Page 1

9071

HD/SD-SDI AFD Code Inserter

Product Manual

Cobalt Digital Inc.

2406 E. University Ave.

Urbana, IL 61802

Voice 217.344.1243 • Fax 217.344.1245

www.cobaltdigital.com

9071-OM (V4.0)

Page 2

Copyright

©Copyright 2012, Cobalt Digital Inc. All Rights Reserved.

Duplication or distribution of this manual and any information contained within is strictly prohibited without the express written

permission of Coba lt Digital Inc. This manual and a ny information contained within, may not be re produced, distribute d, or

transmitted in any form, or by any means, for any purpose, without the express written permission of Cobalt Digital Inc.

Reproduction or reverse engineering of software used in this device is prohibited.

Disclaimer

The information in this document has been carefully examined and is believed to be entirely reliable. However, no responsibility

is assumed for inaccuracies. Furthermore, C obalt Digit al Inc. res erves the right to ma ke changes to any pro ducts herein to improve

readability, function, or design. Cobalt Digital Inc. does not assume any liability arising out of the application or use of any

product or circuit described herein.

Trademark Information

Cobalt® is a registered trademark of Cobalt Digital Inc.

COMPASS

openGear

®

and FUSION3G® are registered trademarks of Cobalt Digital Inc.

®

is a registered trademark of Ross Video Limited. DashBoard™ is a trademark of Ross Video Limited.

Congratulations on choosing the Cobalt

of modular processing and conversion gear for broadcast TV environments. The Cobalt Digital Inc. line

includes video decoders and encoders, audio embedders and de-embedders, distribution amplifiers, format

converters, remote contro l system s and much more. Shou ld you have qu estions pe rtainin g to the instal lation or

operation of your 9071, please contact us at th e contact inform ation on the front cove r.

®

9071 HD/SD-SDI AFD Code Inse rter. The 9071 is part of a full line

Manual No.: 9071-OM

Document Version: V4.0

Release Date: December 10, 2012

Applicable for

Firmware Version

3314

(or greater):

Description of

product/manual

changes:

- Revise manual for latest card functionality and

minor edits.

- Update to add new Rear I/O Module.

9071-OM (V4.0)

Page 3

Table of Contents

Chapter 1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Overview ................................................................................................................ 1-1

9071 Card Software Versions and this Manual...................................................... 1-2

Cobalt Reference Guides........................................................................................ 1-2

Manual Conventions............................................................................................... 1-3

Warnings, Cautions, and Notes .................................................................. 1-3

Labeling Symbol Definitions...................................................................... 1-4

Safety Summary ..................................................................................................... 1-4

Warnings..................................................................................................... 1-4

Cautions...................................................................................................... 1-4

9071 Functional Description .................................................................................. 1-5

9071 Input/Output Formats ........................................................................ 1-5

User Control Interface ................................................................................ 1-7

9071 Rear I/O Modules .............................................................................. 1-9

Video Formats Supported by the 9071....................................................... 1-9

Technical Specifications....................................................................................... 1-10

Warranty and Service Information ....................................................................... 1-12

Cobalt Digital Inc. Limited Warranty....................................................... 1-12

Contact Cobalt Digital Inc.................................................................................... 1-13

Chapter 2 Installation and Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Overview ................................................................................................................ 2-1

Installing the 9071 Into a Frame Slot ..................................................................... 2-1

Installing a Rear I/O Module.................................................................................. 2-3

9071 Rear I/O Modules .............................................................................. 2-5

Setting Up 9071 Network Remote Control ............................................................ 2-6

9071-OM (V4.0) 9071 PRODUCT MANUAL i

Page 4

Chapter 3 Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Overview................................................................................................................. 3-1

Control and Display Descriptions........................................................................... 3-1

Function Submenu/Parameter Submenu Overview .................................... 3-2

DashBoard™ User Interface ....................................................................... 3-3

Cobalt® Remote Control Panel User Interfaces .......................................... 3-3

Accessing the 9071 Card via Remote Control........................................................ 3-4

Accessing the 9071 Card Using DashBoard™ ........................................... 3-4

Ancillary Data Line Number Locations and Ranges .............................................. 3-6

9071 Function Submenu List and Descriptions...................................................... 3-7

Video Proc .................................................................................................. 3-8

AFD ............................................................................................................ 3-9

Timecode .................................................................................................. 3-10

Licensable Features .................................................................................. 3-14

Presets ...................................................................................................... 3-14

Troubleshooting .................................................................................................... 3-17

Error and Failure Indicator Overview....................................................... 3-17

Basic Troubleshooting Checks.................................................................. 3-20

9071 Processing Error Troubleshooting.................................................... 3-21

Troubleshooting Network/Remote Control Errors.................................... 3-22

In Case of Problems .................................................................................. 3-22

ii 9071 PRODUCT MANUAL 9071-OM (V4.0)

Page 5

Overview

Chapter 1

Chapter 1 Introduction

This manual provides insta9071llation and operating instructions for the

9071 HD/SD-SDI AFD Code Inserter card (also referred to herein as the

9071).

This manual consists of the following chapters:

• Chapter 1, “Introduction” – Provid es informa tion about this manual

and what is covered. Als o pr ovi des general information re gar di ng the

9071.

• Chapter 2, “Installation and Setup” – Provides instructions for

installing the 9071 i n a fr ame, and option ally i nsta lling 9071 Rear I/O

Modules.

• Chapter 3, “Operating Instructions” – Provides overviews of

operating controls and instructions for using the 9071.

This chapter contains the following information:

• 9071 Card Software Versions and this Manual (p. 1-2)

• Manual Conventions (p. 1-3)

• Safety Summary (p. 1-4)

• 9071 Functional Description (p. 1-5)

• Technical Spe cification s (p. 1-10)

• Warranty and Service Information (p. 1-12)

• Contact Cobalt Digital Inc. ( p. 1-13)

9071-OM (V4.0) 9071 PRODUCT MANUAL 1-1

Page 6

1 9071 Card Software Versions and this Manual

9071 Card Software Versions and this Manual

When applicable, Cobalt Digital Inc. provides for continual product

enhancements through software updates. As such, functions described in this

manual may pertain specifically to cards loaded with a particular software

build.

The Software Version of your card can be ch eck ed by vi ewi ng the Card Inf o

menu in DashBoard™. You can then check our websi te fo r the late st software

version currently released for the card as described below.

Check our website and proceed as follows if your card’s software does not

match the latest versi on:

Card Software earlier than

latest version

Card Software newer than

version in manual

Card is not loaded with the latest software. Not all

functions and/or specified performance described in

this manual may be available.

You can update your card with new Update

software by going to the Support>Firmware link at

www.cobaltdigital.com. Download “Firmware

Update Guide”, which provides simple instructions

for downloading the latest firmware for your card

onto your computer, and then uploading it to your

card through DashBoard™.

Software updates are field-installed without any

need to remove the card from its frame.

A new manual is expediently released whenever a

card’s software is updated and specifications

and/or functionality have changed as compared

to an earlier version (a new manual is not

necessarily released if specifications and/or

functionality have not changed). A manual earlier

than a card’s software version may not completely

or accurately describe all functions available for

your card.

If your card shows features not described in this

manual, you can check for the latest manual (if

applicable) and download it by going to the

Support>Documents>Product Information and

Manuals link at www.cobaltdigital.com.

Cobalt Reference Guides

From the Cobalt® web home page, go to Support>Documents>Reference

Guides

updates, and other topics.

1-2 9071 PRODUCT MANUAL 9071-OM (V4.0)

for easy to use guide s covering network remot e control , card fir mware

Page 7

Introduction Manual Conventions

Manual Conventions

In this manual, display messages and connectors are shown using the exact

name shown on the 9071 itself. Examples are provided below.

• Connector names are shown like this: SDI IN

In this manual, the terms below are applicable as follows:

• 9071 refers to the 9071 HD/SD-SDI AFD Code Inserter card.

• Frame refers to the 8321 (or similar) frame that houses the Cobalt

COMPASS

• Device and/or Card refers to a COMPASS

• System and/or Video System refers to the mix of interconnected

®

cards.

®

card.

production and terminal equipment in which the 9071 and other

COMPASS

• Functions and/or features that are available only as an option are

®

cards operate.

denoted in th is manual like this:

®

Warnings, Cautions, and Notes

Certain items in this manual are highlighted by special messages. The

definitions are provided bel ow.

Warnings

Warning messages indicate a possible hazard which, if not avoided, could

result in pe rsonal injury or death.

Cautions

Caution messages indicate a problem or incorrect practice which, if not

avoided, could result in improper operation or damage to the product.

Notes

Notes provide supplemental information to the accompanying text. Notes

typically precede the text to which they apply.

9071-OM (V4.0) 9071 PRODUCT MANUAL 1-3

Page 8

1 Safety Summary

Labeling Symbol Definitions

Attention, consult accompanying documents.

Electronic device or assembly is susceptible to damage from an ESD

event. Han dle only using appropriate ESD prevention practices.

If ESD wrist strap is not available, handle card only by edges and avoid

contact with any connectors or components.

Symbol (WEEE 2002/96/EC)

For product disposal, ensure the following:

• Do not dispose of this product as unsorted municipal waste.

• Collect this product separately.

• Use collection and return systems available to you.

Safety Summary

Warnings

! WARNING !

Cautions

CAUTION

CAUTION

CAUTION

T o redu ce risk of electr ic shock do not remove line voltage service barrier cover on frame

equipment containing an AC power supply. NO USER SERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED SERVICE PERSONNEL.

This device is intended for environmentally controlled use only in appropriate video

terminal equipment operating environments.

This product is intended to be a component product of an openGear® frame. Refer to the

openGear frame Owner's Manual for important safety instructions regarding the proper

installation and safe operation of the frame as well as its component products.

Heat and power distribution requirements within a frame may dictate specific slot

placement of cards. Cards with many heat-producing components should be arranged to

avoid areas of excess heat build-up, particularly in frames using only convection cooling.

The 9071 has a moderate power dissipation (12 W max.). As such, avoiding placing the

card adjacent to other cards with similar dissipation values if possible.

CAUTION

CAUTION

1-4 9071 PRODUCT MANUAL 9071-OM (V4.0)

If required, make certain Rear I/O Module(s) is installed before installing the 9071 into the

frame slot. Damage to card and/or Rear I/O Module can occur if module installation is

attempted with card already installed in slot.

If card resists fully engaging in r ear I/O module mating connector, check for alignment and

proper insertion in slot tracks. Damage to card and/or rear I/O module may occur if

improper card insertion is attempted.

Page 9

Introduction 9071 Functional Description

9071 Functional Description

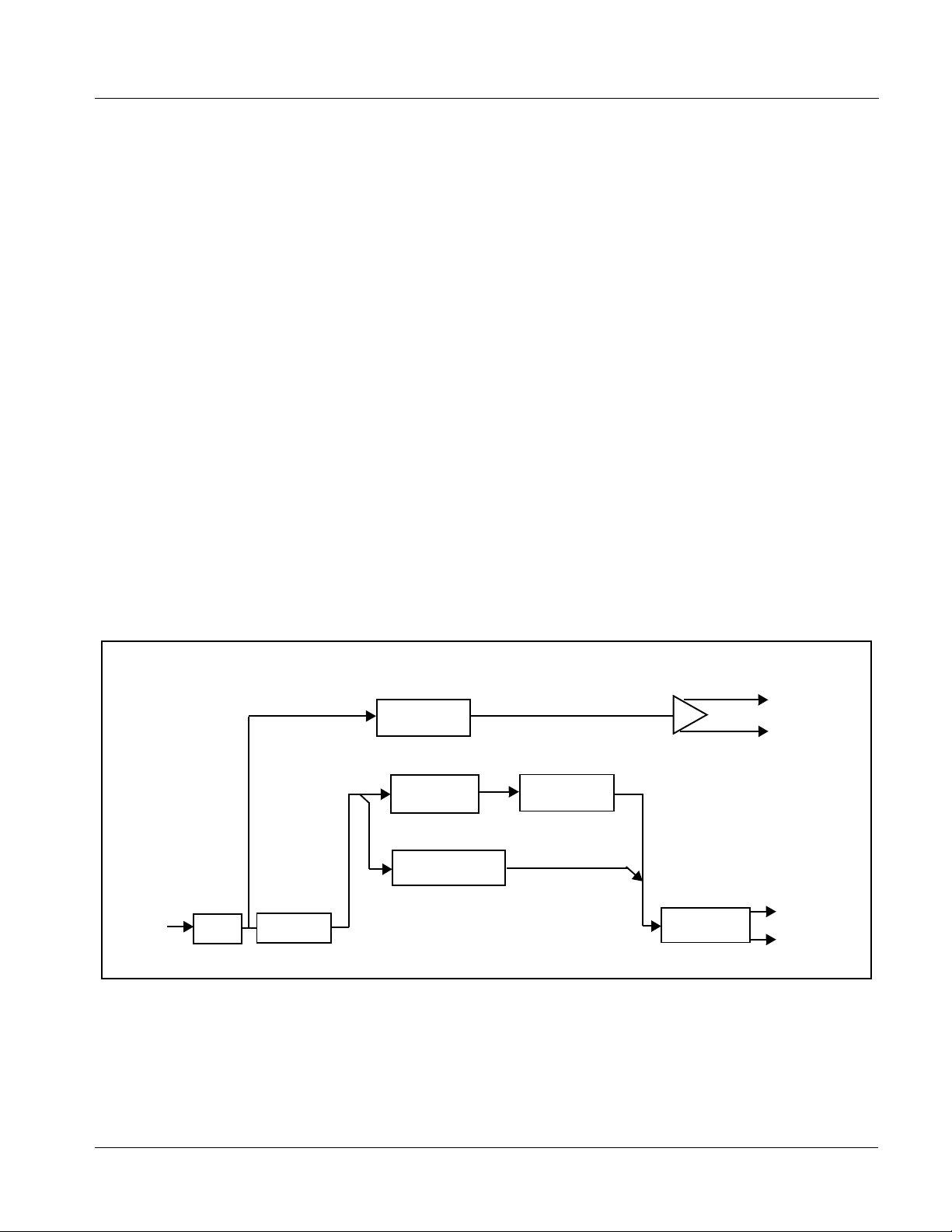

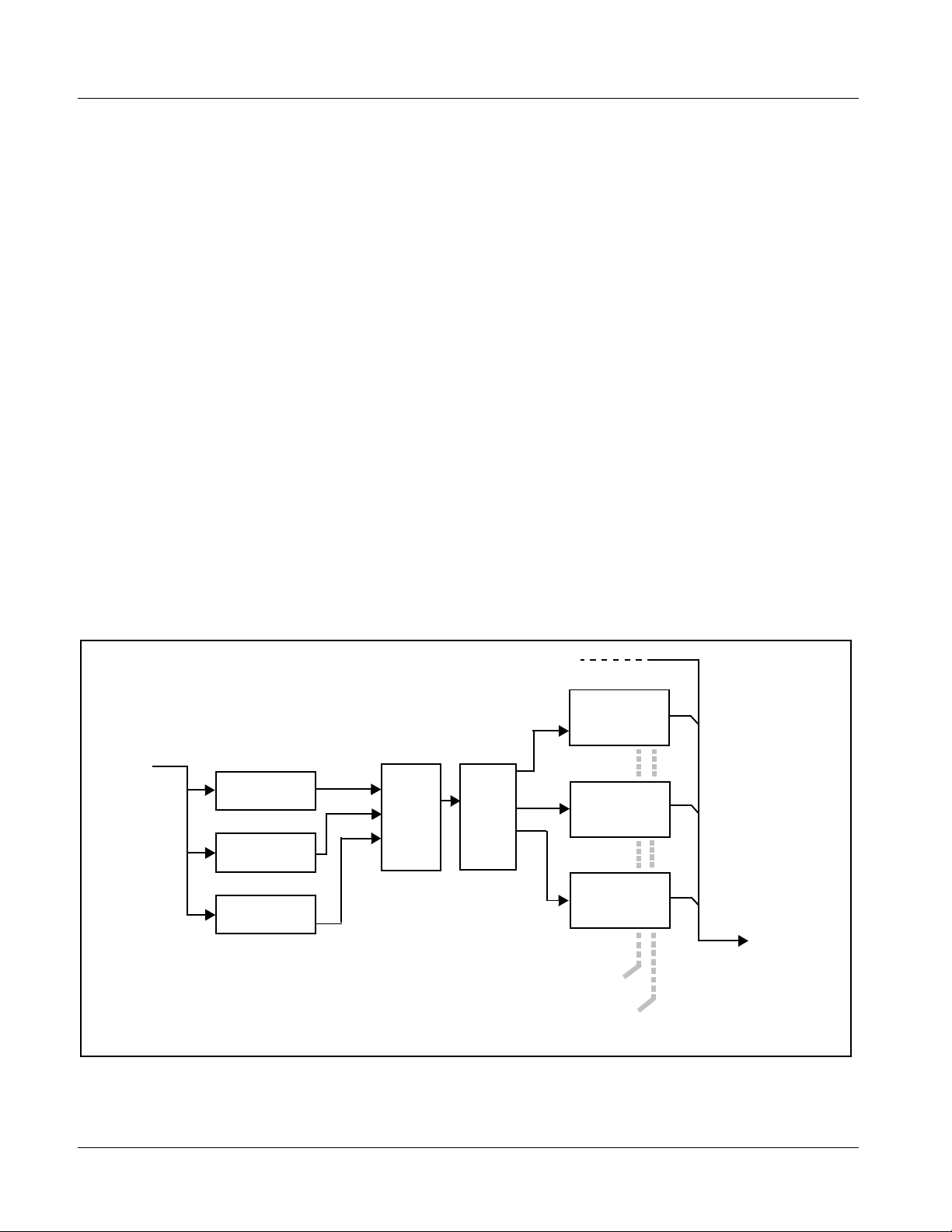

Figure 1-1 shows a functional block diagram of the 9071. The AFD inserter

function provides for assignment and insertion of AFD codes into the SDI

output video. Using this f unction, AFD codes in accordance with the standa rd

4-bit AFD code designations can be applied to the output video.

This function checks for any existing AFD code within the received video

input. If a code is present, the code is displayed. When used in conjunction

with a separate downstream card capable of providing AFD-directed scaling,

the image can in turn b e scaled in accord ance with th e AFD coding embedd ed

by this card.

The function also allows the selection/changing of the AFD code ancillary

data line number for the outputted AFD code.

9071 Input/Output Formats

The 9071 provides the following inputs and outputs:

• Inputs:

• HD/SD SDI IN – dual-rate HD/SD-SDI input

HD/SD

SDI IN

EQ

Deserialize

• Outputs:

• SDI OUT – four HD/SD-SDI buffered video outputs

• RCK OUT– four HD/SD-SDI reclocked buffered video outputs

Reclock

Video

Processing

Timecode

Processing

Figure 1-1 9071 Functional Block Diagram

AFD Code

Insertion

Serializer/

Cable Drivers

•

•

•

•

•

•

RCK OUT x4

SDI OUT x4

9071BDV4

Video Processor

The 9071 provides full color processing control (luma gain and lift, chroma

saturation, and color phase) of the output video.

9071-OM (V4.0) 9071 PRODUCT MANUAL 1-5

Page 10

1 9071 Functional Description

AFD Inserter

This function provides for assignment and insertion of AFD codes into the

SDI output video. Using this function, AFD codes in accordance with the

standard 4-bit AFD code designations can be applied to the output video.

This function checks for any existing AFD code within the received video

input. If a code is present, the code is displayed. When used in conjunction

with a separate downstream card capable of providing AFD-directed scaling,

the image can in turn be scaled in a ccordance with the AFD codi ng embedde d

by this card.

The function also allows the selection/changing of the AFD code and

ancillary data line number for the outputted AFD code.

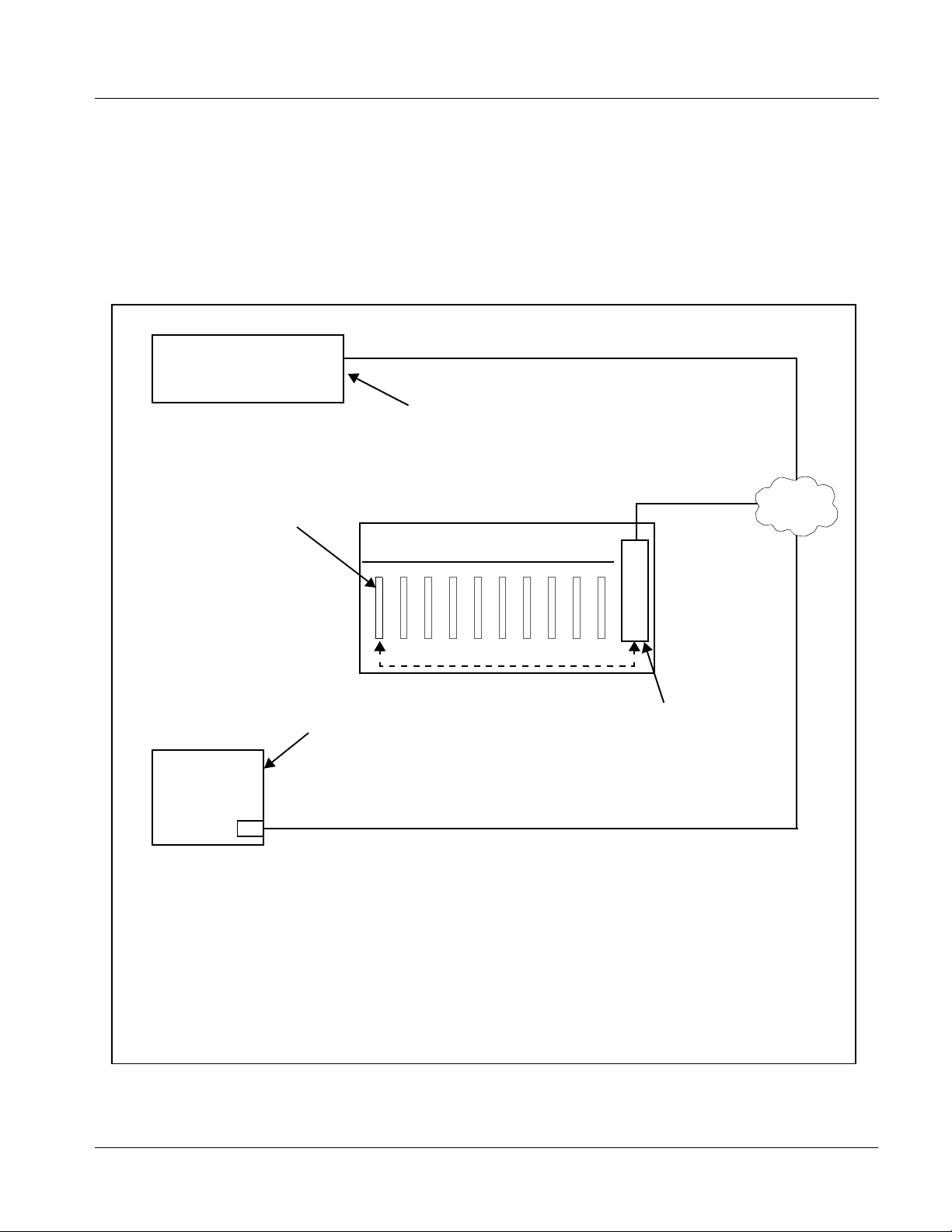

Timecode Processor

(See Figure 1-2.) This func ti on provides for extracti on of t imec ode da ta from

the input video, and in turn re-insertion of timecode data into the output SDI.

The function can monitor the SDI video input of the card for supported

timecode formats, an d then select and priori tize among SDI VITC,

SDI A TC VITC, and SDI ATC LTC ti mecode sour ces. If the prefe rred form at

is detected, the preferred format is used by the card; if the preferred format is

not detected, the card uses other formats (where available) as desired.

SDI

Video

Input

SDI VITC

Detect/Extract

SDI ATC_VITC

Detect/Extract

SDI ATC_LTC

Detect/Extract

The function provides conversion between various timecode formats and

provides independent insertion and line number controls for each SDI

timecode output format.

HD/SD–SDI

(From Video Proc)

SDI VITC

Timecode

Proc/Embed

Priority/

Select

Buffer/

Format

ATC_VITC

Timecode

Proc/Embed

ATC_LTC

Timecode

Proc/Embed

Insert

Control

Line

Number

Control

HD/SD–SDI

Video Output

Figure 1-2 Timecode Processor

1-6 9071 PRODUCT MANUAL 9071-OM (V4.0)

Page 11

Introduction 9071 Functional Description

User Control Interface

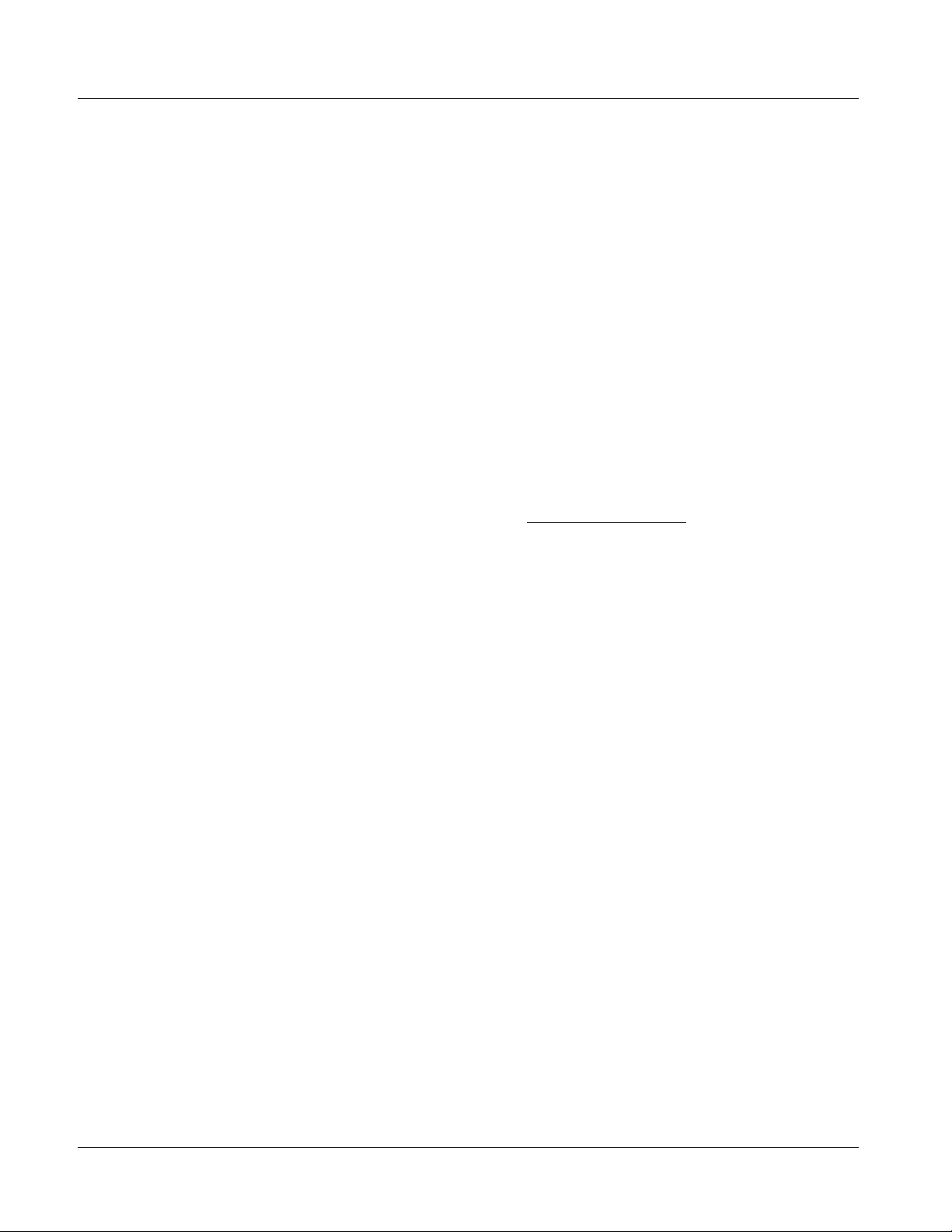

Figure 1-3 shows the user control interface options for the 9071. These

options are individually described below.

Note: All user control interfaces described here are cross-compatible and can oper-

ate together as desired. Where applicable, any control setting change made

using a particular user interface is reflected on any other connected interface.

OGCP-9000 Control Panel

OGCP-9000/CC Control Panel

Card Edge Controls

9071 card can be

controlled using built-in

card edge controls

Computer

with NIC

or

DashBoard™ Remote Control

Using a computer with

DashBoard™ installed, 9071

card can be remotely controlled

over a LAN

Remote Control Panel

Using the Control Panel,

9071 card can be remotely

controlled over a LAN

LAN

20-Slot Frame with MFC-8320-N network

controller card

In conjunction with a frame equipped

with an MFC-8320-N network

controller card, 9071 card can be

remotely controlled over a LAN

Note: • To communicate with DashBoard™ or a Remote Control Panel, the frame must have the optional

MFC-8320-N network controller card installed.

• DashBoard™ and the Remote Control Panels provide network control of the 9071 as shown. The

value displayed at any time on the card, or via DashBoard™ or a Control Panel is the actual value

as set on the card, with the current value displayed being the actual value as effected by the card.

Parameter changes made by any of these means are universally accepted by the card (for

example, a change made using the card edge controls will change the setting displayed on

DashBoard™ and a Control Panel; a change made using DashBoard™ will similarly change the

setting displayed on a Control Panel and the card itself).

Figure 1-3 9071 User Control Interface

9071-OM (V4.0) 9071 PRODUCT MANUAL 1-7

Page 12

1 9071 Functional Description

• Built-in Card Edge User Interface – Using the built-in card edge

controls and display, card control settings can be set us ing a front

panel menu which is described in Cha pter 3,“Operati ng Instructi ons”.

Note: Some of the 9071 functions described in this manual are available only when

using the DashBoard™, or Cobalt

Control Panel user interfaces.

• DashBoard™ User Interfa ce – Using DashBoard™, the 9071 and

other cards installed in openGear®

®

OGCP-9000 or OGCP-9000/CC Remote

1

frames such as the Cobalt®

HPF-9000 or 8321 Frame can be controlled from a computer and

monitor.

DashBoard™ allows users to view all frames on a network with

control and monitoring for all populated slots inside a frame. This

simplifies the setup and use of numerous modules in a large

installation and offers the ability to centralize monitoring. Cards

define their controllable parameters to DashBoard™, so the control

interface is always up to date.

The DashBoard™ software can be downloaded from the Cobalt

Digital Inc. website: www.cobaltdigital.com

(enter “DashBoard” in

the search window). The DashBoard™ user interface is described in

Chapter 3,“Operating Instructions”.

Note: If network remote control is to be used for the frame and the frame has not yet

been set up for remote control, Cobalt

Control User Guide” (PN 9000RCS-RM) provides thorough information and

step-by-step instructions for setting up network remote control of

COMPASS

Download a copy of this guide by clicking on the Support>Downloads link at

www.cobaltdigital.com and then select DashBoard Remote Control Setup

Guide as a download, or contact Cobalt

Inc. (p. 1-13).

®

cards using DashBoard™.

®

reference guide COMPASS Remote

®

as listed in Contact Cobalt Digital

• Cobalt

®

OGCP-9000, OGCP-9000/CC and WinOGCP Remote

Control Panels – The OGCP-9000, OGCP-9000/CC, and WinOGCP

Remote Control Panels conveniently and intui ti vel y provi de

parameter monitor and c ontrol of the cards within the 20-slot f rame.

The remote control panels allow quick and intuitive access to

hundreds of cards in a fa ci lity, and can monitor and al l o w adj ust ment

of multiple p arameters at one time.

The remote control panels are totally compatible with the openGear

control software DashBoard™; any changes made with either system

are reflected on the other.

1. openGear® is a registered trademark of Ross Video Limited. DashBoard™ is a trademark of Ross

Video Limited.

1-8 9071 PRODUCT MANUAL 9071-OM (V4.0)

®

Page 13

Introduction 9071 Functional Description

9071 Rear I/O Modules

The 9071 physically interfaces to system video connections at the rear of its

frame using a Rear I/O Module.

All inputs and outputs shown in the 9071 Functional Block Diagram (Figure

1-1) enter and exit the card via the card edge backplane connector. The

Rear I/O Module breaks out the 9071 card edge connections to BNC

connectors that interface with other components and systems in the signal

chain.

These required BNC connections are provided by either an 8310-BNC or

8310-C-BNC frame (which both have a built-in BNC connector backplane

module), or by using an optional 9071 Rear I/O Module.

Video Formats Supported by the 9071

The 9071 supports all current SMPTE standard SD and HD video formats.

Table 1-1 lists and provides details regarding the audio and video formats

supported by the 9071.

Table 1-1 Supported Audio and Video Formats

Item Description/Specification

SDI Input / Output Video Raster Structure: Frame Rate:

1080PsF 23.98; 24

1080p 23.98; 24

(1)

1080i

720p 23.98; 24; 25; 29.97; 30; 50; 59.94;

(1)

486i

(1)

575i

(1) All rates displayed as frame rates; interlaced (“i”) field rates are two times the rate value shown.

25; 29.97; 30

60

29.97

25

9071-OM (V4.0) 9071 PRODUCT MANUAL 1-9

Page 14

1 Technical Specifications

Technical Specifications

Table 1-2 lists the technical specifications for the 9071 HD/SD-SDI AFD

Code Inserter card.

Table 1-2 Technical Specifications

Item Characteristic

Part number, nomenclature 9071 HD/SD-SDI AFD Code Inserter

Installation/usage environment Intended for installation and usage in frame meeting openGear®

modular system definition.

Power consumption < 12 Watts maximum

Environmental:

Operating temperature:

Relative humidity (operating or storage):

Frame communication 10/100 Mbps Ethernet with Auto-MDIX.

Indicators Card edge display and indicators as follows:

32° – 104° F (0° – 40° C)

< 95%, non-condensing

• 4-character alphanumeric display

• Remote Activity LED indicator

• Input Format LED indicator

Controls Card edge switches as follows:

• Menu Enter pushbutton switch

• Menu Exit pushbutton switch

• Up/down selection toggle switch

Resolution: 10-bit video data path

Serial Digital Video Input Data Rates Supported:

SMPTE 292 HD-SDI: 1.485 Gbps or 1.485/1.001 Gbps

SMPTE 259M-C SD-SDI: 270 Mbps

Impedance:

75 Ω terminating

Equalization (HD):

328 ft (100 m) Belden 1694A

Equalization (SD):

1000 ft (305 m) Belden 1694A

Return Loss:

> 15 dB at 5 MHz – 1.485 GHz

1-10 9071 PRODUCT MANUAL 9071-OM (V4.0)

Page 15

Introduction Technical Specifications

Table 1-2 Technical Specifica tions — continued

Item Characteristic

Serial Digital Video Outputs Number of Outputs:

Four HD/SD-SDI BNC per IEC 60169-8 Amendment 2

Impedance:

75 Ω

Return Loss:

> 15 dB at 5 MHz – 270 MHz

> 12 dB at 270 MHz – 1.485 GHz

Signal Level:

800 mV ± 10%

DC Offset:

0 V ± 50 mV

Jitter (HD ):

< 0.15 UI (all outputs)

Jitter (SD ) :

< 0.10 UI (all outputs)

Overshoot:

< 0.2% of amplitude

Reclocked Serial Digital Video Outputs Number of Outputs:

Four HD/SD-SDI BNC per IEC 60169-8 Amendment 2

Impedance:

75 Ω

9071-OM (V4.0) 9071 PRODUCT MANUAL 1-11

Page 16

1 Warranty and Service Information

Warranty and Service Information

Cobalt Digital Inc. Limited Warranty

This product is warranted to be free from defects in material and workmanship for a period of five (5)

years from the date of shipment to the original purchaser, except that 4000, 5000, 6000, 8000 series

power supplies, and Dolby

material and workmanship for a period of one (1) year.

Cobalt Digital Inc. 's (“Cobalt”) sole obligation under this warranty shall be limited to, at its option, (i)

the repair or (ii) replacement of the product, and the determinati on of whether a defect is covered under

this limited warranty shall be made at the sole discretion of Cobalt.

This limited warranty applies onl y to the original end-purchaser of the pr oduct, and is not assigna ble or

transferrable therefrom. This warranty is limited to defects i n material a nd workman shi p, and shal l not

apply to acts of God, accidents, or negligence on behalf of the purchaser, and shall be voided upon the

misuse, abuse, alteration, or modification of the product. Only Cobalt authorized factory

representatives are authorized to make repairs to the product, and any unauthorized attempt to repair

this product shall immediately void the warranty. Please contact Cobalt Technical Support for more

information.

®

modules (where applicable) are warranted to be free from defects in

To facilitate the resolution of warranty related issues , Cobalt recommends registering the product by

completing and returning a product registration form. In the event of a warrantable defect, the

purchaser shall notify Cobalt with a description of the problem, and Cobalt shall provide the purchaser

with a Return Material Authorization (“RMA”). For return, defective product s should be double boxed,

and sufficiently protected, in the original packaging, or equivalent, and shipped to the Cobalt Factory

Service Center, postage prepaid and insured for the purchase price. The purchaser should include the

RMA number, description of the problem encountered, date purchased, name of dealer purchased

from, and serial number with the shipment.

Cobalt Digital Inc. Factory Service Center

2406 E. University Avenue Office: (217) 344-1243

Urbana, IL 61802 USA Fax: (217) 344-1245

www.cobaltdigital.com Email: info@cobaltdigital.com

THIS LIMITED WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES

EXPRESSED OR IMPLIED, INCLUDING THE WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE AND OF ALL OTHER OBLIGATIONS OR

LIABILITIES ON COBALT'S PART. ANY SOFTWARE PROVIDED WITH, OR FOR USE WITH,

THE PRODUCT IS PROVIDED “AS IS.” THE BUYER OF THE PRODUCT ACK NOWLEDGES

THAT N O OTHER REPRESENTATIONS WERE MADE OR RELIED UPON WITH RESPECT TO

THE QUALITY AND FUNCTION OF THE GOODS HEREIN SOLD. COBALT PRODUCTS ARE

NOT AUTHORIZED FOR USE IN LIFE SUP PORT APPLICATIONS.

COBALT'S LIABILITY, WHETHER IN CONTRACT, TORT, WARRANTY, OR OTHERWISE, IS

LIMITED TO THE REPAIR OR REPLACEMENT, AT ITS OPTION, OF ANY DEFECTIVE

PRODUCT, AND SHALL IN NO EVENT INCLUDE SPECIAL, INDIRECT, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES (INCL UDING LOST PROFITS), EVEN IF IT HAS BEEN

ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

1-12 9071 PRODUCT MANUAL 9071-OM (V4.0)

Page 17

Introduction Contact Cobalt Digital Inc.

Contact Cobalt Digital Inc.

Feel free to contact ou r th oro ugh and professional support representatives for

any of the following:

• Name and address of your local dealer

• Product information and pricing

• Technical support

• Upcoming trade show i nformation

Phone: (217) 344-1243

Fax: (217) 344-1245

Web: www.cobaltdigital.com

General Information: info@cobaltdigital.com

Technical Support: support@cobaltdigital.com

9071-OM (V4.0) 9071 PRODUCT MANUAL 1-13

Page 18

This page intentionally blank

1-14 9071 PRODUCT MANUAL 9071-OM (V4.0)

Page 19

Chapter 2 Installation and Setup

Overview

This chapter contains the following information:

• Installing the 9071 Into a Frame Slot (p. 2-1)

• Installing a Rear I/O Module (p. 2-3)

• Setting Up 9071 Network Remote Control (p. 2-6)

Installing the 9071 Into a Frame Slot

Chapter 2

CAUTION

CAUTION

Heat and power distribution requirements within a frame may dictate specific

slot placement of cards. Cards with many heat-producing compon ents should

be arranged to avoid areas of excess heat build-up, particularly in frames

using only convection cooling. The 9071 has a moderate power dissipation

(12 W max.). As such, avoiding placing the card adjacent to other cards with

similar dissipation values if possible.

CAUTION

This device contains semiconductor devices which are

susceptible to serious damage from Electrostatic

Discharge (ESD). ESD damage may not be immediately

apparent and can affect the long-term reliability of the

device.

Avoid handling circuit boards in high static environments

such as carpeted areas, and when wearing synthetic fiber

clothing. Always use proper ESD handling precautions

and equipment when working on circuit boards and

related equipment.

9071-OM (V4.0) 9071 PRODUCT MANUAL 2-1

Page 20

2 Installing the 9071 Into a Frame Slot

Note: • If installing the 9071 in an 8310-C-BNC or 8310-BNC frame (which is

pre-equipped with a 100-BNC rear I/O module installed across the entire

backplane) or a slot already equipped with a suitable I/O module, proceed to

card installation steps below.

• If installing the 9071 in a slot with no rear I/O module, a Rear I/O

Module is required before cabling can be connected. Refer to Installing a

Rear I/O Module (p. 2-3) for rear I/O module installation procedure.

CAUTION

If required, make certain Rear I/O Module(s) is installed before installing the

9071 into the frame slot. Damage to card and/or Rear I/O Module can occur if

module installation is attempted with card already installed in slot.

Note: Check the packaging in which the 9071 was shipped for any extra items such

as a Rear I/O Module connection label. In some cases, this label is shipped

with the card and to be installed on the Rear I/O connector bank corresponding to the slot location of the card.

Install the 9071 into a frame slot as follows:

1. Determine the slot in which the 9071 is to be installed.

2. Open the frame front access panel.

3. While holding the card by the card edges, align the card such that the

plastic ejector tab is on the bottom.

4. Align the card with the top and bottom guides of the slot in which the

card is being installed.

5. Gradually slide the card into the slot. When re sistance is noticed, gently

continue pushing the card until its rear printed circuit edge terminals

engage fully into the rear I/O module mating connector.

CAUTION

If card resists fully engaging in rear I/O module mating connector, check for

alignment and proper insertion in slot tracks. Damage to card and/or rear I/O

module may occur if improper card insertion is attempted.

Verify that the card is fully engaged in rear I/O module mating connector.

6.

7. Close the frame front access panel.

8. Connect the input and output cables as shown in Table 2-1.

9. Repeat steps 1 through 8 for other 9071 cards.

2-2 9071 PRODUCT MANUAL 9071-OM (V4.0)

Page 21

Installation and Setup Installing a Rear I/O Module

Note: The 9071 BNC inputs are internally 75-ohm terminated. It is not necessary to

terminate unused BNC inputs or outputs.

Note: To remove a card, press down on the ejector tab to unseat the card from the

rear I/O module mating connector. Evenly draw the card from its slot.

10. If network remote control is to be used for the frame and the frame has

not yet been set up for remote control, perform setup in accordance with

Setting Up 9071 Network Remote Control (p. 2-6).

Note: If installing a card in a frame already equipped for, and connected to

DashBoard™, no network setup is required for the card. The card will be discovered by DashBoard™ and be ready for use.

Installing a Rear I/O Module

Note: This procedure is applicable only if a Rear I/O Module is not currently

installed in the slot where the 9071 is to be installed.

If installing the 9071 in a 8310-C-BNC or 8310-BNC frame (which is

pre-equipped with a 100-BNC rear I/O module installed across the entire

backplane) or a slot already equipped with a suitable I/O module, omit this

procedure.

Install a Rear I/O Module as follows:

1. On the frame, determine the slot in which the 9071 is to be installed.

2. In the mounting area corresponding to the slot location, install

Rear I/O Module as shown in Figure 2-1.

9071-OM (V4.0) 9071 PRODUCT MANUAL 2-3

Page 22

2 Installing a Rear I/O Module

Align and engage mounting tab on Rear

I/O Module with the module seating slot

1

on rear of frame chassis.

DSCN3483A.JPG

Hold top of Rear I/O Module flush against

frame chassis and start the captive screw.

2

Lightly tighten captive screw.

DSCN3487A.JPG

Figure 2-1 Rear I/O Module Installation

2-4 9071 PRODUCT MANUAL 9071-OM (V4.0)

Page 23

Installation and Setup Installing a Rear I/O Module

9071 Rear I/O Modules

Table 2-1 shows and describes the full assortment of Rear I/O Modules

specifical ly for use with the 9071.

Table 2-1 9071 Rear I/O Modules

9071 Rear I/O Module Description

RM20-9071-A Provides the following connections:

• HD/SD-SDI coaxial input (SDI IN)

• Four reclocked SDI input copies (RCK OUT 1- 4)

• Four buffered SDI coaxial outputs (SDI OUT 1- 4)

RM20-9071-A/S Split Rear Module. Provides each of the following

connections for two 9071 cards:

• HD/SD-SDI coaxial input (

• HD/SD-SDI reclocked i nput cop ies (

RCK OUT 2

• Buffered SDI coaxial outputs (

SDI OUT 2

Note: RM20-9071-A/S Rear I/O Module compatible

)

)

only with 20-slot frames.

SDI IN)

RCK OUT 1 and

SDI OUT 1 and

9071-OM (V4.0) 9071 PRODUCT MANUAL 2-5

Page 24

2 Setting Up 9071 Network Remote Control

Setting Up 9071 Network Remote Control

Perform remote control setup in accordance with Cobalt® reference guide

“COMPASS™ Remote Control User Guide” (PN 9000RCS-RM).

Note: • If network remote control is to be used for the frame and the frame has not

yet been set up for remote control, Cobalt

Remote Control User Guide (PN 9000RCS-RM) provides thorough information and step-by-step instructions for setting up network remote control of

COMPASS™ cards using DashBoard™. (Cobalt

OGCP-9000/CC Remote Control Panel product manuals have complete

instructions for setting up remote control using a Remote Control Panel.)

Download a copy of this guide by clicking on the Support>Downloads link

at www.cobaltdigital.com and then select DashBoard Remote Control Setup

Guide as a download, or contact Cobalt

Inc. (p. 1-13).

• If installing a card in a frame already equipped for, and connected to

DashBoard™, no network setup is required for the card. The card will be discovered by DashBoard™ and be ready for use.

®

reference guide COMPASS™

®

OGCP-9000 and

®

as listed in Contact Cobalt Digital

2-6 9071 PRODUCT MANUAL 9071-OM (V4.0)

Page 25

Overview

Chapter 3

Chapter 3 Operating Instructions

This chapter contains the following information:

If you are already familiar

with using DashBoard or a

Cobalt Remote Control

Panel to control Cobalt

cards, please skip to 9071

Function Submenu Li st and

Descriptions (p. 3-7).

• Control and Display Descriptions (p. 3-1)

• Accessing the 9071 Card via Remote Control (p. 3-4)

• Ancillary Data Line Number Locations and Ranges (p. 3-6)

• 9071 Function Submenu List and Descriptions (p. 3-7)

• Troubleshooting (p. 3-17)

Control and Display Descriptions

This secti on describes the user interface controls, indicators, and displays for

using the 9071 card. The 9071 function s can be acces sed and contr olle d using

any of the user interfaces described here.

The format in which the 9071 functional controls, indicators, and displays

appear and are used varies depending on the user interface being used.

Regardless of the user interface being used, access to the 9071 functions (and

the controls, ind icato rs, an d disp lays r elat ed to a particul ar f uncti on) fo llows a

general arrangement of Function Submenus under which related controls can

be accessed (as described in Function Submenu/Parameter Submenu

Overview below).

Note: DashBoard™ and the Remote Control Panel provide greatly simplified user

interfaces as compared to using the card edge controls. For this reason, it is

strongly recommended that DashBoard™ or a Remote Control Panel be

used for all card applications other than the most basic cases. Card edge

control codes are not included in this manual. If card-edge control is to be

used, obtain a copy of “Manual Supplement – Card-Edge Control Reference

Master List and Instructions for Using Compass

Codes” (989CEC-MS.pdf) at

www.cobaltdigital.com>Support>Documents>Reference Guides.

9071-OM (V4.0) 9071 PRODUCT MANUAL 3-1

®

Card-edge (Local) Control

Page 26

3 Control and Display Descriptions

Note: When a setting is changed, settings displayed on DashBoard™ (or the

Remote Control Panel) are the settings as effected by the 9071 card itself and

reported back to the remote control; the value displayed at any time is the

actual value as set on the card.

Function Submenu/Parameter Submenu Overview

The functions and related pa rameters avai lable on the 9071 car d are organ ized

into function submenus, which consist of parameter groups as shown below.

Figure 3-1 shows how the 9071 card an d its submenus ar e orga nized, and also

provides an overview of how navig ation is performed be tween cards, func tion

submenus, and parameters.

If using DashBoard™ or a Remote Control Panel, the

desired 9071 card is first selected.

9071

Submenu a Submenu b

Individual Parameters

Each submenu consists of groups of parameters

related to the function submenu.

Figure 3-1 Function Submenu/Parameter Submenu Overvie w

• • •

The desired function submenu is next

selected.

Function Submenus consist of parameter

groups related to a particular 9071 card

function.

Submenu z

3-2 9071 PRODUCT MANUAL 9071-OM (V4.0)

Page 27

Operating Instructions Control and Display Descriptions

DashBoard™ User Interface

(See Figure 3-2.) Th e 9071 fu nction submenus are or gani zed i n DashBoa rd™

using tabs (see example in Figure 3-2). When a tab is selected, each

parametric control or selection list item associated with the function is

displayed. Scalar ( numer ic ) parametric values ca n t hen be adjusted as desi red

using the GUI slider controls. Items in a list can then be selected using GUI

drop-down lists.

Figure 3-2 DashBoard™ Tab Example

Cobalt® Remote Control Panel User Interfaces

Similar to the functi on submenu tabs u sing DashBoard™, the Remote Control

Panels have a Select Submenu key that is used to display a list of function

submenus. From this lis t, a c ontrol kn ob on the Con trol Panel is use d to s elect

a function from the list of displayed function submenu items.

Note: Refer to “OGCP-9000 Remote Control Panel User Manual” (PN

OGCP-9000-OM) or “OGCP-9000/CC Remote Control Panel User Manual”

(PN OGCP-9000/CC-OM) for complete instructions on using the Control Panels.

9071-OM (V4.0) 9071 PRODUCT MANUAL 3-3

Page 28

3 Accessing the 9071 Card via Remote Control

Accessing the 9071 Card via Remote Control

Access the 9071 card using DashBoard™ or Cobalt® Remote Control Panel

as described below.

Accessing the 9071 Card Using DashBoard™

1. On the computer connected to the frame LAN, open DashBoard™.

2. As shown below, in the left side Basic View Tree locate the Network

Controller Card associated with the frame containing the 9071 card to be

accessed (in this example, “MFC-8320-N SN: 00108053”).

DB_ACCESS1.PNG

3. As shown below, expand the tree to access the cards within the frame.

Click on the card to be accessed (in this example,

“Slot 7: CDI-9071”).

.

9071_DB_ACCESS2A.PNG

As shown on the next page, when the card is a ccess ed a Das hBoard ™ its

function submenu screen showing tabs for each function is displayed.

(The particular submenu screen displayed is the previously displayed

screen from the last time the card was accessed by DashBoard™).

3-4 9071 PRODUCT MANUAL 9071-OM (V4.0)

Page 29

Operating Instructions Accessing the 9071 Card via Remote Control

Card Access/Navigation

Tree Pane

Card Info

Pane

Card Function Submenu

and Controls Pane

9071-OM (V4.0) 9071 PRODUCT MANUAL 3-5

Page 30

3 Ancillary Data Line Number Locations and Ranges

Ancillary Data Line Number Locations and Ranges

Table 3-1 lists typical default output video VANC line number locations for

various ancillary data items that may be passed or handled by the card.

Table 3-1 Typical Ancillary Data Line Number Locations/Ranges

Default Line No. / Range

Item

SD HD

AFD 12 (Note 2) 9 (Note 2)

ATC_VITC 13 (Note 2) 9/8 (Note 2)

ATC_LTC — 10 (Note 2)

®

Dolby

Metadata 13 (Note 2) 13 (Note 2)

SDI VITC Waveform 14/16 (Note 2) —

Closed Captioning 21 (locked) 10 (Note 2)

Notes:

1. The card does not check for conflicts on a given line number. Make certain the selected line is available

and carrying no other data.

2. While range indicated b y d rop -dow n li st o n G UI m ay al lo w a particular range o f ch oi ces , the actual range

is automatically cl amped (limi ted) to c ert ain rang es to preven t inadv ertent c onfli ct wi th active pictu re a rea

depending on video format. Limiting ranges for various output formats are as follows:

Format Line No. Limi ting Format Line No. Limiting Format Line No. Limiting

525i 12-19 720p 9-25 1080p 9-41

625i 9-22 1080i 9-20

Because line number allocation is not standardized for all ancillary items,

consideration should be given to all items when performing set-ups. Figure

3-3 shows an example of improper and corrected VANC allocation within an

HD-SDI stream.

ATC_VITC = 9 /8

CC = 10

Dolby Meta data = 13

Card 1

ATC_VITC = 9/ 8

CC = 10

Dolby Metadata = 13

Card 1

AFD Insertion

attempted usin g

VANC line 9

(default)

AFD Insertion

corrected to us e

VANC line 18

ATC_VITC = 9/8

AFD = 9

CC = 10

Dolby Meta data = 13

Card n

ATC_VITC = 9/8

CC = 10

Dolby Metadata = 13

AFD = 18

Card n

Conflict between

ATC_VITC and AFD both

on VANC line 9

Conflict between

ATC_VITC on line 9/8 and

AFD (now on line 18)

resolved

Figure 3-3 Example VANC Line Number Allocation Conflict and Resolution

3-6 9071 PRODUCT MANUAL 9071-OM (V4.0)

Page 31

Operating Instructions 9071 Function Submenu List and Descriptions

9071 Function Submenu List and Descriptions

Table 3-2 individually lists and describes each 9071 function submenu “tab”

and its related list selections, co ntrols, and parameters . Where helpful,

examples showing usage of a function are also provided. Table 3-2 is

primarily based upon using DashBoard™ to access each function and its

corresponding submenus and parameters.

Note: All numeric (scalar) parameters displayed on DashBoard™ can be changed

using the slider controls, arrows, or by numeric keypad entry in the corresponding numeric field. (When using numeric keypad entry, add a return after

the entry to commit the entry.)

On DashBoard™ itself and in Table 3-2, the function submenu items are

organized using tabs as shown below.

The table below provides a quick-reference to the page numbers where each

function submenu item can be found.

Function Submenu Item Page Function Submenu Item Page

Video Proc 3-8 Licensable Features 3-14

AFD 3-9 Presets 3-14

Timecode 3-10

9071-OM (V4.0) 9071 PRODUCT MANUAL 3-7

Page 32

3 9071 Function Submenu List and Descriptions

Table 3-2 9071 Function Submenu/Parameter List

Provides the following Video Proc parametric controls.

• Video Proc Video Proc (On/Off) provides master on/off control of all Video Proc

• Reset to Unity Reset to Unity provides unity reset control of all Video Proc functions.

• Luma Gain Adjusts gain percentage applied to Luma (Y channel).

functions.

• W hen set to Off, all processing is bypassed.

• W hen set to On, currently displayed parameter settings take effect.

When Confirm is clicked, a Confirm? pop-up appears, requesting

confirmation.

• Click Yes to proceed with the unity reset.

• Click No to reject unity reset.

(0% to 200% range in 0.1% steps; unity = 100%)

Video Proc

• Luma Lift Adjusts lift applied to Luma (Y-channel).

(-100% to 100% range in 0.1% steps; null = 0.0%)

• Color Gain Adjusts gain percentage (saturation)

applied to Chroma (C-channel).

(0% to 200% range in 0.1% steps; unity = 100%)

• Color Phase Adjusts phase angle applied to Chroma.

(-360° to 360° range in 0.1° steps; null = 0°)

• Gang Luma and Color Gain When set to On, changing either the Luma Gain or Color Gain controls

increases or decreases both the Luma and Chroma levels by equal

amounts.

3-8 9071 PRODUCT MANUAL 9071-OM (V4.0)

Page 33

Operating Instructions 9071 Function Submenu List and Descriptions

Table 3-2 9071 Function Submenu/Parameter List — continued

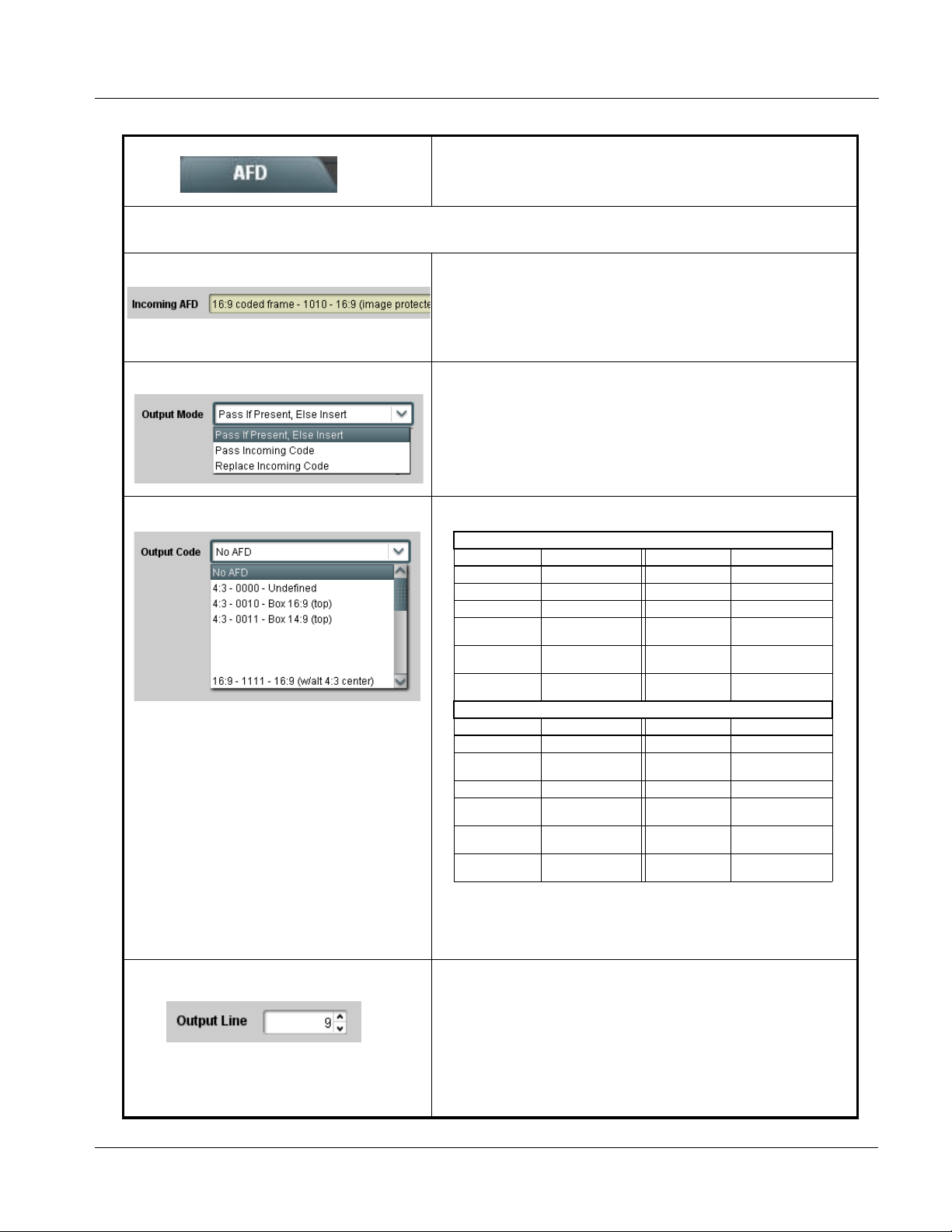

Allows assignment of AFD (Active Format Description)

AFD

Note: This function only marks the SDI output with an AFD code. Actual AFD processing must be performed by a downstream

card or system that recognizes an AFD code assigned here.

• Incoming AFD Displays incoming AFD setting as follows:

codes to the SDI output video.

• If AFD code is present, one of the 1 1, four-bit AFD codes is displayed (as

shown in the example to the left). Also displayed is the VANC line

number of the incoming AFD code.

• If no AFD setting is present in the video signal, No AFD Present is

displayed.

• Output Mode Drop-down selection determines action to take in presence or absence of

existing AFD code on input video.

AFD

• Output Code Drop-down list assigns desired AFD to output SDI.

4:3 Coded Frame

AFD Code

•

•

•

16:9 Coded Frame

AFD Code

1: AFD codes numbering and definitions conform to SMPTE 2016-1-2007.

2: Image Prot ecte d impl ies pictu re cont ent that must not be cropped by

(1)

Description AFD Code

– No code present 1001 Full frame

0000 Undefined 1010 16:9 (center)

0010 Box 16:9 (top) 1011 14:9 (center)

0011 Box 14:9 (top) 1101 4:3 (with alternate

0100 Box > 16:9 (center) 1110 16:9 (with alternate

1000 Full frame 1111 16:9 (with alternate

(1)

Description AFD Code

– No code present 1001 4:3 (center)

0000 Undefined 1010 16:9 (image

0010 Full frame 1011 14:9 (center)

0011 4:3 (center) 1101 4:3 (with alternate

0100 Box > 16:9 (center) 1110 16:9 (with alternate

1000 Full frame 1111 16:9 (with alternate

conversion processes or display devices. Alternate center formats may

have protected center areas, with areas outside of the protected area not

containing mandatory content.

(1)

(1)

Description

14:9 center)

14:9 center)

4:3 center)

Description

protected)

14:9 center)

14:9 center)

4:3 center)

(2)

(2)

(2)

(2)

(2)

• Output Line Allows selecting the line location of the AFD data within the video signal

Ancillary Data space. (Range is 9 thru 41.)

Note: • Although the output line drop-down will allow any choice within the

9 thru 41 range, the actual range is automatically clamped (limited)

to certain ranges to prevent inadvertent conflict with active picture

area depending on video format. See Ancillary Data Line Number

Locations and Ranges (p. 3-6) for more information.

• The card does not check for conflicts on a given line number.

Make certain the selected line is available and carrying no other

data.

9071-OM (V4.0) 9071 PRODUCT MANUAL 3-9

Page 34

3 9071 Function Submenu List and Descriptions

Table 3-2 9071 Function Submenu/Parameter List — continued

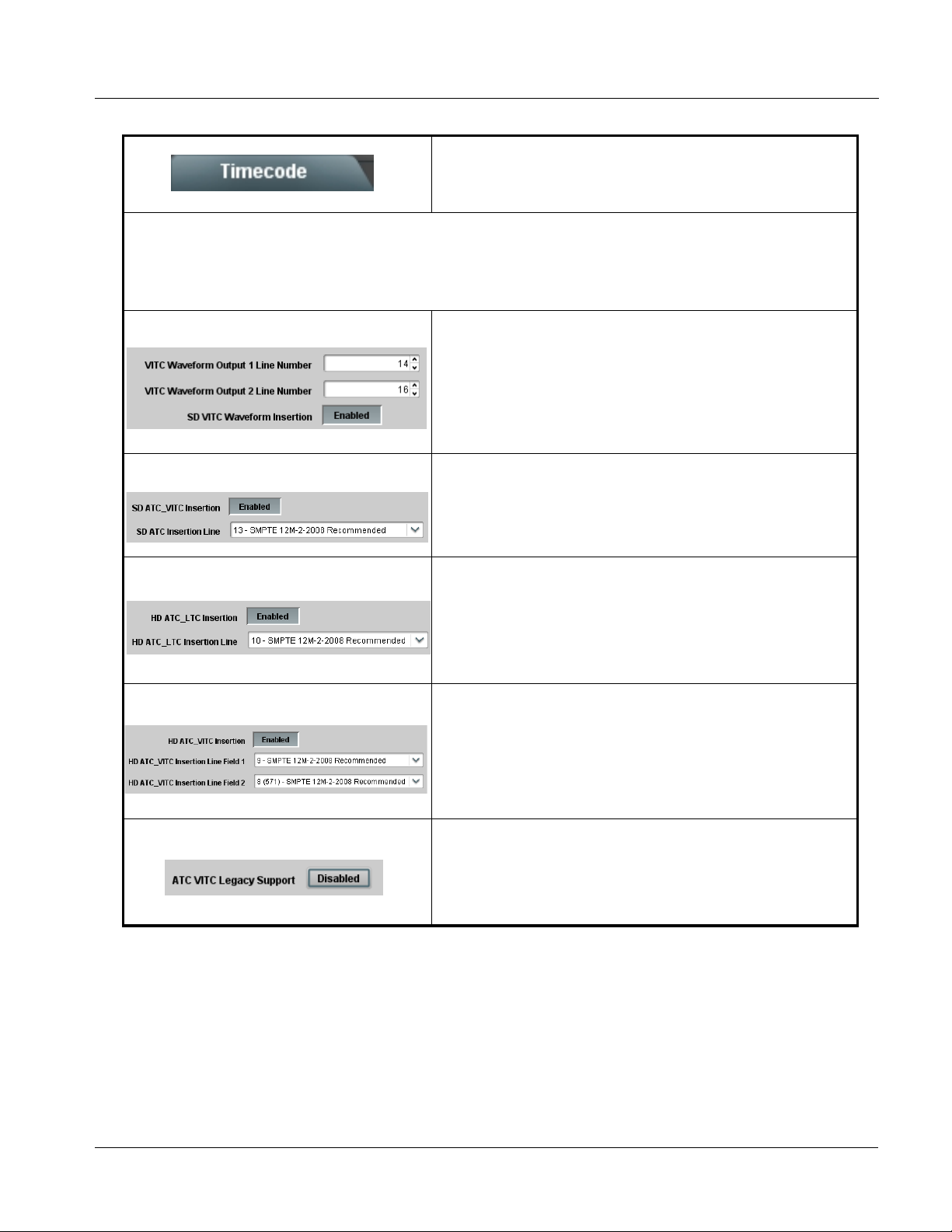

Provides timecode data extraction from various

sources, and provides formatting and re-insertion

Timecode

Shown below is an example in which received SDI video with SDI VITC waveform timecode is to be converted to SDI

ATC_VITC timecode data. Each Timecode control is fully described on the pages that follow.

controls for inserting the timecode into the output video.

525i 5994

w/ VITC

Waveform

A

Noting that the incoming video contains VITC

9083

525i 5994

w/ ATC_VITC

waveform timecode data (as shown in the status

display), set the Source Priority drop-down lists to

include VITC Waveform timecode data (SDI VITC) as

a choice. This extracts VITC Waveform timecode

data from the incoming video.

In this example, it is desired to provide SDI

B

ATC_VITC timecode data in the output video. As

such, set HD ATC VITC Insertion Insertion to

Enabled.

In the example here, the line numbers are set to the

default SMPTE 12M-2-2008 recommended values.

525i SDI

w/ VITC

Waveform

SDI VITC

Detect/Extract

A

A

Priority/

Select

Buffer/

Format

SDI VITC

Timecode

Proc/Embed

ATC_VITC

Timecode

Proc/Embed

B

SDI ATC_VITC

Detect/Extract

ATC_LTC

Timecode

Line

Control

Proc/Embed

525i SDI

w/ATC_VITC

ATC_VITC Insertion = Enabled

ATC_LTC Insertion = Enabled

ATC_VITC1 = Line 9 (default SMPTE 12M-2)

ATC_VITC2 = Line 8 (571) (default SMPTE 12M- 2)

ATC_LTC = Line 10 (default SMPTE 12M-2)

SDI ATC_LTC

Detect/Extract

Insert

Control

Number

3-10 9071 PRODUCT MANUAL 9071-OM (V4.0)

Page 35

Operating Instructions 9071 Function Submenu List and Descriptions

Table 3-2 9071 Function Submenu/Parameter List — continued

(continued)

• Timecode Source Status Displays Displays the current status and contents of the supported timecode

• Incoming ATC Packet Removal Control Enables or disables removal of existing input video ATC timecode packets

• Source Priority As described here, selects the priority assigned to each of the four

formats shown to the left.

• If a format is receiving timecode data, the current content (timecode

running count and line number) is displayed.

• If a format is not receiving timecode data, Unlocked is displayed.

from the output. This allows removal of undesired existing timecodes from

the output, resulting in a “clean slate” where only desired timecodes are

then re-inserted into the output. (For example, if both SD VITC Waveform

and SD ATC_VITC timecode data are present on the input video, and only

ATC_VITC is desired, using the Removal control will remove both

timecodes from the output. The ATC_VITC timecode by itself can then be

re-inserted on the output using the other controls discussed here.)

Note: When the Scaler is enabled, ATC packets are automatically

removed. The Timecode function must be used to re-insert the

timecode data into the output video.

supported formats in the event the preferred source is unavailable.

Each of the four Source Priority selection lists allows assignment of

source priority from the following choices:

Source Priority 1 thru Source Priority 4 select the preferred format to be

used in descending order (i.e., Source Priority 2 selects the second-most

preferred format, and so on.

9071-OM (V4.0) 9071 PRODUCT MANUAL 3-11

Page 36

3 9071 Function Submenu List and Descriptions

Table 3-2 9071 Function Submenu/Parameter List — continued

(continued)

• Output Stat us Dis play Displays the current content and source being used for the timecode data

as follows:

• Output status OK (in this example, running SDI VITC timecode received

and outputted).

• Timecode not available due to lack of appropriate input timecode data on

enabled formats.

Note: Timecode output requires that source and priority are appropriately

selected (as described above in Source Priority). Also, video input

must contain appropriate timecode data.

• Timecode Insertion button set to Disabled; output insertion disabled.

Note: • If timecode is not available from Source Priority selections

performed, timecode on output reverts to Free Run (internal

count) mode.

• Because the 1’s digit of the display Frames counter goes from 0 to

29, the fractional digit (along with the 1’s digit) indicates frame

count as follows:

0.0 Frame 0

0.1 Frame 1

1.0 Frame 2

1.1 Frame 3

•

•

•

29.1 Frame 59

• Offset Contr ols Allows the current timecode count to be advanced or delayed on the

output video.

• Offset Advance or Delay selects offset advance or delay.

• Offset Field delays or advances or delays timecode by one field.

• Offset Frame delays or advances or delays timecode by up to 5

frames.

Note: Default settings are null, with both controls set at zero as shown.

3-12 9071 PRODUCT MANUAL 9071-OM (V4.0)

Page 37

Operating Instructions 9071 Function Submenu List and Descriptions

Table 3-2 9071 Function Submenu/Parameter List — continued

(continued)

Note: • Although the output line drop-down on the controls described below will allow a particular range of choices, the actual

range is automatically clamped (limited) to certain ranges to prevent inadvertent conflict with active picture area

depending on video format. See Ancillary Data Line Number Locations and Ranges (p. 3-6) for more information.

• The card does not check for conflicts on a given line number. Make certain the selected line is available and carrying

no other data.

• SD VITC Waveform Insertion Controls For SD output, enables or disables SD VITC waveform timecode insertion

• SD ATC Insertion Control For SD output, enables or disables SD ATC_VITC timecode insertion into

• HD ATC_LTC Insertion Control For HD output, enables or disables ATC_LTC timecode insertion into the

into the output video, and selects the VITC1 and VITC2 line numbers (6

thru 22) where the VITC waveform is inserted.

Note: • If only one output line is to be used, set both controls for the same

line number.

• SD VITC Waveform Insertion control only affects VITC

waveforms inserted (or copied to a new line number) by this

function.

the output video, and selects the line number for ATC_VITC.

output video, and selects the line number for ATC_LTC timecode data.

• HD ATC_VITC Insertion Control

• ATC_VITC Legacy Support Control When enabled, accommodates equipment requiring ATC_VITC packet in

For HD output, enables or disables ATC_VITC timecode insertion into the

output video, and selects the line number for ATC_VITC1 and

ATC_VITC2.

Note: If only one output line is to be used, set both controls for the same

line number.

both fields as a “field 1” packet (non-toggling).

Note: Non-toggling VITC1 and VITC2 packets do not conform to

SMPTE 12M-2-2008 preferences. As such, ATC_VITC Legacy

Support should be enabled only if required by downstream

equipment.

9071-OM (V4.0) 9071 PRODUCT MANUAL 3-13

Page 38

3 9071 Function Submenu List and Descriptions

Table 3-2 9071 Function Submenu/Parameter List — continued

Licensable Features

Allows activation of optional licensed features.

Note: For card pre-ordered with licensed feature(s), the activation steps described below are not required; the feature will

already be installed activated. To order features and obtain a license key, contact Cobalt

sales@cobaltdigital.com or at the contact information in Contact Cobalt Digital Inc. in Chapter 1, “Introduction”. Please

provide the “SSN” number of your card (displayed in the Card Info pane) when contacting us for your key.

• License Feature and Key Entry window Act ivat e licensable feature as descr ibed below.

1. Enter the feature key string in the Feature Key box. Press return or

click outside of the box to acknowledge entry.

Note: Entry string is case sensitive. Do not enter any spaces.

2. In the DashBoard™ Card Info pane, wait for the feature identification to

be shown for the card product number (for example, “-UM” appearing

after the card part number) and Valid Key Entered to be displayed.

This indicates the key was correctly entered and recognized by the

card.

Note: If DashBoard™ card function submenu/control pane does not

re-appear, close the card and re-open it.

3. Click and confirm Reboot. When the card function submenu/control

pane appears again, the licensable feature will be available.

Note: Applying the licensable feature and its reboot has no effect on

prior settings. All control settings and drop-down selections are

retained.

®

sales at

Allows up to 16 card user set tin gs co nfi gur at ion pres et s

to be saved in a Preset and then recalled (loaded) as

Presets

desired. All current settings (including list selections

and scalar (numeric) control settings such as Gain, etc.)

are saved when a Preset Save is invoked.

The Preset Name field and Preset Save button

allow custom user setting configurations to be

labeled and saved to a Preset for future use.

The Preset Load button and the Selected Preset

drop-down list allow saved presets to be selected

and loaded as desired. When a preset is loaded, it

immediately becomes active with all user settings

now automatically set as directed by the preset.

Saved presets can be uploaded to a computer for

use with other same-model COMPASS™ cards.

Each of the items to the left are described in detail on

the following pages.

3-14 9071 PRODUCT MANUAL 9071-OM (V4.0)

Page 39

Operating Instructions 9071 Function Submenu List and Descriptions

Table 3-2 9071 Function Submenu/Parameter List — continued

(continued)

• Preset Save and Load • Preset Save stores all current card control settings to the currently

• Selected Preset Selected Preset 1 thru Selected Preset 16 range in drop-down list

•

•

•

• Preset Name With one of 16 presets selected, provides for entry of custom name for the

selected preset.

(For example, if Preset 1 is selected in the Selected Preset drop-down

list, clicking and confirming Preset Save will then save all current card

control settings to Preset 1)

• Preset Load loads (applies) all card control settings defined by

whatever preset (Preset 1 thru Preset 16) is currently selected in the

Selected Preset drop-down list.

(For example, if Preset 3 is selected in the Selected Preset drop-down

list, clicking and confirming Preset Load will then apply all card control

settings defined in Preset 3)

The above buttons have a Confirm? pop-up that appears, requesting

confirmation.

Note: Applying a change to a preset using the buttons described above

rewrites the previous preset contents with the invoked contents.

Make certain change is desired before confirming preset change.

selects one of 16 stored presets as ready for Save (being written to) or for

Load (being applied to the card).

Note: The preset names shown to the left are the default (unnamed)

preset names. All 16 presets in this case are loaded identically with

the factory default settings.

preset (as shown in example below).

Entering text in Preset

Name field (in this

example, “RCVR21”)

applies custom name to

selected Preset (in this

example, Preset 2)

Note: • Preset name can be seven ASCII characters maximum.

• The Preset ID number does not need to be entered; it is

added automatically.

• Card Name Text entry field provides for optional entry of card name, function, etc. (as

shown in this example).

Note: Card name can be 31 ASCII characters maximum.

9071-OM (V4.0) 9071 PRODUCT MANUAL 3-15

Page 40

3 9071 Function Submenu List and Descriptions

Table 3-2 9071 Function Submenu/Parameter List — continued

(continued)

• Reset Current Preset • Reset Current Preset resets all parameters (including preset custom

• Download Presets Download Presets allows all 16 presets to be stored to a specified location

Download a presets file to a computer on the card’s DashBoard network to save presets. Preset files stored on a computer can

then be uploaded back to the card.

Note also that a presets file can also be uploaded to other same-model COMPASS

using a single card can be easily applied to other same-model cards without repeating the setup work on the other cards.

Download (save) card presets to a

network computer by clicking

Download

Presets – Save

at the bottom of

the Presets

page.

Browse to a desired

save location (in

this example, My

Documents\Cobalt

Presets).

The file can then be

renamed if desired

(RCVR21 Presets

in this example)

before saving.

name entered) of the currently selected Preset (as displayed in the

Selected Preset field) to factory default settings.

The above button has a Confirm? pop-up that appears, requesting

confirmation.

on a network computer for use with other same-model COMPASS™

cards.

®

Refer to Cobalt

Guide” (PN 9000RCS-RM) for instructions on using the Download Presets

function.

reference guide “COMPASS™ Remote Control User

®

cards. In this manner, presets built up

Upload (open) card presets from a network

computer by clicking Upload

at the bottom of

DashBoard.

Browse to the location

where the file was saved

on the computer or

drive (in this example,

My Documents\Cobalt

Presets).

Select the desired file

and click Open to load

the file to the card.

To upload presets

saved from one card

to another same-model card, simply click Upload on the

other same-model card’s DashBoard page and repeat the

same steps here.

Note: • Preset transfer between card download and file

upload is on a group basis (i.e., individual presets

cannot be downloaded or uploaded separately).

• After uploading a presets file, engagement of a

desired preset is only assured by pressing the Preset

Load button for a desired preset.

3-16 9071 PRODUCT MANUAL 9071-OM (V4.0)

Page 41

Operating Instructions Troubleshooting

Troubleshooting

This section provides general troubleshooting information and specific

symptom/c orrective action for the 9071 card and its remote control interface.

The 9071 card requires no periodic maintenance in its normal operation; if

any error indication (as described in this section) occurs, use this section to

correct the condition.

Error and Failure Indicator Overview

The 9071 card itself and its remote control systems all (to varying degrees)

provide error and failure indications. Depending on how the 9071 card is

being used (i.e, standalone or network controlled through DashBoard™ or a

Remote Control Panel), check all available indications in the event of an error

or failure condition.

The various 9071 card and remote control error and failure indicators are

individually described below.

Note: The descriptions below provide general information for the various status and

error indicators. For specific failures, also use the appropriate subsection

listed below.

• Basic Troubleshooting Checks (p. 3-20)

• 9071 Processing Error Troubleshooting (p. 3-21)

• Troubleshooting Network/Remote Control Errors (p. 3-22)

9071-OM (V4.0) 9071 PRODUCT MANUAL 3-17

Page 42

3 Troubleshooting

9071 Card Edge Status/Error Indicators and Display

Figure 3-4 shows and describes the 9071 card edge status indicators and

display. These indicators and the display show status and error conditions

relating to the card itself and remote (network) communications (where

applicable). Because these indicators are part of the card itself and require no

external interface, the indicators are particularly useful in the event of

communications problems with external devices such as network remote

control de vices.

4-Character Alphanumeric Display

Menu Selection

Exit Submenu Pushbutton

Enter Submenu Pus hbutton

Toggle Switch

RMT

RMT

Indicator

1080

720

625

MENU DEPTH

525

Input Format

Indicators

Menu Depth

Indicators

Item Function

Alphanumeric

Display

RMT LED Blue LED flashes when card is receiving control message from remote network control (e.g., DashBoard™ or

Input Format

LEDs

Displays 4-digit alphanumeric code indicating status or errors as follows:

• E0XX: Video Errors

• E002: Video Acquiring Lock

®

Remote Control Panel)

Cobalt

Four blue LEDs indicate the input signal raster format being received and locked onto by the card (1080, 720,

625, 525). Continuous cycling of the LEDs indicates the card has not locked onto a particular format (as in

the case of no signal input).

Figure 3-4 9071 Card Edge Status Indicators and Display

3-18 9071 PRODUCT MANUAL 9071-OM (V4.0)

Page 43

Operating Instructions Troubleshooting

DashBoard™ Status/Error Indicators and Displays

Figure 3-5 shows and describes the DashBoard™ status indicators and

displays. These indicator icons and displays show status and error conditions

relating to the 9071 card itself and remote (network) communications.

Indicator Icon or Display Error Description

Red indicator icon in Card Access/Navigation Tree pane shows card with Error

condition (in this example, the Card Access/Navigation Tree pane shows a general

error issued by the 9071 card in slot 8).

Specific errors are displayed in the Card Info pane (in this example “No connection

to device” indicating 9071 card is not connecting to frame/LAN).

Gray indicator icon in Card Access/Navigation Tree pane shows card(s) are not

being seen by DashBoard™ due to lack of connection to frame LAN (in this

example, both a 9071 card in slot 7 and the MFC-8320-N Network Controller Card

for its frame in slot 0 are not being seen).

Yellow indicator icon in Card Access/Navigation Tree pane shows card with Alert

condition (in this example, the Card Access/Navigation Tree pane shows a general

alert issued by the MFC-8320-N Network Controller Card).

Clicking the card slot position in the Card Access/Navigation Tree (in this example

Network Controller Card “Slot 0: MFC-8320-N”) opens the Card Info pane for the

selected card. In this example, a “Fan Door Open” specific error is displayed.

Figure 3-5 DashBoard™ Status Indicator Icons and Displays

Access the Card Inf o pane fo r a speci fic car d by clic king the c ard slot positio n

in the Card Access/Navigation Tree pane (as shown in the example in Figure

3-6).

9071-OM (V4.0) 9071 PRODUCT MANUAL 3-19

Page 44

3 Troubleshooting

By clicking on “Slot 0: MFC-8320-N”

in this example, Card Info is

displayed for frame Network

Controller Card

Figure 3-6 Selecting Specific Cards for Card Info Status Display

Basic Troubleshooting Checks

Failures of a general nature (affecting many cards and/or functions

simultaneously), or gross inoperability errors are best addressed first by

performing basic checks before proceeding further. Table 3-3 provides basic

system checks that typically locate the source of most general problems. If

required and applicable, perform further troubleshooting in accordance with

the other troubleshooting tables in this section.

Status for selected card is

shown here (in this

example, connection OK

and “Fan Door Open”

alert)

Card general information

is displayed in lower

portion of Card Info pane

9071_TS_CARD_INFO_ACCESS.PNG

Table 3-3 Basic Troubleshooting Checks

Item Checks

Verify power presence and

characteristics

Check Cabl e connection

secureness and connecting

points

• On both the frame Network Contro ller Card and t he 9071, in all cases when po wer is

being properly supplied there is always at least one indicator illuminated. Any card

showing no illuminated indicators should be cause for concern.

• Check the Power Consumed indications for both the +12 V and -7.5 V supply rails

for the 9071 card. This can be observed using the DashBoard™ Card Info pane.

• If either of the rail supplies show no power being consumed, either the frame

power supply, connections, or the 9071 card itself is defective.

• If either of the rail supplies show excessive power being consumed (see

Technical Specifications (p. 1-10) in Chapter 1, “Introduction”), the 9071 card

may be defective.

Make certain all ca ble connec tions are ful ly secure (inc luding coa xial cable att ach ment

to cable ferrules on BNC connectors). Also, make certain all connecting points are as

intended. Make certain the selected connecting points correlate to the intended card

inputs and/or outputs. Cabling mistakes are especially easy to make when working

with large I/O modules.

3-20 9071 PRODUCT MANUAL 9071-OM (V4.0)

Page 45

Operating Instructions Troubleshooting

Table 3-3 Basic Troubleshooting Checks — continued

Item Checks

Card seating within slots Make certain all cards are properly seated within its frame slot. (It is best to assure

proper seating by ejecting the card and reseating it again.)

Check status indicators and

displays

Troubleshoot by substitution All cards within the frame can be hot-swapped, replacing a suspect card or module

On both DashBoard™ and the 9071 card edge indicators, red indications signify an

error condition. If a stat us indi cator si gnifie s an error, proceed to the following tables in

this section for further action.

with a known-good item.

9071 Processing Error Troubleshooting

Table 3-4 provides 9071 processing troubleshooting information. If the 9071

card exhib its any of the symptoms listed in Table 3-4, follow the

troubleshooting instructions provided.

In the majority of cases, most errors are caused b y simple errors where th e

9071 is not appropriately set for the type of signal being received by the card.

Note: The error indications shown below are typical for the corresponding error con-

ditions listed. Other error indications not specified here may also be displayed

on DashBoard™ and/or the 9071 card edge status indicators.

Note: Where errors are displayed on both the 9071 card and network remote con-

trols, the respective indicators and displays are individually described in this

section.

Table 3-4 Troubleshooting Processing Errors by Symptom

Symptom Error/Condition Corrective Action

• DashBoard™ shows Video

yellow icon and Input Invalid

message in 9071 Card Info

pane.

• Card edge Input Format LEDs

show continuous cycling.

Ancillary data (closed captioni ng,

timecode, Dolby

AFD) not transferred through

9071.

9071-OM (V4.0) 9071 PRODUCT MANUAL 3-21

®

metadata,

No video input present Make certain intended vid eo sou r ce is

connected to appropriate 9071 ca rd video input.

Make certain BNC cable connections between

frame Rear I/O Module for the card and signal

source are OK.

• Control(s) not enabled • Make certain respective control is set to On or

Enabled (as appropriate).

• VANC line number conflict

between two or more

ancillary data items

• Make certain each ancillary data item to be

passed is assigned a unique line number (see

Ancillary Data Line Number Locations and

Ranges on page 3-6).

Page 46