Page 1

1601 J. P. Hennessy Drive, LaVergne, TN USA 37086 615/641-7533 800/688-6359 www.ammcoats.com Manual Part No.: 8184554 01

HENNESSY INDUSTRIES INC. Manufacturer of AMMCO

®

, COATS®and BADA®Automotive Service Equipment and Tools. Revision Date: 01/05

Nitrogen Inflation System

Kit 8184553

For use with COATS Model Series Tire

Changers for Adding Nitrogen to the

Tire Changer as the Inflation Gas

®

Installation Instructions

with Parts Identification

READ these instructions before placing unit in

service KEEP these and other materials delivered

with the unit in a binder near the machine for

ease of reference by supervisors and operators.

Disclaimer

This is a supplemental instruction for handling nitrogen inflation systems and does not cover the safe operation of the machine, tire/rim

match, or evaluation of safe wheels and tires, or instructions covering

the safe inflation processes. If you need copies of operating instructions

call 1-800-688-6359 or refer to the internet at www.ammcoats.com.

: Do not exceed the design pressure of the equipment

when attaching a separate nitrogen gas inflation supply to the tire

changer. If the nitrogen gas pressure exceeds the design pressure of the

machine, the pressure relief valve will activate continuous; if the pressure

relief is increased, the machine is operating above the design pressure

and could create a hazardous condition.

For reference:

COATS tire changer models 90XX have a system designed for 145 PSI max-

imum input pressure.

COATS tire changer models 30XX, 40XX, 50XX, 60XX, and 70XX have a sys-

tem designed for 175 PSI maximum input pressure.

To comply with this requirement, a small (1/4-inch) adjustable pressure regulator may be required in series with the nitrogen input system; one is available from COATS as p/n 8183424, or Grainger p/n 4ZM14 (0-150 PSI

adjustable). Use the gauge on the tank to set the pressure.

CAUTION

Page 2

Parts Identification for the Nitrogen

Conversion Kit 8184553

Item Part No. Qty. Description

1 8120408 1 1/4-inch Bolt

2 8182090 1 1/4-inch ID Rubber Hose by 60-

inch long

3 8101428 3 Hose Clamp

4 8120344 1 1/4-inch NPT Plug

5 8000378 2 1/4-inch Barbed Fitting

Other Parts Required Per Location: The installer is

responsible for furnishing the correct matching quick

connector to the nitrogen source. This will normally be

the male end with either male or female 1/4-inch NPT.

Converting Standard COATS®50xx, 60xx,

or, 70xx Tire Changer To Nitrogen Tire

Inflation

Before beginning this modification or attempting any

maintenance, remove the electrical power and air

source from the machine; also, bleed off any stored

compressed air by exhausting through the air blast foot

valve.

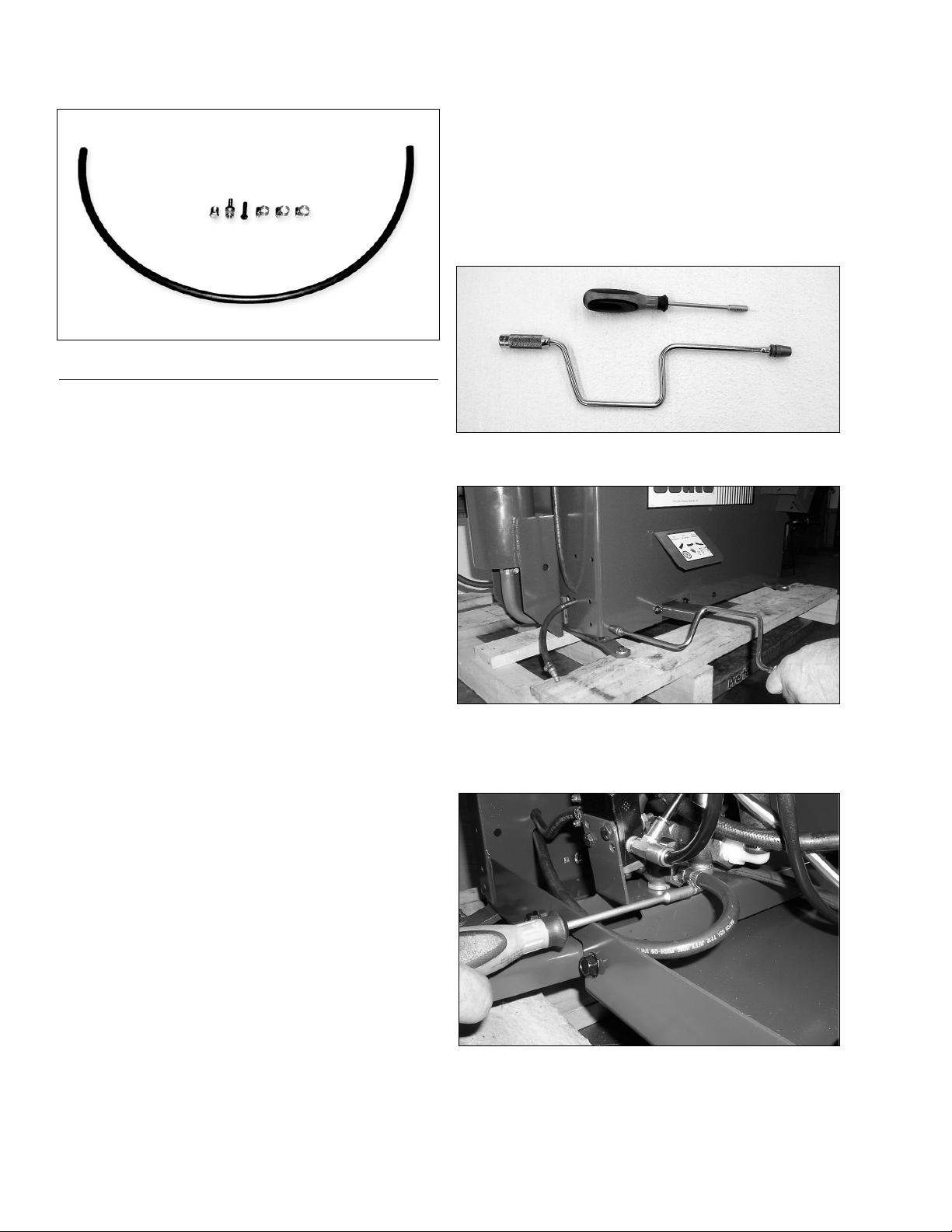

Tools Required: Speed Handle with 3/8-inch Socket,

Spinner Handle 1/4-inch

1. With the speed handle and 3/8-inch socket,

remove the machine’s side panel.

2. Using the 1/4-inch spinner handle, loosen the hose

clamp and remove the rubber hose that is attached to

the upstream side of the 1/4-inch valve. This is the hose

between the 1/4 and 3/4-inch valve.

2

Page 3

3. With the hose that was just removed, from the kit

insert a 1/4-inch bolt into the hose end and using the

1/4-inch spinner handle, tighten the hose clamp. This

will prevent air pressure from escaping at the 3/4-inch

valve.

4. Next, using the length of hose from the kit, route

the hose through one of the holes in the back of the

chassis. Position the hose over the fitting on the 1/4inch valve and tighten the hose clamp from kit. At opposite end of the hose, install quick coupling fitting as

required for connection to nitrogen.

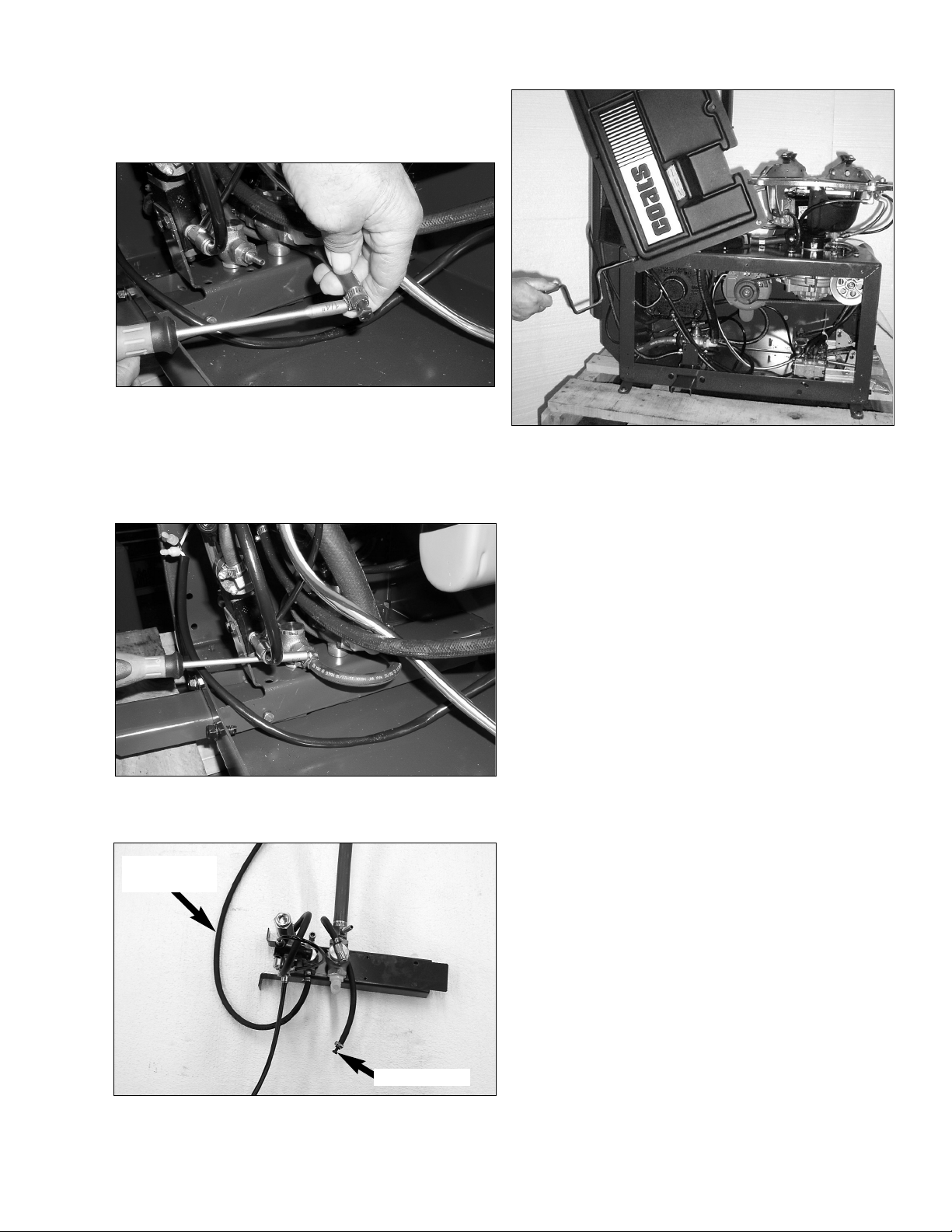

5. This is a diagram of the changes with the valve system removed from the chassis for clarity.

6. Replace the side pane.

7. Reconnect the air pressure supply to the machine

and the nitrogen supply to the machine and inspect for

leaks. If no leaks exist, test the machine for full function

before returning the machine to operation.

3

Plug In Hose

New Hose

for Nitrogen

Page 4

Converting Standard COATS®9010 or 9024

Tire Changer To Nitrogen

Before beginning this modification or attempting any

maintenance, remove the electrical power and air

source from the machine; also, bleed off any stored

compressed air by exhausting through the air blast foot

valve.

1. Tools required: two six inch adjustable wrenches.

2. On the right rear of the machine, locate the filter-

lubricator system and note the tee fitting on the input

side of the filter. The clear tubing represents the inflation system inside the tire changer and the black tube

represents the operational system of the machine.

3. Using the wrench to move the tube furrel toward

fitting, pull out on the clear plastic tube and remove

from the ELL fitting.

4

Page 5

4. Next, remove the ELL fitting and replace with the

1/4-inch NPT pipe plug fitting from the kit.

5. Next, install the clear plastic tube to the ELL.

Install a quick coupling fitting as required for connecting

to nitrogen. Connect the nitrogen supply and observe

the input pressure in the surge tank from the gauge

mounted on top of the tank. If the pressure exceeds

150 PSI, a pressure regulator must be added to prevent

the pressure relief from continuous activation caused

by the over pressure.

Pressure Gauge on Surge Tank

Nitrogen connection without regulator.

6. A pressure regulator to reduce the input nitrogen

pressure is available from COATS as p/n 8183424 or

one can be purchased from “Grainger” as p/n 4ZM14

(0-150 PSI adjustable). After installing the regulator,

adjust the pressure for a reading of 145 PSI on the

surge tank gauge.

A pressure regulator is directional sensitive

and must be installed correctly to adjust

pressure.

Nitrogen connection with in-line regulator.

7. Reconnect the air pressure supply to the machine

and the nitrogen supply to the machine and inspect for

leaks. If no leaks exist, test the machine for full function

before returning the machine to operation.

5

CAUTION

Page 6

Converting Standard COATS®40-50 Tire

Changer To Nitrogen Tire Inflation

Before beginning this modification or attempting any

maintenance, remove the air source from the machine;

also, bleed off any stored compressed air by exhausting

through the air blast foot valve.

Tools Required: Speed Handle, 3/8-inch Socket, 9/16inch socket, Spinner Handle 1/4-inch, Knife, 12-inch

Adjustable Wrench.

1. To start, remove both the front and rear side panels from the machine. This requires the speed handle

and the 3/8 inch and the 9/16 inch sockets.

2. On the front side of the machine, remove the inflation pedal by rotating the pedal upward and sliding to

the left.

3. Remove the nylon tube from the repeater valve by

pressing the brass tube furl toward the fitting and

pulling outward on the nylon tube. The opposite end of

this tube is attached to the 1/4-inch brass poppet inflation valve.

4. With an adjustable wrench, loosen and remove the

nut holding the top 1/4-inch brass inflation valve. Next,

remove the nut holding the lower 3/4-inch inflation

valve. Note that each valve has a spacer between the

chassis and the valve; take care not to misplace these

as they must be used when reinstalling the valves.

6

Page 7

5. From the back side of the machine, manipulate the

1/4-inch valve through the access opening. Next, cut

the 1/4-inch rubber hose supplying air to the valve. This

hose is between the 1/4-inch brass valve and the 3/4inch brass valve.

6. Using the 1/4-inch bolt (from kit), insert it into the

cut hose and with the hose clamp (from kit) secure the

bolt inside the hose. This will prevent air escaping at the

3/4-inch valve.

7. With wrenches, remove the cut hose from the

valve fitting. Next, install the new length of hose from

kit into the valve with clamp (from kit) and tighten.

Route the opposite end of the hose to the end of the

machine for connection to the nitrogen supply service.

8. Next, reposition the 3/4-inch valve with spacer and

install the retaining nut; do not over tighten the nut.

Next install the 1/4-inch valve with spacer and route the

black plastic hose as before to the foot valve end of the

machine.

9. Reattach the black plastic hose to the repeater

valve.

7

Page 8

8184554 01 01/05 © Copyright 2004 Hennessy Industries and COATS All Rights Reserved Printed in USA

10. Replace both side panels. Install a quick coupling

fitting as required for connecting to nitrogen.

11. Reconnect the air pressure supply to the

machine and the nitrogen supply to the machine and

inspect for leaks. If no leaks exist, test the machine for

full function before returning the machine to operation.

Loading...

Loading...