Page 1

9229-QS

Quad Split Video Processor

User Manual

Cobalt Digital Inc.

9229-UM

Version: 1.2

9229-QS User Manual •••• (V 1.2) Page 1

Page 2

9229-QS • Quad-Split Video Processor User Manual

• Cobalt Digital Inc. Part Number: 9229-UM

• Document Version: 1.2

• Printed in the United States.

• Last Author: CGG

• Printing Date: 2/15/2013

The information contained in this manual is subject to change without notice or obligation.

Copyright

© 2013 Cobalt Digital Inc.. All rights reserved.

Contents of this publication may not be reproduced in any form without the written permission of

Cobalt Digital Inc.. Reproduction or reverse engineering of copyrighted software is prohibited.

Patents

This product is protected by the following US Patents: 4,205,346; 5,115,314; 5,280,346;

5,561,404; 7,034,886; 7,508,455. This product is protected by the following Canadian Patents:

2039277; 1237518; 1127289. Other patents pending.

Notice

The material in this manual is furnished for informational use only. It is subject to change without

notice and should not be construed as commitment by Cobalt Digital Inc.. Cobalt Digital Inc.

assumes no responsibility or liability for errors or inaccuracies that may appear in this manual.

Trademarks

• is a registered trademark of Ross Video Limited.

•

• All other product names and any registered and unregistered trademarks mentioned in this

manual are used for identification purposes only and remain the exclusive property of

their respective owners.

is a registered trademark of Cobalt Digital Inc.

Page 2 9229-QS User Manual •••• (V 1.2)

Page 3

Important Regulatory and Safety Notices

Before using this product and any associated equipment, refer to the “Important Safety

Instructions” listed below to avoid personnel injury and to prevent product damage.

Products may require specific equipment, and/or installation procedures to be carried out to satisfy

certain regulatory compliance requirements. Notices have been included in this publication to call

attention to these specific requirements.

Symbol Meanings

This symbol on the equipment refers you to important operating and maintenance

(servicing) instructions within the Product Manual Documentation. Failure to heed this

information may present a major risk of damage or injury to persons or equipment.

Warning — The symbol with the word “Warning” within the equipment manual

indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

Caution — The symbol with the word “Caution” within the equipment manual

indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury. It may also be used to alert against unsafe practices.

Notice — The symbol with the word “Notice” within the equipment manual indicates a

situation, which if not avoided, may result in major or minor equipment damage or a

situation which could place the equipment in a non-compliant operating state.

ESD Susceptibility — This symbol is used to alert the user that an electrical or

electronic device or assembly is susceptible to damage from an ESD event.

Important Safety Instructions

Caution — This product is intended to be a component product of the 8321 or

equivalent 20-slot frame. Refer to the frame User Manual for important safety

instructions regarding the proper installation and safe operation of the frame as well as

its component products.

9229-QS User Manual •••• (V 1.2) Page 3

Warning — Certain parts of this equipment namely the power supply area still

present a safety hazard, with the power switch in the OFF position. To avoid electrical

shock, disconnect all A/C power cards from the chassis’ rear appliance connectors

before servicing this area.

Page 4

Warning — Service barriers within this product are intended to protect the operator

and service personnel from hazardous voltages. For continued safety, replace all

barriers after any servicing.

This product contains safety critical parts, which if incorrectly replaced may present a

risk of fire or electrical shock. Components contained with the product’s power supplies

and power supply area, are not intended to be customer serviced and should be

returned to the factory for repair. To reduce the risk of fire, replacement fuses must be

the same time and rating. Only use attachments/accessories specified by the

manufacturer.

Warning —This product includes an “Ethernet Port” which allows this product to be

connected to a local area network (LAN). Only connect to networks that remain inside

the building. Do not connect to networks that go outside the building.

EMC Notices

United States of America

FCC Part 15

This equipment has been tested and found to comply with the limits for a class A Digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his own expense.

Notice — Changes or modifications to this equipment not expressly approved by

Cobalt Digital Inc. could void the user’s authority to operate this equipment.

CANADA

This Class “A” digital apparatus complies with Canadian ICES-003.

Cet appariel numerique de la classe “A” est conforme a la norme NMB-003 du Canada.

EUROPE

This equipment is in compliance with the essential requirements and other relevant provisions of

CE Directive 93/68/EEC.

INTERNATIONAL

This equipment has been tested to CISPR 22:1997 along with amendments A1:2000 and

A2:2002, and found to comply with the limits for a Class A Digital device.

Page 4 9229-QS User Manual •••• (V 1.2)

Notice — This is a Class A product. In domestic environments, this product may

cause radio interference, in which case the user may have to take adequate measures.

Page 5

Maintenance/User Serviceable Parts

Routine maintenance to this Cobalt Digital Inc. product is not required. This product contains no user

serviceable parts. If the frame does not appear to be working properly, please contact Technical

Support using the numbers listed under the “Contact Us” section on the last page of this manual. All

Cobalt Digital Inc. products are covered by a generous 5-year warranty and will be repaired without

charge for materials or labor within this period. See the “Warranty and Repair Policy” section in this

manual for details.

Environmental Information

The equipment that you purchased required the extraction and use of natural resources for its

production. It may contain hazardous substances that could impact health and the environment.

To avoid the potential release of those substances into the environment and to diminish the need for the

extraction of natural resources, Cobalt Digital Inc. encourages you to use the appropriate take-back

systems. These systems will reuse or recycle most of the materials from your end-of-life equipment in

an environmentally friendly and health conscious manner.

The crossed-out wheeled bin symbol invites you to use these systems.

If you need more information on the collection, reuse, and recycling systems, please contact your local

or regional waste administration.

You can also contact Cobalt Digital Inc. for more information on the environmental performances of

our products.

9229-QS User Manual •••• (V 1.2) Page 5

Page 6

Page 6 9229-QS User Manual •••• (V 1.2)

Page 7

Contents

Introduction 1-1

In This Chapter.......................................................................................................................1-1

Overview.................................................................................................................................1-2

Functional Block Diagrams ....................................................................................................1-3

Documentation Terms and Conventions.................................................................................1-4

Installation 2-1

In This Chapter.......................................................................................................................2-1

Before You Begin...................................................................................................................2-2

Card Overview........................................................................................................................2-3

Card Installation......................................................................................................................2-5

Cabling....................................................................................................................................2-7

Ethernet Port Cabling..............................................................................................................2-9

GPI Cabling..........................................................................................................................2-10

A Word of Thanks....................................................................................................1-1

Features ....................................................................................................................1-2

Looping Configuration.............................................................................................1-3

Static Discharge........................................................................................................2-2

Unpacking.................................................................................................................2-2

Card-edge LEDs....................................................................................................... 2-3

Rear Modules ...........................................................................................................2-5

Installing the Rear Modules......................................................................................2-5

Installing the Card....................................................................................................2-6

Looping Rear Module (RM20-9229-C)....................................................................2-7

Ethernet Communication Cabling.............................................................................2-9

GPI Cable Connections ..........................................................................................2-10

Configuration 2-1

In This Chapter.......................................................................................................................3-1

Video Format and Reference Configuration...........................................................................3-2

Video Input and Output Configuration...................................................................................3-3

Configuring the Video Outputs.................................................................................3-3

Configuring the Input Signal Timing Display...........................................................3-4

Signal Loss Alarm Setup .......................................................................................... 3-5

Ethernet Communication Setup ..............................................................................................3-6

GPI Communication Setup .....................................................................................................3-7

GPI Overview...........................................................................................................3-7

GPI Communication Setup.......................................................................................3-7

Loading the Factory Defaults..................................................................................................3-9

Software Upgrades................................................................................................................3-10

9229-QS User Manual •••• (V 1.2) Contents •••• i

Page 8

Operation 4-1

In This Chapter .......................................................................................................................4-1

Adjusting the Proc Amp Controls...........................................................................................4-2

Configuring the Quad Split Sources........................................................................................4-3

Assigning Sources to the Quad Split.........................................................................4-3

Applying a Border....................................................................................................4-3

Notes on Timing .....................................................................................................................4-5

Appendix A. DashBoard Menus 5-1

In This Appendix....................................................................................................................5-1

Status Tabs..............................................................................................................................5-2

Configuration Menus..............................................................................................................5-5

Video Configuration.................................................................................................5-5

GPI Configuration ....................................................................................................5-7

Ethernet.....................................................................................................................5-8

Personality................................................................................................................5-9

Load/Save.................................................................................................................5-9

Proc Amps Menus.................................................................................................................5-10

Quad Split Menus .................................................................................................................5-11

Appendix B. Specifications 6-1

In This Appendix....................................................................................................................6-1

RM20-9229-C Specifications..................................................................................................6-2

Appendix C. Service Information 7-1

In This Chapter .......................................................................................................................7-1

Troubleshooting Checklist......................................................................................................7-2

Warranty and Repair Policy....................................................................................................7-3

Contact Cobalt Digital Inc......................................................................................................7-1

Visit us at the Cobalt Digital Inc. website. ..............................................................................7-1

ii •••• Contents 9229-QS User Manual •••• (V 1.2)

Page 9

Introduction

In This Chapter

This chapter contains the following sections:

• Overview

• 9229-QS Functional Block Diagram

• Documentation Terms and Conventions

A Word of Thanks

Congratulations on choosing a 9229-QS Quad-Split Video Processor. The Cobalt Digital Inc. line

includes video decoders and encoders, audio embedders and de-embedders, distribution amplifiers,

format converters, and much more. Cobalt Digital Inc. modular conversion gear will meet your signal

conversion needs now, and well into the future.

Should you have a question pertaining to the installation or operation of your 9229-QS, please contact

us at the numbers listed on the back cover of this manual. Our technical support staff is always

available for consultation, training, or service.

9229-QS User Manual •••• (V 1.2) Introduction •••• 1-1

Page 10

Overview

The 9229-QS takes four SDI input streams and can reduce them into four quadrants in a single stream.

The 9229-QS has four SDI outputs which can be independently configured to display either the fullscreen input or the Quad Split stream. When the output is showing full-screen, all HANC and VANC

data, including the embedded audio data on the input is carried through to the output. When the output

is showing Quad Split, all HANC and VANC data, including embedded audio, is stripped.

In addition, the RM20-9229-C Rear Module was designed to be used with the 9229-QS to loop its

inputs to a system, such as the CrossOver® production switcher, for a multi-viewer application.

GPI control allows external devices to choose which of the input selections, including the Quad Split,

will be assigned to the outputs.

Features

The following features are included for the 9229-QS:

• Compliance with SDI SMPTE 292M (1.485Gbps) and SMPTE 259M (270Mbps)

• Multi-Definition support of popular formats such as 1080i, 720p, 480i, 576i, 1080PsF

• Assign any input, or Black, to any quadrant

• Text overlay to name the four input sources in the Quad Split

• Configure GPIs to trigger any of the outputs or a specific quadrant

• Specify how the input signal timing is reported (relative to the reference or the output)

• Four passive looping inputs

• User selectable card analog reference

• Report status and configuration remotely via the DashBoard Control System™

• Ethernet 10/100 Mbit connectivity for easy upgrades in the field

• Independent Proc-Amp control on outputs

• Full DashBoard control and monitoring

• Fully compliant with openGear specifications and installs in the 8300 series frames

• 5 year transferable warranty

1-2 •••• Introduction 9229-QS User Manual •••• (V 1.2)

Page 11

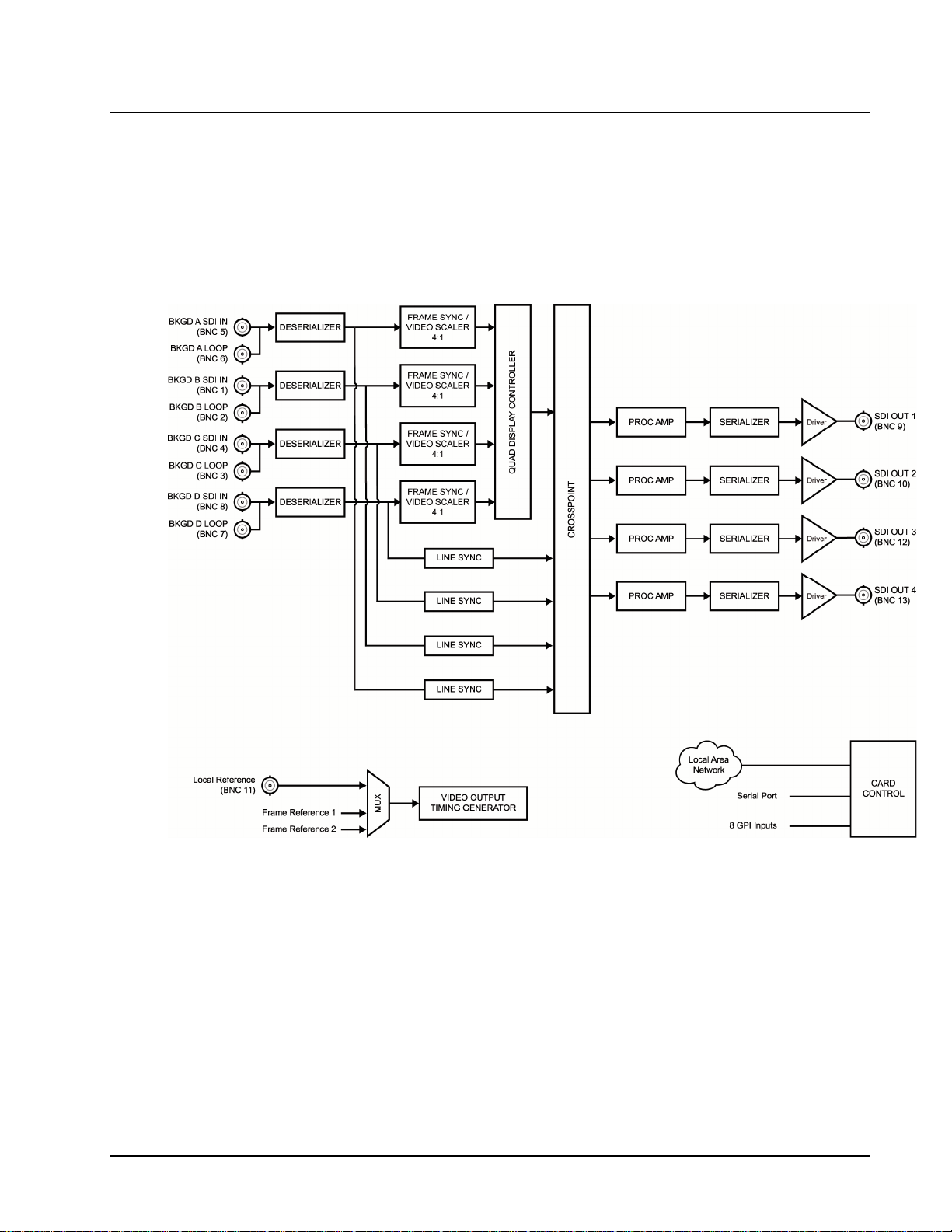

Functional Block Diagrams

This section provides the functional block diagrams for the 9229-QS.

Looping Configuration

This section includes the block diagram when using the 9229-QS with the RM20-9229-C Rear

Module.

Figure 1.2 9229-QS Block Diagram — RM20-9229-C Rear Module

9229-QS User Manual •••• (V 1.2) Introduction •••• 1-3

Page 12

Documentation Terms and Conventions

The following terms and conventions are used throughout this manual:

• “Operator” and “User” refer to the person who uses the 9229-QS.

• “Board”, and “Card” refer to openGear terminal devices within openGear frames,

including all components and switches.

• “Looping Rear Module” refers to the RM20-9229-C Rear Module.

• “DashBoard” refers to the DashBoard Control System™.

• “Bkgd” refers to a Background source (A, B, C, or D).

• “UL” refers to the Upper Left quadrant.

• “UR” refers to the Upper Right quadrant.

• “LL” refers to the Lower Left quadrant.

• “LR” refers to the Lower Right quadrant.

1-4 •••• Introduction 9229-QS User Manual •••• (V 1.2)

Page 13

9229-QS User Manual •••• (V 1.2) Introduction •••• 1-5

Page 14

Page 15

Installation

In This Chapter

This chapter provides instructions for the basic physical installation and communications setup of your

9229-QS.

The following topics are discussed:

• Before You Begin

• Card Overview

• Card Installation

• Cabling

• Ethernet Port Cabling

• GPI Cabling

9229-QS User Manual •••• (V 1.2) Installation •••• 2-1

Page 16

Before You Begin

Static Discharge

Throughout t hi s chapter, pl ease heed the fo llowing cautionary note :

ESD Susceptibility — Static discharge can cause serious damage to sensitive

semiconductor devices. Avoid handling circuit boards in high static environments such as

carpeted areas and when synthetic fiber clothing is worn. Always exercise proper grounding

precautions when working on circuit boards and related equipment.

Unpacking

Unpack each card you received from the shipping container and ensure that all items are included. If

any items are missing or damaged, contact your sales representative or Cobalt Digital Inc. directly.

2-2 •••• Installation 9229-QS User Manual •••• (V 1.2)

Page 17

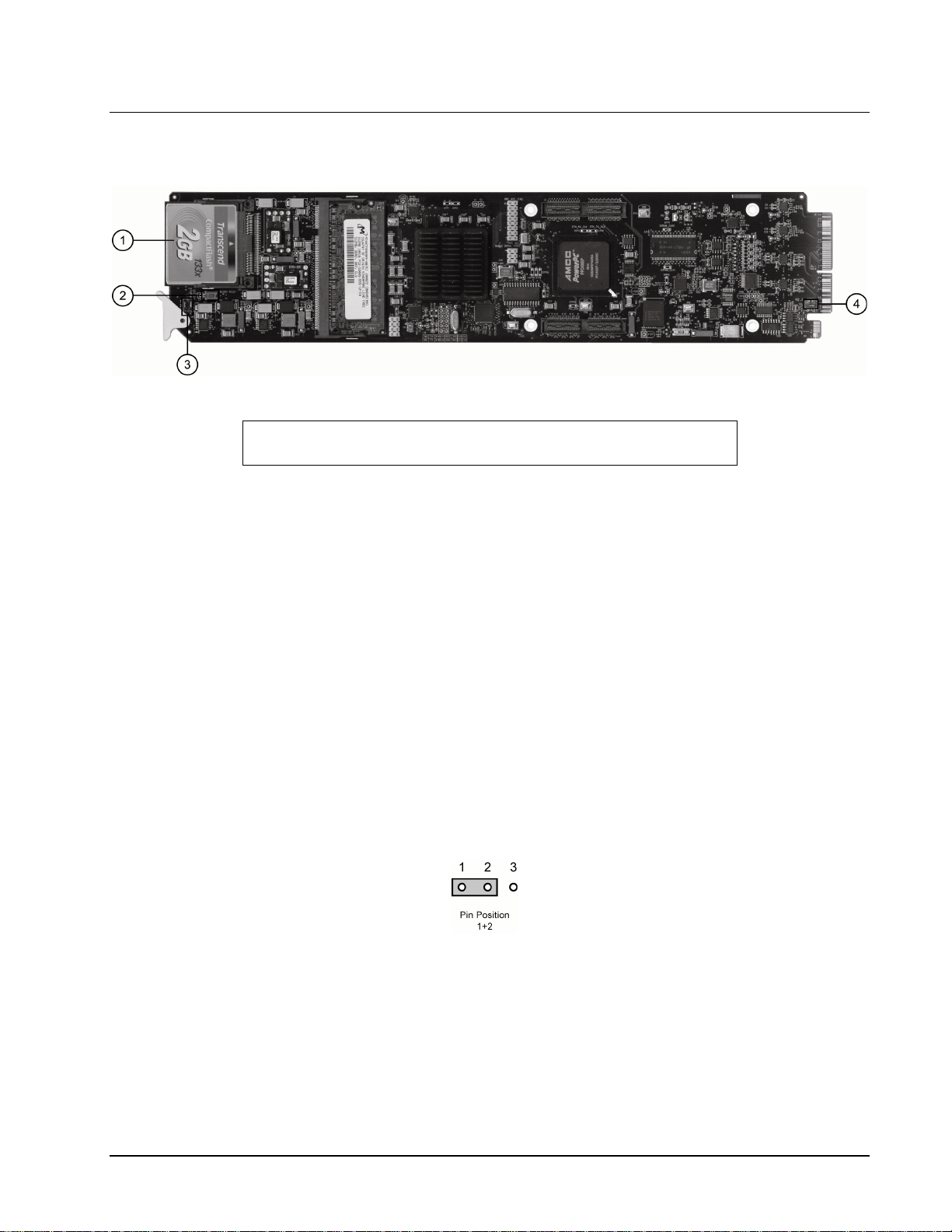

Card Overview

This section provides an overview of the 9229-QS components.

1) CompactFlash™ Card 3) JP5, JP6

2) Board Reset B utton (SW1) 4) Reference Term i nation (JP7)

1. CompactFlash™ Card

The CompactFlash™ card is reserved for future usage.

2. Board Reset Button (SW1)

Pressing this button resets the microprocessor and re-initializes the card. This is a hard reset of the card

and settings are not saved. This may cause loss of data and should only be performed as advised by

Cobalt Digital Inc. Technical Support.

Figure 2.1 Card-edge Components

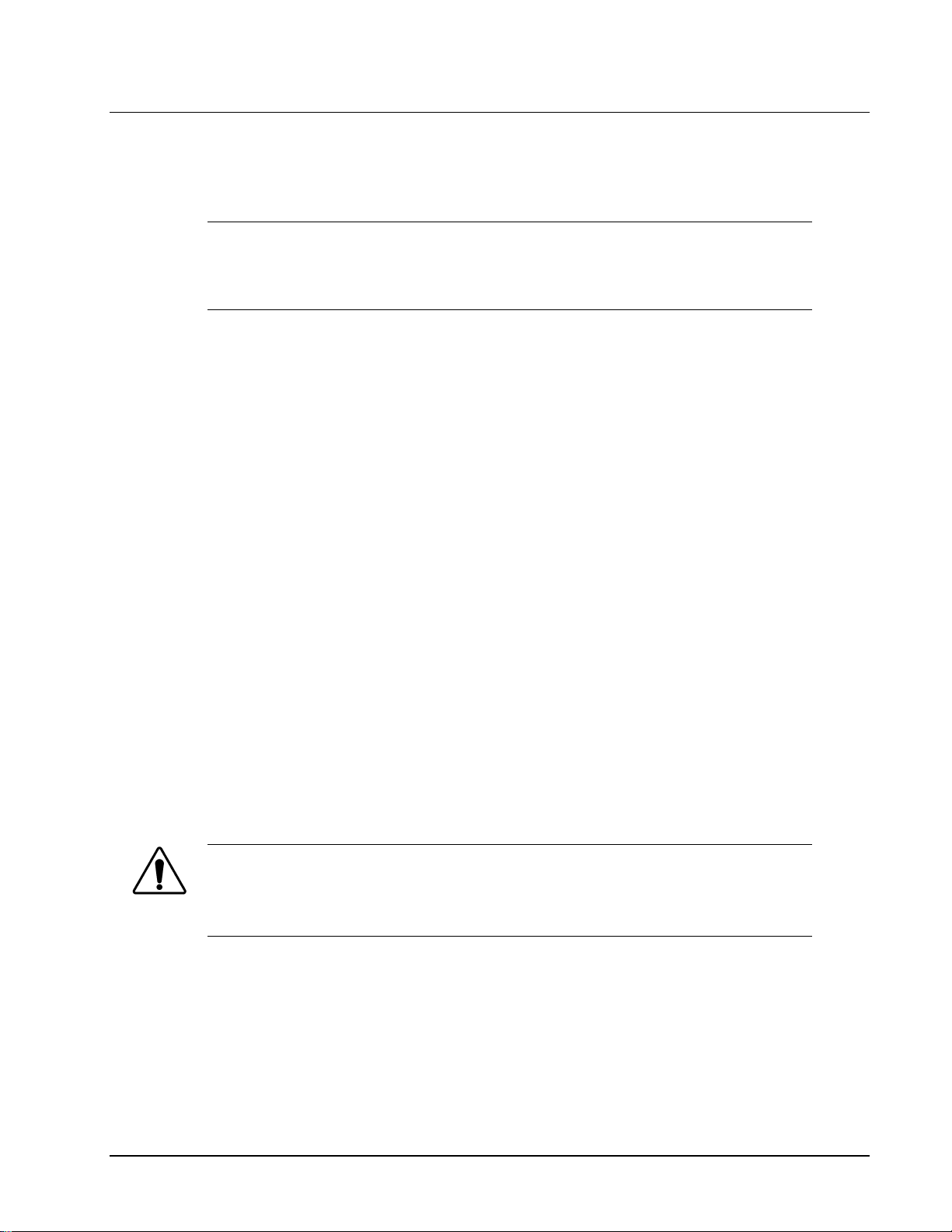

3. JP5, JP6

These jumpers are not yet implemented and must be left in the default position of Pin 1 (top) and Pin 2

(center).

4. Reference Termination (JP7)

JP7 is a 3-position jumper block used to configure the 75ohm termination on the local analog

reference input on BNC 11 of the RM20-9229-C Rear Module.

Pin 1 (left) + Pin 2 (center) position — In this position, the analog reference is terminated

with an 75ohm resistor. This configuration is to be used for point-to-point cabling, or on

the last card of a daisy chain topology. This is the default position (Figure 2.2 ).

Figure 2.2 JP7 — Default Position

Pin 2 (center) + Pin 3 (right) position — In this position, the 75ohm terminator is

removed and the analog reference is not terminated. This configuration is used in a daisy

chain cabling topology where only the last card needs to be terminated.

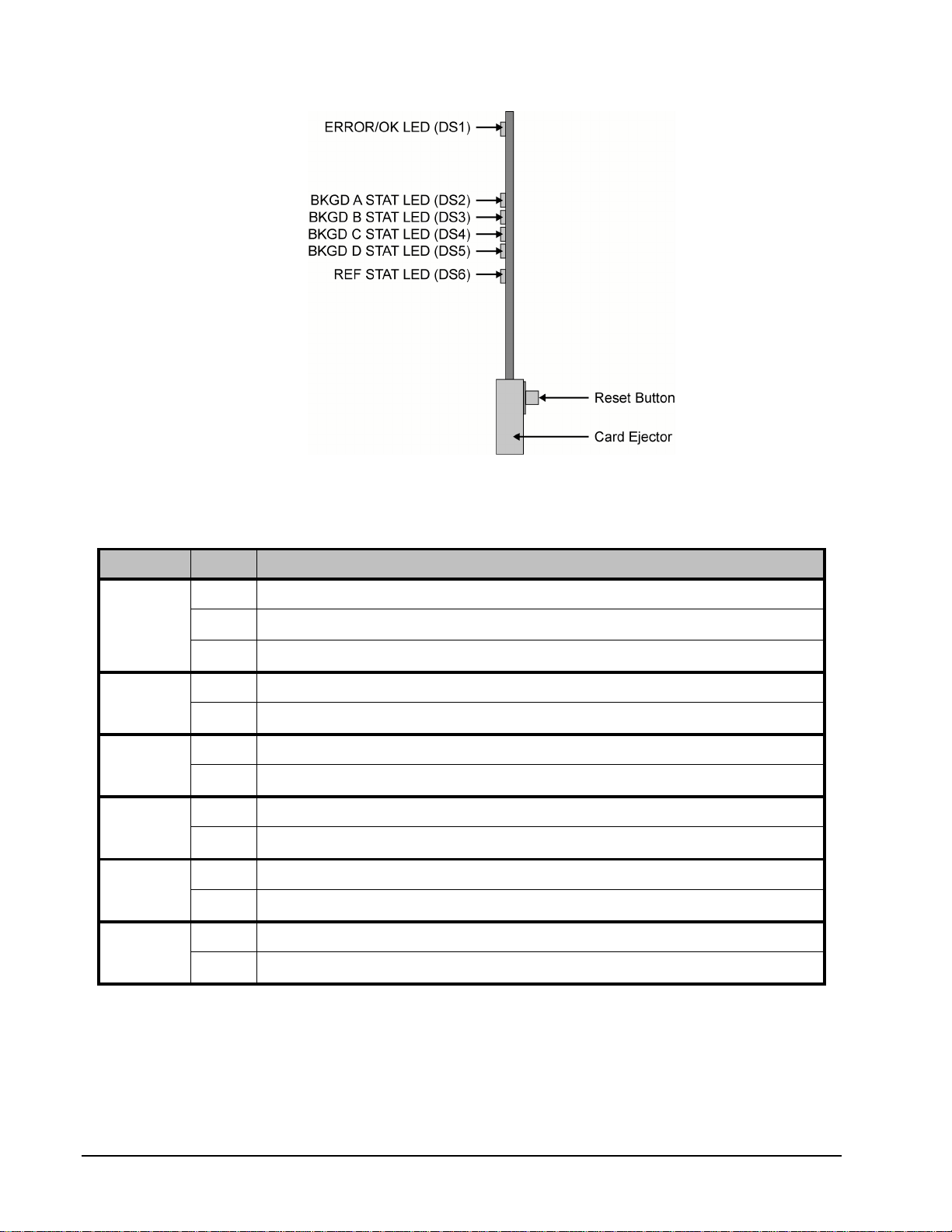

Card-edge LEDs

This section describes the card-edge LEDs. Figure 2.3 outlines the locations of the card-edge controls.

9229-QS User Manual •••• (V 1.2) Installation •••• 2-3

Page 18

Figure 2.3 Card-edge Controls

Table 2.1 LEDs on the Card-edge

LED Color Display and Description

Green When this LED is green, the card is in normal operation with no errors.

ERROR/OK

BKGD A

STAT

BKGD B

STAT

BKGD C

STAT

BKGD D

STAT

REF STAT

Red When this LED is red, the card is experiencing internal errors.

Off When this LED is off, there is no power to the card.

Green When this LED is green, the Bkgd A video input is valid.

Red When this LED is red, the Bkgd A input is not present or is invalid.

Green When this LED is green, the Bkgd B video input is valid.

Red When this LED is red, the Bkgd B input is not present or is invalid.

Green When this LED is green, the Bkgd C input is valid.

Red When this LED is red, the Bkgd C input is not present or is invalid.

Green When this LED is green, the Bkgd D input is valid.

Red When this LED is red, the Bkgd D input is not present or is invalid.

Green When this LED is green, the reference signal is valid.

Red When this LED is red, the reference signal is not present or is invalid.

2-4 •••• Installation 9229-QS User Manual •••• (V 1.2)

Page 19

Card Installation

This section provides a brief overview of the required Rear Modules and physical installation of the

9229-QS.

Note — The 9229-QS requires either the RM20-9229-C Rear Module and therefore is

not compatible with the 8310-BNC frames (frames with the pre-installed 100-BNC fixed

backplane).

Rear Modules

The procedure for installing the Rear Module in your openGear frame is the same regardless of the

frame or module used. However, a different module is required depending on the openGear frame you

are using. The Rear Module requires four slots in an HPF-9000 or 8321 series 20-slot frame.

RM20-9229-C Rear Module

The RM20-9229-C Rear Module provides a passive looping BNC on all four SDI inputs (Bkgd A, B,

C, and D). The SDI source signal should be connected to the BNC IN input and if required, the SDI

input signal may be propagated to one more downstream equipment using the associated BNC Loop

output. Refer to the section “Looping Rear Module RM20-9229-C” for BNC designations and for

additional cabling information.

If you are using the BNC Loop output(s), then the looping SDI cable must drive only one

piece of downstream equipment properly terminated with a 75 Ohm load at all time. If the

downstream equipment must be disconnected for servicing, it is recommended to first

disconnect the cable at the BNC Loop output of the RM20-9229-C Rear Module, otherwise

the looping cable without termination will cause signal reflection that will likely corrupt the

9229-QS SDI input signal.

If you are not using the looping output, then the BNC Loop should be left open without any

cable or standalone 75 Ohm termination attached to the BNC.

Installing the Rear Modul es

If the Rear Module is already installed, skip this section.

Caution — It is not recommended to install this card in the Slots 1,2 combination in

an 8310 series frame, or in Slots 1,2, 3, 4 in the 8321 series frames. These

combinations provide the least air flow cooling in the frame and the card may overheat

if installed in this location.

Use the following procedure to install a Rear Module in 20-slot frame:

1. Refer to the frame product manual to ensure that the frame is properly installed according

to instructions.

2. (non-current) If you are installing the 9229-QS in an 8310 series frame, Cobalt Digital

Inc. recommends installing the Rear Module in one of the following combinations:

• Slots 3, 4 • Slots 7, 8

9229-QS User Manual •••• (V 1.2) Installation •••• 2-5

Page 20

• Slots 5, 6 • Slots 9, 10

3. (non-current) If you are installing t he RM20-9229-QS-B Rear Module in a 20-slot frame

Cobalt Digital Inc. recommends installing the Rear Module in one of the following

combinations:

• Slots 5, 6, 7, 8 • Slots 13, 14, 15, 16

• Slots 9, 10, 11, 12 • Slots 17, 18, 19, 20

4. If you are installing the RM20-9229-C Rear Module in a 20-slot frame, Cobalt Digital

Inc. recommends installing the Rear Module in one of the following combinations:

• Slots 5, 6, 7, 8 • Slots 13, 14, 15, 16

• Slots 9, 10, 11, 12 • Slots 17, 18, 19, 20

5. Remove the Blank Plates from the rear of the selected card frame slots.

6. Seat the bottom of the Rear Module in the seating slot at the base of the backplane of the

frame.

7. Align the top holes of the Rear Module with the screw holes on the top-edge of the frame

backplane.

8. Verify that the 9229-QS aligns with the Rear Module before fully tightening any of the

slot screws.

9. Using a Phillips screwdriver and the supplied screws, fasten the Rear Module to the

backplane. Do not over tighten.

10. Install the supplied BNC label to the rear module.

11. Ensure proper frame cooling and ventilation by having all rear frame slots covered with

Rear Modules or Blank Plates.

This completes the procedure for installing a Rear Module in the 20-slot frame.

Installing the Card

Use the following procedure to install the card in a 20-slot frame:

1. Ensure that the 20-slot frame is properly installed.

2. (non-current) If you are installing the 9229-QS in a DFR-8310 series frame, install the

card into an odd-numbered slot (e.g. slot 5, 7, or 9.

2. If you are installing the 9229-QS in a 20-slot frame and depending on the rear module

and slot combination you chose for the rear module, install the card into one of the

following slots:

RM20-9229-C Rear Module — Install the card in slot 6, 10, 14, or 18.

4. Hold the card by the edges and carefully align the card edges with the slots in the frame.

5. Fully insert the card into the frame until the card is properly seated in the Rear Module.

2-6 •••• Installation 9229-QS User Manual •••• (V 1.2)

Page 21

Cabling

Looping Rear Module (RM 20-9229-C)

The Looping feature is only available for the 9229-QS when using the RM20-9229-C Rear Module in

a 20-slot frame. Refer to Figure 2.6 for cabling designations.

Figure 2.6 RM20-9229-C Cable Connections

1) Bkgd B In BNC 6) Bkgd A Loop Out BNC 11) REF IN BNC 16) GPI 3,4 Port

2) Bkgd B Loop Out BNC 7) Bkgd D Loop Out B NC 12) OUT 3 BNC 17) GPI 5,6 Port

3) Bkgd C Loop Out B NC 8) Bkgd D In BNC 13) OUT 4 BNC 18) GPI 7,8 Port

4) Bkgd C In BNC 9) OUT 1 BNC 14) Serial COM Port 19) Ethernet 10/100 Port

5) Bkgd A In BNC 10) OUT 2 BNC 15) GPI 1,2 Port

Cabling for Looping Rear Modules

Use the following procedure to connect video input and output cables to the Rear Module:

1. Refer to Table 2.2 for tested cable lengths. Note that other configurations respecting the

total cable lengths are possible, but are not listed here.

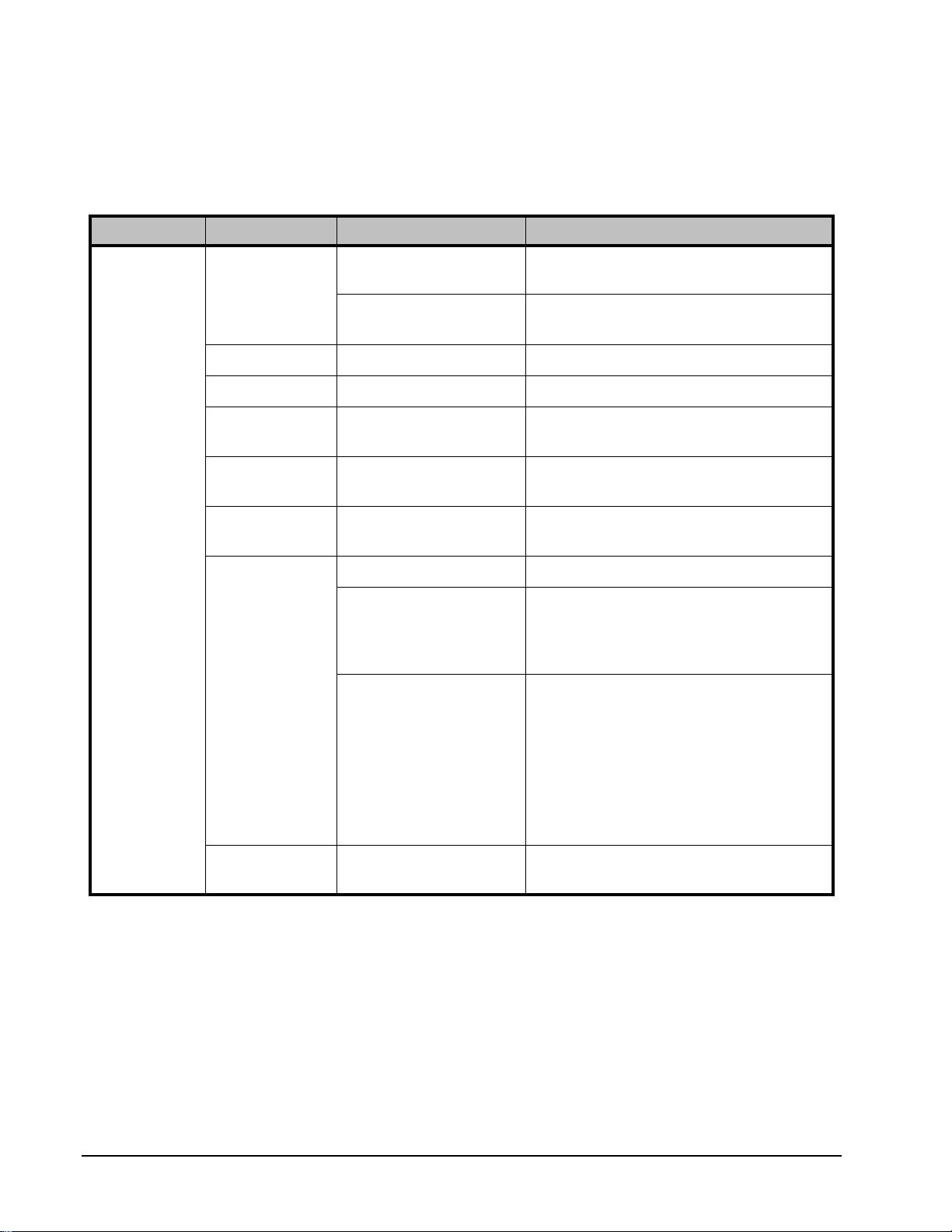

Table 2.2 Cabling Lengths for the RM20-9229-C Rear Module

Configuration Input Cable Length Loop Cable Length Total Cable Length

270Mbps

1.5Gbps

145m 5m 150m

5m 145m 150m

50m 4m 54m

4m 50m 54m

9229-QS User Manual •••• (V 1.2) Installation •••• 2-7

Page 22

2. Connect the appropriate input and output sources to the BNC connectors on the Rear

Module. You do not need to terminate the Loop BNC(s) if you are not setting up a

looping application.

3. To use an external reference source other than the Frame Ref 1 and Frame Ref 2:

• Connect the reference input source to REF IN BNC (item 112 in Fig. 2.6).

• Configure JP7 to for the 75ohm termination on the local reference. Refer to the

section “Card Overview” for details.

This completes the procedure for connecting video input and output cables to the Rear Module.

2-8 •••• Installation 9229-QS User Manual •••• (V 1.2)

Page 23

Ethernet Port Cabling

The Ethernet Port on the Rear Module is used to connect to an ethernet network for communications,

software upgrades using DashBoard .

This section presents a general overview of the ethernet connection process. The exact steps for

connecting your card to your facility via an ethernet network depends on the network requirements of

your facility.

Note — Contact your IT Department before connecting the card to your facility

network to ensure that there are no conflicts. They will provide you with an appropriate

value for the IP Address, Subnet Mask, and Gateway for the card.

Ethernet Communication Cabling

In order to properly complete this procedure, you need the following cables and equipment:

Ethernet Cable — This is a standard network CAT-5 cable to connect the card to your

facility network. You can use a standard straight-through ethernet cable, with no need for a

crossover cable as the card includes an Auto-MDIX ethernet PHY that will switch from

straight to crossover automatically as needed. Cobalt Digital Inc. does not supply this cable.

Use the following procedure to connect the card to an ethernet network:

1. Ensure that you are running DashBoard Control System version 2. 3.0 or higher before

proceeding. The DashBoard Control System software and user manual are available to

download from the Cobalt Digital Inc. website.

2. Connect the card to the same subnet as your DashBoard computer or to a network that has

a route to the network your DashBoard computer is on. Refer to the section “Cabling”

for the Ethernet 10/100 port location on your Rear Module.

3. Make a note of the IP Address as this information is required when configuring the

communication settings fo r your card.

Network topologies vary greatly between facilities. Contact your IT Department for

assistance in connecting your card to the appropriate network at your location.

This completes the procedure for connecting the card to an ethernet network. For information on setting

up the ethernet communications for the card, refer to the section “Ethernet Communication Setup”.

9229-QS User Manual •••• (V 1.2) Installation •••• 2-9

Page 24

GPI Cabling

F

The 9229-QS includes eight General Purpose Input (GPI) pins to interface with external equipment.

There are eight input pins labeled GPIO 1-8 on the terminal block of the Rear Module (Figure 2.4 ,

Figure 2.5 , or Figure 2.6 ). Ports are pre-configured to be only an input (GPI). Electrically, the ports

are setup for contact closure to ground, with a 1Kohm pull-up resistor to +5V, and default to a logical

high state.

Note — The default state for the GPI/O contacts is active low signaling. If a GPI cable

is absent from the Rear Module, no GPI will be triggered and executed inadvertently by

the card.

GPI Cable Connections

The GPI ports are available on four 3-pin WECO® connectors located on the Rear Module. Four 3-pin

mating WECO® plugs are provided with the Rear Module. This section provides information for

connecting GPI/Tally cables to the installed Rear Modules of the 20-slot frame.

Use the following procedure to cable the rear module for GPIs:

1. Locate the GPI ports on the Rear Module. Refer to the Rear Module labeling and Refer

to the section “Cabling” for port locations.

2. Wire the GPI ports as follows:

The left and right pins are the two GPI signals while the center pin is the common

Ground (GND).

Refer to Figure 2.9 for GPI configuration on the Rear Module.

Figure 2.9 RM20-9229-C GPI Connections

This completes the procedure for cabling the rear module for GPIs. For details on setting up the

communications for the GPI ports, refer to the section “GPI Communication Setup”.

2-10 •••• Installation 9229-QS User Manual •••• (V 1.2)

Page 25

Configuration

In This Chapter

This chapter provides instructions for configuring the 9229-QS using the options available in the

DashBoard Control System™.

The following topics are discussed:

• Video Format and Reference Configuration

• Video Input and Output Configuration

• Ethernet Communicatio n Setup

• GPI Communication Set up

• Loading the Factory Defaults

• Software Upgrades

Note — Before proceeding, ensure that you are running DashBoard software version

2.3.0 or higher. The DashBoard Control System software and user manual are available

to download from the Ross Video website.

9229-QS User Manual •••• (V 1.2) Configuration •••• 3-1

Page 26

Video Format and Reference Configuration

Use the following procedure to configure the video format and reference on the card using

DashBoard:

1. Display the Device tab of the card by double-clicking its status indicator in the Basic

Tree View.

2. Display the Video tab as follows:

• From the Device tab, select the Config tab.

• Select the Video tab located at the bottom of the Config tab.

3. Select a Reference Input from the Reference Input list. You can choose from the

following:

• Frame 1 — Select this option to use the reference source connected to the FRAME

REF 1 port on the 20-slot frame.

• Frame 2 — Select this option to use the reference source connected to the FRAME

REF 2 port on the 20-slot frame.

• External — Select this option to use the external reference source connected to

REF IN on the Rear Module.

› Use JP7 on the card to enable or disable a 75ohm terminator on the External

Reference input. Refer to the section “Card Overview” for information on

configuring JP7.

4. Select the card output video format from the Output Format menu. Ensure that it is the

same format as in the input video format.

This completes the procedure for configuring the video format and reference on the card using

DashBoard.

Operating Tip — — Use the Signal tab to monitor the Signal status, including the

reference and the Background sources. Refer to the section “Status Tabs” for more

information.

3-2 •••• Configuration 9229-QS User Manual •••• (V 1.2)

Page 27

Video Input and Output Configuration

Keep the foll owing in mind when configuring your video inputs and outputs:

• You can configure any of the four outputs independently to display the Quad Split or any

of the backgrounds. Note that when a Bkgd source is fed through full screen, the ancillary

data will also pass.

• The Quad sources can be any of the four Background sources, or an internally generated

black.

• The Quad outputs are configured directly from the Quad Split tab.

• Each output has a Proc Amp that can adjust parameters such as the black offset and gain.

• All of the outputs can be enabled to add dither, clip to SMPTE black or allow super-black,

or clip to SMPTE white or allow super-white.

Configuring the Video Outputs

Use the following procedure to configure your video outputs on the card:

1. Display the Device tab of the card by double-clicking its status indicator in the Basic

Tree View.

2. Display the Video tab as follows:

• From the Device tab, select the Config tab.

• Select the Video tab located at the bottom of the Config tab.

3. From the Output Setup area, locate the Output BNC you want to configure.

4. Choose an output to configure as follows:

• Output 1 — Select this field to configure the source on Output 1.

• Output 2 — Select this field to configure the source on Output 2.

• Output 3 — Select this field to configure the source on Output 3.

• Output 4 — Select this field to configure the source on Output 4.

5. Select the output that you want to assign to the selected Output BNC from the

corresponding Output field. You can choose between the following:

• Quad Split — Select this option to assign the Quad Split to the selected output.

• Bkgd A — Select this option to assign Bkgd A to the selected output.

• Bkgd B — Select this option to assign Bkgd B to the selected output.

• Bkgd C — Select this option to assign Bkgd C to the selected output.

• Bkgd D — Select this option to assign Bkgd D to the selected output.

9229-QS User Manual •••• (V 1.2) Configuration •••• 3-3

Page 28

6. From the Dithering field, select the type of dithering you want to apply to all outputs.

You can choose between the following:

• Disabled — Select this option to disable the Dithering feature.

• Enabled low — Select this option to enable 2 b it dithering.

• Enabled medium — Select this option to enable 3 bit dithering.

• Enabled high — Select this option to enable 4 bit dithering.

7. Enable the Clip White or Clip Black feature as follows:

• Clip at Black — Select this box to enable the card to clip to SMPTE black on all

outputs. An unchecked box allows super-black.

• Clip at White — Select this box to enable the card to clip to SMPTE white on all

outputs. An unchecked box allows super-white.

This completes the procedure for configuring your outputs on the card.

Configuring the Input Signal Ti ming Display

The Timing Display feature enables you to configure how the input signal timing is reported by

DashBoard. This information is displayed in the Bkgd A, B, C, and D Timing fields of the Signal tab

in the number of clocks and lines. Negative values indicate the input signal timing is earlier than the

reference. Positive values indicate the input signal timing is later than the reference. Note that there are

4400 clocks per line when using the 1080i 59.94Hz format.

Use the following procedure to configure the input signal timing for your 9229-QS:

1. Display the Device tab of the card by double-clicking its status indicator in the Basic

Tree View.

2. Display the Personality tab as follows:

• From the Device tab, select the Config tab.

• Select the Personality tab located at the bottom of the Config tab.

3. Configure how the signal timing by selecting one of the following options from the

Timing Display menu:

• Relative to Reference — Select this option to display the timing offset values of

the SDI inputs and output relative to the selected analog reference as follows:

› A negative offset value indicates that the SDI signal is earlier than the analog

reference.

› A positive value indicates that the SDI signal is later than the analog reference.

• Input to Output — Select this option to display the timing offset values of the SDI

BKGD inputs relative to the SDI output of the card as follows:

› A negative offset value indicates that the SDI BKGD input signal is earlier than

the SDI OUT signal.

› A positive value indicates that the SDI BKGD input signal is later than the SDI

OUT signal.

3-4 •••• Configuration 9229-QS User Manual •••• (V 1.2)

Page 29

This completes the procedure for configuring the input signal timing for your 9229-QS.

Signal Loss Alarm Setup

The Signal Loss Alarm feature enables DashBoard to display status alarms when a loss of signal is

experienced on the Background input sources. The alarm information displays in the Signal tab of

DashBoard and on the card-edge LEDs. For more information on the status LEDs, refer to the section

“Card-edge LEDs”.

Use the following procedure to set up the Signal Loss Alarm feature:

1. Display the Device tab of the card by double-clicking its status indicator in the Basic

Tree View.

2. Display the Video tab as follows:

• From the Device tab, select the Config tab.

• Select the Video tab located at the bottom of the Config tab.

3. Enable or disable the alarms by selecting or deselecting the required boxes in the Signal

Loss Alarm area as follows:

• Bkgd A — Select this box to enable DashBoard to report the status of the

Background A input source.

• Bkgd B — Select this box to enable DashBoard to repor t the status of the

Background B input source.

• Bkgd C — Select this box to enable DashBoard to repor t the status of the

Background C input source.

• Bkgd D — Selecting this box enables DashBoard to report the status of the

Background D i nput source.

This completes the procedure for setting up the Signal Loss Alarm.

9229-QS User Manual •••• (V 1.2) Configuration •••• 3-5

Page 30

Ethernet Communication Setup

To enable the card to perform software upgrades, the card must be configured with valid ethernet

settings for the 10/100 Ethernet port on the Rear Module of the card. The settings can be specified

manually (Static) or may be obtained automatically from a server on your network (DHCP).

Use the following procedure to set up ethernet communications for the card:

1. Display the Device tab of the card by double-clicking its status indicator in the Basic

Tree View.

2. Display the Ethernet tab as follows:

• From the Device tab, select the Config tab.

• Select the Ethernet tab located at the bottom of the Config tab.

3. To obtain network settings automatically:

• Select DHCP from the Method drop-down list.

• To sa ve the new settings, click Apply Changes. Note that clicking Cancel will

revert to the previous settings.

4. To manually configure the ethernet settings:

• Select Static from the Method drop-down list.

• Enter the IP Address, Subnet Mask, and Default Gateway settings for the card.

• To sa ve the new settings, click Apply Changes. Note that clicking Cancel will

revert to the previous settings.

This completes the procedure for setting up ethernet communications for the card.

Note — The Ethernet Status field in the Ethernet tab displays the current status of

your connection. Refer to Table 5.4 for a list of the messages.

3-6 •••• Configuration 9229-QS User Manual •••• (V 1.2)

Page 31

GPI Communication Setup

This section explains how to configur e communications for GPIs on the card usi ng the menus and

options available in DashBoard.

Note — The 9229-QS does not support Tallies at this time.

GPI Overview

When configured as a GPI, a port behaves as an input, and can be used to trigger actions such as

switching between the Quad Split display or full-screen BKGD input display. A push-button switch, or

an ON-OFF switch, may be directly connected between the port and the adjacent ground pin.

Alternatively, a external device may drive a low level. Minimum pulse duration is 1ms, anything

shorter will be filtered out.

GPI Communication Setup

You can configure the GPI to control the display configuration. Each output can be set to display the

Quad Split, a Bkgd source, or to cycle through the sources each time the specific GPI/Tally is

triggered.

Note — Each GPI should be set to a different function. Setting more than one GPI to

the same function can cause unexpected behavior. Multiple GPIs can be set to None at

the same time.

Use the following procedure to configure remote control for GPIs:

1. Display the Device tab of the card by double-clicking its status indicator in the Basic

Tree View.

2. Display the GPI/Tally tab as follows:

• From the Device tab, select the Config tab.

• Select the GPI/Tally tab located at the bottom of the Config tab.

3. Assign a transition event to a GPI /Tally by selecting the function from the Function

drop-down list to the required GPI/Tally. Choose from the following:

• None — Select this option to not assign a function to the selected GPI/Tally. The

Polarity setting is ignored. This is the default setting.

• Output xx - Quad — Selecting this option causes the specified output, where xx

represents the output, to display the Quad Split when the GPI is triggered.

• Output xx - Bkgd # — Selecting this option causes the specified output, where xx

represents the output, to display the specified full-screen input when the GPI is

triggered.

• Output xx - Cycle — Selecting this option causes the specified output, where xx

represents the output, to cycle through the Quad Split and full-scre en inputs when the

GPI is triggered.

9229-QS User Manual •••• (V 1.2) Configuration •••• 3-7

Page 32

• yy Quad - Black — Selecting this option causes the specified quadrant, where yy

represents the quadrant (UL, UR, LL, and LR), to show black when the GPI is

triggered.

• yy Quad - Bkgd # — Selecting this option causes the specified quadrant, where yy

represents the quadrant, to show the specified Bkgd source when the GPI is triggered.

• yy Quad - Cycle — Selecting this option causes the specified quadrant, where yy

represents the quadrant, to cycle through Black and the four inputs when the GPI is

triggered.

4. Select a Polarity for the GPI from the Polarity column. Choose from the following:

• High/Rising — Select this option to have the GPI triggered on a static High level,

or on a Low-to-High pulse.

• Low/Falling — Select this option to have the GPI triggered o n a static Low level or

on a High-to-Low pulse. This is the default setting.

This completes the procedure for configuring remote control for GPIs.

3-8 •••• Configuration 9229-QS User Manual •••• (V 1.2)

Page 33

Loading the Factory Defaults

If required, the card menu parameters can be reset to the factory default values using the option

available in the Load/Save tab.

Note —Ethernet settings, reference input selection, and the output formats are not

reset using this method.

Use the following procedure to reset the card to the factory default configuration in DashBoard:

1. Display the Device tab of the card by double-clicking its status indicator in the Basic

Tree View.

2. Display the Load/Save tab as follows:

• From the Device tab, select the Config tab.

• Select the Load/Save tab located at the bottom of the Config tab.

3. From the Global Settings area, click Load Factory Defaults to display the Confirm

dialog.

4. Press Yes to load the factory default values for all menu parameters, or No to cancel the

load and close the dialog.

This completes the procedure for resetting the card to the factory default configuration in DashBoard.

9229-QS User Manual •••• (V 1.2) Configuration •••• 3-9

Page 34

Software Upgrades

The card can be upgraded in the field using the 10/100 Ethernet port on the Rear Module and using the

options available in DashBoard. Refer to the section “Ethernet Communication Setup” for setting up

ethernet communications.

Use the following procedure to upgrade the software on a card:

1. Contact Technical Support for the latest software version file.

2. Display the Device tab of the card by double-clicking its status indicator in the Basic

Tree View.

3. From the Device tab, click Upload to display the Select file Upload dialog.

4. Navigate to the *.bin file you wish to upload.

5. Click Open.

6. If you are upgrading a single card, click Finish to start the upgrade. Proceed to step 8.

7. If you are upgrading multiple cards:

• Click Next > to display the Select Destination menu. This menu provides a list of

the compatible cards based on the card selected in step 2.

• Specify the card(s) to upload the file to by selecting the check box(es) for the cards

you wish to upload the file to.

• Verify that the card(s) you wish to upload the file to. The Error/Warning fields

indicate any errors, such as incompatible software or card type mismatch.

• Click Finish.

8. Monitor the upgrade.

• A Upload Status dialog enables you to monitor the upgrade process.

• Note that if the ethernet c onnection is invalid, such as the ethernet cable is unplugged

from the card rear module, the card uses the internal frame communication bus for

the upload process resulting in a longer upgrade process.

• The card reboots automatically once the file is uploaded. The card is temporarily

taken offline.

• T he reboot process is complete once the status indicators for the Card State and

Connection return to their previous status.

Operating Tip — If you are running DashBoard v2.3 or lower, you must click

Reboot in the Device tab to complete the upgrade process.

This completes the procedure for upgrading the software on a card.

3-10 •••• Configuration 9229-QS User Manual •••• (V 1.2)

Page 35

Troubleshooting

If you encounter problems when upgrading your card software, verify the following:

• Your network settings on the card are valid. Refer to Table 5.4 for a list of settings.

• Ethernet cable is properly connected if you are uploading the file via a network

connection.

• The file you are attempting to load is a *.bin file that is for the card you are upgrading.

9229-QS User Manual •••• (V 1.2) Configuration •••• 3-11

Page 36

3-12 •••• Configuration 9229-QS User Manual •••• (V 1.2)

Page 37

Operation

In This Chapter

This chapter provides a summary of the operational features, such as Proc Amp controls and assigning

input sources to the Quad Split.

The following topics are discussed:

• Adjusting the Proc Amp Controls

• Configuring the Quad Split Sources

• Notes on Timing

Notes — Before proceeding, ensure that you are running DashBoard software version

2.3.0 or higher. The DashBoard Control System software and user manual are available

for download from the Ross Video website.

9229-QS User Manual •••• (V 1.2) Operation •••• 4-1

Page 38

Adjusting the Proc Amp Controls

Each output on the card has a Proc Amp that can adjust the black offset, the video gain, the chroma

gain and the CB gain. This section briefly outlines how to adjust the options available in the Proc Amp

tab.

Use the following procedure to adjust an output using a Proc Amp:

1. Display the Device tab of the card by double-clicking its status indicator in the Basic

Tree View.

2. Select an output signal to adjust as follows:

• Select the Proc Amps tab.

• Select the Output tab for the output signal you want to adjust. The Output tabs are

located at the bottom of the Proc Amps tab.

3. Select the Enable box to ensure the color adjustments are applied. The Enable box must

be selected in order for any color correction to take effect on the selected output.

4. Adjust the Video Gain of the card video outputs as follows:

• Use the Video Gain slider to adjust the amount of Video Gain you want to apply.

Increasing overall gain causes an increase in contrast while also making colors more

saturated and vivid. Decreasing overall gain causes a decrease in contrast while de-

saturating colors.

5. Adjust the Chroma Gain of the card video outputs as follows:

• Use the Chroma Gain slider to adjust the chrominance video signal components (Cr

and Cb) simultaneously. Increasing the chroma gain value causes the video signal

colors to become increasingly saturated and more vivid. Decreasing the chroma gain

value de-saturates color from the video signal until it is black and white.

6. Adjust the CB Gain of the card video outputs as follows:

• Use the CB Gain slider to adjust the Cb component of the chrominance video signal.

Increasing the Cb Gain value causes the video signal colors to become increasingly

saturated with blue. Decreasing the Cb Gain value desaturates blue from the video

signal.

7. Adjust the Black Offset of the card video outputs as follows:

• Use the Black Offset slider to adjust the Black Offset you want to apply. Increasing

the Black Offset value causes a lightening effect. Decreasing the Black Offset value

causes a darkening effect.

Operating Tip — To reset the Proc Amp settings to the default values, click Reset

and then Yes in the Confirm dialog box.

This completes the procedure for adjusting an output using a Proc Amp.

4-2 •••• Operation 9229-QS User Manual •••• (V 1.2)

Page 39

Configuring the Quad Split Sources

This section briefly describes how to set up your Quad Split sources using the Quad Split tab in

DashBoard. From the Quad Split tab, you can assign any input to any quadrant and add a text label to

display at the bottom of the applicable quadrant. All active video content will be visible, including the

480i Line 21 content. Note that when a loss of input in a quadrant occurs, the 9229-QS fills that

quadrant with a blue pattern.

Note — The ancillary data (HANC and VANC) of the Quad Split is empty but filled with

valid black.

Assigning Sources to the Quad Split

Use the following procedure to assign sources to a Quad Split quadrant:

1. Display the Device tab of the card by double-clicking its status indicator in the Basic

Tree View.

2. From the Device tab, select the Quad Split tab.

3. Select the Video/Label tab.

4. Select the quadrant you wish to configure.

5. Assign a video source to the specific quadrant by selecting an option from the

corresponding drop-down menu. Choose from the following:

• Black — Select this option to assign black to the specific quadrant.

• Bkgd A — Select this option to assign the Bkgd A input to the specific quadrant.

• Bkgd B — Select this option to assign the Bkgd B input to the specific quadrant.

• Bkgd C — Select this option to assign the Bkgd C input to the specific quadrant.

• Bkgd D — Select this option to assign the Bkgd D input to the specific quadrant.

6. To apply a text label to the quadrant:

• Locate the Source Label area of the Quad Split tab.

• Enter a text label in the applicable text box for the input source.

• Press Enter on your keyboard to apply the new text.

This completes the procedure for assigning sources to the Quad Split.

Applying a Border

The Color/Border feature allows you to set the color (RGB format), transparency, and overall thickness

of the border that is applied to the specified source. Borders are created from the outside edge of the

quadrant and expand inward. The border is applicable to the specified source and not a specific

quadrant.

9229-QS User Manual •••• (V 1.2) Operation •••• 4-3

Page 40

Use the following procedure to adjust the border of a quadrant source:

1. Display the Device tab of the card by double-clicking its status indicator in the Basic

Tree View.

2. From the Device tab, select the Quad Split tab.

3. Select the Color/Border tab.

4. Select the source you wish to configure a border for.

5. Adjust the color of the border as follows:

• Use the Red slider to adjust the amount of red that is mixed in the border of the

specified source. Note that 0 has no intensity, and 255 has full intensity.

• Use the Green slider to adjust the amount of green that is mixed in the border of the

specified source. Note that 0 has no intensity, and 255 has full intensity.

• Use the Blue slider to adjust the amount of blue that is mixed in the border of the

specified source. Note that 0 has no intensity, and 255 has full intensity.

6. Use the Trans slider to adjust the transparency of the border, around the specified

source, from opaque (0%) to fully transparent (100%)

7. Use the Border slider to adjust the thickness of the border in pixel units. Notice that as

you adjust the thickness of the border, it expands inwards from the edge of the quadrant.

A value of 0 removes the border. For best results, it is recommnded to increase the border

width in increments of 2 pixels.

This completes the procedure for adjusting the border of a quadrant source.

4-4 •••• Operation 9229-QS User Manual •••• (V 1.2)

Page 41

Notes on Timing

This section provides additional information on the timing features of the 9229-QS:

• An external black burst or tri-level reference source must be received by the card. The

card will not output video unless either the frame-based Frame Ref 1 or Frame Ref 2

reference, or the Rear Module REF IN BNC (BNC 9) is used.

• On the current software release, SDI output timing of the card is currently fixed at 0.5 line

after the selected analog reference. For example, when using a 1080i output format, the

Output Timing field in the Signal tab will be +2200 clocks because the output timing

measurement is relative to the selected analog reference.

• Each video input has a line sync that can support a full line of SD or HD video including

horizontal blanking.

• When showing full screen BKGD inputs (no Quad Split), line syncs are used and all

BKGD video inputs must be timed within +/- 0.5 line offset from the selected analog

reference. Exceeding this tolerance will result in shifting the full screen output display by

one or several lines.

• When using Quad Split, frame syncs are used and the BKGD video inputs do not need to

be timed to the selected analog reference. The video scaling requires a frame store

operation and the BKGD inputs will be delayed by up to one frame before being displayed

in the Quad Split quadrants.

• All of the video outputs must be the same video format as the video inputs. If the formats

do not match, the card reports an error in the DashBoard Signal Status area and on the

card-edge LEDs.

• When using Quad Split, inputs that are mis-timed will be aligned to the next frame

boundary.

• By default, DashBoard displays output timing relative to the reference. Signal timing is

reported in Clocks and Lines.

• Use the Timing Display option in the Personality tab to configure ho w DashBoard

displays the input signal timing. You can choose to report the timing as relative to the

output or relative to the reference.

9229-QS User Manual •••• (V 1.2) Operation •••• 4-5

Page 42

4-6 •••• Operation 9229-QS User Manual •••• (V 1.2)

Page 43

Appendix A. DashBoard Menus

In This Appendix

The DashBoard Control System enables you to monitor and control openGear frames and cards from a

computer. DashBoard communicates with other cards in the 20-slot frames thro ugh a MFC-8300 Series

Network Controller Card. This controller card is required in order to use DashBoard to monitor the

9229-QS. Refer to the MFC-8300 Series User Manual for details.

This appendix briefly summarizes the menus, items, and parameters available from the DashBoard

Control System™ for the 9229-QS. Default values are noted with an asterisk (*).

The following topics are discussed:

• Status Tabs

• Configuratio n Menus

• Proc Amps Menus

• Quad Split Menus

Note — Before proceeding, ensure that you are running DashBoard software version

2.3.0 or higher. The DashBoard Control System software and user manual are available

to download from the Ross Video website (www.opengear.tv).

9229-QS User Manual •••• (V 1.2) Appendix A. DashBoard Menus •••• 5-1

Page 44

Status Tabs

The following table summarizes the read-only information displayed in the Status tabs.

Table 5.1 Status Menu Functions

Tab Title Item Parameters Description

Product 9229-QS

Supplier Cobalt Digital Inc.

Product (Read-

only)

Hardware

(Read-only)

Board Rev ##

Serial Number ###########

Software Rev #.# build ### Indicates the software and build versions

Firmware Rev ##.## Indicates the FPGA version number

Voltage (V) # Supply Voltage, in Volts

Current (A) # Current consumption of card in Amperes

Power (W) # Power consumption of card in Watts

Rear Module # Indicates the type of Rear Module in the slot

FPGA Core Temp ##C* / ##F FPGA core temperature

CPU Headroom x.xx / y.yy / z.zz

†

CPU Load average

RAM Available ## / ## MB Memory Used / Total Memory

Displays the amount of memory used on the

CompactFlash card

An error has occurred, such as incompatible

CompactFlash card, or an error reading the card

CF Card Status

#.## of 2.0 GB used

Missing CompactFlash card is not present

Unreadable

Displays RAM memory usage where:

• x represents the memory in use

Playout RAM x / y / z MB

• y represents the memory cache from

previously loaded files

• z represents the total playout memory

Signal

Reference Status Green - OK Valid reference signal

(Read-only)

*

A warning is displayed in DashBoard when the FPGA Core Temperature reaches 85°C. If the temperature reaches 11 0°C,

the card will automatically shut down to avoid permanent damage and will have to be reset, rebooted, or power cycled

to resume normal operation.

†

The CPU Load average is displayed in the following format where x.xx represents in t he last minute, y.yy represents the

last five minutes and z.zz is th e l ast fifteen minutes.

5-2 •••• Appendix A. DashBoard Menus 9229-QS User Manual •••• (V 1.2)

Page 45

Tab Title Item Parameters Description

Red - No reference No signal detected on selected reference input

Red - Reference Unlocked Signal detected, but not locked (or lock lost)

Red - Invalid Re ference

Unknown No signal pres ent, or format is not recognized

480i 59.94 Composite NTSC reference detected

720p 59.94

1080i 59.94 Tri-level sync at 59.94Hz detected

Reference Format

576i 50 Composite PAL reference detected

720p 50

1080i 50 Tri-level sync at 50Hz detected

1080PsF 24 Progressive segmented frames at 24Hz

1080PsF 23.98 Progressive segmented frames at 23.98Hz

Green - OK Normal operation

Green - Alarm Suppressed An alarm condition exists but is silenced

Bkgd A Status

Yellow - Incompatible format

Red - No signal No signal present on the input

Bkgd B Status Same parameters as a bove

Signal detected, but incompatible with the

current video mode

Signal present but format does not match the

video outp ut format configurat ion of the card

Signal (Readonly)

Bkgd C Status Same parameters as above

Bkgd D Status Same para meters as above

Green - Normal (not in

bypass)

Bypass Relay

Red - Active (in bypass)

Relative to Reference

Timing Display

Input to Output

Bkgd A Timing

## clocks ## lines

Green status

Video is being routed through the card; Quad

Split may be active

BKGD A bypasses the card and is looped

passively on Output 1 through the relay

The BKGD Timing fields display the timing

values relative to the selected analog reference

The BKGD Timing fields display the timing

values relative to the SDI output of the card

Indicates the timing of the BKGD A input signal

relative to the reference signal or relative to the

output as specified in the Timing Display

feature where 1 clock is:

• 1 period of 27MHz (SD), or

• 1 period of 148.x MHz (HD)

Indicates that the timing is within the specified

range for the card

9229-QS User Manual •••• (V 1.2) Appendix A. DashBoard Menus •••• 5-3

Page 46

Tab Title Item Parameters Description

Indicates that the card is operating outside the

Yellow status

specified line sync range. You may encounter

vertical shifts and/or missing ancillary data when

viewing at full-screen.

Indicates the absence of an input signal. Verify

Gray status

that the cable is properly secured to the rear

module.

Bkgd B Timing Same parameter s as above

Bkgd C Ti ming Same parameters as above

Bkgd D Timing Same paramete rs as abov e

Output Timing ## clocks ## lines

Indicates the timing of the output signals relative

to the reference

5-4 •••• Appendix A. DashBoard Menus 9229-QS User Manual •••• (V 1.2)

Page 47

Configuration Menus

This section briefly summarizes the options and tabs available in the Config tab.

Video Configuration

The following table summarizes the Video tab options available in Dashboard.

Table 5.2 Video Tab Options

Menu Item Parameters Description

Frame 1* The card is using Frame Reference 1

Frame 2 The card is using Frame Reference 2

Reference Input

External

480i 59.94

The card is using the reference input on:

• BNC 11 (RM20-9229-C Rear Module)

Reference

Setup

Output Setup

Output Setup

720p 59.94

1080i 59.94

Output Format

Output 1

Output 2 Same parameters as above. The default setting is Quad Split.

Output 3 Same parameters as above. The default setting is Bkgd A.

576i 50

720p 50

1080i 50

1080PsF 24

1080PsF 23.98

Quad Split*

Bkgd A Output 1 displays the Bkgd A source

Bkgd B Output 1 displa ys the Bkgd B source

Bkgd C Output 1 displays the Bkgd C source

Bkgd D Output 1 displays the Bkgd D source

Specifies the format of the output signal of the

card

Output 1 displays the Quad Split as configured

using the options in the Quad Split tab

Output 4 Same parameters as above. The default setting is Bkgd B.

Dithering

9229-QS User Manual •••• (V 1.2) Appendix A. DashBoard Menus •••• 5-5

Disabled* Dithering is disabled

Enabled - low Dithering is enabled and set to 2bits

Page 48

Menu Item Parameters Description

Enabled - medium Dithering is enabled and set to 3bits

Enabled - high Dithering is enabled and set to 4bits

Signal Loss

Alarm

Clip at Black

Check box is selected SuperBlack is clipped on all outputs

Check box is unselected* SuperBlack is not clipped

Check box is selected SuperWhite is clipped on all outputs

Clip at White

Check box is unselected* SuperWhite is not clipped

Check box is selected*

Bkgd A

Check box is unselected

Bkgd B Same parameters as above

Bkgd C Same parameters as above

Bkgd D Same parameters as above

An alarm is triggered when a missing or an

invalid signal is detected on the BKGD A input

The alarm is suppressed when a missing or an

invalid signal is detected on the BKGD A input

5-6 •••• Appendix A. DashBoard Menus 9229-QS User Manual •••• (V 1.2)

Page 49

GPI Configuration

The menu items available in the GPI/Tally Setup tab enable you to configure the functions and

polarity of each GPI connected to the 9229-QS.

Table 5.3 GPI/Tally Setup Menu Items

Menu Item Parameter Description

GPI/Tally #

Function

Polarity

None*

Output # - Quad Split

Output # - Bkgd #

Output # - Cycle

# Quad - Black

# Quad - Bkgd #

# Quad - Cycle

High/Rising

Low/Falling*

The port is not configured and the GPI has no

effect

When triggered, the specified output displays the

Quad Split

When triggered, the specified output displays the

specified Bkgd source at full-screen

On each trigger, the output will cycle through the

possible Bkgd sources, and the Quad Split

The specified quadrant displays black when the

GPI is triggered

The specified quadrant displays the selected

Bkgd source when the G PI is triggered

The specified quadrant output cycles through t he

available input sources and black when the GPI

is triggered

Sets the polarity of the edge or level trigger. In

the case of edge trigger, a Low-to-High

transition starts the function. In the case of level

trigger, a high level starts the function.

Sets the polarity of the edge or level trigger. In

the case of the edge trigger, a High-to-Low

transition starts the function. In the case of a

level trigger, a low level starts the function.

9229-QS User Manual •••• (V 1.2) Appendix A. DashBoard Menus •••• 5-7

Page 50

Ethernet

The Ethernet tab enables you to set up ethernet communications on the 9229-QS.

Table 5.4 Ethernet Tab Items

Menu Item Parameter Description

Ethernet

Static

Method

DHCP*

IP Address ##.#.#.### The IP Address for the card

Subnet Mask ###.#.#.# The subnet mask for the card

Default Gateway ##.#.#.#

Apply Changes

Cancel

OK Ethernet communications for the card are valid

Link Down

Ethernet Status

User manually supplies the Ethernet Setup

settings

Automates the assignment of the Ethernet

settings

The gateway for communication outside of the

local area network (LAN)

Applies and saves any changes made to the

Ethernet Settings

Cancels any setting changes and resets the

Ethernet Settings to the previous values

Ethernet communications for the card are

invalid. The ethernet cable may be disconnected

from the rear module or the network may be

down.

The following conditions are occurring:

• The Method is set to DHCP.

No IP Address

MAC Address (readonly)

5-8 •••• Appendix A. DashBoard Menus 9229-QS User Manual •••• (V 1.2)

##:##:##:##:##:## The MAC Address for the card

• The ethernet cable connected to card rear

module is securely connected.

• A valid IP Address is no longer available. The

DHCP server may be down or is still powering

up after a loss of power.

Page 51

Personality

The menu items available in the Personality tab enable you to configure how signal timing is reported

in DashBoard.

Table 5.5 Personality Tab Items

Menu Item Parameter Description

The BKGD A, B, C, D Timing fields in the

Timing Display

Relative to Reference*

Timing Display

Input to Output

Signal tab display the timing values relative to

the selected analog reference

The BKGD A, B, C, D Timing fields in the

Signal tab display the timing values relative to

the SDI output of the card

Load/Save

The menu items available in the Load/Save tab enable you to reset menu parameters for the card to the

factory default values.

Table 5.6 Load/Save Tab Items

Menu Item Parameter Description

Global

Settings

Load Factory

Defaults

Resets all DashBoard parameters and values

(excluding ethernet, reference, and output format

settings) to the factory default values

9229-QS User Manual •••• (V 1.2) Appendix A. DashBoard Menus •••• 5-9

Page 52

Proc Amps Menus

The following table summarizes the Proc Amps tab options available in DashBoard.

Table 5.7 Proc Amps Menu Items

Menu Item Parameters Description

Out #

Check box is selected

Enable

Check box is unselected*

Video Gain (%) 0 to 200

Chroma Gain (%) 0 to 200

CB Gain (%) 0 to 200

Enables the adjustment of Proc Amp settings for

the selected output

The Proc Amp settings for the selected output

are inactive

‡

Adjusts the Chroma and Luma Gain values

simultaneously

Adjusts the Cr and Cb values of the output video

signals:

§

• Increasing the gain increases the saturation of

colors

• Decreasing the gain desaturates the colors

until the signal is black and white

Adjusts the Cb component of the chrominance

video signal:

**

• Increasing the value causes the video signal

colors to become increasingly saturated with

blue

• Decreasing the value desaturates blue from

the video signal

Selects how much of the input video signal

values are mapped to black in the output signal:

Black Offset (IRE) -8 to 100

††

• Increasing the value increases the black level

and lightens the image

• Decreasing the value darkens the image

Procamp Reset

‡

The default value is 100.

§

The default value is 100.

**

The default value is 100.

††

The default value is 0.

5-10 •••• Appendix A. DashBoard Menus 9229-QS User Manual •••• (V 1.2)

Resets the Proc Amp menu settings for the

selected output to the default values

Page 53

Quad Split Menus

The following table summarizes the Quad Split tab options available in DashBoard.

Table 5.8 Quad Split Options

Menu Item Parameters Description

Black The upper left quadrant displays black

Video/Label -

Quadrant

Selection

Video/Label -

Source Label

Color/Border -

Bkgd #

‡‡

The upper left quadrant displays the Bkgd A

source

The upper left quadrant displays the Bkgd B

source

The upper left quadrant displays the Bkgd C

source

The upper left quadrant displays the Bkgd D

source

Upper Left

Bkgd A*

Bkgd B

Bkgd C

Bkgd D

Upper Right Same parameters as above. The default setting is Bkgd B.

Lower Left Same parameters as above. The default setting is Bkgd C.

Lower Right Same parameters as above. The default setting is Bkgd D.

Bkgd A Bkgd A*

Bkgd B Bkgd B*

Enter text in this field to configure the label for

the specified source. Note that a blank field

Bkgd C Bkgd C*

hides the text overlay in the display quadrant.

Bkgd D Bkgd D*

Adjusts the amount of red that is mixed in the

Red 0-255

border of the specified source (0 has no

intensity, 255 has full intensity)

Adjusts the amount of green that is mixed in the

Green 0-255

border of the specified source (0 has no

intensity, 255 has full intensity)

Adjusts the amount of blue that is mixed in the

Blue 0-255

border of the specified source (0 has no

intensity, 255 has full intensity)

Adjusts the transparency of the border, around

the specified source, from opaque (0%) to fully

Trans 0-100