CNCDIY CNC 6040 User Manual

CNC 6040 Router / Engraver System

CNCDIY CNC Routing Machines System User’s Manual

CNCDIY CNC Routing Machine System

Website: www.cncdiy.org

Email: cncdiy_selling@ymail.com

CNC 6040

ROUTER / ENGRAVER / DRILLING / MILLING MACHINE

User’s Manual

Latest update: 9 September 2009

1

CNC 6040 Router / Engraver System

CNCDIY CNC Routing Machines System User’s Manual

Copyright

© 2010 CNCDIY CNC Routing Machine System. All Rights Reserved.

Declaration

z Although, the routing machine system is produced by CNCDIY Routing Machine System, it

cannot be called a real commercial product. The user must require having relative knowledge

about mechatronics. All matters concerning the machinery, electronics, computer equipment,

are likely due to improper use or a virus, software compatibility reasons, result in failure, this

failure may cause a certain degree of risk and economic losses. CNCDIY Routing Machine

System does not bear the direct and indirect losses corresponding responsibilities.

z Any routing machine you purchased from CNCDIY Routing Machine System is only paid

for the price of the machine and relative device itself only, does not included any software

and software training costs. You can follow this "User’s Manual" learning how to operate or

through the network under the guidance from our staff. Each routing machine system is

operation normally after a standard test produce to identify the three-axis can be controlled

and able to run imported tool path properly. This recognition of our work is completed. All

the software training is not in our capacity. CNCDIY Routing Machine System is a vast

CNC-DIY enthusiast platform, we are very happy in our own knowledge, ability and time to

give novices within reach of as much as possible help, but please do not use these to help and

look at the FAQ to make is that we have obligations.

z Software copyright: This machine does not come with any software, operational use, and

covered in this guide are all related software from the Internet, the original author enjoys

copyright to the author's official Web site at your own download a trial version or purchase

licensed software, because not authorized the use of for all damage caused by the software

and legal issues from the users themselves.

2

CNC 6040 Router / Engraver System

CNCDIY CNC Routing Machines System User’s Manual

Reminder

z The machine uses a parallel interface and control computer connected through the parallel

port control software MACH3 controlled carving machine to run the various axes in

accordance with instructions, make sure you prepare for the routing machine control

computer has a parallel port, and the required work in EPP parallel port mode, any other

mode may result in engraving machine cannot operate normally, the EPP mode is set to be

carried out in the computer motherboard BIOS, all manufacturers to set methods vary, please

refer to the instructions to set up your computer. Part of the desktop computer does not have

built-in parallel port, users can be purchased parallel port PCI expansion card slot to use. But

any commercially available USB-parallel port adapter does not allow normal operation of the

machine

z Controlling the computer should be dedicated and, if possible do not install other

applications software; do not recommend the use of laptop computers to control the

engraving machine, part of the notebook computer's battery-saving chip may interfere with

the pulse signal, some parallel port voltage is low, may lead to pulse signal is lost the use of

engraving machine could not be properly controlled.

Warning

z The machine system is to rely on related software control, the need for the right software

settings in order to function properly, in the absence of fully recognized under the temerity to

set the correct test machine loaded knife can be dangerous or permanent damage to

machinery. During the software installation and settings, do not open the control box power

supply, in order to avoid malfunction causing damage.

z Do not at any time the power electronic control box connected to the case, pulling the plug

inserted above the line terminal; spindle power each time you open the speed control knob

must be transferred before the low-end office and then start-up; both spindle switch or driver

switches repetition interval of the switch at least once every 30 seconds or more; not pay

attention to the above questions is likely to cause some damage control circuits.

z As the use of the AC110V or AC220V voltage, power state, do not open the electronic

control cover, do not touch the spindle motor terminals, operation of the spindle motor driven

high-speed rotary cutting tool, do not touch, and a closer look at sculpture, the working must

be worn goggles or protective masks! The operator must wear a protective mask and a

goggle.

3

CNC 6040 Router / Engraver System

CNCDIY CNC Routing Machines System User’s Manual

Warranty

All electrical products manufactured or marketed by CNCDIY Routing Machine System has a

warranty period of 6 months from the day they are shipped out of our warehouses. The electrical

products are included CNC driver and DC spindle driver only and the VFD driver is not included

The mentioned warranty covers repair material and labor costs, at CNCDIY Routing Machine

System facilities, incurred in the repair of the products.

Within the warranty period, CNCDIY Routing Machine System will repair or replace the

products verified as being defective. The purchaser must send the damaged or broken part back

to Hong Kong office of CNCDIY Routing Machine System after providing photos to show the

damage part and proving the causes of the problem to our staff.

It is entirely up to CNCDIY Routing Machine System to determine whether a repair is to be

considered under warranty.

4

CNC 6040 Router / Engraver System

CNCDIY CNC Routing Machines System User’s Manual

Contents

Chapter 1 Introduction 4

Chapter 2 Safety and Protection 4

2-1 Gloves 4

2-2 Handling Posture 4

Chapter 3 Hardware Installation 7

3-1 Installation Precaution 7

3-2 Understanding of Your Machine System 8

3-3 Machine Specifications 9

3-4 Spindle (D57 and C57) Specifications 10

3-5 Stepping Motor Specifications 11

3-6 Components Check 12

3-7 Tools and Materials Requirement 13

3-8 Machine Installation 15

3-9 Electrical Connection 20

3-10 Basic Testing with CNC Control Box 25

Chapter 4 Installation of Mach 3 Software 27

4-1 Connect to the CNC Control Box 27

4-2 Basic Setting of Mach 3 software 27

4-3 Stepping motor setting in Mach 3 with different coupling type 32

4-4 Load a G code file 34

4-5 Testing with CNC machine 35

Chapter 5 Installation of EMC2 Software 36

5-1 Connect to the CNC Control Box 36

5-2 Basic Setting of EMC2 software 36

5-3 Stepping motor setting in EMC2 different coupling type 39

Chapter 6 Test Your System 42

5

CNC 6040 Router / Engraver System

CNCDIY CNC Routing Machines System User’s Manual

Chapter 1 Introduction

Thank you for your selection of our product. We have provided CNCDIY routing machine

system, also very honored that you have the time to read, prepared by the Walter, "Quick Start

Guide" in the hope of its initial contact with routing machine will be able to help! This is not a

company. We are formed from some CNC lovers in different Places and hope provide some low

price and high quality DIY CNC machines for you!

We hope to provide some low price and high quality DIY CNC machines for you! All of our

machine set are included a CNC Machine body with 3 Stepping Motors, a CNC controller, a 24V

Switching Power Supply and a Driller. Each machine set is installed completely and pass testing

before shipping, users can use the machine immediately when received.

Chapter 2 Safety and Protection

Before you open the packages and check the machine parts, please care about the following

items

2-1 Gloves

Your hands are easy hunt by the sharp edges of the parts and the

packages. The Gloves can reduce the risk for your hands!

2-2 Handling Posture

Some of parts are heavy, when you move or put up them, please be careful and take care you

body with good Handling Posture

“LIFTING - PUSHING - PULLI NG – LOWERING”

6

CNC 6040 Router / Engraver System

CNCDIY CNC Routing Machines System User’s Manual

Chapter 3 Hardware Installation

3-1 Installation Precaution

The CNC Routing Machine system contains numerous delicate electronic circuits and

components which can become damaged. Prior to installation, carefully read the user’s manual

and follow these procedures:

z When connecting hardware components to the connectors of the Control system, make sure

they are connected tightly and securely.

z Before using the product, please verify that all cables and power connectors of your

hardware components are connected

z Before unplugging the power, make sure the power supply voltage has been set according to

the local voltage standard.

z Do not place the machine system on an uneven surface.

z Do not place the machine system in a high-temperature environment.

z Turning on the control system power during the installation process can lead to damage to

system components as well as physical harm to the user.

z If you are uncertain about any installation steps or have a problem related to the use of the

product, please consult a certified computer technician.

z The main material of the routing machine is used aluminum alloy, cannot be used due to

any inadvertently fall or collision to damage the machine. Please placed the routing

machine system in a firm, stable, level of desktop, thin desktop will result in a greater

resonance in the noise during the machine running.

z Electric control box is installed well with a switching power supply, a stepper drive

controller and a spindle power driver. Please place it in the level of ventilation. Electric

control box cannot have electromagnetic interference within around 10 meters. Please also

care about wrestling and fear flows effect!

z Remember to tidy up the wiring harness, messy take place. It is likely to impede the normal

movement of the routing machine. Please consider the stroke area for the moving gantry

and any sliding part with sufficient margin of the wiring harness.

7

CNC 6040 Router / Engraver System

CNCDIY CNC Routing Machines System User’s Manual

3-2 Understanding of Your Machine System

For the future use and maintenance, user should understand your routing machine system first.

The major parts are shown in below figure and include a set of routing machine, a CNC control

box, spindle with bracket, and an attachment box. The attachment box is included 4 sets of platen,

5 of basic tooling, a pair of brushes for spindle replacing, a pair of spindle handles and a Hex

wrench and some screws. (Note: The screws are attached to a few random, different parts may

require different lengths and types of screws, is depending on the actual needs of their own,

separately purchased locally)

ZAxis

Stepping

CableChain

Motor

YAxis

Stepping

Motor

XAxis

Stepping

Motor

Working

Tabl e

CNCRoutingMachine

Spindle

CNCControlBox

8

CNC 6040 Router / Engraver System

CNCDIY CNC Routing Machines System User’s Manual

3-3 Machine Specification

CNC6040 Router / Engraver System

1. Effective Travel: 400mm(X) * 580mm(Y) * 60mm(Z)

2. Machine Outside Dimensions: 850mm * 640mm * 470mm

3. Maximum Workpiece

750mm*480mm*90mm

Dimensions:

4. Working Table Dimensions: 750mm*480mm*20mm

5. Sliding Units:

i) X Axis Dia. 16mm Guide

ii) Y Axis Dia. 20mm Guide

iii) Z Axis Dia. 13mm Guide

6. Driving Units: New Ball Bearing (BB) 1605

7. Coupling Plum Coupling / Simple Coupling

8. Stepping Motor Type: 57 Two-Phase 1.45A~2A (New)

9. Main Materials of Machine Aluminum Alloy 6061

10. Actual carving precision: 0.08mm (carving different hardness materials vary)

11. Repeat positioning accuracy: 0.06mm

12. Engraving speed: 0 ~ 2000mm/min

13. Machine weight: 53KG (excluding packaging)

14. Acceptable Processing

PVC, PCB, Plastic, Woods, Brass and Aluminum

materials

Driving Units

The diffient type of driving units are using on X, Y and Z axis for the smooth driving unit! The

basic information is shown below:

Model Ball Bearing Screw

Axis Name

Diameter(mm)

Pitch(mm)

X Y Z

16 16 16

5 5 5

9

CNC 6040 Router / Engraver System

CNCDIY CNC Routing Machines System User’s Manual

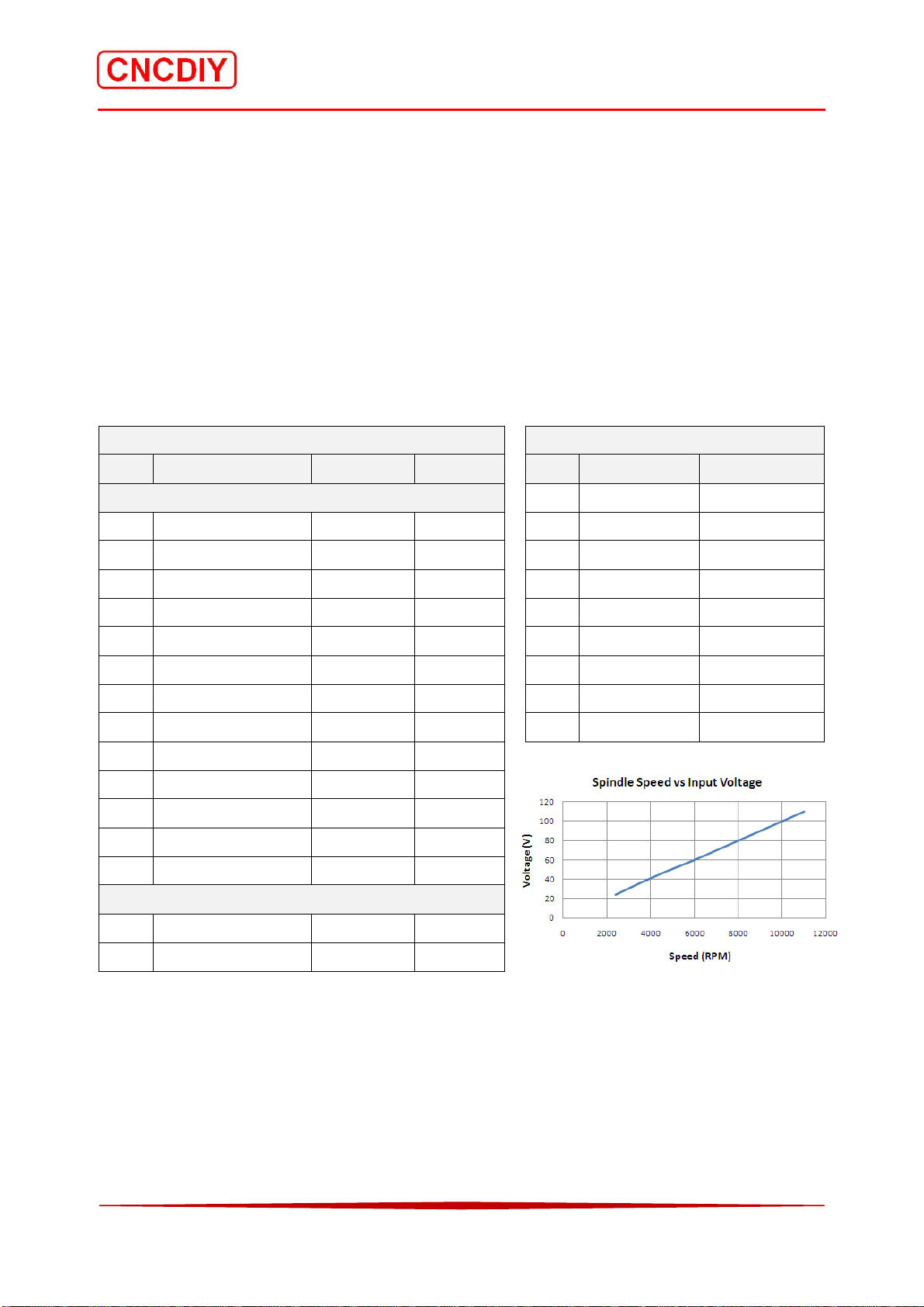

3-4 Spindle (D57 and C57) Specifications

The spindle is a used of ELECTROCRAFT E240 motor installed an ER11 chuck and a Plastic

Cooling Fan. The original is a DC servo motor, it is a waste and the encoder has been damaged.

This is a good choice and environmentally friendly for using the small CNC.

The ER 11 chuck is using with tooling diameter of 3.175mm. It can reduce the radial runout and

increasing the routing Precision to 0.03mm. The ER 11 chuck is included two handles for

locking the cutting tools.

Specification Speed Vs Voltage

Seq. Description Details Unit Seq. Voltage (V) Speed(rpm)

A. Motor

1 24 2400

1 Voltage Range 24 – 110 V 2 36 3500

2 Rated Power 200 W 3 48 4700

3 Peak Torque 1.7 Nm 4 60 6000

4 Stall Torque 0.22 Nm 5 70 7000

5 Peak Current 24.5 Amps 6 80 8000

6 Stall Current 3.1 Amps 7 90 9000

7 Radial Load 4.5 kg 8 100 10000

8. Axial Load 2.3 kg 9 110 11000

9. Voltage Constant 7.8 V/kRPM

10. Diameter 57 mm

11.

12

AxialDiameter

Axiallength

8 mm

42 mm

13 Weight 1.1 kg

B. ER Chuck

1. Hold Diameter 3.175 mm

2. Precision 0.03 mm

10

CNC 6040 Router / Engraver System

CNCDIY CNC Routing Machines System User’s Manual

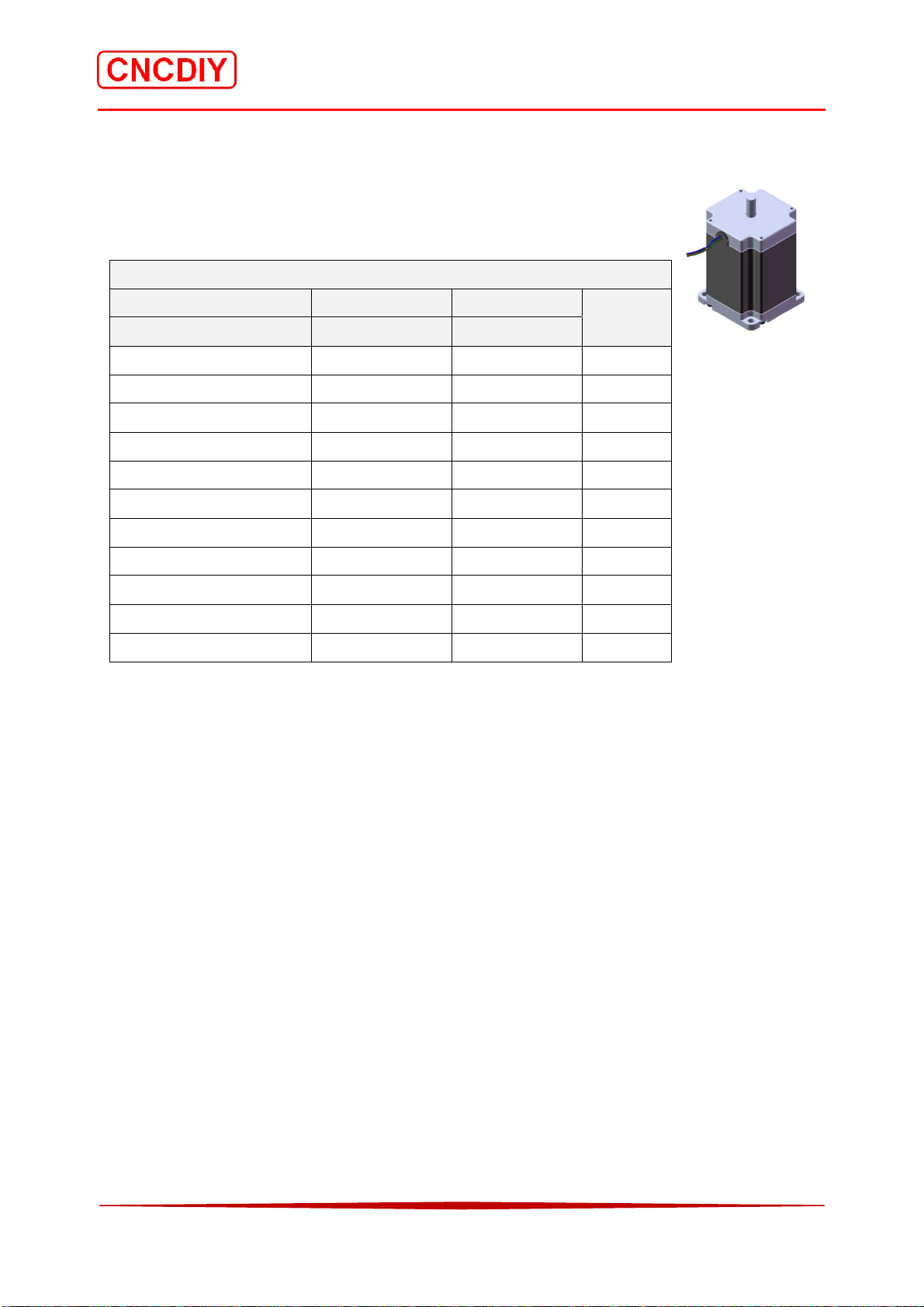

3-5 Stepping Motor Specifications

The stepping motors are selecting the new Chinese stepping motors or used

Japanses and USA stepping motors.

Specification

Machine Model CNC3040 CNC3020

Stepping Motor Model 57BYGH218 Not fixed

Step Angle 1.8 1.8 (deg)

Motor Length 51 N/A (mm)

Rate Voltage 2.6 2.6 (V)

Rate Current 2 2 (A)

Phase Resistance 1.3 N/A

Phase Inductance 4 N/A (mH)

Holding Torque 9 N/A (kg.cm)

Lead Wire 4 N/A (NO.)

Rotor Inertia 275 N/A (g.cm2)

Detent Torque 0.36 N/A (kg.cm)

Motor Weight 0.65 N/A (kg)

Unit

(Ω)

11

CNC 6040 Router / Engraver System

CNCDIY CNC Routing Machines System User’s Manual

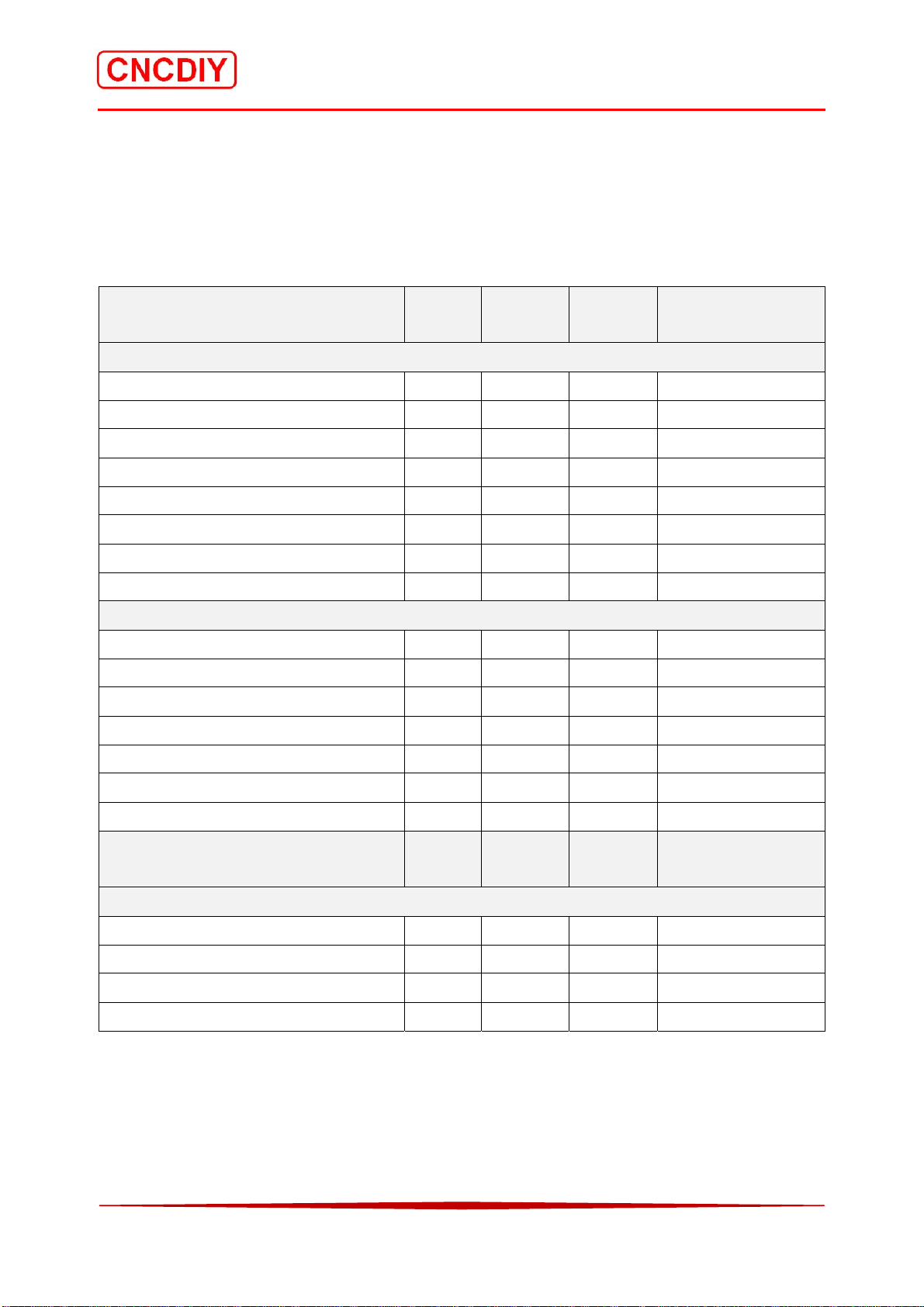

3-6 Components Check

A check listed is shown in Figure 3.6 below. Please check them with your received components

and pull a tick or an across for record.

Figure 3.6 Components Chec k List

Items Qty

Parts

Number

Received

Remarks

or not?

A .Stepping Motor Part

1. 57 Type Stepping Motor 3 S01

2. Plum Coupling 3 S02

3. Stepping Motor Support 12 S03

4. Knob 3 S04

5.Chain Support (For Z axis only) 1 S05

6. Crank Bolt M5 60mm 12 SB01

7. Bolt M5 6.5mm 1 SB02

8. Bolt M3 4mm 2 SB03

E. Spindle Part

1.D57 Spindle 1 S01

2.D57 Spindle Bracket 1 S02

3.ER11 Chuck 1 S03

4.ER 11 Head 1 S04

5.Crack Bolt M8 60mm 4 SB01

6. Top Handle 1 SH01

7.Bottom Handle 1 SH02

Items Qty

Parts

Number

Received

Remarks

or not?

F. Accessories Parts

1. Control Box CB001 1 N/A

2. A39773XB001 1 N/A Installed in CB001

3. Cutting Tools CTS001 1 N/A

4. Parallel Port 1 N/A

12

CNC 6040 Router / Engraver System

CNCDIY CNC Routing Machines System User’s Manual

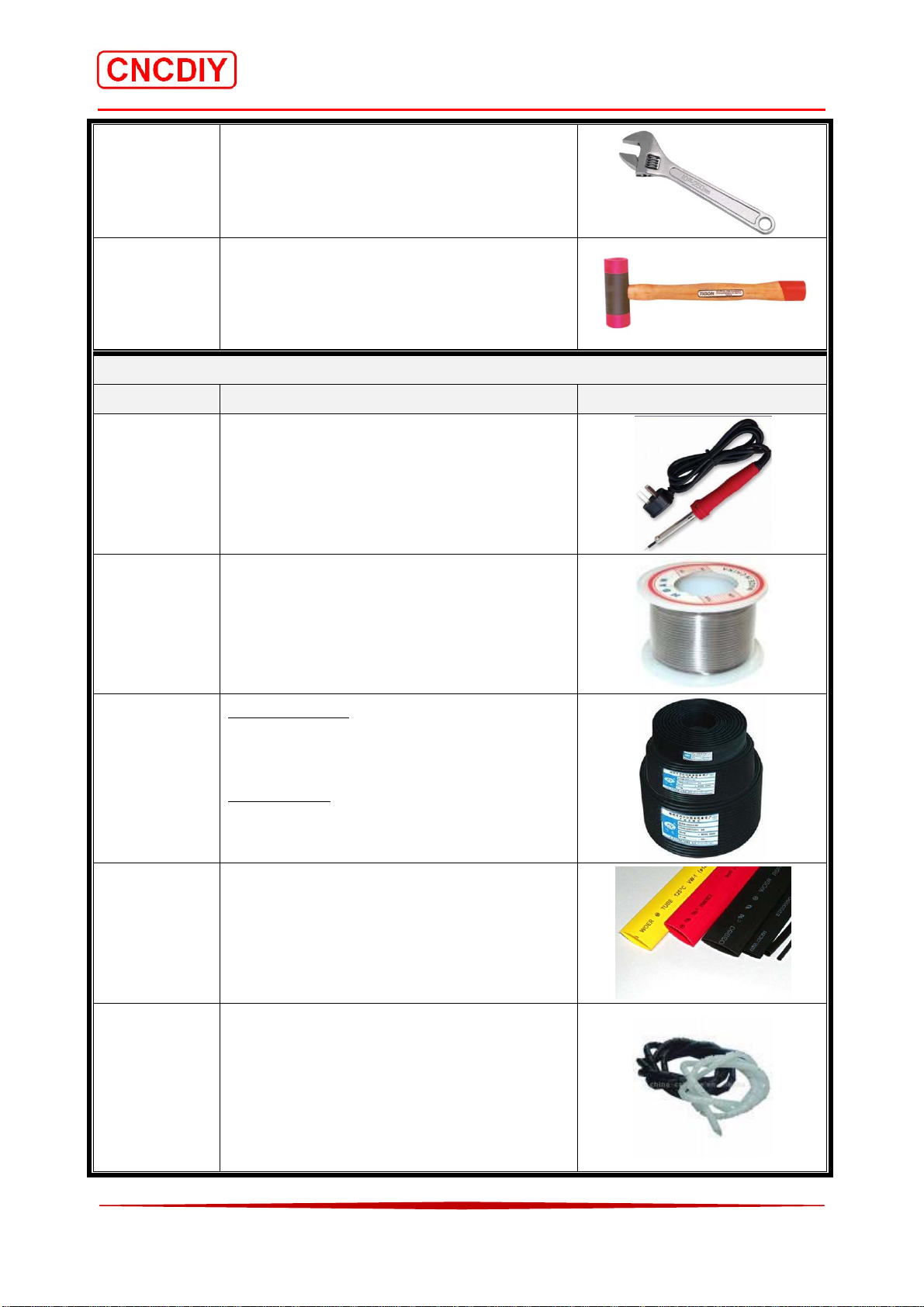

3-7 Tools and Materials Requirement

In this chapter, there are discuss the major tools for the assembly work!

Figure 3.7 Tools list

A. Mechanical Part

Tools Name Description Picture

Processing

Platform

Frame Level

Dial Test

Indicator

Calliper

The Processing platform is an important for

assembly. A Processing platform can make

sure the machine table is level.

1. The best is metal Processing platform.

2. Any level plate or platform can also be

used such as metal plate /table or wood plate

/table.

The frame level use to measure the working

table, Horizontal and vertical parts

Measures displacement at an angle of a lever

or plunger perpendicular to the axis of the

indicator. A regular dial indicator measures

linear displacement along that axis.

Measure the distance between two

symmetrically opposing sides.

Height Gauge

Square ruler

Hexagon keys

Screwdriver

Measure vertical distances. The pointer is

sharpened to allow it to act as a scriber and

assist in marking out work pieces.

To measure the right angle when you

assembling the Gantry Frame Part and the

Base Part.

The Metric Hexagon keys are the main

assembly tooling! The long armtypeofthe

Hexagon keys is most useful and save your

energy! The sizes are from 1.5 to 10.

The flat and crosshead types of screwdrivers

are needed. The electric screwdriver is highly

recommended!

13

CNC 6040 Router / Engraver System

CNCDIY CNC Routing Machines System User’s Manual

Spanner

Hammer

The nuts and crank bolts installation

The small adjustment and part assemble!

(Plastic)

B. Electrical Parts

Tools Name Description Picture

Soldering

iron

To melt the solder for wire connection.

The best power range is between 30W~

60W.

Soldering Tin

To melt to join wire cable

Power Cable

300/300V

HeatShrinkable

plastic

Spiral

Wrappings

1. 4 wires Cable

Model RVV4*1

Length: 5.9m (19.4ft)

2 wires Cable

Model RVV2*1

Length: 3.1m (10.2ft)

To protect the wire’s join

The recommended sizes are 3mm and 5mm

To protect the cable

The recommended inside diameter are 5mm

and 8mm

14

Loading...

Loading...