Page 1

DUBAI • HOUSTON • NEWCASTLE • SINGAPORE • SHANGHAI • PUSAN • PERTH

TECHNICAL DATA

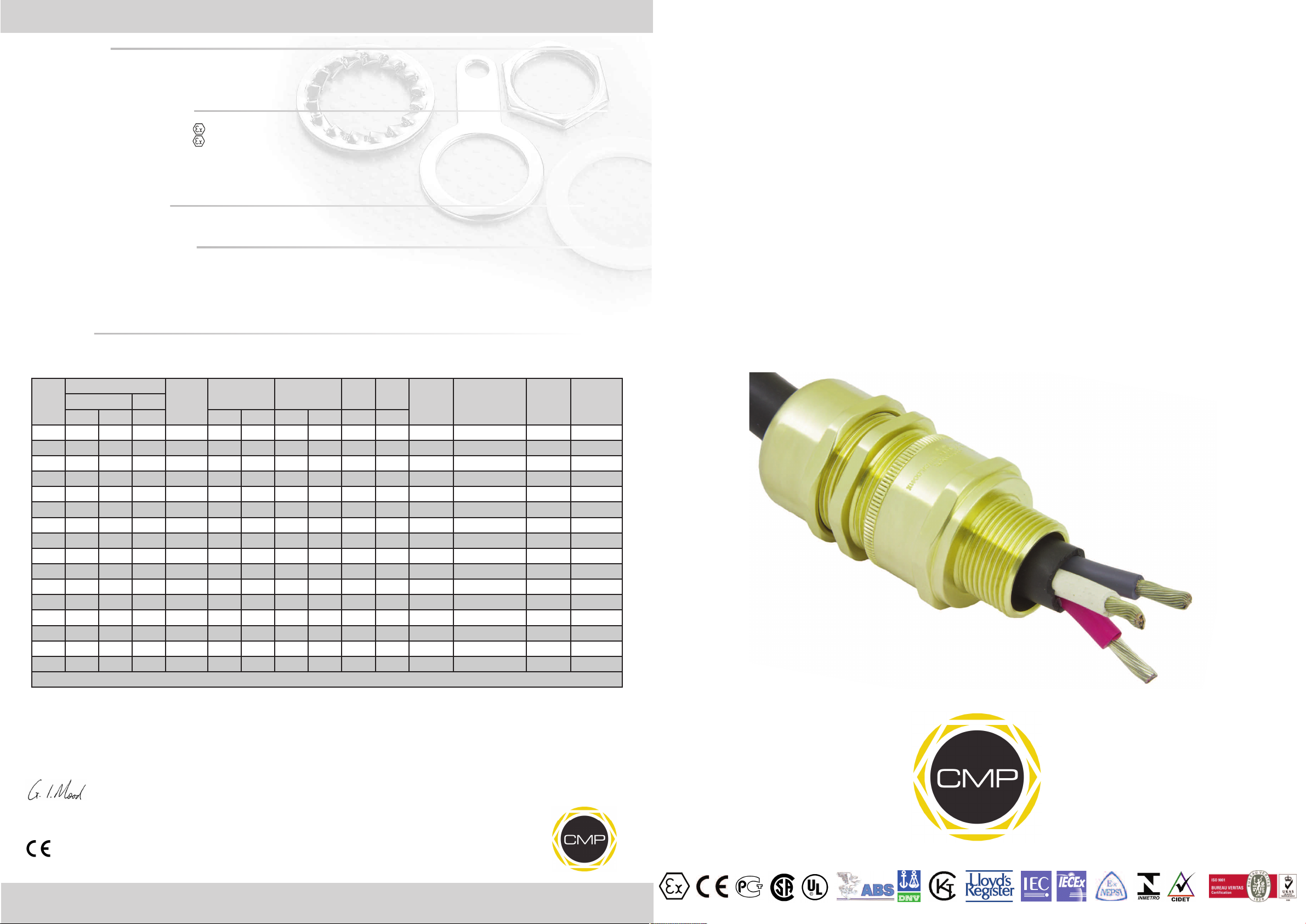

CABLE GLAND TYPE : SS2K, SS2K/PB & SS2K/TA

INGRESS PROTECTION : IP66, NEMA 4X

PROCESS CONTROL SYSTEM : BS EN ISO 9001

: ISO/IEC 80079-34:2011

INSTALLATION INSTRUCTIONS FOR

CMP CABLE GLAND TYPES

HAZARDOUS AREA CLASSIFICATION

ATEX CERTIFICATION No : SIRA 06ATEX1097X & SIRA 07ATEX4326X

ATEX CERTIFICATION CODE : II 2/3 GD Ex d IIC / Ex e II / Ex nR II / Ex tD A21 IP66 (SS2K/TA is not Ex d IIC)

IEC Ex CERTIFICATION No : IEC Ex SIR.06.0041X

IEC Ex CERTIFICATION CODE : Ex d I / Ex e I / Ex e II / Ex nR II / Ex tD A21 IP66 (Ex e II / Ex nR II / Ex tD A21 IP66 for SS2K/TA)

cCSAus CERTIFICATION No. : 1211841 (SS2K only)

cCSAus CERTIFICATION CODE : Ex d IIC / Ex e

INSTALLATION INSTRUCTIONS

Installation should only be performed by a competent person using the correct tools. Spanners should be used for tightening. Read all instructions before

beginning installation.

SPECIAL CONDITIONS FOR SAFE USE

1. The SS2K, SS2K/PB and SS2K/TA cable gland shall only be used where the temperature at the point of entry is in the range -60°C to +130°C.

2. The SS2K, SS2K/PB and SS2K/TA cable gland are only suitable for fixed installations. Cables must be effectively clamped to prevent pulling or twisting.

3. The entry component threads may need additional sealing to maintain the ingress protection ratings as applicable to the associated equipment to

which it is attached.

4. According to the CEC C22.1-98, Section 18-106 Part 3, Tapered Threads shall have five fully engaged threads and where non-tapered threads are

used in Group IIC there must be eight fully engaged threads.

ACCESSORIES

The following accessories are available from CMP Products, as optional extras, to assist with fixing, sealing and earthing :-

Locknut | Earth Tag | Serrated Washer | Entry Thread (I.P.) Sealing Washer | Shroud **

vailable Entry Threads

A

Cable

Gland

Size

20S/16 M20 1/2" 3/4" 10.0 3.1 8.7 3.1 8.7 24.0 26.4 42.0 20S16SS2K1RA PVC04 0.072

20S M20 1/2" 3/4" 10.0 6.1 11.7 6.1 11.7 24.0 26.4 42.0 20SSS2K1RA PVC04 0.072

20 M20 1/2" 3/4" 10.0 6.5 14.0 6.5 14.0 27.0 29.7 47.0 20SS2K1RA PVC05 0.079

25 M25 3/4" 1" 10.0 11.1 20.0 11.1 20.0 36.0 39.6 56.0 25SS2K1RA PVC09 0.149

32 M32 1" 1 1/4" 10.0 17.0 26.3 17.0 26.3 41.0 45.1 58.0 32SS2K1RA PVC10 0.170

40 M40 1 1/4" 1 1/2" 15.0 23.5 32.2 22.0 32.2 50.0 55.0 60.0 40SS2K1RA PVC13 0.224

50S M50 1 1/2" 2" 15.0 31.0 38.2 29.5 38.2 55.0 60.5 62.0 50SSS2K1RA PVC14 0.298

50 M50 2" 2 1/2" 15.0 35.6 44.1 35.6 44.1 60.0 66.0 64.0 50SS2K1RA PVC17 0.308

63S M63 2" 2 1/2" 15.0 41.5 50.0 40.1 50.1 70.0 77.0 66.0 63SSS2K1RA PVC20 0.480

63 M63 2 1/2" 3" 15.0 47.2 56.0 47.2 56.0 75.0 82.5 67.0 63SS2K1RA PVC22 0.458

75S M75 2 1/2" 3" 15.0 54.0 62.0 52.8 62.0 79.0 86.9 68.0 75SSS2K1RA PVC24 0.621

75 M75 3" 3 1/2" 15.0 61.1 68.0 59.1 68.0 84.0 92.4 70.0 75SS2K1RA PVC26 0.526

90 M90 3" 3 1/2" 15.0 66.6 80.0 66.6 79.4 108.0 118.8 75.0 90SS2K1RA PVC31 1.795

100 M100 4" - 15.0 76.0 91.0 76.0 91.0 122.0 134.2 81.0 100SS2K1RA PVC32 2.100

115 M115 - - 15.0 86.0 98.0 86.0 98.0 138.0 151.8 85.0 115SS2K1RA LSF34 3.096

130 M130 - - 15.0 97.0 115.0 97.0 115.0 154.0 169.4 92.0 130SS2K1RA LSF35 4.530

* Codes shown are for SS2K glands, for SS2K/PB add “PB” e.g. 20SS2KPB1RA, for SS2K/TA add “TA” e.g. 20SS2KTA1RA

** CMP SOLO LSF Halogen Free Shrouds also available for the full range on request.

I, the undersigned, hereby declare that the equipment referred to herein conforms to the requirements of the ATEX Directive 94/9/EC and the

following standards:-

EN60079-0:2006, EN60079-1:2007, EN60079-7:2007, EN60079-15:2005, BS 6121:1989, EN50262:1998 (Amd 2001), EN61241-0:2004,

EN61241-1:2004

Standard Option

Metric NPT NPT Min Max Min Max Max Max

: I M2 Ex d I / Ex e I (not SS2K/TA)

Minimum

Thread

Length

able Bedding

C

Diameter

Dimensions are displayed in millimetres unless otherwise stated

verall Cable

O

Diameter

cross

A

Flats

cross

A

Corners

Protrusion

Length

rdering

O

Reference

(Brass Metric)

*

Shroud

Ref

**

Cable Gland

Weight

(Kgs)

SS2K, SS2K/PB & SS2K/TA

CABLE GLAND FOR USE IN HAZARDOUS AREAS WITH UNARMOURED AND BRAID ARMOURED CABLE

(WITH LEAD SHEATH ON “PB” VERSIONS & TAPE ARMOUR WITH “TA” VERSIONS).

INCORPORATING EC DECLARATION OF CONFORMITY TO DIRECTIVE 94/9/EC

CABLE GLAND TYPES

CABLE GLAND TYPES

SS2K, SS2K/PB

SS2K, SS2K/PB

& SS2K/TA

& SS2K/TA

Cable Gland Selection Table

SS2K - For use with unarmoured

and braid armoured cable

SS2K/PB - For use with

unarmoured and braid armoured

cables with lead sheaths

CMP Document No. FI430 Issue FI430 Issue 4 0113

Dr Geof Mood - Technical Director - (Authorised Person)

Glasshouse Street • St. Peters • Newcastle upon Tyne • NE6 1BS

0518

Notified Body: Sira Certification Service, Rake Lane, Chester CH4 9JN, England.

E-Mail: cmp@cmp-products.com • Web: www.cmp-products.com

www.cmp-products.com

SS2K/TA - For use with

Tape Armour cable

Tel: +44 191 265 7411 • Fax: +44 191 265 0581

Logo’s shown for illustration purposes only. Please check certification for details

Page 2

DUBAI • HOUSTON • NEWCASTLE • SINGAPORE • SHANGHAI • PUSAN • PERTH

www.cmp-products.com

INSTALLATION INSTRUCTIONS FOR CMP CABLE GLAND TYPES SS2K, SS2K/PB & SS2K/TA

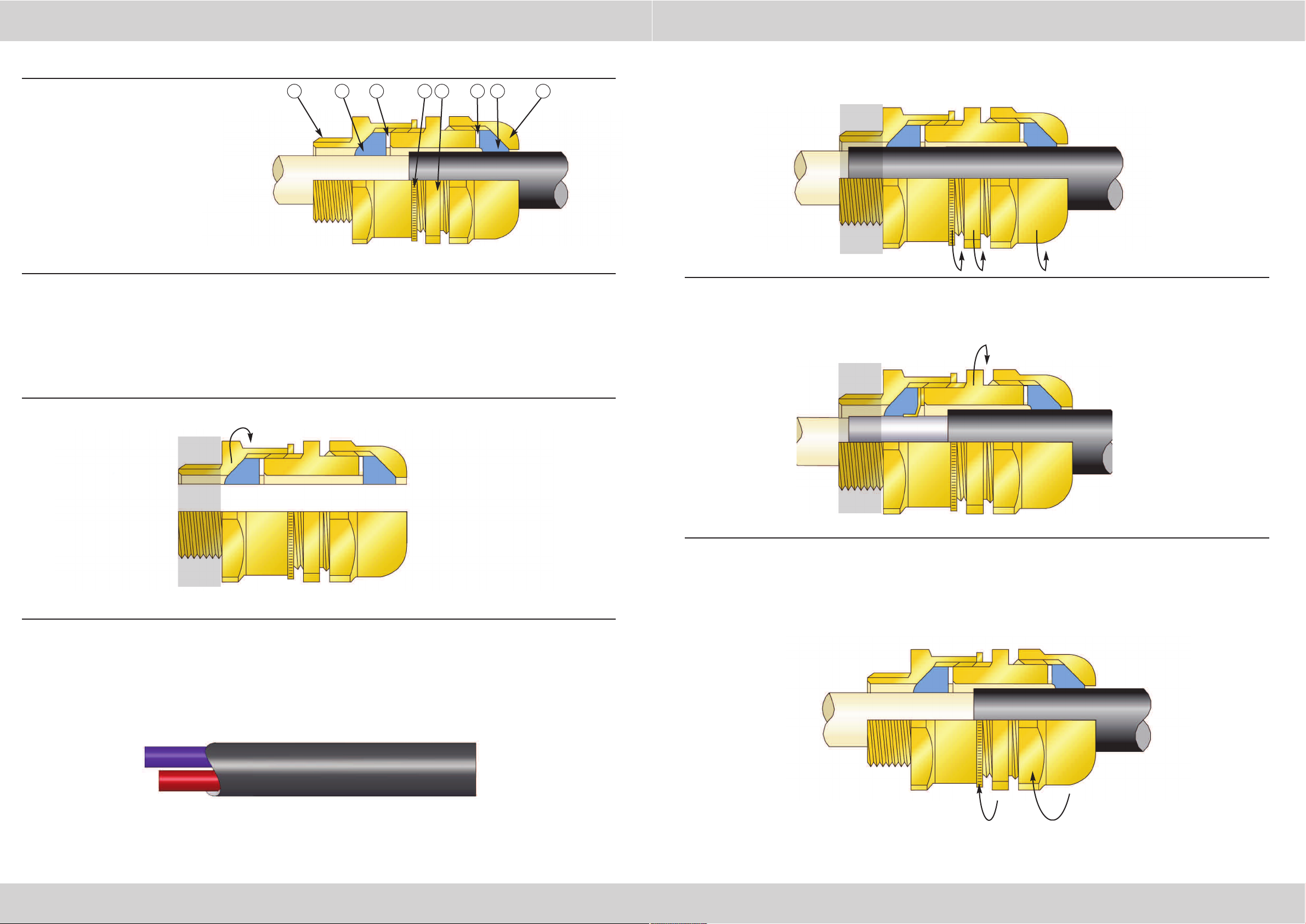

CABLE GLAND COMPONENTS

1. Entry Item

2. Seal

3. Skid Washer (Star Washer in PB versions)

4. Lock Ring

5. Main Item

6. Skid Washer

7. Outer Seal

8. Outer Seal Nut

4321

PLEASE READ ALL INSTRUCTIONS CAREFULLY BEFORE BEGINNING THE INSTALLATION

The SS2K / SS2K/PB cable gland can be used with all types of unarmoured cable and braid armoured

cable where the braid is terminated inside the enclosure. The inner seal is used to provide a flameproof

seal and cable anchor and the outer seal provides further anchoring and an additional environmental

seal. An electrical earth connection is automatically made to the cable lead sheath through the star

washer when “PB” versions are used, or to the tape when “TA” versions are used.

65 7

8

3. Ensure the seals (2) and (7) are in a relaxed state by slackening the locking ring (4), main item

(5) and outer seal nut (8) if necessary.

4. Pass the cable through the gland to the desired position. Tighten the main item (5) into the

entry item (1) until the seal is felt to make contact with the cable and then tighten one further turn

using a spanner. An electrical earth will automatically be made against lead sheath, or tape armour

cable through the star washer (3).

NOTE: There is no need to dismantle the cable gland prior to installation

1. Fit the gland into the equipment and fully tighten the entry item (1).

If installed in a clearance hole, fit a locknut and tighten.

2. Determine the conductor length required to suit the geometry of the equipment and prepare the

cable accordingly. Remove the outer sheath where required to reveal the insulated conductors, lead

sheath, or tape where applicable.

N.B. “PB” version shown

5. Tighten the outer seal nut (8) until the outer seal (7) contacts the cable and then tighten one full

turn further using a spanner. Tighten the lock ring (4) against the entry item. This completes the

installation.

www.cmp-products.com

DUBAI • HOUSTON • NEWCASTLE • SINGAPORE • SHANGHAI • PUSAN • PERTH

Loading...

Loading...