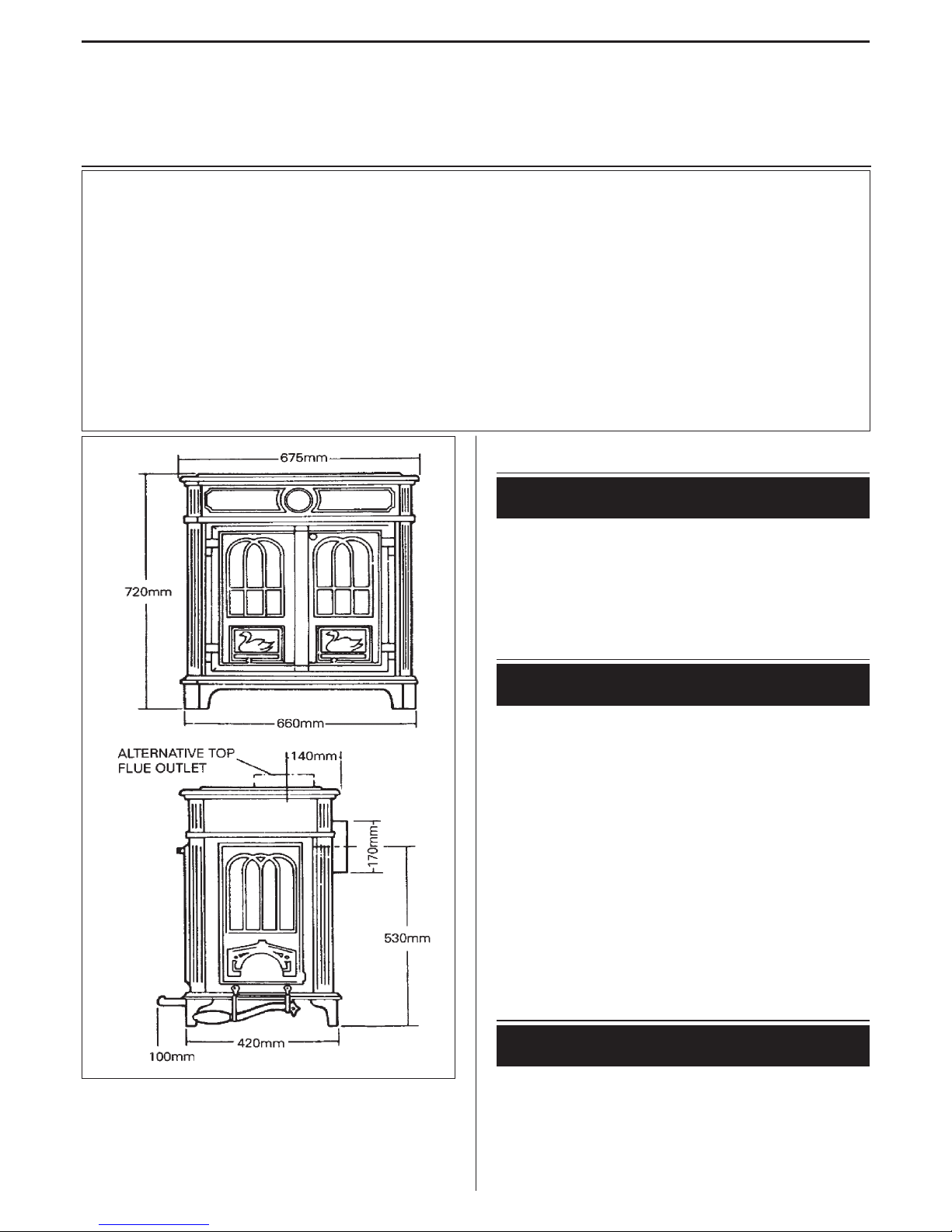

Coalbrookdale SEVERN Installation Instructions Manual

NOTE: STOVE CAN BE INSTALLED AS A TOP OR

BACK FLUE APPLIANCE.

The Severn Stove is intended to provide space heating

only. The appliance and burning rate are controlled by

the manual adjustment setting of the sliding levers only

at the bottom of each firedoor.

Rating

Space Heating 15kW (50,000 Btu/h)

For correct operation of the appliance, the height of the

chimney from its base should not be less than 5.5m and

terminate above the roof in accordance with current

Building Regulations and regional statutory requirements

as outlined in BS 6461 Parts 1 and 2.

The structural flue through the chimney should not be

less than 200mm diameter. Pargeted lined flues,

228mm x 228mm must be in sound condition, and any

internal offsets should not be less than 60˚ to the

horizontal. Check that the flue exit is not obstructed or

reduced in size.

IMPORTANT: FAILURE TO OBSERVE THE

RECOMMENDED MINIMUM SIZES OR METHODS OF

FLUE CONNECTION MAY LEAD TO FUME EMISSION

INTO THE ROOM AND REDUCED BURNING RATES.

The internal and external condition of the chimney

should be checked before the appliance is installed and

rectified where necessary to prevent air leakage or

porosity.

9/00 EINS 33742

Installation Instructions

for Freestanding

Severn Stove

Consumer Protection Act 1987

As manufacturers and suppliers of cooking and heating products, in

compliance with Section 10 of the Consumer Protection Act 1987,

we take every care to ensure, as far as is reasonably practicable, that

these products are so designed and constructed as to meet the

general safety requirement when properly used and installed. To this

end, our products are thoroughly tested and examined before

despatch.

IMPORTANT NOTICE: Any alteration that is not approved by AgaRayburn, could invalidate the approval of the appliance, operation of

the warranty and could also affect your statutory rights.

Control of Substances - Health & Safety

Important

This appliance may contain some of the materials that are indicated

below. It is the Users/Installers responsibility to ensure that the

necessary personal protective clothing is worn when

handling where applicable, the pertinent parts that contain any of the

listed materials that could be interpreted as being injurious to health

and safety, see below for information.

Firebricks, Fuel beds, Artificial Fuels - when handling use

disposable gloves.

Fire Cement - when handling use disposable gloves.

Glues and Sealants - exercise caution - if these are still in liquid

form use face mask and disposable gloves.

Glass Yarn, Mineral Wool, Insulation Pads, Ceramic Fibre,

Kerosene Oil - may be harmful if inhaled, may be irritating to skin,

eyes, nose and throat. When handling avoid inhaling and contact

with skin or eyes. Use disposable gloves, face-masks and eye

protection. After handling wash hands and other exposed parts.

When disposing of the product, reduce dust with water water spray,

ensure that parts are securely wrapped.

SEVERN

PERFORMANCE

THE CHIMNEY

EXISTING CHIMNEYS

The flue through the chimney should be formed with

200mm diameter minimum moisture and acid resistant

liners to BS 1181 or precast linings as specified in the

current Building Regulations and Codes of Practice for

Chimneys and Flues BS 6461 Part 1 and BS 7566 Parts

1 to 4.

When repairing existing chimneys, it is recommended

that the Building Inspector be consulted before the

commencement of work with particular attention to the

chimney height and its termination.

NOTE: THE CHIMNEY MUST BE SWEPT BEFORE

INSTALLATION.

The Chimney

The flue should not less than 200mm diameter and its

soundness confirmed by smoke testing or consulting

HETAS who will give advice on the test method.

Ensure the chimney liners are free of any internal

projections such as building jointing composition before

the appliance is installed.

Factory-Made Insulated Chimney

It is recommended that the internal face of the chimney,

be refractory lined and otherwise comply with BS 4543

The recommended minimum diameter is 175mm.

Chimney manufacturers should be contacted for further

advice.

Chimney Terminations

All chimneys should terminate above the roof level in

accordance with current Building Regulations and

statutory requirements as outlined in BS 6461 Part 1

and BS 7566 Parts 1 to 4.

However well designed, constructed and positioned the

satisfactory performance of a flue can be adversely

affected by the downdraught caused by adjacent tall

buildings and trees or even nearby hill. These deflect the

wind creating a zone of high pressure over the terminal

causing it to blow directly down the chimney flue.

A suitable anti-downdraught terminal such as the

Marcone will usually effectively combat low pressure

down-blow but no known cowl is likely to prevent

downdraught due to a high pressure zone.

NOTE: ADVISE THE USER TO ENSURE THE CHIMNEY

FLUES ARE THOROUGHLY SWEPT AT A MINIMUM OF

12 MONTHLY INTERVALS AFTER THE APPLIANCE IS

COMMISSIONED.

The appliance and recess, hearth and chimney flue

installation should be in accordance with the current

Building Regulations and BS 6461 Part 1 and BS 7566

Parts 1 to 4.

The appliance can be installed in a fire resistant recess

in which the hearth must be level and together with the

adjacent walls, conform to the current Building

Regulations.

A rectangular recess is required, not less than 975mm

wide, not less than 350mm deep from the face of the

recess and 1320mm minimum height for a top flue

outlet appliance.

The clearance between the appliance and any

combustible material must be maintained as indicated in

Figs. 1a, 1b, 2a and 3.

A permanent unobstructed air vent is required having a

minimum effective area of 100cm

2

and communicating

directly to outside air or an adjacent room which itself

has a permanent air vent direct to outside air.

Effect of Extractor Fan

Avoid if possible, the installation of an extractor fan in

the same room as the appliance or the room where the

permanent vent is located.

Compensating extra air inlets must be introduced

equivalent to the capacity of the fan when fitted.

In Fig. 1b the stove is installed in an existing recess

directly below the chimney flue. The exit end of the flue

pipe must extend a minimum of 150mm into the

overhanging brickwork. Any cavities or pockets above

the register plate should as far as possible be filled, with

the flue pipe exit extended into the throat of the

chimney.

If the flue liner or insulated chimney is used, the

diameter should not be less than 200mm in both cases.

Fig. 2b shows a back flue outlet into chimney

EXTENDED LENGTHS OF HORIZONTAL PIPEWORK

MUST BE AVOIDED AND ARE NOT RECOMMENDED,

AND SHALL NOT EXCEED 150mm.

In Fig. 3 the stove is connected to an existing brick flue

with a length of flue pipe. Square bends and horizontal

runs must not be used and a cleaning door included at

every bend.

NOTE: WHATEVER METHOD OF INSTALLATION IS

UTILISED, AIR MUST NOT BE ALLOWED TO ENTER

THE CHIMNEY EXCEPT THROUGH THE STOVE AND

ALL JOINTS MUST BE AIRTIGHT. IF THE CHIMNEY IS

UNLINED AND THERE IS ANY DOUBT ABOUT ITS

CONDITION, IT SHOULD BE LINED IN ACCORDANCE

WITH CURRENT BUILDING REGULATIONS.

PROVISION MUST ALWAYS BE MADE FOR SWEEPING

THE CHIMNEY.

Important

Cement pipes and fittings must not be used within 2m

of the stove outlet. Chimneys of plain pipe are not

recommended but certain proprietary makes of insulated

chimney are suitable.

Handle the firedoors with care to ensure the glass

panels remain intact.

The stove is delivered fully assembled but all fire cement

joints should be examined for soundness and if necessary

re-sealed before installation.

1. Position the stove in required position relative to

chimney flue and on non-combustible hearth ensuring

there is sufficient room allowed on stove R.H. side to

enable operation of riddling tool.

Blank off and seal with cover plate, flue outlet not

used.

2. Cut length of 150mm diameter pipe to suit chosen

method of flue connection. Insert flue pipe spigot in

stove outlet socket and caulk joint with soft rope and

cement.

3. Connect flue pipe to chimney with selected method.

4. Check that the bottomgrate reciprocates correctly

and that the throat plate is correctly located/sealed.

2

PREPARATION OF

BUILDERS RECESS OPENING

AIR SUPPLY

FLUE LAYOUT

FLUE LAYOUT

Loading...

Loading...