CMWORKS Lodestar Parts Manual

Operating, Maintenance & Parts Manual

Rated Loads 1/8 To 3 Tonnes

125 Kg To 3000 Kg

®

Follow all instructions and warning for

inspecting, maintaining and operating

this hoist.

The use of any hoist presents some risk of personal injury or

property damage. That risk is greatly increased if proper

instructions and warnings are not followed. Before using this

hoist, each operator should become thoroughly familiar with all

warnings, instructions, and recommendations in this manual.

Retain this manual for future reference and use.

Forward this manual to the hoist operator.

Failure to operate the equipment as directed in the manual

may cause injury.

Before using the hoist, fill in the information below.

Refer to the hoist identification plate.

Model Number

Serial Number

Purchase Date

Voltage

Rated Load

Electric Chain

00001996 (REV AB) 627NH

CM HOIST PARTS AND SERVICES ARE AVAILABLE IN THE UNITED STATES AND IN CANADA

PARTS FOR YOUR HOIST ARE AVAILABLE FROM YOUR LOCAL AUTHORIZED REPAIR STATION. FOR THE NAME

OF THE NEAREST PARTS OR SERVICE CENTER, VISIT OUR WEB SITE WWW.CMWORKS.COM

OR CALL OUR CUSTOMER SERVICE DEPARTMENT.

2

SAFETY PRECAUTIONS

Each Lodestar Electric Hoist is built in accordance with the specifications contained herein and at the time of manufacture complied with our interpretation of applicable sections of the *American Society of Mechanical Engineers Code B30.16 “Overhead

Hoists,” the National Electrical Code (ANSI/NFPA 70) and the Occupational Safety and Health Act. Since OSHA states the National

Electrical Code applies to all electric hoists, installers are required to provide current overload protection and grounding [on the

branch circuit section] in keeping with the code. Check each installation for compliance with the application, operation and maintenance sections of these articles.

The safety laws for elevators, lifting of people and for dumbwaiters specify construction details that are not incorporated into the

hoists. For such applications, refer to the requirements of applicable state and local codes, and the American National Safety

Code for elevators, dumbwaiters, escalators and moving walks (ASME A17.1). Columbus McKinnon Corporation cannot be responsible for applications other than those for which CM equipment is intended.

*Copies of this standard can be obtained from ASME Order Department, 22 Law Drive, Box 2300, Fairfield, NJ 07007-2300, U.S.A.

THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH IF NOT FOLLOWED

COULD ENDANGER THE PERSONAL SAFETY AND/OR PROPERTY OF YOURSELF AND

!

!

Usage of hoists that do not involve lifting of the load on

the lower hook or using hoists in the inverted position

without special precaution may cause an accident

resulting in injury and/or property damage.

Consult Columbus McKinnon for information concerning

using hoists in these applications.

Improper operation of a hoist can create a potentially

hazardous situation which, if not avoided, could result in death

tially hazardous situation, the operator shall:

1. NOT operate a damaged, malfunctioning or unusually

performing hoist.

2. NOT operate the hoist until you have thoroughly read and

understood this Operating, Maintenance and Parts Manual.

3. NOT operate a hoist which has been modified.

4. NOT lift more than rated load for the hoist.

5. NOT use hoist with twisted, kinked, damaged, or worn

load chain.

6. NOT use the hoist to lift, support, or transport people.

7. NOT lift loads over people.

8. NOT operate a hoist unless all persons are and remain

clear of the supported load.

9. NOT operate unless load is centered under hoist.

10.NOT attempt to lengthen the load chain or repair dam-

aged load chain.

11.Protect the hoist’s load chain from weld splatter or other

damaging contaminants.

12.NOT operate hoist when it is restricted from forming a

straight line from hook to hook in the direction of loading.

13.NOT use load chain as a sling, or wrap load chain

around load.

14.NOT apply the load to the tip of the hook or to the hook

latch.

15.NOT apply the load unless load chain is properly seated

in the chain wheel(s) or sprocket(s).

16.NOT apply load if bearing prevents equal loading on all

load supporting chains.

17.NOT operate beyond the limits of the load chain travel.

18.NOT leave load supported by the hoist unattended unless specific precautions have been taken.

19.NOT allow the load chain or hook to be used as an electrical or welding ground.

20.NOT allow the load chain or hook to be touched by a live

welding electrode.

OTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL AND ANY PROVIDED

WITH THE EQUIPMENT BEFORE

ATTEMPTING TO OPERATE YOUR LODESTAR HOIST.

WARNING

TO AVOID INJURY:

WARNING

!

or serious injury. To avoid such a poten-

21.NOT remove or obscure the warnings on the hoist.

22.NOT operate a hoist on which the safety placards or de-

cals are missing or illegible.

23.NOT operate a hoist unless it has been securely attached

to a suitable support.

24.NOT operate a hoist unless load slings or other approved

single attachments are properly sized and seated in the

hook saddle.

25.Take up slack carefully - make sure load is balanced and

load holding action is secure before continuing.

26.Shut down a hoist that malfunctions or performs unusually

and report such malfunction.

27.Make sure hoist limit switches function properly.

28.Warn personnel of an approaching load.

!

CAUTION

Improper operation of a hoist can create a potentially

hazardous situation which, if not avoided, could result in minor or moderate injury. To avoid such a potentially hazardous situation, the

operator shall:

1. Maintain a firm footing or be otherwise secured when

operating the hoist.

2. Check brake function by tensioning the hoist prior to

each lift operation.

3. Use hook latches. Latches are to retain slings, chains,

etc. under slack conditions only.

4. Make sure the hook latches are closed and not

supporting any parts of the load.

5. Make sure the load is free to move and will clear all

obstructions.

6. Avoid swinging the load or hook.

7. Make sure hook travel is in the same direction as shown

on the controls.

8. Inspect the hoist regularly, replace damaged or worn

parts, and keep appropriate records of maintenance.

9. Use the hoist manufacturer’s recommended parts when

repairing the unit.

10.Lubricate load chain per hoist manufacturer’s

recommendations.

11.NOT use the hoist load limiting or warning device to

measure load.

12.NOT use limit switches as routine operating stops unless

allowed by manufacturer. They are emergency devices

only.

13.NOT allow your attention to be diverted from operating

the hoist.

14.NOT allow the hoist to be subjected to sharp contact with

other hoists, structures, or objects through misuse.

15.NOT adjust or repair the hoist unless qualified to perform

such adjustments or repairs.

!

3

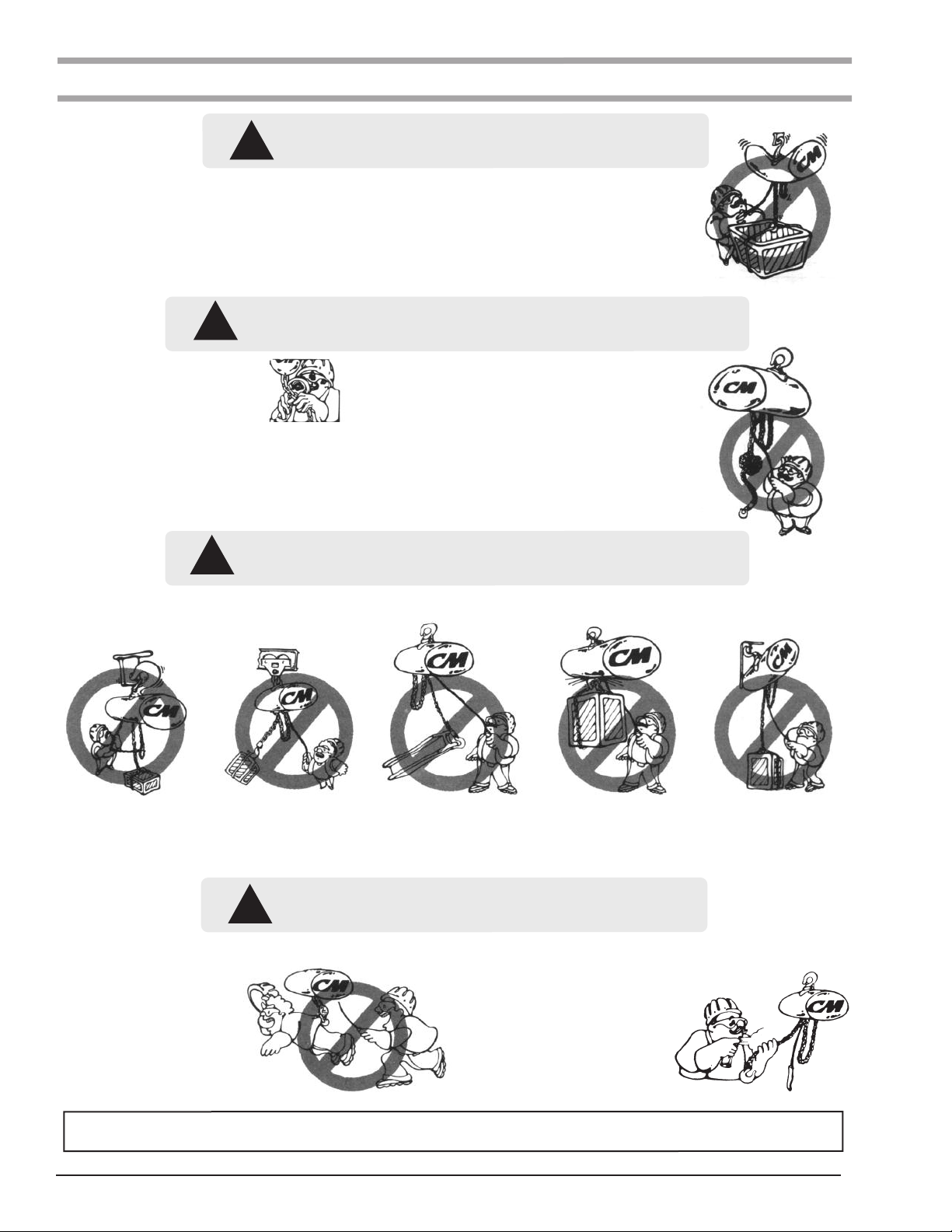

HOIST SAFETY IS UP TO YOU...

1

Know the capacities of your hoists and the

weight of your loads. Then match them.

CHOOSE THE RIGHT HOIST FOR THE JOB...

Choose a hoist with a capacity for the job.

The application, the size and type of load,

!

2

fore use, in addition to regular, periodic

maintenance inspections.

tices and legibility.

to the attention of supervisors. Be sure defective hoists are tagged and taken out of

INSPECT

All hoists should be visually inspected be-

Inspect hoists for operational warning no-

Deficiencies should be noted and brought

!

WARNING

!

the attachments to be used and the period of

use must also be taken into consideration in

selecting the right hoist for the job.

Remember the hoist was designed to ease

WARNING

service until repairs are made.

Under no circumstances should you oper-

ate a malfunctioning hoist.

Check chain for gouged, twisted, distorted

links and foreign material. Do not operate

hoists with twisted, kinked or damaged chain.

Load chain should be properly lubricated.

Hooks that are bent, worn or whose open-

WARNING

– DO NOT LIFT MORE THAN RATED LOAD.

our burden and carelessness not only endangers the operator, but in many cases, a

valuable load.

– DO NOT OPERATE DAMAGED OR MALFUNCTIONING HOIST.

– DO NOT OPERATE WITH TWISTED, KINKED OR DAMAGED

CHAIN.

ings are enlarged beyond normal throat

opening should not be used. If latch does

not engage throat opening of hook, hoist

should be taken out service.

Check for misphasing – hook travel should

correspond to control direction.

– DO NOT PULL AT AN ANGLE. BE SURE HOIST AND LOAD

ARE IN A STRAIGHT LINE.

– DO NOT USE LOAD CHAIN AS A SLING.

3 USE HOIST PROPERLY

Be sure hoist is solidly held in the

uppermost part of the support

hook arc.

Be sure hoist and load are in a

straight line. Do not pull at an

angle.

!

4 LIFT PROPERLY

Do not lift co-workers with a hoist.

Make sure everyone is clear of the load

when you lift.

Do not remove or obscure operational

warning notices.

Be sure load is hooked securely.

Do not tip load the hook. Do not

load hook latch. Hook latch is to

prevent detachment of load under

slack chain conditions only.

WARNING

Do not use load chain as a sling.

Such usage damages the chain

and lower hook.

– DO NOT LIFT PEOPLE OR LOADS

OVER PEOPLE.

5

and free of dust, dirt, moisture, etc., which

will in any way affect the operation or

safety of the equipment.

lubricated.

hoist before returning it to full service.

MAINTAIN PROPERLY

CLEANING: Hoists should be kept clean

LUBRICATION: Chain should be properly

AFTER REPAIRS: Carefully operate the

Do not operate with hoist head

resting against any object. Lift the

load gently. Do not jerk it.

VIOLATION OF ANY OF THESE WARNINGS LISTED MAY RESULT IN SERIOUS PERSONAL INJURY TO THE OPERATOR OR NEARBY PERSONNEL BY RELEASED LOAD OR BROKEN HOIST COMPONENTS.

4

FOREWORD

This manual contains important information to help you properly install, operate and maintain your hoist for maximum performance,

economy and safety.

Please study its contents thoroughly before putting your hoist into operation. By practicing correct operating procedures and by

carrying out the recommended preventive maintenance suggestions, you will experience long, dependable and safe service.

After you have completely familiarized yourself with the contents of this manual, we recommend that you carefully file it for future

reference.

The information herein is directed to the proper use, care and maintenance of the hoist and does not comprise a handbook on the

broad subject of rigging.

Rigging can be defined as the process of lifting and moving heavy loads using hoists and other mechanical equipment. Skill acquired

through specialized experience and study is essential to safe rigging operations. For rigging information, we recommend consulting

a standard textbook on the subject.

TABLE OF CONTENTS

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Foreword . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

General Information

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-8

CM Repair/Replacement policy . . . . . . .(Back Page)

Accessories

Hook Suspensions . . . . . . . . . . . . . . . . . . . . . . . . . .9

Lug Suspension . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Series 635 Low Headroom Trolley . . . . . . . . . . . . . .9

Series 635 Motor Driven Trolley . . . . . . . . . . . . . . . .9

Latchlok Hooks . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Chain Container . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Installation

Unpacking Information . . . . . . . . . . . . . . . . . . . . . .10

Installing Suspension . . . . . . . . . . . . . . . . . . . .10-11

Recommended Torques . . . . . . . . . . . . . . . . . . . . .11

Attaching Load Chain . . . . . . . . . . . . . . . . . . . . . . .12

Installing Series 635 Low Headroom Trolley . . . . .12-13

Power Supply and Electrical Connections . . . . . . . . . .14

Operating Instructions

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Operating Instruction-Hoist . . . . . . . . . . . . . . . .16-17

Safety Procedures . . . . . . . . . . . . . . . . . . . . . . . . .17

Inspection

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Frequent Inspections . . . . . . . . . . . . . . . . . . . .18-19

Periodic Inspections . . . . . . . . . . . . . . . . . . . . .18-19

Preventative Maintenance . . . . . . . . . . . . . . . . . . .18

Hook Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Load Chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Maintenance

Load-limiter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Hoist Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . .21

Trolley Lubrication . . . . . . . . . . . . . . . . . . . . . . . . .21

Adjustments

Electric Brake . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Limit Switches . . . . . . . . . . . . . . . . . . . . . . . .23-24

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . .25-27

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . .28-29

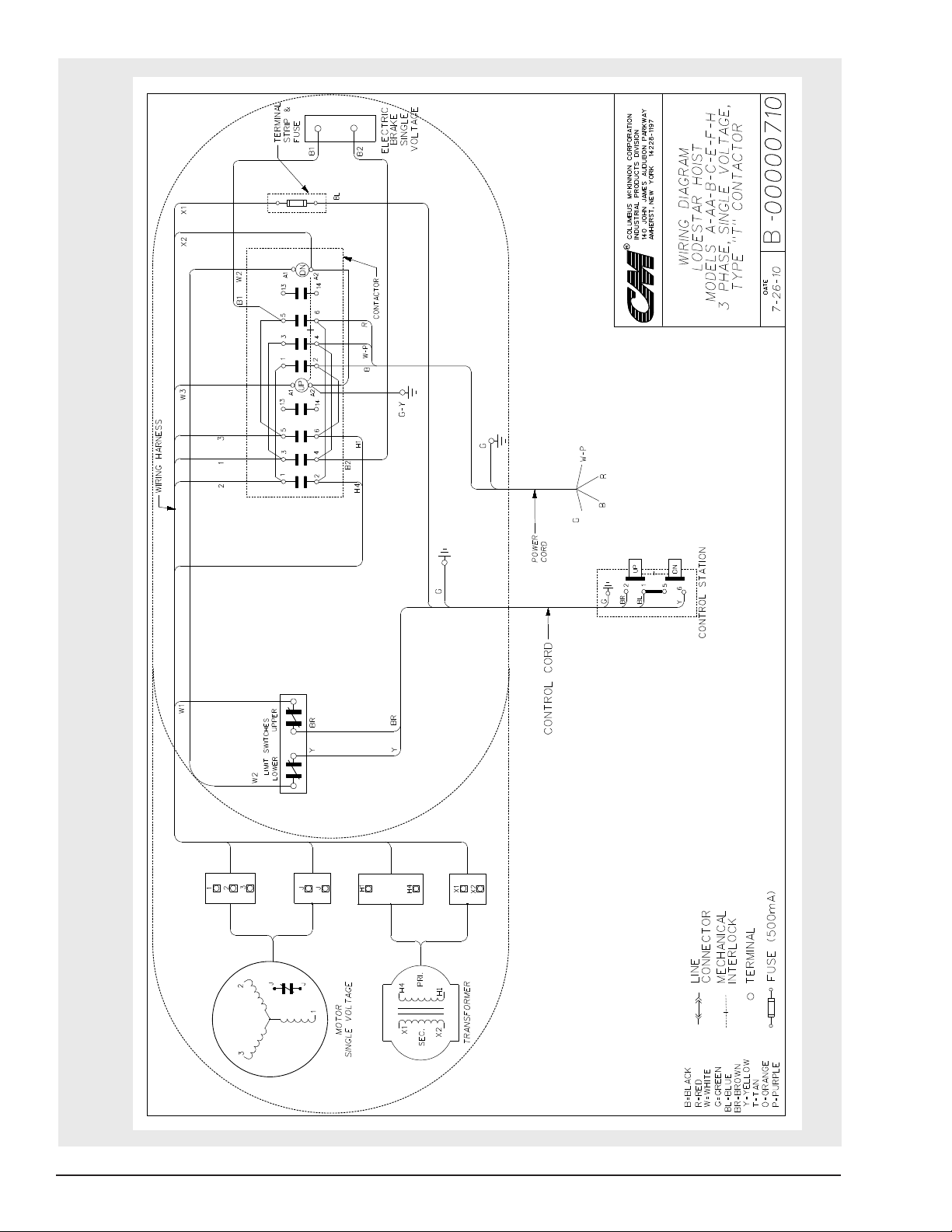

Typical Wiring Diagrams . . . . . . . . . . . . . . . . . .30-72

Assembly Instructions

Hook or Lug Suspensions . . . . . . . . . . . . . . . . . . .73

Lower Hook Block Pin . . . . . . . . . . . . . . . . . . . . . .73

Removal and Installation of Load Chain . . . . . .73-74

Cutting Chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Ordering Instructions . . . . . . . . . . . . . . . . . . . . . . . . . .75

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76-137

Lubricants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .138

Recommended Spare Parts . . . . . . . . . . . . . . . . . . .138

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .139

LIST OF TABLES

Table Title Page

1 Lodestar Electric Chain Hoist Specs. . . . . . 6-8

2 Recommended Torques . . . . . . . . . . . . . . . . 11

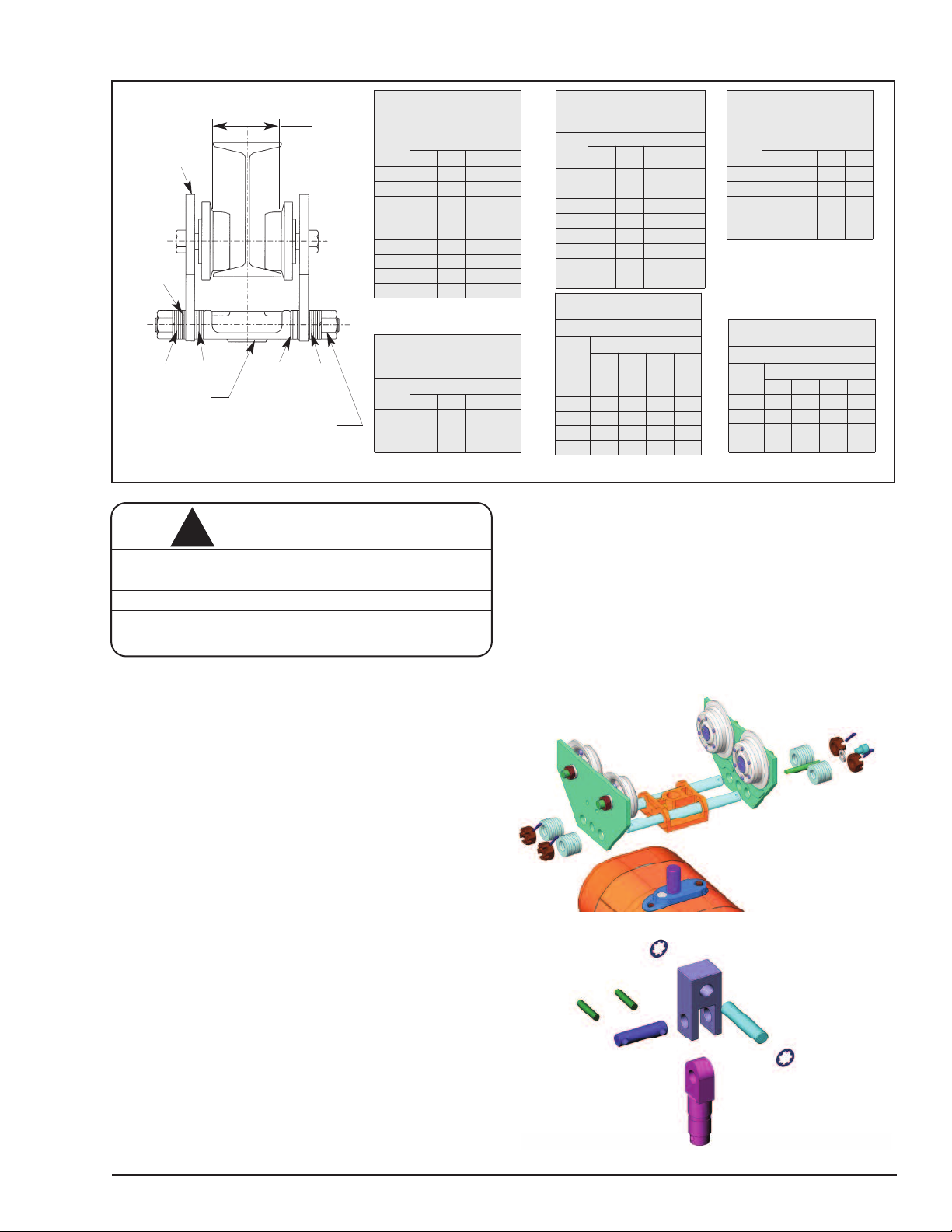

3 Series 635 Trolley Side Frame Spacing . . . . .13

4 Minimum Frequent Inspections . . . . . . . . . . . .19

5 Minimum Periodic Inspections . . . . . . . . . . . .19

6 Limit Switches . . . . . . . . . . . . . . . . . . . . . . . .22

7 Troubleshooting . . . . . . . . . . . . . . . . . . . . .25-27

8 Electrical Data . . . . . . . . . . . . . . . . . . . . . .28-29

LIST OF ILLUSTRATIONS

Figure Table Page

1 Hook Suspensions . . . . . . . . . . . . . . . . . . . . . .9

2 Lug Suspensions . . . . . . . . . . . . . . . . . . . . . . .9

3 Series 635 Low Headroom Trolley . . . . . . . . . .9

4 Series 635 Motor Driven Trolley . . . . . . . . . . . .9

5 Upper or Lower Latchlok Hook . . . . . . . . . . . . .9

6 Chain Container . . . . . . . . . . . . . . . . . . . . . . . .9

7 Attaching Load Chain . . . . . . . . . . . . . . . . . . .11

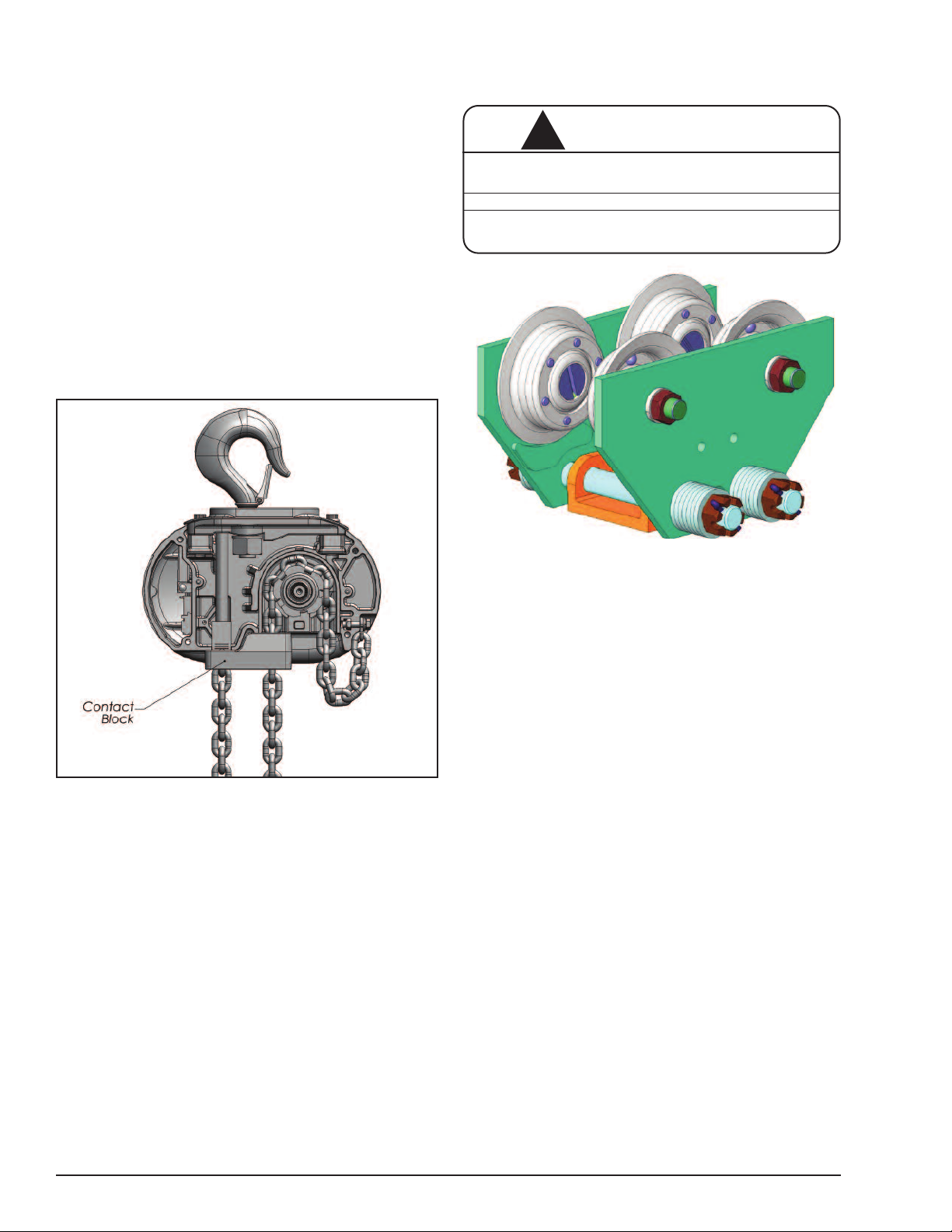

8 Contact Block . . . . . . . . . . . . . . . . . . . . . . . . .12

9 Series 635 Low Headroom Trolley . . . . . . . . .12

10 1/8 to 2 Ton Hoist to Trolley Assembly . . . . . .13

11 3 Ton Hoist to Trolley Assembly . . . . . . . . . . .13

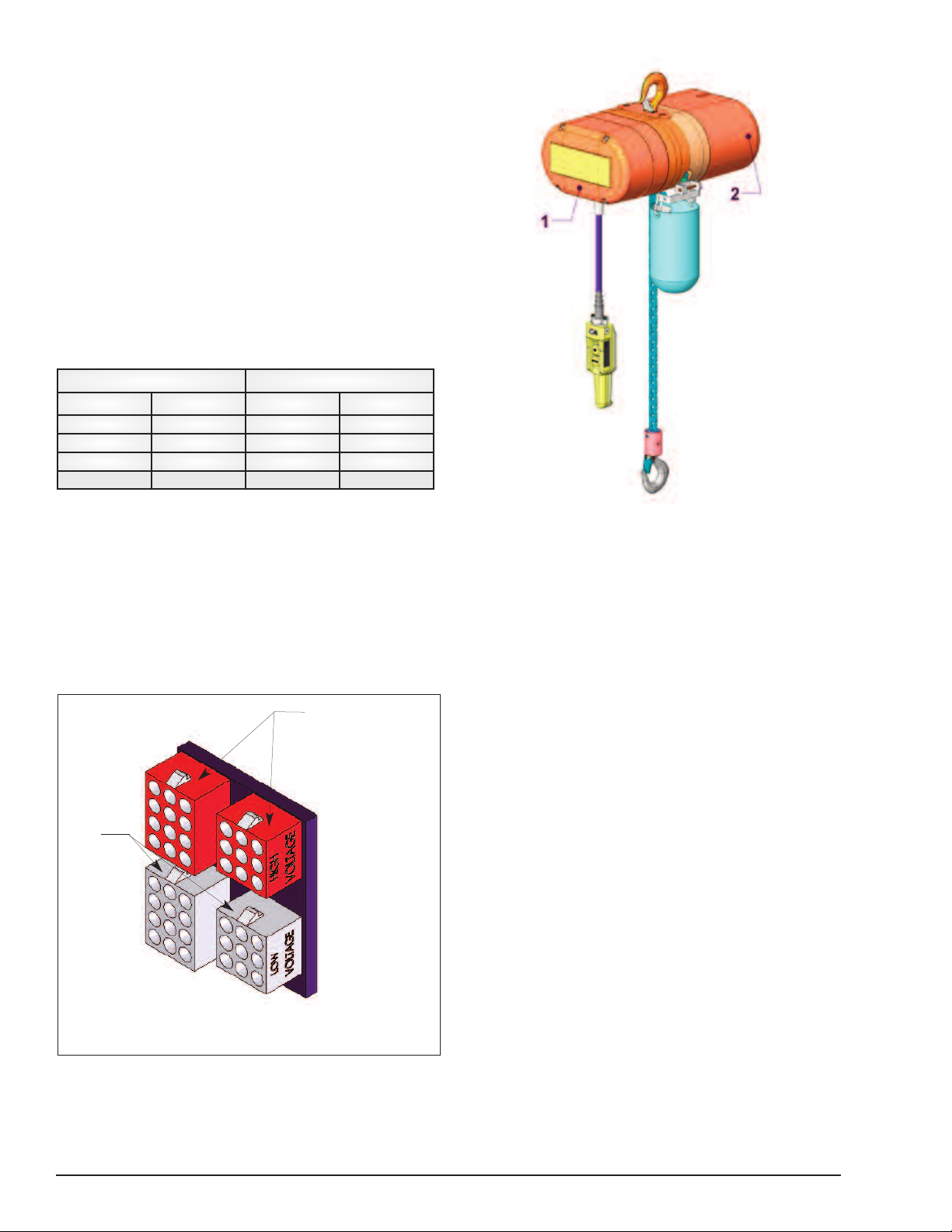

12 Voltage Change Board . . . . . . . . . . . . . . . . . .14

13 Locations of Components . . . . . . . . . . . . . . . .14

14 Hook Inspection . . . . . . . . . . . . . . . . . . . . . . .18

15 Chain Wear areas . . . . . . . . . . . . . . . . . . . . .20

16 Gaging Load Chain Wear . . . . . . . . . . . . . . . .20

17 Chain Inspection . . . . . . . . . . . . . . . . . . . . . .20

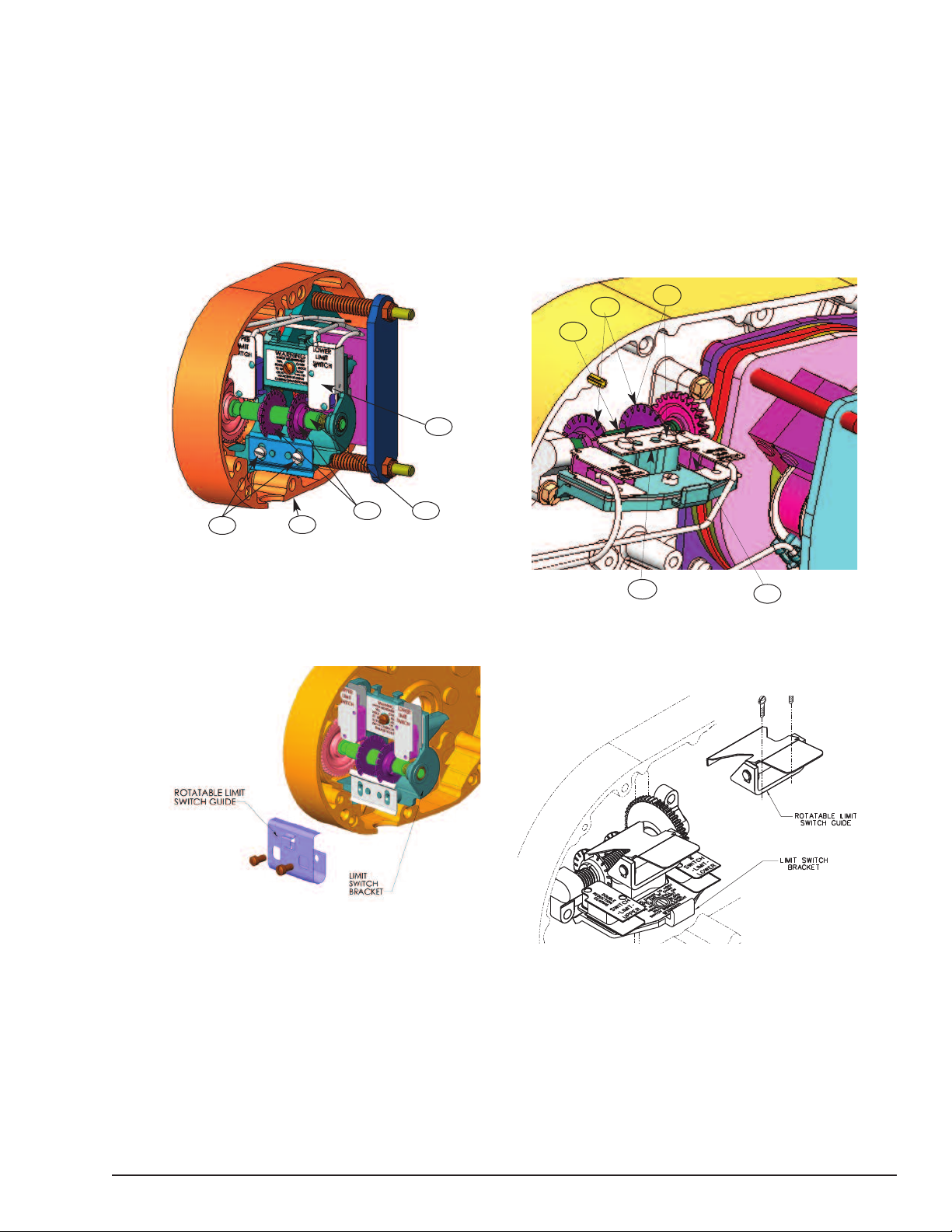

18 Limit Switches Models, V1 Models . . . . . . . . .23

18A Rotatable Limit Switches, V1 Models . . . . . . . . .23

19 Limit Switches, V2 Models . . . . . . . . . . . . . . .23

19A Rotatable Limit Switch, V2 Models . . . . . . . . .23

20 Typical Wiring Diagrams . . . . . . . . . . . . . .30-72

21 Swivel Hook Suspensions . . . . . . . . . . . . . . .73

22 Chain Embossing . . . . . . . . . . . . . . . . . . . . . .73

23A Cutting Chain By Nicking . . . . . . . . . . . . . . . .75

23B Cutting Chain With A Bolt Cutter . . . . . . . . . . .75

5

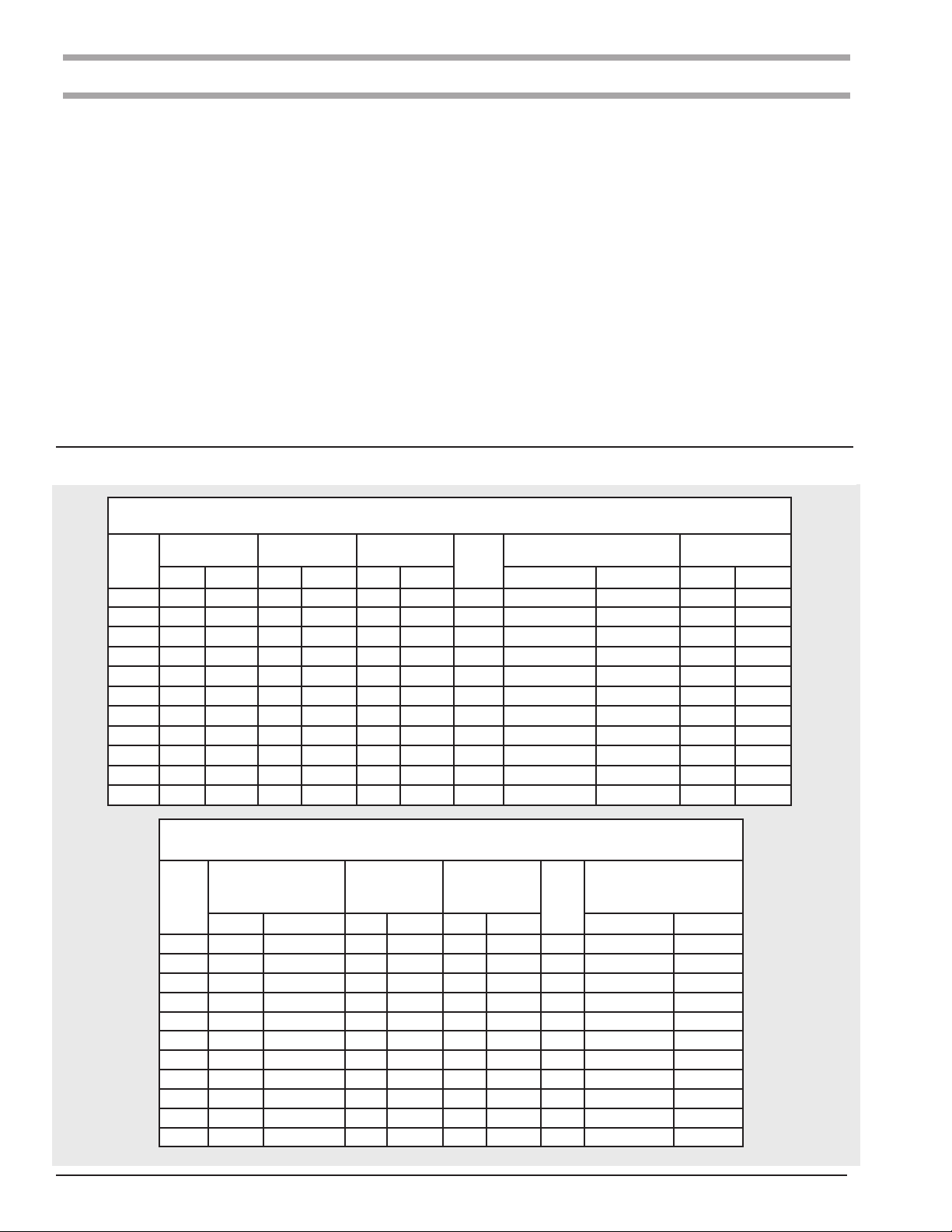

GENERAL INFORMATION

SPECIFICATIONS

The Lodestar Electric Chain Hoist is a highly versatile materials

handling device that can be used to lift loads that are within

rated capacity. The mechanical features of these hoists include

an alloy steel lift wheel, Load Limiter, hardened steel chain

guides, hardened steel gear train, life-time lubrication, forged

steel hooks and lightweight aluminum frame. The electrical features

include hoist-duty motor, rugged hoist brake, magnetic reversing

contactor and voltage conversion board (dual voltage units).

The hoist is available with hook or lug suspensions that are

supplied separately. Table 1 summarizes the Lodestar Electric

Chain Hoist models and the Series 635 Trolleys available. It should

be noted that standard single speed hoists are available with

10 (3M), 15 (4.6M) and 20 (6.1M) foot lifts and the standard lift

for two speeds hoists is10 feet. However, hoists with longer lifts

are available on a special, per order basis.

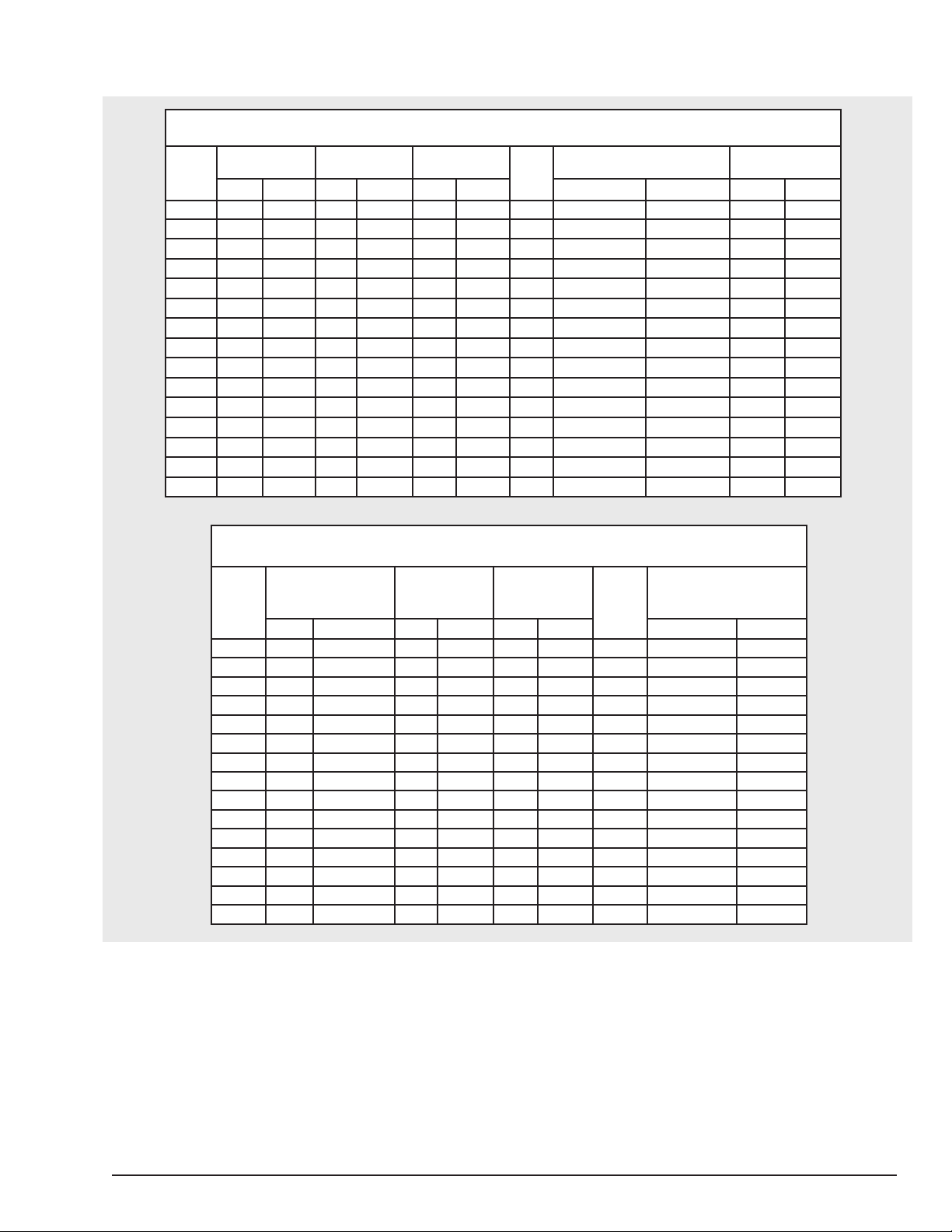

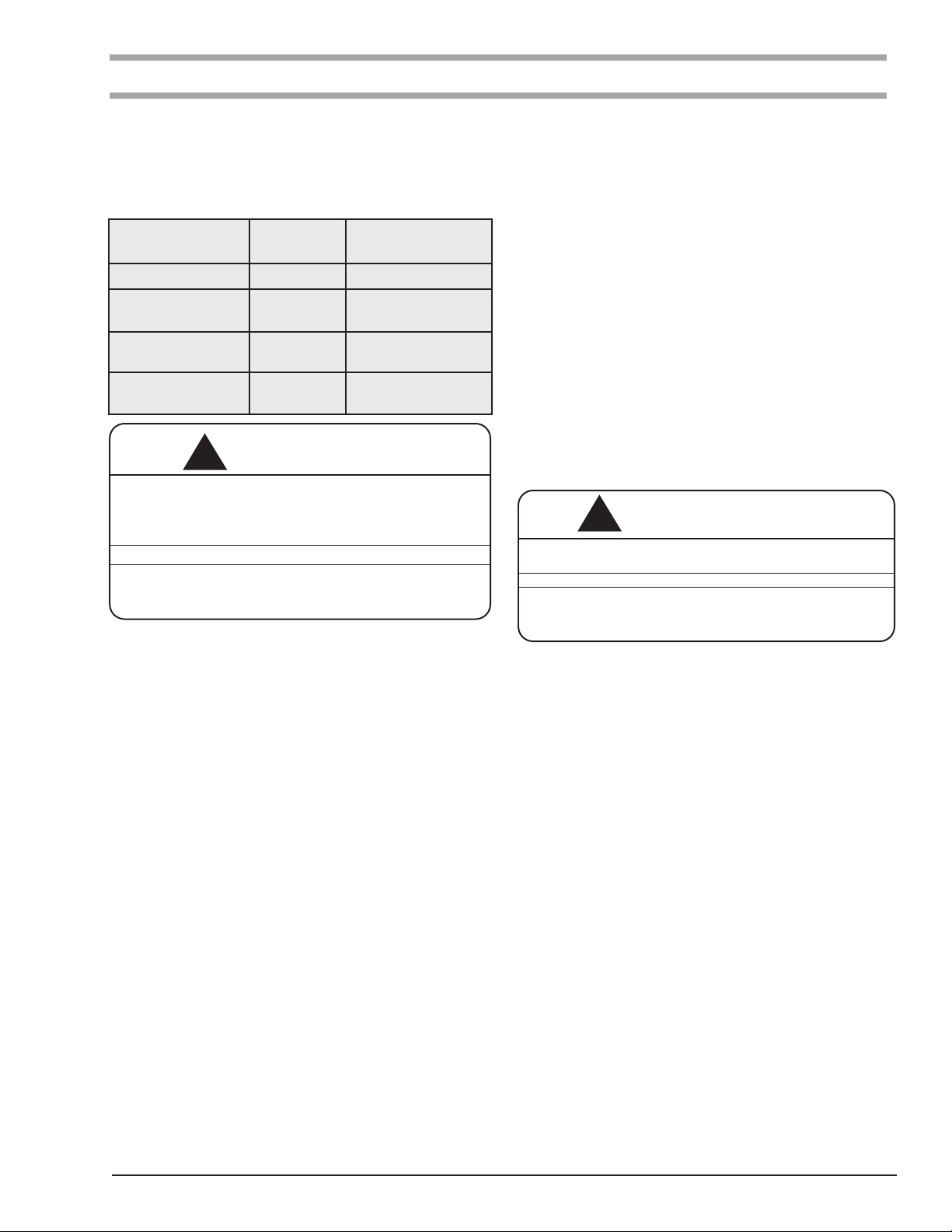

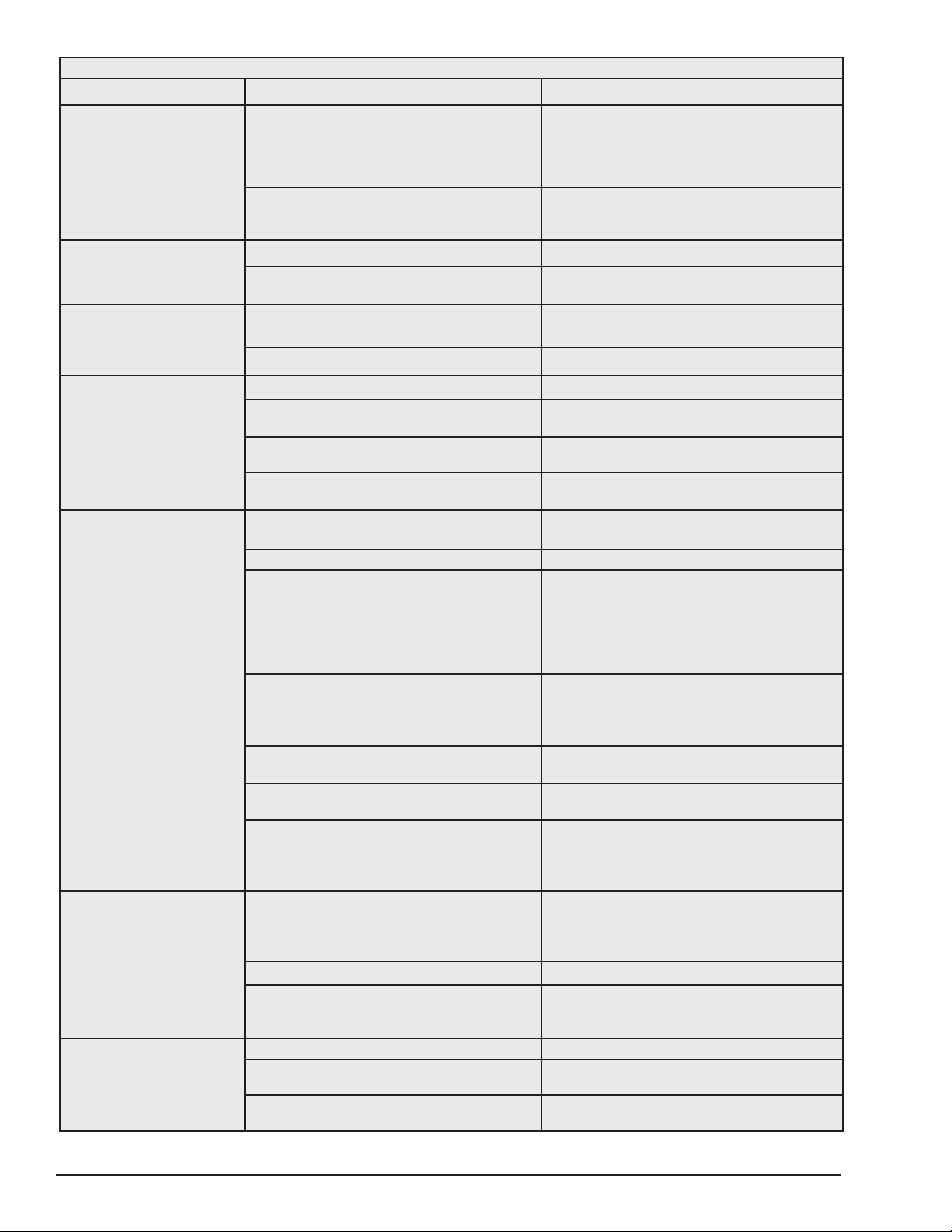

Table 1.a. Specifications

Lodestar Electric Chain Hoists

Single Speed 115-1-60

Model

Load Capacity

Tonne kg ft/min m/min ft/min m/min in x in mm x mm lb/ft kg/m

A 1/8 125 32 9.8 26.7 8.1 1 .250 x .7445 6.35 x 18.9 0.585 0.87

AA 1/8 125 60 18.3 50.0 15.2 1 .250 x .7445 6.35 x 18.9 0.585 0.87

B 1/4 250 16 4.9 13.3 4.1 1 .250 x .7445 6.35 x 18.9 0.585 0.87

C 1/4 250 32 9.8 26.7 8.1 1 .250 x .7445 6.35 x 18.9 0.585 0.87

E 1/2 500 8 2.4 6.7 2.0 2 .250 x .7445 6.35 x 18.9 1.17 1.74

F 1/2 500 16 4.9 13.3 4.1 1 .250 x .7445 6.35 x 18.9 0.585 0.87

J 1/2 500 32 9.8 26.7 8.1 1 .312 x .8583 7.92 x 21.8 0.585 0.87

H 1 1000 8 2.4 6.7 2.0 2 .250 x .7445 6.35 x 18.9 1.17 1.74

L 1 1000 16 4.9 13.3 4.1 1 .312 x .8583 7.92 x 21.8 0.94 1.40

R 2 2000 8 2.4 6.7 2.0 2 .312 x .8583 7.92 x 21.8 1.88 2.80

RT 3 3000 5.3 1.6 4.4 1.4 3 .312 x .8583 7.92 x 21.8 2.82 4.20

Lifting Speed

60Hz units

Lifting Speed

50Hz units

CM REPAIR/REPLACEMENT POLICY

All Columbus McKinnon (CM®) Lodestar Electric Chain Hoists

are i nspe c t e d an d per f o r m ance t este d prio r to

shipment. If any properly maintained hoist develops a

performance problem due to a material or workmanship

defect, as verified by CM®, repair or replacement of the unit

will be made to the original purchaser without charge. This

repair/replacement policy applies only to Lodestar Hoists

installed, maintained and operated as outlined in this

manual, and specifically excludes parts subject to normal

wear, abuse, improper installation, improper or inadequate

maintenance, hostile environmental effects and unauthorized

repairs/modifications.

We reserve the right to change materials or design if, in our

opinion, such changes will improve our product. Abuse,

repair by an unauthorized person, or use of non-CM replacement parts voids the guarantee and could lead to dangerous

operation. For full Terms of Sale, see Sales Order Acknowledgement. Also, refer to the back cover for Limitations of

Warranties, Remedies and Damages, and Indemnification

and Safe Operation.

Chain

Falls

Chain Size

Chain Weight

per length of lift

Lodestar Electric Chain Hoists

Single Speed 115-1-60

Model

Shortest Distance

Between Hooks

in mm HP kW HP kW lb kg

A 16.9 429 0.25 0.19 0.21 0.16 54 72 32.8

AA 19.9 505 0.50 0.37 0.42 0.31 54 76 34.3

B 16.9 429 0.25 0.19 0.21 0.16 54 73 33.1

C 16.9 429 0.50 0.37 0.42 0.31 54 75 34.2

E 21.6 549 0.25 0.19 0.21 0.16 54 78 31.8

F 16.9 429 0.50 0.37 0.42 0.31 54 76 34.5

J 18.1 460 1.00 0.75 0.83 0.62 54 127 57.5

H 21.6 549 0.50 0.37 0.42 0.31 54 81 36.7

L 18.1 460 1.00 0.75 0.83 0.62 54 125 56.7

R 25.8 655 1.00 0.75 0.83 0.62 54 148 67.1

RT 32.1 815 1.00 0.75 0.83 0.62 54 166 75.4

Motor Power

60Hz

Motor Power

50Hz

IP

Rating

Net Weight 10’ lift less

upper suspension

6

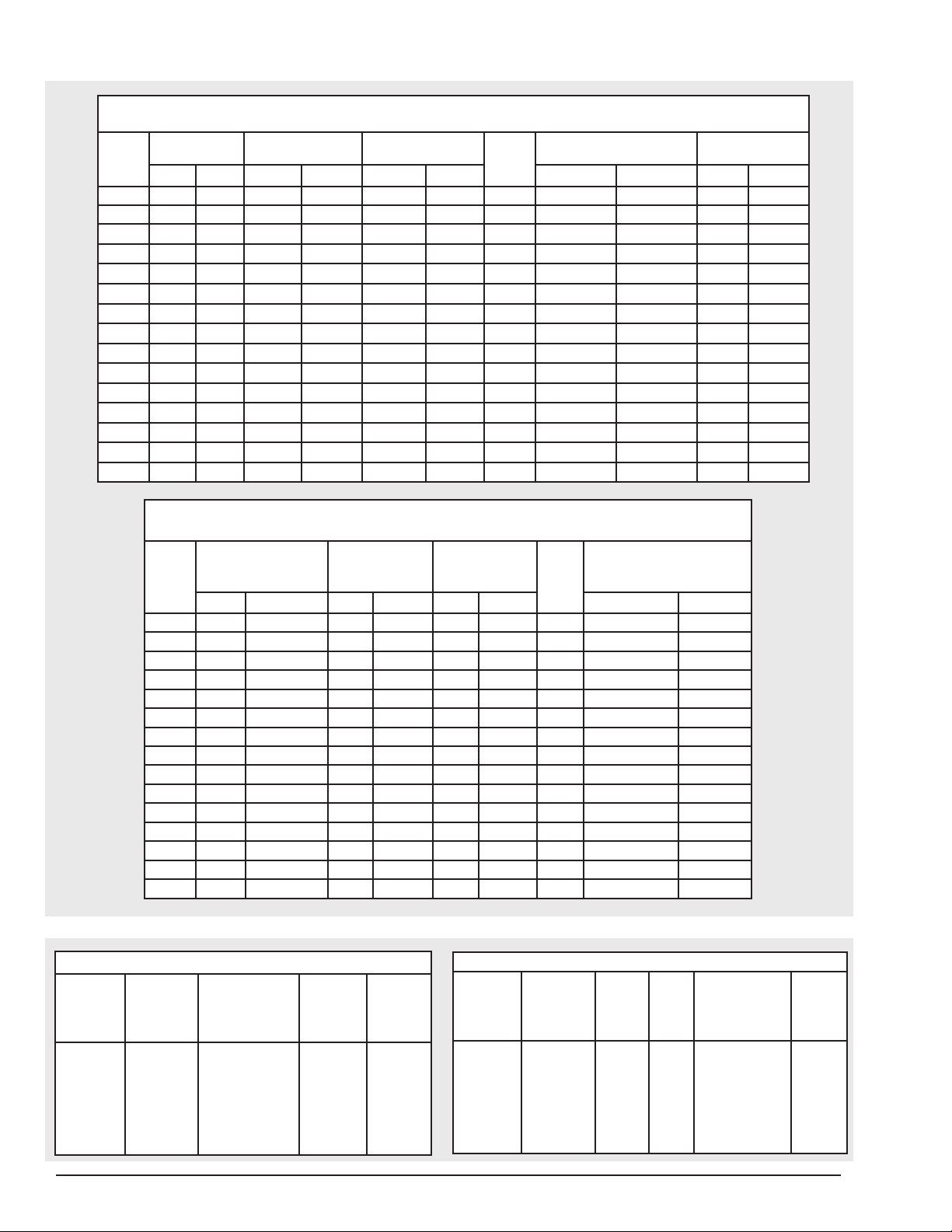

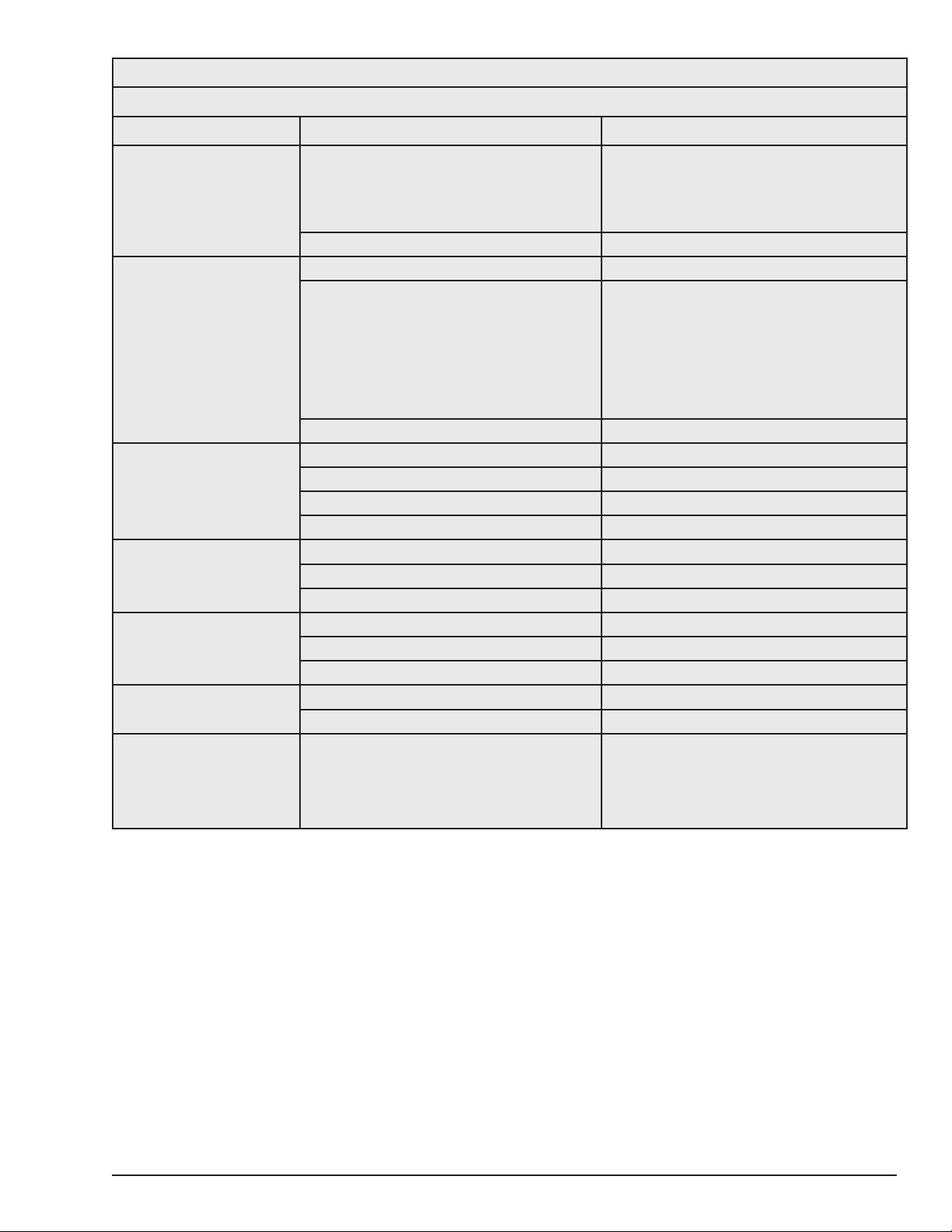

Table 1.b.Specifications, cont’d

Single Speed 230/460-3-60 or 220/380-3-50 or 220/415-3-50

Lodestar Electric Chain Hoists

Model

Load Capacity

Tonne kg ft/min m/min ft/min m/min in x in mm x mm lb/ft kg/m

A 1/8 125 32 9.8 26.7 8.1 1 .250 x .7445 6.35 x 18.9 0.585 0.87

AA 1/8 125 60 18.3 50.0 15.2 1 .250 x .7445 6.35 x 18.9 0.585 0.87

B 1/4 250 16 4.9 13.3 4.1 1 .250 x .7445 6.35 x 18.9 0.585 0.87

C 1/4 250 32 9.8 26.7 8.1 1 .250 x .7445 6.35 x 18.9 0.585 0.87

E 1/2 500 8 2.4 6.7 2.0 2 .250 x .7445 6.35 x 18.9 1.17 1.74

F 1/2 500 16 4.9 13.3 4.1 1 .250 x .7445 6.35 x 18.9 0.585 0.87

J 1/2 500 32 9.8 26.7 8.1 1 .312 x .8583 7.92 x 21.8 0.585 0.87

JJ 1/2 500 64 19.5 53.3 16.3 1 .312 x .8583 7.92 x 21.8 0.94 1.40

H 1 1000 8 2.4 6.7 2.0 2 .250 x .7445 6.35 x 18.9 1.17 1.74

L 1 1000 16 4.9 13.3 4.1 1 .312 x .8583 7.92 x 21.8 0.94 1.40

LL 1 1000 32 9.8 26.7 8.1 1 .312 x .8583 7.92 x 21.8 0.94 1.40

R 2 2000 8 2.4 6.7 2.0 2 .312 x .8583 7.92 x 21.8 1.88 2.80

RR 2 2000 16 4.9 13.3 4.1 2 .312 x .8583 7.92 x 21.8 1.88 2.80

RT 3 3000 5.3 1.6 4.4 1.4 3 .312 x .8583 7.92 x 21.8 2.82 4.20

RRT 3 3000 10.7 3.3 8.9 2.7 3 .312 x .8583 7.92 x 21.8 1.88 2.80

Lifting Speed

60 Hz units

Lifting Speed

50Hz units

Chain

Falls

Chain Size

Chain Weight

per length of lift

Lodestar Electric Chain Hoists

Single Speed 230/460-3-60 or 220/380-3-50 or 220/415-3-50

Model

Shortest Distance

Between Hooks

Motor Power

60Hz

Motor Power

50Hz

IP

Rating

Net Weight 10’ lift less

upper suspension

in mm HP kW HP kW lb kg

A 16.9 429 0.25 0.19 0.21 0.16 54 70 31.9

AA 19.9 505 0.50 0.37 0.42 0.31 54 73 32.9

B 16.9 429 0.25 0.19 0.21 0.16 54 71 32.2

C 16.9 429 0.50 0.37 0.42 0.31 54 72 32.8

E 21.6 549 0.25 0.19 0.21 0.16 54 76 30.9

F 16.9 429 0.50 0.37 0.42 0.31 54 73 33.1

J 18.1 460 1.00 0.75 0.83 0.62 54 121 54.7

JJ 18.1 460 2.00 1.49 1.67 1.24 54 127 57.5

H 21.6 549 0.50 0.37 0.42 0.31 54 78 35.4

L 18.1 460 1.00 0.75 0.83 0.62 54 119 53.9

LL 18.1 460 2.00 1.49 1.67 1.24 54 127 57.6

R 25.8 655 1.00 0.75 0.83 0.62 54 142 64.4

RR 25.8 655 2.00 1.49 1.67 1.24 54 150 68.0

RT 32.1 815 1.00 0.75 0.83 0.62 54 160 72.7

RRT 32.1 815 2.00 1.49 1.67 1.24 54 173 78.4

7

Table 1.c. Specifications, cont’d

Two Speed 230-3-60 or 460-3-60 or 575-3-60 or 220-3-50 or 380-3-50 or 415-3-50 or 550-3-50

Lodestar Electric Chain Hoists

Model

Load Capacity

Tonne kg ft/min m/min ft/min m/min in x in mm x mm lb/ft kg/m

A-2 1/8 125 10.7/32 3.3/9.8 8.9/26.7 2.7/8.1 1 .250 x .7445 6.35 x 18.9 0.585 0.87

AA-2 1/8 125 20/60 6.1/18.3 16.7/50 5.1/15.2 1 .250 x .7445 6.35 x 18.9 0.585 0.87

B-2 1/4 250 5.3/16 1.6/4.9 4.4/13.3 1.4/4.1 1 .250 x .7445 6.35 x 18.9 0.585 0.87

C-2 1/4 250 10.7/32 3.3/9.8 8.9/26.7 2.7/8.1 1 .250 x .7445 6.35 x 18.9 0.585 0.87

E-2 1/2 500 2.7/8 0.8/2.4 2.2/6.7 0.7/2 2 .250 x .7445 6.35 x 18.9 1.17 1.74

F-2 1/2 500 5.3/16 1.6/4.9 4.4/13.3 1.4/4.1 1 .250 x .7445 6.35 x 18.9 0.585 0.87

J-2 1/2 500 10.7/32 3.3/9.8 8.9/26.7 2.7/8.1 1 .312 x .8583 7.92 x 21.8 0.585 0.87

JJ-2 1/2 500 21.3/64 6.5/19.5 17.8/53.3 5.4/16.3 1 .312 x .8583 7.92 x 21.8 0.94 1.40

H-2 1 1000 2.7/8 0.8/2.4 2.2/6.7 0.7/2 2

L-2 1 1000 5.3/16 1.6/4.9 4.4/13.3 1.4/4.1 1 .312 x .8583 7.92 x 21.8 0.94 1.40

LL-2 1 1000 10.7/32 3.3/9.8 8.9/26.7 2.7/8.1 1 .312 x .8583 7.92 x 21.8 0.94 1.40

R-2 2 2000 2.7/8 0.8/2.4 2.2/6.7 0.7/2 2 .312 x .8583 7.92 x 21.8 1.88 2.80

RR-2 2 2000 5.3/16 1.6/4.9 4.4/13.3 1.4/4.1 2 .312 x .8583 7.92 x 21.8 1.88 2.80

RT-2 3 3000 1.8/5.3 0.5/1.6 1.5/4.4 0.5/1.4 3 .312 x .8583 7.92 x 21.8 2.82 4.20

RRT-2 3 3000 3.6/10.7 1.1/3.3 3/8.9 0.9/2.7 3 .312 x .8583 7.92 x 21.8 1.88 2.80

Lifting Speed

60Hz units

Lifting Speed

50Hz units

Chain

Falls

Chain Size

.250 x .7445

Chain Weight

per length of lift

6.35 x 18.9 1.17 1.74

Lodestar Electric Chain Hoists

Two Speed 230-3-60 or 460-3-60 or 575-3-60 or 220-3-50 or 380-3-50 or 415-3-50 or 550-3-50

Capacity

Tons

(kg)

Model

Shortest Distance

Between Hooks

Motor Power

60Hz

Motor Power

50Hz

IP

Rating

Net Weight 10’ lift less

upper suspension

in mm HP kW HP kW lb kg

A-2 16.9 429 0.25 0.19 0.21 0.16 54 76 34.6

AA-2 19.9 505 0.50 0.37 0.42 0.31 54 78 35.2

B-2 16.9 429 0.25 0.19 0.21 0.16 54 77 34.9

C-2 16.9 429 0.50 0.37 0.42 0.31 54 77 35.1

E-2 21.6 549 0.25 0.19 0.21 0.16 54 82 33.6

F-2 16.9 429 0.50 0.37 0.42 0.31 54 78 35.4

J-2 18.1 460 1.00 0.75 0.83 0.62 54 133 60.2

JJ-2 18.1 460 2.00 1.49 1.67 1.24 54 135 61.1

H-2 21.6 549 0.50 0.37 0.42 0.31 54 83 37.6

L-2 18.1 460 1.00 0.75 0.83 0.62 54 131 59.4

LL-2 18.1 460 2.00 1.49 1.67 1.24 54 135 57.6

R-2 25.8 655 1.00 0.75 0.83 0.62 54 154 61.2

RR-2 25.8 655 2.00 1.49 1.67 1.24 54 158 69.8

RT-2 32.1 815 1.00 0.75 0.83 0.62 54 172 71.6

RRT-2 32.1 815 2.00 1.49 1.67 1.24 54 181 82.1

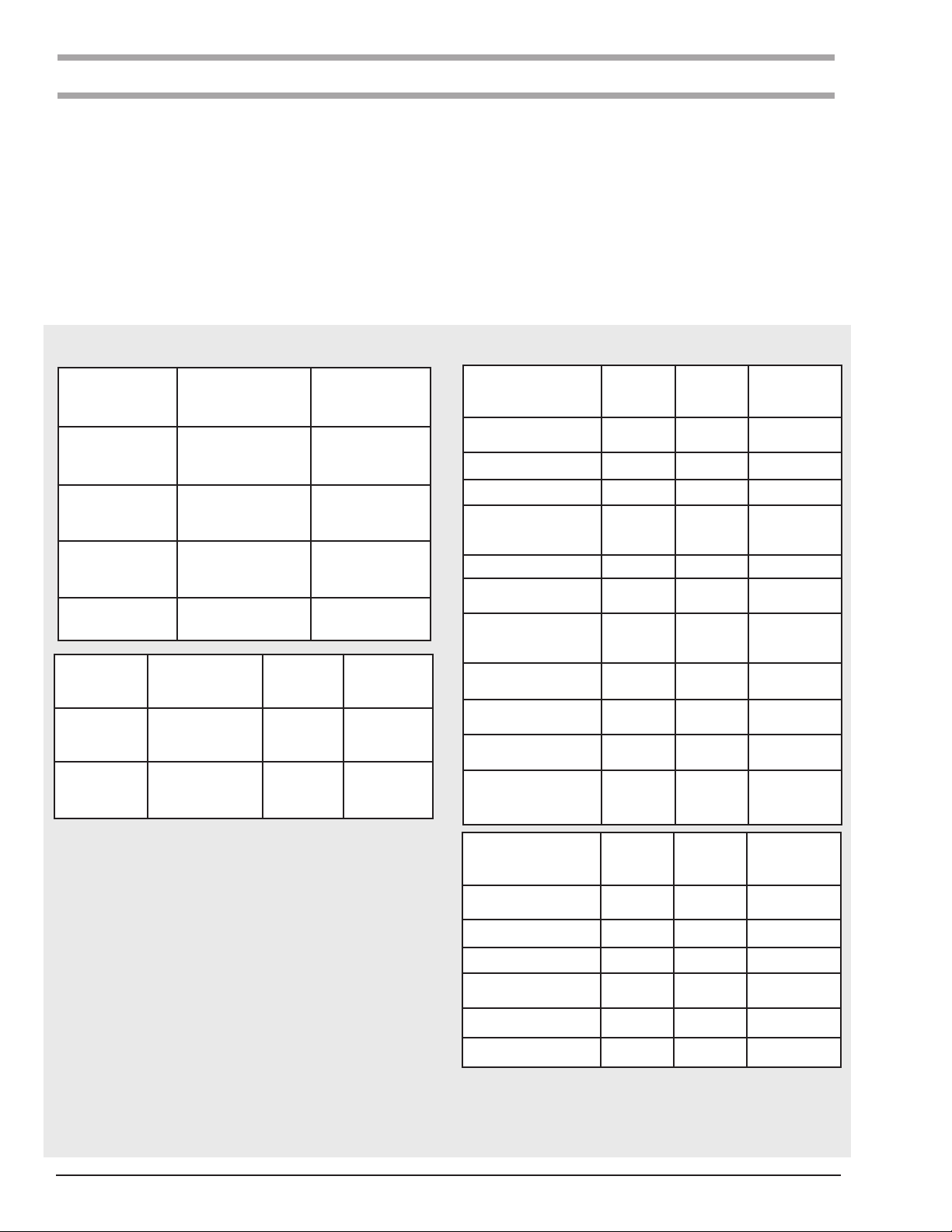

Table 1.d. Specifications, cont’d

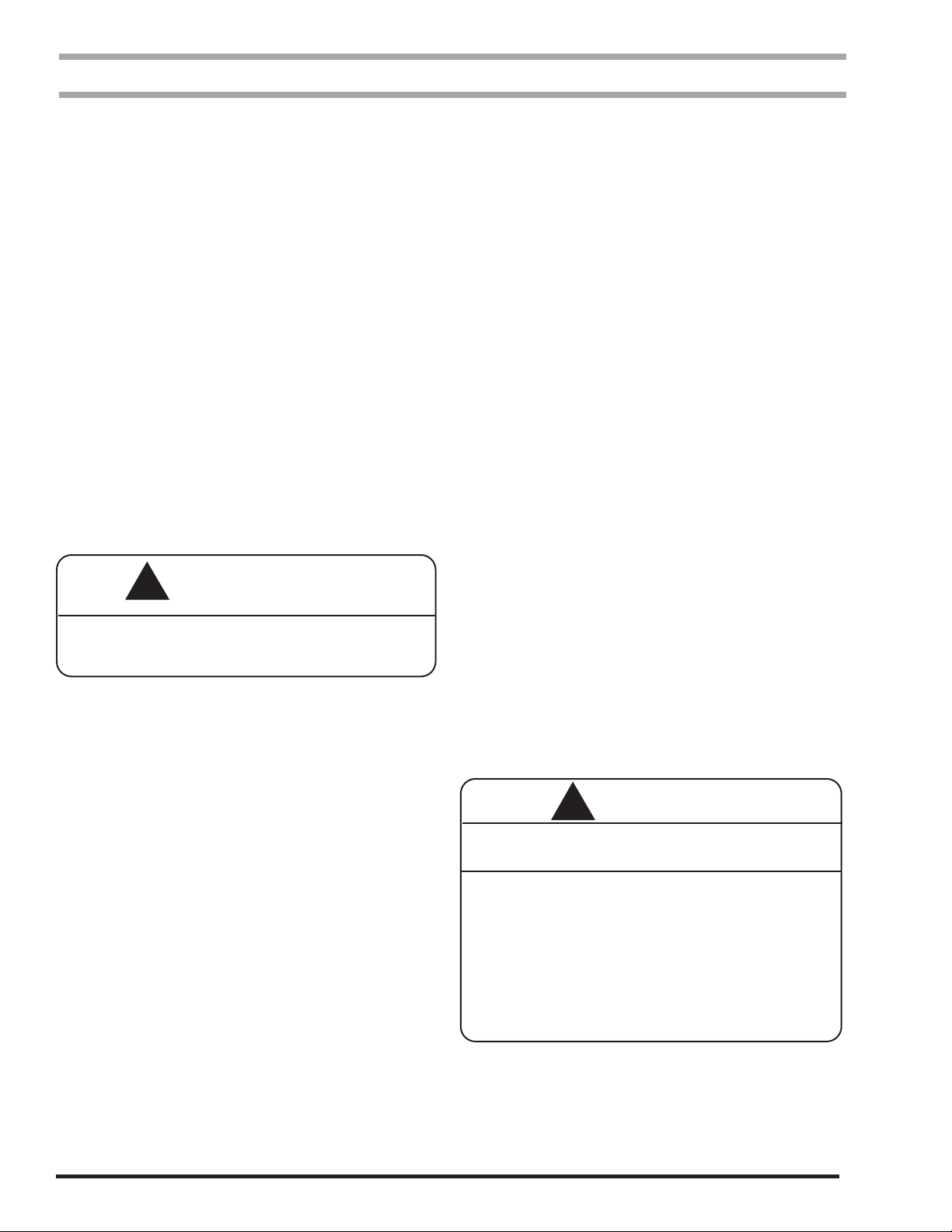

Series 635 Low Headroom Trolleys

For Use

With

Models

Adj. For

STD

S-Beams

Depth In. (mm)

Tread

Dia. of

Wheels

In. (mm)

Min. Rad.

Curve

In. (mm)

Capacity

Tons

(kg)

Table 1.e. Specifications, cont’d

Series 635 Motor Driven Trolleys

For Use

With

Models

*Travel

Speed

FPM

(MPM)

Motor

H.P.

(kW)

Adj. For

STD

S-Beams

Depth In.(mm)

Min.

Rad.

Curve

In.(mm)

= to 1

(125 to 2000)

2 (2000)

3 (3000)

8

A thru LL-2

R thru RR-2

RT thru RRT-2

4 - 15 (102 - 381)

6 - 18 (152 - 457)

8 - 15 (203 - 381)

3= (79.4)

4< (120.6)

4 (101.6)

24 (610)

24 (610)

30 (762)

= to 2

(125 to 2000)

3 (3000)

A thru RR-2

RT thru RRT-2

75 (23)

75 (23)

; (.19)

; (.19)

6 - 15 (152 - 381)

6 - 15 (152 - 381)

30 (762)

30 (762)

ACCESSORIES

Hook Suspensions

Swivel and rigid type hook suspensions (see Figure 1) are

available for all Lodestar Electric Hoists. However, rigid type

hook suspensions are normally recommended for most application. The hook suspensions are intended for suspending

the hoist from a trolley which has a single load bar (such as

®

CM’s

Series 632 and 633 Trolleys) or for suspending the

hoist from a fixed structure.

Figure 1. Hook Suspensions

Lug Suspension

Lug suspensions (see Figure 2) are available for all Lodestar

Electric Hoists. These are rigid type suspensions wherein the

lug shown replaces the hook (Figure 1) in the suspension

adapter. The Lug suspensions are required for suspending

the hoist from the Series 635 Low Headroom and Motor

Driven Trolleys described next.

Figure 4. Series 635 Motor Driven Trolley

Series 635 Motor Driven Trolley

The motor driven trolleys (see Figure 4) are self-contained

and supplied complete with independent controls and wiring,

including a four directional control station. A rigid lug suspension

(see Figure 2) is required to suspend the hoist from the Motor

Driven Trolley. The hoist and trolley are joined electrically by

connecting the hoist control and power cords (supplied) into

the hoist or trolley. The trolley is adjustable for operation on a

range of American Standard “S” beams as indicated in Table

1 and it will also operate on flat flanged beams.

Latchlok

®

Hooks

CM’s Latchlok hooks (see Figure 5) are available to replace

the standard upper and lower hooks used on the Lodestar

Electric Hoists.

Figure 2. Lug Suspensions

Series 635 Low Headroom Trolley

These are manual push type trolleys (see Figure 3) designed

for use with the Lodestar Electric Chain Hoists. A rigid lug

suspension (see Figure 2) is required to suspend the hoist

from the trolley. The trolley is adjustable for operation on a

range of American Standard “S” beams as indicated in

Table 1, and it will also operate on flat flanged beams.

Figure 3. Series 635 Low Headroom Trolley

Figure 5. Upper or Lower Latchlok®Hook

Figure 5. Latchlok

®

Hook

Chain Container

This accessory (see Figure 6) is used to hold slack chain

and it is supplied complete with mounting hardware and

instructions. The chain container is recommended for those

applications where the slack chain would interfere with the

load or drag on the floor as may be the case with double or

triple reeved units. Chain containers can be furnished for

units already in use.

Figure 6. Chain Container

9

INSTALLATION

UNPACKING INFORMATION

When received, the hoist should be carefully inspected for

damage which may have occurred during shipment or handling. Check the hoist frame for dents or cracks, the external

cords for damaged or cut insulation, the control station for cut

or damaged enclosure, and inspect the load chain for nicks

and gouges. If shipping damage has occurred, refer to the

packing list envelope on the carton for claim procedure.

Before installing the hoist, make sure that the power supply to

which it will be connected is the same as that shown on the

nameplate located on the side of the hoist.

NOTE: See Electrical Installation instructions

INSTALLING THE SUSPENSION

A. Single Reeved Units:

Remove the hook suspension and (2) suspension screws

from the packaging. Place the suspension assembly into the

recess on top of the hoist so that the adaptor body follows the

contour of the hoist. Insert the suspension screws through

the holes in the adapter and hand thread these into the selflocking nuts enclosed in the hoist. .

CAUTION

!

USE OF IMPACT TOOLS (ELECTRIC OR PNEUMATIC)

MAY CAUSE PREMATURE FAILURE OF ATTACHING

HARDWARE.

Securely tighten the screws to the recommended seating

torque (see Table 2) using a 12 point socket: 3/8" for Models A, B,

C, & F and 1/2 " for Models J-LL.

B. Double Reeved Units:

Remove the hook suspension,(2) suspension screws, (1) dead

end pin, (1) washer, and (1) cotter pin from the packaging. It

should be noted that the suspension includes a dead end bolt

and block for supporting the dead end of the load chain as

shown in Figure 7.

Place the suspension assembly into the recess on top of the

hoist. The dead end block should project through the bottom

of the hoist with the pin hole and slot aligned to the underside

of the hoist as shown in Figure 7. If these are not aligned as

shown, lift the head of the bolt from the hex recess in the

adapter and turn the bolt and block assembly and reseat the

bolt head to obtain the proper alignment. Do not change the

position of the dead end block on the bolt to attain this alignment.

Check the position of the pin hole in the dead end block to

make sure it has not been disturbed from its factory setting.

The distance from the top of the pin hole to the bottom of the

hoist should not exceed 1/4" (6.35mm) for Models E,E-2, H,

H-2 and 7/16" (11.11mm) for Models R, R-2, RR, RR-2. If the

distance is not correct, adjust the position of the dead end

block to obtain the proper distance (see fig. 21, p 73.)

enclosed in the hoist frame. Securely tighten the screws to

the recommended seating torque (see Table 2) using a 12

point socket: 3/8" for Models E & H and 1/2" for Models R & RR.

The dead end of the load chain is temporarily positioned

( a few links from the end) by a wire tie. Do not remove this tie

before attaching the chain to the dead end block. (See Fig. 7)

C. Triple Reeved Units:

These hoists have a sheave hanger which is loosely

connected to the top of the frame by a thin metal plate for

shipping purposes. To attach the suspension, support the

sheave hanger from the underside of the hoist and remove

the nut and seat from the sheave stud. Remove and discard

the shipping plate and retain the sheave stud nut and seat

since they will be reused later.

Remove the suspension assembly from the carton and the

two suspension screws. Place the suspension assembly over

the sheave stud and into the recess on top of the hoist.

Insert the suspension screws through the holes in the

suspension adapter and hand thread these into the selflocking nut enclosed in the hoist. Securely tighten the screws

to the recommended seating torque (see Table 2) using a 12

point, 1/2" socket.

After the suspension assembly is installed, secure the sheave

stud to the suspension adapter using the round slotted nut

and seat that were formerly used to attach the shipping plate

to top of the hoist frame. Place the seat over the stud with the

flat side down and then rotate the seat so that there is

clearance between the seat and the suspension lug or hook.

Assemble the nut to the stud and turn the nut by hand until

the nut seats in the seat and the sheave hanger is snug in the

frame. Then back off the nut until the hole in the stud is in line

with one of the slots in the nut. Using a hammer, drive the

retaining pin (packed with the suspension assembly) into the

hole in the sheave stud until the end of the pin is flush with

the edge of the nut.

WARNING

!

Using other than CM supplied high strength suspension

screws to attach the suspension adapter to the hoist may

cause the screws to break and allow the hoist and load to fall.

Use only the CM supplied suspension screws to attach the

suspension to the hoist and hand torque these screws to

the recommended seating torque as specified in tables 2a

and 2b.

DO NOT apply any type of lubricant to the threads of these

screws. Lubricating the threads will reduce the effort to seat

the screws and as a result, tightening the screws to the

above recommended torque may break the screw,damage

the suspension adapter, strip the nuts and/or damage the

hoist frame.

TO AVOID INJURY:

Now, insert the suspension screws through the holes in the

adapter and hand thread these into the self-locking nuts

10

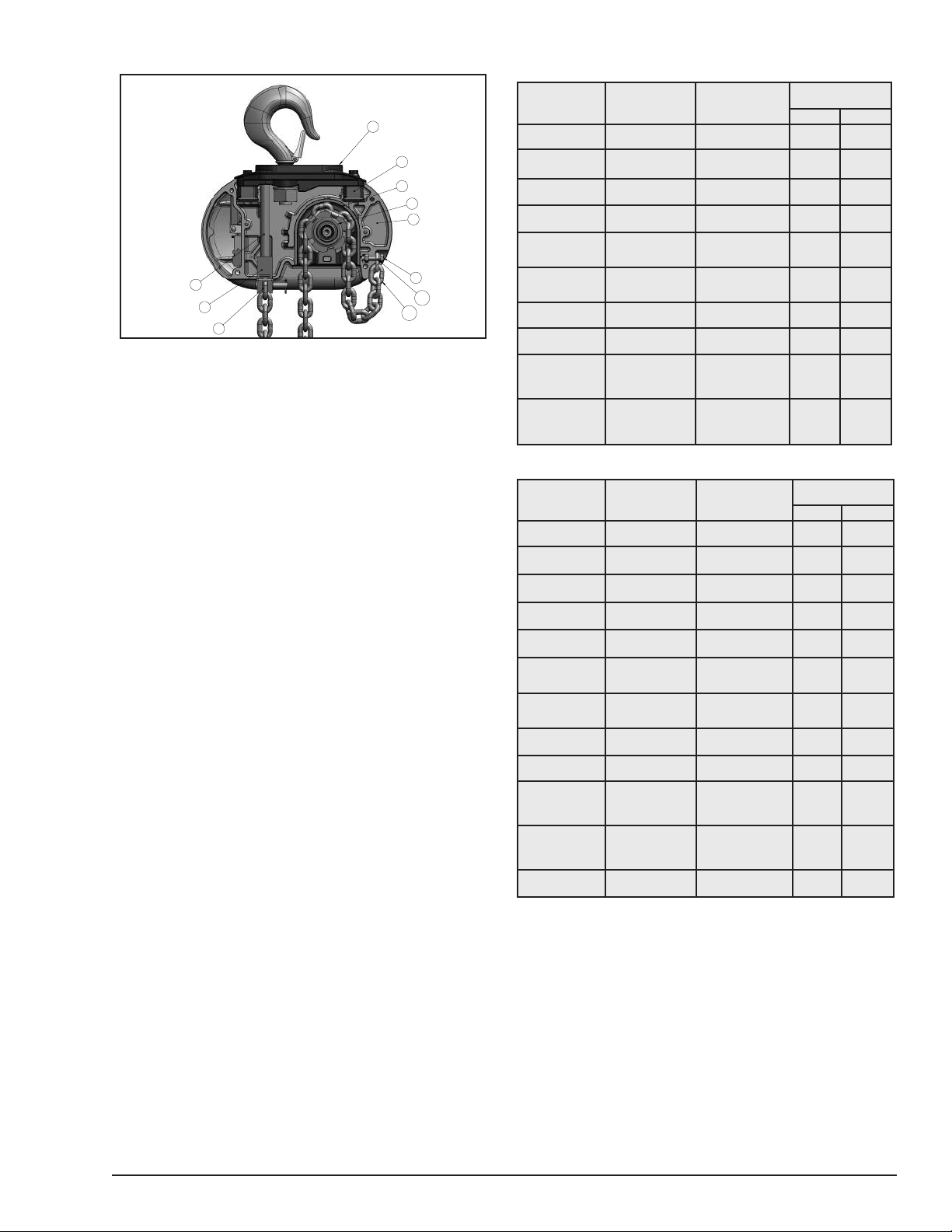

Figure 7. Attaching Load Chain Double Reeved Models

1. Dead end block 7. Lift-wheel

2. Suspension assembly 8. Motor housing

3. Suspension self-locking nut 9. Loose end screw

4. Dead end bolt 10. Loose end link

5. Dead end link 11. Loose end

6. Chain guide

(Do not order parts by these numbers. See parts list)

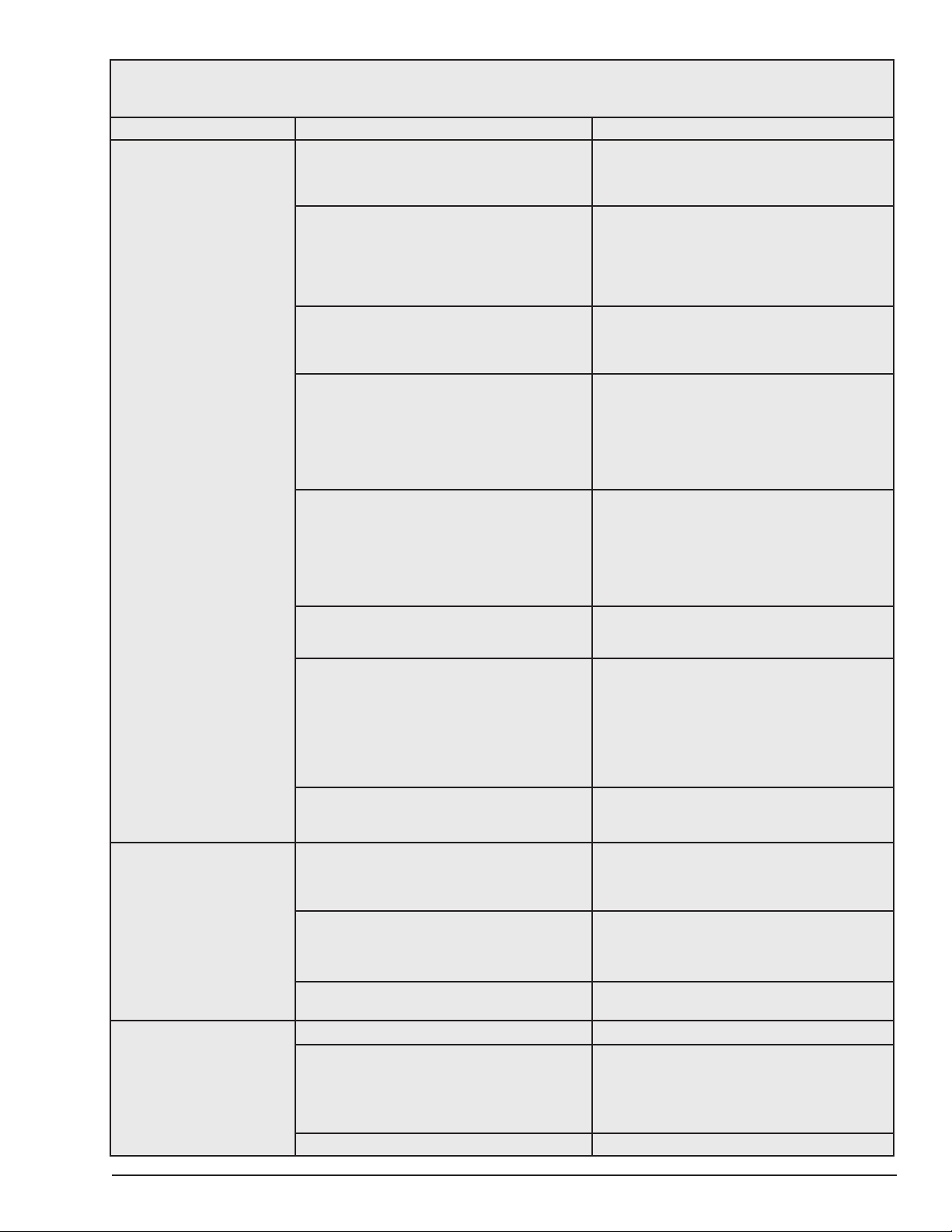

Table 2.a. Recommended Torques: V1 Models A-H

*Recommended

Fastener

Brake End

cover

Motor End

cover

Brake Attaching

Screw

s

Power Cord

Strain Relief Nut

Motor Housing/

Gear Housing/

Back Frame

Lower Hook Block

Screws -

Doubled Reeved

Suspension

Adapter Screws

Lift-Wheel

Locking Nut 1"-12 Hex Nut

Reversing

Contactor

Connecting

Screws-1ø

Reversing

Contactor

Connecting

Screws-3ø

Fastener

Description Tool Required

1/4-20 Slotted Fillister

Head Screw

1/4-20 Slotted Fillister

Head Screw

1/4-20 Slotted Fillister

Head Screw

1/4-20 Hex Nut

1/4"-20 Socket Head

Cap Screw

1/4"-20 Socket Head

Cap Screw

3/8"-16-12

Point Cap Screw

Terminal

Clamp

Screw

Terminal

Clamp

Screw

Slotted Blade

Screw Driver

Slotted Blade

Screw Driver

Slotted Blade

Screw Driver

7/16" - 6 or 12

Point Socket

3/16" Hex Driver 7.9 - 8.3 10.7 - 11.3

3/16" Hex Driver 5.0 - 5.8 6.8 - 7.9

3/8 "

12 Point Socket

1-1/2" - 6 or 12

Point Socket

Phillips No.2 or

3/16" Slotted Head

Screw Driver

Phillips No.2 or

3/16" Slotted Head

Screw Driver

Seating Torque

ft-lbf N-m

4.0 - 5.0 5.4 - 6.8

4.0 - 5.0 5.4 - 6.8

4.2 - 5.0 5.6 - 6.8

1.7 - 2.0 2.3 - 2.7

35.0 - 45.0 47.5 - 61.0

55.0 - 60.0 74.6 - 81.3

0.6 - 1.0 0.8 - 1.3

0.6 - 1.0 0.8 - 1.3

Table 2.b. Recommended Torques: V2 Models J-RRT

*Recommended

Fastener

Brake End

cover

Motor End

cover

Brake Attaching

s

Screw

Brake Hex Stud

Power Cord

Strain Relief Nut

Motor Housing/

Gear Housing/

Back Frame

Lower Hook Block

Screws -

Doubled Reeved

Suspension

Adapter Screws

Lift-Wheel

Locking Nut 1-1/8"-12 Hex Nut

Reversing

Contactor

Connecting

Screws-1ø

Reversing

Contactor

Connecting

Screws-3ø

Stator Mounting

Screws

Fastener

Description Tool Required

1/4-20 Slotted Fillister

Head Screw

1/4-20 Slotted Fillister

Head Screw

1/4-20 Slotted Fillister

Head Screw

1/2" Hex w/ 5/16 -18

Threaded End

1/4-20 Slotted Rd.

Head Screw

5/16"-18 Socket Head

Cap Screw

5/16"-18 Socket Head

Cap Screw

1/2"-20-12

Point Cap Screw

Terminal

Clamp

Screw

Terminal

Clamp

Screw

1/4"- 20 Hex Cap

Screw

Slotted Blade

Screw Driver

Slotted Blade

Screw Driver

Slotted Blade

Screw Driver

1/2" Open-End

Wrench

Slotted Blade

Screw Driver

1/4" Hex Driver 14.2 - 15.0 19.2 - 20.3

1/4" Hex Driver 10.0 - 11.3 13.6 - 15.3

1/2 "

12 Point Socket

1-11/16" - 6 or 12

Point Socket

Phillips No.2

Phillips No.2 or

3/16" Slotted Head

Screw Driver

7/16" - 6 or 12

Point Socket

Seating Torque

ft-lbf N-m

4.0 - 5.0 5.4 - 6.8

4.0 - 5.0 5.4 - 6.8

4.2 - 5.0 5.6 - 6.8

4.2 - 5.0 5.6 - 6.8

1.7 - 2.0 2.3 - 2.7

70.0 - 80.0 94.9 -108.5

85.0 - 90.0 115 .2 -1 2 2.0

1.3 1.7

0.6 - 1.0 0.8 - 1.3

4.2 - 5.0 5.8 - 6.8

* All torque values are for clean, dry fasteners. DO NOT apply oil or any other

lubricant to the fastner threads.

11

ATTACHING LOAD CHAIN

To attach the chain to the dead end block on Models E, E-2,

H, H-2, R, R-2 and RR-2, proceed as follows:

1. Suspend the hoist from an adequate support.

2. On Models E, E-2, H and H-2, insert the last link of the

load chain into the dead end block (2) and secure it with

the dead end pin, washer and cotter pin furnished with

the suspension. Ensure there are no twists in the chain.

3. On Models R, R-2, RR and RR-2, slide the contact block

up the chain until it is against the bottom of the hoist and

the dead end block is projecting through the square

opening in the bottom of the block. Insert the last link of the

load chain, making sure there are no twists between the

hook block and the dead end block, into the dead end

block. Push the contact block up slightly and secure the

load chain to the dead end block using the dead end pin,

washer and cotter pin furnished with the suspension. The

dead end pin also supports the contact block (See Figure 8)

INSTALLING THE SERIES 635 LOW HEADROOM

TROLLEY (See Figure 9)

!

Operating the trolley on a beam that has no rail stops may

allow the trolley to fall off the end of beam.

Install rail stops at each end of the beam on which the trolley

.

is to operate.

WARNING

TO AVOID INJURY:

Figure 8. Contact Block Used on Models R, R-2, RR and RR-2

4. Do not remove the plastic ties from the load chain at this

time.

After the suspension is installed, hoists with a hook suspension can be suspended from its permanent support and then

connected to the power supply system (refer to page 14). For

hoists with a lug suspension that are to be suspended from a

Series 635 Low Headroom Trolley, attach the hoist to the trolley

per the following instructions.

Figure 9. Series 635 Low Headroom Trolley: 1 and 2 Ton (1000 and 2000 kg)

Trolley Shown - 3 Ton (3000 kg) Similar.

For hoists with a lug suspension that are to be suspended

from a Series 635 Motor Driven Trolley, attach the hoist to the

trolley, wire the hoist and trolley together and connect the

trolley to the power supply system per the instructions supplied with the trolley.

The stops must be positioned so as to not exert impact force

on the hoist frame or trolley wheels. They must contact the

ends of the trolley side frames.

It is recommended that the trolley be mounted on the beam

prior to attaching the hoist to the trolley. Before attempting

to mount the trolley on the beam, measure the actual width

of the beam flange on which the trolley is to operate. Using

the measurement and Table 3, determine the arrangement of

the spacer washers. Loosely assemble the side frames, load

bracket, spacer washers and nuts on the suspension bolts as

shown in Table 3.

12

Table 3. Series 635 Low Headroom Trolley Side Frame Spacing

Standard Load Bracket

3 7/16” Wide

“X”

Side

Frame

Suspension

Bolt

A

B

Load

Bracket

!

If CM’s washer spacing recommendations are not followed, trolley

may fall from beam.

Measure the actual beam flange on which the trolley is to operate

and use Table 3 to determine the arrangement of the spacer wash-

ers for that flange width.

C

D

Suspenison

Bolt Nuts

WARNING

TO AVOID INJURY:

1 Ton Capacity

Flange

Width

2 5/8 10 0 0 10

3 3/8 8 2 2 8

3 5/8 7 3 3 7

4 5/8 4 6 6 4

5 1/4 2 8 8 2

5 5/8 1 9 9 1

Flange

Width

6 1/4 5 6 6 4

No. of Spacers

A B C D

3 9 1 1 9

4 6 4 4 6

5 3 7 7 3

Standard Load Bracket

5 7/16” Wide

1 Ton Capacity

No. of Spacers

A B C D

6 6 5 5 5

7 2 9 9 1

*Dimension applies to minimum S-Beam and will vary with larger S-Beams..

Note: Due to the variations in beam flange widths,

it is suggested that the beam flange width be measured to determine the exact distribution of spacer

washers. The distance between trackwheel flanges

(dimension “X”) should be 1/8 to 3/16 inch (3.18 to

4.77 mm) greater than the beam flange width for

straight runway beams, and 3/16 to 1/4 inch (4.77 to

6.35 mm) greater than the beam flange width if runway system includes sharp curves. Also, the use of

other than CM supplied washers may result in trackwheel to beam flange variations and thus Table 3

will not apply.

Standard Load Bracket

4 3/16” Wide

2 Ton Capacity

Flange

Width

3 3/8 8 0 0 8

3 5/8 7 1 1 7

4 5/8 4 4 4 4

5 1/4 3 5 6 2

5 5/8 2 6 7 1

Flange

Width

6 1/4 8 2 1 8

7 1/8 5 5 5 4

7 1/4 4 6 5 5

7 7/8 2 8 8 1

No. of Spacers

A B C D

4 6 2 2 6

5 3 5 5 3

6 0 8 8 0

Standard Load Bracket

6 11/16” Wide

2 Ton Capacity

No. of Spacers

A B C D

7 5 5 4 5

8 1 9 8 1

Standard Load Bracket

4 13/16” Wide

3 Ton Capacity

Flange

Width

4 5/8 5 3 3 4

5 1/4 3 5 5 2

5 5/8 3 5 6 1

Flange

Width

6 1/4 6 3 2 6

7 1/8 3 6 5 3

No. of Spacers

A B C D

4 6 1 1 7

5 4 4 4 3

Standard Load Bracket

3 7/16” Wide

1 Ton Capacity

No. of Spacers

A B C D

6 7 2 2 6

7 4 5 5 3

On the 3 ton (3000 kg) trolley (refer to Figure 11), drive one

retaining pin into the hole on one end of the lug pin. Raise the

hoist into position so that the lug is between the legs of the

shackle. Align the holes in the shackle and lug. Insert the lug

pin in the aligned holes and secure the lug pin by driving the

remaining retaining pin into the hole in the lug pin. Make

certain that the shackle pin is properly seating in the load

bracket by manipluating the hoist and checking for freedom

of movement (swinging) in both planes and all four directions.

Note that the shackle pin should be retained and centered in

the shackle by the retainers.

On the 1/8 to 2-ton (125 to 2000 kg) trolleys, assemble the

suspension lug on hoist to the trolley on beam as shown in

Figure 10. The lug is inserted in the trolley load bracket and

retained by the vertical load bar pin. A socket head cap

screw and lockwasher are used to keep the in place.

For the 3-ton (3000 kg) trolley, a shackle and pin assembly

consisting of a pin retained in a central position by retainers

is packed loose with the suspension. Insert this assembly into

the opening in the top of the load bracket with the legs of the

shackle down. Position the shackle pin in the groove provided

for the same in the load bracket making sure it is centered

between the suspension bolts.

Now install the trolley on the beam by sliding one side frame

out far enough to allow all the trackwheels to clear the beam

flange. Lift the trolley up so that the trackwheels are riding

on the beam, draw the side frames together and tighten the

nuts snugly. Insert the cotter pins through the slotted nuts and

holes in the supension bolts and spread the legs of the cotter

pins to secure.

Figure 10. 1/8 to 2 Ton (125 to 2000 kg) Hoist to Trolley Assembly

Figure 11. 3 Ton (3000 kg) Hoist to Trolley Assembly

13

POWER SUPPLY AND ELECTRICAL CONNECTIONS

The hoist should be connected to a branch circuit which

complies with the requirements of the National Electrical

Code and applicable local codes.

It is recommended, especially for a single phase hoist

with a (1) horsepower motor (.75 Kilowatts), that a line with

adequate capacity be run directly from the power supply

to the hoist to prevent problems with low voltage and circuit

overloads.

For grounding of the hoist, the power cord includes a

gounding conductor (green yellow, G-Y). Before connecting

the hoist to the power supply, check that the power to be

used agrees with the position of voltage change plug on the

voltage change board. The nominal hoist voltage rating

correspo nding to the voltage range given on hoist

identification plate is:

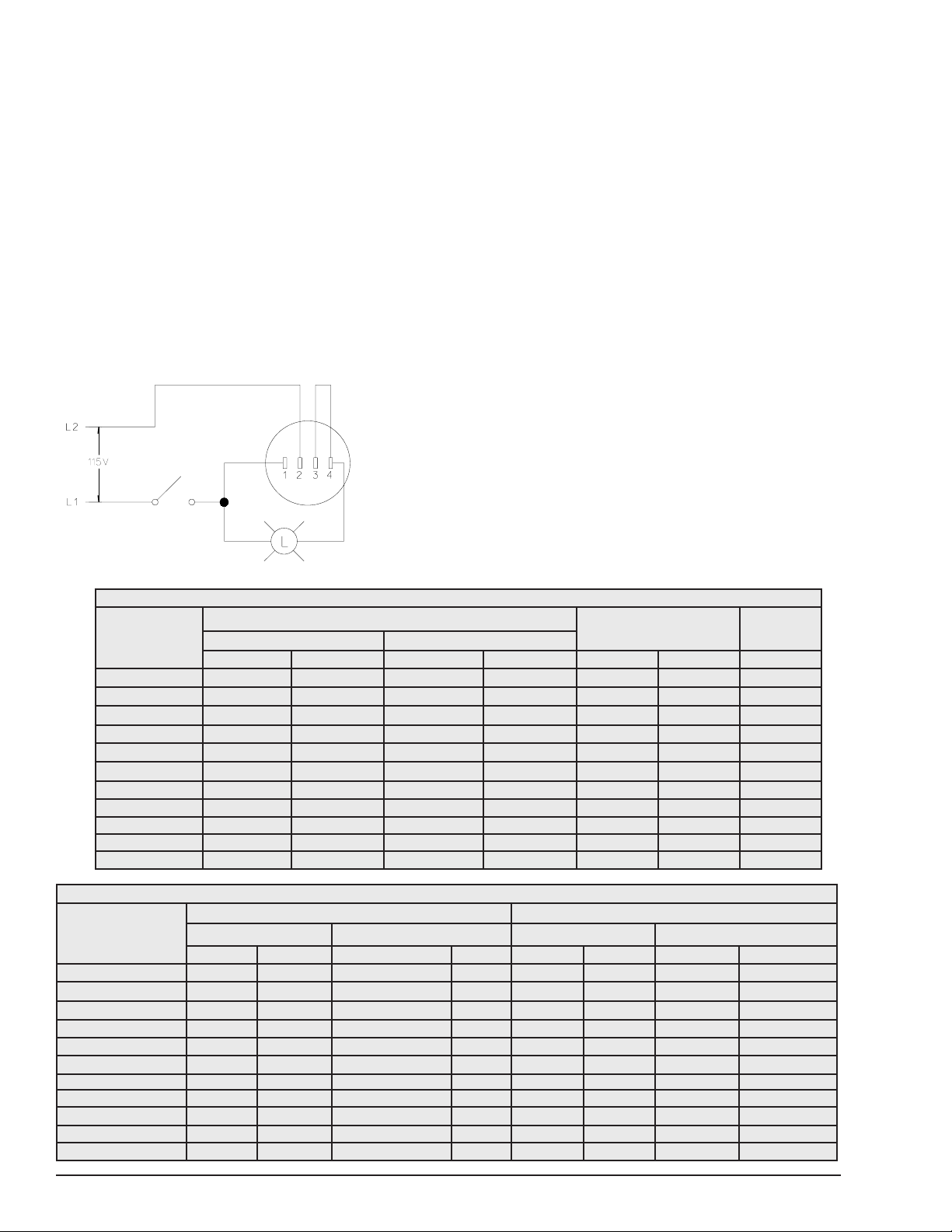

SINGLE SPEED UNITS TWO SPEED UNITS

Range Nominal Range Nominal

110-120 115 -- -208-240 230 208-240 230

440-480 460 440-480 460

550-575 575 550-575 575

THREE PHASE HOIST

Unless ordered on a special basis, all single speed/dual

voltage (230/460-3-60, 220/380-3-50 and 220/415-3-50)

hoists are factory arranged to operate on 460-3-60 (or 380-350 or 415-3-50). However, a voltage change board is

provided to easily and quickly change from 460 to 230

(or 380 to 220 or 415 to 220) volt operation. The voltage

change board shown in Figure 12 is located in the hoist as

shown in Figure 13.

HIGH

VOLTAGE (RED)

LOW

VOLTAGE

(WHITE)

Figure 12. Voltage Change Board

Figure 13. Location of Components

Voltage conversion board is located under back frame

cover (1) for Models A-H and under motor housing

cover (2) for Models J-RRT.

The voltage change board is color coded to indicate high

and low voltage connections. Connecting the 9 and 12 pin

plugs into the “Red” voltage change board receptacles will

connect the hoist for high voltage (380-3-50, 415-3-50 or

460-3-60). To change the hoist voltage to low voltage (208-360, 220-3-50 or 230-3-60) simply remove the 9 and 12 pin

plugs from the “Red” receptacles and insert same into the

“White” receptacles located on the voltage change board.

Be sure to make a notation of the new hoist voltage on the

tag attached to the power cord.

POWER PHASING

Since the motor in a three phase hoist can rotate in either

direction, depending on the manner in which it is connected

to the power supply, the direction of hook movement must be

checked prior to each usage.

NOTE: Serious damage can result if the hook is run to the

upper or lower limit of travel with the hook operating in a

direction opposite to that indicated by the control station.

Therefore, proceed as follows:

1. Make temporary connecions at the power supply.

2, Operate (UP) control momentarily. If hook raises,

connections are correct and can be made permanent.

3. If hook lowers, it is necessary to change direction by

inter-changing the Grey lead and the Black lead of hoist

power supply. Under no circumstances should the internal

wiring of the control device or hoist be changed to

reverse hook direction. The wiring is inspected and

tested before leaving the factory.

14

Do not force the Lodestar Load-limiter to compensate for

improperly adjusted limit switches or reverse voltagephasing.

!

Allowing the hook block to run into the bottom of the hoist

when raising a load or allowing the chain to become taut

between the loose end screw and the frame when lowering a

load may break the chain and allow the load to drop.

Do not allow the hook block to contact the bottom of the

hoist or the loose end chain to become taut.

CHECKING FOR TWIST IN LOAD CHAIN

Models E,H, E-2, H-2,R, RR, R-2, RR-2

WARNING

TO AVOID INJURY:

WARNING

!

Failure to properly ground the hoist presents the danger of

electric shock.

TO AVOID INJURY:

Permanently ground the hoist as instructed in this manual.

To avoid these low voltage problems, the hoist must be

connected to an electrical power supply system that complies

with the National Electrical Code and applicable local codes.

This system must also provide (slow blow fuses or inverse-time

type circuit breakers) and provisions for grounding the hoist.

The best way to check for this condition is to run the lower

hook, without a load, up to within about 2 feet (.61 meters)

of hoist. If the dead end of the chain has been properly

installed, a twist can occur only if the lower hook block has

been capsized between the strands of chain. Reverse capsize to remove twist.

Models RT, RT-2, RRT and RRT-2

On these models, the load chain is dead ended on top of the

lower hook block. If the chain has been properly installed, the

only way a twist can occur is if the lower hook block has been

capsized between the strands of chain. If this has occurred,

two strands of chain will be wrapped around each other and

to remove this, reverse the capsize.

CHECKING FOR ADEQUATE VOLTAGE AT HOIST

The hoist must be supplied with adequate electrical power

in order to operate properly. For proper operation, the voltage, (measured at the hoist end of the standard power cord

with the hoist operating in the , up direction with full load)

must be as indicated in the table below.

MINIMUM

NOMINAL

VOLTAGE

115-1-60 104 98

230-1-60 207 196

230-3-60 187 460-3-60 396 -

575-3-60 495 -

220-3-50 198 380-3-50 365 415-3-50 399 -

550-3-50 495 -

RUNNING

VOLTAGE

MINIMUM

STARTING

VOLTAGE

Low voltage may also be caused by using an undersized

cord and/or connectors to supply power to the hoist. The

following chart should be used to determine the size wires

in the extension cord in order to minimize the voltage drop

between the power source and the hoist.

SINGLE

LENGTH

OF

EXTENSION

CORD

UP TO

50 FEET

80 FEET

(24.4 M)

120 FEET

(36.7 M)

200 FEET

(61.0 M)

For runs beyond 200 Feet contact factory.

!

Failure to provide a proper power supply system for the hoist

may cause hoist damage and offers the potential for a fire.

Provide each hoist with a 20 amp, minimum, overcurrent

protected power supply system per the National Electrical Code

and applicable local codes as instructed in this manual

PHASE

HOISTS

MINIMUM

WIRE SIZE

#14 AWG

#12 AWG

#10 AWG

Contact

Factory

WARNING

TO AVOID INJURY:

THREE

PHASE

HOIST

MINIMUM

WIRE SIZE

#16 AWG

#16 AWG

#14 AWG

#14 AWG

SIGNS OF INADEQUATE ELECTRICAL POWER

(LOW VOLTAGE) ARE:

• Noisy hoist operations due to brake and/or contactor

chattering.

• Dimming of lights or slowing of motors connected to

the same circuit.

• Heating of the hoist motor and other internal components as

well as heating of the wires and connectors

in the circuit feeding the hoists.

• Failure of the hoist to lift the load due to motor stalling.

• Blowing of fuses or tripping of circuit breakers.

Remember, operation with low voltage can void the CM

repair/replacement policy. When in doubt about any of the

electrical requirements, consult a qualified electrician.

WARNING

Working in or near exposed energized electrical equipment

presents the danger of electric shock.

TO AVOID INJURY:

DISCONNECT POWER AND LOCKOUT/TAGOUT

DISCONNECTING MEANS BEFORE REMOVING COVER OR

SERVICING THIS EQUIPMENT.

15

CHECKING LIMIT SWITCH OPERATION IF HOIST IS

EQUIPPED

With hoists that are equipped with an adjustable screw limit

switch, the limit switch will automatically stop the hook at

any predetermined point when either hoisting or lowering.

!

Allowing the hook block to run into the bottom of the hoist

when raising a load or allowing the chain to become taut

between the loose end screw and the frame when lowering

a load may break the chain and allow the load to drop.

Do not allow the hook block to contact the bottom of the

hoist or the loose end chain to become taut.

Operate hoist over the entire length of its rated lift, checking

upper and lower limit switches for correct operation as follows:

1. Press

top of hook block is about one foot (305 mm) below

the hoist.

2. Cautiously continue raising the hook until the upper

limit switch stops the upward motion. The upper

limit switch is set at the factory to stop the hook

block 3 inches (76.2 mm) from bottom of the hoist

on all units with standard 10 foot (3m) lift except

Models AA and AA-2. Factory setting is 6 inches

(152.4 mm) for these models and for all other models

equipped with chain for lifts longer than 10 feet (3m).

3. If adjustment is necessary, see page 23.

4. Press (DOWN) control and cautiously lower hook

until lower limit switch stops the downward motion

From 7 to 11 chain links (depending on hoist model)

should be between the loose end link and the hoist

entry. See Figures 7 and 8.

5. If adjustment is necessary, see page 23.

NOTE: If the hoist is equipped with a chain

container/bag, reset the upper and lower limit

switches as indicated on page 23.

Under no condition should the hook block or load

be permitted to come in contact with the chain

container/bag. If contact is made, the function of

the chain container can be interfered with and its

fasterners imperiled.

NOTE: When chain bag is filled to capacity the

bag must be no more than 75% filled.

CONTROL CORD

Unless ordered on a special basis, the hoist is supplied with

a control cord that will position the control station approximately

4 feet above the lower hook when it is at the lower limit of the

lift. If this places the control station too close to the floor,

a “control cord alteration kit” (Part Number 28642) can be

obtained from CM for shortening the length of the control cord.

!

Tying knots or loops to shorten the drop of the control station

will make the strain relief ineffective and the internal conductors

of the cord may break.

Shorten the control cord using the control cord alteration kit

and the instructions provided with the kit.

WARNING

TO AVOID INJURY:

(UP) control and raise the lower hook until

WARNING

TO AVOID INJURY:

OPERATING INSTRUCTIONS

GENERAL

1. The Load-limiter is designed to slip on an excessive overload. An overload is indicated when the hoist will not raise the

load. Also, some clutching noise may be heard if the hoist is

loaded beyond rated capacity. Should this occur,

immediately release the

the hoist. At this point, the load should be reduced to the rated

hoist capacity or the hoist should be replaced with one of the

proper capacity. When the excessive load is removed, normal

hoist operation is automatically restored.

CAUTION: The Load-limiter is susceptible to overheating

and wear when slipped for extended periods. Under no

circumstance should the clutch be allowed to slip for

more than a few seconds.

Due to the above, a hoist equipped with a Load-limiter is not

recommended for use in any application where there is a

possibility of adding to an already suspended load to the

point of overload. This includes dumbwaiter (*see below)

installations, containers that are loaded in mid-air, etc.

(*) Refer to limitations on Page 3 concerning dumbwaiter

applications.

2. All hoists are equipped with an adjustable screw limit

switch, which automatically stops the hook at any pre-

determined point when either hoisting or lowering.

3. The control station used on two speed hoists is similar to

single speed unit, except that either of two definite

speeds may be selected by the operator in both hoisting

and lowering. Each control when partially depressed

provide SLOW speed and when fully depressed gives

FAST speed. Partial release of control returns hoist to

slow speed, while complete release allows hoist to stop.

Rated lifting speeds are shown on hoist identification

plate. SLOW speed is intended as a means of carefully

controlling or “spotting” the load, although the hoist may

be operated solely at this speed if desired. It is not

necessary to operate in the SLOW speed position as the

hoist will pick up a capacity load at FAST speed from a

standing start. In other words, it is not necessary to

hesitate at the slow position when moving control from

STOP to FAST position or vice versa.

4. If material being handled must be immersed in water,

pickling baths, any liquid, dusty or loose solids, use a

sling chain of ample length so that the hook is always

above the surface. Bearings in the hook block are

shielded only against ordinary atmospheric conditions.

HOIST

1. Before picking up a load, check to see that the hoist is

directly overhead.

2. WHEN APPLYING A LOAD, IT SHOULD BE DIRECTLY

UNDER HOIST OR TROLLEY. AVOID OFF CENTER

LOADING OF ANY KIND.

3. Take up a slack load chain carefully and start load easily

to avoid shock and jerking of hoist load chain. If there is

any evidence of overloading, immediately lower the load

and remove the excess load.

4. DO NOT allow the load to swing or twist while hoisting.

5. DO NOT allow the load to bear against the hook latch.

(UP) control to stop the operation of

16

HOIST WITH LOW HEADROOM TROLLEY

This unit should be moved by pushing on the suspended

load or by pulling the empty hook. However, the unit can

also be moved by pulling on the control station since an

internal steel cable extends the length of the control cord

and is anchored to the hoist and to the control station.

HOIST WITH MOTOR DRIVEN TROLLEY

This unit should be moved by operating the controls marked

(Forward) and (Reverse) in control station. Unless altered

by the erector, depressing (Forward) control will move the

hoist toward motor housing end. Anticipate the stopping

point and allow trolley to coast to a smooth stop. Reversing

or “plugging” to stop trolley causes overheating of motor and

swaying of load.

SAFE OPERATING INSTRUCTIONS AND PROCEDURES

For safety precautions and a list of Do’s and Do Not’s for

safe operation of hoists, refer to page 3.

1. Permit only competent personnel to operate unit.

2. When preparing to lift a load, be sure that the attachments to

the hook are firmly seated in hook saddle. Avoid off

center loading of any kind, especially loading on the

point of hook.

3. DO NOT allow the load to bear against the hook latch. The

latch is to help maintain the hook in position while the chain is

slack before taking up slack chain.

11. Take up a slack load chain carefully and start load easily

to avoid shock and jerking of hoist load chain. If there is

any evidence of overloading, immediately lower the load

and remove the excess load.

12.When lifting, raise the load only enough to clear the floor

or support and check to be sure that the attachments

to the hook and load are firmly seated. Continue lift only

after you are assured the load is free of all obstructions.

13. DO NOT allow the load to swing or twist while hoisting.

14.Never operate the hoist when flammable materials

or vapors are present. Electrical devices produce arcs

or sparks that can cause a fire or explosion.

15. STAY ALERT! Watch what you are doing and use common

sense. Do not use the hoist when you are tired, distracted or

under the influence of drugs, alcohol or medication causing

diminished control.

!

Allowing the load to bear against the hook latch and/or

hook tip can result in loss of load.

Do not allow the load and/or attachments to bear

against the hook latch and/or hook tip. Apply load to

hook bowl or saddle only.

4. DO NOT wrap the load chain around the load and hook onto

itself as a choker chain.

Doing this will result in:

a. The loss of the swivel effect of the hook which could result

in twisted chain and a jammed lift wheel.

b. The upper limit switch, if so equipped, is by-passed and

the load could hit the hoist.

c. The chain could be damaged at the hook.

5. Before lifting load, check for twists in the load chain. On double

and triple reeved units, a twist can occur if the lower hook block

has been capsized between the strands of chain. Reverse

the capsize to remove twist.

6. Stand clear of all loads and avoid moving a load over the

heads of other personnel. Warn personnel of your

intentions to move a load in their area.

7. DO NOT leave the load suspended in the air unattended.

8. DO NOT use this or any other overhead materials handling

equipment for lifting persons.

9. DO NOT load hoist beyond the rated capacity shown

on ID plate. When in doubt, use the next larger capacity

CM Lodestar Hoist.

10.Warn personnel of your intention to lift a load in the area.

Tie off the load with auxiliary chains or cables before

access to the area beneath the load is permitted.

WARNING

TO AVOID INJURY:

17

INSPECTION

To maintain continuous and satisfactory operation, a regular

inspection procedure must be initiated to replace worn or

damaged parts before they become unsafe. Inspection

intervals must be determined by the individual application

and are based on the type of service to which the hoist will

be subjected.

The type of service to which the hoist is subjected can be

classified as “Normal”, “Heavy”, or “Severe”.

Normal Service: Involves operation with randomly distributed

loads within the rated load limit, or uniform loads less than

65 percent of rated load for not more than 25 percent of the time.

Heavy Service: Involves operating the hoist within the rated

load limit which exceeds normal service.

Severe Service: Normal or heavy service with abnormal

operating conditions or constant exposure to the elements

of nature.

Two classes of inspection - frequent and periodic - must

be performed.

Frequent Inspections: These inspections are visual exami-

nations by the operator or other designated personnel.

Records of such inspections are not required. The frequent

inspections are to be performed monthly for normal service,

weekly to monthly for heavy service, and daily to weekly for

severe service, and they should include those items listed in

Table 4.

Periodic Inspections: These inspections are visual

inspections of external conditions by an appointed person.

Records of periodic inspections are to be kept for continuing

evaluation of the condition of the hoist.

CAUTION: Any deficiencies found during inspections

are to be corrected before the hoist is returned to service.

Also, the external conditions may show the need for

disasembly to permit a more detailed inspection, which,

in turn, may require the use of nondestructive type testing

PREVENTATIVE MAINTENANCE

In addition to the above inspection procedure, a preventive

maintenance program should be established to prolong the

useful life of the hoist and maintain its reliability and continued

safe use. The program should include the periodic and

frequent inspections with particular attention being paid to

the lubrication of the various components using the recommended lubricants (see page 127).

HOOK INSPECTION

Hooks damaged from chemicals, deformations or cracks,

or that have more than a 10° twist from the hook’s unbent

plane, excessive opening or seat wear must be replaced.

Also, hooks that are opened and allow the latch to not

engage the tip must be replaced. Any hook that is twisted

or has excessive throat opening indicates abuse or overloading of the unit. Inspect other load sustaining parts, hook

block screws, load pins and hook block bodies for damage.

On latch type hooks, check to make sure that the latch is

not damaged or bent and that it operates properly with

suffcient spring pressure to keep the latch tightly against

the tip of the hook and allow the latch to spring back to the

tip when released. If the latch does not operate properly, it

should be replaced. See Figure 14 to determine when the

hook must be replaced.

Periodic inspections are to be performed yearly for normal

service, semi-annually for heavy service and quarterly for

severe service, and they are to include those items listed in

Table 5.

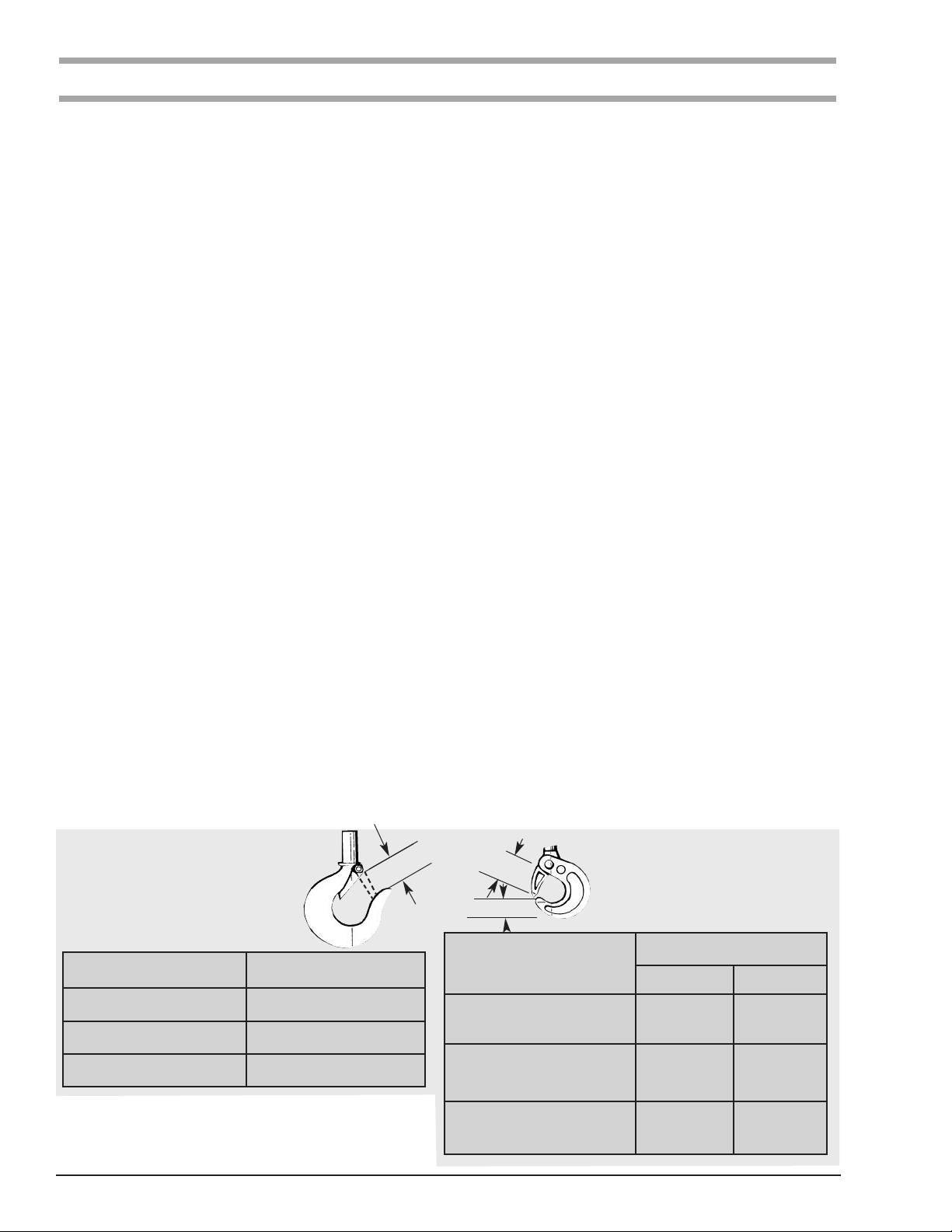

LATCH TYPE HOOK

(Upper and Lower)

TO MEASURE OPENING,

MEASURE

OPENING

DEPRESS LATCH AGAINST

HOOK BODY AS SHOWN.

Models

A, A-2, AA, AA-2, B, B-2,

C, C-2, F AND F-2

E, E-2, H, H-2, J, J-2, JJ, JJ-2,

L, L-2, LL AND LL-2

R, R-2, RR AND RR-2,

RT, RT-2, RRT AND RRT-2

Figure 14. Hook Inspection

Replace Hooks When

Opening is Greater Than

1 3/16 (30.2 mm)

1 5/16 (33.3mm)

1 1/2 (38.1 mm)

“A” Max.

“B” Max.

Models

A, A-2, AA, AA-2, B, B-2, C, C-2,

E, E-2, F, F-2, H, H-2, J, J-2, JJ,

JJ-2, L, L-2, LL, LL-2

R, R-2, RR, RR-2

RT, RT-2, RRT AND RRT-2

LATCHLOK®HOOK

(Upper and Lower)

Replace Hook

When Opening or Seat are:

“A” Max. “B” Min.

1 31/64 in.

(37.7mm)

1 59/64 in.

(48.8mm)

2 1/2 in

(63.5mm)

21/32 in.

(16.7mm)

27/32 in.

(21.4mm)

1 1/8 in

(28.6mm)

18

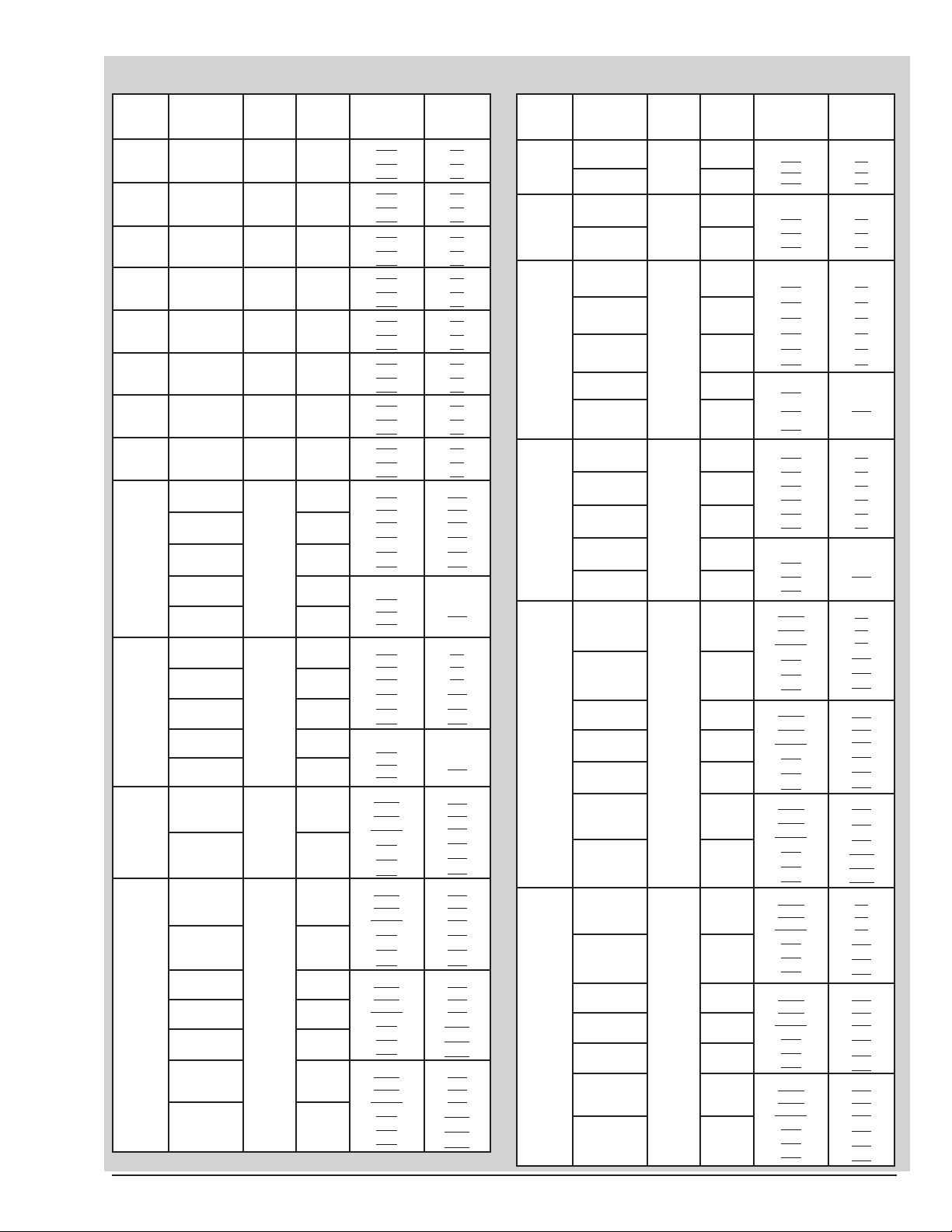

TYPE OF SERVICE

Normal Heavy Severe

Monthly

Weekly

to Monthly

Daily

to Weekly

Table 4. Minimum Frequent Inspections

ITEM

a) Brake for evidence of slippage.

b) Control functions for proper operation.

c) Hooks for damage, cracks, twists, excessive throat opening, latch engagement and latch

operation - see page 18.

d) Load chain for adequate lubrication, as well as for signs of wear, damaged links or foreign

matter - see page 20.

e) Load chain for proper reeving and twists.

Table 5. Minimum Periodic Inspections

TYPE OF SERVICE

Normal Heavy Severe

Yearly

Every 6 Months

Every 3 Months

ITEM

a) All items listed in Table 4 for frequent inspections.

b) External evidence of loose screws, bolts or nuts.

c) External evidence of worn, corroded, cracked or distorted hook block, suspension screws,

gears, bearings and dead end block and chain pin.

d) External evidence of damage to hook retaining nut and pin. Also check the upper suspension

adapter making sure it is fully seated in the hoist frame and that both screws are tight.

e) External evidence of damage or excessive wear of the liftwheel and hook block sheave

chain pockets. Widening and deepening of the pockets may cause the chain to lift-up in

the pocket and result in binding between liftwheel and chain guides or between the

sheave and hook block. Also, check the chain guide for wear or burring where the chain

enters the hoist. Severely worn or damaged parts should be replaced.

f) External evidence of excessive wear of brake parts, and AC brake adjustment - see page 22.

g) External evidence of pitting or any deterioration of contactor contacts. Check the operation

of the control station making sure the buttons operate freely and do not stick in either

position.

h) Inspect the electrical cords and cables and control station enclosure for damaged insulation.

i) Inspect trolley trackwheels for external wear on tread and flange and for wear on internal

bearing surfaces as evidenced by a looseness on the stud. Suspension components for

damage, cracks, wear and operation. Also check suspension adapter screws for proper

tightness - see page 11.

j) Inspect the loose end link, loose end screw and dead end block on double reeved units.

Replace worn or distorted parts.

k) Inspect the suspension lug or hook for excess free play or rotation. Replace worn parts

as evidenced by excess free play or rotation.

l) Inspect for signs of lubricant leaks at the gasket between the gear housing and back

frame. tighten screws holding back frame to gear housing. If leak persists, repack housing

and gears with grease and install a new gasket.

m) On the Models RT, RT-2, RRT and RRT-2:

1. Inspect shackle and lug pins for wear. Replace if worn.

2. Check dead end screw in lower hook black for wear and tighteness*.

3. Check shackle pin for proper seating in groove of load bracket.

4. Inspect cloverleaf plate on bottom of sheave hanger for wear or burring.

Replace if worn.

5. Inspect sheave stud nut and seat for wear. Replace if worn or damaged.

*When tightening the special, dead end socket head screw, it should be held firmly in place and torqued from the nut end only to avoid damage to the screw

and/or dead end chain link (Refer to step J on page 45).

19

LOAD CHAIN

Chain should feed smoothly into and away from the hoist

or hook block. If chain binds, jumps or is noisy, first clean and

lubricate it (see below). If trouble persists, inspect chain and

mating parts for wear, distortion or other damage.

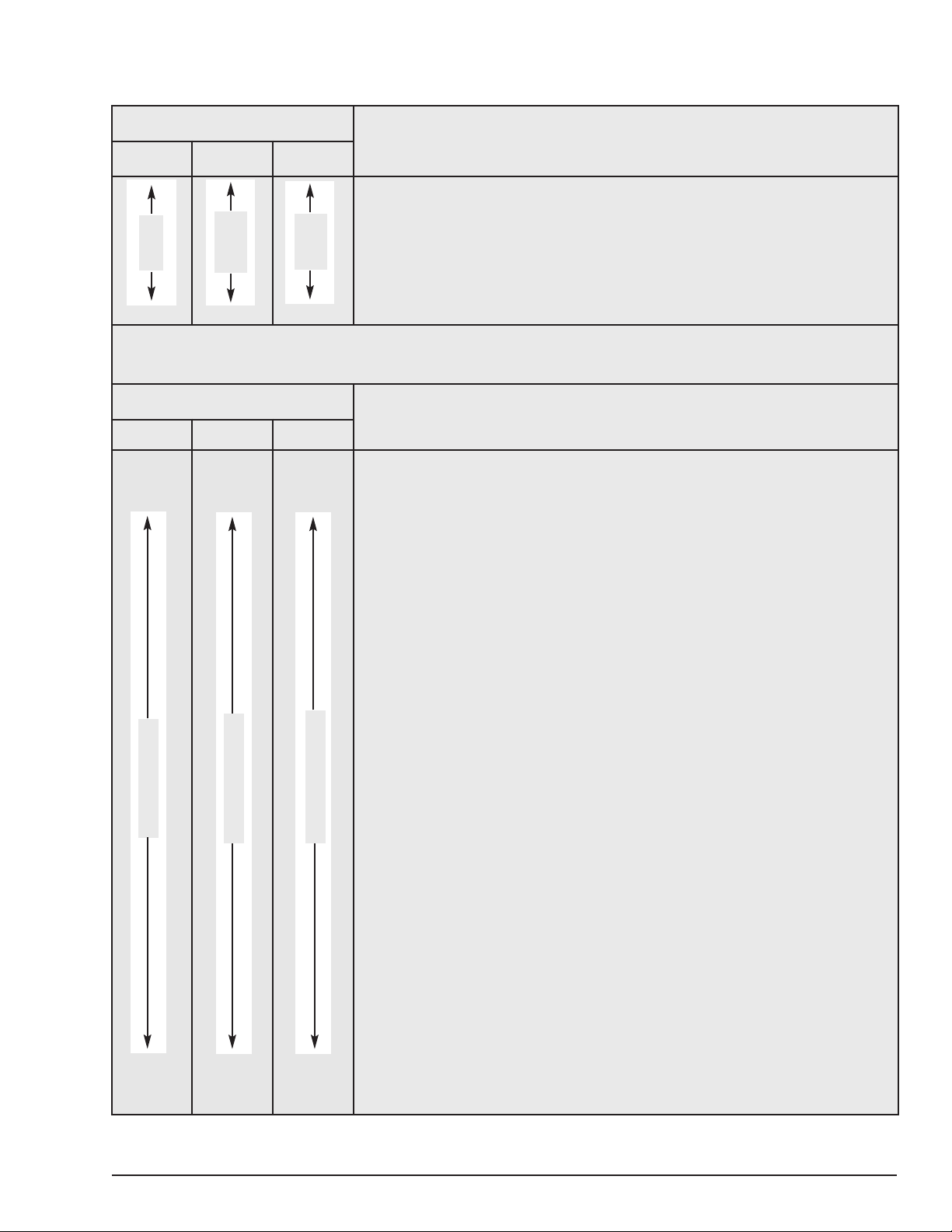

Chain Inspection

First Clean chain with a non-caustic/non-acid type solvent and

make a link by link inspection for nicks, gouges, twisted links,

weld splatter, corrosion pits, striations (minute parallel lines),

cracks in weld areas, wear and stretching. Chain with any one

of these defects must be replaced.

Slack the portion of the chain that normally passes over the liftwheel. Examine the interlink area for the point of maximum wear

(polishing, see Figure 15). Measure and record the stock diameter

at this point of the link. Then measure stock diameter in the same

area on a link that does not pass over the liftwheel (use the link

adjacent to the loose end link for this purpose). Compare these

two measurements. If the stock diameter of the worn link is 0.010

inches (0.254 mm), or more, less than the stock diameter of the

unworn link, the chain must be replaced.

On double reeved units, repeat this examination of the chain

that passes through the hook block.

Models

A thru H

A-2 thru H-2

J thru RRT

J-2 thru RRT-2

Dia. of

Chain Stock

0.250"

(6.35mm)

0.312"

(7.9mm)

No. of Links

to Gage

19

21

Max. Gage Length

Allowable Used Chain

14 13/16"

(376 mm)

18 7/8"

(479 mm)

Figure 17. Chain Embossing

Use only Star (*) grade load chain and original replacement

parts. Use of other chain and parts may be dangerous

and voids factory warranty.

Figure 15. Chain Wear Areas

Gaging Load Chain Wear

To determine if load chain should be continued in service,

check gage lengths as indicated in Figure 16. Chain worn

beyond length indicated, nicked, gouged or twisted should

be replaced before returning hoist to service. Chain should

be clean, free of twists and pulled taut before measuring.

Note that worn chain can be an indication of worn hoist

components. For this reason, the hoist’s chain guides, hook

blocks and liftwheel should be examined for wear and

replaced as necessary when replacing worn chain.

Also, these chains are specially heat treated and hardened

and should never be repaired.

IMPORTANT:

Do not use replaced chain for other purposes

such as lifting or pulling. Load chain may break suddenly without visual deformation. For this reason, cut replaced chain

into short lengths to prevent use after disposal.

!

USE OF COMMERICAL OR OTHER MANUFACTURER’S

CHAIN AND PARTS TO REPAIR CM HOISTS MAY CAUSE

LOAD LOSS.

Use only CM supplied replacement load chain and parts.Chain

and parts may look alike, but CM chain and parts are made of

specific material or processed to achieve specific properties.

WARNING

TO AVOID INJURY:

20

Figure 16. Gaging Load Chain Wear

MAINTENANCE

LOAD-LIMITER