Calibration Procedures on Cobe Centrysystem 3:

I) Balance Chamber Calibration:

- Verify that pressure regulators PRV and PRV2 are calibrated as well as pressure

transducers PDI and PDO with switches SW2 and SW1-8 are closed (after switching

system power off, setting the calibration switches SW2 and SW1-8 to CAL position

(i.e. down) is necessary to enter into the calibration mode).

- Switch the power button on, select calibrate option C, and keep selecting until

“Balance Chamber” option appears.

- Start calibration.

- Step 1: Bypass the machine by shunting the bypass ports.

- Step 2: Remove bypass mode. The numbers corresponding to LS1 and LS2 appear on

the screen (chamber 1 and 2 diaphragms are forced to the left by dialysate prep

system in the chamber i.e. HL1 and HL2). The numbers should increase from 0000 to

above 0040. If not, then replace the affected CCA Hall-effect sensor. Wait for 2

minutes so the values can stabilize.

- Step 3: GP3 pump forces the chamber diaphragms 1 and 2 to the right side HR1 and

HR2.The numbers should start at 00FF and decrease beyond 00D0. If not, then

replace the affected CCA Hall-effect sensor.

- Step 4: The numbers of the NOVRAM # 67 to # 70 (UFC 8/6 M&L and

UFC 8/7 M&L) appear. Turn the switches on the UF board on and store the values

recorded.

- Check the status for dialysate flow (should be ± 30 mL/min within 500 mL/min).

- Check UF service screen 1 (window 1).

- Verify that the control bytes are within 3 of each other: 8M (chamber 1 flow) and 8L

(chamber 2 flow).

- Verify that control bytes are within 5 within each other:

4L (chamber 1 fill time)

5L (chamber 2 fill time)

6L (chamber 1 cycle time)

7L (chamber 2 cycle time)

- Repeat calibration until desired results are reached otherwise set SW2 and SW1-8

open.

II) Dialysate Pressure Transducer Calibration (PDO and PDI):

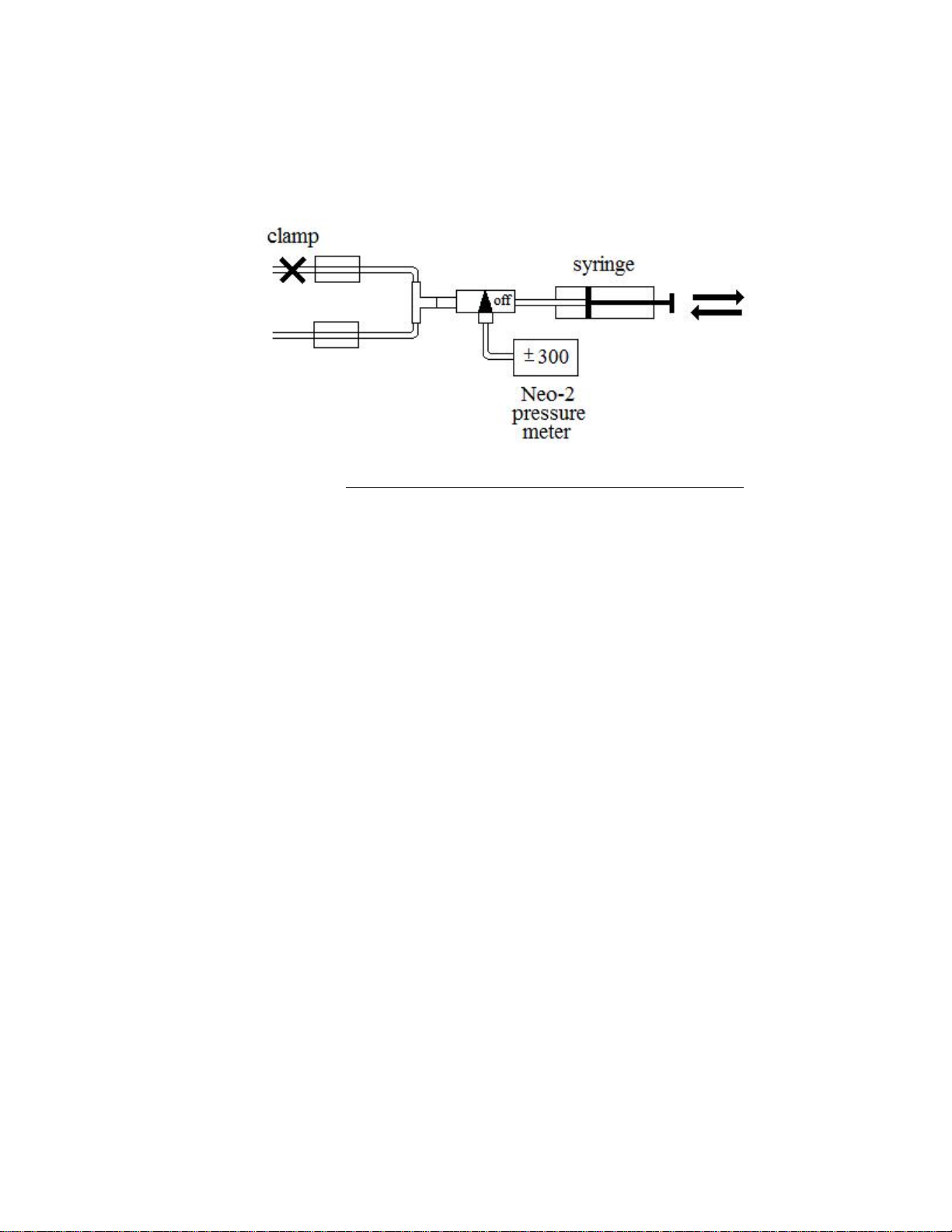

- There is a need for clamps, a T-connector and a syringe.

- The setup diagram is shown below in Figure 2:

Figure 1 - Setup for Dialysate Pressure Transducer Calibration

- Verify switches SW2 and SW1-8 are closed after switching the system power off.

- Switch power button on, select calibrate option C, and keep selecting until “Dialysate

Pressure Transducers” option appears.

- Start calibration.

- Step 1: Bypass the machine, clamp the tubing with padded hemostats at output of

PDO between PDO and bypass tee. Mark tubing between PDO transducer and check

valve with piece of tape. Remove tubing from PDO transducer at check valve.

Remove tubing from PDI transducer at fluid ground. Remove any water from tubing.

Connect the 2 tubing pieces with chevron or T connector. Connect the pressure meter

Neo-2 and syringe to T-connector ports. Adjust the syringe until the pressure meter

reads -300 mmHg for 3 seconds. The numbers on the screen should be between 30 to

50 H. Continue the process of calibration.

- Step 2: Adjust the syringe until pressure meter reads 300 mmHg for 3 seconds. The

numbers on the screen should be between B0 to D0 H. Continue the process of

calibration.

- Step 3: Adjust the syringe until the pressure meter reads -300 mmHg for 3 seconds.

The numbers on the screen should read 30 to 50 H. Continue the process of

calibration.

- Step 4: Adjust the syringe until the pressure meter reads 300 mmHg for 3 seconds.

The numbers on the screen should be between B0 to D0 H. Continue the process of

calibration.

- Step 5: The displayed numbers are:

PDO Gain NOVRAM # 81 – UFC 9/5M (control)

PDO Offset NOVRAM # 82 – UFC 9/5L (control)

PDO Gain NOVRAM # 119 – UFM 9/8L (monitor)

PDO Offset NOVRAM # 120 – UFM 9/9M (monitor)

PDI Gain NOVRAM # 117 – UFM 9/7L (monitor)

PDI Offset NOVRAM # 118 – UFM 9/8M (monitor)

- Save and store the parameter values and then switch SW2 and SW1-8 on.

III) Blood Handling Pressure Transducer Calibration (Arterial/Venous Pressure

Transducers):

- Set the switches SW2 and SW1-8 down after turning the system power off. Turn the

power button on, go to the option “Calibrate”, and then select option A “Automatic

Calibration”. Select “Blood Handling Pressure Transducers”.

- Start calibration.

- Step 1: Connect the pressure meter and syringe to the “Venous Pressure” transducer

(to the left); adjust the syringe until the pressure reading is 300 mmHg for 3 seconds;

continue.

- Step 2: Move the meter and syringe to “Arterial Pressure” transducer; adjust the

syringe until the pressure reading is -300 mmHg for 3 seconds; continue.

- Step 3: Move the meter and syringe and open the transducers to the atmospheric

pressure for 3 seconds; continue.

- Step 4: The displayed values are:

Art. Pres. Offset (control) NOVRAM # 129 – BHC 2/6M

Ven. Pres. Offset (control) NOVRAM # 130 – BHC 2/6L

Art. Pres. Gain (control) NOVRAM # 131 – BHC 2/7M

Ven. Pres. Gain (control) NOVRAM # 132 – BHC 2/7L

Art. Pres. Offset (monitor) NOVRAM # 145 – BHM 2/6M

Ven. Pres. Offset (monitor) NOVRAM # 146 – BHM 2/6L

Art. Pres. Gain (monitor) NOVRAM # 147 – BHM 2/7M

Ven. Pres. Gain (monitor) NOVRAM # 148 – BHM 2/7L

- Save and store the parameter values. Switch SW2 and SW1-8 back on. Prove with the

status screen (“Run” mode) that the “Arterial Pressure” and “Venous Pressure” are

-4 to 4 mmHg. Connect the pressure meter and syringe to the “Venous Pressure”

transducer (left) and adjust the syringe until the pressure is -40 mmHg on the pressure

meter while the “Venous Pressure” reads on display -36 to -44 mmHg. Adjust the

syringe until the pressure is 380 mmHg; verify the “Venous Pressure” reads

372 to 388 mmHg and clamp the line so that the read pressure is 360 to 400 mmHg

with the line clamped. Move the meter and syringe to the “Arterial Pressure”

transducer and adjust the syringe similar to the “Venous Pressure” transducer but with

complementary values 40 mmHg, 36 to 44 mmHg, -372 to -388 mmHg, and

-360 to -400 mmHg.

- Allow the temperature to stabilize for 5 seconds and monitor the “Venous Pressure”

and “Arterial Pressure” for two minutes. If a change of more than 4 mmHg is

recorded, locate and repair the leak as well as re-conduct the test.

IV) Dialysate Flow Calibration (GP1):

- Set the switches SW2 and SW1-8 down after turning the system power off. Turn the

power button on, go to the option “Calibrate”, and then select option C “Device

Calibration”. Select “Dialysate Flow”.

- Start calibration.

- Step 1: The parameters appearing on the screen are:

Flow Gain 70 – A8 H

Flow Offset 00 – 50 H

Flow / Temperature Corr. 00 – 20 H

The above values are the allowed ranges which can be acquired. If any value is out of

its respective range, select “Exit” option B: if the flow gain is out of range, set

NOVRAM # 6 to 85 H; if the flow offset is out of range, set NOVRAM # 5 to 35 H;

if the flow / temperature corr. is out of range, set NOVRAM # 7 to 06 H. After

changing the appropriate NOVRAM parameter, exit and store the value.

- Step 2: A timer of 60 seconds allows the flow to go up to 400 mL/min.

- Step 3: Place the drain hose in a graduated cylinder (of capacity 750 mL) and

measure the flow for 1 minute; press modify to change the flow value as indicated by

the graduated cylinder (if the value is far off from 400 mL, a higher reading is traced

to a malfunctioning flow pump GP2 or GP1 or a leak in the vacuum system while a

low reading is traced to a leak in the drain system).

- Step 4: A timer of 60 seconds allows the flow to go up to 600 mL/min.

- Step 5: Place the drain hose in the graduated cylinder and measure the flow for

1 minute; press modify to change the flow value as indicated by the graduated

cylinder (if the value is far off from 600 mL, a higher reading is traced to a

malfunctioning flow pump GP2 or GP1 or a leak in the vacuum system while a low

reading is traced to a leak in the drain system).

- Save and store the parameter values and then switch SW2 and SW1-8 on.

- Select “Run” mode in order to operate the system. The flow should be within

± 30 mL/min form the value of Operating parameter # 21 which corresponds to the

dialysate flow rate.

V) Deaeration Level Sensor Calibration (LS1):

- Set the switches SW2 and SW1-8 down after switching the system power off. Turn

the power button on, go to the option “Calibrate”, and then select option C “Device

Calibration”. Select “Deaeration Level Sensor”.

- Start calibration.

- Step 1: V1 is turned off so that no water enters the machine; therefore, LS1 is forced

to its lowest level. Wait for 1 minute, and then press continue.

- Step 2: V1 is turned full on; hence, LS1 is forced to its highest level. Wait for

1 minute, and then press continue.

- Step 3: The displayed numbers on the screen are:

LS1 Trip Point (hi) (control) NOVRAM # 1 – DPC E/5M

LS1 Trip Point (lo) (control) NOVRAM # 2 – DPC E/5L

LS1 Trip Point (hi) (monitor) NOVRAM # 47 – DPM 3/8M

LS1 Trip Point (lo) (monitor) NOVRAM # 48 – DPM 3/8L

- Save and store the parameter values and then switch SW2 and SW1-8 on.

- Select “Run” mode in order to operate the system.

- Verify the readings as follows:

1. Turn off the water for 1 minute.

2. Select the DP1 service screen 6.

3. The values of the control byte 7M and the monitor byte 7L appear.

4. Add the bits to each value.

5. Select the DP service screen E.

6. Verify that the control byte 5L reads within 5 bits of the monitor byte 7L

adjusted value.

7. Turn the water on, power off then power on.

8. Press fill and wait 1 minute.

9. Select the DP service screen 6.

10. The values of the control byte 7M and monitor byte 7L appear.

11. Subtract 8 bits from each number.

12. Select the DP service screen E.

13. Verify that the control byte 5M reads within 5 bits of the control byte 7M

adjusted value.

14. Select DP service screen 3.

15. Verify that the monitor byte 8M reads within 5 bits of the monitor byte 7L

adjusted value.

16. If the values fall within specification, the new parameters are reserved;

otherwise the calibration process is repeated.

VI) Blood Leak Calibration:

- Set the switches SW2 and SW1-8 down after switching the system power off. Turn

the power button on, go to the option “Calibrate”, and then select option C “Device

Calibration”. Select “Blood Leak Calibration”.

- Start calibration (with dialyzer hoses connected to shunt block).

- Step 1: A timer of 20 minutes allows the blood leak detector calibrate.

1

DP: Dialysate Pressure

- Step 2: The displayed values are as follows:

LED Dark ADC value with LED off

LED Light ADC value with LED on

DAC Gain Blood leak DAC gain

STO AUG Storage average of light

- Verify that STO AUG is in the range of 5E to 6A H.

- Save and store the parameter values and then switch SW2 and SW1-8 on.

VII) Blood Leak Temperature Compensation Calibration:

- Verify the blood leak temperature compensation by checking the NOVRAM

parameter # 122. Select the service screen UFM window B byte 6M, and verify that

the value is 67 H. If not, exit the service screen, enter the calibration mode, then

select the NOVRAM parameter # 122 and change it to 67 H.

- Set the switches SW2 and SW1-8 down after switching the system power off. Turn

the power button on, go to the option “Calibrate”, and then select option C “Device

Calibration”. Select “Blood Leak Temperature Compensation”.

- Start calibration.

- Step 1: A timer allows the machine to stabilize.

- Step 2: Another timer allows the machine to re-stabilize.

- Step 3: The displayed number corresponds to the “Blood Leak Temperature

Compensation” gain.

- Save and store the parameter value and then switch SW2 and SW1-8 on.

- Select “Run” mode in order to operate the system.

- Verify that for a temperature range of 30º – 38º C (Operating parameters # 1 and # 2),

with dialyzer hoses connected to the dialyzer (“Ready” mode), and with dialysate

temperature of 30º C (allow 15 minutes for the system to stabilize), the UF service

screen D monitor byte 6M is recorded. When the dialysate temperature is adjusted to

38º C, the UF service screen D gives the monitor byte 6M reading which is within 5

bits from the latter reading (at 30º C).

VIII) Pressure / Flow Correction Calibration:

- PRV1, PRV2, and dialysate pressure transducers PDI and PDO must be calibrated

before using this procedure.

- Set the switches SW2 and SW1-8 down after switching the system power off. Place

all the concentrate lines in their rinse ports. Turn the power button on, go to the

option “Calibrate”, and then select option C “Device Calibration”. Select “Pressure /

Flow Calibration”.

- Start calibration. Verify that the machine is not in bypass mode, and clear the

“Dialysate Line Occluded” alarm if necessary.

- Step 1: Wait 2 minutes for the displayed value to stabilize. The pressure value must

read about 275 mmHg. Continue.

- Step 2: Wait 1 minute for the displayed value to stabilize. The pressure value must

read about -275 mmHg. Continue.

- Step 3: Save and store the parameter values and then switch SW2 and SW1-8 on.

- Select “Run” mode in order to operate the system.

- To verify the values obtained, select the status screen. Adjust the dialysate pressure to

-20 mmHg using a syringe placed at the dialysate sample port. After 1 minute, note

the chamber 1 fill time (UFC SW1 4L). When the LED DS1 on the UF CCA board is

on, inject about 10 cc of water into the dialysate sample port. Verify that the

“Dialysate Pressure” is 150 to 300 mmHg (high). The next time DS1 is on (10 to 15

seconds), note the chamber 2 cycle time (UFC SW1 7L). Verify that the difference

between the two times of chambers 1 and 2 cycles is less than 0A H. When LED DS1

on UF CCA is on, withdraw 20 cc of water from the dialysate sample port. Verify that

the “Dialysate Pressure” is -150 to -300 mmHg (low). The next time DS1 is on (10 to

15 seconds), note chamber 2 cycle time (UFC SW1 7L). Verify that the difference

between the two times of chambers 1 and 2 cycles is less than 0A H. Observing the

status screen, adjust “Dialysate Pressure” to -8 up to 8 mmHg with syringe placed at

the dialysate sample port. The values must be within specification; otherwise, the

calibration process is repeated.

IX) UF Pump Calibration (DP3):

- PRV3 must be calibrated before completing this procedure.

- Set the switches SW2 and SW1-8 down after switching the system power off. Fill a

beaker (of capacity of 750 mL) with 500 mL of warm water. Clamp the tubing below

P10 on the original packaged machines but after P10 on repackaged machines

(i.e. not between PRV3 and P10). Uncap P10. Connect one end of the tubing segment

to P10, and place the other end in the beaker. Connect the pressure monitoring line to

the dialyzer sample port, and place the other end in the beaker. Turn the power button

on, go to the option “Calibrate”, and then select option C “Device Calibration”. Select

“UF Pump”.

- Start calibration.

- Step 1: Continue.

- Step 2: A timer allows the UF pump to warm up. If the pump is already warm, press

the top soft key. When the process is complete, press “Continue”. Place a tubing

segment from P10 into a graduated cylinder. Press “Continue”.

- Step 3: Wait for 200 pulses.

- Step 4: Read the amount of fluid present in the graduated cylinder. If the amount is

under 80 mL or over 120 mL, manually adjust the UF pump stroke volume screw and

retest. Press “Modify” and use the up and down keys to change the screen value to

match the measured value.

- Save and store the parameter values and then switch SW2 and SW1-8 on.

- Select “Run” mode in order to operate the system.

- To verify the obtained values, enter into setup mode. Load the fluid filled segment in

the air bubble detector. Turn the blood pump on, and press “Pressure / UFC”. Verify

that the time left is 4:00 minutes. Adjust the “Target Loss” until “UF Rate” is 2 kg/hr.

Empty the graduated cylinder, and replace the tubing from P10 in graduated cylinder.

Press “Mode”, “Ready” and “Dialyze”. Select any UF service screen: when the

control byte 3L reads C8 H, move the tubing from the cylinder to a beaker (capacity

of 150 mL). Verify that the amount of fluid in the cylinder reads 99 to 101 mL. If the

value is within specifications, then remove the tubing and hemostat, recap P10,

remove the water filling the tubing and pressure monitoring line, and replace the

panels. If not, repeat the calibration process.

X) Blood Pump Flow Calibration:

- Set the switches SW2 and SW1-8 down after switching the system power off. Install

a fluid-filled tube into the ultrasonic air bubble detector. Turn the power button on, go

to the option “Calibrate”, and then select option C “Device Calibration”. Select

“Blood Pump Flow”.

- Start calibration.

- Step 1: Turn the blood pump on. Adjust the flow rate to 100 mL/min. Wait for at least

5 minutes, and then verify that the displayed RPM2 value is 13.2 to 14.7. If not,

increase or decrease the blood pump speed until the displayed RPM meets the

specification. Continue.

- Step 2: Adjust the flow rate to 40 mL/min Wait at least 5 minutes, and then verify that

the displayed RPM value is 53.4 to 59.0. If not, increase or decrease the blood pump

speed until the displayed RPM meets the specification. Continue.

- Step 3: The displayed numbers are:

BP Gain (high byte) NOVRAM # 133 – BHC 2/8M

BP Gain (low byte) NOVRAM # 134 – BHC 2/8L

BP Offset (high byte) NOVRAM # 135 – BHC 2/9M

BP Offset (low byte) NOVRAM # 136 – BHC 3/6M

- Save and store the parameter values and then switch SW2 and SW1-8 on.

- Select “Run” mode in order to operate the system.

- To verify the values obtained, press the button “Blood Pump On/Off”, and adjust the

blood pump rate to 100 mL/min. Wait 1 minute, and then select the BH service

screen 4. Verify that the control word 7 reads 0FBC to 121D H. Adjust the blood

pump rate to 400 mL/min. Wait 1 minute, and verify that the control word 7 reads

03FB to 0467 H. If the values do not fall within the given range, repeat the calibration

procedure.

XI) pH Probe Calibration:

- Set the bicarbonate level to 20. Place a pair of hemostats (i.e. clamps) on the acid line.

Wait 5 minutes. Withdraw dialysate solution from the bicarbonate sample port, and

fill one of two 100 mL beakers with the solution. Set the switches SW2 and SW1-8

down after switching the system power off. Fill the second beaker with a 7.0 buffer

solution. Fill a 150 mL beaker with RO water. Remove the pH probe from the

2

RPM: Rotations Per Minute

mounting bracket, and install the mounting cap in place of the probe. Place the pH

probe immediately after removing into the beaker filled with RO water (never allow

the pH probe to dry out). Turn the power button on, go to the option “Calibrate”, and

then select option C “Device Calibration”. Select “pH Probe”.

- Start calibration.

- Step 1: Rinse with water, and leave the pH probe in the 7.0 buffer. Wait for 1 minute

then press “Continue”.

- Step 2: Rinse and leave the pH probe in the bicarbonate solution. Wait for 1 minute

then press “Continue”.

- Step 3: The displayed values are:

pH Offset NOVRAM # 46 – DPM 3/7L (02 – 4E H)

pH Gain NOVRAM # 45 – DPM 3/7M (10 – 6A H)

- Save and store the parameter values and then switch SW2 and SW1-8 on.

- Select “Run” mode in order to operate the system.

- To verify the values obtained, validate that the pH probe is in the bicarbonate

solution. Select any DP service screen, and verify that the monitor byte 4M reads A4

to B0 H. Rinse and leave the pH probe in the 7.0 buffer solution. Verify that the

monitor byte 4M reads 72 to 7C H. If the values are within specification, turn the

power off, replace the pH probe and mount the cap back on the tubing near the probe.

Otherwise, recalibrate.

XII) Temperature and Conductivity Calibration:

- Connect all the concentrate lines into their respective rinse ports. Ensure that the

NOVRAM parameters # 89 to # 95 are set to their default values: check the UFC

SWB bytes 5M, 5L, 6M, 6L, 7M, 7L, and 8M. Turn the power of the system off.

Place the conductivity and temperature sensor of the Neo-2 pressure meter in series

with the dialyzer hoses (replacing the role of the dialyzer). Place the Hansen

connector shunts on the bypass block connectors. Set the switches SW2 and SW1-8

down. Figure 3 illustrates how all the calibration switches should be directed for this

procedure.

Figure 2 - Diagram Illustrating Position of Calibration Switches on DP and UF CCA Boards

- Turn the power button on, go to the option “Calibrate”, and then select option C

“Device Calibration”. Select “Temperature and Conductivity”.

- Start calibration.

- Step 1: The displayed values correspond to the NOVRAM parameters # 89 through

95. A timer allows the machine to stabilize for 10 minutes (if the timer does not

appear, the calibration values of the NOVRAM parameters # 89 through 95 are then

out of range; correct them and restart the calibration procedure).

- Step 2: After the timer times out, press “Continue”.

- Step 3: The numbers shown are:

T0 Offset (control) NOVRAM # 12 – DPC F/6L

T1 Offset (control) NOVRAM # 18 – DPC 4/5M

T2 Offset (monitor) NOVRAM # 37 – DPM F/6L

T3 Offset (control) NOVRAM # 31 – DPC 5/7M

T4 Offset (monitor) NOVRAM # 116 – UFM 9/7M

T1 Off Redundant (monitor) NOVRAM # 51 – DPM A/6M

T3 Off Redundant (monitor) NOVRAM # 36 – DPM 1/6L

Save the obtained values.

- Step 4: Continue.

- Step 5: Set the following calibration switches upward (indicating normal run mode):

DP CCA: SW5 MC1 LO UF CCA: SW6 MC2 LO

SW8 CC1 LO

SW11 CC2 LO

Set the following calibration switches downward (indicating calibration mode):

DP CCA: SW9 CC1 HI UF CCA: SW3 MC2 HI

SW10 CC2 HI

SW13 MC1 HI

Continue.

- Step 6: The numbers shown are:

CC1 Gain (control) NOVRAM # 15 – DPC F/8M

CC1 Offset (control) NOVRAM # 14 – DPC F/7L

CC2 Gain (control) NOVRAM # 28 – DPC 5/5L

CC2 Offset (control) NOVRAM # 27 – DPC 5/5M

MC1 Gain (monitor) NOVRAM # 41 – DPM 3/5M

MC1 Offset (monitor) NOVRAM # 42 – DPM 3/5L

MC2 Gain (monitor) NOVRAM # 113 – UFM 9/5L

MC2 Offset (monitor) NOVRAM # 114 – UFM 9/6M

- Save and store the parameter values and then place all the calibration switches in the

normal run position (including the conductivity cells, thermistors, and NOVRAM

switches). Switch SW2 and SW1-8 on.

- Select “Run” mode in order to operate the system.

• Concentrate Pump Volume Calibration Verification:

- Verify that the machine is set for “Bicarbonate” mode. Enter the “Setup”

mode and allow the machine to run for 5 minutes without having the

concentrate lines connected. While the machine is running, fill a graduated

cylinder with 100 cc of water.

- On the original package machines, clamp the bicarbonate concentrate line on

the pump side of the 130 micron filter. On the repackaged machines, clamp

the tubing where it enters the diaphragm pump (at rear of panel A).

- Disconnect the bicarbonate male connector from the rinse port, and remove

the tubing from the male connector end of the 130 micron filter. Immediately

place the tubing with the filter into the graduated cylinder, remove the clamp

and start the stopwatch. Allow the machine to pull water from the graduated

cylinder for 1 minute after which 45 – 53 mL of water must be left in the

graduated cylinder. If the volume is not correct, repeat the process of

disconnection, loosen the locking nut on the rear of the bicarbonate

concentrate pump, and turn the adjustment screw clockwise to increase the

volume of water left in the graduated cylinder until the volume recording is

within range.

- If the concentrate pump was adjusted, secure the adjustment screw by holding

the screw and tightening the locking nut (ensure that the adjustment screw

does not move). Repeat the step of disconnection until the level left of water

in the cylinder is 45 – 53 mL to verify that the calibration did not change after

locking the adjustment screw.

- Reassemble the bicarbonate tubing and place the male connector into the

bicarbonate rinse port.

- Set SW9 on the dialysate prep. CCA in CAL (i.e. down) position to force the

acid pump to run. Fill the graduated cylinder with 100 cc of water.

- Clamp the acid concentrate line at the pump side of the 130 micron filter.

Disconnect the acid male connector from the rinse port, and remove the

tubing from the male connector end of the 130 micron filter. Immediately

place the tubing with the filter into the graduated cylinder, remove the clamp

and start the stopwatch.

- Allow the machine to pull water from the graduated cylinder for 1 minute

after which the level of the water left in the graduated cylinder must be 43 –

53 mL. If the volume is not correct, loosen the locking nut on the rear of the

acid concentrate pump and turn the adjustment screw clockwise to increase

the volume of water left in the graduated cylinder. Repeat the process until

the volume is correct.

- If the concentrate pump was adjusted, secure the adjustment screw by holding

the screw and tightening the locking nut; this ensures that the screw does not

move. Repeat the process of clamping until the amount of water in the

graduated cylinder is specified, thus verifying that the calibration did not

change after locking the adjustment screw.

- Reassemble the bicarbonate tubing and place the male connector into the

bicarbonate rinse port. Set SW9 on the dialysate prep. CCA in CAL position

to force the acid pump to run. Fill the graduated cylinder with100 cc of water.

Clamp the acid concentrate line at the pump side of the 130 micron filter.

Disconnect the male acid connector from the rinse port, and remove the

tubing from the male connector end of the 130 micron filter. Immediately

place the tubing with the filter into the graduated cylinder. Remove the clamp

and start the stopwatch. Allow the machine to pull water from the graduated

cylinder for 1 minute after which the level of water left in the cylinder should

be 45 – 53 mL. If the volume is not correct, loosen the locking nut on the rear

of the acid concentrate pump and turn the adjustment screw clockwise to

increase the volume of water left in the graduated cylinder. Repeat the steps

of clamping until the level of water in the cylinder is recorded again to verify

that the calibration did not change after locking the adjustment screw.

Reassemble the acid tubing and place the male connector into the acid rinse

port. Set SW9 on the dialysate prep. CCA to normal run position.

• Temperature Calibration Verification:

- Verify that the command temperature is 37º C. Note the readings of the

following parameters (each for 2 minutes, totaling to 10 minutes):

Measured temperature

Status screen temperature

T2 corrected (any DP service screen, monitor byte 3M)

T3 corrected (DP service screen 5, control byte 7L)

T3 corrected (DP service screen 9, monitor byte 7L)

- Calculate average value for each parameter. Verify that the average measured

temperature is 36.7º to 37.3º C. Verify that the largest measured deviation

from the average is 0.4º C or less.

- Verify that the average status screen temperature (T4) is within 0.2º C of the

average measured temperature. Verify that the average T2 reading (located in

any DP service screen, as monitor byte 3M) is A2 to AD H. Also verify that

the average T3 reading (located in DP service screen 9, as monitor byte 7L) is

9D to A7 H.

• Acetate/Acid Calibration Verification:

This verification process is followed alone when there is acid concentrate solution

only; when acid is present with bicarbonate solution, the latter calibration

verification procedure is followed along with this process.

- Place the bicarbonate connector in the rinse port. Verify that the machine is in

setup mode, and select the acetate procedure. Connect the acetate connector

to the acetate concentrate supply or acid connector in the acid concentrate

supply.

- Set the “Sodium Level” to 130 mEq/L. Allow the machine conductivity

reading to stabilize (note that one conductivity reading is taken from the

reference meter while the other is taken from the screen every 2 minutes,

totaling to 6 readings in 10 minutes).

- Calculate the average measured conductivity and verify that the average

measured conductivity is 12.7 to 13.1 mS/cm (CC2 low). Verify that the

largest measured deviation from the average is 0.4 mS/cm.

- Verify that the average screen conductivity is within ± 0.2 mS/cm of the

average measured value (MC2 low).

- Set the “Sodium Level” to 160 mEq/L. Verify that the meter reads

15.4 to 15.8 mS/cm (CC2 high). Also verify that the average screen

conductivity is within ± 0.2 mS/cm of the average measured value (MC2

high). Disconnect the acetate/acid supply.

• Bicarbonate Calibration / Stability Verification:

- Place the acetate and acid connectors in their rinse ports. Verify that the

machine is in setup mode with the bicarbonate procedure selected. Connect

the bicarbonate connector to the bicarbonate concentrate supply. Clamp the

acid line.

- Set the “Bicarb Level” to 20 mEq/L. Allow the machine conductivity reading

to stabilize (note that one conductivity reading is taken from the reference

meter while the other is taken from the screen every 2 minutes, totaling to

6 readings in 10 minutes).

- Calculate the average conductivity, and verify that the average measured

conductivity is 1.7 to 2.1 mS/cm. Also verify that the largest measured

deviation from the average is 0.2 mS/cm.

- Verify that MC1 low (bicarbonate corrected conductivity; located in any DP

service screen, as monitor byte 3L) reads 57 to 66 H. Set the “Bicarb Level”

to 40 mEq/L. Allow the machine conductivity reading to stabilize.

- Verify that the meter conductivity reads 3.1 to 3.5 mS/cm (CC1 high). Also

verify that MC1 high (bicarbonate corrected conductivity; located in any DP

service screen, as monitor byte 3L) reads A7 to B6 H.

• Final Conductivity Verification Using Bicarbonate and Acid: (With setting Operating

parameter # 5 to 160 H):

- Place all the concentrate connectors in their rinse ports. Verify that the

machine is in setup mode with bicarbonate procedure selected. Connect the

acid connector to the acid concentrate supply. Connect the bicarbonate

connector to the bicarbonate concentrate supply.

- Set “Bicarb. Level” to 35 mEq/L and “Sodium Level” to 130 mEq/L. Allow

the machine conductivity reading to stabilize (note that one conductivity

reading is taken from the reference meter while the other is taken from the

screen every 2 minutes, totaling to 6 readings in 10 minutes).

- Calculate the average measured conductivity, and verify that the average

measured conductivity is 12.8 to 13.2 mS/cm (CC2 low). Verify that the

largest measured deviation from the average is 0.4 mS/cm or less. Also verify

that any screen conductivity is within ± 0.2 mS/cm of any measured value

(MC2 low).

- Set “Sodium Level” to 160 mEq/L. Verify that the meter reads

15.8 to 16.2 mS/cm (CC2 high). Also verify that the average screen

conductivity is within ± 0.2 mS/cm of the average measured value (MC2

high). Note that the operating parameter # 5 should be set back to its original

value after finishing the verification process.

- If the above values do not meet the required specification, repeat the

calibration procedure. Otherwise, and only if the “Acetate Calibration

Verification” does not need to be performed, return the bicarbonate and acid

connectors to their rinse ports.

Loading...

Loading...