Page 1

E2 User Manual

E2- ROUTER INTERFACE BOX Rev. 1

User manual Rev. 1

1. Overview

This unit provides speed control on a router, on/off on router and vacuum or

coolant, connector for limits & home, built in safety charge pump, and

buffering of all I/Os.

It is designed to go between an existing controller and the PC. So wiring is

very simple. This way you can add the feature with our having to rewire the

control that is working Ok.

Revision: 10/21/2010 http://cnc4pc.com/TechDocs/ E2R1_USER_MANUAL.pdf 1/10

Page 2

E2 User Manual

2. Features

IEEE 1284 Standard compatible.

Includes the circuitry

recommended by the IEEE 1284

Level 1 standards for bidirectional

parallel communications between

personal computers and

peripherals.

DB25 connector to connect the

stepper motor driver board. This

connectors uses only pins 2-9.

Microcontroller based SCHP.

This board comes with a

microcontroller that allows the

implementation of a complex

algorithm for sampling and

analyzing the SCHP signal.

AC plugs for router and vacuum

or coolant pump.

Speed Control Signal Can Be

PWM or 0-25HZ Pulse Stream.

Speed Control can go from 30 to 100% of

the router’s rated speed.

Works with 110 or 220VAC at 60

or 50 HZ.

For 2.5HP or 1800 Watt Routers.

Buffered inputs and outputs.

Outputs are buffered through the

use of high speed and high

current buffers allowing the card

to output the signals without using

the power from the parallel port. It

can take the +3.3 or +5vdc signal

from the parallel port and deliver

solid +5vdc at 24 milliamps.

• Connector for Limit and Home

Switches. A C16 – Index & Home

Board or a custom cable with

switches or sensors can be

connected.

Works directly with popular

CNC hardware and software.

Such as Geckodrive G540,

Xylotex, HobbyCNC, Rockcliff, or

Rutex, and parallel port control

software, such as mach2, Linux

EMC, TurboCNC, CNCPlayer,

CNCZeus and others. (Not all

tested).

All TTL 5VDC signals. Interface

directly with parallel port interface

products and other CNC4PC

cards. 5VDC (TTL) cards are very

common among automation

devices.

Revision: 10/21/2010 http://cnc4pc.com/TechDocs/ E2R1_USER_MANUAL.pdf 2/10

Page 3

E2 User Manual

3. Specifications.

This box is based on the C33 – Router Multifunction Interface Board. For specifics,

please check the board’s manual:

http://cnc4pc.com/Tech_Docs/C33R1_1_User_Manual.pdf.

4. Configuration Steps:

1. Connect the cable as shown below:

Fig. 1.

Revision: 10/21/2010 http://cnc4pc.com/TechDocs/ E2R1_USER_MANUAL.pdf 3/10

Page 4

E2 User Manual

Fig. 2.

Revision: 10/21/2010 http://cnc4pc.com/TechDocs/ E2R1_USER_MANUAL.pdf 4/10

Page 5

E2 User Manual

5. Configure the Safety Charge Pump:

For Configuring the Safety Charge Pump in Mach X: Use the dialog window

Config / Ports and pins / Output Signals. Enable the Charge Pump output and

assign it to pin 17. Press the apply button.

Fig. 3. Charge Pump configuration

Selecting the SCHP operation mode.

The Safety Charge Pump can be

activated or deactivated by

moving the jumper position.

Revision: 10/21/2010 http://cnc4pc.com/TechDocs/ E2R1_USER_MANUAL.pdf 5/10

Page 6

E2 User Manual

6. Configure the Relays:

Assign two outputs to pins 1 and 16. Pin 1 controls the router and pins 16

controls the coolant.. Use the dialog window Config / Ports and pins / Output

Signals. Enable the two outputs and assign them to pins 1 and 16. Press the apply

button.

Fig. 4

Assign the two outputs to the Spindle and Food Relay. Use the dialog window

Config / Ports and pins / Spindle Setup. Make sure you uncheck the “disable

relays” box and assign the outputs to each relay. Press the apply button.

Fig. 5

Revision: 10/21/2010 http://cnc4pc.com/TechDocs/ E2R1_USER_MANUAL.pdf 6/9

Page 7

E2 User Manual

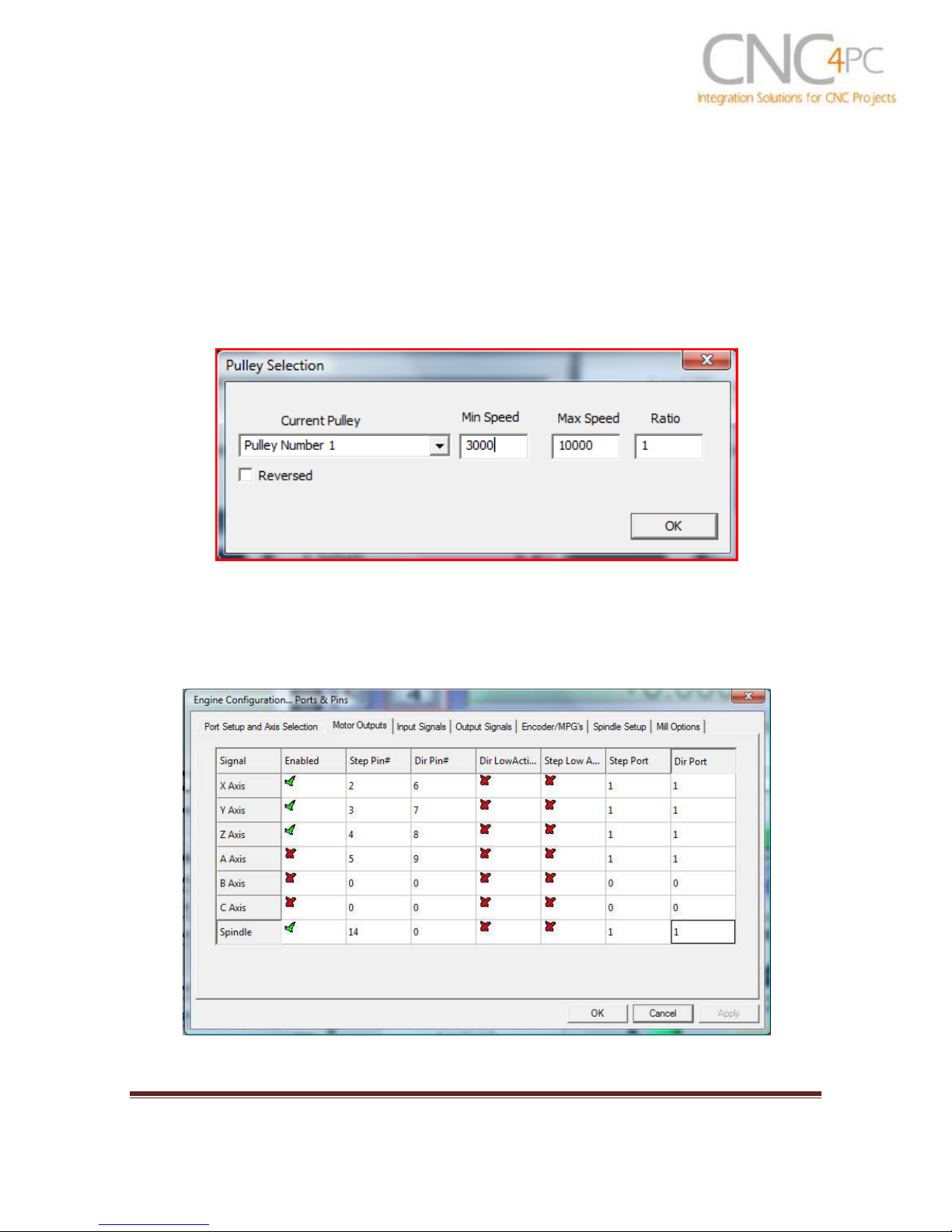

7. Configure the Speed Control:

Set the speeds that you expect for the spindle. Use the dialog window Config /

Spindle Pulleys. Remember that the min speed is 30% de value of the max speed.

If the router has a speed control knob, make sure to set it to the max speed. Press

the apply button.

Fig. 6

Set pin 14 for sending the pulse stream. E Use the dialog Config / Motor

Outputs. Enable the spindle and assign pin 14 for step.

Revision: 10/21/2010 http://cnc4pc.com/TechDocs/ E2R1_USER_MANUAL.pdf 7/9

Page 8

E2 User Manual

Set the frequency the box is going to work on (50 or 60Hz) and the desired

control method (PWM or Step and Direction).

The spindle can be controlled with PWM or Step and Direction. Use the dialog

window Config / Ports and pins / Spindle Setup. Under Motor Control select PWM

or Step and Direction. Instructions will be given for both control methods. Just

make sure whatever you select in the control software must match the jumper

position on the board. Press the apply button.

Set the jumper to select the appropriate control method, it can be PWM or step. If

using PWM play with different PWM Base frequencies, to up to 10,000. Leave the

one that works better for the setup.

Revision: 10/21/2010 http://cnc4pc.com/TechDocs/ E2R1_USER_MANUAL.pdf 8/9

Page 9

E2 User Manual

If using step and direction tune the spindle to go at max speed. Use the

dialog window Config / Motor Tuning / Spindle. Set velocity and acceleration to the

maximum value. Step length to 3..

Revision: 10/21/2010 http://cnc4pc.com/TechDocs/ E2R1_USER_MANUAL.pdf 9/9

Page 10

E2 User Manual

LIMIT SWITCHS CONNECTOR

RJ45 PIN

DESCRIPTION

CONTROLLER PINS

1

GND

2

Z HOME/LIMIT

Port 1 Pin 11

3

Y HOME/LIMIT

Port 1 Pin 12

4

X HOME/LIMIT

Port 1 Pin 13

5

NOT USED

6

NOT USED

7 5V

8

NOT USED

Wiring the Limits:

Disclaimer:

Use caution. CNC machines could be dangerous machines. DUNCAN USA, LLC

or Arturo Duncan are not liable for any accidents resulting from the improper use of

these devices. The C33 is not fail-safe device, and it should not be used in life

support systems or in other devices where its failure or possible erratic operation

could cause property damage, bodily injury or loss of life.

Revision: 10/21/2010 http://cnc4pc.com/TechDocs/ E2R1_USER_MANUAL.pdf 10/9

Loading...

Loading...