Page 1

9215-EO-EM

AES/EBU Fiber Audio Embedder

User Manual

Cobalt Digital Inc.

9215-UM

Version: 1.1

9215-EO-EM User Manual •••• (V 1.1) Page 1

Page 2

9215-EO-EM • Fiber Transmitter / AES-EBU Audio Embedder User Manual

• Cobalt Digital Inc. Part Number: 9215-OM

• Document Version: 1.1

• Printed in the United States.

• Last Author: CGG

The information contained in this manual is subject to change without notice or obligation.

Copyright

© 2013 Cobalt Digital Inc.. All rights reserved.

Contents of this publication may not be reproduced in any form without the written permission of

Cobalt Digital Inc.. Reproduction or reverse engineering of copyrighted software is prohibited.

Patents

This product is protected by the following US Patents: 4,205,346; 5,115,314; 5,280,346;

5,561,404; 7,034,886; 7,508,455. This product is protected by the following Canadian Patents:

2039277; 1237518; 1127289. Other patents pending.

Notice

The material in this manual is furnished for informational use only. It is subject to change without

notice and should not be construed as commitment by Cobalt Digital Inc.. Cobalt Digital Inc.

assumes no responsibility or liability for errors or inaccuracies that may appear in this manual.

Trademarks

• is a registered trademark of Ross Video Limited.

•

• All other product names and any registered and unregistered trademarks mentioned in this

manual are used for identification purposes only and remain the exclusive property of

their respective owners.

is a registered trademark of Cobalt Digital Inc.

Page 2 9215-EO-EM User Manual •••• (V 1.1)

Page 3

Important Regulatory and Safety Notices

Before using this product and any associated equipment, refer to the “Important Safety

Instructions” listed below to avoid personnel injury and to prevent product damage.

Products may require specific equipment, and/or installation procedures to be carried out to satisfy

certain regulatory compliance requirements. Notices have been included in this publication to call

attention to these specific requirements.

Symbol Meanings

This symbol on the equipment refers you to important operating and maintenance

(servicing) instructions within the Product Manual Documentation. Failure to heed this

information may present a major risk of damage or injury to persons or equipment.

Warning — The symbol with the word “Warning” within the equipment manual

indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

Caution — The symbol with the word “Caution” within the equipment manual

indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury. It may also be used to alert against unsafe practices.

Notice — The symbol with the word “Notice” within the equipment manual indicates a

situation, which if not avoided, may result in major or minor equipment damage or a

situation which could place the equipment in a non-compliant operating state.

ESD Susceptibility — This symbol is used to alert the user that an electrical or

electronic device or assembly is susceptible to damage from an ESD event.

Important Safety Instructions

Caution — This product is intended to be a component product of an 8300 series

frame. Refer to the frame User Manual for important safety instructions regarding the

proper installation and safe operation of the frame as well as its component products.

Warning — Certain parts of this equipment namely the power supply area still

present a safety hazard, with the power switch in the OFF position. To avoid electrical

shock, disconnect all A/C power cards from the chassis’ rear appliance connectors

before servicing this area.

9215-EO-EM User Manual •••• (V 1.1) Page 3

Page 4

Warning — Service barriers within this product are intended to protect the operator

and service personnel from hazardous voltages. For continued safety, replace all

barriers after any servicing.

This product contains safety critical parts, which if incorrectly replaced may present a

risk of fire or electrical shock. Components contained with the product’s power supplies

and power supply area, are not intended to be customer serviced and should be

returned to the factory for repair. To reduce the risk of fire, replacement fuses must be

the same time and rating. Only use attachments/accessories specified by the

manufacturer.

EMC Notices

United States of America

FCC Part 15

This equipment has been tested and found to comply with the limits for a class A Digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his own expense.

Notice — Changes or modifications to this equipment not expressly approved by

Cobalt Digital Inc. could void the user’s authority to operate this equipment.

CANADA

This Class “A” digital apparatus complies with Canadian ICES-003.

Cet appariel numerique de la classe “A” est conforme a la norme NMB-003 du Canada.

EUROPE

This equipment is in compliance with the essential requirements and other relevant provisions of

CE Directive 93/68/EEC.

INTERNATIONAL

This equipment has been tested to CISPR 22:1997 along with amendments A1:2000 and

A2:2002, and found to comply with the limits for a Class A Digital device.

Notice — This is a Class A product. In domestic environments, this product may

cause radio interference, in which case the user may have to take adequate measures.

Page 4 9215-EO-EM User Manual •••• (V 1.1)

Page 5

Important Laser Safety Measures and Notices

Before using this product and any associated equipment, refer to the sections below so as to avoid

personnel injury and to prevent product damage. For further safety information when using fiber

products, consult the following publications:

• IEC-60825- 2, Safety of Laser Products - Part 2: Safety of Optical Fiber

Communication Systems (OFCS) (for use outside of the U.S.A.)

• ANSI Z136.2, Safe Use of Optical Fiber Communication Systems Utilizing Laser

Diode and LED Sources (for use in the U.S.A.)

Products may require specific equipment, and /or installation procedures be carried out to satisfy

certain regulatory compliance requirements.

Caution — Before operating or servicing this product, all personnel should be familiar

with laser safety and fiber handling practices.

Safety Measures for Operation

During normal operation of this product, heed the following safety measures:

• Do not stare at, or into, broken, or damaged, fibers.

• Do not stare at, or into, optical connectors.

• Only properly trained and authorized personnel should be permitted to perform

laser/fiber optic operations.

• Ensure that appropriate labels are displayed in plain view and in close proximity to the

optical port on the protective housing/access panel of the terminal equipment.

Safety Measures for Maintenance and Servicing

Warning — Do not use optical equipment, such as a microscope or an eye loupe, to

stare at the energized fiber end. Doing so may damage your eyes.

During maintenance and servicing of this product, only properly trained and authorized personnel

shall be allowed to use optical test or diagnostic equipment.

Laser Information

CLASS 1 LASER PRODUCT

IEC 60825-1:2007

Caution — INVISIBLE LASER RADIATION WHEN OPEN. AVOID EXPOSURE TO

THE BEAM.

9215-EO-EM User Manual •••• (V 1.1) Page 5

Page 6

Maintenance/User Serviceable Parts

Routine maintenance to this Cobalt Digital Inc. product is not required. This product contains no user

serviceable parts. If the frame does not appear to be working properly, please contact Technical

Support using the numbers listed under the “Contact Us” section on the last page of this manual. All

Cobalt Digital Inc. products are covered by a generous 5-year warranty and will be repaired without

charge for materials or labor within this period. See the “Warranty and Repair Policy” section in this

manual for details.

Environmental Information

The equipment that you purchased required the extraction and use of natural resources for its

production. It may contain hazardous substances that could impact health and the environment.

To avoid the potential release of those substances into the environment and to diminish the need for the

extraction of natural resources, Cobalt Digital Inc. encourages you to use the appropriate take-back

systems. These systems will reuse or recycle most of the materials from your end-of-life equipment in

an environmentally friendly and health conscious manner.

The crossed-out wheeled bin symbol invites you to use these systems.

If you need more information on the collection, reuse, and recycling systems, please contact your local

or regional waste administration.

You can also contact Cobalt Digital Inc. for more information on the environmental performances of

our products.

Page 6 9215-EO-EM User Manual •••• (V 1.1)

Page 7

9215-EO-EM User Manual •••• (V 1.1) Page 7

Page 8

Page 9

Contents

Introduction 1-1

In This Chapter.......................................................................................................................1-1

Overview.................................................................................................................................1-2

Functional Block Diagram......................................................................................................1-3

Documentation Terms and Conventions.................................................................................1-4

Installation 2-1

In This Chapter.......................................................................................................................2-1

Before You Begin...................................................................................................................2-2

Installing the 9215-EO-EM.....................................................................................................2-2

Cabling for the 9215-EO-EM .................................................................................................2-6

Software Upgrades for the 9215-EO-EM ...............................................................................2-7

A Word of Thanks....................................................................................................1-1

Features ....................................................................................................................1-2

Static Discharge........................................................................................................2-2

Unpacking.................................................................................................................2-2

Working with Fiber Optic Connectors......................................................................2-2

Rear Modules for the 9215-EO-EM .........................................................................2-3

Installing a Rear Module..........................................................................................2-3

Installing the 9215-EO-EM ......................................................................................2-4

8321 Series Frame Cabling Overview......................................................................2-6

Performing Software Upgrades ................................................................................2-7

User Controls 3-1

In This Chapter.......................................................................................................................3-1

Card Overview........................................................................................................................3-2

Control and Monitoring Features............................................................................................3-4

Status and Selection LEDs on the 9215-EO-EM......................................................3-4

Reference Compatibility.........................................................................................................3-6

Frame Rate Compatibility.........................................................................................3-6

Operation Notes......................................................................................................................3-7

Audio Proc Amp Controls ........................................................................................3-7

Minimum Delay Overview.......................................................................................3-7

Menus 4-1

In This Chapter.......................................................................................................................4-1

SNMP Monitoring and Control ..............................................................................................4-2

DashBoard Menus for the 9215-EO-EM ................................................................................4-3

Status Tab.................................................................................................................4-3

Setup Menus.............................................................................................................4-6

Input Status Menus...................................................................................................4-8

AES Inputs 1-8 Menus..............................................................................................4-9

9215-EO-EM User Manual •••• (V 1.1) Contents •••• i

Page 10

Embedded Outputs Menus......................................................................................4-10

Alarm Enables Menus.............................................................................................4-11

Card-edge Menu System.......................................................................................................4-14

Navigation ..............................................................................................................4-14

Card-edge Menus....................................................................................................4-14

Menu Descriptions..................................................................................................4-16

Specifications 5-1

In This Chapter .......................................................................................................................5-1

9215-EO-EM Technical Specifications ..................................................................................5-2

Channel Status Data Table......................................................................................................5-4

Passing the Status Bytes............................................................................................5-4

Service Information 6-1

In This Chapter .......................................................................................................................6-1

Troubleshooting Checklist......................................................................................................6-2

Bootload Button........................................................................................................6-2

Warranty and Repair Policy....................................................................................................6-3

ii •••• Contents 9215-EO-EM User Manual •••• (V 1.1)

Page 11

Introduction

In This Chapter

This chapter contains the following sections:

• Overview

• 9215-EO-EM Functional Block Diagram

• Documentation Terms and Conventions

A Word of Thanks

Congratulations on choosing a 9215-EO-EM AES/EBU Fiber Audio Embedder. The Cobalt Digital

Inc. line includes video decoders and encoders, audio embedders and de-embedders, distribution

amplifiers, format converters, and much more. Cobalt Digital Inc. modular conversion gear will meet

your signal conversion needs now, and well into the future.

Should you have a question pertaining to the installation or operation of your 9215-EO-EM, please

contact us at the numbers listed on the back cover of this manual. Our technical support staff is always

available for consultation, training, or service.

9215-EO-EM User Manual •••• (V 1.1) Introduction •••• 1-1

Page 12

Overview

The 9215-EO-EM is a broadcast-quality embedder with one multi-rate SDI input which supports up to

16 channels of embedded audio and eight AES 75ohm unbalanced audio inputs. A single mode fiber

interface with an LC/UPC connector provides an SDI output.

The 9215-EO-EM can take in up to eight AES inputs and embeds them into any of the 16 possible

audio channels in an SD or HD-SDI output. If the input is a synchronous 48kHz signal, the audio will

be embedded into the SDI signal unaltered. If the input is not a synchronous 48kHz signal, it may be

converted using Sample Rate Conversion (SRC) before it is embedded on the SDI output.

The AES inputs have the following adjustments available: delay, gain, invert, and sum.

Card status and control parameters are displayed and configured using the DashBoard Control

System™.

Features

The 9215-EO-EM includes the following features:

• Supports HD-SD SDI SMPTE-292M, 1.5Gbps and SMPTE 259M, 270Mbps

• Supports AES-3id-2001, and EBU tech 3250

• Audio embedding for all popular formats 480i, 576i, 720p, and 1080i

• Embeds four audio groups with selection of primary and backup sources

• Eight AES-3id 75ohm unbalanced inputs with SRC on DIN 1.1/2.3 connectors

• One SDI processed output

• Automatic input video format detection

• SNMP support available

• Input buffer with a bypass option

• User defined loss of signal output

• Audio controls such as gain, invert, delay, and sum

• Internally generated test patterns and test tones

• Reports status and configuration remotely via the DashBoard Control System™

• Fits 20-slot frame

• 5-year transferable warranty

1-2 •••• Introduction 9215-EO-EM User Manual •••• (V 1.1)

Page 13

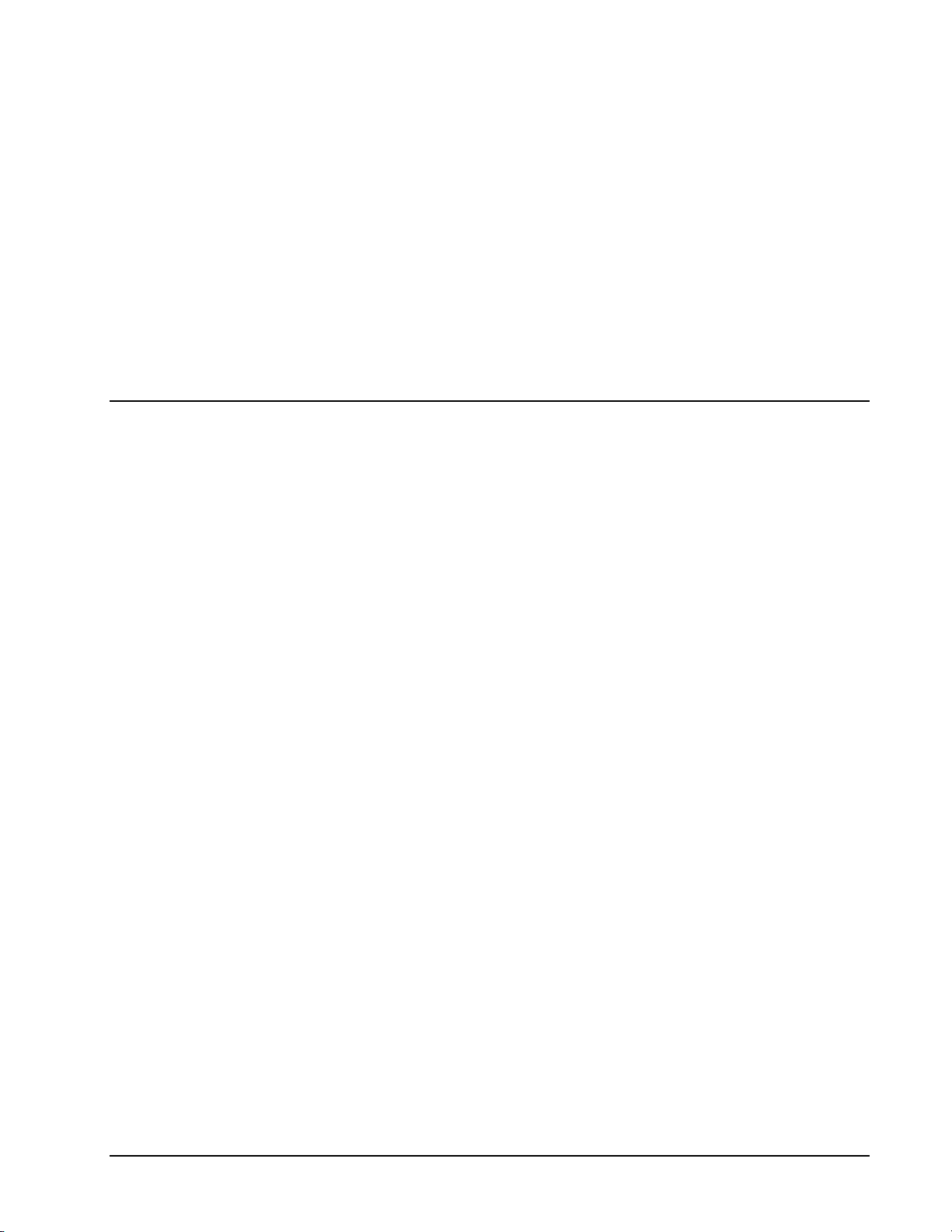

Functional Block Diagram

This section provides a functional block diagram that outlines the workflow of the 9215-EO-EM.

Figure 1.1 9215-EO-EM — Simplified Block Diagram

9215-EO-EM User Manual •••• (V 1.1) Introduction •••• 1-3

Page 14

Documentation Terms and Conventions

The following terms and conventions are used throughout this manual:

• “Frame” refers to a 20-slot frame that houses the 9215-EO-EM, as well as any openGear

frames.

• All references to frame includes all versions of the 20-slot frame and any available options

unless otherwise noted.

• “Operator” and “User” refer to the person who uses 9215-EO-EM.

• “Board”, and “Card” refer to openGear terminal devices within openGear frames,

including all components and switches.

• “System” and “Video system” refer to the mix of interconnected production and terminal

equipment in your environment.

• “-line mode ” refers to broadcast situations using NTSC composite (analog) signal

reference inputs.

• “-line mode ” refers to broadcast situations using PAL-B composite (analog) signal

reference inputs.

• “PAL” refers to PAL-B unless otherwise stated.

• “Operating Tips” and “Note” boxes are used throughout this manual t o provide

additional user information.

1-4 •••• Introduction 9215-EO-EM User Manual •••• (V 1.1)

Page 15

Installation

In This Chapter

This chapter provides instructions for installing the Rear Module(s) for the 9215-EO-EM, installing the

card into the frame, cabling details, and updating the card software.

The following topics are discussed:

• Before You Begin

• Installing the 9215-EO-EM

• Cabling for the 9215-EO-EM

• Software Upgrades for the 9215-EO-EM

9215-EO-EM User Manual •••• (V 1.1) Installation •••• 2-1

Page 16

Before You Begin

Static Discharge

Throughout t hi s chapter, please heed the foll owing cautionary note:

ESD Susceptibility — Static discharge can cause serious damage to sensitive

semiconductor devices. Avoid handling circuit boards in high static environments such as

carpeted areas and when synthetic fiber clothing is worn. Always exercise proper grounding

precautions when working on circuit boards and related equipment.

Unpacking

Unpack each 9215-EO-EM you received from the shipping container and ensure that all items are

included. If any items are missing or damaged, contact your sales representative or Cobalt Digital Inc.

directly.

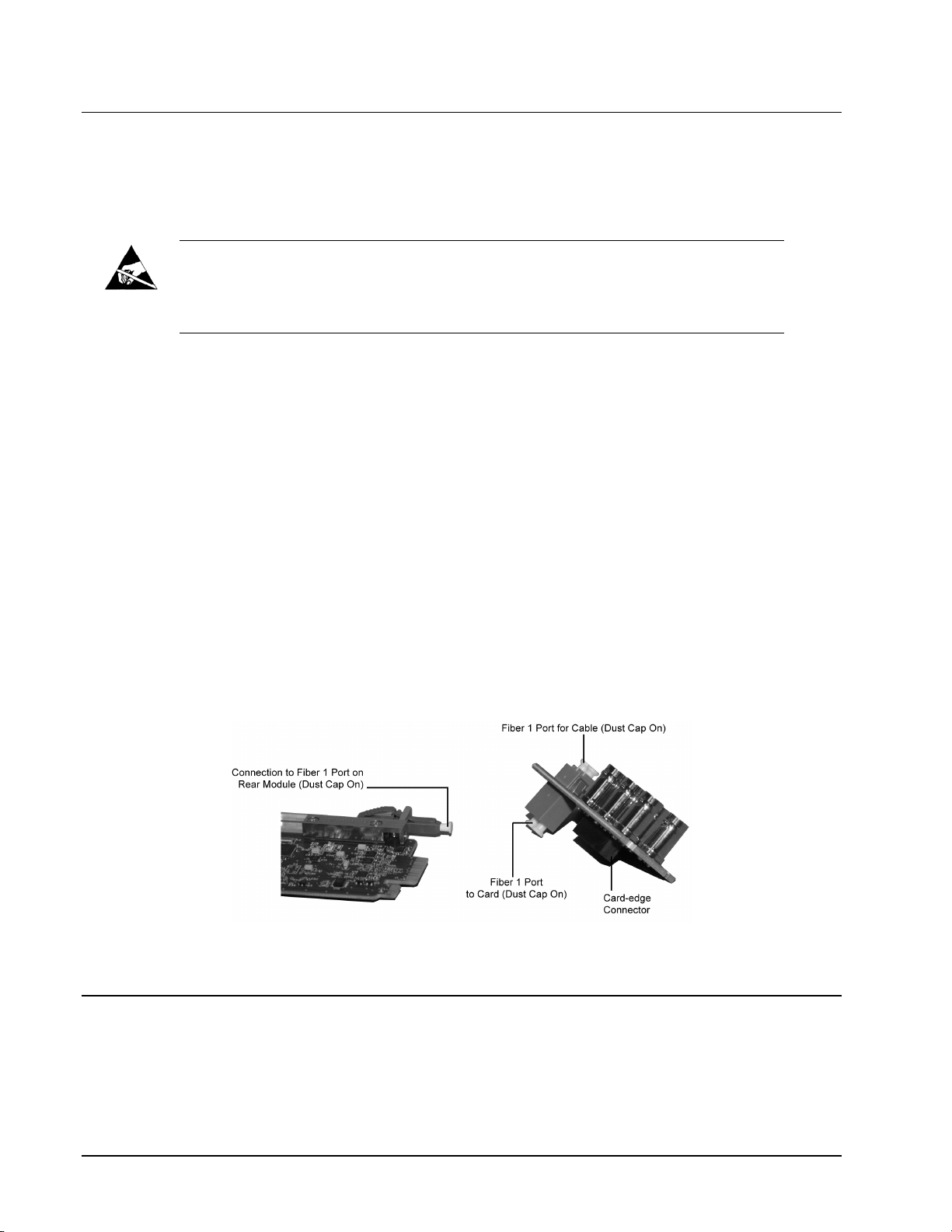

Working wi th Fiber Optic Connectors

Keep the following in mind when working with fiber optic connectors:

• Every time you are required to insert a connector into a device or mating sleeve, you must

clean the connector. All exposed surfaces of the ceramic ferrule must be clean. Follow

your facility practices of cleaning fiber optic connectors.

• Connectors must always be inserted into a device or have a dust cap on. Refer to Figure

2.1 for dust cap locations.

• A poor optical connection is often similar to a poor electrical connection. Try removing

the connector, cleaning, and re-inserting the connector. A bad connection can result in

experiencing instability of signal, high loss, or a noisy signal.

Figure 2.1 Card Connectors with Dust Caps Installed

Installing the 9215-EO-EM

This section outlines how to install a Rear Module in a 20-slot frame. You cannot install the 9215-EOEM in a 8310 series or a 8320 series frame.

2-2 •••• Installation 9215-EO-EM User Manual •••• (V 1.1)

Page 17

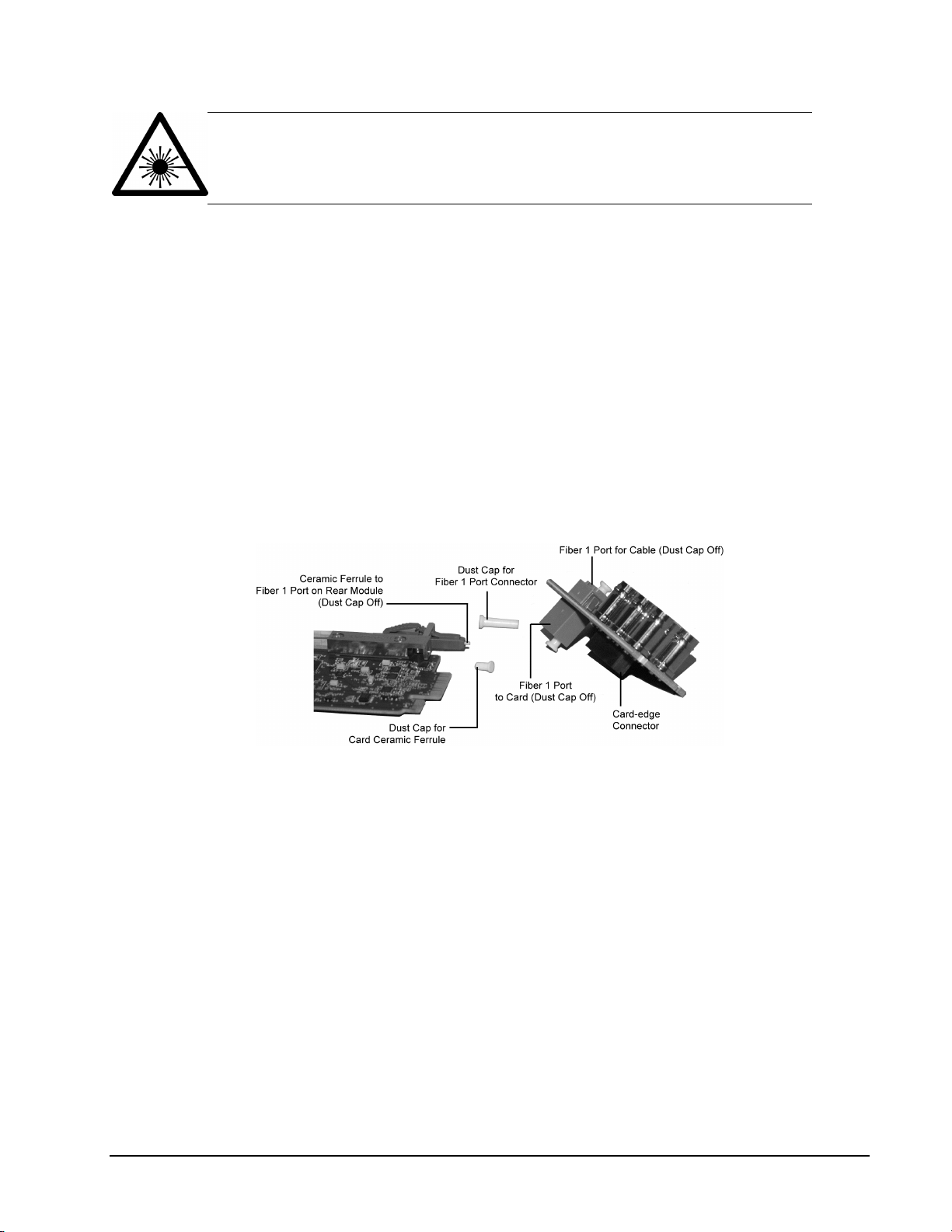

Caution — Never attempt to look down the barrel of a connected fiber or device

transmitting an optical signal. The transmitted light is not in the visible spectrum and

may cause permanent eye damage. Turn off all laser sources before disconnecting

devices.

Rear Modules for the 9215-EO-EM

When installing the 9215-EO-EM in the 20-slot frame, the RM-20-9215-B Full Rear Module is

required. Refer to the section “8321 Series Frame Cabling Overview” for cable designations.

Installing a Rear Module

If the Rear Module is already installed, proceed to the section “Installing the 9215-EO-EM”.

Use the following procedure to install a Rear Module in your 20-slot frame:

1. Locate the card frame slots on the rear of the frame.

2. Remove the Blank Plate from the slot you have chosen for the 9215-EO-EM installation.

3. Remove the dust cap from the Fiber ports on the Rear Module that faces the interior of

the frame. Refer to Figure 2.1 and Figure 2.2 for dust cap locations.

Figure 2.2 Card Connectors Connectors with Dust Caps Removed

4. Install the bottom of the Rear Module in the Module Seating Slot at the base of the

frame’s back plane.

5. Align the top hole of the Rear Module with the screw on the top-edge of the frame back plane.

6. Using a Phillips screwdriver and the supplied screw, fasten the Rear Module to the back

plane of the frame. Do not over tighten.

7. Ensure proper frame cooling and ventilation by having all rear frame slots covered with

Rear Modules or Blank Plates.

This completes the procedure for installing a Rear Module in the frame.

Installing the 9215-EO-EM

The 9215-EO-EM uses a single mode, LC/UPC connector to interface with the RM20-9215-B Full

Rear Module. This section outlines how to install the 9215-EO-EM in a frame.

9215-EO-EM User Manual •••• (V 1.1) Installation •••• 2-3

Page 18

Use the following procedure to install the 9215-EO-EM in the frame:

1. Locate the Rear Module you installed in the procedure “Installing a Rear Module”.

2. Ensure that the Rear Module the 8320AR-044 Full Rear Module.

3. Remove the dust caps from the connector on the card end.

• Refer to Figure 2.1 and Figure 2.3 for dust cap locations.

• Refer to the section “Important Laser Safety Measures and Notices” at the

beginning of this manual for safety information when handling fiber opt i c

components.

Figure 2.3 Card Connectors with Dust Caps Removed

4. Ensure that the exposed surface of the ceramic ferrule of the connectors is clean. Refer to

the section “Working with Fiber Optic Connectors” for cleaning tips.

5. Hold the card by the edges and carefully align the card-edges with the slots in the frame.

6. Fully insert the card into the frame until the rear connection plus is properly seated in the

Rear Module. You will feel a click when the card mates onto the rear module.

7. Affix the supplied Rear Module Label to the BNC area of the Rear Module.

8. Remove the dust cap from the Fiber 1 port (the topmost fiber optic port) on the Rear

Module that faces the exterior of the frame.

9. Ensure the ceramic ferrule of the Fiber 1 port connector is clean..

10. Cable your rear module as outlined in the section “Cabling for the 9215-EO-EM”.

This completes the procedure for installing the 9215-EO-EM in the frame.

2-4 •••• Installation 9215-EO-EM User Manual •••• (V 1.1)

Page 19

Cabling for the 9215-EO-EM

This section provides information for connecting cables to the installed Rear Modules on the 8321s.

Connect the input and output cables according to the following sections.

The 9215-EO-EM accommodates eight synchronous AES input streams at 48kHz or any asynchronous

AES streams from 32kHz to 96kHz with SRC enabled. Note that SRC should only be used with Pulse

Code Modulation (PCM) digital audio and not any form of compressed signal, such as Dolby®.

The optical connector used to mate the card to the rear module is designed for blind mate optical

connectors. All fiber interfaces are single mode fibers.

Notice — Every time you are required to insert a connector into a device or mating

sleeve, you must clean the connector. All exposed surfaces of the ceramic ferrule must

be clean. Follow your facility practices of cleaning fiber optic connectors.

Connectors must always be inserted into a device or have a dust cap on.

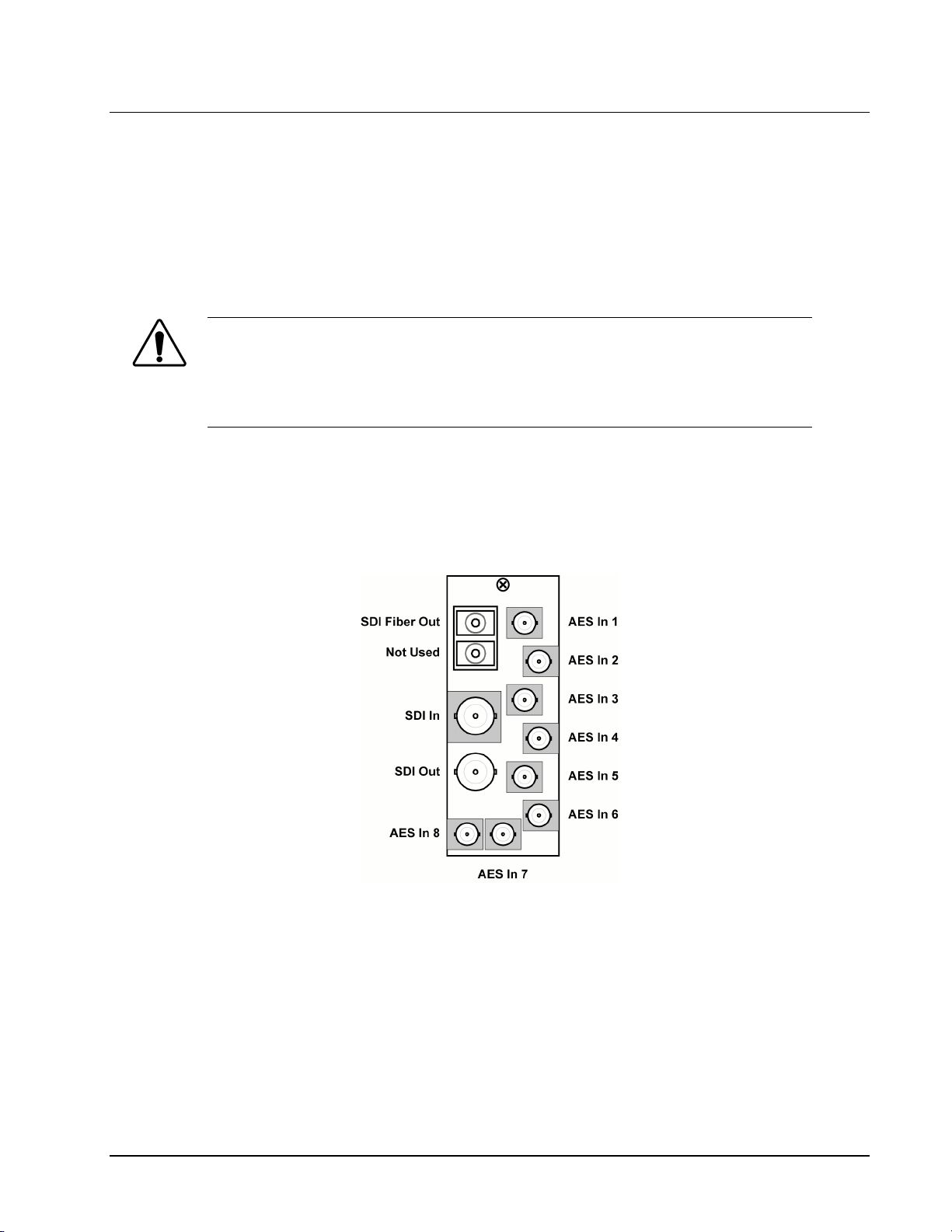

20-Slot Frame Cabling Overview

In the 20-slot frame, the 9215-EO-EM is used with the RM20-9215-B Full Rear Module. Each card

occupies two slots and provides one SDI input, one SDI output, one fiber output, and eight unbalanced

AES inputs. (Figure 2.4 )

Figure 2.4 Cable Connections for the RM-20-9215-B

Rear Module

9215-EO-EM User Manual •••• (V 1.1) Installation •••• 2-5

Page 20

Software Upgrades for the 9215-EO-EM

r

This section provides instructions for installing a license key and upgrading the software for your 9215EO-EM using the DashB oard Control System™.

Performing Softw ar e Upgrades

DashBoard enables you to upload software updages to the 9215-EO-EM.

Use the following procedure to upload software to the 9215-EO-EM:

1. Contact Technical Support for the latest software version file.

2. In DashBoard, display the Device tab of the 9215-EO-EM by double-clicking its status

indicator in the Basic Tree View.

3. From the Device tab, click Upload to display the Select File for upload dialog box.

4. Navigate to the *.bin upload file you wish to upload. DashBoard automatically selects the

last directory that you loaded from.

5. Click Open to display a confirmation dialog box. This dialog box displays the selected

upload file name, type, size, and the file creation date.

6. From the Confirmation dialog box, select one of the following:

• Cancel — Select this option to cancel the upload of the file and return to the Device

View.

• Continue — Select this option to upload the file. While uploading, an Uploading

Progress dialog box opens.

Notice — Clicking the Cancel button while uploading will leave the card in an invalid state. Do

not click Cancel unless the uploading progress has stopped completely for 60 seconds or more.

If upload fails, repeat the upload process from DashBoard. If the upload process fails again, refe

to the section “Bootload Button”.

7. Monitor the upgrade progress ba r displayed in DashBoard while the software is upgraded

on your 9215-EO-EM.

8. To complete the upgrade process, you must reboot the card as follows:

Note — The communications processor of the 9215-EO-EM requires approximately 30

seconds to re-start and re-establish network communications.

• The 9215-EO-EM automatically saves all your settings before starting the reboot

process.

• The status of all the cards in the frame are grayed out until the reboot process is

complete.

This completes the procedure to upload software to the 9215-EO-EM.

2-6 •••• Installation 9215-EO-EM User Manual •••• (V 1.1)

Page 21

User Controls

In This Chapter

This chapter provides a general overview of the user controls available on the 9215-EO-EM.

The following topics are discussed:

• Card Overview

• Control and Monitoring Features

• Reference Compatibility

• Operation Notes

9215-EO-EM User Manual •••• (V 1.1) User Controls •••• 3-1

Page 22

Card Overview

This section provides a general overview of the 9215-EO-EM components. For information on the

LEDs available on the card-edge, refer to the section “Control and Monitoring F e atures”.

Figure 3.1 9215-EO-EM — Card-edge Components

1) Function Select Switch 3) Four Character Display 5) Fiber Opt i c Connector

2) Mode Selec t Switch 4) Boot l oad Button

1. Function Select Switch

Use this switch to select general operation functions and menu items. This switch works in

conjunction with the Mode Select Switch.

2. Mode Select Switch

Use this switch to enable, disable, and select specific configurations within the operational function

modes menu (selected first with the Function Select Switch).

3. Four Character Display

This display is located on the card-edge and reports the menu and options selected using the

Function Select Switch and the Mode Select Switch.

4. Bootload Button

Use this button for factory service in the unlikely event of a complete card failure. Do not press

this button unless instructed to do so by Cobalt Digital Inc. Technical Support personnel.

5. Fiber Optic Connector

The 9215-EO-EM use a blind mate, single mode, LC/UPC connector to interface with the Full

Rear Module (RM20-9215-B). The rear module is passive, which allows for the 9215-EO-EM to

be replaced without the need to remove any connected BNC or fiber optic cables.

The fiber optic connector for the card includes a dust cap. The dust cap must stay on at all times

when not installed in a frame. Ensure to keep the fibers end face clean and use the caps to protect

the fiber from scratches and collecting dust.

3-2 •••• User Controls 9215-EO-EM User Manual •••• (V 1.1)

Page 23

For More Information...

• on using the switches, refer to the section “Card-edge Menu System”.

• on the LEDs located on the card-edge, refer to the section “Status and Selection LEDs on

the 9215-EO-EM”.

• on handling fiber optic components, refer to the section “Important Laser Safety

Measures and Notices” at the beginning of this manual.

• on using fiber connectors, refer to the section “Working with Fiber Optic Connectors”.

9215-EO-EM User Manual •••• (V 1.1) User Controls •••• 3-3

Page 24

Control and Monitoring Features

This section provides information on the card-edge LEDs for the 9215-EO-EM. Refer to Figure 3.2

for the location of the LEDs and controls.

Figure 3.2 9215-EO-EM Card-edge Controls

Status and Selection LEDs on the 9215-EO-EM

The front-edge of the 9215-EO-EM has LED indicators for the power, video input status, and

communication activity. Basic LED displays and descriptions are provided in Table 3.1.

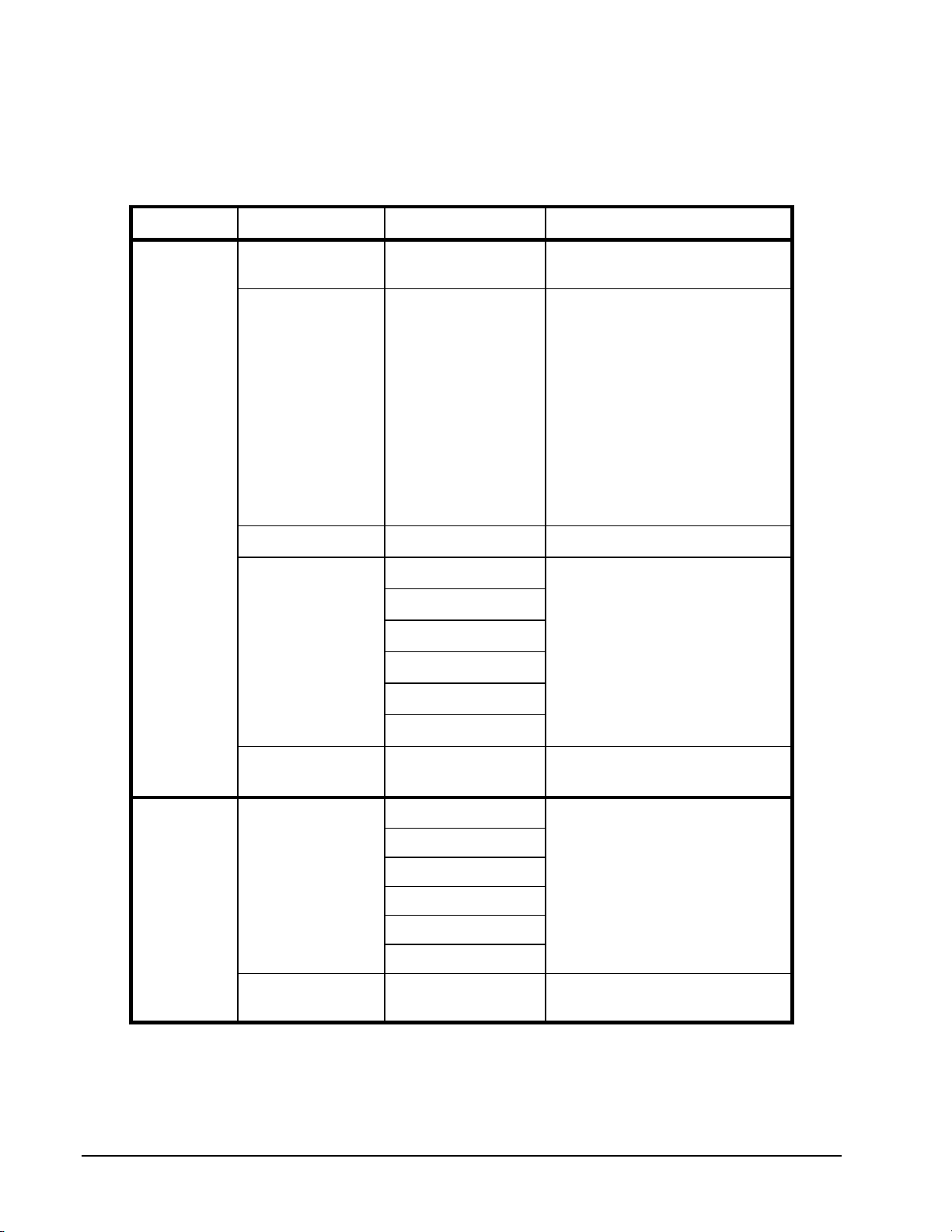

Table 3.1 LEDs on the 9215-EO-EM

LED Color Display and Description

When lit green, this LED indicates that the card is functioning

normal and that no anomalies have been detected. The following

OK/ERROR

Green

Flashing Green

Flashing Green

and Orange

Orange When lit orange, this LED indicates the card is powering on.

conditions must be satisfied:

• a valid input signal is present

• a valid reference signal is present when a reference is required,

and that the reference standard matches the input standard.

When flashing green, this LED indicates the bootloader is waiting

for a software upload.

When lit green with flashing orange, this LED indicates there is a

signal error, such as a missing or invalid input or reference.

3-4 •••• User Controls 9215-EO-EM User Manual •••• (V 1.1)

Page 25

LED Color Display and Description

Red When lit red, this LED indicates the card is not operational.

Off When off, this LED indicates there is no power to the card.

Green When lit, this LED indicates that the video input is valid.

VIDEO OK

REF OK

AES # OK

Flashing Green

When flashing, this LED indicates that video is present, but the

input format is unsupported.

Off When unlit, this LED indicates the absence of an input signal.

Green When lit, this LED indicates a valid reference signal.

Flashing Green

Off

Yellow

When flashing, this LED indicates that the reference signal is

present but the format is invalid.

When unlit, this LED indicates that a reference signal is not

present or is not supported.

When lit, an LED indicates a valid signal is detected on the

corresponding AES input.

9215-EO-EM User Manual •••• (V 1.1) User Controls •••• 3-5

Page 26

Reference Compatibility

It is important to remember that if you are using Frame 1 or Frame 2 as the reference, the input video

frame rate must match the reference frame rate.

Frame Rate Compatibility

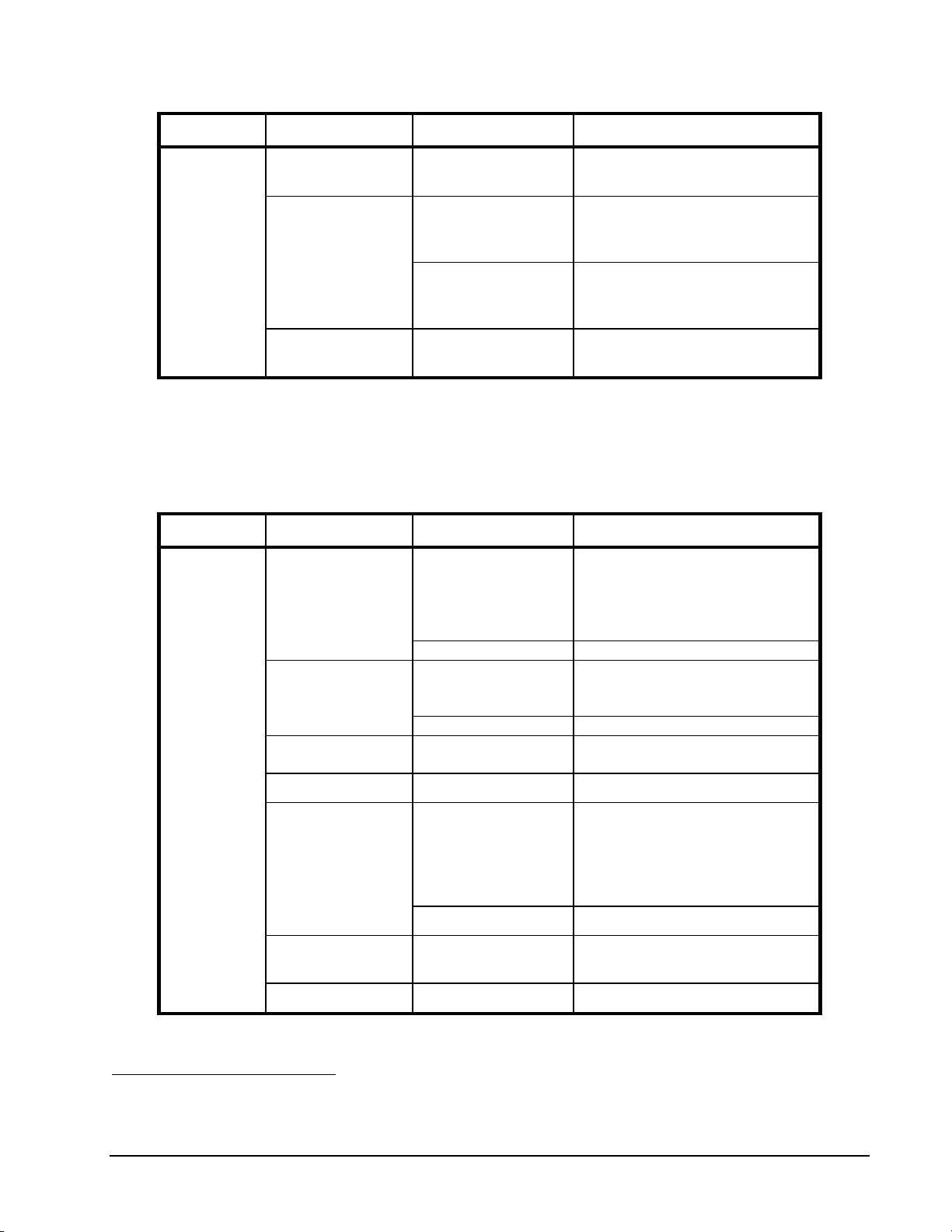

Refer to Table 3.2 for frame rate compatibility.

Table 3.2 Compatible Video Formats

Reference

480i/59.94 720p/59.94 1080i/59.94 576i/50 1080i/50 720p/50

Output

480i/59.94

720p/59.94

1080i/59.94

576i/50

720p/50

1080i/50

99999

99999

99999

99

99

99

99

99

99

9

99

9

99

9

99

99999

99999

99999

99

99

99

99

99

99

9

99

9

99

9

99

3-6 •••• User Controls 9215-EO-EM User Manual •••• (V 1.1)

Page 27

Operation Notes

This section provides brief notes when operating the 9215-EO-EM.

Audio Proc Amp Controls

The 9215-EO-EM includes Processing Amplifiers (Proc Amps) for the audio outputs on the card. Note

that these features are not available when using the card-edge controls.

Proc Amp adjustments are applied in the following order:

1. Sum — This option enables both channels to carry the average of the two input channels

(A+B/2). When the input is summed, the original signals are no longer available for output.

This option only operates with AES input pairs.

2. Delay — This option enables you to adjust the delay of the audio channel. If you have

enabled the Delay Lock feature, changing the delay value for one channel automatically

changes the value for the other channel.

3. Gain — This option allows you to adjust the gain by +/- 20dB in 1dB increments. If you

have enabled the Gain Lock feature, changing the gain value for one channel automatically

changes the value for the other channel.

4. Invert — This option enables you to invert the polarity of the audio signal for the selected

channel.

Minimum Delay Overview

The line buffer stores incoming video in relation to the incoming video clock timing. The video data is

then read out in relation to the reference timing. This allows the input video to be switched between

sources that may not be perfectly timed without timing glitches. Video source timing must remain

within the buffer window to properly switch between sources. Table 3.3 provides information on the

buffer window available depending on how the Minimum Delay feature is configured in DashBoard.

Table 3.3 Minimum Delay

If the option is... Format Minimum Delay Maximum Delay

Disabled

Enabled

HD 1/4 line 1/2 line

SD 1/4 line 1/2 line

HD 1/64 line 1/32 line

SD 1/32 line 1/16 line

9215-EO-EM User Manual •••• (V 1.1) User Controls •••• 3-7

Page 28

3-8 •••• User Controls 9215-EO-EM User Manual •••• (V 1.1)

Page 29

Menus

In This Chapter

This chapter provides a summary of the menus available for the 9215-EO-EM.

The following topics are discussed:

• SNMP Monitoring and Control

• DashBoard Menus for the 9215-EO-EM

• Card-edge Menu System

9215-EO-EM User Manual •••• (V 1.1) Menus •••• 4-1

Page 30

SNMP Monitoring and Control

The Network Controller Card in a 20-slot frame provides optional support for remote monitoring of

your frame and using the Simple Network Management Protocol (SNMP), which is compatible with

many third-party monitoring and control tools.

Refer to your 9215-EO-EM Management Information Base (MIB) files for a breakdown of SNMP

controls on the cards. Refer to the MFC-8300 Series User Manual for additional information on

SNMP Monitoring and Control.

4-2 •••• Menus 9215-EO-EM User Manual •••• (V 1.1)

Page 31

DashBoard Menus for the 9215-EO-EM

This section briefly summarizes the menus, items, and parameters available from the DashBoard

Control System™ for the 9215-EO-EM. Parameters marked with an asterisk (*) are the factory default

values.

The DashBoard Control System™ enables you to monitor and control openGear frames and cards from

a computer. DashBoard communicate s with o ther cards in the 20-slot frame through the Network

Controller Card.

Status Tab

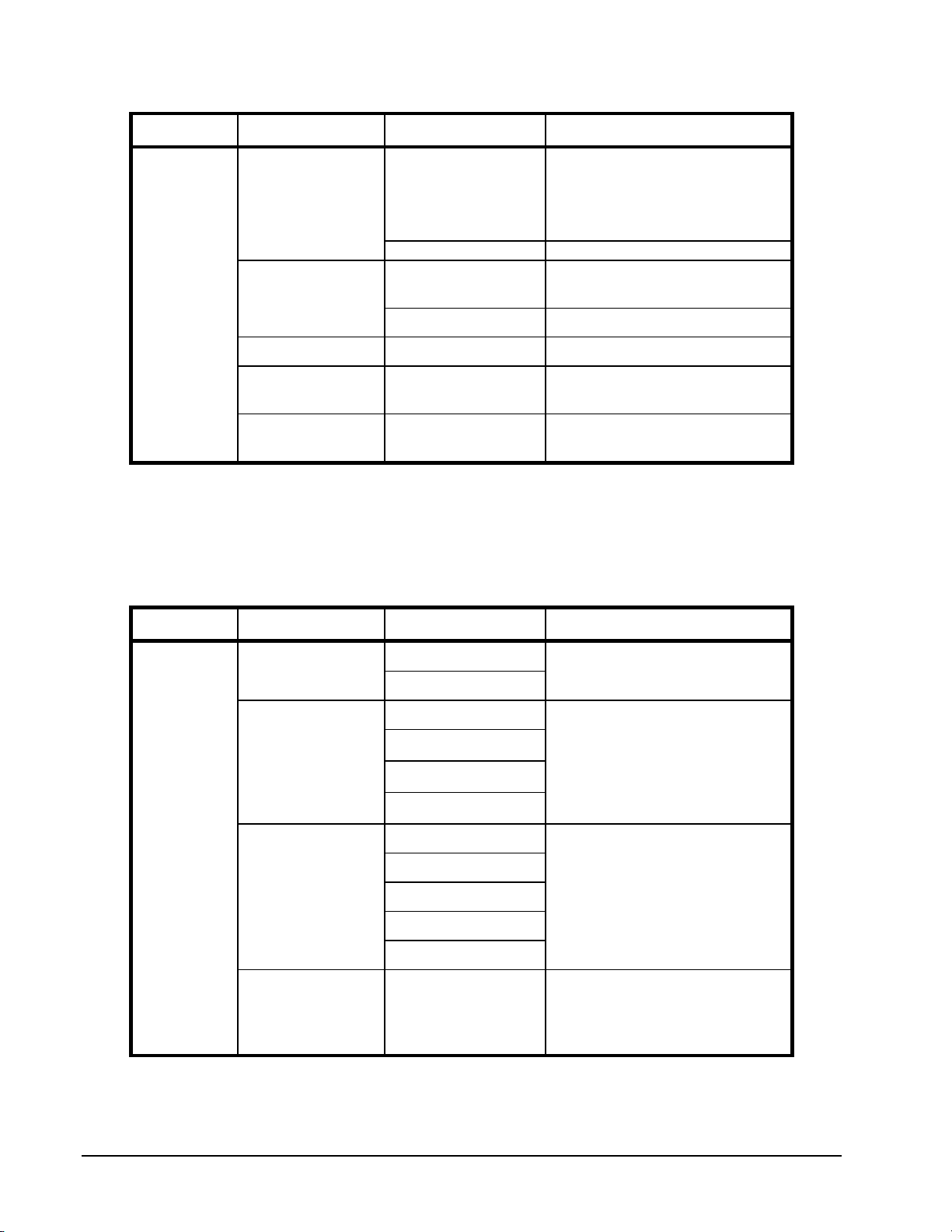

Table 4.1 summarizes the Status tab parameters available in DashBoard for the 9215-EO-EM.

Table 4.1 Status Tab Items

Menu Item Parameters Description

Product 9215-EO-EM

Supplier Cobalt Digital Inc.

Product

(Readonly)

Hardwar

e (Readonly)

Board Rev ##

Rear Module # Type of rear module in the slot

Board S/N ###### Indicates the card serial number

Software Rev ##.## Indicates the software version

Firmware Rev #.### Indicates the firmware version

OK

FPGA load invalid

Incomp I/O Module

Current out of spec

HW Status

Internal Error

SFP Temp Low

SFP Temp High

SFP Power High

SFP Power Low

SFP Tx Fault

SFP Not Detected

Indicates the status of the hardware

including the SFP module. Some messages

displayed are dependent on the settings in

the Alarms Enable tab.

Voltage (mV) # Supply Voltage

Current (mA) # Current consumption o f card

Hardwar

e (Read-

Optical Module

Temperature (C)

#

Indicates the temperature of the Optical

Module

only)

9215-EO-EM User Manual •••• (V 1.1) Menus •••• 4-3

Page 32

Menu Item Parameters Description

Optical Tx

Wavelength (nm)

# Indicates the wavelength being transmitted

CPU Headroom # Processing power available

RAM Available #/## On-board processing memory available

Uptime (h) #

Displays the number of hour s si nce the last

reboot of the card

Configuration Bank # Storage count

OK

No Input

Invalid Format

Signal Status

Incompatible

Non-Sync Video

Indicates when the channel is functioning

normally or if anomalies are detected

Group Not Present

Group Channel

Silent

OK

AES Inpu t Not

Present

Signal

(Readonly)

Audio Status

Source Missing

Source Async

AES Input Silent

Group 4 Reduced

to 20bit

*

Indicates the status of the audio source

Backup Source

Missing

Backup Source

Async

OK

Indicates that a valid reference source is

present

The following conditions are occurring:

Reference Status

No Ref - Video

• Card reference is set to Frame 1 or Frame

2

• A valid reference signal is not present

• Card has gone to Video Timing Mode

*

This parameter indicates that there are more than 3 groups of 24-bit SD embedded audio sources.

4-4 •••• Menus 9215-EO-EM User Manual •••• (V 1.1)

Page 33

Menu Item Parameters Description

The following conditions are occurring:

• Card reference is set to Frame 1 or Frame

2

No Ref - Free Run

Reference Status

Invalid Format Video

Invalid Format Free Run

Input Format # Indicates the input video format

Reference Format # Indicates the reference video format

• A valid reference signal is not present

• A valid video signa l is not present

• Card has gone to Free Run Mode

Card has detected an invalid

format and has switched to Video Timing

Mode

The following conditions are occurring:

• Card has detected an invalid

format

• Input video is missing or invalid

• Card has switched to Free Run Mode

†

reference

b

reference

Signal

(Readonly)

Output Format # Indicates the output video format

OK

Temp High

Temp Low

Optical Module

Status

Rx Power High

Indicates the status of the card Optical

Module

Rx Power Low

Rx Fault

Not Detected

Optical Tx Power

(dBm)

#

Indicates the output power of the Optical

Module

PCM

No Input

Embedded A udio

Status - Group #

PCM-Silent

Indicates the presence of input

Non-PCM

Async

Mixed

†

Refer to the section “Reference Compatibility” for a complete list of supported references.

9215-EO-EM User Manual •••• (V 1.1) Menus •••• 4-5

Page 34

Menu Item Parameters Description

PCM

Signal –

AES

Inputs

(Readonly)

AES #

No Input

PCM-Silent

Indicates the presence of input

Non-PCM

Async

Mixed

Setup Menus

Table 4.2 summarizes the Setup Menu optio ns available in DashBoard.

Table 4.2 Setup Menu Items

Menu Item Parameters Description

Frame 1*

Reference

Minimum Delay

Frame 2

Video

Checkbox selected*

Checkbox unselected

Selects the reference source

Provides the shortest video delay

through the card . When using SD,

the delay is 7us. When using HD,

the delay is 1.5us.

The total vi deo delay through t he

card will be the values above plus

half a video line

Black

Setup

Loss of Input

4-6 •••• Menus 9215-EO-EM User Manual •••• (V 1.1)

Blue

Custom*

Y slider

Cr slider

Cb slider

Sets the output to Black in the event

of a loss of video input

Sets the output to Blue in the event

of a loss of video input

Sets the output to a custom color in

the event of a loss of video input.

Use the Y, Cr, and Cb sliders to

configure the color.

Sets the luminance component of the

Loss of Input Custom video signal.

Sets the Cr component of the Loss

of Input Custom video signal.

Sets the Cb component of the Loss

of Input Custom video signal.

Page 35

Menu Item Parameters Description

Setup

Test Pattern None

100% Color Bars

Frequency Sweep

Black

Test Pattern

SD Audio

Silence Threshold

(dB)

Silence Timeout

(sec)

Blue

Matrix Pathological

Luma Ramp

Y/C Ramp

75% SMPTE Bars

20 Bit* Embeds 20bit audio

24 Bit Embeds 24bit audio

Auto

-96 to 0

1 to 60

Specifies the type of test pattern to

output

Specifies the type of test pattern to

output

Embeds 20-24bit audio depending

on the source and number of bits

Audio below the specified threshold

value is considered silent

Audio silent for longer than the

specified value raises an alarm

Unlocked*

Edit Permission

Locked

All Audio Reset

Factory Defaults

Reset

All menu options are unlocked and

can be edited.

All menu items, except this one, are

locked and read-only.

Resets the parameters in the

Embedded Audio Outputs tab to

factory defaults

Resets all parameters to factory

defaults.

9215-EO-EM User Manual •••• (V 1.1) Menus •••• 4-7

Page 36

Input Status Menus

Table 4.3 summarizes the Input Status Me nu op tions available in DashBoard.

Table 4.3 Input Status Menu Items

Menu Item Parameters Description

Video

Input &

Embed

Input Format (readonly)

CRC Errors (readonly)

Error Count Reset Resets the CRC Errors field

Embedded Audio Group #

Channel # (read-

only)

#

#

PCM

No Input

PCM-Silent

Non-PCM

Async

Displays the format of the video

input

Displays the count of the CRC

errors on the video input. This 14bit

counter is reset on loss of video, or

by user request. The counter is nonlatching, and will roll over from

maximum count to zero.

• For SD formats, it displays both

active picture and full frame

errors.

• For HD formats, it displays the

total count of errors.

Displays the status of each group

and channel of embedded audio

Mixed

Word Length (readonly)

Ch A Status (read-

Audio –

only)

AES #

Ch B Status (readonly)

4-8 •••• Menus 9215-EO-EM User Manual •••• (V 1.1)

#bit

PCM

No Input

PCM-Silent

Non-PCM

Async

Mixed

Same as above

Displays the word length of the

audio in number of bits

Displays the status of the Channel A

input

Page 37

Menu Item Parameters Description

Word Length (readonly)

#bit Displays the number of bits of audio

The incoming AES signal is

Audio –

AES #

Emphasis (read-

‡

only)

Checkbox selected

Checkbox unselected

indicating 50/15 or CCiTT J.17

emphasis

The incoming AES signal is

indicating no emphasis or the

emphasis is not indicated

Sample Rate (readonly)

#

Displays the sample rate of the AES

input

AES Inputs 1-8 Menus

Table 4.4 summarizes the AES Inputs 1-4 and AES Inputs 5-8 Menus options available in

DashBoard.

Table 4.4 AES Inputs 1-8 Menu Items

Menu Item Parameters Description

Both channels will carry the average

of the two input channels (A+B/2).

When the input is summed, the

original signals are no longer

available for output.

SRC is not used on an input. Select

this option when using non-PCM

audio data

Adjusts the delay of the channel of

audio

AES #

Sum

Checkbox selected

Checkbox unselected* Disables this feature

Sample Rate

Off

Conversion

On* SRC is used on an input

Ch A Delay (ms) 0* to 1000

Ch B Delay (ms) Same as above

Locks the Delay slider of both

channels together. If the values for

Delay Lock

Checkbox selected

the two channels are different, that

change is maintained when the

channels are locked.

Checkbox unselected* The Delay slider is unlocked

Ch A Gain (dB) -18 to +18

§

Adjusts the gain of the channel of

audio

Ch B Gain (dB) Same as above

‡

If the SRC is ON, emphasis of the incoming AES signal is not indicated.

§

The default value is 0.

9215-EO-EM User Manual •••• (V 1.1) Menus •••• 4-9

Page 38

Menu Item Parameters Description

Locks the Gain slider of both

channels together. If the values for

AES #

Gain Lock

Ch A Invert

Ch B Invert Same as above

Checkbox selected

Checkbox unselected* The Gain slider is unlocked

Checkbox selected

Checkbox unselected* The audio signal is not inverted

the two channels are different, that

change is maintained when the

channels are locked.

Inverts the audio signal of the

channel

Input Reset

Inputs #-# Reset

Resets the parameters for the

selected input to the default values

Resets the indicated input

parameters to the default values

Embedded Outputs Menus

Table 4.5 summarizes the Embedded Outputs Menu options available in DashBoard.

Table 4.5 Embedded Outputs Menu Items

Menu Item Parameters Description

Enable

Checkbox selected*

Checkbox unselected

Mute

Group# Ch#

Ch # Source

#Hz Tone

#kHz Tone

Determines if the group is inserted

in the output or not

Configures the Primary Source that

is inserted in to the embedded group

if present

Group #

Ch # Backup Sour ce

Presets Pass

4-10 •••• Menus 9215-EO-EM User Manual •••• (V 1.1)

Mute

Group# Ch#

AES #

#Hz Tone

#kHz Tone

Configures the Backup Source that

is inserted when the Primary Source

is unavailable

Configures the gro up source settings

with the original group as the

Primary Source and original group

as the Backup Source

Page 39

Menu Item Parameters Description

Configures the gro up source settings

with the original group as the

Primary Source, and AES inputs as

the Backup Source

Configures the gro up source settings

with AES inputs as the Primary

Source, and embed as the Backup

Source

Group #

Insert

Presets

Overwrite

Alarm Enables Menus

Table 4.6 summarizes the Alarm Enables Menu options available in DashBoard.

Table 4.6 Alarms Menu Items

Menu Item Parameters Description

Video

Input &

Reference

Alarm

No Input

Invalid Input

Incompatible Input

Non-Sync Video

No Reference

Invalid Reference

Checkbox selected*

Checkbox unselected Disables the alarm

Checkbox selected*

Checkbox unselected Disables the alarm

Checkbox selected*

Checkbox unselected Disables the alarm

Checkbox selected*

Checkbox unselected Disables the alarm

Checkbox selected*

Checkbox unselected Disables the alarm

Checkbox selected*

Signal Status field reports a loss of

input

Input Format field displays an alarm

when the input video is a format that

is not supported

Input Format field reports when the

frame rate is not the same as the

reference input

Signal Status field reports if the

video input is asynchronous to the

reference

Reference Status field reports loss of

input conditions

Reference Format field reports when

the reference is a format that is not

supported

Checkbox unselected Disables the alarm

9215-EO-EM User Manual •••• (V 1.1) Menus •••• 4-11

Page 40

Menu Item Parameters Description

Hardware Status field reports when

Hardware

Incompat Rear

Module

Checkbox selected*

Checkbox unselected Disables the alarm

a rear module is not compatible with

the card

Optical

Module

Alarms

Embedded

Input

Audio Group #

Alarm on

Abnormal

Temperature

Alarm on

Abnormal Power

Alarm on Not

Detected

Group not present

Channel # Silent

Hardware Status field reports when

Checkbox selected*

Checkbox unselected Disables the alarm

Checkbox selected*

Checkbox unselected Disables the alarm

Checkbox selected*

Checkbox unselected Disables the alarm

Checkbox selected*

Checkbox unselected Disables the alarm

Checkbox selected*

Checkbox unselected Disables the alarm

the temperature of the SFP module

is not in range (high/low)

Hardware Status field reports when

the power consumption of the SFP

module is not in range (high/low)

Hardware Status field reports when

the optical module is not detected

Signal Status field reports when a

group is not present on the input

Signal Status field reports when the

specified channel is detected as

silent

Signal Status field reports when the

AES

Checkbox selected*

Input no present

Checkbox unselected Disables the alarm

source for the specified input is not

present

Inputs AES #

Embedded

Checkbox selected*

Channel # Silent

Checkbox unselected Disables the alarm

Checkbox selected*

Source Missing

Checkbox unselected Disables the alarm

Signal Status field reports when the

specified channel is detected as

silent

Embedded Audio Status field

reports when the selected source is

not present or is silent

Outputs Group #

Source Async

4-12 •••• Menus 9215-EO-EM User Manual •••• (V 1.1)

Checkbox selected*

Checkbox unselected Disables the alarm

Embedded Audio Status field

reports when the selected source is

asynchronous to the input video

Page 41

Menu Item Parameters Description

An alarm is displayed when the

Embedded

Backup Source

Missing

Backup Source

Async

Checkbox selected*

Checkbox unselected Disables the alarm

Checkbox selected*

Checkbox unselected Disables the alarm

selected Backup Source is not

present or is silent

An alarm is displayed when the

selected Backup Source is not

synchronous to the input video

Outputs Group #

Checkbox selected*

SD 24Bit

Checkbox unselected Disables the alarm

All Alarms Set Enables all alarms

All Alarms Clear Disables all alarms

Audio Status field reports when the

selected configuration would embed

4 groups of 24bit audio in an SD

output. Group 4 is down-sampled to

20bit audio.

9215-EO-EM User Manual •••• (V 1.1) Menus •••• 4-13

Page 42

Card-edge Menu System

This section summarizes the Card-edge Menu system of the 9215-EO-EM and how to navigate the

menus and options using the SW1 and SW2 switches on the 9215-EO-EM card-edge. A list of the

available menus and parameters is provided in Table 4.7.

Navigation

Use the following procedure to navigate the card-edge menus of the 9215-EO-EM:

1. Rotate SW1 to the required menu.

2. Toggle SW2 to select the required parameter.

This completes the procedure for navigating the card-edge menus of the 9215-EO-EM.

Note — Do not power down the card before ensuring that all edited parameters are

saved. Saving edited parameters can take up to 10 seconds.

Card-edge Menus

Table 4.7 lists all the menus, and menu items available using the card-edge controls. To activate some

of these parameters, it may be necessary to toggle SW2 in either direction, or it may require that SW2

be held in either direction for a few seconds. Default values are indicated with an asterisk (*). Refer to

the section “Menu Descriptions” for a brief summary of the menus available on the card-edge.

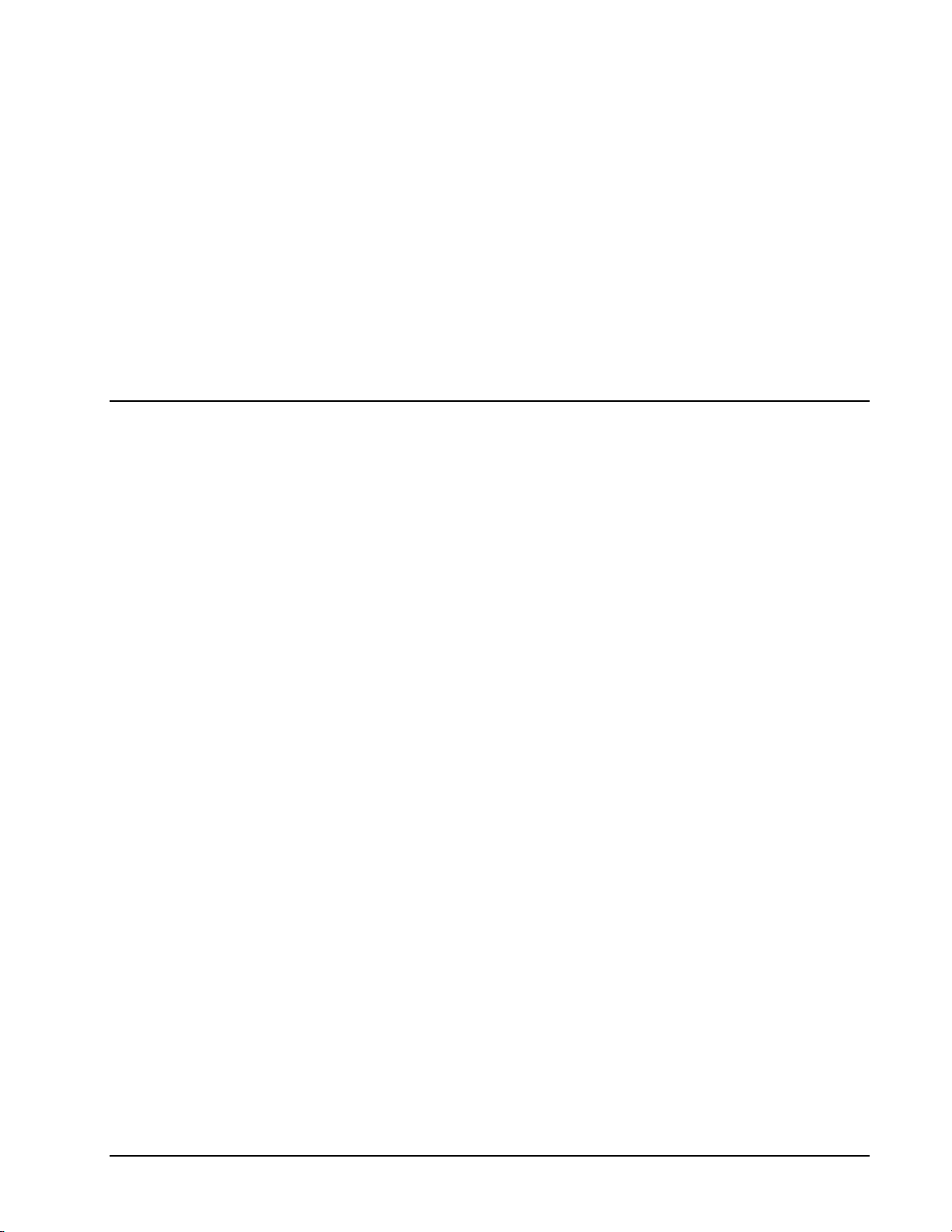

Menu

Select

0

1

2

3

4

Table 4.7 Card-edge Menus and Items

Card-Edge Menu

Label

9215-EO-EM slot # Home

Fact Def Factory Default n/a Factory Default

Ref Src Reference Source

LOI Loss of Input

Test Patt Test Pattern

Menu Name

Card-Edge

Item Label

Fr 1* Frame 1 Reference

Fr 2 Frame 2 Reference

Vid Video

Black

Blue

Custom*

None*

75% SMPTE Bars

YC Ramp Y/C Ramp

Item Name

L Ramp Luma Ramp

4-14 •••• Menus 9215-EO-EM User Manual •••• (V 1.1)

Page 43

Menu

Select

5

6

Card-Edge Menu

Label

Grp Sel Group Select

Grp Enbl Group Enable

Menu Name

Card-Edge

Item Label

Matr Path Matrix Pathological

Blue Flat Field Blue

Black Flat Field Black

Frq Swp Frequency Sweep

100% 100% Full Field Bars

Grp 1 Group 1

Grp 2 Group 2

Grp 3 Group 3

Grp 4 Group 4

Enabled*

Disabled

Mute

Item Name

T4k 4kHz Tone

T2k 2kHz Tone

Ch1 Src Channel 1 Source

7

Ch2 Src Cha nnel 2 Source Same as above

8

Ch3 Src Cha nnel 3 Source Same as above

9

Ch4 Src Cha nnel 4 Source Same as above

A

Ch1 Bkp Cha nnel 1 Backup Source

B

T1k 1kHz Tone

T.5k 500Hz Tone

A1A – A8B AES 1A to AES 8B

G1C1 - G4C4

Mute

T4k 4kHz Tone

T2k 2kHz Tone

T1k 1kHz Tone

Group 1, Channel 1 to Group 4,

Channel 4

B

Ch1 Bkp Cha nnel 1 Backup Source

9215-EO-EM User Manual •••• (V 1.1) Menus •••• 4-15

T.5k 500Hz Tone

A1A - A8B AES 1A to AES 8B

Page 44

Menu

Select

Card-Edge Menu

Label

Menu Name

Card-Edge

Item Label

Item Name

G1C1-G4C4

Ch2 Bkp Channel 2 Backup Source Same as above

C

Ch3 Bkp Channel 3 Backup Source Same as above

D

Ch4 Bkp Channel 4 Backup Source Same as above

E

Menu Descriptions

This section briefly summarizes the menu parameters available in the card-edge display of the 9215EO-EM.

0 — Home

This read-only menu displays the product name and the slot the card is installed in the frame.

1 — Factory Defaults

This function enables you to return all controls to their factory default values.

Use the following procedure to reset the card parameters to factory default values using the card-edge

controls:

1. Rotate SW1 to 1. The Four Character Display displays “Fact Def”.

Group 1, Channel 1 to Group 4,

Channel 4

2. Toggle SW2 down and hold for 3 seconds.

3. Release SW2.

This completes the procedure to reset the card parameters to factory default values.

2 — Reference Source

This menu enables you to select where the card will look for a reference. The choices are Frame

Reference 1 (Fr 1), Frame Reference 2 (Fr 2), and Video (Vid). Refer to the section “Reference

Compatibility” for details.

3 — Loss of Input

Use this menu to select what type of video displays at the system’s outputs when the input video signal

is lost or invalid.

4 — Test Pattern

This menu enables you to specify the type of test pattern to output. Note that this setting is not retained

on power down.

5 — Group Select

This menu enables you to select the embedded group before assigning sources to the channels, enabling

the group, and selecting backup sources. This menu is used in conjunction with Menus 6 to E.

4-16 •••• Menus 9215-EO-EM User Manual •••• (V 1.1)

Page 45

6 — Group Enable

Use this menu to determine if the selected group is embedded in the output or not.

7, 8, 9, A — Channel # Source

Use Menus 7 to A to configure the source that is inserted into the embedded group if present. These

menus are used in conjunction with Menu 5 (Gr oup Select). The following are the default values based

on the group selected:

Group 1 — When Menu 5 is set to Grp1, the default value of Menu 7 is G1C1.

Group 2 — When Menu 5 is set to Grp 2, the default value of Menu 8 is G2C2.

Group 3 — When Menu 5 is set to Grp 3, the default value of Menu 9 is G3C3.

Group 4 — When Menu 5 is set to Grp 4, the default value of Menu A is G4C4.

B, C, D, E — Channel # Backup Source

Use Menus B to E to configure the Backup Source that is inserted when the Primary Source is

unavailable. This menu is used in conjunction with Menu 5 (Group Select). The following are the

default values based on the group selected:

Group 1 — When Menu 5 is set to Grp1, the default value of Menu B is G1C1.

Group 2 — When Menu 5 is set to Grp 2, the default value of Menu C is G2C2.

Group 3 — When Menu 5 is set to Grp 3, the default value of Menu D is G3C3.

Group 4 — When Menu 5 is set to Grp 4, the default value of Menu E is G4C4

9215-EO-EM User Manual •••• (V 1.1) Menus •••• 4-17

Page 46

4-18 •••• Menus 9215-EO-EM User Manual •••• (V 1.1)

Page 47

Specifications

In This Chapter

This chapter includes the technical specifications for the 9215-EO-EM

The following topics are discussed:

• 9215-EO-EM Technical Specifications

• Channel Status Data Table

9215-EO-EM User Manual •••• (V 1.1) Specifications •••• 5-1

Page 48

9215-EO-EM Technical Specifications

This section includes the technical specifications** for the 9215-EO-EM.

Table 5.1 9215-EO-EM Technical Specifications

Category Parameter Specification

Number of Inputs 1

SDI Input

Optical Output

SDI Data Rates and SMPTE

Standards Accommodated

Impedance 75ohm terminating

Return Loss >15dB to 1.485GHz

Cable Length with Equalizer >10dB from 1.485GHz to 2.97GHz

Connector Type >300m of Belden 1694A cable @ 270Mbps

Number of Outputs 1

SMPTE Standards Accommodated SMPTE 259M-C, SMPTE 292M

Nominal Wavelength 1310µm

Output Power -7dBm to -2dBm

Connector Type Single Mode, LC/UPC

Number of Outputs 1

SDI Data Rates and SMPTE

Standards Accommodated

Impedance 75ohm

SMPTE 292M, SMPTE 259M-C

SMPTE 292M, SMPTE 259M-C

SDI Outputs

AES Inputs

AES Inputs

Environmental

Power

Return Loss

Signal Level

DC Offset

Rise and Fall Time (20-80%)

Overshoot <10%

Connector Type BNC

Number of Inputs 8 AES-3id inputs

Impedance 75ohm

Input Resolution 24bits

Nominal Signal Level 1V p-p

Sampling Rate

Connector Type DIN 1.1/2.3

Operating Range

Total Power Consumption

>15dB to 1.485GHz

>10dB 1.485GHz to 2.97GHz

800mV, ±10%

0V ±50mV

700ps typical (270Mbps)

120ps typical (1.485Gbps, 2.97Gbps)

48kHz compliant with SMPTE 272M-A or any rate

from 20kHz to 96kHz with SRC on

5°C to 40°C ambient

<8W

**

Specifications are subject to change without notice.

5-2 •••• Specifications 9215-EO-EM User Manual •••• (V 1.1)

Page 49

9215-EO-EM User Manual •••• (V 1.1) Specifications •••• 5-3

Page 50

Channel Status Data Table

The following table shows the channel status bit information that is used for all output audio.

Table 5.2 Channel Status Data

Byte Bit Function Transmitted

Professional or Consumer use of Channel Status

0

Block

1 Normal Audio or Non-Audio Mode Normal Audio (0)

0

2-4 Emphasis No Emphasis (100)

5 Lock Indication Locked (0)

6-7 Sampling Rate 48kHz (01)

0-3 Channel Mode 2 channel stereo (0001)

1

4-7 User Bit Mode 192-bit (0001)

0-2 Auxiliary Bit Usage 20-bit audio sample, Aux bits undefined (000)

3-5 Sample Word Length 20- or 24-bits (101)2

6-7 Alignment Level Not Indicated (00)

3 0-7 Multi-channel Modes Undefined (0)

0-1 Digital Audio Reference Signal Not a Reference (0)

2 Reserved 0

4

3-6 Sampling Frequency Not Indicated (0000)

7 Sampling Frequency Scaling Flag No Scaling (0)

5 0-7 Reserved Unused (0)

6-9 ASCII Source ID Unused (0)

10-13 ASCII Destination ID Unused (0)

14-17 Local Sample Address Unused (0)

18-21 Time of Day Unused (0)

22 0-7 C data reliability

23 0 -7 CRC Calculated CRC

Professional (1)

Only the first 5 Status Bytes are marked as Reliable. All

other Status Bytes are marked as Unreliable.

Passing the Status Bytes

The 9215-EO-EM replaces Channel Status Bytes according to Error! Reference source not found. or

passes Status Bytes through from input to output. The following conditions must be met for Status

Bytes to pass:

• AES inputs must be 48kHz synchronous

• SRC is set to OFF

• Data Word Length in the Channel Status Bytes must match what is embedded

5-4 •••• Specifications 9215-EO-EM User Manual •••• (V 1.1)

Page 51

Service Information

In This Chapter

This chapter contains the following sections:

• Troubleshooting Checklist

• Warranty and Repair Policy

9215-EO-EM User Manual •••• (V 1.1) Service Information •••• 6-1

Page 52

Troubleshooting Checklist

Routine maintenance to this openGear product is not required. In the event of problems with your

9215-EO-EM, the following basic troubleshooting checklist may help identify the source of the

problem. If the module still does not appear to be working properly after checking all possible causes,

please contact Technical Support at the numbers listed under the “Contact Us” section at the end of

this manual.

1. Visual Review – Performing a quick visual check may reveal many problems, such

as connectors not properly seated or loose cables. Check the module, the frame, and

any associated peripheral equipment for signs of trouble.

2. Power Check – Check the power indicator LED on the distribution frame front panel

for the presence of power. If the power LED is not illuminated, verify that the power

cable is connected to a power source and that power is available at the power main.

Confirm that the power supplies are fully seated in their slots. If the power LED is

still not illuminated, replace the power supply with one that is verified to work.

3. Reseat the Card in the Frame – Eject the card and reinsert it in the frame.

4. Check Control Settings – Refer to the Installation and Operation sections of the

manual and verify all user-adjustable component settings.

5. Input Signal Status – Verify that source equipment is operating correctly and that a

valid signal is being supplied.

6. Output Signal Path – Verify that destination equipment is operating correctly and

receiving a valid signal.

7. Card Exchange – Exchanging a suspect card with a card that is known to be

working correctly is an efficient method for localizing problems to individual cards.

Bootload Button

In the unlikely event of a complete card failure, you may be instructed by Cobalt Digital Inc. Technical

Support to perform a complete software reload on the 9215-EO-EM.

Use the following procedure to perform a software reload on the 9215-EO-EM:

1. Eject the card.

2. Press and hold the Bootload button, while re-inserting the card into the frame.

3. Release the button.

The PWR LED will flash GREEN while the card is waiting for a new software load.

If a new software load is not sent to the card within 60 seconds, the card will attempt to

restart with the last operational software load.

Software can be uploaded to the 9215-EO-EM via DashBoard. Refer to your DashBoard Control

System Software User Manual for further instructions.

6-2 •••• Service Information 9215-EO-EM User Manual •••• (V 1.1)

Page 53

Warranty and Repair Policy

Cobalt Digital Inc. Limited Warranty

This product is warranted to be free from defects in material and workmanship for a period of five (5)

years from the date of shipment to the original purchaser, except that 4000, 5000, 6000, 8000 series

power supplies, and Dolby

material and workmanship for a period of one (1) year.

Cobalt Digital Inc.'s (“Cobalt”) sole obligation under this warranty shall be limited to, at its option, (i)

the repair or (ii) replacement of the product, and the determination of whether a defect is covered under

this limited warranty shall be made at the sole discretion of Cob a lt.

This limited warranty applies only to the original end-purchaser of the product, and is not assignable or

transferrable therefrom. This warranty is limited to defects in material and workmanship, and shall not

apply to acts of God, accidents, or negligence on behalf of the purchaser, and shall be voided upon the

misuse, abuse, alteration, or modification of the product. Only Cobalt authorized factory

representatives are authorized to make repairs to the product, and any unauthorized attempt to repair

this product shall immediately void the warranty. Please contact Cobalt Technical Support for more

information.

To facilitate the resolution of warranty related issues, Cobalt recommends registering the product by

completing and returning a product registration form. In the event of a warrantable defect, the

purchaser shall notify Cobalt with a description of the problem, and Cobalt shall provide the purchaser

with a Return Material Authorization (“RMA”). For return, defective products should be double boxed,

and sufficiently protected, in the original packaging, or equivalent, and shipped to the Cobalt Factory

Service Center, postage prepaid and insured for the purchase price. The purchaser should include the

RMA number, description of the problem encountered, date purchased, name of dealer purchased from,

and serial number with the shipment.

®

modules (where applicable) are warranted to be free from defects in

Cobalt Digital Inc. Factory Service Center

2406 E. University Avenue Office: (217) 344-1243

Urbana, IL 61802 USA Fax: (217) 344-1245

www.cobaltdigital.com Email: info@cobaltdigital.com

THIS LIMITED WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES

EXPRESSED OR IMPLIED, INCLUDING THE WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE AND OF ALL OTHER OBLIGATIONS OR

LIABILITIES ON COBALT'S PART. ANY SOFTWARE PROVIDED WITH, OR FOR USE WITH,

THE PRODUCT IS PROVIDED “AS IS.” THE BUYER OF THE PRODUCT ACKNOWLEDGES

THAT NO OTHER REPRESENTATIONS WERE MADE OR RELIED UPON WITH RESPECT TO

THE QUALITY AND FUNCTION OF THE GOODS HEREIN SOLD. COBALT PRODUCTS ARE

NOT AUTHORIZED FOR USE IN LIFE SUPPORT APPLICATIONS.

COBALT'S LIABILITY, WHETHER IN CONTRACT, TORT, WARRANTY, OR OTHERWISE, IS

LIMITED TO THE REPAIR OR REPLACEMENT, AT ITS OPTION, OF ANY DEFECTIVE

PRODUCT, AND SHALL IN NO EVENT INCLUDE SPECIAL, INDIRECT, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES (INCLUDING LOST PROFITS), EVEN IF IT HAS BEEN

ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

9215-EO-EM User Manual •••• (V 1.1) Service Information •••• 6-3

Page 54

Page 55

Contact Us

Contact Cobalt Digital Inc.

PHONE

E-MAIL

POSTAL

SERVICE

General Business Office

and Technical Support

Fax

General Information

Sales Information

Cobalt Digital Inc.

217.344.1243

217.344.1245

Info@cobaltdigital.com

Sales@cobaltdigital.com

2406 East University Avenue

Urbana, IL 61802 USA

Visit us at the Cobalt Digital Inc. website.

http://www.cobaltdigital.com/

• Online catalog

• Related products and full product lines

• Trade show information

• Dealer information

• Cobalt Digital Inc. news

Loading...

Loading...