CMT ORANGE TOOLS CMT333 Instruction Manual

Instruction Manual

Manual de instrucciones

Manuel d’utilisation

Manuale di istruzioni

Gebrauchsanweisungen

EN p. 4

ES p. 8

FR p. 12

IT p. 16

DE S. 20

CMT333

UNIVERSAL HINGES BORING SYSTEM

Base por sistema de taladro manual de bisagras

Base modulaire pour têtes de perçage manuel

Base modulare per testine a foratura manuale

Modulbasis für Handbohrung-Köpfe

3

www.cmtorangetools.com

2

www.cmtorangetools.com

UNIVERSAL HINGES BORING SYSTEMUNIVERSAL HINGES BORING SYSTEM

11

42

Ø35

Ø8

1

CMT333-4211

for Grass hinges 42/11

43

Ø26

Ø10

21,5

21,5

4

CMT333-4300

for window handles 43/00

9,5

45

Ø35

Ø8

2

CMT333-4595

for Blum hinges 45/9,5

6

48

Ø35

Ø10

5

CMT333-4806

for Salice hinges 48/6

9

48

Ø35

Ø8

3

CMT333-4809

for Mepla hinges 48/9

5,5

52

Ø35

Ø10

6

CMT333-5255

for Hettich, Würth hinges 52/5,5

Ø26

38

7,5

7

CMT333-3875

for small hinges 38/7,5

Ø26

38

7,5

7

CMT333-3875

for small hinges 38/7,5

For use on standing drilling machines

For use on standing drilling machines

For use on CMT Industrio router table

Assembly

www.cmtorangetools.comwww.cmtorangetools.com

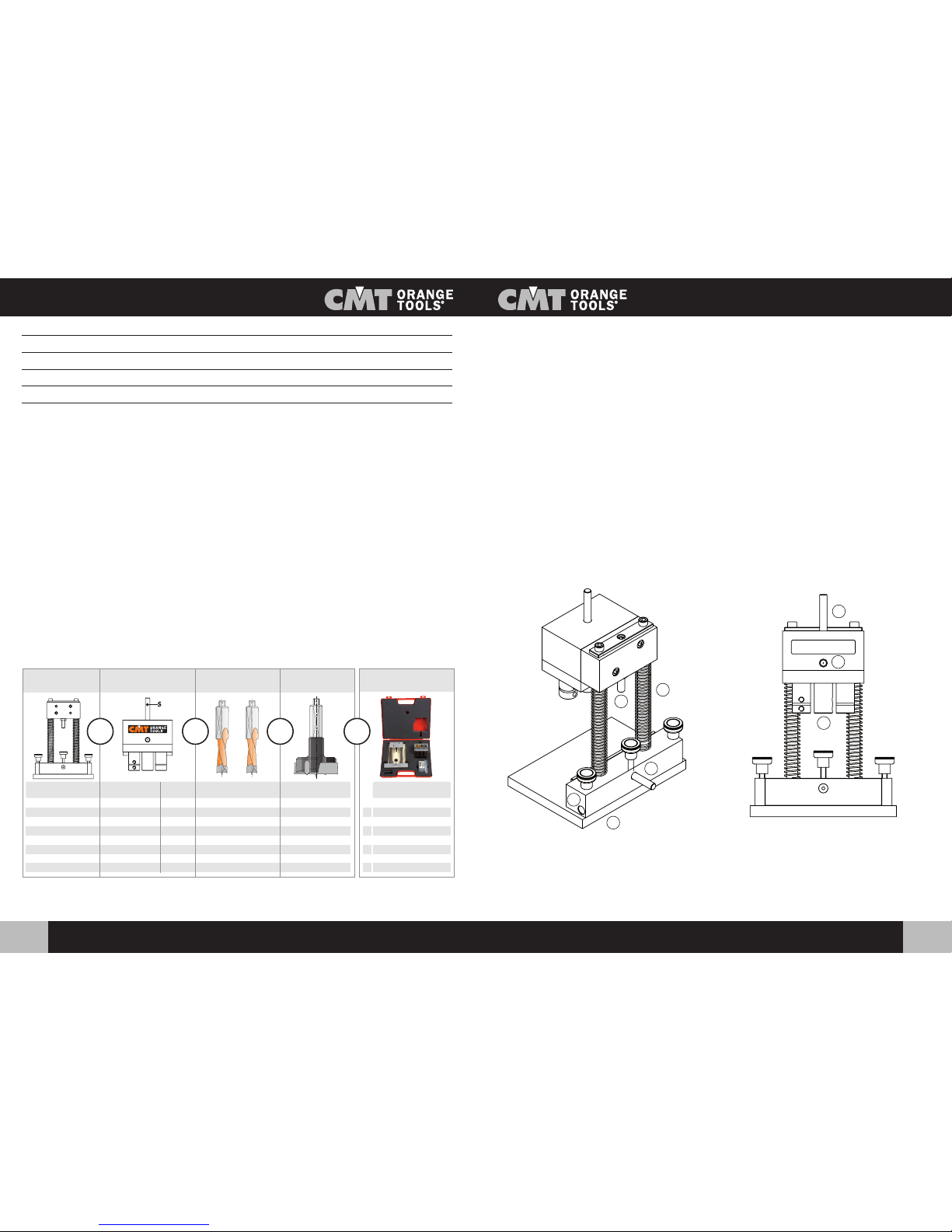

This drilling system was designed by CMT for all craftsmen and DIY buffs who require to drill holes for

hinges by various manufacturers in a precise reliable manner.

The system is made up of a multipurpose support to which a 3-arbor chuck head with a space between

holes that varies according to the type of hinge used can be fitted.

The support is made up of two chromed steel runner bars with springs (1) and a threaded bar (2) for

setting drilling depth. On the base, it is possible to adjust drilling distances; from the edge of the panel

to the hinge by means of the stop plate with pin and centre clamp knob (3) whereas, from the underside

of the panel to the hinge, this Is done with a Ø10mm (3/8”) cylindrical bar (not included) that is fitted in

the hole at the side of the base (4). In the bottom part of the support, there are two side holes for fitting

the support board (5) or mounting CMT worktables on the plates.

The head is made up of a shaft (6) with a diameter of 8mm (5/16”) (for use on all drills), which allows

the rotation of three bit holder arbors (7), each of which has two dowels for fitting the bits. The shaft and

the arbors have been burnished in order to avoid the formation of rust.

Two radial ball bearings have been fitted inside each arbor’s head to ensure the utmost drilling precision.

On the front, there is a hole with a sphere (8) for the lubrication of the head with Mobil SHC100.

1

2

3

4

5

6

8

7

COMPONENT CHARACTERISTICS

www.cmtorangetools.com

5

INDEX PAGE

Introduction, General Notes & Set Assembly pag.4

Characteristics of the components pag.5

Installation & Use pag.6

Maintenance & Safety pag.7

Information on this publication

This booklet is an integral part of the product. Carefully read the warnings and instructions it contains, as

they provide important indications regarding user safety and maintenance. This manual is used by users

under their own responsibility.

C.M.T. UTENSILI SpA cannot be held responsible or liable to prosecution for damage due to incorrect use

of the documentation.

Keep this manual in a safe place for any further consultation that may be required.

General notes

This manual was prepared with the intention of providing all the indications regarding technical aspects,

installation, adjustment, use and maintenance.

Data and designs are provided for illustrative purposes. The manufacturer reserves the right to make any

modifications to the product without prior notice.

If any further information is required, out technical assistance service should be contacted.

Assembling the set according to the type of hinge

Thanks to the following table, assembling the set is extremely easy.

According to the hinge model, the CMT333 multipurpose support, chuck head, two blind hole bits and

hinge drill bit (code 317.350.11) must be ordered.

N.B.: blind hold bits are sold individually, like all the other items, so when ordering, it is necessary to indicate a

quantity of two

INDEX, INTRODUCTION & ASSEMBLY OF THE SET

4

www.cmtorangetools.com

Boring bit

Support

modular base

ORDER NO. ORDER NO.

S

ORDER NO.

Left-hand rotation

ORDER NO.

Right-hand rotation

Boring heads Drill bits

1

2

3

4

5

6

7

8

Make your set

Choose your hinge

Grass 42/11

Blum 45/9,5

Mepla 48/9

Window handles 43/00

Salice 48/6

Hettich, Würth 52/5,5

Small hinges 38/7,5

System 32 32

CMT333 CMT333-4211

8mm

310.080.12 (2 pcs.) 317.350.11

CMT333 CMT333-4595

Hexagonal

310.080.12 (2 pcs.) 317.350.11

CMT333 CMT333-4809

8mm

310.080.12 (2 pcs.) 317.350.11

CMT333 CMT333-4300

Hexagonal

310.100.12 (2 pcs.) 317.260.11

CMT333 CMT333-4806

8mm

310.100.12 (2 pcs.) 317.350.11

CMT333 CMT333-5255

Hexagonal

310.100.12 (2 pcs.) 317.350.11

CMT333 CMT333-3875

8mm

310 your choice (2 pcs.) 317.260.11

CMT333 CMT333-325

Hexagonal

(3 pcs. RH + 2 pcs. LH)

+ + + =

www.cmtorangetools.comwww.cmtorangetools.com

Dismantling

To change the head, the two rear screws must be removed and, due to the precise match and use, it may

be necessary to give a light knock with a plastic mallet on the top/front part of the support.

Cleaning

Periodically clean the drilling group of machining waste, using compressed air and a cloth with ethylic

alcohol.

Lubrication

The drilling groups are supplied already lubricated. During the first hours’ work, there may be a loss of

lubricant due to an excessive amount having been applied.

Every 200 machining hours, grease with 5 grams of “MOBIL SHC100” grease.

Consignment / Unpacking

The support of the CMT333 head is supplied packed in a handy case, in which the head chosen and

three bits can also be placed.

When the product is received, check that the contents correspond exactly to the items ordered and that

nothing has been damaged during transport.

In the event of any obvious defects being noted, do not use the set, but immediately inform the manufacturer.

No lifting equipment is required for handling the set, as it is light-weight (<20 kg).

Storage

In the event of the product having to be stored, proceed as follows:

- Clean of any machining scrap.

- Protect ground parts with a coating of grease and/or liquids for protection against corrosion or rust.

- Store in a fresh dry location at a temperature of between -5° and 30° C.

- Protect the drilling group from dirt and dust.

- If stored for over six months, before use, it is advisable to replace the lubrication grease.

Safety

During machining, always use personal protection: hearing protection device, dust mask, protective goggles. Never wear loose garments, make certain sleeves are rolled up and do not wear ties.

Follow the regulations described here scrupulously. The manufacturer is exempt from all responsibility in

the event of failure to comply with instructions and indications. The system must not be used in any other

way than that for which it is intended. Cleaning, lubrication and maintenance work must never be carried

out on the system when the drilling group is running.

If unusual noise or vibrations are noted with the system is started, stop machining and contact our Technical Office.

MAINTENANCE & SAFETY

7

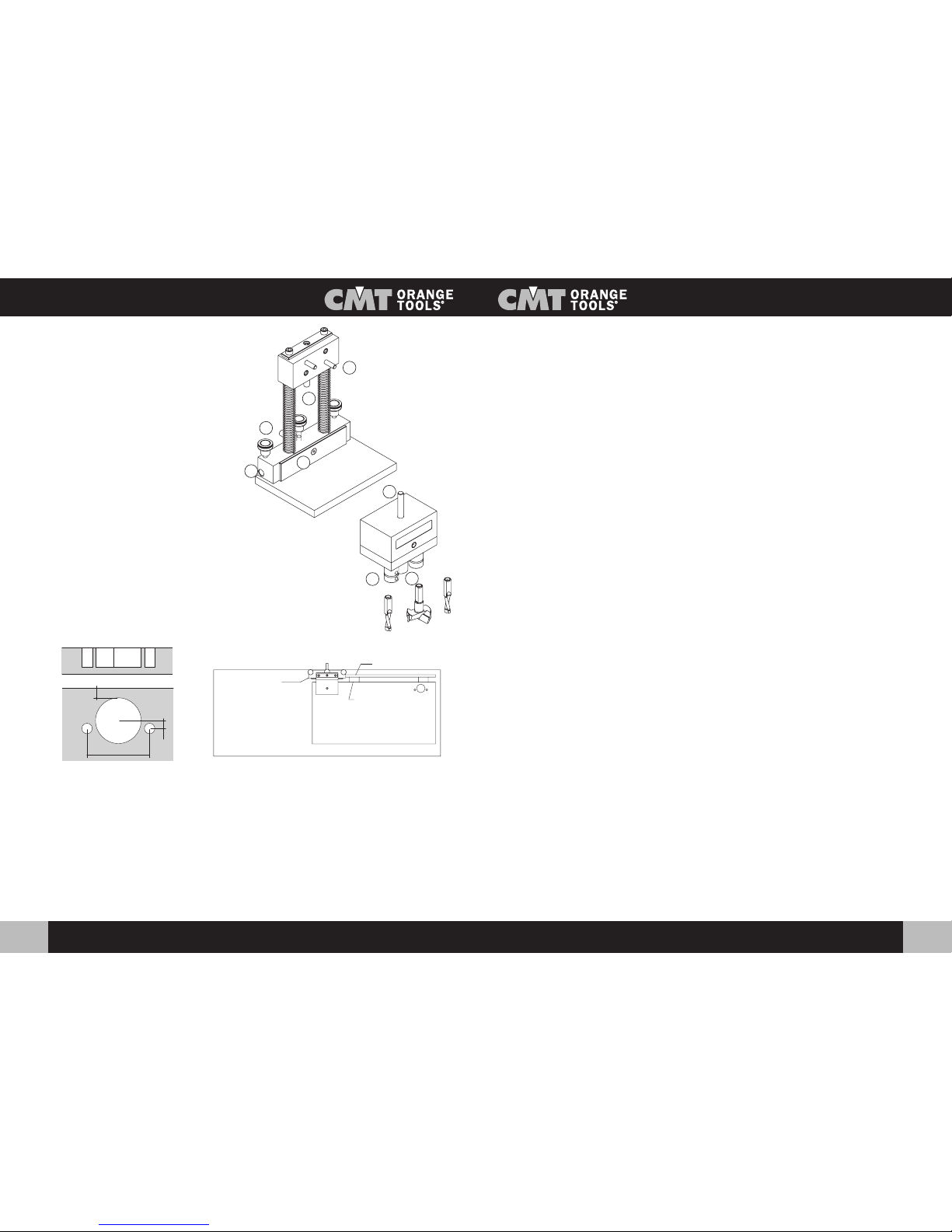

According to the hinge model, install the relative chuck

head (Fig. 2) on the multipurpose support (Fig. 1) by

means of the two rear locking screws (1).

Position the drilling system on a work surface suited

to the type of machining. Procure a steel bar with a

diameter of Ø10mm (3/8”) and a length suited to

the type of machining to be carried out and fit it in

the side hole (2). Adjust the reference stop and lock

everything with the two clamp knobs (3) and fix one

or more reference shims on the table according to the

length of the workpiece to be drilled (Fig. 4).

Set drilling distances (Fig. 3): From the panel’s edge

to the hinge (D) by means of the plate and centre

clamp knob (4) and the drilling depth (H) with the

threaded bar and lock nut (5), then position the

workpiece to be drilled (Fig. 4). The bits suited to the

head chosen are then fitted to the three arbors: on

the centre arbor (6) fit and lock the Ø35mm bit for right hand hinges, whereas, on the two side arbors (7),

fit left-hand Ø8mm or Ø10mm bits for blind holes.

(according to the type of hinge), which are fixed with

the two dowels, (Fig. 2).

48

D

6

H

Use

Use is easy and rapid. Once the equipment is ready, all that has to be done is to fit the shaft of the drilling

system (8) to the arbor of a normal electric or battery-powered column drill and carry out the drilling.

Drilling speed depends on the work piece and the type of bit used.

Maximum rotation speed: 5000 rpm.

N.B.: Before starting the drilling system, check that the tools are correctly tightened and direction of

machine rotation, to ensure that the tool turns in the correct drilling direction.

1

Fig. 1

3

4

5

Fig. 2

Fig. 3 Fig. 4

2

8

7

6

INSTALLATION & DRILLING ADJUSTMENT

6

STEEL BAR Ø10mm (3/8”)

REFERENCE SHIMS

WORK SURFACE

WORKPIECE

CMT333

www.cmtorangetools.comwww.cmtorangetools.com

Loading...

Loading...