Page 1

DUBAI • HOUSTON • NEWCASTLE • SINGAPORE • SHANGHAI • PUSAN • PERTH

TECHNICAL DATA

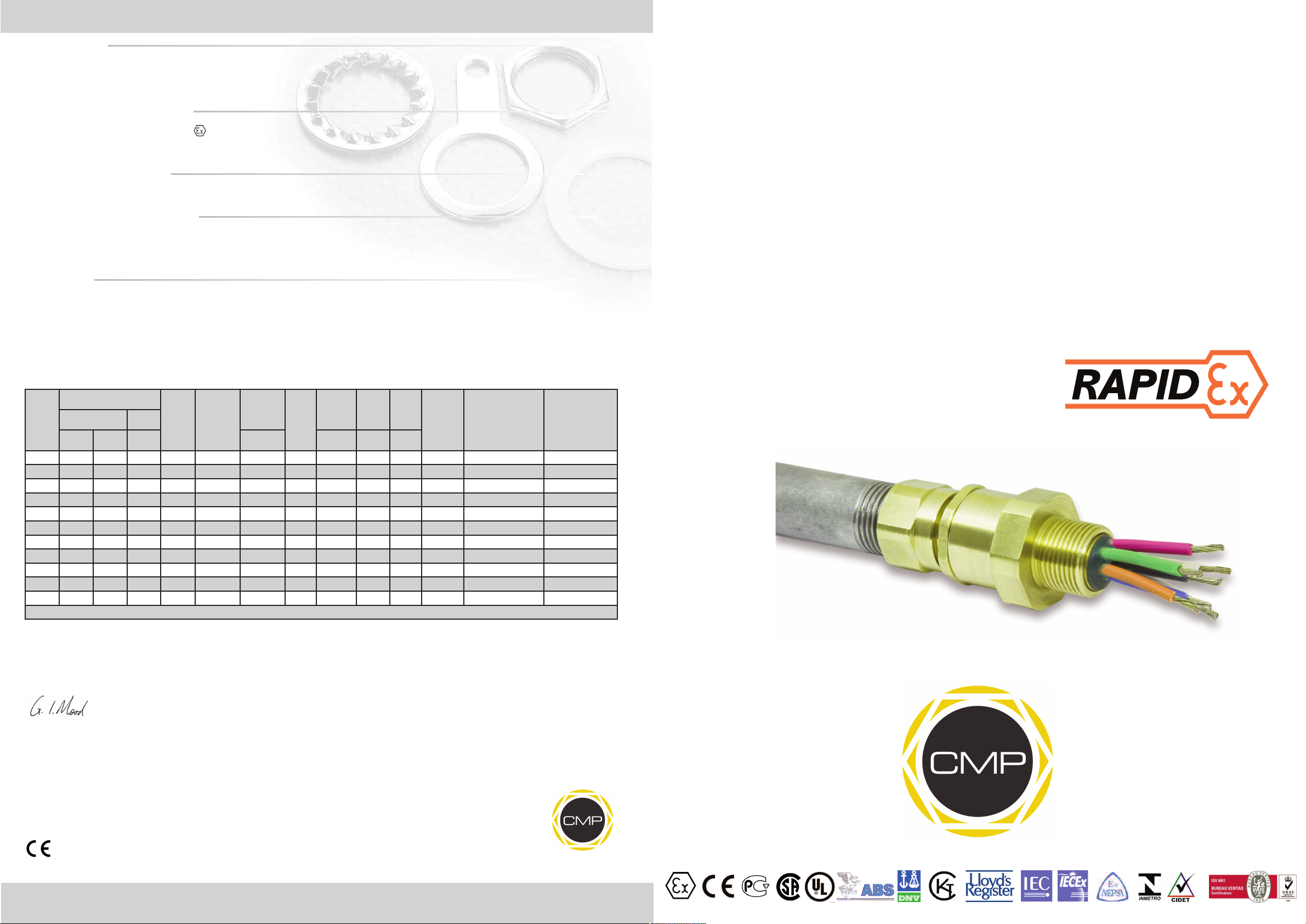

CABLE GLAND TYPE : PXRC-REX

INGRESS PROTECTION : IP66 minimum

PROCESS CONTROL SYSTEM : BS EN ISO 9001

: ISO/IEC 80079-34:2011

HAZARDOUS AREA CLASSIFICATION

ATEX CERTIFICATION No : SIRA 06ATEX1097X

ATEX CERTIFICATION CODE : II 2 GD Ex d IIC / Ex e II / Ex tD A21 IP66

IEC Ex CERTIFICATION No : IEC Ex SIR.06.0044X

IEC Ex CERTIFICATION CODE : Ex d IIC / Ex e II / Ex tD A21 IP66

INSTALLATION INSTRUCTIONS

Installation should only be performed by a competent person using the correct tools. Spanners should be used for tightening. Read all instructions

before beginning installation.

SPECIAL CONDITIONS FOR SAFE USE

1. The cable gland ranges shall only be used where the temperature, at the point of entry, is in the following ranges:

-60°C to +85°C.

2. The entry component threads may need additional sealing to maintain the ingress protection ratings as applicable to the associated equipment to

which it is attached.

ACCESSORIES

The following accessories are available from CMP Products, as optional extras, to assist with fixing, sealing and earthing :-

Locknut | Earth Tag | Serrated Washer | Entry Thread (I.P.) Sealing Washer | Shroud

INSTALLATION INSTRUCTIONS FOR

CMP CONDUIT GLAND TYPE PXRC-REX

BARRIER CABLE GLAND FOR USE IN HAZARDOUS AREAS WITH BRAID, UNARMOURED CABLE OR

INDIVIDUAL CORES HOUSED IN CONDUIT.

INCORPORATING EC DECLARATION OF CONFORMITY TO DIRECTIVE 94/9/EC

CABLE GLAND

CABLE GLAND

TYPE PXRC-REX

TYPE PXRC-REX

Available Entry Threads

Cable

Gland

Size

20 M20 1/2” 3/4” 15.0 1/2” 12.6 21 13.9 27.0 29.7 24.0 20PXRCREX1RA031 0.100

25 M25 3/4” 1” 15.0 3/4” 17.5 38 19.9 36.0 39.6 26.0 25PXRCREX1RA032 0.250

32 M32 1” 1-1/4” 15.0 1” 23.6 59 26.2 41.0 45.1 27.0 32PXRCREX1RA033 0.460

40 M40 1-1/4” 1-1/2” 15.0 1-1/4” 30.0 89 32.3 50.0 55.0 28.0 40PXRCREX1RA034 0.615

50S M50 1-1/2” 2” 15.0 1-1/2” 36.6 115 38.9 55.0 60.5 29.0 50SPXRCREX1RA035 0.710

50 M50 2” 2-1/2” 15.0 2” 41.0 115 44.2 60.0 66.0 30.0 50PXRCREX1RA036 0.700

63S M63 2” 2-1/2” 15.0 2” 47.9 140 50.0 70.0 77.0 30.0 63SPXRCREX1RA036 0.850

63 M63 2-1/2” 3” 15.0 2-1/2” 53.7 140 58.0 75.0 82.5 30.0 63PXRCREX1RA037 0.820

75S M75 2-1/2” 3” 15.0 2-1/2” 59.9 140 62.4 79.0 86.9 32.0 75SPXRCREX1RA037 1.100

75 M75 3” 3-1/2” 15.0 3” 64.3 140 68.1 84.0 92.4 32.0 75PXRCREX1RA038 1.090

90 M90 3” 3-1/2”” 15.0 3-1/2” 75.3 140 80.1 108.0 118.8 44.0 90PXRCREX1RA038 1.500

* Please specify MALE & FEMALE threads requires when ordering

I, the undersigned, hereby declare that the equipment referred to herein conforms to the requirements of the ATEX Directive 94/9/EC and the

following standards:-

EN60079-0:2009, EN60079-1:2007, EN60079-7:2007, BS 6121:1989, EN50262:1998 (Amd 2011), EN61241-0:2004, EN61241-1:2004

Standard Option

Metric NPT NPT Max Max Max Max

Minimum

Thread

Length

Standard

Female

Connection

Thread

Diameter

Over

Conductors

All dimensions in millimetres unless otherwise stated

Number

Cores

Overall

Cable

Diameter

Of

Across

Flats

Across

Corners

Nominal

Protrusion

Length

Ordering Reference

(Brass Metric M X F)*

Cale Gland Weight

(Kgs)

Cable Gland Selection Table

CMP Document No. FI415 Issue 5 01/13

Dr Geof Mood - Technical Director - (Authorised Person)

Glasshouse Street • St. Peters • Newcastle upon Tyne • NE6 1BS

E-Mail: cmp@cmp-products.com • Web: www.cmp-products.com

0518

Notified Body: Sira Certification Service, Rake Lane, Chester CH4 9JN, England.

www.cmp-products.com

Tel: +44 191 265 7411 • Fax: +44 191 265 0581

Logo’s shown for illustration purposes only. Please check certification for details

Page 2

DUBAI • HOUSTON • NEWCASTLE • SINGAPORE • SHANGHAI • PUSAN • PERTH

www.cmp-products.com

INSTALLATION INSTRUCTIONS FOR CMP CABLE GLAND TYPE PXRC

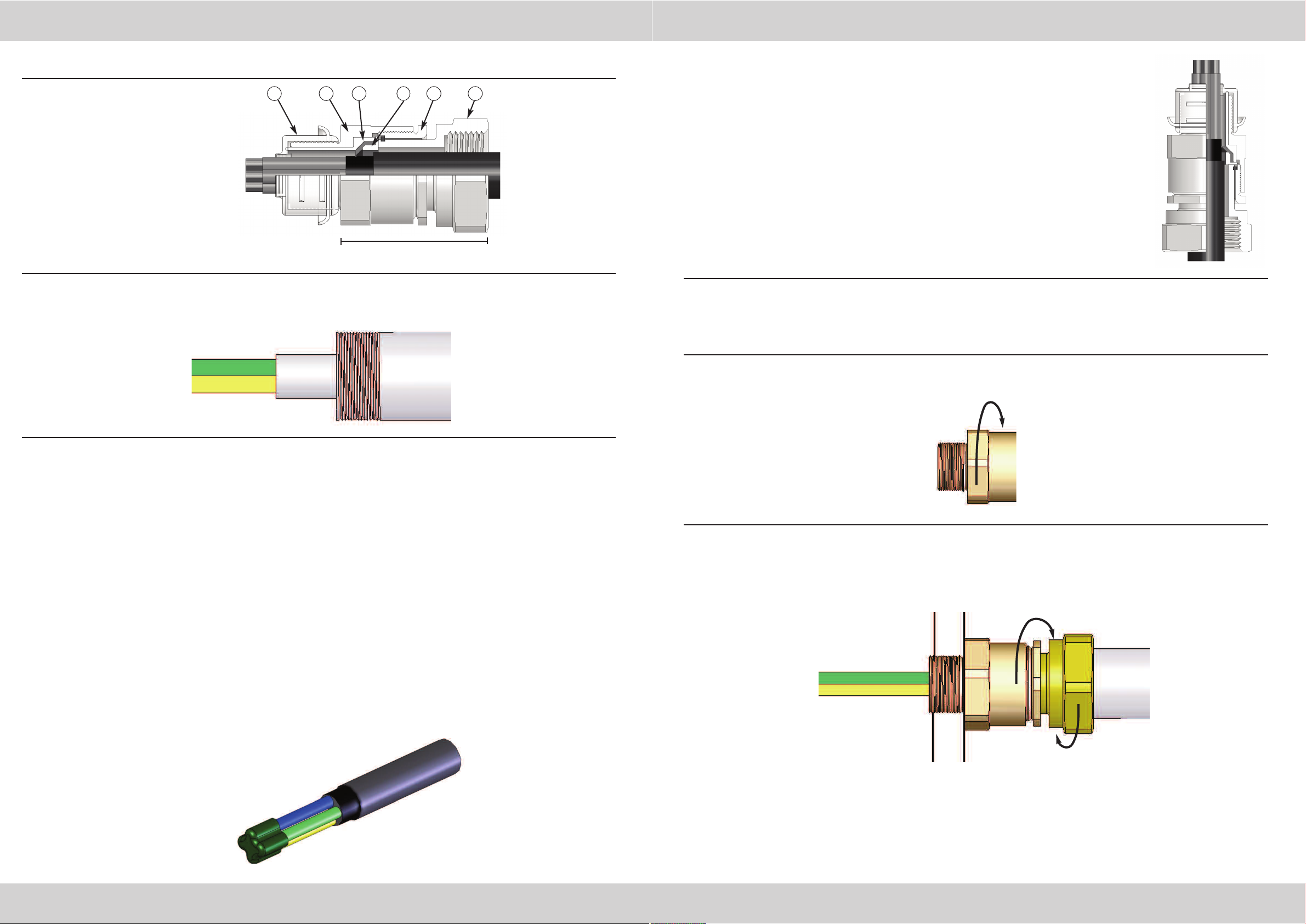

CABLE GLAND COMPONENTS

1. Entry Component

2. Compound Tube & Resin Dam

3. Washer

4. Nut

5. Running Coupling

6. Thread Shield

21

PLEASE READ ALL INSTRUCTIONS CAREFULLY BEFORE BEGINNING THE INSTALLATION

1. Prepare the cable (if used) by removing the outer sheath from the cores so that they are exposed

within the Compound Tube when finally assembled.

3

4 56

Guide Length “L”

3. Pass the cable/cores through the gland so that the cable sheath / the tape

around the cores (if a cable is not being used) just passes through the resin

dam. (Use guide length “L” to determine how far to push the cable into the

gland.

Secure the Entry Item assembly to the Running Coupling (5) by tightening Nut

(4).

Fit the Thread Shield (6) and hold the assembly upright.

5. Refer to ‘RapidEx Resin’ assembly instructions to fill the connector Compound Tube

with the required amount of resin. The resin should not be mixed or applied at

temperatures below 5°C (40°F).

6. Once the resin has cured, remove the Thread Shield (6) and slacken the nut (4). Fit the Entry

Item (1) into the equipment.

2. If the installation involves a cable, remove any bedding or fillers from around the cable cores.

If the cable cores have braid screens, these should be unravelled and then twisted together to form a

single core if required.

If the cable has individual and / or overall foil screens, the foils must be removed completely and the

drain wire(s) passed through insulation tubing.

NOTE: To ensure a proper seal, the drain wire should be exposed for up to 5mm next to the resin dam

(so that the resin can bond to the drain wire elements). If heat shrink tubing is used it should be

shrunk onto the drain wire.

Electrical tape MUST be wrapped around the tips of the cable cores to prevent damage to the resin dam

when the cable is installed.

If the installation uses only cores (i.e. no cable sheath) then tape must be wrapped around the cores at

the position at which it will engage the resin dam.

Use the length of the gland as a guide to position the tape as shown above (guide length “L”).

7. Attach the conduit to the Running Coupling (5) and fully tighten. Finally, fully tighten nut (4) to

complete the installation.

www.cmp-products.com

8. Attach the conduit and tighten the running coupling (5) to complete the installation.

DUBAI • HOUSTON • NEWCASTLE • SINGAPORE • SHANGHAI • PUSAN • PERTH

Loading...

Loading...