Coalbrookdale MUCH WENLOCK Installation Instructions Manual

NOTE: THERE ARE TWO SETS OF BACK OUTLET

‘FLOW AND RETURN’ CONNECTIONS ON THE L.H. OR

R.H. SIDE OF THE BOILER. THE STOVE CAN BE

INSTALLED AS A TOP OR BACK FLUE OUTLET

APPLIANCE.

The maximum room size (of normal construction) and

radiator surface that can be heated are:

04/04 EINS 33744

Installation Instructions

for Freestanding

Much Wenlock Stove

with Boiler

Consumer Protection Act 1987

As manufacturers and suppliers of cooking and heating products, in

compliance with Section 10 of the Consumer Protection Act 1987,

we take every care to ensure, as far as is reasonably practicable, that

these products are so designed and constructed as to meet the

general safety requirement when properly used and installed. To this

end, our products are thoroughly tested and examined before

despatch.

IMPORTANT NOTICE: Any alteration that is not approved by AgaRayburn could invalidate the approval of the appliance, operation of

the warranty and could also affect your statutory rights.

Control of Substances - Health and Safety

Important

This appliance may contain some of the materials that are indicated

below. It is the Users/Installers responsibility to ensure that the

necessary personal protective clothing is worn when

handling where applicable, the pertinent parts that contain any of the

listed materials that could be interpreted as being injurious to health

and safety, see below for information.

Firebricks, Fuel beds, Artificial Fuels - when handling use

disposable gloves.

Fire Cement - when handling use disposable gloves.

Glues and Sealants - exercise caution - if these are still in liquid

form use face mask and disposable gloves.

Glass Yarn, Mineral Wool, Insulation Pads, Ceramic Fibre,

Kerosene Oil - may be harmful if inhaled, may be irritating to skin,

eyes, nose and throat. When handling avoid inhaling and contact

with skin or eyes. Use disposable gloves, face-masks and eye

protection. After handling wash hands and other exposed parts.

When disposing of the product, reduce dust with water spray,

ensure that parts are securely wrapped.

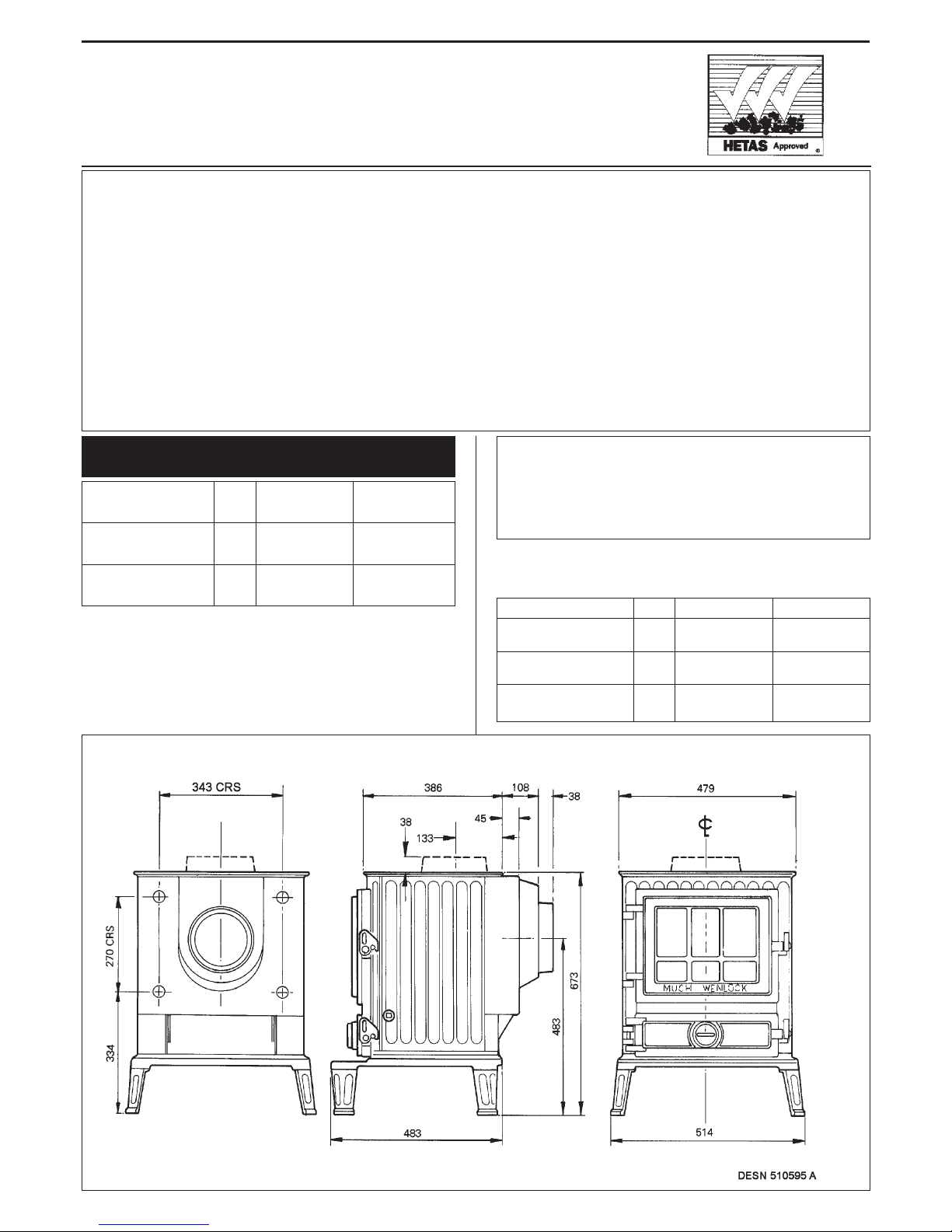

THE MUCH

WENLOCK

RATING

Top Flue

Outlet

4.3

14,500

6.1

21,000

Direct Space Heating

kW

Btu/h

kW

Btu/h

Water Heating

Rear Flue

Outlet

3.9

13,500

7.3

25,000

WARNING

BOILER MODEL

UNDER NO CIRCUMSTANCES MUST THE

APPLIANCE BE FIRED DRY AS DAMAGE WILL OCCUR

Top Flue Rear Flue

Direct Space Heating

73.6

2600

67.9

2400

14.5

156.25

12.2

131.25

12.2

131.25

9.9

106.25

m

3

ft

3

m

3

ft

3

m

3

ft

3

Pipe and Radiator Surface

(no domestic hot water)

Radiator Surface

(with domestic hot water)

The recommended heating surface area is based on an

average heat emission of 0.5 kW/m

2

(160 Btu/h/ft2).

These figures are maxima and must not be exceeded.

A margin (about 10% or 1.4m

2

- 15ft2) is recommended.

The Much Wenlock Stove with Boiler is intended to

provide space heating and the heating of domestic hot

water and radiators has been approved by the HETAS LTD

Appliance Approval Scheme. The appliance and burning

rate are controlled by the manual adjustment setting of

the ashpit door spinwheel only.

1. A 140 litre capacity indirect hot water storage cylinder

of the double feed type, complying with BS 1566 Part

1: DF TYPE 8 should be lagged and fixed vertically as

near as possible to the stove.

The 28mm minimum diameter primary flow and return

pipes must not exceed 10m in length and pipes longer

than 5m must be lagged. Ensure that the flow pipe

rises continuously from the stove boiler to the cylinder

to ensure good gravity circulation. In combined

systems, the water draw-off pipes to the taps must be

dead-leg connections from the vent/expansion pipe.

2. One boiler flow connection (preferably that to the

cylinder), must have an open vent. The connection to

the boiler must be such that air cannot be trapped in

the boiler. Any pipe size reduction must be made on

the vertical pipe of the vented flow pipe.

The heating flow and return pipes may be 22mm and

should preferably be connected to opposite tappings

to each other on each side of the boiler.

3. All installations must be fitted with a drain tap at the

lowest point of the system.

4. It is recommended that a gravity heat leak radiator 0.9

- 1.4m2(10-15ft2) heating surface be included, or a

reverse acting cylinder thermostat to activate the

pump in the event of overheating.

5. Long reach male fittings will be required to make

pipework connection into the boiler.

For correct operation of the appliance, the height of the

chimney from its base should not be less than 5.5m and

terminate above the roof in accordance with current

Building Regulations Section J/1/2/3 and requirements as

outlined in BS 6461 Part 1 and BS 7566 Parts 1 to 4

should be observed.

The structural flue through the chimney should not be

less than 175mm diameter. Pargeted lined flues, 230mm

x 230mm must be in sound condition, and any internal

offsets should not be less than 60˚ to the horizontal.

Check that the flue exit is not obstructed or reduced in

size.

IMPORTANT: FAILURE TO OBSERVE THE

RECOMMENDED MINIMUM SIZE OR METHODS OF

FLUE CONNECTION MAY LEAD TO EMISSION INTO

THE ROOM AND REDUCED BURNING RATES.

Existing Chimney

The internal and external condition of the chimney should

be checked before the appliance is installed and

rectification made where necessary to prevent air leakage

or porosity.

The flue through the chimney should be formed with

175mm diameter minimum moisture and acid resistant

liners to BS 1181 or precast linings as specified in the

current Building Regulations and requirement in BS 6461

Part 1 and BS 7566 Parts 1 to 4 should be observed.

When repairing existing chimneys, it is recommended

that the Building Inspector be consulted before

commencement of work with particular attention to the

chimney height and its termination.

NOTE: THE CHIMNEY MUST BE SWEPT BEFORE

INSTALLATION.

Where the chimney is believed to have served an open

fire installation it is possible that the higher flue gas

temperature from a closed appliance may loosen

deposits that were previously firmly adhered, with the

consequent risk of flue blockage. It is therefore

recommended that the chimney be swept a second time

after one month of regular use.

New Chimney

The flue should not be less than 175mm diameter and its

soundness confirmed by smoke testing or consulting

HETAS LTD who will give advice on the test method.

Ensure the chimney liners are free of any internal

projections such as building jointing composition before

the appliance is installed.

Factory-made Insulated Chimneys

It is recommended that the internal face of the chimney,

be refractory lined and otherwise comply with BS 4543.

The recommended minimum diameter is 150mm and

chimney manufacturers should be consulted for further

advice.

HOT WATER SYSTEM

THE CHIMNEY

PERFORMANCE

2

Chimney Terminations

All chimney should terminate above roof level in

accordance with current Building Regulations Section

J/1/2/3 and as outlined in BS 6461 Part 1 and BS 7566

Parts 1 to 4.

However well designed, constructed and positioned, the

satisfactory performance of a flue can be adversely

affected by the downdraughts caused by adjacent tall

buildings and trees or even a nearby hills. These deflect

the wind, creating a zone of high pressure over the

terminal causing it to blow directly down the chimney

flue.

A suitable anti-downdraught terminals such as the

MARCONE will usually effectively combat low pressure

down-blow but no known cowl is likely to prevent

downdraught due to a high pressure zone.

NOTE: ADVISE THE USER TO ENSURE THE CHIMNEY

FLUES ARE THOROUGHLY SWEPT AT A MINIMUM OF

12 MONTHLY INTERVALS AFTER THE APPLIANCE IS

COMMISSIONED.

The appliance and recess, hearth and chimney flue

installation should be in accordance with the relevant

current recommendation of the British Codes of Practice

BS 8303 and BS 6461 Part 1 and BS 7566 Parts 1 to 4,

with the boiler and heating installation complying with BS

5449 Part 1.

The boiler section must also be installed in accordance

with the bye laws of the Local Water Undertaking,

Regulations for the Electrical Equipment of Buildings published by the Institute of Electrical Engineers, and any

relevant requirement of the Local Authority.

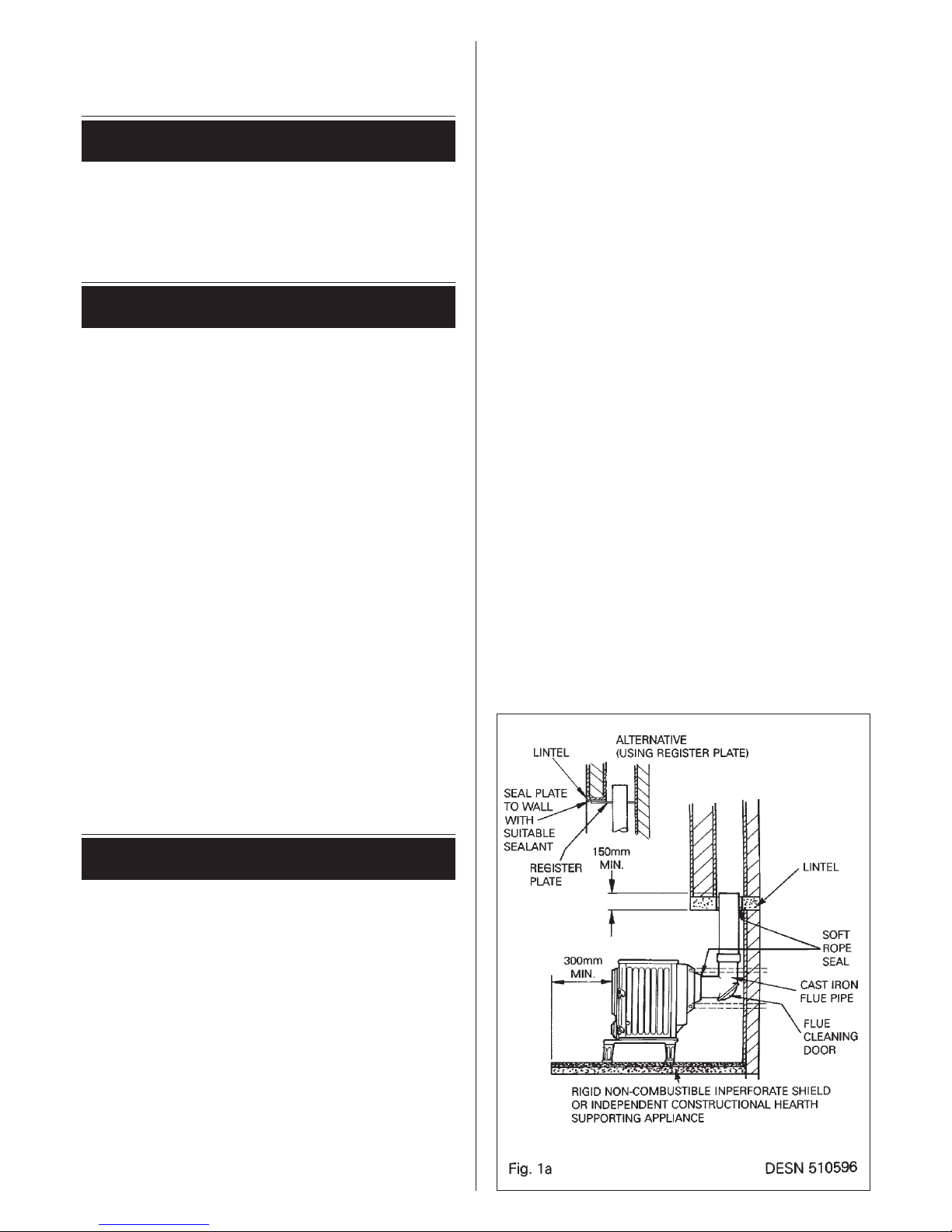

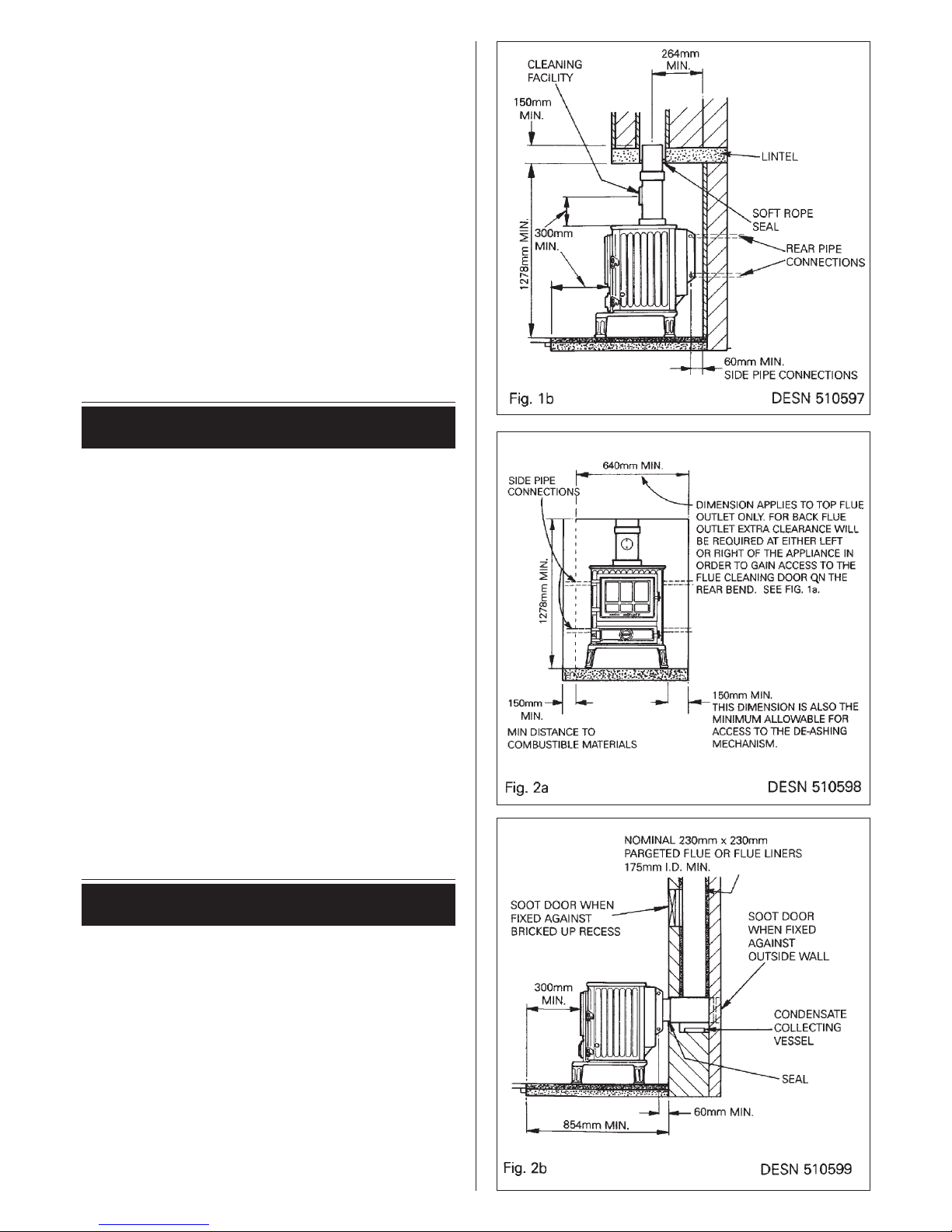

The appliance can be installed in a non-combustible

recess in which the hearth must be level and together

with the adjacent walls, conform to the current Building

Regulations. See Figs. 1b and 2a.

A rectangular recess is required, not less than 640mm

wide, not less than 480mm deep from the face of the

recess and 1278mm minimum height for a top flue outlet

version. Holes will be required in one or both sides for the

pipework.

The clearance between the appliance and any

combustible material must be maintained as indicated in

Figs. 1a, 1b, 2a, 2b and 3.

A permanent unobstructed air vent is required having a

minimum effective area of 60cm

2

and communicating

directly to outside air or an adjacent room which itself has

a permanent air vent direct to outside air.

Air Extract Fans

Building Regulations 1990 permit the installation of an air

extract fan in a room containing a solid fuel appliance. The

appliance must be able to operate effectively whether or

not the fan is running. To this end:

1. Ensure the fan duty is capable of coping with the

respective room volume. Avoid an oversize fan duty

performance.

2. Follow the directions recommended by the fan

manufacturer on the necessary air ingress needed for

3

PREPARATION OF

BUILDERS RECESS OPENING

AIR SUPPLY

Loading...

Loading...