unit

General installation requirements

The Terminal Control Unit must be installed in a location which is

• indoors

• not exposed to water

• close to a ship ground connection point.

Make sure the Compass Safe Distance is maintained. See General

specifications for the TCU on page 65.

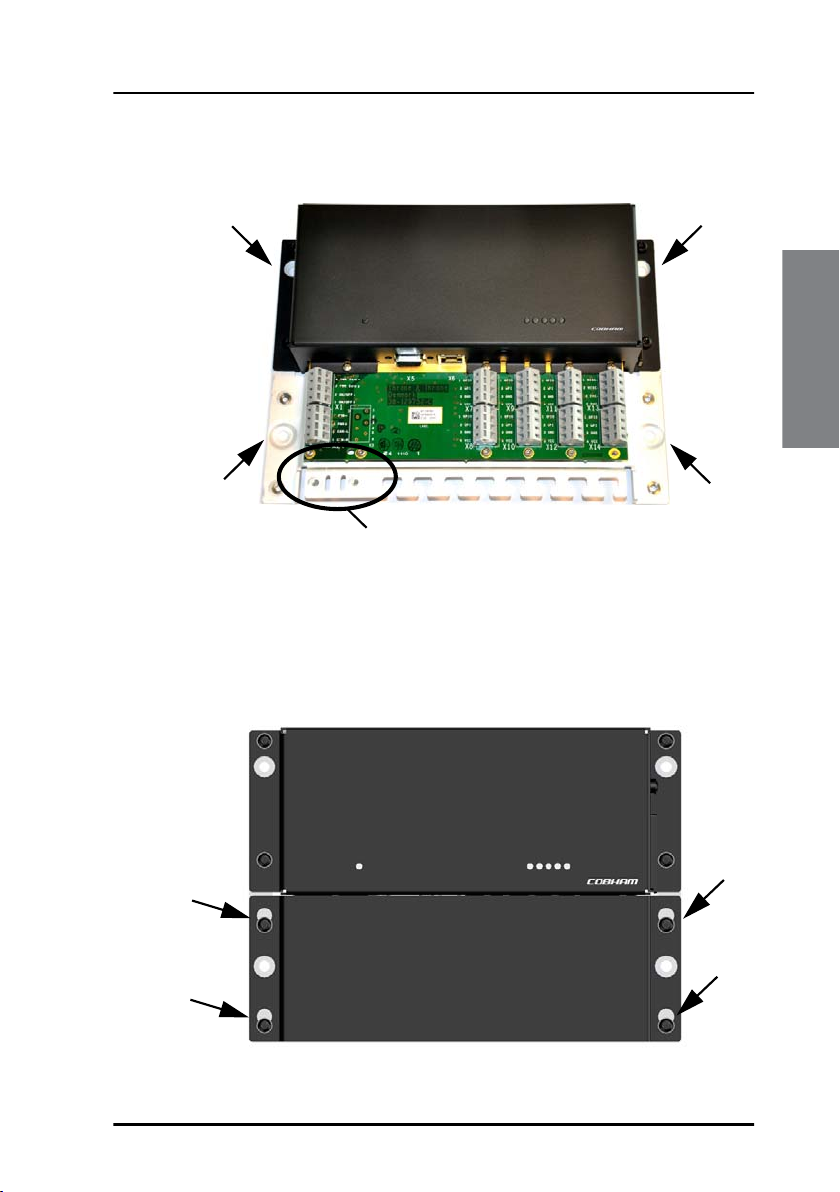

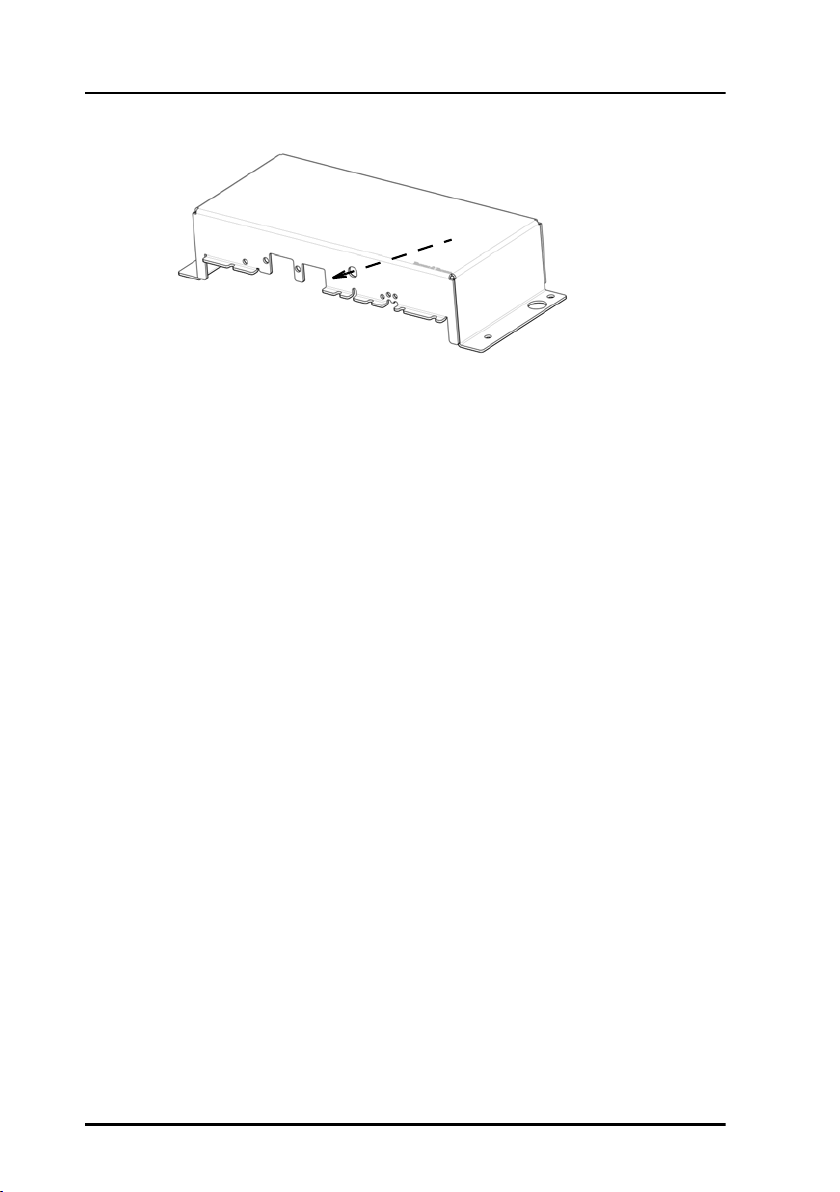

Mounting the Terminal Control Unit

The Terminal Control Unit is designed to be mounted on a flat surface, e.g.

on a bulkhead.

Important

To mount the Terminal Control Unit, do as follows:

1. Using four screws, mount the Terminal Control Unit on the mounting

surface. The mounting holes are Ø6. If you mount the Terminal Control

4 Installing the Terminal Control Unit

If the Terminal Control Unit is not mounted on a surface with

a good connection to ship ground, you must connect a

separate cable for this purpose. See Grounding the Terminal

Control Unit on page 26.

Page 15

Chapter 2: Installation

Unit on a vertical surface, make sure the cable relief is facing down as

shown in the picture below.

Cable relief

for CAN

2. Tighten the screws.

3. Connect all cables as described in Connecting cables on page 13 and

fasten the cables to the cable relief with cable strips.

Installation

4. When all cables are installed, mount the cover for the spring-loaded

terminals. Tighten the screws to 1.5 Nm.

Installing the Terminal Control Unit 5

Page 16

Chapter 2: Installation

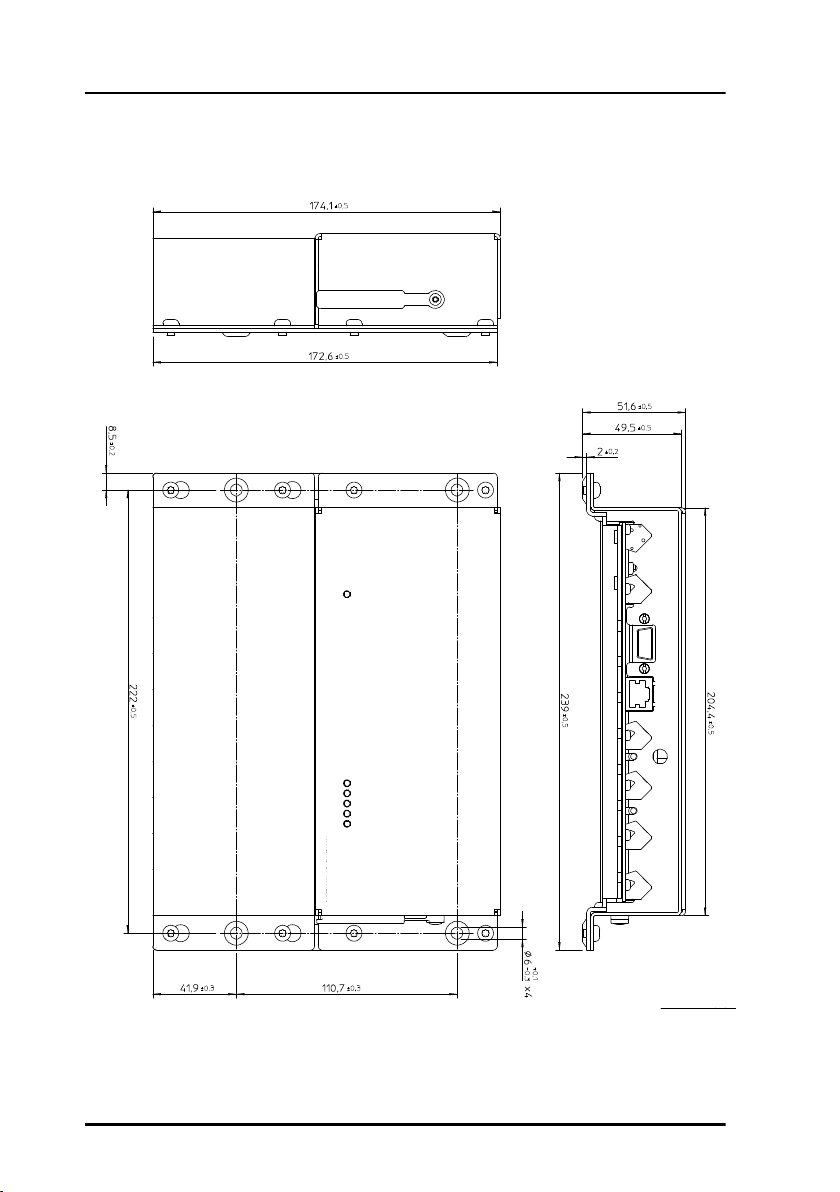

Outline drawing

Dimensions are in mm

6 Outline drawing

Page 17

Chapter 2: Installation

Installing Ship Security Alert (SSA) buttons

Placing the SSA buttons

To fulfil the IMO requirement on covert activation, the alert button

installation must be concealed using appropriate covert installation

techniques. One of the alert buttons must be placed on the ship’s

navigation bridge. To make testing easier we recommend installing the test

button close to one of the covert alert buttons, but in such a way that the

constant light does not disturb navigation (night sight). The test button

must be installed where it is easy to test the SSA installation at regular

intervals.

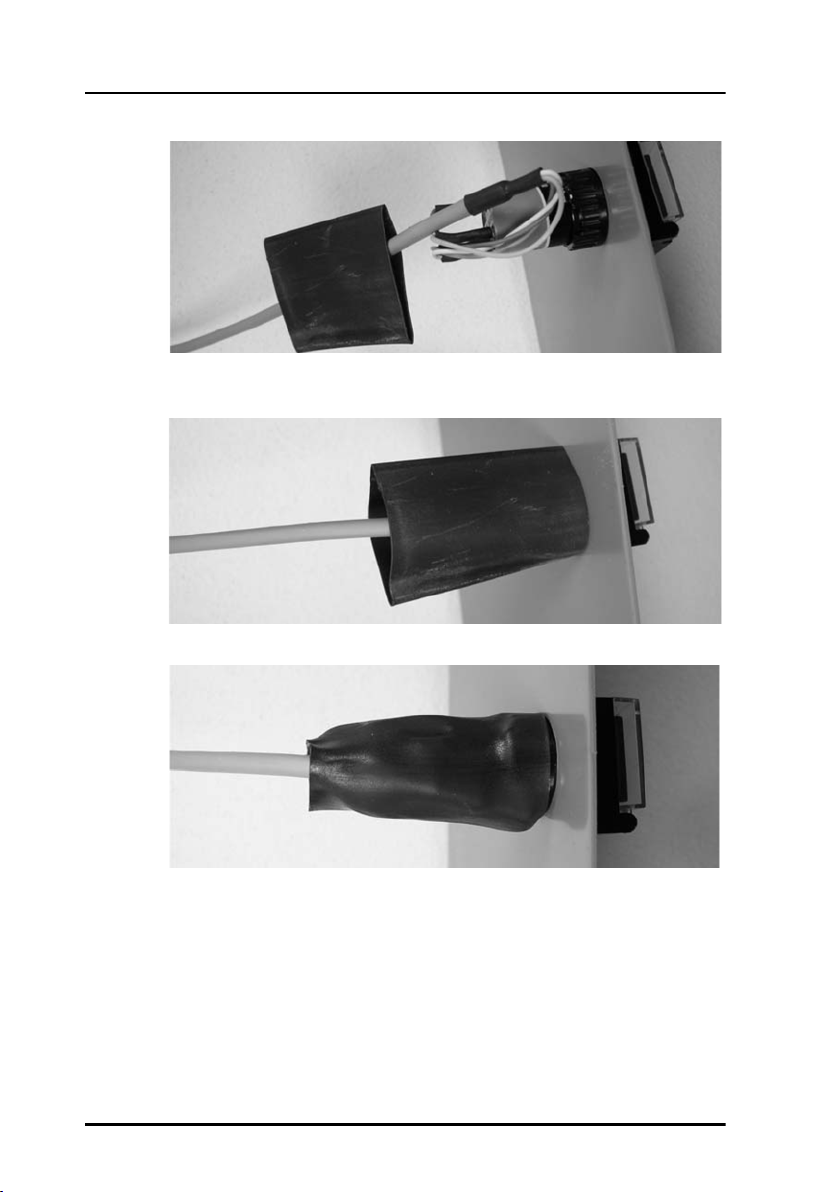

Installing the SSA buttons

When the place for installation is determined, do as follows:

1. Drill a hole with a diameter of 16 mm.

2. Place the mounting-nut and the large piece of heat-shrink 19x30 mm

on the back of the hole.

Installation

3. Slip the wires from the covert alert button through the hole, the

mounting nut, the heat-shrink, and all the way to the Terminal Control

Unit.

The 19x30 mm heat-shrink is for cable strain relief on the back of the

button.

4. Tighten the mounting nut.

5. Bend the cable in an S shape on the side of the switch.

Installing Ship Security Alert (SSA) buttons 7

Page 18

Chapter 2: Installation

6. Pull the heat-shrink to the back of the board where the button is

installed.

7. Shrink the heat-shrink with heat.

For information on wiring, see GMDSS or SSA systems (SAILOR 6110 or

SAILOR 6120) on page 21. For information on how to configure the SSA

buttons, see Configuring SSA buttons on page 39. For information on how

to use the SSA buttons, see Use of SSA buttons on page 44.

8 Installing Ship Security Alert (SSA) buttons

Page 19

Chapter 2: Installation

Installing Non-SOLAS Alarm Panels

The Non-SOLAS Alarm Panel is used in Non-SOLAS Distress systems to send

Distress alerts. You may use the SAILOR 3042E Alarm Panel.

The Non-SOLAS Alarm Panel can be mounted on a wall or desktop.

For information on wiring, see Non-SOLAS Distress systems (SAILOR

6150) on page 23.

Installation

Installing Non-SOLAS Alarm Panels 9

Page 20

Chapter 2: Installation

Installing the Glonass option

An optional Glonass module is available for the Terminal Control Unit. The

Glonass module enables the Terminal Control Unit to receive a Glonass

signal and make it available to other parts of the system.

Caution! Before removing the cover enclosing the electronic

circuits, first make sure you are wearing a wrist strap

connected to the work place.

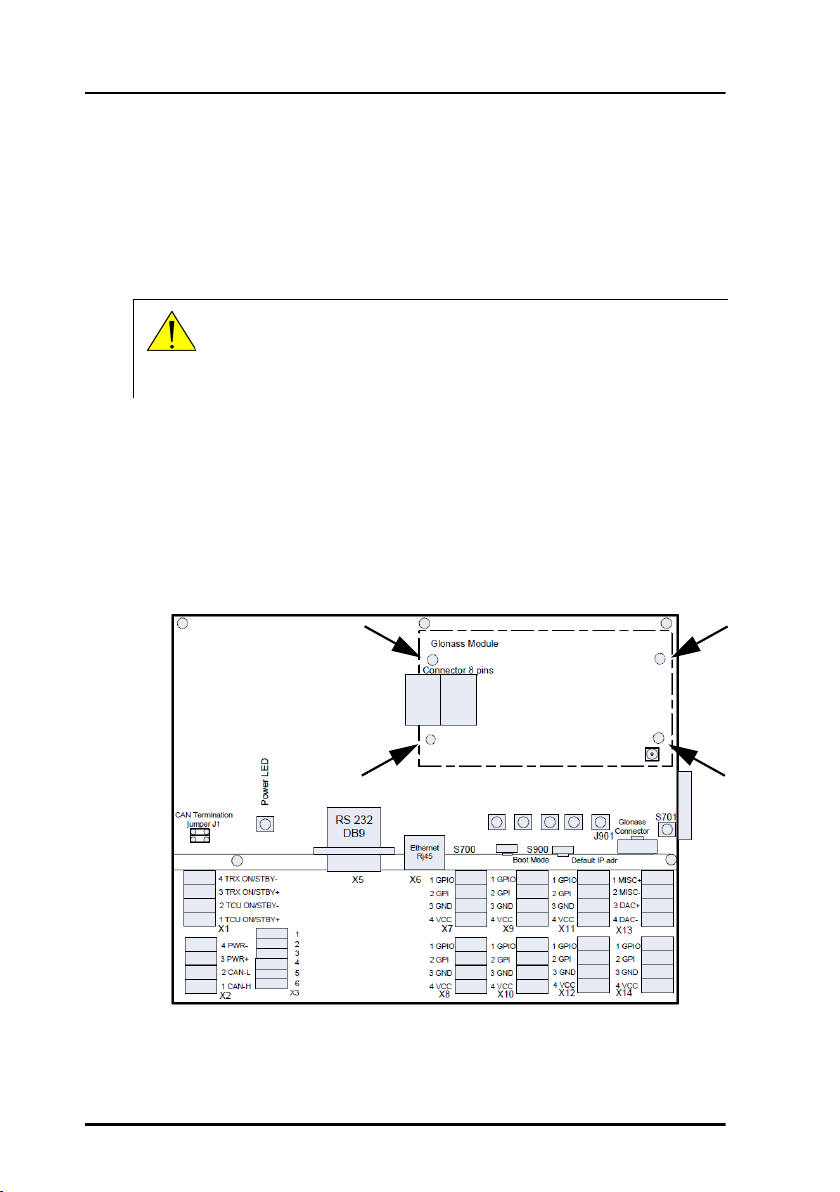

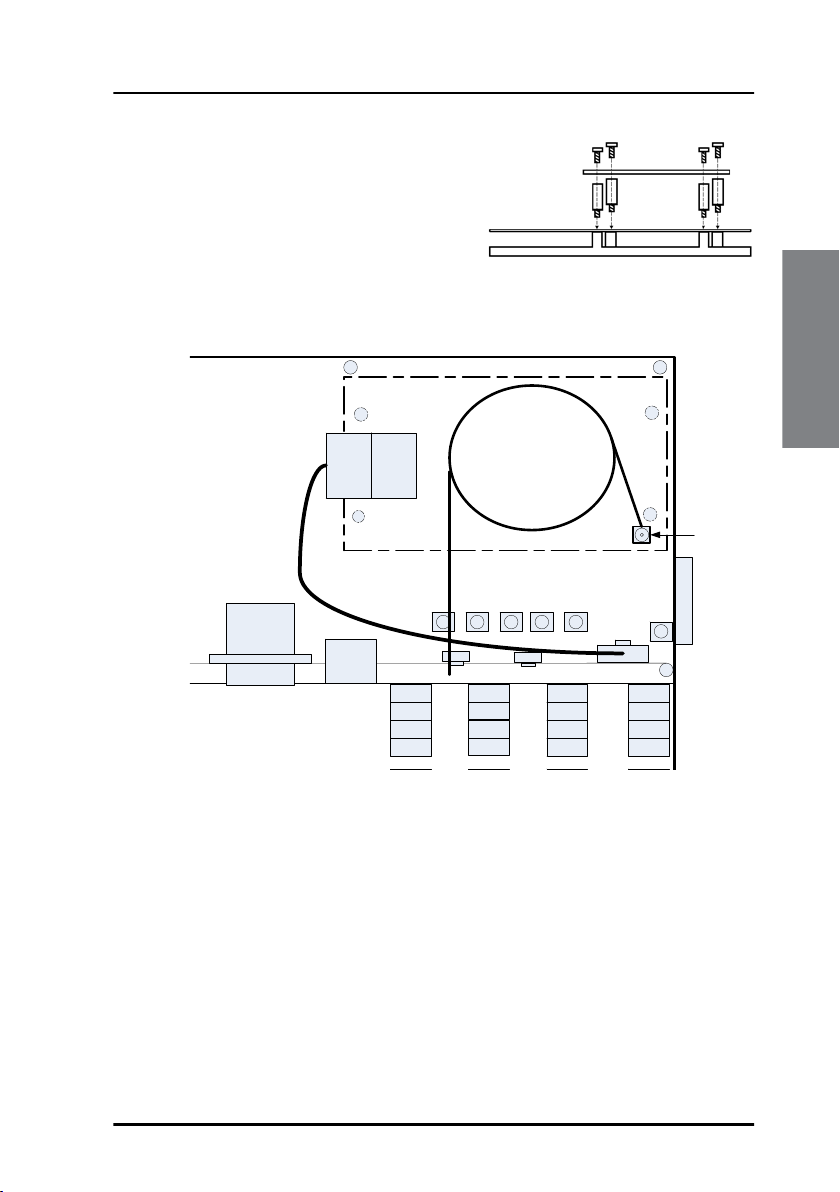

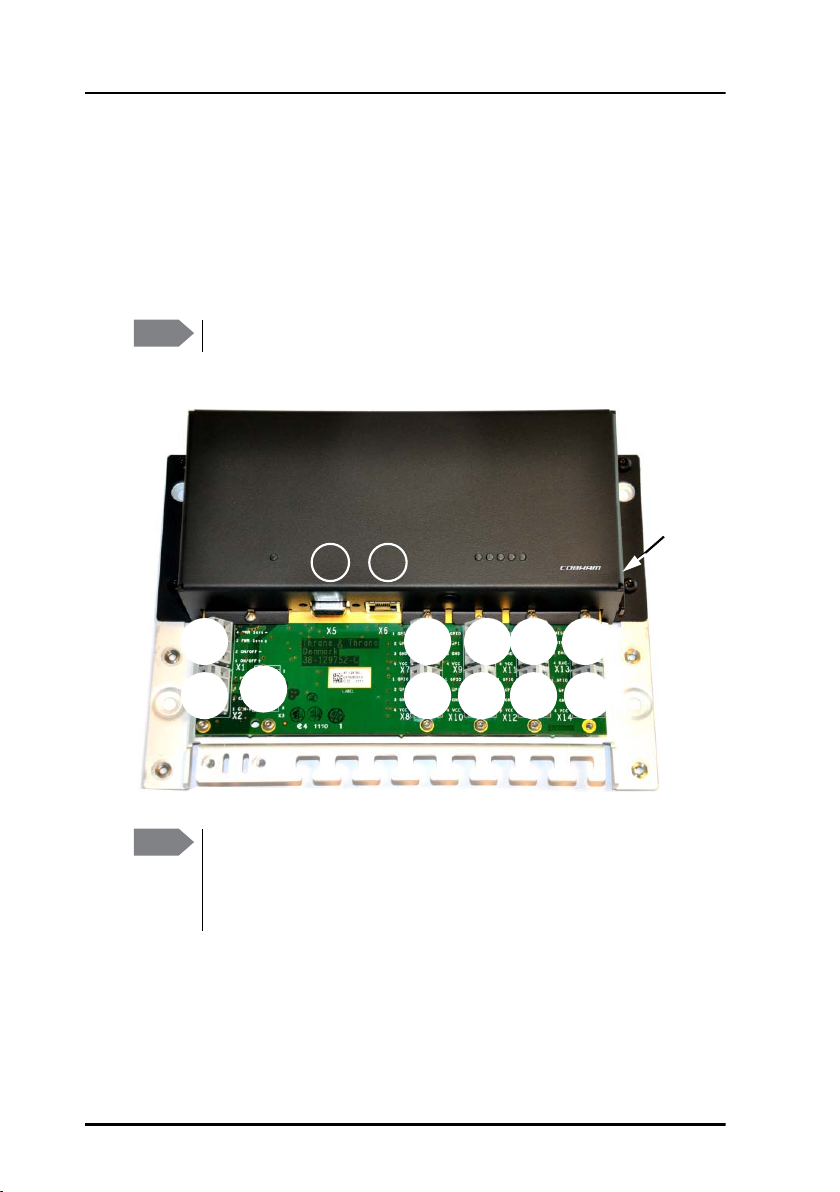

To install the Glonass module, do as follows:

1. Unscrew the screws holding the cover for the electronic circuits and

remove the cover.

2. Mount the four threaded spacers in the positions shown below, through

the main PCB and into the threaded bushings in the bottom of the

Terminal Control Unit. Tighten them to 1 Nm.

Spacers and screws x 4

10 Installing the Glonass option

Page 21

Chapter 2: Installation

3. Place the Glonass module over the

four spacers and mount the four

screws through the holes in the

Glonass module and into the

spacers.

Tighten the screws to 1 Nm.

4. Connect the cable harness from the Glonass module to the connector

J901 in the Terminal Control Unit.

RS 232

DB9

X5

Glonass Module

Connector 8 pins

5 X STATUS LED’s

Ethernet

S700

Rj45

1 GPIO

X6

2 GPI

3 GND

4 VCC

X7

1 GPIO

2 GPI

3 GND

4 VCC

X9 X11

1 GPIO

2 GPI

3 GND

4 VCC

Coax Cable

Connector

J901

1 MISC+

2 MISC-

3 DAC+

4 DAC-

X13

Glonass

Glonass

antenna

connector

5. Lead the external connector on the antenna cable through the hole

indicated in the drawing below and fasten it to the cover with the nut

on the connector.

Installation

Installing the Glonass option 11

Page 22

Chapter 2: Installation

6. Connect the internal connector on the antenna cable to the antenna

connector on the Glonass module as shown in the drawing in step 4.

7. Mount the cover and fasten the screws to 1.5 Nm.

For information on how to configure the Glonass module see Configuring

the Glonass option on page 42.

12 Installing the Glonass option

Page 23

Chapter 3

Connecting cables 3

This chapter provides a description of the connectors on the Terminal

Control Unit and gives guidelines to cabling. It has the following sections:

• Connector overview

• Power control (X1)

• CAN interface (X2)

• RS-232 interface (X5)

• LAN interface (X6)

• SSA and Alarm Panel (X7 to X14)

• Grounding the Terminal Control Unit

• Cable requirements

Connecting cables

13

Page 24

Chapter 3: Connecting cables

Connector overview

The drawing below shows the connectors on the Terminal Control Unit and

the SD card slot for inserting an SD memory card.

X5 and X6 are standard connectors for RS-232 (9-pin D-sub) and Ethernet

(RJ-45), all other connectors are spring-loaded terminals.

Note

Note

X3 and X13 are for future use.

SD card

slot

X5 X6

X1

X2

X3

X7

X9 X11 X13

X14X12X10X8

Some of the spring terminals can change function depending on

the connected equipment or by means of software commands.

See the available functions in SSA and Alarm Panel (X7 to X14) on

page 21.

14 Connector overview

Page 25

Chapter 3: Connecting cables

Power control (X1)

By default, when the system is powered on, the Terminal Control Unit and

the connected mini-C Terminal are always on. If you want to change this

behaviour, you must configure the X1 connector using a software

command (Constant_On 0). For details see Setting up software

controlled power management on page 40.

Important

If you have configured X1 with the command

Constant_On 0, you cannot switch on the system until

you connect pin 1 and 2 in X1 with a switch.

Remote on/standby

When X1 is configured for power

management, Pin 1 and 2 in the connector X1

can be used for switching between on and

standby on the Terminal Control Unit and

the mini-C Terminal. Connect a switch

between the two pins if you want to be able

to set the Terminal Control Unit and the miniC Terminal in standby mode independently of the rest of the system.

• Open contact: The Terminal Control Unit and the mini-C Terminal are in

standby mode.

• Closed contact: The Terminal Control Unit and the mini-C Terminal are

always on.

Pin 3 and 4 are for future use.

Power management (only SAILOR 6140 and SAILOR

6150)

Connecting cables

Note

When X1 is enabled and the switch is open (standby), you can control the

power management with software. See Setting up software controlled

power management on page 40.

Note that software controlled power saving functions are not

available in GMDSS, SSA nor LRIT systems.

Power control (X1) 15

Page 26

Chapter 3: Connecting cables

CAN interface (X2)

The Terminal Control Unit has one CAN interface (spring-loaded terminals)

used for communicating with connected equipment, such as a Message

Terminal and/or a mini-C GMDSS terminal. The CAN interface is located in

the bottom left corner of the Terminal Control Unit as shown below.

Important

Do not connect the shield of the CAN cable to the chassis of

the Terminal Control Unit, or to any other ship ground

connection on the Terminal Control Unit. For safety reasons

the CAN shield must only be connected to ship ground at the

power supply.

CAN termination

jumper

CAN

interface

To connect the CAN interface, insert the wires as shown in the drawing

above. Use the tool supplied with the Terminal Control Unit to open the

spring-loaded terminals.

Power input

There are 2 different options for the power input:

• The Terminal Control Unit can be powered through the CAN bus

(extended range: 10.5-32 V DC).

Note

If your power source is supplying more than 15 V, the system

is not protected against incorrect wiring.

16 CAN interface (X2)

Page 27

Chapter 3: Connecting cables

• In systems where CAN power is not available, you can connect your

power supply or battery to pin3 PWR+ and pin 4 PWR- shown in the

drawing on page 16, if the power supply is within the limits stated in

General specifications for the TCU on page 65.

Caution! If your power source is a battery, you must

configure an under-voltage protection for the

battery. The battery may be damaged if the

correct under-voltage protection is not applied!

For details, see the next section, Under-voltage

protection.

Under-voltage protection

If the power source is a battery, you must configure the Terminal Control

Unit to the correct under-voltage protection as follows:

1. Connect a computer to the Terminal Control Unit and start a terminal

program as described in Using commands on page 35.

2. At the tt6194:/$ prompt, type in the relevant command,

depending on the source voltage:

• Disable UVP: Type avr_uvp 0

• 24 V: Type avr_uvp 1

• 12 V: Type avr_uvp 2

• CAN voltage: type avr_uvp 3

120 Ohm termination for CAN interface

Caution! Before removing the cover enclosing the electronic

circuits, first make sure you are wearing a wrist strap

connected to the work place in to avoid ESD

(ElectroStatic Discharge).

Connecting cables

CAN interface (X2) 17

Page 28

Chapter 3: Connecting cables

A double jumper, J1 in the drawing on page 16, connects a 120 Ohm

termination for the CAN interface. If you have terminated the CAN

connection elsewhere and want to remove the termination in the Terminal

Control Unit, you must remove the jumper. To access the jumper you must

first remove the cover by unscrewing the screws holding the cover.

18 CAN interface (X2)

Page 29

Chapter 3: Connecting cables

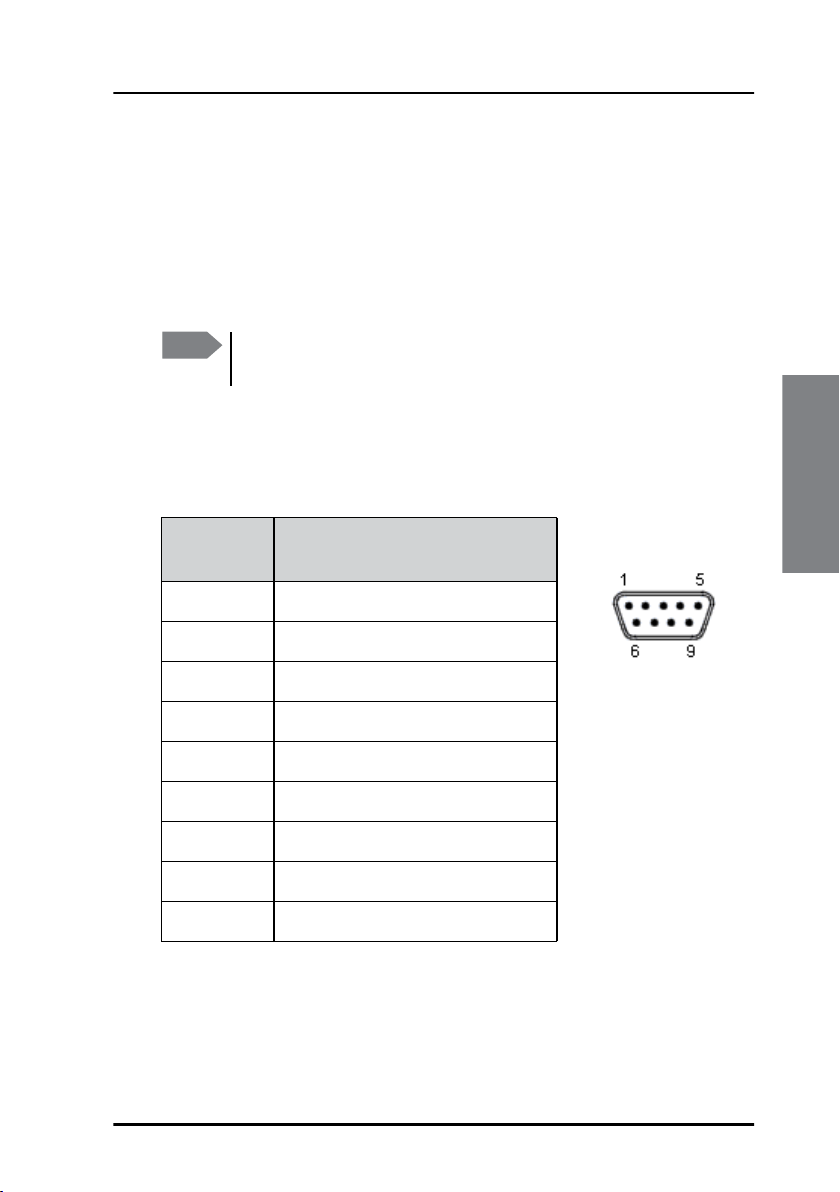

RS-232 interface (X5)

Overview

There is one RS-232 connector, 9-pin D-Sub, on the Terminal Control Unit.

The RS-232 (DTE) interface can be used for entering commands or running

scripts on the Terminal Control Unit.

Note

The default setup for the RS-232 interface is 115200 bps 8N1.

You must use this setting the first time you connect.

Pin-out

The figure and table below show the connector outline and pin

assignments.

Pin

number

1 Not Connected

2 RxD (Receive Data) Input

3 TxD (Transmit Data) output

4 Not Connected

5 GND

6 Not Connected

7 Not Connected

8 Not Connected

9 Not Connected

Pin function

D-Sub, 9 pin male

Connecting cables

Table 1:

RS-232 interface (X5) 19

Page 30

Chapter 3: Connecting cables

LAN interface (X6)

Overview

There is one Ethernet (10/100 MB) connector on the Terminal Control Unit.

We recommend connecting to the slave unit, in order to reserve the free

LAN connectors for user interfaces on the master unit.

The Ethernet interface can be used to connect a computer and use the

easyMail program supplied on CD with the Terminal Control Unit, the

ThraneLink Management Application or a terminal program to access the

Terminal Control Unit or the connected SAILOR 3027.

Note

To access the Terminal Control Unit through the LAN interface

you must know the IP address of the Terminal Control Unit. The

ThraneLink Management Application lists all connected units with

their IP addresses. For details, see Updating software on page 59.

You may also define a temporary IP address for the Terminal

Control Unit.

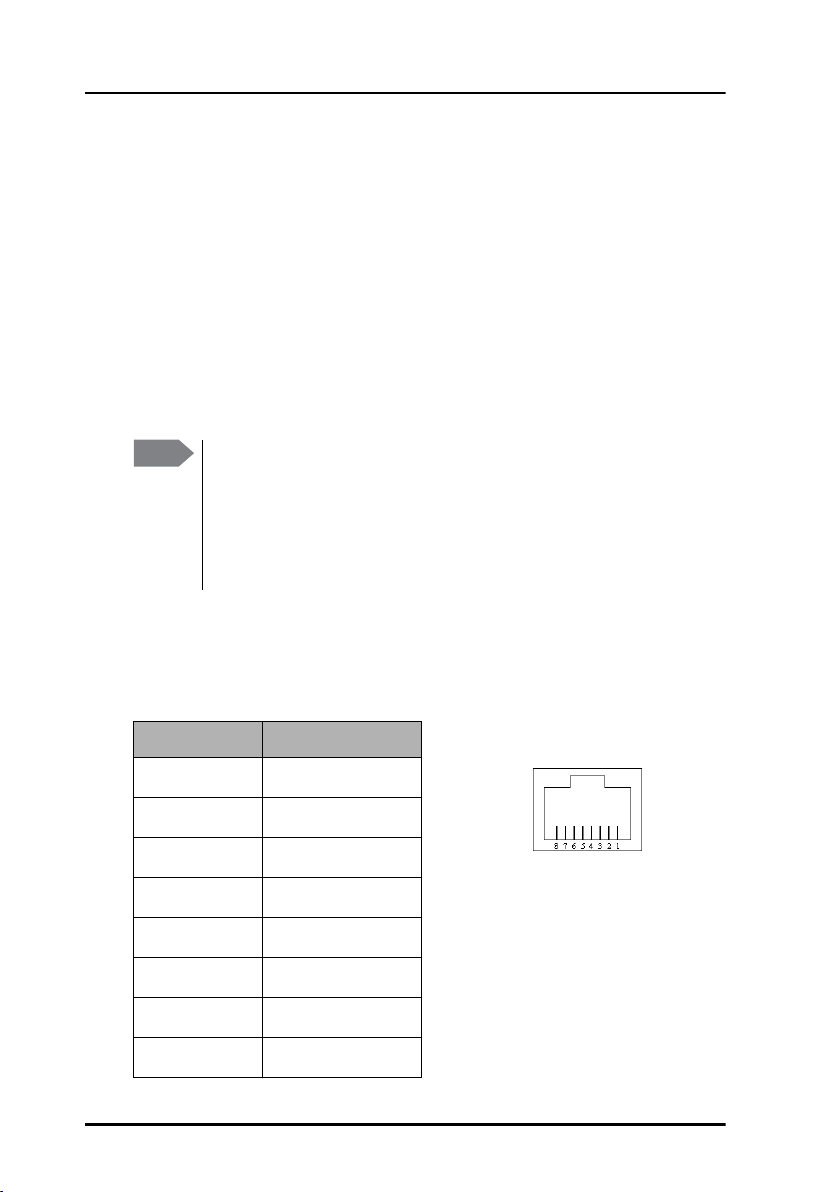

Pin-out

The figure and table below show the connector outline and pin

assignments.

Pin number Pin function

1

2

3

4

5

6

7

Rx+

Rx-

Tx+

Not connected

Not connected

Tx-

Not connected

RJ-45 female

8

20 LAN interface (X6)

Not connected

Page 31

Chapter 3: Connecting cables

SSA and Alarm Panel (X7 to X14)

Some of the spring-loaded terminals can have different functions,

depending on the system configuration.

The function of the I/O pins are automatically configured to match the

connected type of satellite terminal. Depending on the connected terminal,

some of the I/O pins are preconfigured, and some of the I/O pins are

configurable.

The general purpose inputs and outputs can be used for various

applications, e.g. temperature sensors, trawl indicators, flow meters/level

sensors or ignition ON indication.

Note

The following sections describe some of the possible configurations.

For specifications of the general purpose inputs/outputs, see

Specifications for I/O pins on page 66.

GMDSS or SSA systems (SAILOR 6110 or SAILOR

6120)

You can use the Terminal Control Unit for connecting alarm and test

buttons for use in SSA systems. When a SAILOR 3027C or SAILOR 3027SSA

terminal is connected, X7 to X14 are automatically configured as shown

below. X13 is not used.

Important

If you are not using all terminal blocks assigned for SSA alarm

buttons (X7 to X12), make sure pin 1 and 2 are shorted in the

terminal blocks that are not used. This only applies to the

alarm buttons X7 to X12, not to the test button X14.

Connecting cables

SSA and Alarm Panel (X7 to X14) 21

Page 32

Chapter 3: Connecting cables

The Terminal Control Unit can connect up to 6 alarm buttons and 1 test

button. The pin-out is shown below.

The following spring-loaded terminals are used for the buttons:

• SSA Alarm buttons: X7, X8, X9, X10, X11 and X12.

• SSA Test button: X14.

Note

Before inserting the wires into the terminals, make sure there is no

jumper between pin 1 and 2 (Output and Input).

Connect the buttons as shown below:

Brown

3

Green

4

Yellow

White

Green

Yellow

Brown

Terminal

Block

X7-X12

Terminal

Block

X14

PIN 1 Out 1

PIN 2 In

PIN 3 GND

PIN 4 3,3V

PIN 1 Out

PIN 2 In

PIN 3 GND

PIN 4 3,3V

22 SSA and Alarm Panel (X7 to X14)

NONC

SSA

Button 1-6

2

NO

a

SSA Test

1

Button

2

b

Page 33

Chapter 3: Connecting cables

Note that there may also be a white wire in the cables for the SSA Alarm

buttons. Do not connect the white wire from the red SSA alarm buttons only from the Test button.

Non-SOLAS Distress systems (SAILOR 6150)

The multi-purpose interface on the Terminal Control Unit can also connect

to Non-SOLAS Alarm Panels e.g. in Non-SOLAS Distress installations. When

a SAILOR 3027D is connected, X8, X10, X12 and X14 are automatically1

configured as shown in the two following drawings. X13 is not used.

With 1 TT-3042E Non-SOLAS Alarm Panel (Inmarsat C Distress

Alarm Box):

6$,/25

1RQ62/$6

6KLSJURXQGKXOO

6KLHOG

3RZHUVXSSO\

&KDVVLV

'&RXWSXW

7HUPLQDO

:

&

:

&$1

&$1EXV

LQFOXGLQJ

SRZHU

&$1EXVLQFOXGLQJSRZHU

&$1

SRZHU

RQO\

:

/$1

&RPSXWHURU

6$,/25

ZLWKHDV\0DLO

:

1&

%URZQ

1&

1RQ62/$6

:KLWH

12

$ODUP3DQHO

12

*UHHQ

<HOORZ

&$1;

/$1;

&KDVVLV

;

7HUPLQDO&RQWURO8QLW

9&&

3LQN

6$,/25

,PSRUWDQW,IQR

VHFRQGDODUPSDQHO

LVFRQQHFWHGWR;

\RXPXVWFRQQHFWSLQ

/('

DQGLQ;

*UH\

;

;

;

&OHDU

EXWWRQ

%X]]HU

Connecting cables

Note

Make sure to connect 1 and 2 in X12 if you only have 1 TT-3042E

Non-SOLAS Alarm Panel.

1. See extra information for use with 1 TT-3042E Non-SOLAS Alarm Panel in

the block diagram and the note below it.

SSA and Alarm Panel (X7 to X14) 23

Page 34

Chapter 3: Connecting cables

With 2 TT-3042E Non-SOLAS Alarm Panels (Inmarsat C Distress

Alarm Box):

6$,/25

1RQ62/$6

6KLSJURXQGKXOO

6KLHOG

3RZHUVXSSO\

&KDVVLV

'&RXWSXW

7HUPLQDO

&$1

:

&

:

&$1EXV

LQFOXGLQJ

SRZHU

&$1EXVLQFOXGLQJSRZHU

&$1

SRZHU

RQO\

6$,/25

RUFRPSXWHU

ZLWKHDV\0DLO

:

:

/$1

1&

%URZQ

1&

:KLWH

12

12

*UHHQ

<HOORZ

;

&$1;

/$1;

&KDVVLV

1RQ62/$6

$ODUP3DQHO

9&&

3LQN

7HUPLQDO&RQWURO8QLW

1RQ62/$6

$ODUP3DQHO

/('

/('

*UH\

*UH\

;

6$,/25

Each Non-SOLAS Alarm Panel uses two connector blocks as shown in the

drawings above. Note that X10 pin 1 is shared by the two Non-SOLAS Alarm

Panels.

1&

%URZQ

1&

:KLWH

12

12

9&&

3LQN

<HOORZ

;

;

&OHDU

EXWWRQ

%X]]HU

*UHHQ

The following spring-loaded terminals are used:

• Non-SOLAS Alarm Panels: X8, X10 and X12.

• Buzzer/Mute button: X14

24 SSA and Alarm Panel (X7 to X14)

Page 35

Non-SOLAS Alarm Panel

Connect the Non-SOLAS Alarm Panel(s) as shown below:

7HUPLQDO

%ORFN

;DQG

;

3,12XW

3,1,1

3,1*1'

3,19

*UHHQ

%URZQ

:KLWH

<HOORZ

1&

1&

12

12

Chapter 3: Connecting cables

6$,/25($ODUP3DQHO

7HUPLQDO

%ORFN

;

3,12XW

3,1,Q

3,1*1'

3,19

3LQN

*UD\

9&&

/('

Buzzer and Mute button

You can also connect a buzzer and a Mute button to X14.

The buzzer indicates incoming or outgoing Distress alerts. The buzzer must

be self-driven (make a sound when connected to power) and it must be

working at 3.3 V DC with a max. current of 100 mA.

The Mute button mutes the buzzer connected to X14 when the button is

pressed. The button must be a non-latched normally-open button of the

type single-pole single-toggle (SPST).

Connect the buzzer and Mute button as shown below:

1

Output

2

Terminal

block X14

Input

Mute

3

GND

4

3V3

button

+

buzzer

Connecting cables

SSA and Alarm Panel (X7 to X14) 25

Page 36

Chapter 3: Connecting cables

Grounding the Terminal Control Unit

The base plate of the Terminal Control Unit must be connected to ship

ground in one of two ways:

• Mount the Terminal Control Unit on a conducting surface connected to

ship ground, or

• connect a ground wire between ship ground and the cable relief for the

CAN cable shown in the picture below.

26 Grounding the Terminal Control Unit

Page 37

Chapter 3: Connecting cables

Cable requirements

The following requirements apply to the cables used with the Terminal

Control Unit. Before using the Terminal Control Unit for the first time,

check that all cables are correctly wired and fastened.

CAN cables

The CAN cables must meet the requirements in the NMEA 2000 standard.

When connecting the CAN backbone, be aware of the following

requirements:

• The CAN bus must have a termination resistance at both ends of the

CAN backbone. If you are using a SAILOR 3027 mini-C Terminal, it is

already terminated with 120 internally. You must provide the

CAN bus with a termination resistance of 120 Wat the other end

of the CAN backbone, either with a separate termination resistance or

inside the last device on the CAN backbone. The Terminal Control Unit

has an internal 120 resistor which can be disconnected by removing a

jumper (see 120 Ohm termination for CAN interface on page 17).

Connecting cables

120

Max.

6 m

Max. 200 m

GND

(ship hull)

Max.

6 m

Max.

6 m

Cable requirements 27

Page 38

Chapter 3: Connecting cables

• The cable length from each device to the CAN T-connector must be

maximum 6 m.

• The total length of the backbone must be maximum 200 m.

• For the distance between the mini-C Terminal and the Power Supply

Unit, refer to the installation manual for your mini-C System.

• Make the ground connection to ship ground (hull) at the power supply and only there.

• Connect the shield of the CAN cable throughout the system.

Ethernet cables

Ethernet cables must be Category 5e or higher. The cables must be

shielded. Max. length is 100 m.

RS-232 cables

Max. length of RS-232 cables is 15 m.

28 Cable requirements

Page 39

Chapter 4

Using the Terminal Control Unit4

This chapter provides a description of how to set up and use the Terminal

Control Unit Terminal Control Unit. It has the following sections:

• Status indicators

• Configuration

• Use of SSA buttons

• Use of Non-SOLAS Alarm Panels

29

Using the Terminal

Page 40

Chapter 4: Using the Terminal Control Unit

Status indicators

Light indicator positions

The Terminal Control Unit has a number of light indicators for signalling

status and errors/warnings.

The indicators show status of power, position and logon as well as status of

the Terminal Control Unit and the satellite terminal and program status.

The drawing below shows the location of the light indicators.

The function of the status indicators is described in the next pages.

30 Status indicators

Page 41

Chapter 4: Using the Terminal Control Unit

The drawing below shows the position of each light indicator.

124635

1. Terminal Control Unit Power/sleep mode, a green indicator

2. Satellite status, a green/red/yellow indicator

3. Position signal, a green/red/yellow indicator

4. Program status in SAILOR 3027, a green/yellow indicator

5. Satellite terminal status, a green/red/yellow indicator

6. Terminal Control Unit status, a green/red/yellow indicator

The following sections show the function of each light indicator.

Using the Terminal

Status indicators 31

Page 42

Chapter 4: Using the Terminal Control Unit

Light indicator functions

Terminal Control Unit Power/sleep mode indicator

Behaviour Meaning

Steady green Terminal Control Unit is on.

Flashing green Terminal Control Unit is in power save mode, see

Setting up software controlled power

management on page 40).

Off Terminal Control Unit is in standby mode.

Satellite status indicator

Behaviour Meaning

Steady green Successfully logged in.

Steady yellow Synchronized.

Steady red No satellite found.

Flashing green Login ongoing.

Off Terminal Control Unit is in standby mode.

32 Status indicators

Page 43

Chapter 4: Using the Terminal Control Unit

Position signal indicator

Behaviour Meaning

Steady green 3D position fix obtained.

Steady yellow No position fix - satellite visible.

Steady red No satellite found.

Flashing green 2D position fix obtained.

Off Terminal Control Unit is in standby mode.

Program status in SAILOR 3027 indicator

Behaviour Meaning

Green Interval programa for current Ocean Region is

running.

Flashing green Interval program for current Ocean Region is

defined but not running.

Yellow DNID is downloaded to the satellite terminal.

Using the Terminal

Off No DNID (or the Terminal Control Unit is in

standby mode).

a. An interval program is a program running at certain intervals, e.g. sending

data or position reports.

Status indicators 33

Page 44

Chapter 4: Using the Terminal Control Unit

Satellite terminal status indicator

Behaviour Meaning

Green Satellite terminal is on (including sleep mode).

Yellow Warning.

If a Message Terminal is connected you can

access the list of active warnings and errors by

selecting the icon in the top right corner of the

display.

Red Critical error.

Off Terminal Control Unit is in standby mode.

Terminal Control Unit Status indicator

Note

Steady green Terminal Control Unit is OK.

Steady yellow No mini-C (SAILOR 3027) is detected.

Flashing yellow Upload to micro controller failed

Steady red Critical error.

Flashing red Button failure. SSA alarm buttons or Non-SOLAS

Off Terminal Control Unit is in standby mode

34 Status indicators

If more than one event cause the same indicator to light up or

flash, the indication for the most critical event is shown. This

means there may be more than one event, even if only one

indication is shown. Check your user interface, e.g. the Message

Terminal, to see the events.

Behaviour Meaning

Alarm Panels are not working properly.

Page 45

Chapter 4: Using the Terminal Control Unit

Configuration

Using commands

Using the com or serial port you can send commands to the Terminal

Control Unit or SAILOR 3027.

PC with

terminal

program

tt6194:/$

SAILOR 6194

TCU

can1:/$

SAILOR 3027

Mini-C

To access the Terminal Control Unit or SAILOR 3027 settings using

commands, do as follows:

1. Connect a computer to the RS-232 or LAN interface.

For details refer to RS-232 interface (X5) on page 19 and LAN interface

(X6) on page 20.

2. Start up a terminal program and connect to the Terminal Control Unit.

The prompt shows:

tt6194:/$

3. To configure the SAILOR 3027 type minic in your terminal

program.

To return to Terminal Control Unit configuration after

configuring SAILOR 3027, press Ctrl + D or type exit.

4. There are two access levels to the Terminal Control Unit:

• normal (User level, default)

• sysadm (administrator level), used for running scripts and for some

commands

To see which type of user is currently active type:

tt6194:/$ su

Current user: normal

To log-on as a system administrator (for running scripts), type:

tt6194:/$ su sysadm

Enter password:

Using the Terminal

Configuration 35

Page 46

Chapter 4: Using the Terminal Control Unit

Per default the password is empty.

To change the password type:

password sysadm, then enter and confirm the new password.

5. Type the commands for Terminal Control Unit or SAILOR 3027.

To list all commands

For a list of all commands for the Terminal Control Unit, type:

tt6194:/$ help

The commands for the currently selected user mode (normal or sysadm)

are listed.

To auto-connect to the SAILOR 3027

To connect directly to a SAILOR 3027 after start-up of the Terminal Control

Unit, do as follows:

1. Connect a computer to the RS-232 interface or the LAN interface of the

TCU and start a terminal program as described in the section Using

commands.

2. Log in as a system administrator:

tt6194:/$ su sysadm

Enter password:

3. To enable auto connect to the SAILOR 3027, type:

tt6194:/$ auto_minic 1

Automatic Mini-C prompt is enabled

(reboot required)

4. To reboot the Terminal Control Unit, type:

tt6194:/$ reboot

<Your 'TELNET' connection has terminated>

can0:/$

You are now connected to the SAILOR 3027.

36 Configuration

Page 47

Chapter 4: Using the Terminal Control Unit

Note

Once auto connect to mini-C is enabled, you can only access the

mini-C, but not the TCU if you use the serial connection.

To disable auto connect, connect via the LAN interface. Then

type:

tt6194:/$ auto_minic 0

Automatic Mini-C prompt is disabled

Configuring the IP address of the Terminal Control Unit

1. Connect a computer to the RS-232 interface or the LAN interface and

start a terminal program as described in the previous section Using

commands.

2. Log in as a system administrator:

tt6194:/$ su sysadm

Enter password:

To see current system configuration

To see the current configuration type:

tt6194:/$ sysconf

Using the Terminal

The Terminal Control Unit returns (example):

tt6194:/$ sysconf

Model type : 0

Serial number : 0340530091

PCB ID : 0340530091

BOM : D.00

Unit BOM :

PCB revision :

PCB variant : 0

Location :

MAC : 00:11:cf:03:b5:c0

Configuration 37

Page 48

Chapter 4: Using the Terminal Control Unit

Use DHCP : 1

IP address : 0.0.0.0

IP mask : 0.0.0.0

IP gateway : 0.0.0.0

IP DNS : 0.0.0.0

ISO address : 0

Unique number : 0x00211628

Dev. inst. : 0

Dev. class inst. : 0

Host : 0

To use a DHCP server

It is recommended to set Use DHCP to on (1). Type the following for

automatically assigning an IP address to the Terminal Control Unit:

tt6194:/$ sysconf h 1

To set a static IP address

If needed in your network you can set a static IP address for the Terminal

Control Unit.

Example: Set Terminal Control Unit to IP address: 169.254.2.2, IP netmask:

255.255.0.0:

tt6194:/$ sysconf h 0

tt6194:/$ sysconf i <169.254.2.2>

tt6194:/$ sysconf a <255.255.0.0>

To set a gateway type:

tt6194:/$ sysconf g <gateway ip address>

To set a DNS server type:

tt6194:/$ sysconf d <dns ip address>

38 Configuration

Page 49

Chapter 4: Using the Terminal Control Unit

Reset button for IP address

The TCU has a button for setting a temporary fixed IP address. When you

push the button, the IP address of the TCU is temporarily set to the default

value (169.254.100.100). For further details see Setting a temporary fixed

IP address on page 63.

Configuring SSA buttons

Configuration of the SSA buttons lies in the SAILOR 3027. To access these

settings enter the terminal program as described in Using commands on

page 35 and type:

minic

The prompt changes to (example): can0:/$

Configuring SSA recipients

If your system uses SSA buttons, the SAILOR 3027 must be configured with

the recipient(s) of the Ship Security Alert. The recipients must be selected

according to the Flag Administration under which the vessel is sailing. The

recipients can be:

• e-mail addresses

• phone numbers (SMS)

• fax numbers

• telex numbers.

Using the Terminal

Specifications of the SSA routing requirements are found in IMO SOLAS

Regulation XI-2/6 and in IMO Circulars MSC/Circ.1072 and MSC/Circ.1073.

To configure the SSA recipients in the connected SAILOR 3027, do as

follows:

1. Connect a computer and access the SAILOR 3027 settings as described

in the previous section Using commands.

2. Enter the command for configuration of SSA recipients.

Configuration 39

Page 50

Chapter 4: Using the Terminal Control Unit

Configuring SSA button type

There are two types of SSA buttons. You can distinguish between the two

types by the color of the test button:

• Standard activation:

Covert alert buttons are latched red buttons.

Test button is green.

• Instant activation:

Covert alert buttons are non-latched red buttons.

Test button is yellow.

To configure the SSA button type in the connected SAILOR 3027, connect

a computer and access the SAILOR 3027 settings as described in Using

commands on page 35. Then enter the command for configuration of SSA

buttons.

Configuring SSA message repeat rate

When an SSA button is pushed, an SSA message is sent with regular

intervals to the SSA message recipients. The default interval is 30 minutes,

but you can change the interval to anything between 20 and 60 minutes.

To change the interval (repeat rate), do as follows:

1. Connect a computer and access the SAILOR 3027 settings as described

in Using commands on page 35.

2. Enter the command for configuration of the repeat rate:

Setting up software controlled power management

Note

By default, when the system is powered on, the Terminal Control Unit and

the connected mini-C Terminal are always on. You can change this

40 Configuration

Software controlled power management is only available for

SAILOR 6140 and SAILOR 6150 (see the next section).

For SAILOR 6110, 6120 and 6130 you can only use a switch

connected to X1 to switch between on and standby. For location

of X1 see Connector overview on page 14.

Page 51

Chapter 4: Using the Terminal Control Unit

behaviour with a command, so that you can use a switch connected to X1

for switching between on and standby. For details on the connector X1, see

Power control (X1) on page 15.

• To enable switching between on and standby, send the command

Constant_On 0.

• To return to always on (default setting), send the command

Constant_On 1.

For information on how to send commands to the Terminal Control Unit,

see Using commands on page 35.

SAILOR 6140 and SAILOR 6150 only

In the SAILOR 6140 and SAILOR 6150 systems you can define programs

that control when to power on and off.

Before you can use power management, the connector X1 must be enabled

with the command "constant_on 0" as described in the previous

section.

X1, closed switch: the system is always on and you cannot control

power management with software.

X1, open switch: the system is in standby and you can control the power

management with software. If a power management program is present,

the Terminal Control Unit shifts between standby and wake-up periods

depending on the timing set up in the program.

• Standby period.

Only the power supply micro controller is powered. The main power

supply is shut down to minimize the power consumption (Power

consumption in standby mode ~10 mW). The system can exit standby

by use of Interval or fixed time wake-up.

• Wake-up period.

The function is equal to always on, except that the Terminal Control

Unit will return to standby when ordered to do so by software.

Configuration 41

Using the Terminal

Page 52

Chapter 4: Using the Terminal Control Unit

Configuring the Glonass option

The Glonass module can be set up in several ways:

• Position data are based solely on the Glonass module

• Position data come preferably from the Glonass module

• Position data will always be those with best 3D fix

Configuration of the Glonass option lies in the SAILOR 3027. To access

these settings enter the terminal program as described in Using commands

on page 35, login as system administrator (sysadm) and type:

minic

The prompt changes to

can0:/$ (example)

To allow external navigational input

External navigational input Command

Allow

can0:/$ cfg -pa 1

Not allow can0:/$ cfg -pa 0

To display the current external navigational input, type:

can0:/$ cfg -pa

External nav input: 1 (Allowed)

To set preferred navigational input

Preferred navigational input Command

GPS

Glonass can0:/$ cfg -pi 2

To display the currently preferred navigational input, type:

can0:/$ cfg -pi

Preferred nav input: 2 (External Glonass)

42 Configuration

can0:/$ cfg -pi 1

Page 53

Chapter 4: Using the Terminal Control Unit

To set navigational input mode

Navigational input mode Command

To use preferred input only

To use 3D fix over preferred input can0:/$ cfg -pm 2

To use preferred input in 2D fix, even if 3D

fix is available

To use input with best Pdop value can0:/$ cfg -pm 4

To use input with best Hdop value can0:/$ cfg -pm 5

To display the currently selected navigational input mode, type:

can0:/$ cfg -pm

External nav input mode: 1 (Preferred input

only)

can0:/$ cfg -pm 1

can0:/$ cfg -pm 3

Configuration 43

Using the Terminal

Page 54

Chapter 4: Using the Terminal Control Unit

Use of SSA buttons

You can connect up to 6 SSA covert alert buttons and one SSA test button

to the Terminal Control Unit.

Important

For information on how to connect the buttons, see GMDSS or SSA

systems (SAILOR 6110 or SAILOR 6120) on page 21. See the previous

section for SSA configuration in the connected satellite terminal.

Do not push the red covert alert buttons, unless you are

under attack or threat. Only test the system using the built-in

test functionality.

Sending a Ship Security Alert

To send an alert using standard activation SSA, do as

follows:

1. Lift the cover for the red covert alert button.

2. Push the button.

An alert is sent after 30-33 seconds to the recipients configured in the

mini-C terminal. Within 30 seconds, if you want to cancel the alert push

the button again to release the button.

If the alert is not cancelled, SSA messages are retransmitted every 30

minutes (by default), until you press the button again to release it.

To send an alert using instant activation SSA, do as

follows:

1. Lift the cover for the red covert alert button.

2. Push the button.

An alert is sent immediately to the recipients configured in the mini-C

terminal. SSA messages are retransmitted every 30 minutes, until you

send an SSA test message (see the next section).

Note

44 Use of SSA buttons

You can change the SSA message repeat rate using a command.

See Configuring SSA message repeat rate on page 40.

Page 55

Chapter 4: Using the Terminal Control Unit

Sending an SSA test message

The SSA test button is green or yellow and should be placed close to the red

covert alert button. The test button is normally lit, but switches off when

pushed.

To send an SSA test message, do as follows:

1. Lift the cover for the green or yellow test button.

2. Push and hold the test button. The light in the test

button is turned off.

3. While holding in the test button, push one of the red

covert alert buttons.

• push for less than 30 seconds: The test button flashes to indicate

that it is operational.

• push for more than 30 seconds: An SSA test message is sent to the

message recipients configured during installation.

The message clearly shows that it is an SSA Test Message. The SSA Test

Message also includes a list of all recipients for SSA Messages.

Use of SSA buttons 45

Using the Terminal

Page 56

Chapter 4: Using the Terminal Control Unit

Use of Non-SOLAS Alarm Panels

You can use the SAILOR 3042E to send a Distress alert to the rescue centre

closest to your location. The SAILOR 6108 Non-SOLAS Alarm Panel works

similar to the SAILOR 6101/6103 Alarm Panels.

Important

To send a Distress Alert, do as follows:

1. Open the cover for the Distress button.

2. Press and hold the button until the

light is steady and the buzzer stops

(more than 5 seconds).

During this time the button light flashes

and the buzzer sounds. After 5 seconds

the red light goes steady on and the

buzzer is silent. This means the Distress

alert is being sent.

Important

Only send a Distress Alert if you are in immediate danger!

The Distress Alert can be compared to a MAYDAY call.

The MRCC normally sends a message to the alerting unit to

gather more information about the situation.

If at all possible, respond to such messages with a Distress

message sent to the same LES that was used for the Distress

Alert. The LES is set up in easyMail.

46 Use of Non-SOLAS Alarm Panels

Page 57

Chapter 5

Scripting 5

This chapter provides an introduction to scripting with the Terminal Control

Unit and an example for a script. It has the following sections:

• Introduction to scripting

• What can scripts do

• Complete example of a Lua script

Introduction to scripting

The Terminal Control Unit supports simple scripting, using Lua language.

Scripting can be used e.g. for automatically reacting on events registered in

the multi-purpose input/output pins. With the Script option you can run

custom-designed scripts dedicated to specific applications with the mini-C.

Typically a script monitors and controls the mini-C by using commands via

the command shell interface.

The scripts are run from

an SD memory card

installed in the SD card

slot of the Terminal

Control Unit.

SD card slot

Scripting

47

Page 58

Chapter 5: Scripting

What can scripts do

In this section you find two scenarios to illustrate the use of a script.

Scenario 1: Monitoring the engine speed

In a mini-C installation the Terminal Control Unit tacho input is connected

to an engine tachometer so the Terminal Control Unit can monitor the

engine speed. In this example we want to:

• Set up a set of speed limits (upper and lower limit) via a message sent to

the mini-C.

• Continually calculate the average engine speed.

• Have a message with speed information sent to a DNID if the speed

limits are exceeded.

This behaviour is not supported by a standard mini-C but it can be

programmed into the Terminal Control Unit via a script that can provide the

following:

1. Read the current engine speed.

2. Calculate a new average engine speed.

3. Check whether the mini-C has received a message containing new

speed limits.

4. Check the current engine speed against the latest speed limits.

5. Issue a message transmission if the speed limits are exceeded.

6. Repeat the sequence from step 1.

This example could be adapted or expanded in countless ways. Generally

the script may perform all actions that are available via the command shell

interface. It has access to a number of inputs and outputs on the Terminal

Control Unit as well as the files on the SD memory card.

48 What can scripts do

Page 59

Chapter 5: Scripting

Scenario 2: Logging the temperature on the SD memory card

The script does not necessarily have to involve the mini-C at all. The

following example is a Terminal Control Unit installation with a temperature

probe connected to an A/D converter input. In this example we want to:

• Log the temperature on the SD memory card every 5 minutes. This data

is then read from the SD card when the equipment is in for service.

This behaviour can be programmed into the Terminal Control Unit via a

script that can provide the following:

1. Read the A/D converter value and calculate a corresponding

temperature.

2. Append the temperature to a log file on the SD memory card.

3. Wait for 5 minutes.

4. Repeat the sequence from step 1.

How to write a script

The scripts that can be used with the Terminal Control Unit are written in

the Lua language, a compact, powerful, and well documented language.

Documentation and tutorials are available from the Lua project home page

at www.lua.org. The Terminal Control Unit includes Lua version 5.1.

First step: writing and running a test script

To illustrate the scripting process we use the following small Lua example

test script. This script makes the Terminal Control Unit write back the text

string Hello world.

-- This is our first test script

print("Hello world")

1. Name the script test1.lua.

2. Copy the script to a SD memory card and insert the card in the Terminal

Control Unit.

What can scripts do 49

Scripting

Page 60

Chapter 5: Scripting

3. Connect to the Terminal Control Unit as described in Using commands

on page 35.

4. Type the command lua s, the location of the script on the SD card

(/sdcard/) and the script name (test1.lua) to run the script.

Example: The following lines show the above procedure executed on a PC

connected to a Terminal Control Unit:

tt6194:/$ su sysadm

Enter password:

tt6194:/$ lua s /sdcard/test1.lua

tt6194:/$ Hello world

22:42:31.721 INFO:lua_task: LUA: Script

terminated.

The lua command is generally used to control script execution:

lua command Action

lua s <file name>

lua e

lua r <lua sentence>

lua c <file name> <code>

Executes the script <file name>

Terminates the script

Executes the sentence <lua

sentence>

Calculates a lock code for the file

<file name>. See also To lock the

Terminal Control Unit running a

script on page 57.

As indicated in the example above a Lua script is stored on an SD memory

card. All references to scripts files (and all other SD card files) are through

the path /sdcard/.

Configuring the Terminal Control Unit: auto execute

A script is executed via the command line and the lua s command. In

most situations automatic script execution is more relevant. This makes it

possible to execute a script automatically after power up of the Terminal

50 What can scripts do

Page 61

Chapter 5: Scripting

Control Unit or in response to a change of state of an IO pin. This is

controlled with the luaconf command.

luaconf a <auto> :

<auto>=0: No auto execute

<auto>=1: Auto execute

<auto>=2: Auto execute and auto restart

luaconf c <old> <new>: Change script lock code

luaconf i <gpi> :

<gpi>=0: No GPI control

<gpi>=1..16: Use GPI for script start/stop

You find a mapping table for general purpose input/output pins at GPIO

mapping table on page 70.

If auto execute is enabled, the Terminal Control Unit searches the SD

memory card for a script called autoexec.lua every time unit is

powered up. The feature is available in two modes:

• Auto execute — The script is executed once

• Auto execute and auto restart — The script is executed

and restarted if it terminates for any reason.

Script execution can also be controlled via an IO-pin (called GPI-control). If

enabled, a script will not auto execute or auto restart until the IO-pin is

pulled high. If a script is forced to stop then the IO-pin is pulled low.

TCU platform input and output

The most simple form of output is basic Lua print, that sends the output to

the serial port. This is convenient for simple program trace and information

output.

More general port access is established through opening of streams:

• A mini-C connected via CAN bus is accessed through the /dev/minic

device.

• The serial COM port is accessed through the /dev/serial device.

The code lines below show how a script opens the mini-C stream, writes

"ver\r" to the stream, reads back some characters, and closes the stream

again:

What can scripts do 51

Scripting

Page 62

Chapter 5: Scripting

f = assert(io.open("/dev/minic","r+"))

f:write("ver\r")

f:flush()

s = f:read(256)

f:close()

Complete example of a Lua script

Communicating with a mini-C

Communicating with a mini-C requires a number of steps and

considerations apart from accessing the /dev/minic device.

First and foremost the mini-C connection is a shell interface that accepts

commands and sends back a response. In case of the "ver" command the

following is sent to and received from the mini-C (example):

Sent to

the mini-CReceived from the mini-C

ver

52 Complete example of a Lua script

ver

Build : tt3027-445 Mar 7 2012

22:10:10

CPU : 1.03

DSP : 1.01

AVR : 0.42

OMAP bootld: 0.00

AVR bootld : 0.10

GPS SW : 6.02 (36023)

GPS HW : 00040005

GPS ROM : 5.00 (28483)

Hardware :

can0:/$

Page 63

Chapter 5: Scripting

The mini-C response includes an echo of the command itself as well as a

trailing prompt for the next command. When reading from the mini-C

device there is no built-in mechanism to separate the command and the

prompt from the actual response.

Furthermore there is no guarantee that the full response is received in a

single read. The script must therefore be able to combine the response from

a number of reads until the succeeding prompt has been received.

Template for basic mini-C communication

The script below includes these functions and may serve as a template for

basic mini-C communication.

function read_timeout(stream, timeout_ms)

local res = ""

repeat

local rd

rd = stream:read(16)

if rd == nil then

timeout_ms = timeout_ms - 100

else

res = res .. rd

end

until timeout_ms <= 0

return res

end

function make_pattern(pattern)

-- Escape all "magic" characters to make it usable as search pattern

return string.gsub(pattern, "([%^%$%(%)%%%.%[%]%*%+%-%?])", "%%%1")

end

function detect_prompt(stream)

local last_prompt = "unknown prompt"

local eq_count = 0

local resp = ""

local retries = 6

repeat

stream:write("\r")

stream:flush()

resp = read_timeout(stream, 500)

if string.len(resp) > 1 then

local new_prompt

local i

1

1. Detecting the mini-C prompt

Complete example of a Lua script 53

Scripting

Page 64

Chapter 5: Scripting

local ctrl_pos = 1

new_prompt = tostring(resp)

-- Only use the part of the string after the last control

char

for i = 1, string.len(new_prompt) do

if string.sub(new_prompt,i) < " " then ctrl_pos = i end

end

new_prompt = string.sub(new_prompt, ctrl_pos)

if new_prompt == last_prompt then

eq_count = eq_count + 1

else

last_prompt = new_prompt

eq_count = 0

end

end

retries = retries - 1

until eq_count > 2 or retries == 0

if retries == 0 then

return nil

else

return last_prompt

end

end

function read_until_prompt(stream, prompt, timeout_ms)

local retbuf = ""

local pr_found

repeat

local newdata = stream:read(16)

if newdata == nil then

timeout_ms = timeout_ms - 100

else

retbuf = retbuf .. newdata

end

pr_found = string.find(retbuf, make_pattern(prompt) .. "$")

until pr_found or timeout_ms <= 0

return retbuf, pr_found

end

PROMPT = ""

function send_cmd(stream, cmd, extra_char)

local resp = ""

local pr

stream:write(cmd .. "\r")

stream:flush()

repeat

local resp_part = ""

resp_part, pr = read_until_prompt(stream, PROMPT, 2000)

1

1. Send a command and return the response in a single call

54 Complete example of a Lua script

Page 65

Chapter 5: Scripting

resp = resp .. resp_part

if extra_char and not pr then

stream:write(extra_char)

extra_char = nil

end

until extra_char == nil

if resp then

local patt

-- remove trailing prompt

patt = make_pattern(PROMPT) .. "$"

resp = string.gsub(resp, patt, "\r\n", 1)

-- remove the command itself

patt = "^%s*" .. make_pattern(cmd) .. "[\r\n]*"

resp = string.gsub(resp, patt, "", 1)

end

return resp, pr

end

function print_cmd_result(stream, cmd, extra)

local result = send_cmd(stream,cmd,extra)

if result then

print(cmd .. " ---->")

print(result)

end

end

-- main chunk

if os.getenv("TCU") then

-- TCU

devname = "/dev/minic"

print("TCU environment")

elseif os.getenv("HOME") then

-- Linux

devname = "/dev/ttyS0"

os.execute("stty -F /dev/ttyS0 raw time 1 min 0 ispeed 38400 ospeed

38400 -echo")

print("Linux environment")

else

-- unsupported system

error("Environment not supported")

end

f = assert(io.open(devname,"r+"))

PROMPT = detect_prompt(f)

assert(PROMPT)

print_cmd_result(f, "st -w")

f:close()

1

2

1. Platform check

2. Printing mini-C communication

Complete example of a Lua script 55

Scripting

Page 66

Chapter 5: Scripting

The script uses a number of techniques worth noting:

• The platform is checked by inspecting the "TCU" environment variable

(see footnote 1. on page 55). That way the script can take different

hardware surroundings into account or prevent the script from running

on unsupported platforms.

• It is necessary to know the mini-C prompt to be able to split it from the

command response. The script detects the prompt by sending a number

of carriage returns to the mini-C - corresponding to empty commands and comparing the responses (see footnote 1. on page 53).

• For convenience the scripts contains a function that sends a command

and returns the response in a single call. This function is called

send_cmd (see footnote 1. on page 54) and is practical for many basic

scripts purposes.

• This script demonstrates mini-C communication by simply printing the

response to an "st -w" command (Hardware Status Screen) (see

footnote 2. on page 55).

Lua environment

The Lua language provides a large number of features that are derived from

the operating environment (file access, time, memory management, etc.).

The TCU implementation of Lua imposes a few constraints on the scripts,

mainly in these areas:

1. The amount of memory is limited. This means the scripts with large

variables or deep recursion may not be usable on a TCU.

2. The file system is limited. It supports FAT16 and FAT32 system but

there is no support for long file names (i.e., file names must follow the

classic "8.3" convention - up to 8 characters base name and up to 3

characters extension). Files can only be stored and accessed on the SD

memory card and they are accessed on the /sdcard/ path (e.g., the file

\subdir\file.ext on and SD card is accessed as /sdcard/subdir/file.ext).

56 Complete example of a Lua script

Page 67

Chapter 5: Scripting

To make it easier to write portable code, the TCU defines a few

environment variables. These are available from Lua via the os.getenv

function:

Variable name Content

HOME /sdcard

TMPDIR /sdcard

TCU The current software version of the TCU (e.g., 1.03)

Script security

In some applications it is important to ensure that only approved scripts are

used and that scripts cannot be altered. The TCU script module has a script

lock function that makes the TCU reject scripts without a specific security

tag.

To lock the Terminal Control Unit running a script

The "Hello World"-script (see First step: writing and running a test script on

page 49) is used here to illustrate how the lock function is set up and how it

works:

Objective: To ensure that the TCU can only execute the original "Hello

World" script. To prepare for locking, an empty comment line is added as

the first line (i.e., line 1):

--

-- This is our first test script

print("Hello world")

1. Copy the script to the SD memory card and insert the card in the TCU.

2. Choose a code word and calculate a corresponding checksum shell with

the following command:

lua c <file name> <code word>

With the file name test1.lua and the code word being 1234, the

command will be like this:

Complete example of a Lua script 57

Scripting

Page 68

Chapter 5: Scripting

tt6194:/$ lua c /sdcard/test1.lua 1234

1:3560946965

tt6194:/$

where 1:3560946965 is the checksum. Note that any changes in the

script file - including subtle changes like extra spaces and different line

endings - will change the checksum. Also a different code word will give

a different checksum.

If the script file does not begin with an empty comment line, the TCU

will refuse to calculate a checksum.

3. This checksum is inserted on the empty comment line in the script:

--1:3560946965

-- This is our first test script

print("Hello world")

4. The final step is to instruct the TCU only to execute scripts with a

matching checksum. This is done by configuring the code word into the

TCU:

luaconf c <current code word> <new code word>

The default code word is empty so in this example (where we chose the

code word 1234) this command will set up the script lock:

tt6194:/$ luaconf c "" 1234

tt6194:/$

Note that the "" in the command indicates an empty string

corresponding to an empty code word.

Now the Terminal Control Unit will only accept scripts that have a

checksum that matches the stored code word. If the checksum does not

match, the execution will abort with a warning: Cannot validate script.

To unlock the Terminal Control Unit running a script

If the TCU has to be unlocked at some point, use the luaconf command

to set the code word back to an empty string. Without a code word

configured, the TCU will execute any script with or without a checksum.

Note that this re-configuration can only be done if the current code word is

known:

tt6194:/$ luaconf c 1234 ""

tt6194:/$

58 Complete example of a Lua script

Page 69

Chapter 6

Service 6

This chapter has the following sections:

• Updating software

• Status signalling

• Setting a temporary fixed IP address

• Returning units for repair

• Repacking for shipment

Updating software

Required tools and files

Before you can update the software for the Terminal Control Unit you must

get a download tool and the new software for the Terminal Control Unit.

Do as follows:

1. Download the TMA from the Cobham eSupport web site (Self-

Service Center, SSC. You find the SSC in the Service and Support

section, 24-7 Service)

2. Install the ThraneLINK Management Application (TMA) on your PC.

3. Locate the new software image for the Terminal Control Unit (.tiif file).

4. Download the .tiif file to a USB memory stick or to a folder on your PC.

.

Service

59

Page 70

Chapter 6: Service

Updating the Terminal Control Unit software

To update the Terminal Control Unit software, do as follows:

1. Start the TMA.

2. The TMA searches for units connected to the local network. All units

found are shown on the screen.

3. Click on the image of the Terminal Control Unit to select it and to check

the current software version. If there are more than one Terminal

Control Unit you can recognize your unit by the serial number.

4. Have the new software ready on the PC, for example on an USB

memory stick. The TMA will automatically find the new software. If new

software is available you can see a yellow circular image on the start

screen and on the Terminal Control Unit page at the bottom, where the

icon for software update flashes.

60 Updating software

Page 71

Chapter 6: Service

5. Click the icon Software update. The following window is displayed

(example):

6. Click the button Update and wait for the update procedure to finish.

The software is now updated and the Terminal Control Unit automatically

restarts with the new software. You can use the ThraneLINK Management

Application at any time to check the software version.

Updating software 61

Service

Page 72

Chapter 6: Service

Status signalling

Light indicators

The Terminal Control Unit has a number of light indicators for signalling

status and errors/warnings. See Status indicators on page 30 for a full

description of the indicators and their function.

Should the system fail, you can use the indicators to see which units are

affected. To see a description of the error you must use the easyMail

application on a connected computer or connect a Message Terminal to

the system. For further information, see the user manual for your mini-C

System.

62 Status signalling

Page 73

Chapter 6: Service

Setting a temporary fixed IP address

The TCU has a button for setting a temporary fixed IP address.

The function of the button is: When you push the button, the IP address of

the Terminal Control Unit is temporarily set to the default value

(169.254.100.100).

With this function, even if the IP address has been changed and you do not

remember the new IP address, you can still access the Terminal Control

Unit. The default value is not saved in the configuration, but is only valid for

the first IP session.

Setting a temporary fixed IP address 63

Service

Page 74

Chapter 6: Service

Returning units for repair

Should your Cobham SATCOM product fail, please contact your dealer or

installer, or the nearest Cobham SATCOM partner. You will find the partner

details on www.cobham.com/satcom where you also find the Cobham

SATCOM Self Service Center web-portal, which may help you solve the

problem.

Your dealer, installer or Cobham SATCOM partner will assist you whether

the need is user training, technical support, arranging on-site repair or

sending the product for repair.

Your dealer, installer or Cobham SATCOM partner will also take care of any

warranty issue.

Repacking for shipment

The shipping carton has been carefully designed to protect the Terminal

Control Unit and its accessories during shipment. This carton and its

associated packing material should be used when repacking for shipment.

Attach a tag indicating the type of service required, return address, model

number and full serial number. Mark the carton FRAGILE to ensure careful

handling.

Note

64 Returning units for repair

Correct shipment is the customer’s own responsibility.

Page 75

Appendix A

Specifications A

General specifications for the TCU

Item Specifications

Power 10.5 to 32 VDC (nom. 12-24 VDC)

Power

consumption

Interfaces Ethernet (10/100 Mbit), RJ45 connector (X6)

Conformity Inmarsat C GMDSS approved/ Wheelmark approved.

IP protection

class

Ambient

temperature