Page 1

DUBAI • HOUSTON • NEWCASTLE • SINGAPORE • SHANGHAI • PUSAN • PERTH

TECHNICAL DATA

CABLE CONNECTOR TYPE : TMC2

INGRESS PROTECTION : IP66, NEMA 4X

PROCESS CONTROL SYSTEM : BS EN ISO 9001

: ISO/IEC 80079-34:2011

HAZARDOUS AREA CLASSIFICATION

ATEX CERTIFICATION No : SIRA 09ATEX1164X

ATEX CERTIFICATION CODE : II 2 GD Ex e IIC Gb / Ex ta IIIC Da

IEC Ex CERTIFICATION No : IEC Ex SIR.09.0068X

IEC Ex CERTIFICATION CODE : Ex e IIC Gb / Ex ta IIIC Da

CSA-Us CERTIFICATION No : 09.2194053X

CSA-Us CERTIFICATION CODE : Class I, Div 2 Groups A, B, C, D; Class II, Div 2, Groups E,F,G; Class III, Div 2; Encloxure type 4X;

Ex e II, Class I Zone 1, AEx e II, AEx ta IIC

INSTALLATION INSTRUCTIONS

Installation should only be performed by a competent person using the correct tools. Read all instructions before beginning installation.

INSTALLATION GUIDANCE NOTES

1. In accordance with NEC requirements, connectors with NPT and Metric entry threads are suitable for both Divisions and Zones.

2. In accordance with CEC requirements, connectors with NPT threads are suitable for both Divisions and Zones. Connectors with Metric threads are

only suitable for Zones unless fitted with an approved Metric to NPT thread conversion adaptor.

SPECIAL CONDITIONS FOR SAFE USE

1. Entry component threads may need additional sealing to maintain the ingress protection rating as applicable to the associated equipment in which

it will be attached

2. The cable ranges shall only be used where the temperature, at the point of entry, is in the following ranges:

TMC Types: -60°C to +110°C.

INSTALLATION INSTRUCTIONS FOR

CABLE CONNECTOR TYPE TMC2

CMP TYPE TMC2 CABLE CONNECTOR FOR USE WITH INTERLOCKED & CORRUGATED CONTINUOUSLY

WELDED METAL CLAD (TYPE MC OR MC-HL) OR TECK ARMORED AND ARMORED & JACKETED CABLES

IN ORDINARY, WET & HAZARDOUS LOCATIONS.

INCORPORATING EC DECLARATION OF CONFORMITY TO DIRECTIVE 94/9/EC

CABLE CONNECTOR

CABLE CONNECTOR

TYPE TMC2

TYPE TMC2

ACCESSORIES

The following accessories are available from CMP Products, as optional extras, to assist with fixing, sealing and earthing :-

Locknut | Earth Tag | Serrated Washer | Entry Thread (I.P.) Sealing Washer

Order Reference Entry Thread

Aluminum NP Brass S. Steel NPT Option Min Max Min Max

TMC2-050A075 TMC2-050NB075 TMC2-050SS075 1/2” - 0.78

TMC2-075A075 TMC2-075NB075 TMC2-075SS075 - 3/4” 0.80

TMC2-050A099 TMC2-050NB099 TMC2-050SS099 1/2” - 0.78

TMC2-075A099 TMC2-075NB099 TMC2-075SS099 - 3/4” 0.80

TMC2-075A118 TMC2-075NB118 TMC2-075SS118 3/4” - 0.79

TMC2-100A118 TMC2-100NB118 TMC2-100SS118 - 1” 0.98

TMC2-100A137 TMC2-100NB137 TMC2-100SS137 1” - 0.98

TMC2-125A137 TMC2-125NB137 TMC2-125SS137 - 1-1/4” 1.00

TMC2-125A162 TMC2-125NB162 TMC2-125SS162 1-1/4” - 1.00

TMC2-150A162 TMC2-150NB162 TMC2-150SS162 - 1-1/2” 1.06

TMC2-125A190 TMC2-125NB190 TMC2-125SS190 1-1/4” - 1.03

TMC2-150A190 TMC2-150NB190 TMC2-150SS190 - 1-1/2” 1.06

TMC2-150A200 TMC2-150NB200 TMC2-150SS200 1-1/2” - 1.06

TMC2-200A200 TMC2-200NB200 TMC2-200SS200 - 2” 1.57

TMC2-150A233 TMC2-150NB233 TMC2-150SS233 1-1/2” - 1.06

TMC2-200A233 TMC2-200NB233 TMC2-200SS233 - 2” 1.57

TMC2-200A272 TMC2-200NB272 TMC2-200SS272 2” - 1.57

TMC2-250A272 TMC2-250NB272 TMC2-250SS272 - 2-1/2” 1.57

TMC2-300A325 TMC2-300NB325 TMC2-300SS325 3” - 1.63

TMC2-350A325 TMC2-350NB325 TMC2-350SS325 - 3-1/2” 1.68

TMC2-350A376 TMC2-350NB376 TMC2-350SS376 3-1/2” - 1.68

TMC2-400A376 TMC2-400NB376 TMC2-400SS376 - 4” 1.73

TMC2-400A425 TMC2-400NB425 TMC2-400SS425 4” - 1.73 3.52 3.94 3.70 4.25 5.23 5.65 3.89 59.19

Min

Thread

Length

All dimensions in inches

Cable Armor

Diameter

0.42 0.63 0.50 0.75 1.20 1.30 1.65 2.29

0.60 0.89 0.69 0.99 1.48 1.60 1.97 3.00

0.79 1.10 0.87 1.18 1.81 1.95 2.13 5.11

0.94 1.28 1.02 1.37 2.05 2.21 2.34 6.70

1.22 1.50 1.30 1.62 2.36 2.55 2.44 8.82

1.49 1.72 1.57 1.90 2.56 2.79 2.44 9.45

1.57 1.88 1.65 2.00 2.75 2.97 2.60 11.06

1.79 2.21 1.91 2.33 2.95 3.19 2.64 12.77

2.14 2.61 2.27 2.72 3.54 3.82 2.76 24.69

2.49 2.97 2.62 3.25 4.33 4.68 3.46 42.68

2.95 3.54 3.16 3.76 4.84 5.23 3.68 53.44

Cable Jacket

Diameter

Across

Flats

Across

Corners

Nominal

Assembly

Length

Approx Weight

Aluminium

(Ozs)

Cable Connector Selection Table

CMP Document No. FI410 Issue 4 0113

I, the undersigned, hereby declare that the equipment referred to herein conforms to the requirements of the ATEX Directive 94/9/EC and the

following standards:-

EN60079-0:2009, EN60079-7:2007, EN60079-21:2009, BS 6121:1989, EN50262:1998 (Amd 2001), EN61241-0:2006, EN61241-1:2004

Dr Geof Mood - Technical Director - (Authorised Person)

Glasshouse Street • St. Peters • Newcastle upon Tyne • NE6 1BS

Tel: +44 191 265 7411 • Fax: +44 191 265 0581

E-Mail: cmp@cmp-products.com • Web: www.cmp-products.com

0518

Notified Body: Sira Certification Service, Rake Lane, Chester CH4 9JN, England.

www.cmp-products.com

Logo’s shown for illustration purposes only. Please check certification for details

Page 2

DUBAI • HOUSTON • NEWCASTLE • SINGAPORE • SHANGHAI • PUSAN • PERTH

www.cmp-products.com

INSTALLATION INSTRUCTIONS FOR CMP CABLE CONNECTOR TYPE TMC2

3

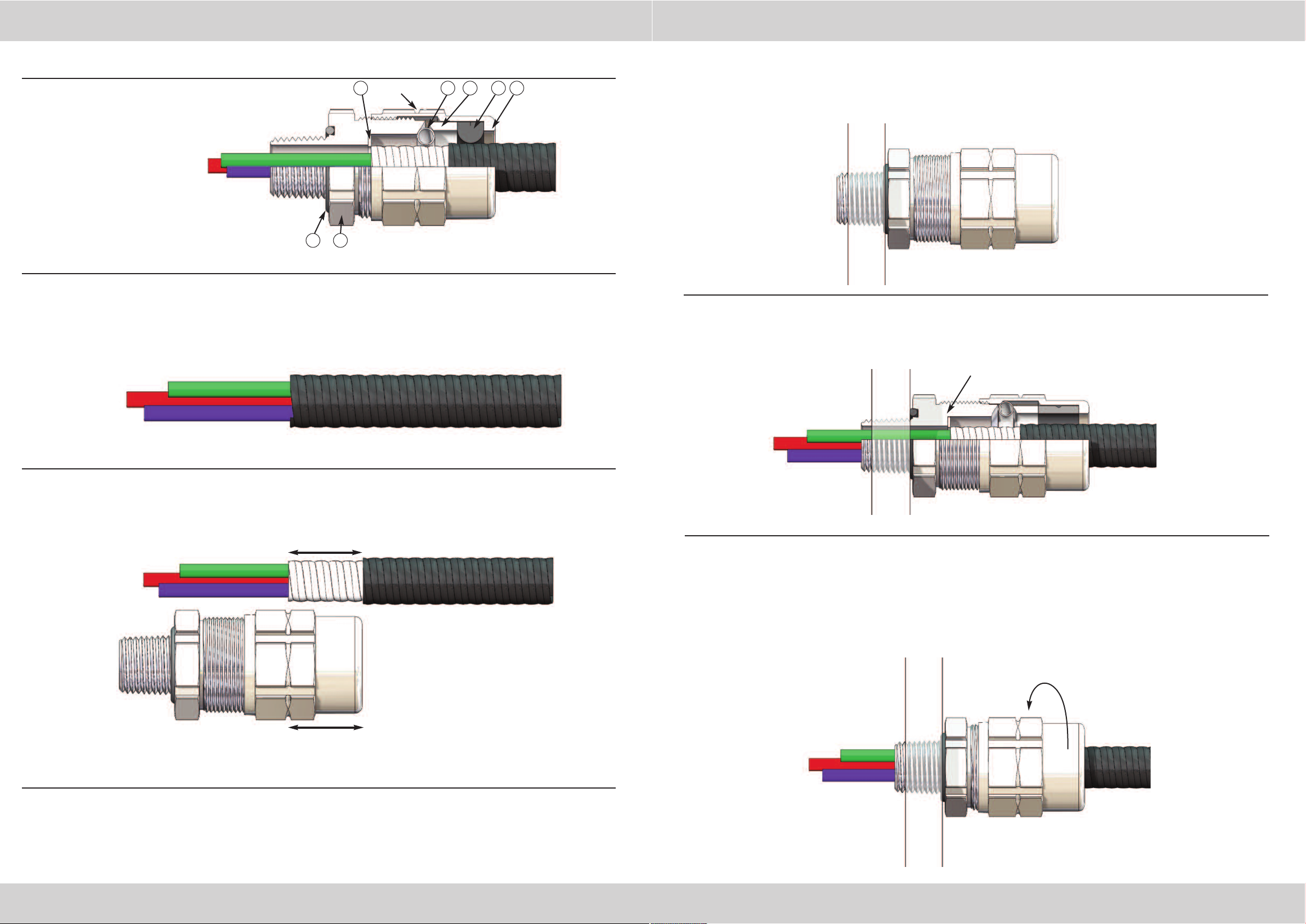

CABLE CONNECTOR COMPONENTS

1. Face Seal

2. Entry Component

3. End Stop

4. Grounding Spring

5. Angled Spacer

6. Jacket Seal

7. Outer Nut

1

2

Armor Measure

Guide

PLEASE READ ALL INSTRUCTIONS CAREFULLY BEFORE BEGINNING THE INSTALLATION

1. Cable preparation.

Strip back the jacket and armor to suit the equipment geometry.

4 5 6 7

3. Screw the connector into the equipment, or if it is fitted into a clearance hole, secure with a

locknut.

Loosen the outer nut to ensure that the Grounding Spring (4) and the Jacket Seal (6) are in a

relaxed state. IT IS NOT NECESSARY TO SEPERATE THE CONNECTOR COMPONENTS.

4. Pass the cable through the connector until the armor makes contact with the end stop.

If it is not possible for the conductors to pass through the end stop then it should be removed so

that the armor can make contact with the integral end stop within the entry component.

End Stop

2. Using the armor measure guide, expose the armor by stripping back the cable jacket by distance “L”.

L

L = Distance from

groove to rear of nut.

L

5. Finally, tighten the Outer Nut (7) to compress the Grounding Spring (4) to secure the armor, and

also to cpmpress the Jacket Seal (6) onto the cable jacket. Do not over-tighten. The Entry

Component (2) and the Outer Nut (7) do not have to close face to face.

THIS COMPLETES THE TERMINATION

www.cmp-products.com

DUBAI • HOUSTON • NEWCASTLE • SINGAPORE • SHANGHAI • PUSAN • PERTH

Loading...

Loading...