CMT ORANGE TOOLS POCKET-PRO PPJ-002 Instruction Manual

PPJ-002

POCKET-PRO™ JOINERY SYSTEM

EQUIPO DE EBANÍSTERIA POCKET-PRO

SYSTÈME D’ASSEMBLAGE POCKET-PRO

SISTEMA DI GIUNZIONE POCKET-PRO

BOHRHILFE POCKET-PRO

EN Instruction Manual for PPJ-002 p. 2

ES Manual de instrucciones para el sistema PPJ-002 p. 8

FR Manuel d’instructions pour le système PPJ-002 p. 14

IT Manuale di istruzioni per il sistema PPJ-002 p. 20

DE Gebrauchsanleitung für die Artikel PPJ-002 S. 26

™

™

™

™

EN

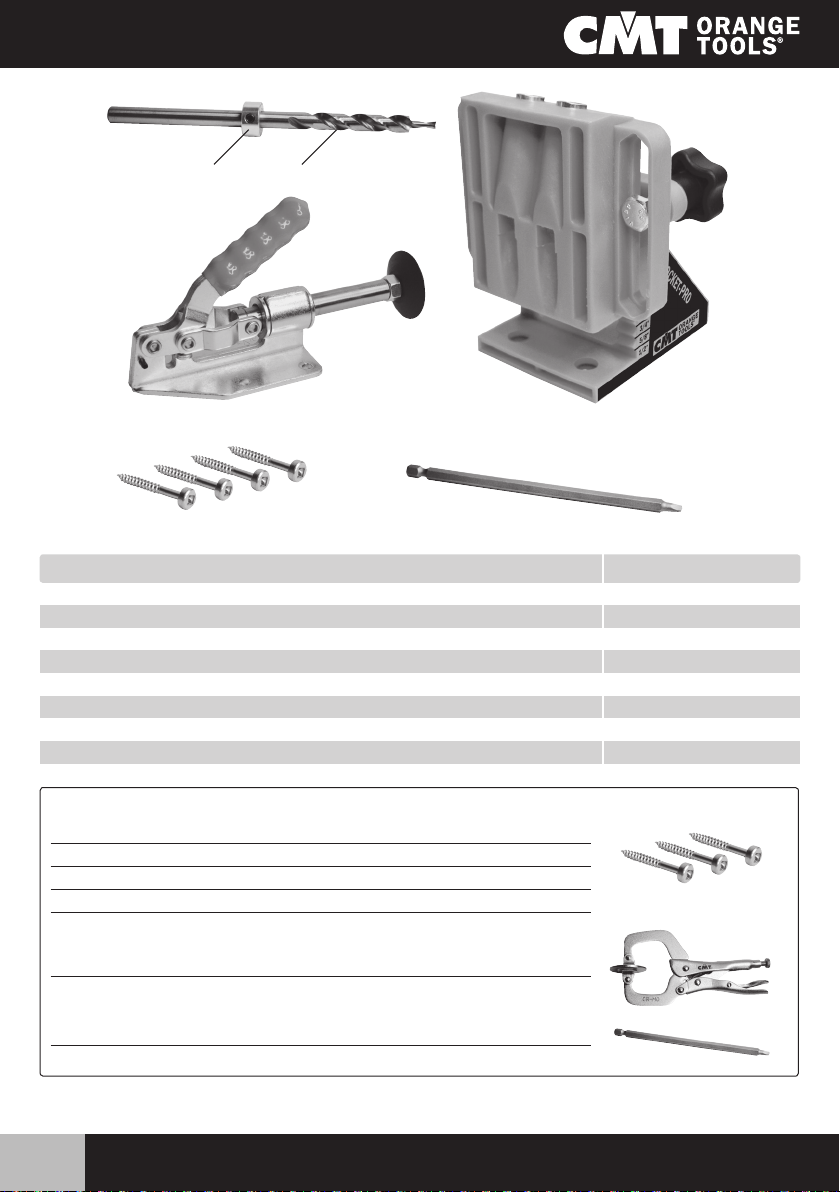

541.095.00 + 515.001.51

999.505.05

990.101X30

DESCRIPTION

POCKET-PRO™ JOINERY SYSTEM SET PPJ-002

SET CONTAINS:

POCKET-PRO™ MAIN PARTS

TOGGLE CLAMP 999.505.05

Ø9,5MM (3/8”) STEP DRILL BIT 515.001.51

Ø9,5MM (3/8”) DEPTH COLLAR FOR STEP DRILL BIT 541.095.00

L=152MM (6”) SQUARE DRIVE SCREW DRIVER BIT 999.505.08

MASTERPACK 30 FINE SCREWS L=31,7MM (1-1/4”) 990.101X30

OPTIONAL

500 FINE SCREWS L=31,7MM (1-1/4”) 990.101X500

500 COARSE SCREWS L=31,7MM (1-1/4”) 990.102X500

500 FINE SCREWS L=38,1MM (1-1/2”) 990.103X500

500 COARSE SCREWS L=38,1MM (1-1/2”) 990.104X500

FACE CLAMP SWIVEL PAD 999.505.06

999.505.08

999.505.10

ORDER NO.

ORDER NO.

L=76MM (3”) SQUARE DRIVE SCREWDRIVER BIT 999.505.07

To order replacement parts, contact your CMT Distributor

2

www.cmtorangetools.com

EN

1/2”

5/8”

3/4”

7/8”

1”

1-1/8”

1/2”

5/8”

3/4”

7/8”

1”

1-1/8”

1-1/4”

1-3/8”

1-1/2”

1-5/8”

1/2”

5/8”

3/4”

7/8”

1”

1-1/8”

1-1/4”

1-3/8”

1-1/2”

1-5/8”

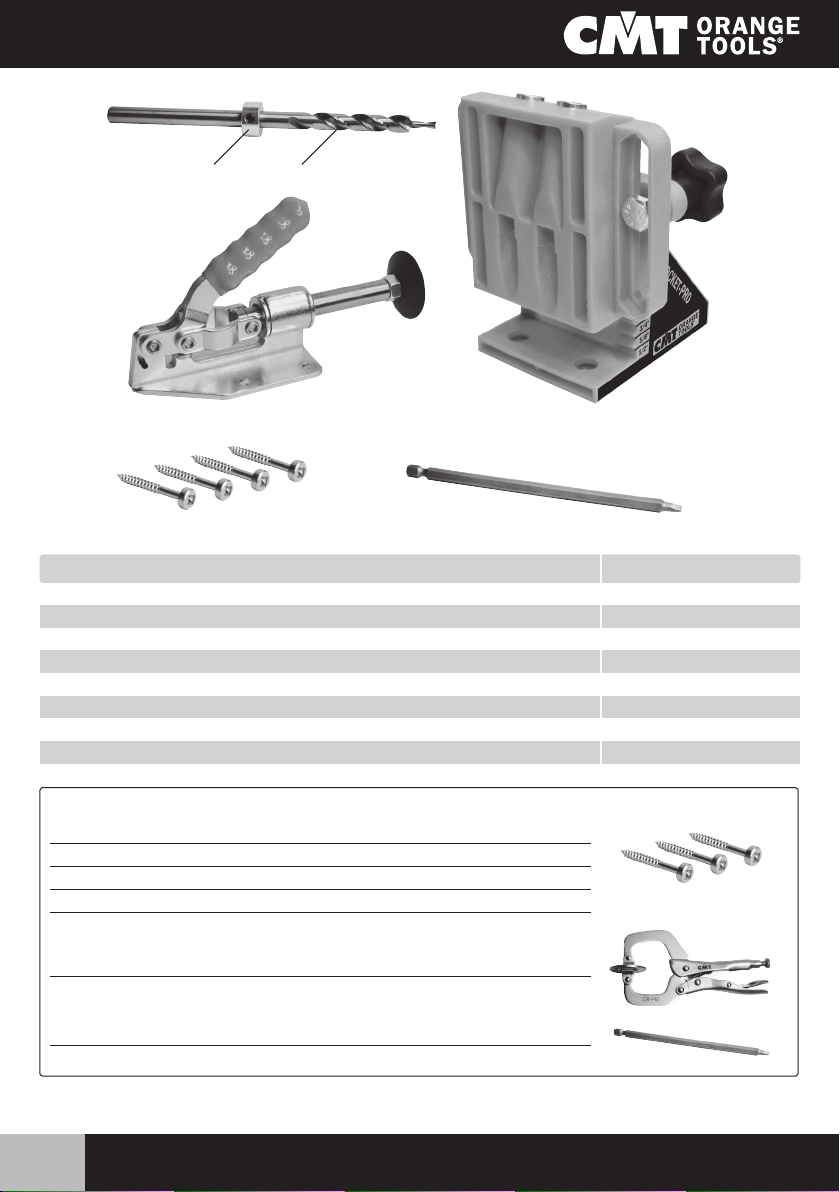

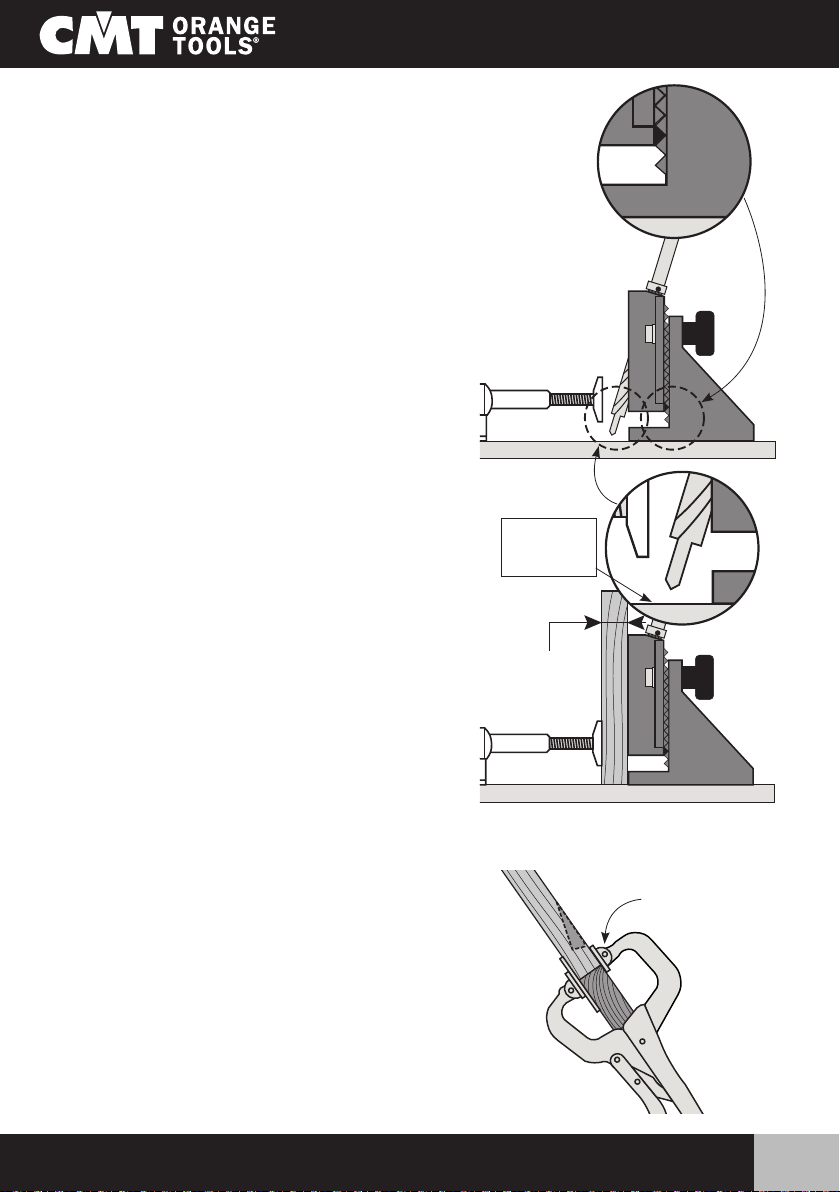

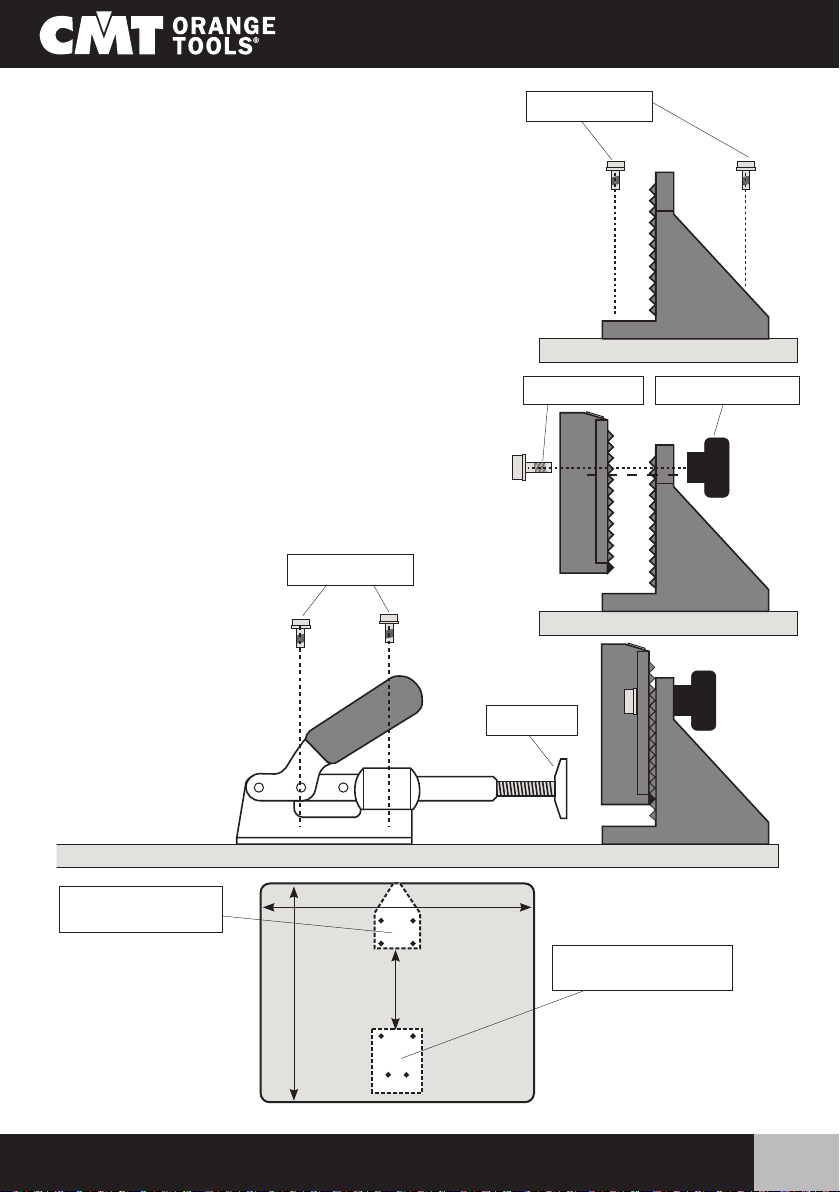

Assembling your Pocket-Pro™

1) Attach the jig to a flat piece of plywood or your workbench.

See illustrations below for suggested dimensions. Screws

should be tight enough to keep the jig from moving on the

plate, but do not overtighten and damage your jig.

2) Assemble the molded Upper Jig to the Jig Base using the

two screws and knobs provided.

3 Attach the Toggle Clamp to the base you constructed in

Step One using four screws. Thread the shaft of the Clamp

Tip into the body of the Toggle Clamp.

M4 screw

M4 screw

Fig. 1

M8 screw

Fig. 2

1-5/8”

1-1/2”

1-3/8”

1-1/4”

1-1/8”

1”

7/8”

3/4”

5/8”

1/2”

Base Plate

1-5/8”

1-1/2”

1-3/8”

1-1/4”

1-1/8”

1”

7/8”

3/4”

5/8”

1/2”

Knob

Fig. 3

Mounting Holes for

Molded Jig

11-3/4”

www.cmtorangetools.com

300mm

4-1/16”

103,2mm

14-3/4”

375mm

Tip

1-5/8”

1-1/2”

1-3/8”

1-1/4”

1-1/8”

1”

7/8”

3/4”

5/8”

1/2”

Mounting Holes

for Molded Jig

3

EN

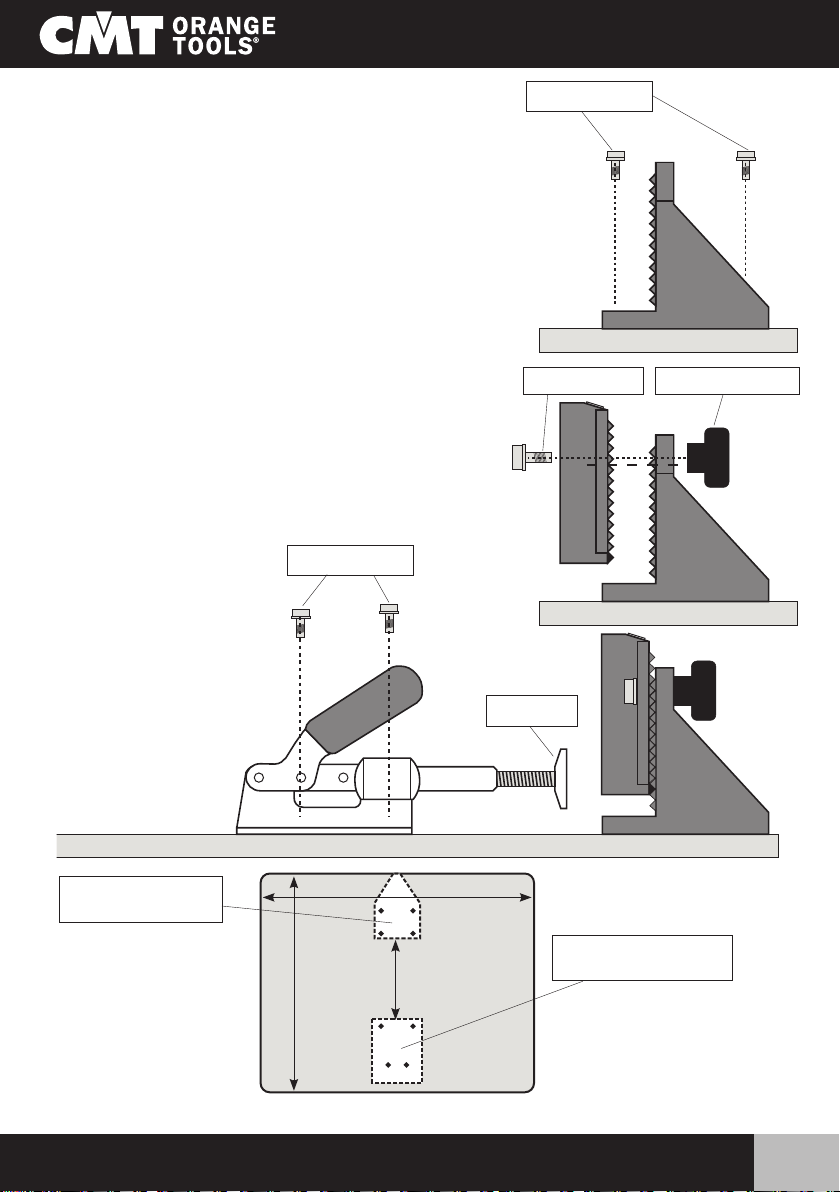

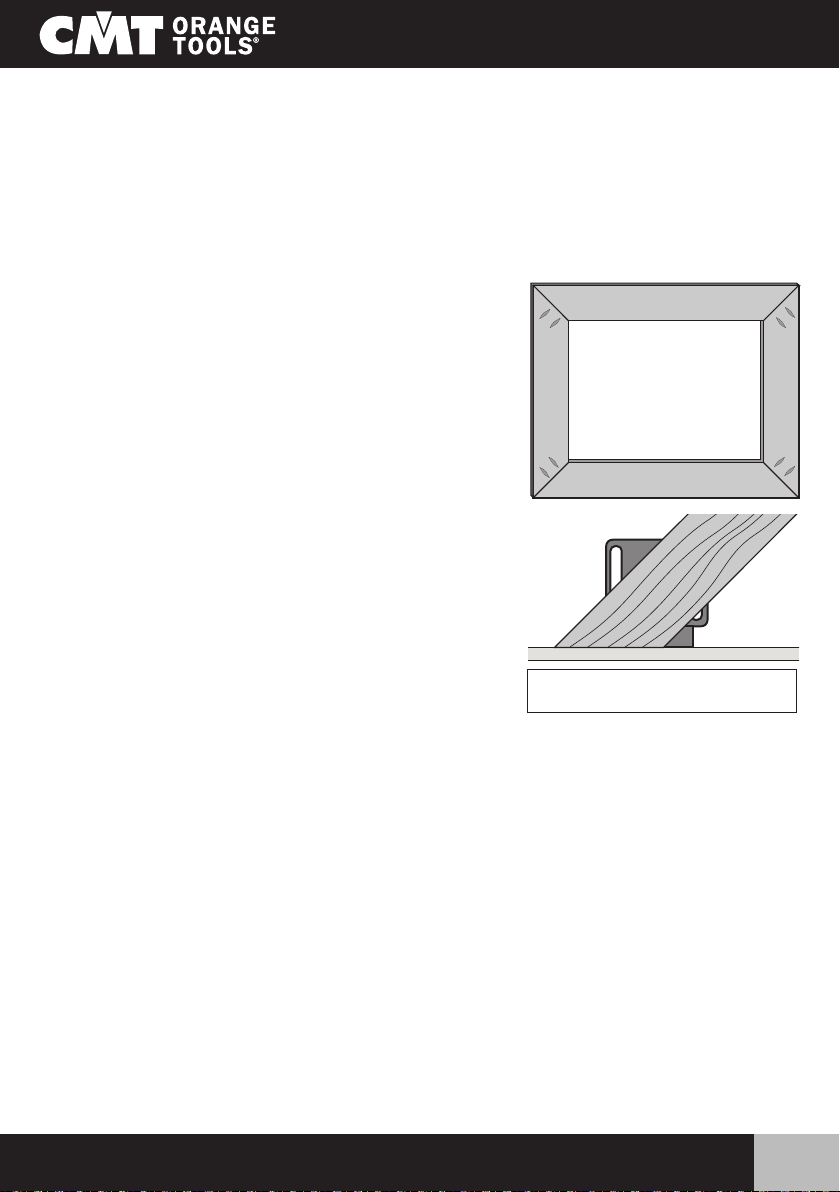

Characteristics of Pocket-Pro™ Joinery

Now that your Pocket-Pro™ Joinery System is assembled, you’re ready for wood joinery. If you have used

other pocket hole systems before, then you’re probably familiar with joints, as well as some of the

basics of using this jig. But, you’ll find some major advantages to the Pocket-Pro™.

For example:

• Some jigs require that you add or remove various portions of the jig to join different stock thicknesses.

Not with the Pocket-Pro™ - you simply adjust the interlocking jig up or down to choose from a full

range of joints, from 1/2” (12,7mm) to 1-5/8” (41,3mm) thick!

• Other jigs require frequent repositioning of the Depth Stop Collar for different styles of joint. Not with

the Pocket-Pro™ - the vast majority of adjustments allow you to leave the Stop in the same position!

• With the Pocket-Pro™, you can quickly adjust the location of the pocket in relation to the end of your

workpiece to use longer screws or to leave more “meat” in the joint.

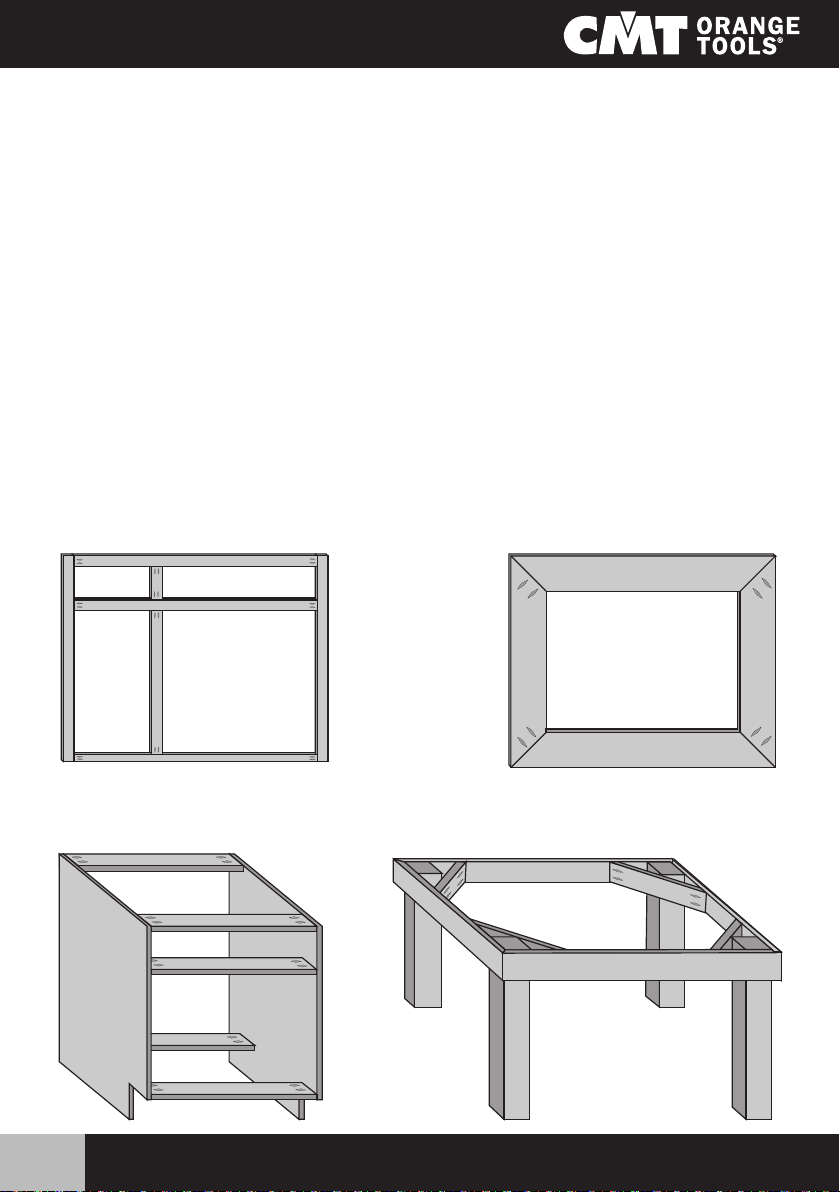

Here are just a few examples of joints you can build with your Pocket-Pro™:

– Leg and Rail Joints

– Cabinets Construction

Face Frames Picture Frames

Cabinets

Leg & Rail

and other furniture jobs

4

www.cmtorangetools.com

1/2”

5/8”

3/4”

7/8”

1”

1-1/8”

1/2”

5/8”

3/4”

7/8”

1”

1-1/8”

1-1/4”

1-3/8”

1-1/2”

1-5/8”

25,4mm (1”)

1/2”

5/8”

3/4”

7/8”

1”

1-1/8”

1-1/4”

1-3/8”

1-1/2”

1-5/8”

Face Frame Joints:

Face Frame joints are among the most common applications of the pocket hole joint, and they are an excellent way

to get accustomed to your Pocket-Pro™. If this is your first

experience with pocket holes, this is an ideal place to start.

We’ll start with a joint in common 3/4” (19mm) stock. Be

sure to make a joint in scrap material first to be certain that

you understand the system.

1) Set the height of the jig for 3/4” (19mm) material. The

“tooth” on the upper jig marked with a black triangle

should fit into the slot marked 3/4” (19mm).

2) Insert the Step Drill Bit into one of the drill guides and

set the Depth Stop Collar so that the tip of the bit will

stop about 1/8” (3,2mm) above the Base. Remove the

bit from the jig.

3) Clamp your workpiece vertically in the jig, so the two

drill guides are centered on the stock. The threaded

tip of the Toggle Clamp should be adjusted so that the

clamp holds your workpiece firmly, but you should not

need to force the clamp closed, as extreme pressure

could damage your jig. Take some time to get familiar

with the correct clamping pressure while working with

scrap.

4) Drill both holes. For best results, allow the bit to come

to full speed within the drill guide before drilling the

workpiece. Drill the hole until the Depth Stop reaches

the top of the drill guide, then keep the bit spinning

while you withdraw it from the wood.

5) Remove the stock from the jig, and position it at right

angles to the other workpiece. Use the Face Clamp

(Optional 999.505.06) or your own C-Clamp or Bar

Clamp to hold the two pieces together. Place the larger

plate of the clamp against the front face of your joint this will keep the faces perfectly flush.

6) Drive self-tapping pocket hole screws into each hole,

using the Driver Bit and your adjustable- clutch driver.

Adjust the torque so you can drive screws without stripping the heads. The workpieces may separate slightly

as you drive the screws, but they should pull tight as

you set the screws. If they separate by more than about

1/8” (3,2mm), you may wish to apply greater pressure

with the clamp.

www.cmtorangetools.com

1/8”

(3,2mm)

Space

MIN 12,7mm - 1/2”

MAX 41,3mm - 1-5/8”

EN

1-5/8”

1-1/2”

1-3/8”

1-1/4”

1-1/8”

1”

7/8”

3/4”

5/8”

1/2”

1)

1-5/8”

1-1/2”

1-3/8”

1-1/4”

1-1/8”

1”

7/8”

3/4”

5/8”

1/2”

2)

CMT Face Clamp

(Optional 999.505.06)

or your own clamp

5)

5

EN

1/2”

5/8”

3/4”

7/8”

1”

1-1/8”

1-1/4”

1-3/8”

1-1/2”

1-5/8”

Angled and Beveled Joints

The Pocket-Pro™ can be used to create a

wide variety of angled and beveled joints. The

unique incremental height adjustment of the

Pocket-Pro™ lets you put the pocket in the

best possible position for your application. As

you become more experienced with the jig you

will find many more applications than we can

possibly illustrate, but this 45° angled joint is

a good illustration of the technique:

1) This joint connects two pieces of 3/4”

(19mm) stock, but we recommend that

you set the jig at the 1” (25,4mm) height.

This has the effect of moving the pocket

farther back from the end of the miter cut,

creating a stronger joint.

2) Drill the holes. If you are joining wide material, you will probably need more than

two holes, so shift the stock in the jig as

needed.

3) In order to assemble the joint, it will help

to create a stop block as shown to hold

the work in position. This technique is useful in many other pocket hole applications.

1)

2)

Block clamped to workpiece

3)

holds stock in position

25,4mm (1”)

The 1” setting is ideal for many

mitered or angled joints. Try other

settings for various thicknesses.

Tongue & Groove and Rabbeted

Joints

The Pocket-Pro™’s incremental adjustment

comes in handy for these common joints. Other pocket hole jigs are positioned so that your

screw would cut through the tongue portion of

the tongue and groove joint.

By adjusting the height of the Pocket-Pro™,

however, you can control precisely where the

screw is positioned. For example, in this illustration, we used 3/4” (19mm) material, then

showed where the screw would be positioned

at the commonly-used 3/4” (19mm) position

in the upper illustration. In the lower drawing,

we show the advantage of the 7/8” (22,2mm)

position with the Pocket-Pro™.

6

Other pocket hole

jig set at 3/4”

(19mm) position

runs the screw

through

the tongue

Pocket-Pro™ set

at 7/8” (22,2mm)

position yields

a stronger joint

www.cmtorangetools.com

EN

1/2”

5/8”

3/4”

7/8”

1”

1-1/8”

1-1/4”

1-3/8”

1-1/2”

1-5/8”

Face Frame joints in other stock thickness

• For thinner stock, adjust your jig to the 1/2” (12,7mm) or 5/8” (15,87mm) setting, then adjust your

depth stop so the tip of the bits stops 1/8” (3,2mm) above the base.

• For thicker stock, adjust the jig to the appropriate stop. You do not need to adjust the Stop Collar,

unless your screws will not otherwise be long enough for a solid joint.

Mitered Joints

Pocket hole joints are an ideal way to assemble picture frames

and other mitered projects.

These instructions assume you will use 3/4” (19mm) thick stock.

Adjust your Jig for thicker or thinner material.

1) Set the height of the jig and the Depth Stop Collar for 3/4”

(19mm) material.

2) Cut the miters on all workpieces.

3) Clamp your workpiece in the jig as shown at right. If the stock

is more than 2-1/2” (63,5mm) wide, you can use the two drill

guides just as you would for a face frame joint. For narrower

material, you can still drill two holes, but you will need to shift

the stock between drilling the first and second holes, so that

neither pocket will be exposed on the edge of your frame.

4) Drill both holes.

5) Clamp each joint with your Face Clamp or C-Clamp and drive

the screws.

Note: Toggle clamp omitted for clarity

Screw Selection

For best results use only self tapping pocket hole screws with fillister or washer heads. We have a variety

of screws available for various applications. In general, use 1” (25,4mm) screws for 1/2” (12,7mm)

stock, 1-1/4” (31,75mm) or 1-1/2” (38,1mm) screws for 3/4” (19mm) stock, and 2-1/2” (61,5mm)

or 3” (76,2mm) screws for 1-1/2” (38,1mm) material. Coarse thread screws are best for softwoods, fine

thread for hardwood.

Maintenance

Your Pocket-Pro™ Jig is molded from high impact plastic. The jig and all other components of the Joining

System are designed for years of trouble free service. Keep the jig and clamps free of dust build-up, and

store them safely when not in use. Lightly oil the drill guides when they begin to seem dry. The only other

maintenance required is occasional sharpening of the Step Drill Bit. Take your bit to a qualified sharpening service for best results.

www.cmtorangetools.com

7

ES

541.095.00 + 515.001.51

999.505.05

990.101X30

990.101X30

LISTA DE REPUESTOS

SISTEMA DE EMPALME POCKET-PRO™ PPJ-002

EL JUEGO INCLUYE:

EQUIPO GRADUADO DE DOS PIEZAS POCKET-PRO™

ABRAZADERA DE PALANCA 999.505.05

BROCAS HELICOIDALES DE Ø9,5MM (3/8”) 515.001.51

ANILLOS DE TOPE DE Ø9,5MM (3/8”) 541.095.00

INSERTO HEXAGONAL L=152MM (6”) 999.505.08

SET 30 TORNILLOS PASO FINO L=31,7MM (1-1/4”) 990.101X30

OPCIONALES

500 TORNILLOS PASO FINO L=31,7MM (1-1/4”) 990.101X500

500 TORNILLOS PASO GRUESO L=31,7MM (1-1/4”) 990.102X500

500 TORNILLOS PASO FINO L=38,1MM (1-1/2”) 990.103X500

500 TORNILLOS PASO GRUESO L=38,1MM (1-1/2”) 990.104X500

PRENSOR DE PINZA AJUSTABLE 999.505.06

999.505.08

999.505.10

CÓDIGO

CÓDIGO

PIEZA CUADRADA PARA DESTORNILLADOR L=76MM (3”) 999.505.07

Para encargar las piezas de repuesto, contacte con nuestro Distribuidor local CMT

8

www.cmtorangetools.com

1/2”

5/8”

3/4”

7/8”

1”

1-1/8”

1/2”

5/8”

3/4”

7/8”

1”

1-1/8”

1-1/4”

1-3/8”

1-1/2”

1-5/8”

1/2”

5/8”

3/4”

7/8”

1”

1-1/8”

1-1/4”

1-3/8”

1-1/2”

1-5/8”

MONTAJE DEL SISTEMA Pocket-Pro™

ES

Montaje del sistema Pocket-Pro™

1) Monte el equipo PPJ-002 sobre un pedazo llano de madera contrachapada sobre el banco de trabajo. Consultar las

ilustraciones debajo para las dimensiones aconsejadas.

Los tornillos tienen que apretarse de manera suficiente

para impedir que el equipo se desplace sobre la placa,

pero no apriete excesivamente ya que el equipo podría

dañarse.

2) Monte la parte superior del equipo sobre la base utilizando

los dos tornillos y los mangos esféricos suministrados.

3) Monte el prensor sobre la base fabricada en el punto 1)

utilizando cuatro tornillos. Enrosque el eje enroscado de la

punta del prensor dentro del cuerpo del prensor mismo.

Tornillo M4

Tornillo M4

Fig. 1

Tornillo M8

Fig. 2

1-5/8”

1-1/2”

1-3/8”

1-1/4”

1-1/8”

1”

7/8”

3/4”

5/8”

1/2”

Placa de la base

Mango esférico

1-5/8”

1-1/2”

1-3/8”

1-1/4”

1-1/8”

1”

7/8”

3/4”

5/8”

1/2”

Fig. 3

Agujeros de montaje

para prensor

11-3/4”

www.cmtorangetools.com

300mm

4-1/16”

103,2mm

14-3/4”

375mm

Punta

Agujeros de montaje para

sistema PPJ

1-5/8”

1-1/2”

1-3/8”

1-1/4”

1-1/8”

1”

7/8”

3/4”

5/8”

1/2”

9

ES

Características de Pocket-Pro™ Joinery

Después de haber montado el sistema de Empalme Pocket-Pro™, Ud. estará listo para entrar en nuevo

mundo de los empalmes de madera. Si ya ha utilizado herramientas de este tipo, ya conocerá muchas

de las aplicaciones que se pueden realizar y las indicaciones de base para su empleo.

Sin embargo, descubrirá que Pocket-Pro™ presenta algunas ventajas importantes. Por ejemplo:

• Algunos productos necesitan que se agreguen o sustituyan algunas partes del equipo para la elaboración de los varios espesores.

No es así para Pocket-Pro™, el cual permite conseguir la realización de encajes con espesor de 12,7

hasta 41,3mm (1/2” hasta 1-5/8”) mediante una simple regulación vertical de la herramienta.

• Algunos equipos necesitan frecuentes desplazamientos de la posición del anillo de tope para los

distintos tipos de empalmes.

¡No es así para Pocket-Pro™, con el cual la mayoría de los ajustes pueden conseguirse dejando el

anillo de profundidad en la misma posición!

• Con Pocket-Pro™ es posible ajustar rápidamente la posición del equipo respecto a la extremidad

de la pieza que trabajar, también utilizando tornillos más largos o dejando un grosor mayor en los

empalmes.

Aquí debajo algunos tipos de empalmes que es posible realizar con el sistema Pocket-Pro™:

– Empalmes de espiga

– Fabricación de pequeños muebles

10

Pequeños

muebles

Bastidores

frontales

Marcos

Patas y travesaños

y más aplicaciones

para muebles

www.cmtorangetools.com

Loading...

Loading...