Page 1

C32- DUAL PORT MULTIFUNCTION CNC

BOARD Rev. 5

USER’S

MANUAL

___________________________________________________________________________

User’s Manual Page i

JULY, 2013

USER'S MANUAL

Page 2

TABLE OF CONTENTS

Page #

Contents

1.0 FEATURES ..................................................................................................................... 1

2.0 SPECIFICATIONS .......................................................................................................... 2

3.0 BOARD DESCRIPTION .................................................................................................. 3

4.0 POWER TERMINALS AND CONFIGURATION JUMPERS ............................................ 3

4.1 Power terminals and configuration Jumpers for inputs ......................................... 3

4.2 Power terminals and Jumper for Driver monitor circuit ......................................... 4

4.3 Controller selection jumpers (IEEE1284/SS) ........................................................... 4

4.4 Driver Fault Jumpers ................................................................................................. 5

5.0 CONFIGURATION DIPSWITCH ..................................................................................... 6

5.1 Position 1 ................................................................................................ ....................... 6

5.2 Position 2 ....................................................................................................................... 6

5.3 Position 3 and 4 ............................................................................................................ 8

6.0 LED INDICATOR ............................................................................................................ 9

7.0 VARIABLE SPEED CONTROL....................................................................................... 9

7.1 Operation Mode Selection Jumper .............................................................................. 10

8.0 PINOUT ......................................................................................................................... 17

9.0 WIRING SAMPLE ......................................................................................................... 18

10.0 CONNECTING A PENDANT ......................................................................................... 19

11.0 CONNECTING A C48 ................................................................................................... 20

12.0 WIRING DIAGRAMS ..................................................................................................... 20

13.0 DIMENSIONS ................................................................................................................ 24

___________________________________________________________________________

User’s Manual Page ii

Page 3

C32 (Rev. 5) User Manual

1.0 FEATURES

Connects directly to the Smooth Stepper (from Warp9).

IEEE 1284 Standard compatible.

Built-in PWM-Based Speed Control.

Built-in Isolated DC-DC converter for analog output voltage.

Two Built-in Electro mechanical Relays with NO and NC positions for

spindle control.

RJ45 Connector for Easy VFD Connection.

Monitors E-Stop, Safety Charge Pump and Drivers.

Monitors VFD alarm signal.(NEW)

Enables and disable the drivers.

Electromechanical Relay with NO and NC positions for general purpose

(Pin 2_16 or Pin 2_17, jumper-selectable).

Microcontroller based SCHP.

RJ45 connectors for all I/Os.

Easy Connections with CNC4PC relay boards and speed control boards.

Connects 4 and 6 axis pendants (MPG2, MPG12, and MPG8)

Optoisolated inputs.

Works with regular parallel ports.

All TTL 5VDC signals.

___________________________________________________________________________

User’s Manual Page 1

Page 4

C32 (Rev. 5) User Manual

PINS

PORT1

PORT2

TOTAL

INPUT

5

12

17

OUTPUT

13

4

17

TOTAL

18

16

34

OPTOISOLATED DIGITAL INPUT SPECIFICATIONS

Numbers of inputs

18

On-state voltage range

2 to 5V DC

Maximum off-state voltage

0.8V

Typical signal delay

2.8uS

DIGITAL OUTPUT SPECIFICATIONS

Number of outputs

16

Maximum output voltage

(5V power supply voltage) +

0.5V

Typical output current

24mA

Maximum off-state voltage

0.44 V

Maximum supported frequency

4M

Typical signal delay

10 nS

Time of transition to high impedance state

120mS*

Buffered outputs.

Status LEDs on all inputs and output connections.

Works directly with popular CNC hardware and software.

34 inputs and outputs on 2 ports.

2.0 SPECIFICATIONS

___________________________________________________________________________

User’s Manual Page 2

Page 5

C32 (Rev. 5) User Manual

3.0 BOARD DESCRIPTION

4.0 POWER TERMINALS AND CONFIGURATION JUMPERS

Before connecting the power supplies, follow steps below.

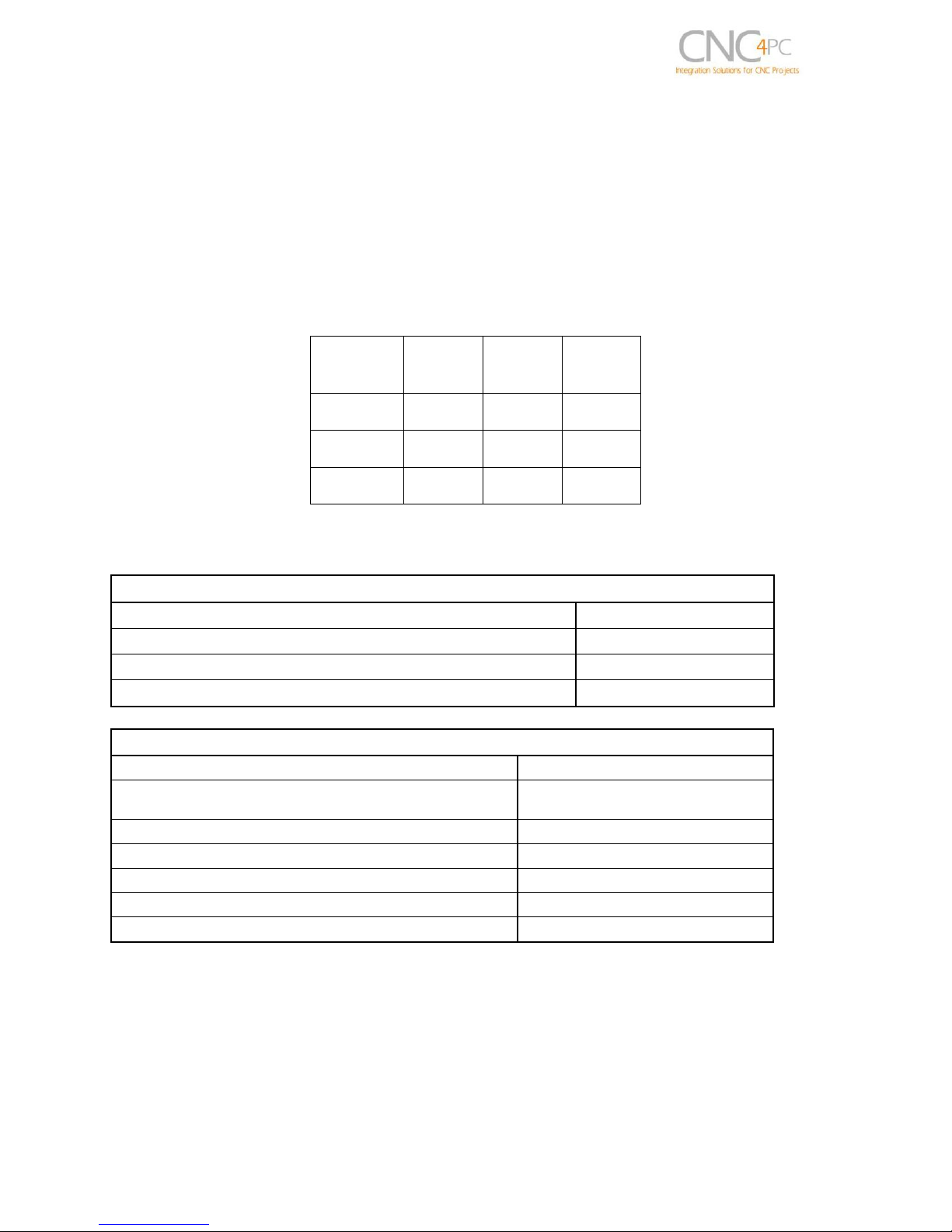

4.1 Power terminals and configuration Jumpers for inputs

These opto-isolated inputs require an external 5VDC to be powered. It is recommended

when isolation between PC and power of inputs is required (set jumpers in REQUIRED

position). Be sure that the GND terminals are common to the GND inputs power.

___________________________________________________________________________

User’s Manual Page 3

Page 6

C32 (Rev. 5) User Manual

If isolation is not required, don't connect any external power supply to these terminals

and set jumpers in "NOT REQUIRED" position.

4.2 Power terminals and Jumper for Driver monitor circuit

Connects an external (5V) power supply, when using drivers with error or alarm signal

common to its power GND. In this case, set jumper in “REQ” position.

In other cases don't connect any power supply to those terminals and set jumpers in

“NOT REQ” position.

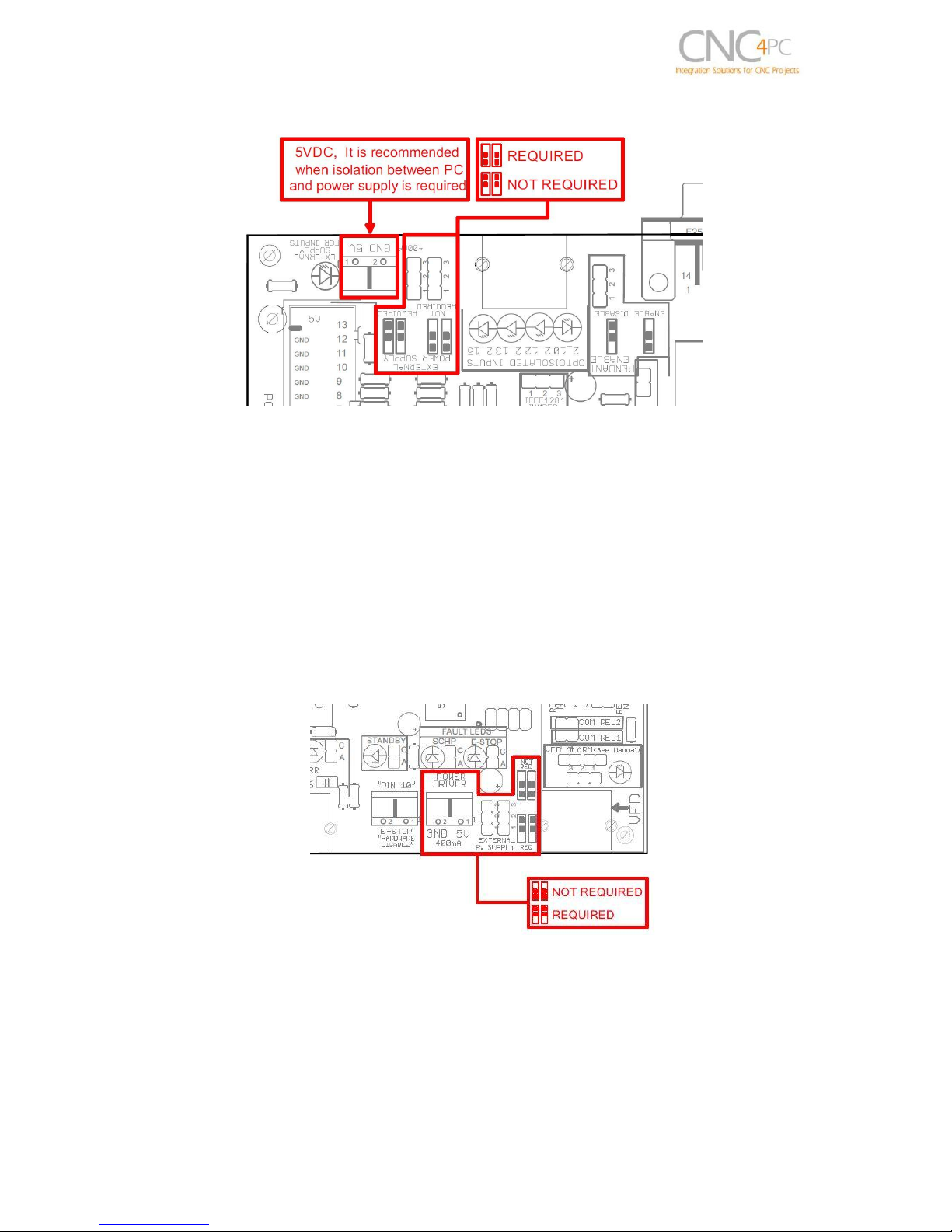

4.3 Controller selection jumpers (IEEE1284/SS)

If using a normal LPT port as control interface, set jumper in “compatible” position.

___________________________________________________________________________

User’s Manual Page 4

Page 7

C32 (Rev. 5) User Manual

By other hand, if using a SS or an ESS as controller, set jumper in “Not compatible”

position

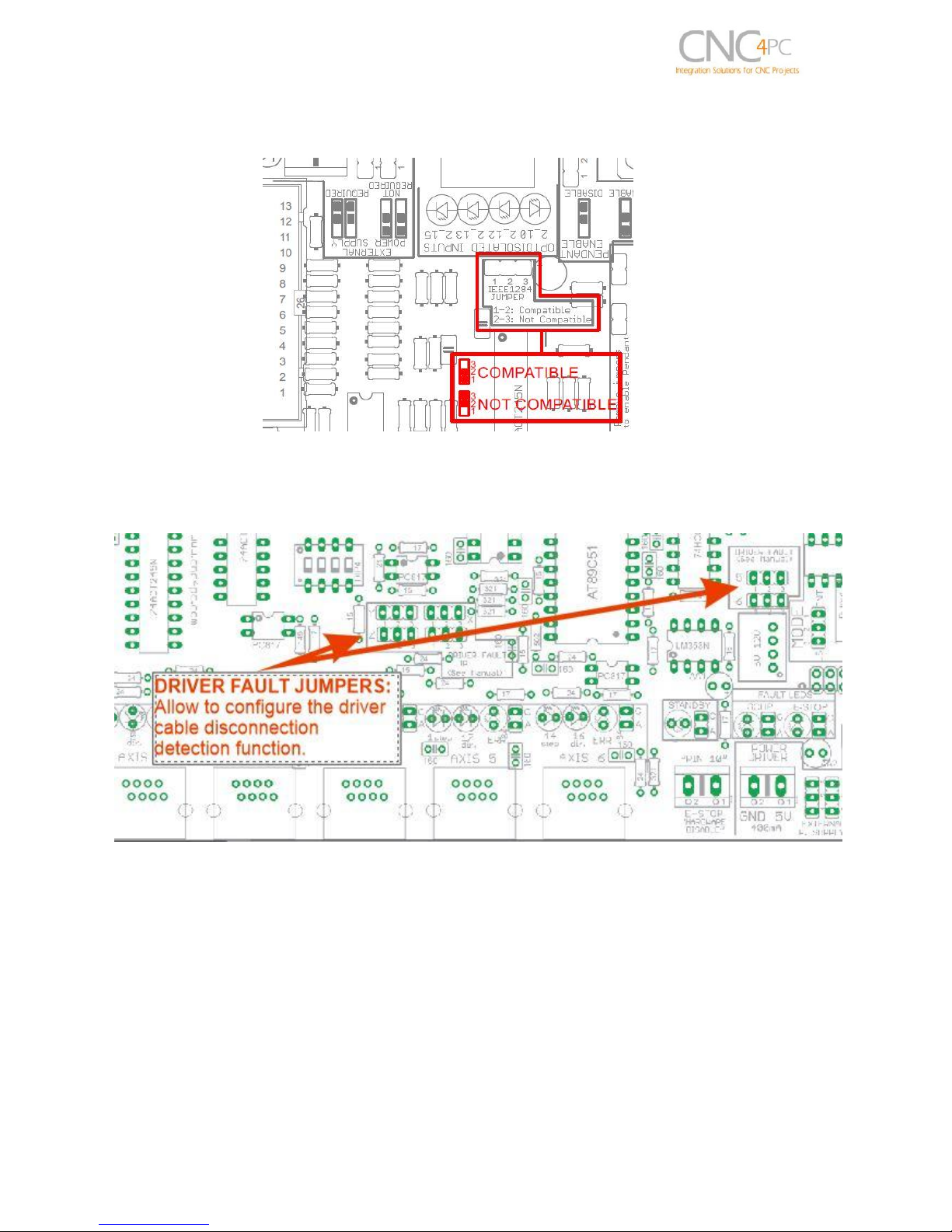

4.4 Driver Fault Jumpers

Some C34 boards have a special circuit that allows to the C32 detecting when the C34

has been disconnected.

To enable this detection function is required set jumper of the axes to be used in 1-2

position. If the C34 does not include this disconnection detection circuit or this function

is not going to be used, set all jumpers in 2-3 position (see the respective C34 User

manual).

If this function is enabled and any C34 is disconnected, the C32 will go to standby mode

and a driver error will be shown.

___________________________________________________________________________

User’s Manual Page 5

Page 8

C32 (Rev. 5) User Manual

DRIVER

DELAY

(Sec.)

G320/340

5

G203

2

G210/201/Keling

2

Viper Servo

driver

5

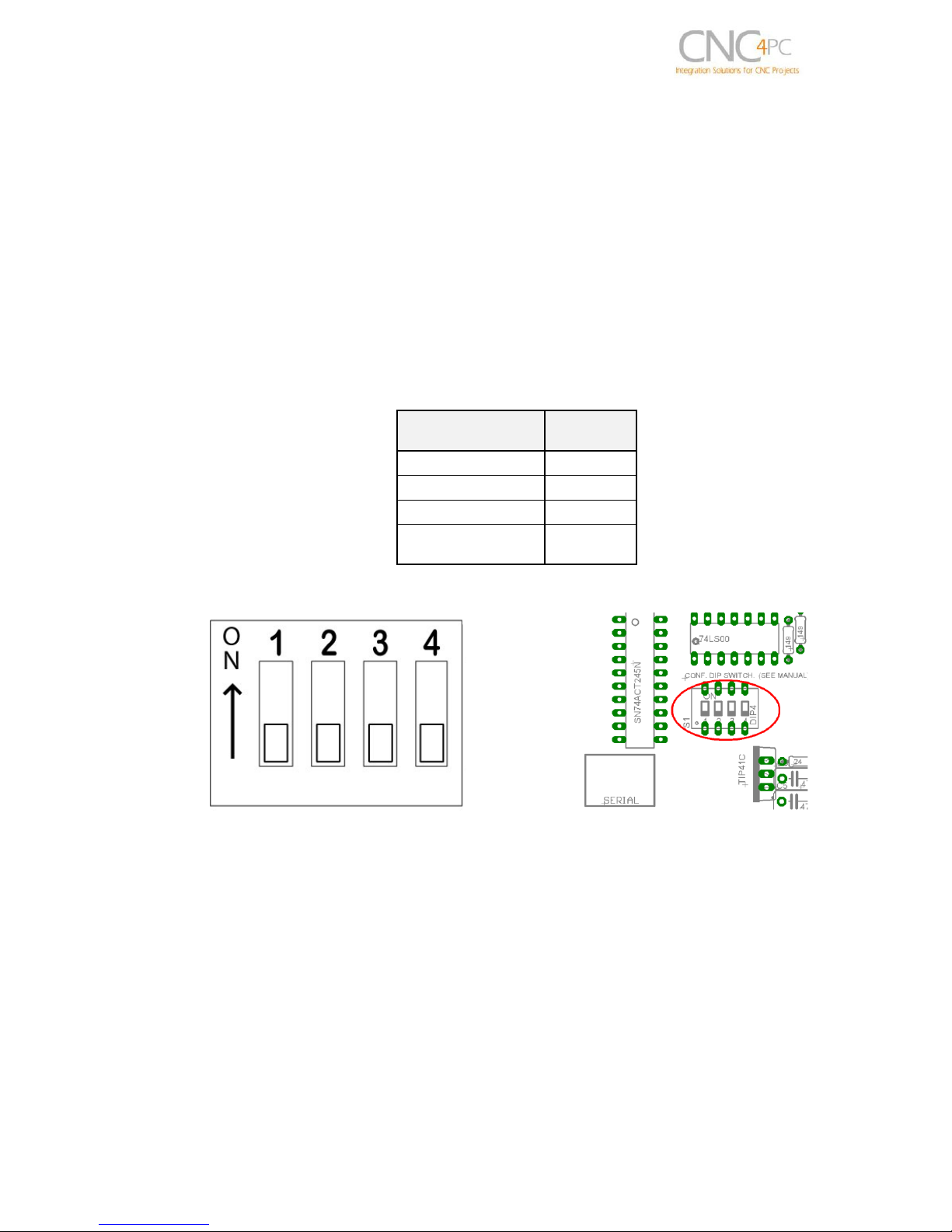

5.0 CONFIGURATION DIPSWITCH

DIPSWITCH allows activating or deactivating the SCHP detection function, and

selecting the driver to use and delays an enable signal for external devices.

5.1 Position 1

The enable output (Pin 17-Port 2) will be activated when the driver enable process

starts. A delay in the signal activation time could be added by selecting the OFF position

in the DIPSWITCH.

The table below shows the delay time for each supported driver.

SWITCH 1 OFF: Delayed enable output (Pin 17-Port 2).

SWITCH 1 ON: Non Delayed enable output (Pin 17-Port 2).

5.2 Position 2

Safety Charge Pump “SCHP”. (Pin 17 “Port 2”)

This board takes advantage of Mach ability to send a specific frequency through one of

the pins of the parallel port when the program is in control of the system.

Selecting the SCHP operation mode

___________________________________________________________________________

User’s Manual Page 6

Page 9

C32 (Rev. 5) User Manual

Onboard DIPSWITCH allows activating or deactivating the SCHP detection function.

SWITCH 2 ON: Activate the SCHP detection function.

SWITCH 2 OFF: Deactivate the SCHP detection function.

Note:When the Safety Charge Pump function is activated, 5V are present in the E-Stop

terminal and a valid SCHP signal is present, Port 2 Pin 17 will go high. This high signal

can be used to enable other external devices, such as enabling other Breakout Boards,

or relays that would enable servos, VFDs, contactors, etc….Variable Speed Control

(pin 14 “Port 1” ) and VFD connection.

For Configuring the Charge Pump in Mach X:

Use the dialog Config / Ports and pins / Output Signals. Enable the Charge Pump

output and configure it as is shown in the Fig. 12 Next, press the apply button.

___________________________________________________________________________

User’s Manual Page 7

Page 10

C32 (Rev. 5) User Manual

OPERATION

MODE

COMPATIBLE

DRIVER

DIP 3

DIP 4

Mode 1

G320/DG4S

0

0

Mode 2

G203

1

0

Mode 3

G210/201/Keling

0

1

Mode 4

Viper

1

1

5.3 Position 3 and 4

Select the driver you will use according to the table below.

This board includes a Microcontroller-based driver monitoring system. It performs

enabling and monitoring functions for servo Drivers, and only enabling function for

stepper drivers. It is required connect the driver ERR/RES (servo drivers) or EN

(stepper driver) terminal to the pin 5 of each RJ45 driver connector.

Here is a brief description of how these functions are performed for each operation

mode.

Operation Mode 1 (G320/DG4S)

When the system starts, the C32 error/reset pins go to a low state (0V), making sure the

driver remains disabled. When SCHP and E-Stop function are checked and validated

and there is no fault signal coming from any driver, the system sends a high (5V) to the

driver’s error/reset pins for about 5 seconds to enable the drivers. After that the system

monitors the driver’s err/res pins. If a fault occurs on any driver (0V in driver ERR/RES

pin) or an external fault occurs (E-Stop or SCHP fault), the system stops and sends an

e-stop signal (Active low) to the controller. All outputs on the board are disabled and

the drivers will be disabled by sending a LOW (0V) to the drivers ERR/RES pin. The

system will remain that way until the conditions to restart are present again.

Operation Mode 2 (G203)

When the system starts, the C32 enable pins go to a HIGH state (5V). When SCHP

and E-Stop function are checked and validated, the system send a LOW (0V) to the

driver’s EN pin for about 2 Sec, enabling the drivers. If an external error occurs, the

system stops, resets the CNC software and sends a HIGH (5V) to the drivers EN pin.

The system will remain that way until the conditions to restart are present again.

Operation Mode 3 (G210/201)

When the system starts, the C32 enable pins go to a LOW state (0V). When SCHP and

E-Stop function are checked and validated, the system send a HIGH (5V) to the Drivers

EN pin for about 2 Sec, enabling the Drivers. If an external error occurs, the system

stops, resets the CNC software and sends a LOW (0V) to the drivers EN pin. The

system will remain that way until the conditions to restart are present again.

___________________________________________________________________________

User’s Manual Page 8

Page 11

C32 (Rev. 5) User Manual

Operation Mode 4 (Viper, Teco and Delta)

When the system starts, the C32 enable pins go to a low state (0V). When SCHP and

E-Stop function are checked and validated and there is no fault signal coming from any

driver, the system sends a high (5V) to the driver Fault output pin, enabling the drivers.

After that the system monitors the driver’s Fault Output pin. If an error is generated in

any driver (0V in driver Fault Output pin) or an external error occurs, the system stops,

resets the CNC software and sends a LOW (0V) to the drivers to ensure they remain

disabled.

6.0 LED INDICATOR

The standby LED lights to indicate that the system is ready but disabled. When Status

LED, (Green LED) lights, it indicates that the system is enabled.

There are 4 possible error sources: a driver fault, E-STOP error, SCHP error or VFD

alarm. An LED will light close to the source of the fault.

7.0 VARIABLE SPEED CONTROL

Variable Speed Control allows controlling the spindle with PWM and direction signals,

as if it was an axis motor. It converts the PWM signal into an analog (0-10VDC) signal.

A Variable Frequency Drive or Inverter works by modifying the frequency for AC motors.

You can control most of these devices with an external analog signal (0-10VDC). That

is, if there is 5VDC control signal, the motor will run at 50% of full speed, if there is

10VDC, the motor will run at 100% of full speed. If there is no voltage, then the motor

will stop.

This function can also be used on many DC motor controllers by replacing the

potentiometer that controls the speed.

WARNING: You will require a voltmeter to fine tune your system.

Before connecting anything, please be sure to read your VFD’s manual and make sure

you understand all the safety issues.

___________________________________________________________________________

User’s Manual Page 9

Page 12

C32 (Rev. 5) User Manual

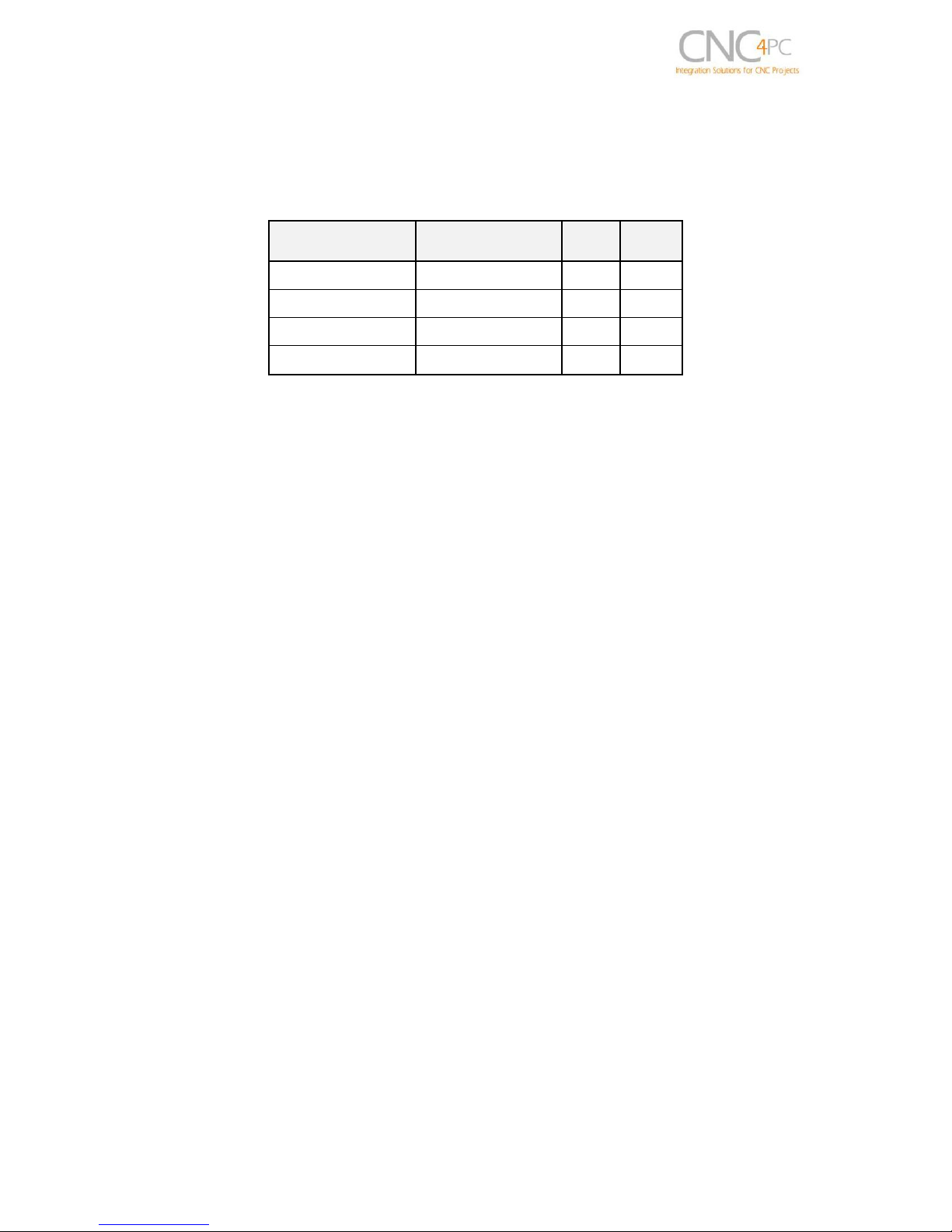

US MODE (INT)

PIN

RELAYS

1_14

1_16

REL 1

REL 2

OPERATION

PWM

1

OFF

ON

Spindle ON CCW

PWM

0

ON

OFF

Spindle ON CW

0 1 OFF

OFF

Spindle Off

0 0 OFF

OFF

Spindle Off

INTERNATIONAL MODE

(INT)

INPUTS

RELAYS

1_14

1_16

REL 1

REL 2

OPERATION

PWM

1

ON

ON

Spindle ON CCW

PWM

0

ON

OFF

Spindle ON CW

0 1 OFF

OFF

Spindle Off

0 0 OFF

OFF

Spindle Off

ELECTROMECHANICAL RELAYS

SPECIFICATIONS

Maximum Current (AC)

7A@240VAC;

10A@125VAC

Maximum Current (DC)

15A@24VDC;

10A@28VDC

7.1 Operation Mode Selection Jumper

This jumper allows selecting the way how the relays are activated when a PWM signal

and REV signal are present in the pins 1_14 and 1_16.

In US mode one relay is used to start on CW and the other one to start on CCW. In

international mode one relay is used for on/off, and the other one to indicate the CW or

CCW rotation of the spindle motor. This board uses the step and direction setting for

the spindle motor under motor output in Mach3 to generate the required action on the

relays. For both cases the presence of PWM will indicate spindle start.

See the tables below.

Relay 1 and 2 (Pins 16 “Port 1”)

They can be used to control the VFD. The relay specifications are shown in the table

below.

___________________________________________________________________________

User’s Manual Page 10

Page 13

C32 (Rev. 5) User Manual

RJ45 for VFD

RJ45

PIN

Function

1

Analog GND

2

Analog Output

3

VFD Alarm (NEW)

4

REL 1 Normally Open Contact

5

Not Used

6

REL 2 Normally Open Contact

7

Ext. 12VDC or 24VDC

8

Relay Common

RJ45 for VFD Connection

This RJ45 port let you make an easy connection between this board and the VFD.

An. GND: Ground of the Analog output signal

Analog Output: Isolated Analog Output Signal (0-10V)

VFD Alarm: Alarm signal generated by the VFD. (See VFD ALARM JUMPERS section)

Ext. 12VDC or 24VDC: External 12VDC or 24VDC power supply used to enable the

VFD.

Relay Common: The signal or voltage wired to this terminal can be connected to the

common terminals of the relay 1 and relay 2. Use the on-board RELAY COMMON

JUMPERS to do this connection. Remove the jumper if this connection is not required.

___________________________________________________________________________

User’s Manual Page 11

Page 14

C32 (Rev. 5) User Manual

VFD Connection and configuration jumpers

VFD Alarm jumpers

Many VFDs have general purpose relay that can be configured to generate an alarm

(Use its N.C. contacts). This board takes advantage of this feature to monitor the VFD

status.

The signal to monitor must be referenced to the Analog GND.

When the used alarm signal is “Analog GND”, set jumper as shown below

___________________________________________________________________________

User’s Manual Page 12

Page 15

C32 (Rev. 5) User Manual

When the used alarm signal is a positive voltage referenced to “analog GND”, set

jumper as shown below

If the VFD alarm monitoring function is not performed, set jumper as shown below

___________________________________________________________________________

User’s Manual Page 13

Page 16

C32 (Rev. 5) User Manual

For additional wiring diagrams, check the bottom of this product’s page:

http://www.cnc4pc.com/Store/osc/product_info.php?products_id=255

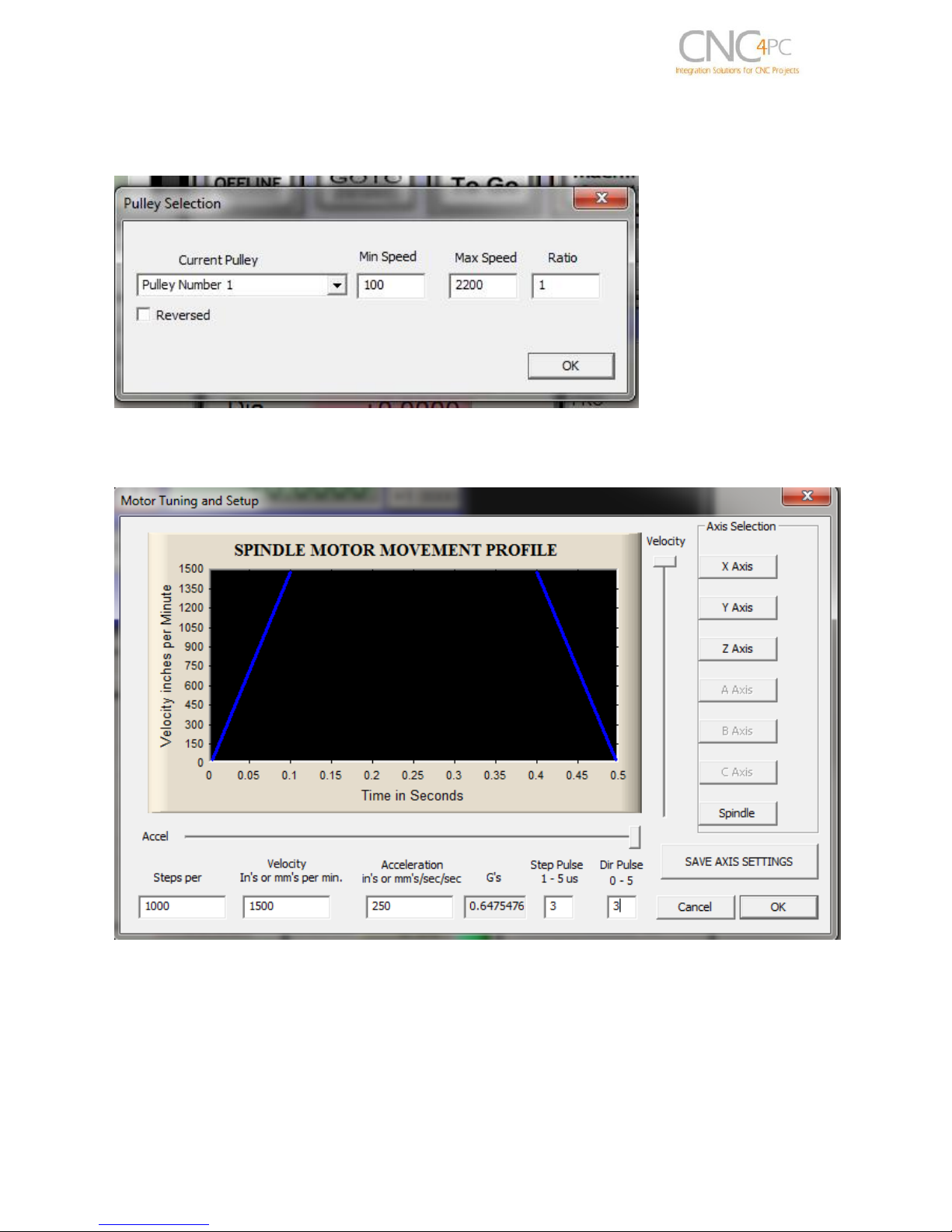

Configuring the Control Software:

For configuring Mach X follow these steps:

Go to Config / Ports&Pins / Motor Outputs. Enable the spindle and select the port and

pins you wired for step and direction.

Ports&Pins configuration screenshot

Go to Config / Ports&Pins / Spindle Setup. In the motor control box, check Use Spindle

Motor Output and PWM Control with a frequency of 300Hz. If using an external motion

controller, like the Smooth Stepper, this needs to be configured in the plugin too.

___________________________________________________________________________

User’s Manual Page 14

Page 17

C32 (Rev. 5) User Manual

Under Pulley Ratios set the pulley ratios of the machine.

Spindle Setup screenshot

Go to Config / Motor Tuning / Spindle. Set the velocity and acceleration to the max.

Motor Tuning and Setup screenshot

After configuring the Mach, these steps should be followed.

Connect a multimeter to the analog output terminals to fine tune the analog output.

Comment the spindle to go at max speed and make sure you get +10vdc. To adjust it

you can play with the potentiometer or the max speed you have set under motor tuning.

___________________________________________________________________________

User’s Manual Page 15

Page 18

C32 (Rev. 5) User Manual

Replacing a Potentiometer:

This circuit can be used to replace a potentiometer of a DC

motor speed control circuits. This speed controller circuits are

very commonly used by SIEG, KB Electronics, and many other

Asian machines. Before explaining how to do it, please first

keep in mind that it can be done if the voltage that goes though

the pot is +12vdc or less. This circuit cannot be used for AC

currents.

In most cases the terminals that go to the potentiometer will

carry these signals:

P1 = GND

P2 = WIPER

P3 = REFERENCE VOLTAGE

These are the steps for replacing a potentiometer:

Measure the voltage difference between P1 and P3. Make sure it measures

under +12vdc.

Fine tune the analog output to the output voltage you got from step 1.

Connect the ground from the analog output to the ground of the potentiometer (P1).

Connect the analog output to the wiper connection of the potentiometer (P2).

___________________________________________________________________________

User’s Manual Page 16

Page 19

C32 (Rev. 5) User Manual

RJ45 PIN P.P. PIN RJ45 PIN P.P. PIN RJ45 PIN P.P. PIN RJ45 PIN P.P. PIN RJ45 PIN P.P. PIN

1 GND_EXT 1 GND_EXT 1 GND 1 GND 1 GND_EXT

2 1_13 2 NC 2 2_17 2 NC 2 2_15

3 1_12 3 E-STOP 3 2_16 3 NC 3 2_13

4 1_11 4 2_11 4 2_1 4 2_16 4 2_12

5 NC 5 1_15 5 2_14 5 2_17 5 2_10

6 NC 6 NC 6 NC 6 NC 6 NC

7 5V_EXT 7 5V_EXT 7 5V 7 5V 7 5V_EXT

8 2_16 8 NC 8 NC 8 NC 8 NC

C16, A32, C45, A61

C3, C48

C15, C8, C9, C55, C56

General Porpuse

Isolated inputs

C19, C15, C5, C8, C9, C47,

C41, C6,C36, C54, C55,

C56

Supported connection

Supported connection

Supported connection

Supported connection

Supported connection

RJ45_7

RJ45_8

RJ45_9

RJ45_10

RJ45_11

8.0 PINOUT

Fig. 9RJ45 Distribution

___________________________________________________________________________

User’s Manual Page 17

Page 20

C32 (Rev. 5) User Manual

M_N: Parallel port or Smooth Stepper pin, where M is the port number and N is the pin

number.

* When connecting optoisolated boards, a connection between the ground of the C32

and the board must be used. This is the case for the C15 and C19.

9.0 WIRING SAMPLE

___________________________________________________________________________

User’s Manual Page 18

Page 21

C32 (Rev. 5) User Manual

Note: This wiring is just to illustrate a sample product application. Specific wiring may

vary from system to system. It is the user’s responsibility to implement it correctly.

For More Information

http://www.cnc4pc.com/Store/osc/product_info.php?products_id=255

10.0 CONNECTING A PENDANT

Set the pendant enable jumper in ENABLE position if a pendant is connected to the

DB25 connector.

Pins 2_10, 2_11, 2_12, 2_13 and 2_15 are able to be used with the pendant (DB25

connector) or as general use input pin (RJ45 connector). Set the Pendant ON/OFF

selection jumper in ON position if a pendant is connected to the DB25 connector.

Otherwise set jumpers in OFF position.

Fig. 9 Pendant ON/OFF selection jumper

___________________________________________________________________________

User’s Manual Page 19

Page 22

C32 (Rev. 5) User Manual

Note: Pins (2_2 - 2_9) are configured as inputs and they are only accessible through

the DB25 for Pendant.

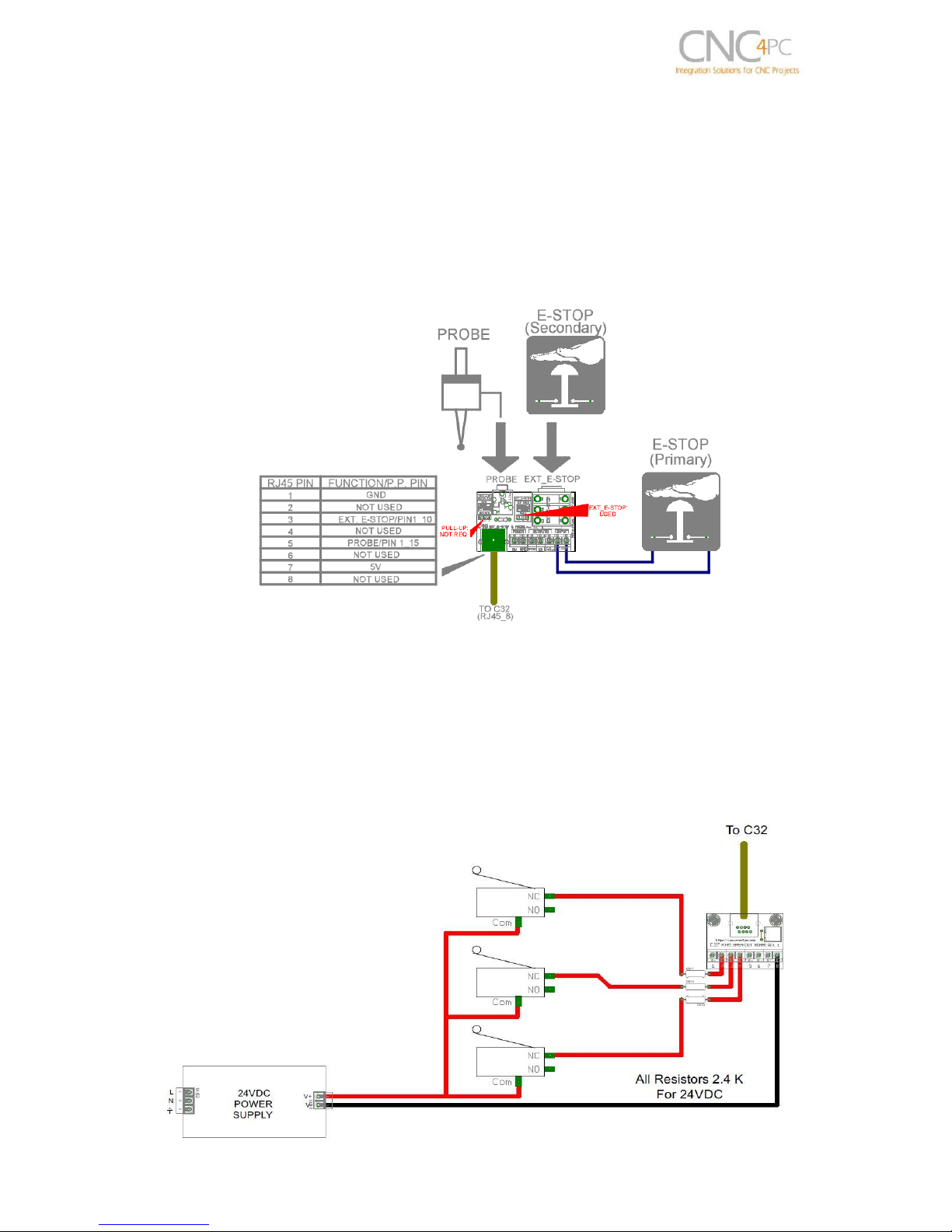

CONNECTING A C48

RJ45_8 provides an easy way to wire an External Probe and an external (Secondary)

E-Stop. Image below shows a wiring sample for this connection

Note: The primary E-stop can be connected to C32 E-Stop terminals or to the C48 E-Stop input

terminals.

11.0 WIRING DIAGRAMS

This connection is for signals of 24VDC, allows what inputs signals can be to 24V. This

requires limiting resistors.

___________________________________________________________________________

User’s Manual Page 20

Page 23

C32 (Rev. 5) User Manual

Wiring diagram to connect switches with 24VDC power supply

While this board supports only TTL +5VDC signals, different kind of sensors and

switches using different voltages can be connected using the diagrams that follow:

Note: The below wiring diagrams are an example, any input can be used for the

connections.

Wiring diagram to connect switches

Wiring diagram to connect NPN open collector proximity sensors

___________________________________________________________________________

User’s Manual Page 21

Page 24

C32 (Rev. 5) User Manual

For a 24V or 12V sensor, the recommended value for the external resistor R1 is 4.7K

Ohm.

Wiring diagram to connect in parallel NPN open collector proximity sensors

Wiring diagram to connect NPN proximity sensors with internal pull up resistor

___________________________________________________________________________

User’s Manual Page 22

Page 25

C32 (Rev. 5) User Manual

Connecting PNP open collector proximity sensor with

the C32 Rev.3

Board

R Value (12V)

R Value (24V)

C32 Rev. 3

470Ω

1KΩ

Wiring diagram to connect PNP open collector proximity sensors

Table 15 R value to Connect PNP open collector proximity sensor with the C33.

Wiring diagram to do an “Auto Tool Zero”

___________________________________________________________________________

User’s Manual Page 23

Page 26

C32 (Rev. 5) User Manual

12.0 DIMENSIONS

All dimensions are in Millimeters.

Disclaimer:

Use caution. CNC machines can be dangerous machines. Neither DUNCAN USA, LLC

nor Arturo Duncan are liable for any accidents resulting from the improper use of these

devices. This product is not a fail-safe device and it should not be used in life support

systems or in other devices where its failure or possible erratic operation could cause

property damage, bodily injury or loss of life.

___________________________________________________________________________

User’s Manual Page 24

Loading...

Loading...