Page 1

APS 3000

Center Post Tire Changer

For servicing single piece automotive

and most tubeless light truck

tire/wheel assemblies.

Any other type, including tube type agricultrual, require

special handling. Tires identifi ed as truck tires need to

adhere to OSHA standard 1910.177.

See

RIM Safety page 4

ÌOperating

Instructions

on page 6.

Operation Instructions

Safety Instructions

Set Up Instructions

Maintenance Instructions

READ these instructions before placing unit in

service. KEEP these and other materials delivered

with the unit in a binder near the machine for ease

of reference by supervisors and operators.

1601 J. P. Hennessy Drive, LaVergne, TN USA 37086 615/641-7533 800/688/6359 www.coatsgarage.com Manual Part No.: 85610910 00

HENNESSY INDUSTRIES INC. Manufacturer of AMMCO

®

, COATS® and BADA® Automotive Service Equipment and Tools. Revision: 3/17

Page 2

Table of Contents

General Information ................................................ iii

General Safety Instructions .................................... iii

Tire Specifications Diagram .................................... iv

Safety Instructions ................................................... v

Owner’s Responsibility .........................................v

Operator Protective Equipment ............................v

Definitions of Hazard Levels..................................v

Specifications ........................................................... vi

Connections .........................................................vi

Working capacity ..................................................vi

Layout Details ......................................................vi

Safety Devices .......................................................... 1

Safety Notices and Decals ....................................... 1

Warning Decal Placement .................................... 2

Remember R.I.M. ...................................................... 4

Principal Operating Parts ......................................... 6

Pneumatic Systems ............................................. 8

Description of the Machine Controls ...................... 9

Installation ............................................................ 9

Space required for positioning ............................. 9

Tire-Changer placement and connections ............ 9

Connection to the Compressed Air Supply .......... 9

Transport ..................................................................10

Unpacking ................................................................10

Set Up .......................................................................11

Wheel Clamping Operation with Smart Lock ...... 12

Wheel Unlocking ................................................ 12

Tightening Adjustment ....................................... 12

Positioning the Valve .......................................... 13

Tire Classification ................................................... 13

Tire Pressure Monitoring System (TPMS) ............ 14

Bead Loosening ...................................................... 15

Upper Bead Loosening ....................................... 15

Lower Bead Loosening ...................................... 16

Match Mounting ................................................. 16

Tire Demounting ..................................................... 17

Upper Bead Demounting ....................................17

Lower Bead Demounting ................................... 18

Tire Mounting ......................................................... 18

Lower Bead Mounting ........................................ 18

Upper Bead Mounting ........................................ 19

Inflation ................................................................... 20

Stages of Inflation .............................................. 21

Mismatched Tires and Wheels ........................... 22

Tubeless Tire Inflation ......................................... 23

Standard Accessories ............................................. 24

Optional Accessories .............................................. 26

Maintenance ........................................................... 27

Standard Maintenance ....................................... 27

Machine Overhaul .............................................. 28

Troubleshooting Chart ........................................... 29

RIM Chart ................................................................ 32

NOTICE

Read entire manual before assembling,

installing, operating, or servicing this

equipment.

ii • Important: Always read and follow operating instructions.

Page 3

General Information

The tire changer is designed to demount and mount tires of passengers cars and light commercial vehicles with

rims from 10” to 34” (254 - 863 mm) and maximum tire diameter of 47” (1200 mm).

The tire changer is designed to demount and mount conventional tires, as well as new generation types, such

as “self-supporting” RUN-FLAT and low profiled tires, with steel and/or light alloy rims.

The tire changer is NOT suitable for demounting inflated or dirty tires, to straighten rims or to remove wheel

bead wires. As a consequence, all these procedures are FORBIDDEN.

General Safety Instructions

The tire changer is to be used exclusively by qualified and authorized personnel.

A qualified operator is someone who fully understands the instructions described in this manual supplied by the

manufacturer, who has been specifically trained and who is aware of safety standards at the workplace.

Those in charge of using the machine shall not be under the influence of drugs, alcohol or other substances,

which could compromise their physical and mental work capabilities.

For greater safety, operators shall wear protective footwear, gloves, protection goggles and shall NOT wear any

form of clothing that could get caught in machine or restrict the operator’s movements.

The operator must be able to:

• Read and understand the danger warnings.

• Understand the characteristics of the machine.

• Keep unauthorised people away from the work area.

• Make sure the machine is started in full observance of all the applicable safety standards and regulations.

• Make sure all operators are familiar with the machine and how to use it safely and correctly.

• Avoid touching moving parts or pressurised parts without first disconnecting the machine from the

electrical and air power supply.

• Read and ensure full comprehension of the use and maintenance manual to be able to use the machine

correctly and safely.

• Keep the use and maintenance manual with care in an easily accessible place, so that it can be consulted

whenever needed.

The tire changer may only be used by specifically trained and authorized personnel.

Tampering or modifications to the equipment that are not authorised in advance by the manufacturer, relieve the

latter from all forms of liability as regards to damages deriving from or referable to such actions.

Removal or tampering with the safety devices provides grounds to immediately cancel the warranty and in-

volves violation of State and Federal OSHA regulations and codes.

The tire changer is equipped with informative and warning decals which are designed and made to last.

If they should deteriorate, user may request replacement decals.

Important: Always read and follow operating instructions. • iii

Page 4

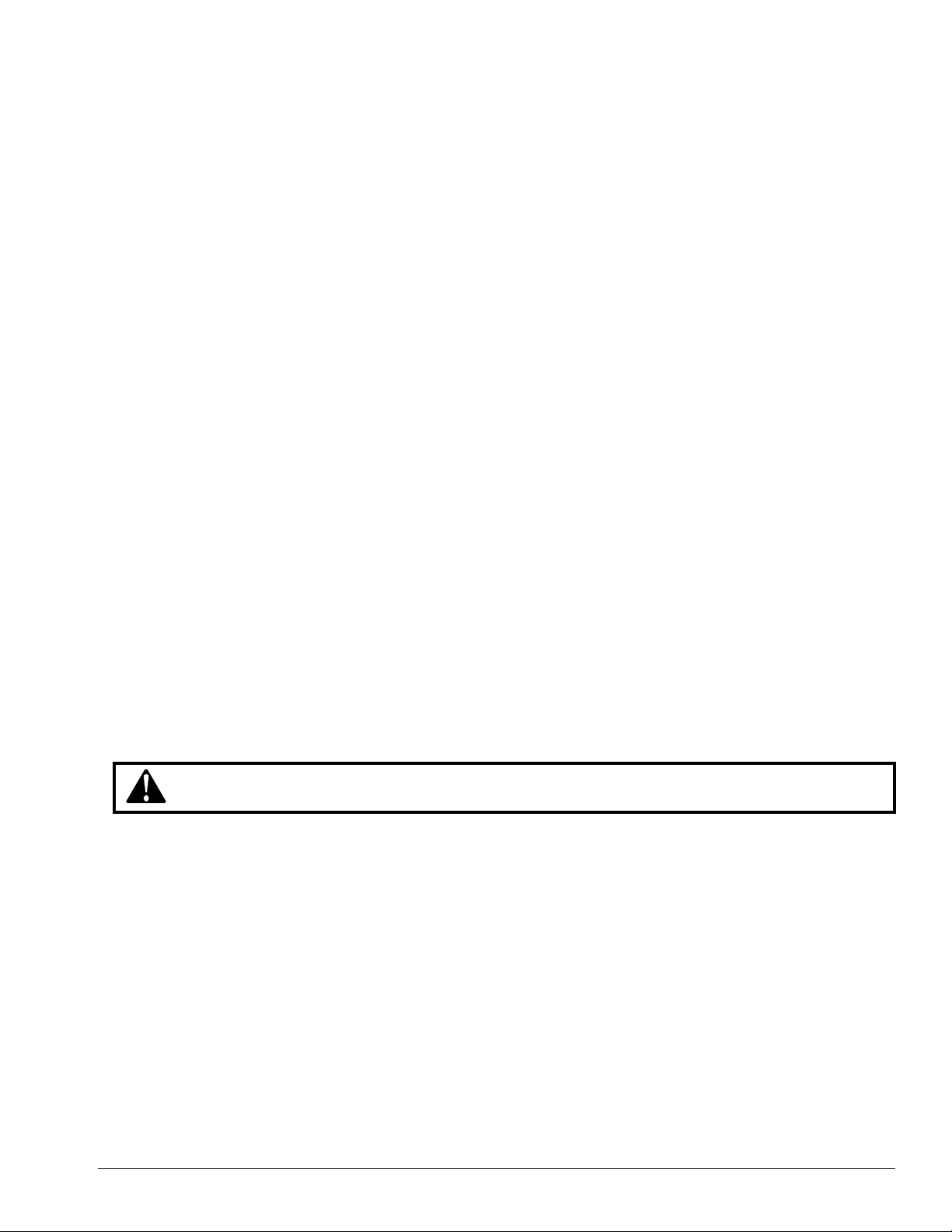

Tire Specifi cations Diagram

Nominal width of

tire in millimeters

Passenger

car tire

Max.

permissible

inflation

pressure

Radial

Ratio of height to

width (aspect ratio)

1

2

P

E

L

A

P

0

S

3

A

I

D

A

R

I

1

D

A

O

L

.

X

A

N

O

I

T

E

R

I

T

A

E

R

N

U

T

A

M

A

R

E

P

M

X

E

R

P

.

A

M

5

3

.

S

S

E

S

B

L

0

T

5

M

C

Rim diameter

code

Load index &

speed symbol

U.S. DOT tire

1

R

5

6

/

S

S

E

L

E

B

U

T

D

R

O

C

X

A

R

T

0

2

5

9

5

H

0

A

R

3

W

T

6

T

R

E

A

S

I

D

E

D

O

T

M

A

L

9

A

B

C

L

L

2

P

L

I

E

S

2

X

X

X

X

E

A

D

W

E

A

2

R

identification number

M

+

S

D

4

P

L

I

E

S

X

X

X

C

O

R

D

M

A

2

X

X

N

U

F

A

C

T

U

R

E

R

Severe snow

conditions

Tire ply

composition

and materials

used

Treadwear, traction

and temperature grades

iv • Important: Always read and follow operating instructions.

Max. load rating

Page 5

Safety Instructions

Owner’s Responsibility

To maintain machine and user safety, the responsibility

of the owner is to read and follow these instructions:

• Follow all installation instructions.

• Make sure installation conforms to all applicable

Local, State, and Federal Codes, Rules, and Regulations; such as State, Federal OSHA Regulations

and Electrical Codes.

• Carefully check the unit for correct initial function.

• Read and follow the safety instructions. Keep them

readily available for machine operators.

• Make certain all operators are properly trained,

know how to safely and correctly operate the unit,

and are properly supervised.

• Allow unit operation only with all parts in place and

operating safely.

• Carefully inspect the unit on a regular basis and

perform all maintenance as required.

• Service and maintain the unit only with authorized

or approved replacement parts.

Definitions of Hazard Levels

Identify the hazard levels used in this manual with the

following definitions and signal words:

DANGER

Watch for this symbol:

It Means: Immediate hazards, which will result in

severe personal injury or death.

WARNING

Watch for this symbol:

It Means: Hazards or unsafe practices, which could

result in severe personal injury or death.

CAUTION

Watch for this symbol:

CAUTION

• Keep all instructions permanently with the unit

and all decals/labels/notices on the unit clean and

visible.

• Do not override or bypass safety features.

Operator Protective Equipment

Personal protective equipment helps make tire servicing safer. However, equipment does not take the

place of safe operating practices. Always wear durable

work clothing during tire service activity. Loose fitting

clothing should be avoided. Tight fitting leather gloves

are recommended to protect operator’s hands when

handling worn tires and wheels. Sturdy leather work

shoes with steel toes and oil resistant soles should be

used by tire service personnel to help prevent injury

in typical shop activities. Eye protection is essential

during tire service activity. Safety glasses with side

shields, goggles, or face shields are acceptable. Back

belts provide support during lifting activities and are also

helpful in providing operator protection. Consideration

should also be given to the use of hearing protection if

tire service activity is performed in an enclosed area, or

if noise levels are high.

It Means: Hazards or unsafe practices, which may

result in minor personal injury or product or property

damage.

Watch for this symbol! It means BE ALERT! Your

safety, or the safety of others, is involved!

Important: Always read and follow operating instructions. • v

Page 6

Specifi cations

Connections:

Power supply: 230V - 50/60 Hz - 1Ph

Operating pressure: 116 - 145 psi

Air supply pressure regulator set at 145 psi

Inflating air-pressure regulator set at 50 psi

Working Capacity:

Rim clamping range: 12” to 34”

Maximum rim width: 16” (406 mm)

Maximum wheel diameter: 47” (1200 mm)

Layout Details:

Minimum overall dimensions mm: 47” x 51” x 70” (1180mm x 1300mm x 1770mm)

Net weight (optional accessories excluded): 870 lb (395 kg)

Operating temperature range: min 41° to 122° F (5° C max 50° C)

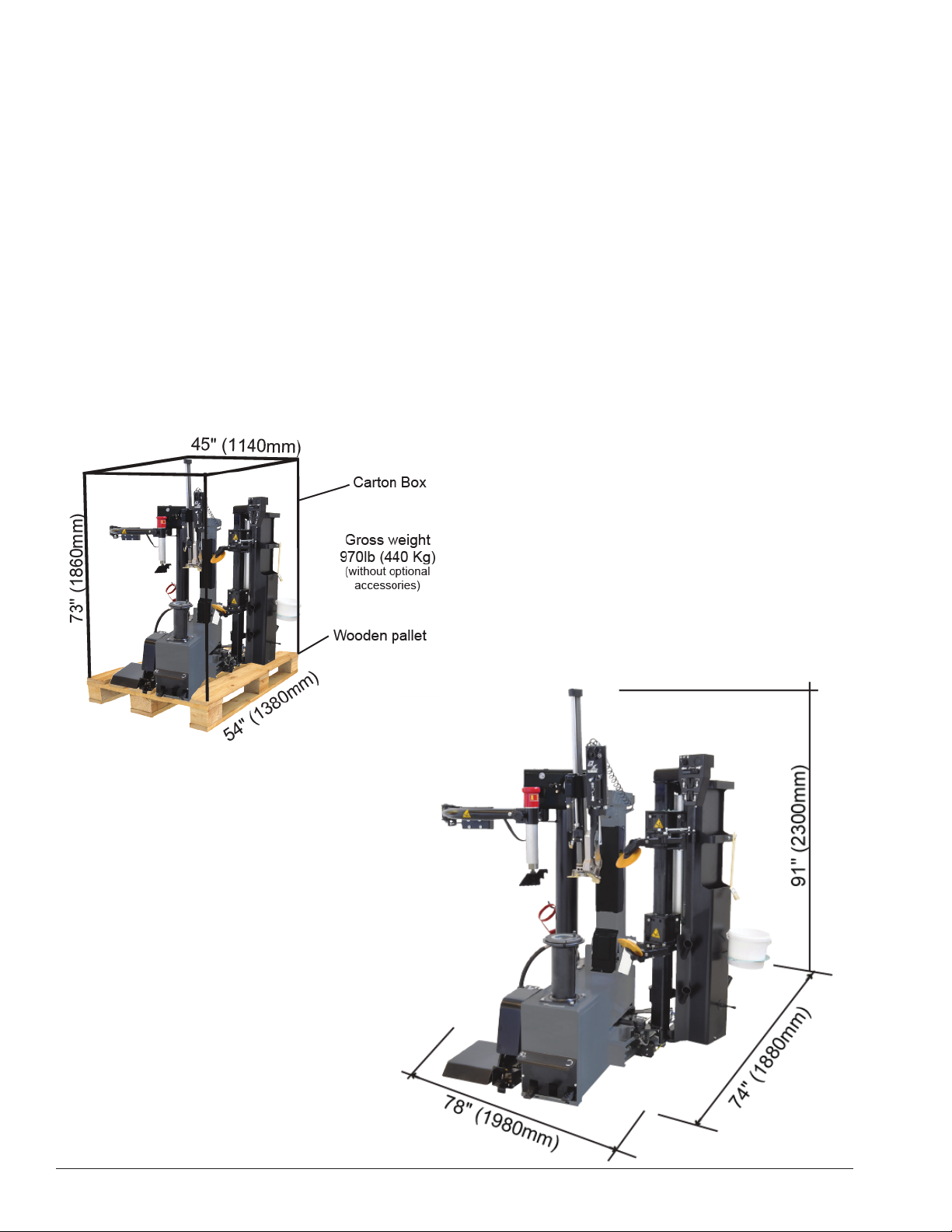

Packing Details

Overall Dimensions

vi • Important: Always read and follow operating instructions.

Page 7

Safety Devices

The tire changer is equipped with safety devices that are designed to guarantee the safety of the machine

operator:

Pneumatic safety valve, arranged inside the machine that prevents the pressure from exceeding 58 PSI

during inflation.

Pressure regulator and gauge that limits the maximum pressure of the circuit to 145 PSI.

Maximum tank pressure valve, fitted on the tank, to prevent the maximum pneumatic pressure from exceeding

160 PSI (optional auxiliary bead seater)

Safety Notices and Decals

Failure to follow danger, warning, and caution instructions may lead to serious personal injury or

death to operator or bystander or damage to property. Do not operate this machine until you read

and understand all the dangers, warnings and cautions in this manual. For additional copies of

either, or further information, contact:

For additional information contact:

Hennessy Industries, Inc.

1601 JP Hennessy Drive

LaVergne, TN 37086

(615) 641-7533 or (800) 688-6359

www.coatsgarage.com

Rubber Manufacturers Association

1400 K Street N. W., Suite 900

Washington, DC 20005

(202) 682-4800

www.rma.org

Tire Guides, Inc.

The Tire Information Center

1101-6 South Rogers Circle

Boca Raton, FL 33487

(561) 997-9229

www.tireguides.com

Important: Always read and follow operating instructions. • 1

Page 8

Warning Decal Placement

Replace any warning label immediately in case of damage or loss.

Do not operate the Tire Changer in case of missing warning labels.

Do not hide any warning label by any means. Do not place objects that can obstruct or reduce the

visual ability of the operator. Refer to the above mentioned codes for ordering warning labels.

2 • Important: Always read and follow operating instructions.

Page 9

Warning Decal Palcement (cont.)

Main Coats

85608119

Front of the machine

Inlet Pressure

8182059

Pinch Point

85610705

Manual Tire Bleed

8183597

Danger Explosion (2x)

8109888 / 8109888Fr

Pinch Point

85609356

Tower

8182373 and FR

Important: Always read and follow operating instructions. • 3

Page 10

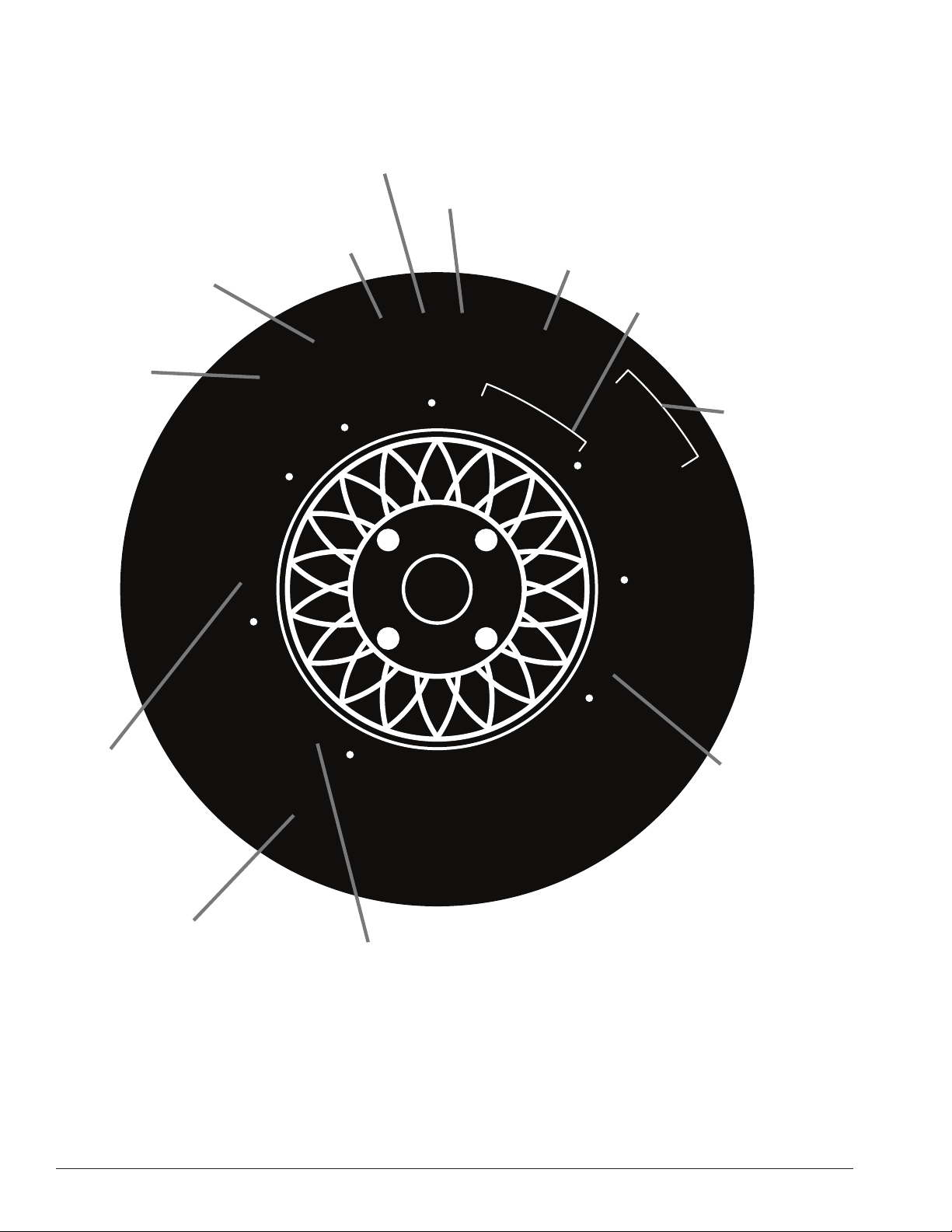

Remember R.I.M.

Three Simple Steps To Help Keep Shops Safe

READ INSPECT MOUNT

R.I.M. is a training program developed by Hennessy Industries to help keep tire technicians safe. By following

the basic principles of R.I.M., technicians can avoid situations that can cause catastrophic accidents like tire explosions.

R.I.M. stands for read, inspect, and mount:

Read the tire size on a new tire before mounting to make sure it is the proper size for the wheel.

Inspect the wheel for cracks, rust, and or other damage that could cause an unsafe situation.

Mount the tire safely, making sure not to put any part of your body over the tire during inflation.

The most serious of possible accidents is a tire explosion. This is often caused by a tire/rim mismatch.

If a tire explodes on a tire changer, pressure causes it to fly straight up at tremendous speed. If a technician is

standing over the tire, he can be seriously injured or killed.

Hennessy’s R.I.M. program allows the technician to avoid situations that can cause tire explosions and other

accidents. The full program, including training videos, brochures, posters, and other materials, are available from

Coats distributors nationwide.

4 • Important: Always read and follow operating instructions.

Page 11

Intentionally left blank

Important: Always read and follow operating instructions. • 5

Page 12

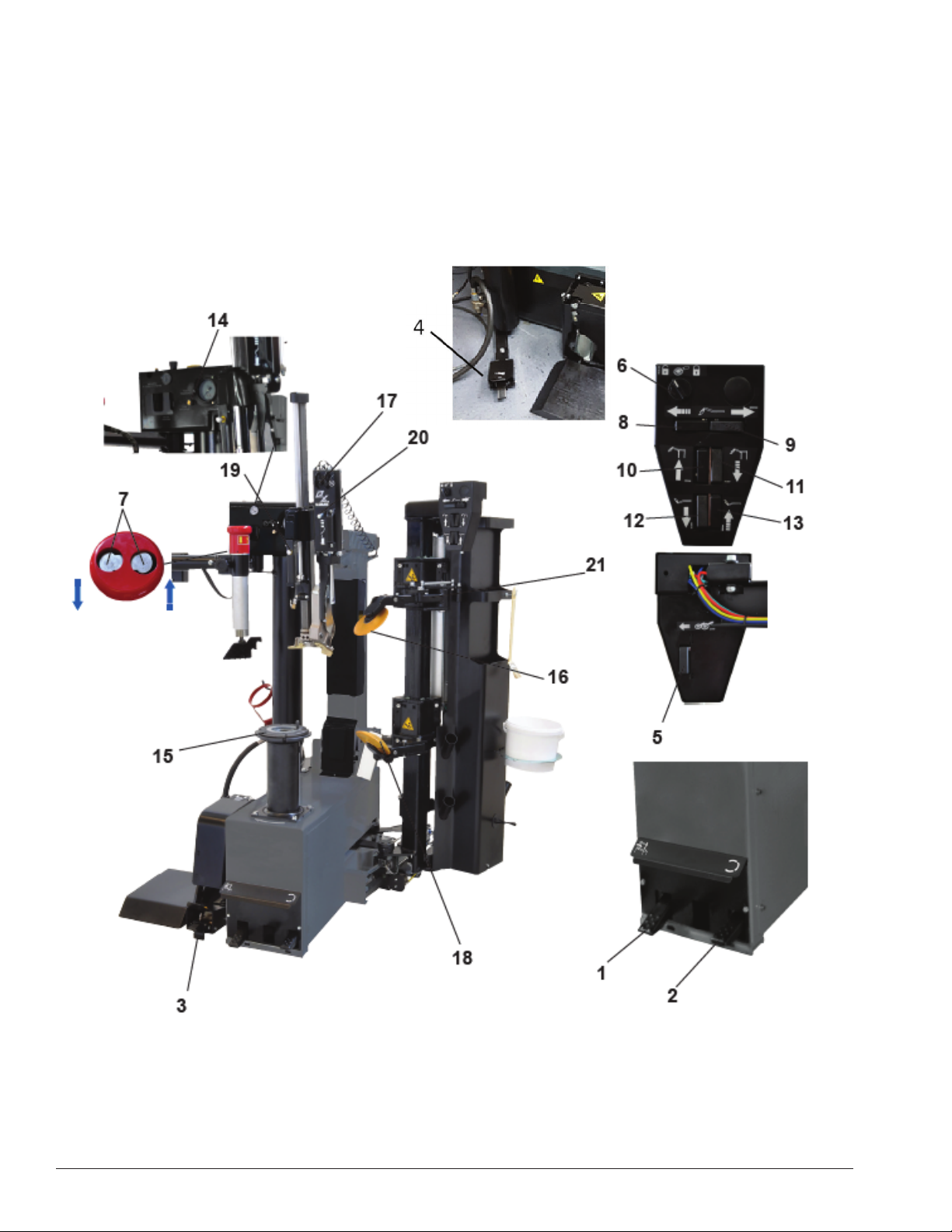

Principal Operating Parts

Do It Now!

Now is a good time to contact product service (800688-6359) to start warranty, otherwise warranty starts

at time of shipment.

Know Your Unit

Compare this illustration with the unit before placing it

into service. Maximum performance and safety will be

obtained only when all persons using the unit are fully

trained in its parts and operation. Each user should learn

the function and location, of all controls.

Prevent accidents and injuries by ensuring the unit is

properly installed, operated and maintained.

6 • Important: Always read and follow operating instructions.

Page 13

CAUTION

Replace any damaged or missing safety decals. They are available from COATS, (800) 688-6359.

1 Tilting tower control pedal

2 Clockwise and counterclockwise clamping chuck (15) rotation control pedal

3 Wheel lifter (optional) control pedal

4 Inflation pedal

5 Button used to activate the “over-run” function of bead loosener disks (16 and 18)

6 Selector used to block the bead breaking carriage and to activate the “over-run” function (5)

7 Bead pressing arm control buttons (up/down)

8 Bead breaking carriage “forwards” movement button

9

Bead breaking carriage “backwards” movement button

10 Upper bead loosener disk lifting button

11 Upper bead loosener disk lowering button

12 Lower bead loosener disk lowering button

13 Lower bead loosener disk lifting button

14 Deflation button

15 Clamping chuck

16 Upper bead loosener disk

17 Lerevless mode control switch

18 Lower bead loosener disk

19 Operating arm control button

20 Leverless tire mounting/demounting system control switch

21 Upper bead loosener arm opening control

Important: Always read and follow operating instructions. • 7

Page 14

Pneumatic Systems

8 • Important: Always read and follow operating instructions.

Page 15

Description of the Machine Controls

Installation

Space required for positioning

When choosing the place of installation be sure that it

complies with current safety-at-work regulations.

The Tire-Changer must be connected to the main

electric power supply and the compressed air system. It

is therefore advisable to install the machine near these

power sources.

The installation area must leave at least the room shown

in picture “fig. 1”, so as to allow all parts of the machine

to operate correctly and without any restriction.

Lighting should be adequate to perform safe operations

and comply with the current regulations for safety at

work.

Tire-Changer placement and connections

Place Tire-Changer onto a flat, smooth and not slippery floor with a suitable load capacity.

The machine need not necessarily be anchored to the ground, but if you prefer to do so, drill 2 deep holes (100

mm) on the ground in correspondance of 2 holes of the machine rear base by using a 10 mm drill bit of suitable

length. Insert the two brackets A and B into the machine base from the front, and drill two holes

the same as previous ones. Insert suitable metal anchor dowels in the holes drilled and secure firmly.

28”

(700mm)

If the machine is installed outside it must be protected by a appropriate lean-to shed. The installation site should

be equipped with an electrical system with an adequate grounding circuit equipped with an appropriate ground

fault 16A circuit breaker, power indicator light, placed in a visible and accessible place by the operator.

NOTE: If the machine is supplied without the electrical plug, the user shall install a 20A plug suitable for the

voltage of the machine and complies with current regulations.

Before connecting the machine, ensure pneumatic and electrical supplies meet those indicated

on the machine’s data plate.

• Even small electrical system jobs must be performed out by qualified personnel.

• The Manufacturer is not responsible for damages caused by electrical connection different from

those on the machine’s data plate.

• Unplug the unit from electrical and pneumatic supplies before moving and servicing.

• During the first connection to the compressed air, attention must be paid to the movement of

certain parts of the machine, which may be sudden and unexpected, creating potential hazards

in the action area.

Connection to the Compressed Air Supply

The pneumatic supply must be a minimum of 116 psi.

Connect the machine to the compressed air supply by the quick

disconnect located at the rear of the machine (Fig. 2).

Important: Always read and follow operating instructions. • 9

Page 16

Transport

The Tire Changer must be transported in its original packaging and kept in the position

indicated on the box.

The packaged machine must be moved with a fork lift of suitable capacity.

Please insert the forks as shown in fig. 1.

Unpacking

Remove the protective cardboard, remove all fixing screw and free the Tire-Changer from its original pallet.

Check the condition of the machine, making sure that no part is damaged or missing, by referring to the picture

on page 10.

If in doubt, please do not use the machine and get in touch with your Distributor for further steps.

Keep packing elements away from children.

All packing elements must be stored in the proper stocking areas.

Note: All the most delicate surfaces of the Tire Changer are coated with a special rust-proof oil.

Some oil traces may leak after coating procedure: please, remove them as necessary.

Use lifting equipment of suitable load-bearing capacity that is able to take the weight of the tire changer.

To lift the machine (fi g. 2), use a transport strap with minimum load-bearing capacity of 970 lb. (440 kg).

After tire changer positioning, take off the transport strap.

After having positioned the machine, in its fi nal

location, remove the accidental tilting safety pin from the

arm (fi g. 3).

Put the pin together with the other standard

accessories delivered with the machine, for any future

need.

10 • Important: Always read and follow operating instructions.

Page 17

Set Up

Connect the machine to the electrical power supply, which must have line fuses and an efficient grounding

system, meeting current standards. It must also be connected to an automatic differential 20A circuit breaker.

NOTE: If the machine is not supplied with an electrical plug, the user shall install a 20A plug that is suitable for

the voltage of the machine and complies with current standards.

Connect the machine to the compressed air supply using the fitting on the lubricator on the back of the

machine.

Loosen the control panel bracket locking cap screw and pivot cap screw, adjust it to a convenient position

for operation, then tighten the cap screw.

Important: Always read and follow operating instructions. • 11

Page 18

Wheel Clamping Operation with Smart Lock

1. Check the correct wheel positioning on the clamping chuck.

Insert SMART LOCK making the centering cone fi t the rim hole

correctly, leaving no space among SMART LOCK nut, the rim and the

Tire-Changer clamping chuck.

2. Keeping the handle pressed down (to avoid residual play),

tilt the locking lever vertically.

3. During wheel clamping operation the Quick-Release system moves

automatically to hooking position (click).

Check the perfect wheel locking onto the clamping chuck before

performing any bead breaking, demounting or mounting operation.

Plastic protection to avoid

any damage to alloy rim

Wheel Unlocking

4. Once the operations on the wheel are completed,

lift up the Quick-Release system outer sleeve.

5. Tilt down the locking lever to unlock SMART LOCK,

in order to pull out the locking nut and remove the

wheel from the clamping chuck.

Tightening Adjustment

The clamping force of SMART LOCK could be loosened after a long time use by a progressive wearing of some

components, this revealed by a progressive slack of the locking lever.

To restore / increase / decrease the SMART LOCK tightening: press the yellow adjustment button and,

by means of the adjustment knob, start turning manually the conical terminal thus acting on the expanding nut.

Then, release the button and keep on turning the conical terminal until the button pops up again.

12 • Important: Always read and follow operating instructions.

Page 19

Positioning the Valve

Fig. 6 shows a rim in the form of a clock. In the following

Mounting and Demounting process steps, you will position

the rim with clock directions, so that the valve and pressure

sensor do not get damaged.

CAUTION

To avoid damaging the valve and pressure sensor,

(if installed) you must always arrange the valve in

the position indicated, following the instructions

when mounting and demounting the tire. fig.6

Tire Classifi cation

LOW PROFILE tires (UHP) are those in which the height (H) and the width (C) have a ratio lower than 0.5 (i.e.

low profile series 45 stands for a ratio of H/C = 0.45).

For tires to be considered as LOW PROFILE (UHP), they must also have a maximum speed code of equal to

or higher than V.

RUN-FLAT tires are those which, even when they have no internal pressure, allow you to continue to drive the

vehicle for a preset number of miles and at a preset speed. These parameters change from one manufacturer to

another. The market currently offers 2 different types of RUN-FLAT tires:

• Those with REINFORCED SIDE (SELF-SUPPORTING) where, thanks to a different mix and a reinforced

structure, the shoulder of the tire is able to bear the weight of the vehicle even when the pressure in the tire

is zero.

• Those with INTERNAL SUPPORT have a ring inside the rim that bears the side of the tire when there is no

pressure inside it. The internal support may be made of plastic or metal.

The tire changer is able to handle all types of LOW PROFILE (UHP) and all types of RUN-FLAT tires with

REINFORCED SIDE; for other types, refer to the specific instructions of the dedicated accessories, if available.

The mounting and demounting procedure is the same, be it a RUN-FLAT tire with REINFORCED SIDE (SELFSUP-PORTING) or a LOW PROFILE tire (UHP).

CAUTION

It is crucial to follow the instructions very carefully in order to avoid irreparable damages to the tire,

which could compromise the vehicle’s safety.

Important: Always read and follow operating instructions. • 13

Page 20

Tire Pressure Monitoring System (TPMS)

TPMS, Tire Pressure Monitoring System is an electronic system designed to monitor the air pressure inside the

tires through special sensors mounted inside the wheels, which provide real-time tire-pressure information and

inside temperature data to the vehicle’s electronic control unit. Tire pressure system alerts the driver when the

tire pressure falls 20% below the recommended pressure, thus increasing your safety on the road.

This chapter describes the correct positioning of TPMS valve during the different working stages, in order to

avoid any damage.

Bead Loosening:

Place TPMS valve at “2:00 o’clock” position.

Start pushing on the tire bead using the upper

bead loosening disk.

Demounting tool positioning:

Place TPMS valve at “2:00 o’clock” position. Bring the

demounting tool into working position. While spinning the

wheel, insert the demounting tool into the drop center

level. Stop tire rotation when the valve reaches 11 o’clock

position.

Upper Bead demounting:

Spin the clamping chuck (clockwise) by pressing pedal 1

until the valve reaches “1 o’clock” position (at about 10 cm

from the demounting tool) so as to avoid possible damages

to the TPMS valve.

Warning: Rim and Tire must spin together as one,

during bead demounting operations, to avoid displacement

of TPMS sensor.

Lower Bead demounting, with demounting tool:

Place TPMS valve below the demounting tool at

“12:00 o’clock” position.

Lower Bead demounting, with bead loosening disk:

Place TPMS valve towards the bead loosening disk.

Lower Bead mounting:

Place TPMS valve at “5:00 o’clock” position, in any case

at about 10 cm from traction point.

Upper Bead mounting:

Place TPMS valve at “5:00 o’clock” position, in any case

at about 10 cm from traction point.

14 • Important: Always read and follow operating instructions.

Page 21

Bead Loosening

Ensure the tire is completely deflated before starting any operation on the wheel.

Before lifting and positioning the wheel onto the clamping chuck, use the proper tool to remove any weights

from the rim, paying attention to not damage the rim.

Before starting any operation, check for the presence of a pressure sensor. If equipped, check its operation with

a dedicated diagnostic tool.

It is possible to unlock the disk support and enable a spring loaded movement, changing the angle of the disk,

increasing its penetration inside the rim. Particularly effective with soft tires.

Upper Bead Loosening

Check the correct centering and locking of the wheel onto the clamping chuck.

Check that the upper disk arm is in the working position.

Turn switch 6 to unlock the bead loosener and position it by pressing buttons 8, 9, 10 and 11 on the

console, so that the distance between the upper disk and the rim edge is 5 mm (fig. 1), then lock the bead

loosener by turning switch 6 again.

Pay special attention to the valve sensor position, if any, during bead breaking operations.

Wrong movements of the bead loosening disks could damage the sensor.

Spin the clamping chuck until the valve is in the

3 o’clock” position.

Lower the bead loosener disk until it touches the tire using

controls 10 for lifting and 11 for lowering.

Start spinning clockwise.

Note: the clamping chuck can spin at 2 different speeds, according to operator’s preferences.

While spinning the wheel, push the upper bead loosener

disk down below the edge of the rim, then press and hold

down the “over-run” function button 5 while gradually lowering the bead loosener disk until the bead is removed from

the rim.

As soon as enough space is available, a proper tire lubricating paste should be carefully applied to both the inner

surface of the rim and the tire bead (fig. 2).

Avoid contacting pressure sensor with lube paste if installed.

Once the bead is loosened, using button 10 to raise the upper bead loosening disk and move away.

Important: Always read and follow operating instructions. • 15

Page 22

Lower Bead Loosening

Keep the bead loosener system set up as for upper bead

loosener disk procedure: the lower bead loosener disk is

always aligned with the upper one, and it is already positioned

at 3-4 mm from lower rim edge.

Lift the lower bead loosener disk until it touches the lower tire

bead using controls 13 for lifting and 12 for lowering.

Rotate wheel clockwise.

While spinning the wheel, push the lower bead loosener disk

up above the edge of the rim, then press and hold down the

“over-run”function button 5 while gradually lifting the bead

loosener disk until the bead is removed from the rim.

As soon as enough space is available, carefully apply tire lube paste to both to the rim inner surface and to the

tire bead (fig. 2).

NOTE: For a better view and control of the lower bead loosening, use the mirror mounted on the main frame.

fi g. 2

While lossening the bead, just press on the bead and never on the side of the tire.

Match Mounting

Driving could be affected by vibrations caused by

deformations of the rim and/or tire. To optimize the

wheel-balancing, it is necessary to position the wheel

onto the Tire Changer again to bead loosen and lubricate

the rim and the tire, spinning the tire around the rim to a

proper position.

Both upper and lower disks make this process easier,

by gently holding the tire steady while the clamping

chuck spins the rim until the correct matching position is

reached.

16 • Important: Always read and follow operating instructions.

Page 23

Tire Demounting

Once the bead loosening process is completed, and the wheel is already positioned on the clamping chuck,

check and ensure its locked and centered.

Upper Bead Demounting

Bring the tilting tower close to the wheel by pressing pedal 1, while simultaneously placing the mounting tool

over the rim edge using the handle (fig. 1). Set the locking button 19 to position 1 (fig. 2) to lower the

operating arm, then lock everything by setting the locking button in position 2. In this way the mounting tool will

automatically move to the right distance from the rim, at about 2 mm.

Rotate the clamping chuck by pressing pedal 2 until the valve is in the “1 o’clock” position (roughly 10 cm dis-

tance from the mounting tool) in order to avoid possible damages to the valve or pressure sensor - if equipped.

Lower the lever 20 to insert the mounting tool between the bead and the rim edge. The mounting tool should

penetrate enough to hook the tire bead to let the operator complete the tire demounting.

Slowly spin the clamping chuck until the mounting tool is positioned correctly. This will facilitate mounting tool

penetration and tire hooking.

By gently pushing the lower bead loosener disk against the tire lower sidewall and the pneumatic bead pressing

arm against the upper sidewall at the “6 o’clock” position, it will be easier to fit the tool into position (fig. 4).

As soon as the bead is perfectly hooked, lift the mounting tool using the

lever 20 to pull out the bead.

To make the lifting easier, set the bead pressing arm at “6 o’clock”

position and press the sidewall (fig. 4) using pneumatic bead pressing

arm.

Press down pedal 2 to rotate the wheel clockwise until the upper bead is

completely off the wheel rim.

NOTE: Rim and Tire must spin together as one. To help the upper bead off

the Rim and reduce the stress to the Tire, insert the plastic lever

(fig. 5) and spin the wheel clockwise while lifting the tire with the lower

bead loosener disk.

Important: Always read and follow operating instructions. • 17

Page 24

Lower Bead Demounting

Press pedal 1 to move the mounting arm away from the

working position.

Before pulling out the lower bead, spin the clamping chuck

to let the valve reach “1” or “2” o’clock position in order to

avoid possible damages to the valve and the pressor sensor

- if equipped.

Raise the lower bead loosening disk to lift the tire until the

lower bead is 1 cm over the upper rim edge (fig. 1).

Spin the wheel clockwise until the tire is completly off Rim.

Check the pressure sensor - if equipped - and replace if

necessary.

NOTE: Rim and Tire must spin together as one.

To help the lower bead off the Rim and reduce the stress to the Tire,

insert the plastic lever and spin the wheel clockwise while lifting the

tire by the lower bead loosener disk.

Tire Mounting

Check the rim and the tire carefully, as per instructions on pg. 4.

If the rim has been removed, lock it again onto the centrer plate

per instructions on pg. 12.

Carefully lubricate the whole inner surface of the Rim and the

beads of the Tire, both externally and internally around the

circumference, for a width of at least 3 cm.

Avoid contacting pressure sensor with lube paste if equipped.

Lower Bead Mounting

Put the Tire on the Rim with it tilted at “12 o’clock” position in

order to make both upper and lower beads go under the upper rim

edge.

Press pedal 1 to approach the mounting arm and position the

mounting / demounting tool on the Rim edge.

Incline the tire down at the “3 o’clock” position, driving the lower

bead on the mounting tool in order to put the lower bead over its

left side and under it on its right side.

Rotate the wheel clockwise by pressing the pedal 2, while

pressing the tire manually at “5 o’clock” position until the lower

bead reaches the drop center level. Keep the tire pressed while

rotating up to “8 o’clock” position to complete the lower bead

mounting.

18 • Important: Always read and follow operating instructions.

Page 25

Upper Bead Mounting

Keep the mounting arm and the mounting tool in working position and proceed with mounting of the upper

bead, then put the tire bead on the rim slightly tilted down to “3 o’clock” position, so that the upper bead rests

on the left side and under the right side of the mounting tool (fig. 1).

Bead correctly positioned over the left side of the

mounting tool and under it on its right side.

Press the pedal 2 to rotate the wheel clockwise, contemporarily press the tire manually from “5 o’clock”

position to force the upper bead at drop-centre position. Keep it pressed while rotating up to “8 o’clock” position

to complete the upper bead mounting (fig. 2).

It is advisable to use the pneumatic bead pressing arm (fig.2) for standard tires that are particularly difficult to

bead loosen. (fig. 3).

Press the buttons (fig. 4) to use using the bead pressing tool to push on the tire bead at “5 o’clock” position,

press pedal 2 and rotate the tire until it is completely mounted. Once the bead has been mounted, the bead

pressing tool will automatically return to the rest position.

Bead correctly positioned over the left side of the

mounting tool and under it on its right side, thus it

can be slightly lowered for easy tire mounting.

Ensure that the Rim and Tire always spin together.

Important: Always read and follow operating instructions. • 19

Page 26

Infl ation

NEVER exceed tire manufacturer's recommended air pressure. Tires can explode,

especially if inflated beyond these limits.

Use clip-on air chuck, keep hands, arms

and entire body back from inflating tire.

Avoid distraction during inflation. Check

tire pressure frequently to avoid over inflation. Excessive pressure can cause tires to

explode, causing serious injury or death to

operator or bystander.

Manual Release Valve

If you change tires defined as truck tires,

they must be inflated per OSHA instructions.

1. Ensure both beads are seated. When both beads

are seated, the tire is ready for inflation.

2. Replace the valve core if it was removed.

3. Depress the inflation pedal to position 2 to inflate

the tire. The pressure limiter will cycle the air flow as

described earlier. On most tires, the pressure limiter

will cease air flow at approximately 60 PSI. On smaller

volume tires the pressure may be higher.

4. Release air pressure from tire by pressing the

manual deflation button (fig. 27). Inflation hose must

be attached to the valve stem. Never add or adjust tire

pressure using an air hose without a clip-on air chuck

and in-line valve. Do not use a hand-held style chuck

(figure 28).

5. Important: When inflating tires that require more

than 60 PSI, always use a safety cage and air hose with

a clip-on air chuck and in-line valve. The air hose must

have enough length between the chuck and the operation/in-line valve to allow the operator to stand outside

the trajectory.

Figure 27 - Location of Deflation Button

Figure 28 - Do Not Use a Hand-held Style Air Chuck

Explosion Hazard

Never exceed 40 PSI while

seating beads. If you use

more than 40 PSI always

use safety cage.

Remember R.I.M.

(see page iv and back cover)

Explosion Hazard

Never infl ate tire

above

manufacturer’s

recommended

pressure after

bead is seated.

20 • Important: Always read and follow operating instructions.

Page 27

Stages of Infl ation on a

Conventional Tire and Rim

Review these descriptions and diagrams carefully. Refer to them as

necessary during bead sealing, bead seating, and inflation to verify that

you are proceeding properly and safely.

Bead Sealing

Bead sealing is the process of capturing air pressure between the

tire and the rim. The tire will usually contain about 1/2 to 2 PSI at initial

bead seal.

Bead Seating

Bead seating usually occurs on the long tapered side of the wheel

first and the shorter side last. Bead seating will usually require at least

7 PSI in the tire. 40 PSI is the maximum safe pressure at this stage

regardless of tire operating pressure. For tires requiring more than 40

PSI to bead seat use safety cage.

Most European import cars and many aftermarket alloy wheels are

very tight and can be difficult to bead seat. Also note that asymmetrical

hump and run-flat tires are extremely difficult to bead seat. Follow tire

manufacturer’s recommended procedure for bead seating.

Inflation

After the beads are seated, the tire is ready to be inflated. Do not

inflate the tire above the manufacturer’s recommended pressure as

stamped on the tire sidewall. The typical inflation pressure for automobile tires is between 24 and 45 PSI. Light truck inflation pressure

typically covers a wider range.

Important: Always read and follow operating instructions. • 21

Page 28

Mismatched Tires and Wheels

Never mount and inflate mis-matched tires and

wheels.

Mismatched tire and wheel combinations will explode,

if you attempt to force a bead seat, causing personal

injury or death to operator and/or bystanders.

22 • Important: Always read and follow operating instructions.

Page 29

NOTE: Sometimes, regular inflation may not be enough to seat the bead of tubeless tires.

This problem may be solved by using the optional accessory TUBELESS INFLATING DEVICE.

Tubeless Tire Infl ation

In order to properly use the optional Tubeless Inflating Device:

Press the safety valve against the rim border, push the activating

button on the handle to blast air and press the inflating pedal 4

to provide air to the wheel valve.

During the inflation stages (and especially during the bead seating operation), you must wear

appropriate personal protective equipment to protect your hearing from possible blast injuries

and from noise levels that sometimes exceed the permitted threshold.

Also use appropriate protection equipment to protect your eyes from possible debris that might

fly due to the high pressure air involved in tire bead seating.

Due to the high pressure air that comes out of the jet when operating the inflating device,

hold the handle firmly with your hand to avoid any backlash.

Important: Always read and follow operating instructions. • 23

Page 30

Standard Accessories

Lube Paste Bucket

(PN 8183710)

Brush

(PN 85000850)

Plastic protections for mounting/demounting tool

(PN 85000850)

Plastic protections for Smart Lock centering cone

(PN 89231516)

Rubber protections for clamping chuck

(PN 89231517)

Plastic protections for clamping chuck driving pin

(PN 89231518)

Plastic cone Ø 70 mm for clamping special alloy rims

(PN 83040730)

Manual Bead Depressor

(PN 89237711)

Bracket Pin

• pin (PN 83036303)

• washer (PN 83040636)

• nut (PN 84394168)

24 • Important: Always read and follow operating instructions.

Page 31

Standard Accessories (cont.)

Adjustment knob for Smart Lock

(PN 82041474)

Cleaning brush for Smart Lock and clamping chuck inner surface

(PN 84292291)

O rings for Smart Lock

• (1) (PN 84293252)

• (2) (PN 84298601)

Air lubricator, air filter/water trap

(PN 82041007)

Wheel lifter for wheel positioning and centering onto

clamping chuck. Lift capacity: 176 lb. (80 kg.)

(PN 89240910)

Tubeless Inflation Device external kit

(PN 89241008)

3 Pin Extensions

• (1) 33mm (PN 83032133)

(2) 72mm (PN 83031335)

•

Important: Always read and follow operating instructions. • 25

Page 32

Optional Accessories

Wheel clamping adaptor, allows clamping reverse mounted

wheels, wheels with no center hole and special wheels (BMW

rims). Suitable to lock any rim with any holes-number onto the

clamping chuck. (PN 89242832)

Reverse mounted wheels Wheels with no center hole Special rims

Truck cone kit, allows clamping VAN and LCV wheels

with center hole diameter from 110 to 190 mm.

(89219117)

Truck cone kit, allows clamping VAN and LCV wheels

with center hole diameter from 140 to 220 mm.

(89219126)

Double face cone for light trucks, allows clamping

VANs and LCVs wheels with center hole diameter

from 75 to 145 mm. (89234456)

Cone for thin steel rims and center hole diameter

from 75 to 120 mm. (89233680)

26 • Important: Always read and follow operating instructions.

Page 33

Maintenance

Standard Maintenance

Routine maintenance according to the following instructions is of crucial importance to ensure the correct

operation and lasting life of the Tire Changer.

Unplug the unit from electrical power source and compressed air supply before servicing it.

Release the compressed air from the circuit by pressing the deflation button 14 for a few seconds.

On daily basis, keep the machine clean of any dirt to ensure the smooth movement of slides,

carriages, and tools and to ensure the correct functioning of clamping chuck and locking systems.

On daily basis, check for worn or damaged plastic mounting tool inserts and plastic and rubber

protections in order to protect alloy rims.

In case of wear or damage, replace them with new inserts and new protections.

Every 2-3 days, check the oil

dropping into the cup (1 drop

every 4-5 activations of the bead

pressing arm or of the bead

loosening system). If necessary,

turn the screw on the top of the

cup with a screwdriver.

Periodically check the oil level which should be kept above

the container trasparent part.

If necessary, unscrew the cup

and topoff by adding oil for

pneumatic systems.

(Chevron Regal® R&O 32)

For long lasting correct

functioning of the pressure

limiter device, check on

regular basis and discharge

the condensation when

needed.

If necessary, drain the

condensation by turning the

drain tap clockwise (keep

the pneumatic supply ON to

perform this adjustment).

On monthly basis, unplug

the machine from pneumatic supply and remove

the filter cup to clean it of

possible solid impurities.

On periodical basis, clean the sliding guides of the bead loosener carriage with naphtha and lube them with oil

or proper grease. Perform the same cleaning and lubricating actions on every junction and mechanical slide.

On periodical basis, check the tensioning of clamping chuck rotation driving belt. If necessary, use a 13mm

wrench to loosen the mounting bolts of the motor support plate, then adjust the belt tension by turning the

tensioning screw and retighten the mounting bolts.

Important: Always read and follow operating instructions. • 27

Page 34

Maintenance (cont.)

The regular cleaning and lubrication of the SMART LOCK

components help ensure long-lasting functioning of the machine.

The replacement of the O-Rings is recommended every

12 - 18 months of SMART LOCK use.

Machine Overhaul

Overhaul maintenance must be carried out by factory authorized personnel ONLY.

Defective parts should be replaced with authorized or approved replacement parts by factory authorized service

personnel.

After 5 years from installation date, the Tire Changer must have all of its main components serviced to ensure

correct functioning and operators safety.

The Manufacturer is not responsible for claims due to non-original spare parts

or for damages caused by removal and tampering to the safety devices.

Removal or tampering with the safety devices (i.e. max. pressure limiter,

pressure regulator) represents a breach of warranty.

28 • Important: Always read and follow operating instructions.

Page 35

Troubleshooting Chart

PROBLEM CAUSE SOLUTION

The clamping chuck does not rotate 1) The power supply is missing;

2) Machine has not plugged

correctly;

3) The fuses have blown;

4) The belt is loosened or broken;

5) The motor pulley is unscrewed;

6) The motor drive is not working

properly;

7) The motor is defective or

damaged.

After the foot control releasing, the

clamping chuck motor rotates at one

speed only or just in one direction

The clamping chuck motor rotates at

one speed only or just in one direc-

tion

The clamping chuck rotates but the

wheel stays still

1) The foot-control has not been

set up or adjusted correctly;

2) The micro-switches screws are

unscrewed or missing;

3) The micro-switch is damaged or

defective;

4) The foot control spring is

damaged or loosened;

1) The micro switch is damaged or

defective;

2) The micro switched is not

connected properly;

3) The motor is damaged;

4) The motor wires are not

connected.

1) Smart Lock system is not

clamping

2) The driving pin is not holding.

1) Check the wall socket;

2) Check the machine plug is

connect properly or if the plug

wires are well connected.

3) Replace the fuses;

4) Tension or replace the belt;

5) Tighten the pulley screw;

6) Re-connect the foot control;

7) Replace the motor.

1) Adjust the clamping chuck

rotation control pedal;

2) Tighten the screws where

necessary or replace the missing

ones;

3) Replace the micro switch;

4) Replace the spring.

1) Replace the micro switch;

2) Check the inverter wire and

connect it if necessary;

3) Replace the motor;

4) Check and connect the motor

wire.

1) Check the system is clamping correctly;

2) Position the pin properly.

The bead loosener disk does not

move vertically or it moves slowly

The bead loosener disk does not

move horizontally or it moves slowly

1) The air supply is missing;

2) The control valve is damaged;

3) The silencers are blocked;

4) The cylinder seal is damaged;

5) The valve is damaged or

defective.

1) The air supply is missing;

2) The control valve is damaged;

3) The silencers are blocked;

4) The cylinder seal is damaged;

5) The valve is damaged or

defective

1) Check the net pressure;

2) Replace the valve;

3) Clean up the silencers or

replace them;

4) Replace the seals;

5) Replace the valve.

1) Check the net pressure;

2) Replace the valve;

3) Clean up the silencers or

replace them;

4) Replace the seals;

5) Replace the valve

Important: Always read and follow operating instructions. • 29

Page 36

Troubleshooting Chart (cont.)

PROBLEM CAUSE SOLUTION

The bead loosener disk positions

itself correctly but does not

perform the “over run”

Bead loosener locking device

does not release

The tool does not move vertically 1) The air supply is missing;

The wheel lifter does not move or

move slowly

The wheel lifter does not stop 1) The control valve is damaged;

1) The air supply is missing;

2) The control valve is damaged or

defective;

3) The cylinders seals are damaged;

4) Movement is not activated;

5) The over run switch is damaged;

6) The valve damaged or defective

1) The air supply is missing;

2) The control valve is damaged;

3) The silencers are blocked;

4) The cylinder seal is damaged;

5) The valve is damaged or defective.

2) The supply union is not connected;

3) The feeding hoses are damaged or

squeezed;

4) Control valve is damaged;

5) The silencers are blocked;

6) The cylinder seal is damaged.

1) The air supply is missing;

2) The control valve is damaged;

3) The silencers are blocked;

4) The cylinder seals are damaged.

2) The foot control spring is damaged

1) Check net pressure;

2) Replace the control valve;

3) Replace the seals;

4) Rotate the switch;

5) Replace the switch;

6) Replace the valve.

1) Check net pressure;

2) Replace the valve;

3) Clean up the silencers or

replace them;

4) Replace the seals;

5) Replace the valve.

1) Check net pressure;

2) Plug the union carefully or

check the air hoses passage;

3) Replace the feeding hoses;

4) Replace the valve;

5) Clean up the silencers or

replace them;

6) Replace the seals.

1) Check net pressure;

2) Replace the valve;

3) Clean up the silencers or

replace them;

4) Replace the seals.

1) Replace the valve;

2) Replace the spring.

The inflating device does not work 1) The air supply is missing;

2) The control valve is damaged;

3) The pressure valve is damaged.

The tilting tower does not move

or moves slowly

The tool hit the rim during mounting operations

1) The silencers are blocked;

2) The silencers have not been adjusted;

3) Foot control release spring is

damaged;

4) The compressed air supply is

missing;

5) Column sleeve too loosened or too

tighten

1) The locking plate has not been

adjusted properly or is defective

2) The unlocking plate springs are

damaged

3) Smart Lock is loosened

1) Check the net pressure;

2) Replace the valve;

3) Replace the valve.

1) Clean up or replace the

silencers;

2) Adjust silencers;

3) Replace foot control release

spring;

4) Check or restore pneumatic

supply;

5) Adjust column sleeve.

1) Adjust or replace the locking

plate

2) Replace the unlocking plate

springs

3) Tighten Smart Lock

30 • Important: Always read and follow operating instructions.

Page 37

NOTES

Important: Always read and follow operating instructions. • 31

Page 38

ONE WORD FOR SAFETY

R.I.M.

READ INSPECT MOUNT

READ…

Mounting and inflating the

wrong size tire can get

you hurt. Read the size on

the tire and make sure it

matches the rim. Be especially careful about putting

a smaller tire on a larger

rim, such as a 16-inch tire

on a 16.5-inch rim.

Inflation of a mismatched

tire and rim can cause an

explosion.

BE CAREFUL OF THESE SITUATIONS:

1. Damaged Bead or

Beads.

2. Rusty Wheels.

(particularly in the

bead seat area)

3. Bent or Cracked

Wheels.

4 A. Mismatched.

(A mis-match of a

16-inch tire to a 16.5inch rim causing an

explosion)

4 B. Mismatched.

(16.5-inch tire on a

16-inch rim)

INSPECT…

Before you put any tire

on a rim, inspect the rim

for rust, tough spots, bent

edges, or cracks that could

prevent the tire from seating right. If you spot any

of these problems, don’t

mount the tire until the rim

has been checked by your

shop foreman.

Inspect the tire for bead

damage.

5. Walk-In Tire and

Rim.

6. Back Injuries.

7. Hand or Finger

Injuries.

(Hands or fingers too

close to inflating tire

or bead seats which

may cause injury.)

MOUNT…

Once you’ve made sure the tire is OK

and the right size and the rim is OK,

mount the tire safely. NEVER, ever lean

over the tire when you’re inflating it. If

a tire does explode, it will go straight

up. You don’t want to be over the tire

if that happens. Also, never over-inflate

the tire, even if the bead doesn’t seat.

Never inflate over 40 PSI. If the tire

hasn’t seated, something is wrong.

Deflate the tire and check it and the

rim again. If it doesn’t work the second

time, try another tire.

8. Standing Clear.

(Never put any part

of your body over the

tire changer during

inflation.)

9. Beads will not

Seat at 40 PSI.

10. Improper

Inflation.

Remember R.I.M. (Read, Inspect, Mount) for every tire.

TIRE FAILURE UNDER PRESSURE IS HAZARDOUS! This tire changer Will Not Restrain

FAILURE TO READ AND FOLLOW ALL WARNINGS AND INSTRUCTIONS IN THIS MANUAL

CAN LEAD TO SERIOUS PERSONAL INJURY

OR DEATH TO OPERATOR OR BYSTANDER.

THE OWNER IS RESPONSIBLE FOR MAINTAINING THE OPERATION INSTRUCTIONS

AND DECALS FOR OPERATOR REFERENCE.

FOR ADDITIONAL COPIES, CONTACT HENNESSY INDUSTRIES, INC., 1601 J.P. HENNESSY

DRIVE, LAVERGNE, TENNESSEE, 37086 - (800)

688-6359.

856100910 00 11/2016 © Copyright 2016 Hennessy Industries and COATS® All Rights Reserved. Printed in U.S.A.

Exploding Tires, rims or other related equipment.

TIRES CAN EXPLODE, ESPECIALLY IF

INFLATED BEYOND SPECIFIED LIMITS. DO

NOT EXCEED TIRE MANUFACTURERS RECOMMENDED AIR PRESSURE.

AN EXPLODING TIRE, RIM, OR BEAD SEATING EQUIPMENT MAY PROPEL UPWARD

AND OUTWARD WITH SUFFICIENT ENERGY

TO CAUSE SERIOUS INJURY OR DEATH TO

OPERATOR AND/OR BYSTANDERS.

Loading...

Loading...