CMP PX780REXDM4M4, PX780REXDM2M2, PX780REXDM6M6, PX780REXDM7M7, PX780REXDM8M8 Installation Instructions Manual

...Page 1

TECHNICAL DATA

PRODUCT TYPE : PX780REX

INGRESS PROTECTION : IP66 when used with CMP sealing accessories

PROCESS CONTROL SYSTEM : ISO 9001

: ISO/IEC 80079-34:2011

EXPLOSIVE ATMOSPHERES CLASSIFICATION

ATEX CERTIFICATION No : CML 18ATEX1327X

ATEX CERTIFICATION CODE : ^II 2G 1D Ex db IIC Gb, Ex eb IIC Gb, Ex ta IIIC Da IP6X

: ^IM2 Ex db I Mb / Ex eb I Mb

IECEx CERTIFICATION No : IECEx CML 18.0190X

IECEx CERTIFICATION CODE : Ex db IIC Gb, Ex eb IIC Gb, Ex db I Mb, Ex eb I Mb, Ex ta IIIC Da IP6X

cCSAus CERTIFICATION No : 1055233

CODE OF PROTECTION : Class I, Div 1 and 2, Groups A,B,C and D; Enclosure Type 4X: Class I Zone 1, AEx de II; Ex de II

INMETRO CERTIFICATION No : TÜV 18.2088X

INMETRO CERTIFICATION CODE : Ex db IIC Gb, Ex eb IIC Gb, Ex db I Mb, Ex eb I Mb, Ex ta IIIC Da IP6X

INSTALLATION INSTRUCTIONS

1. Installation should only be performed by a competent person using the correct tools. Spanners should be used for tightening. Read all instructions before beginning installation.

2. The interface between a cable entry device and its associated enclosure / cable entry will require additional sealing to achieve ingress protection (IP) ratings higher than IP54. The

minimum protection level is IP54 for explosive gas atmospheres and IP6X for explosive dust atmospheres. Parallel threads (and tapered threads when using a non-threaded entry)

require a CMP sealing washer or integral O-ring face seal (where available) to maintain IP66, 67 and 68 (when applicable). It is the installer’s responsibility to ensure the IP rating

is maintained at the interface.

Note: When fitted to a threaded entry, all tapered threads will automatically provide an ingress protection rating of IP68.

3. A CMP earth tag should be used when it is necessary to provide an earth bond connection. CMP earth tags have been independently tested to comply with Category B rating

specified in IEC 62444 (there are no ratings stated in IEC 60079-0). Ratings are shown in the associated table. CMP earth tags slip over the cable gland or accessory entry thread

from inside/outside the enclosure and must be secured with a locknut (if fitted internally).

CMP Ear th Tag Size

20 3.06

25 4.06

32 5.40

40 7.20

50 10.40

63 10.40

75 10.40

SPECIFIC CONDITIONS OF USE

Only one union is to be used with any single cable entry on the associated equipment.

ACCESSORIES

The following accessories are available from CMP Products, as optional extras, to assist with fixing, sealing and earthing :Locknut | Earth Tag | Serrated Washer | Entry Thread (I.P.) Sealing Washer

CMP Products Limited on its sole responsibility declares that the equipment referred to herein conforms to the requirements of the ATEX Directive 2014/34/EU and the following standards:

EN 60079-0:2018, EN 60079-1:2014, EN 60079-7:2015, EN 60079-31:2014

David Willcock – Certification Engineer (Authorised Person)

CMP Products Limited, Cramlington, NE23 1WH, UK

15 April 2019

Short Circuit Ratings Symmetrical Fault Current

(kA) fo r 1 second

2776

SCAN FOR INSTALLATION VIDEOS

INSTALLATION INSTRUCTIONS

FOR UNION TYPE PX780REX

UNION TYPE PX780REX FOR CONNECTING CONDUITS TO ENCLOSURES OR

CONDUITS TO EACH OTHER USING RAPIDEX RESIN IN EXPLOSIVE ATMOSPHERES.

INCORPORATING EU DECLARATION OF CONFORMITY TO DIRECTIVE [2014/34/EU]

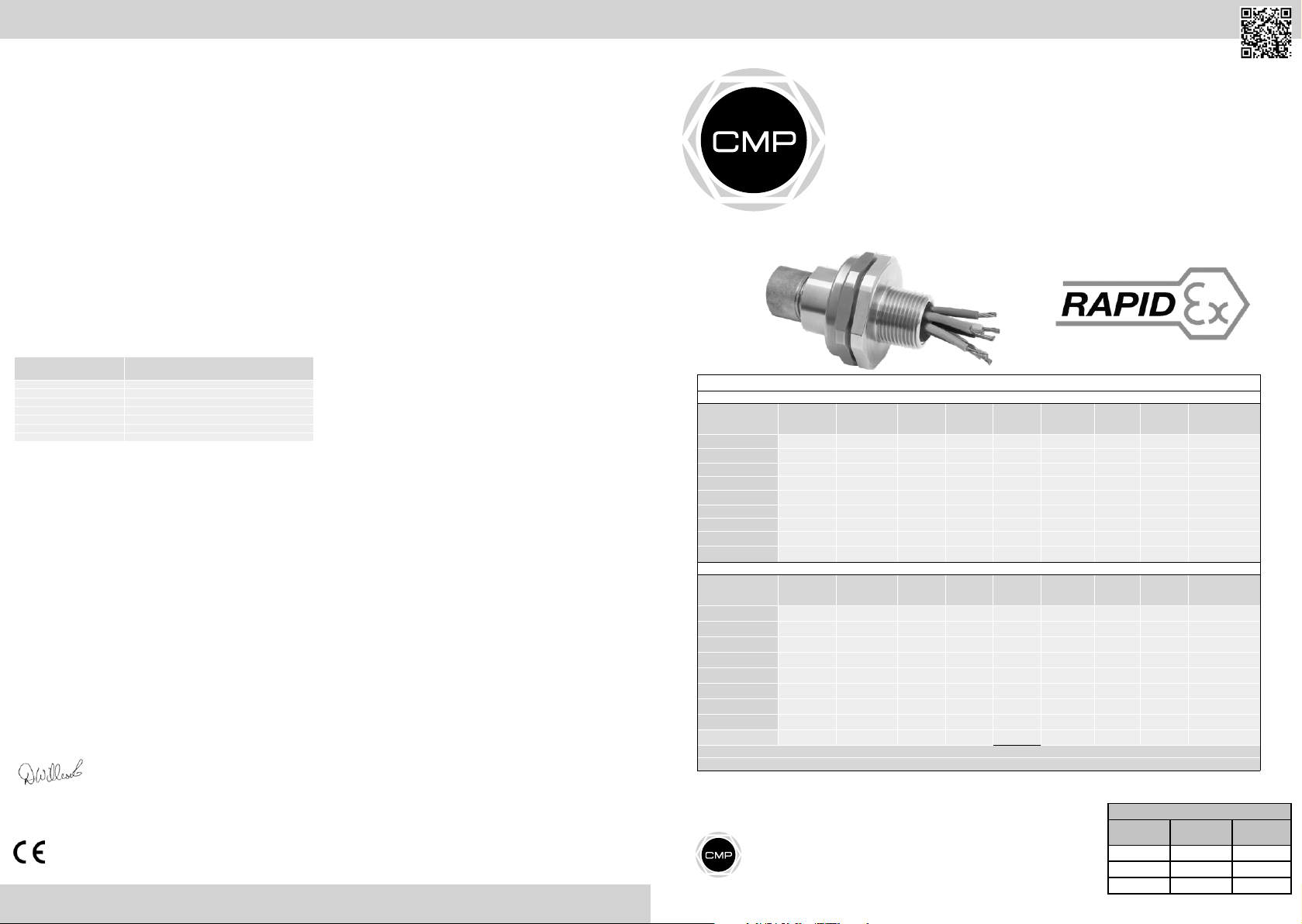

Product Selection Table

Ordering Reference

(Brass, Metric)

PX780REXD M2M2

PX780REXDM3M3

PX780REXDM4M4

PX780REXD M5M5

PX780REXDM6M6

PX780REXD M7M7

PX780REXDM8M8

PX780REXDM9M9

PX780REXDM10M10

Ordering Reference

(Brass, NPT)

PX780 REXDT1T1 1/2” 0.79 1/2”

PX780REXDT2T2 3/4” 0.80 3/4”

PX780REXDT3T3 1” 0.98 1”

PX78 0REX DT4T4 1-1/4 ” 1.01 1-1/4”

PX780REXDT5T5 1-1 /2” 1.0 3 1-1/ 2”

PX780REXDT6 T6 2” 1. 06 2”

PX780REXDT7T7 2-1 /2” 1.5 7 2-1/ 2”

PX780REXDT8T8 3” 1.63 3”

PX780REXDT9T9

For material o ptions please add the follo wing suffix to the Orde ring Reference; Brass (no s uffix required), Ni ckel Plated Brass “5”, 316 Grade Stainles s Steel “4”, Copper Free Alumin ium “1”

Alternate thread types available

Can be supplied with mixed thread types e.g. PX780REX DM10T10 - M100 male thread, 4”NPT female thread, please contact CMP for more information

Male For ward

Thread S ize

M20 X 1.5 15.0 M20 X 1.5

M25 X 1.5 15. 0 M25 X 1.5

M32 X 1.5 15. 0 M32 X 1.5

M40 X 1.5 15 .0 M4 0 X 1.5

M50 X 1.5 15. 0 M50 X 1.5

M63 X 1.5 15 .0 M6 3 X 1.5

M75 X 1.5 15. 0 M75 X 1.5

M90 X 2.0 24. 0 M90 X 2.0

M100 x 2.0 24.0 M100 x 2 .0

Male For ward

Thread S ize

3-1/ 2” 1.69 3-1/2 ”

Glasshouse Street • St. Peters • Newcastle upon Tyne • NE6 1BS

Tel: +44 191 265 7411 • Fax: +44 191 715 464

E-Mail: customerservices@cmp-products.co.uk • Web: www.cmp-products.com

Minimum

Thread Length

Minimum

Thread Length

Female Re ar

Thread S ize

Female Re ar

Thread S ize

All dimensio ns shown are in millimetres u nless otherwise state d

www.cmp-products.com

METRIC

Diamet er

Over Cores

Diamet er

Over Cores

Max.

Numbe r of

12.6 21 3 6.1 46.0 50.3

17.5 30 36 .1 50.0 54.7

23.6 50 35.2 6 0.0 65.7

30.0 59 35 .2 65.0 71.2

41.0 115 35.3 75.0 82. 2

53.7 115 35. 3 90.0 98.7

64.2 140 38.8 100.0 109.7

75.3 140 45.0 120 .0 131.7

83.6 200 83.9 145. 0 159.2

NPT

Numbe r of

12.6

17.5

23.6

30.0

36.6

47.9

59.9

75.3

83.6

Protrusion

Cores

Max.

Cores

Length

Protrusion

Length

21 35.4 46.0 50.3

30 35.0 50.0 5 4.7

50 33.7 60.0 65.7

59 37. 0 65.0 71.2

115 38.2 75.0 82.2

115 3 9.1 90.0 98.7

140 5 4.1 10 0.0 109.7

140 52.5 120. 0 131.7

200 80.0 145.0 159.2

Across

Flats Hex

Across

Flats Hex

Certicate Revision Date

IFS 9 05/19

ATEX / IECEx 6 04/19

cCSAus 5 05/16

Across

Corners Ø

‘D’

Across

Corners Ø

‘D’

FI471

Installation

Torque (Nm)

7

10

15

25

30

45

45

45

45

Installation

Torque (Nm)

7

10

15

25

30

45

45

45

45

Page 2

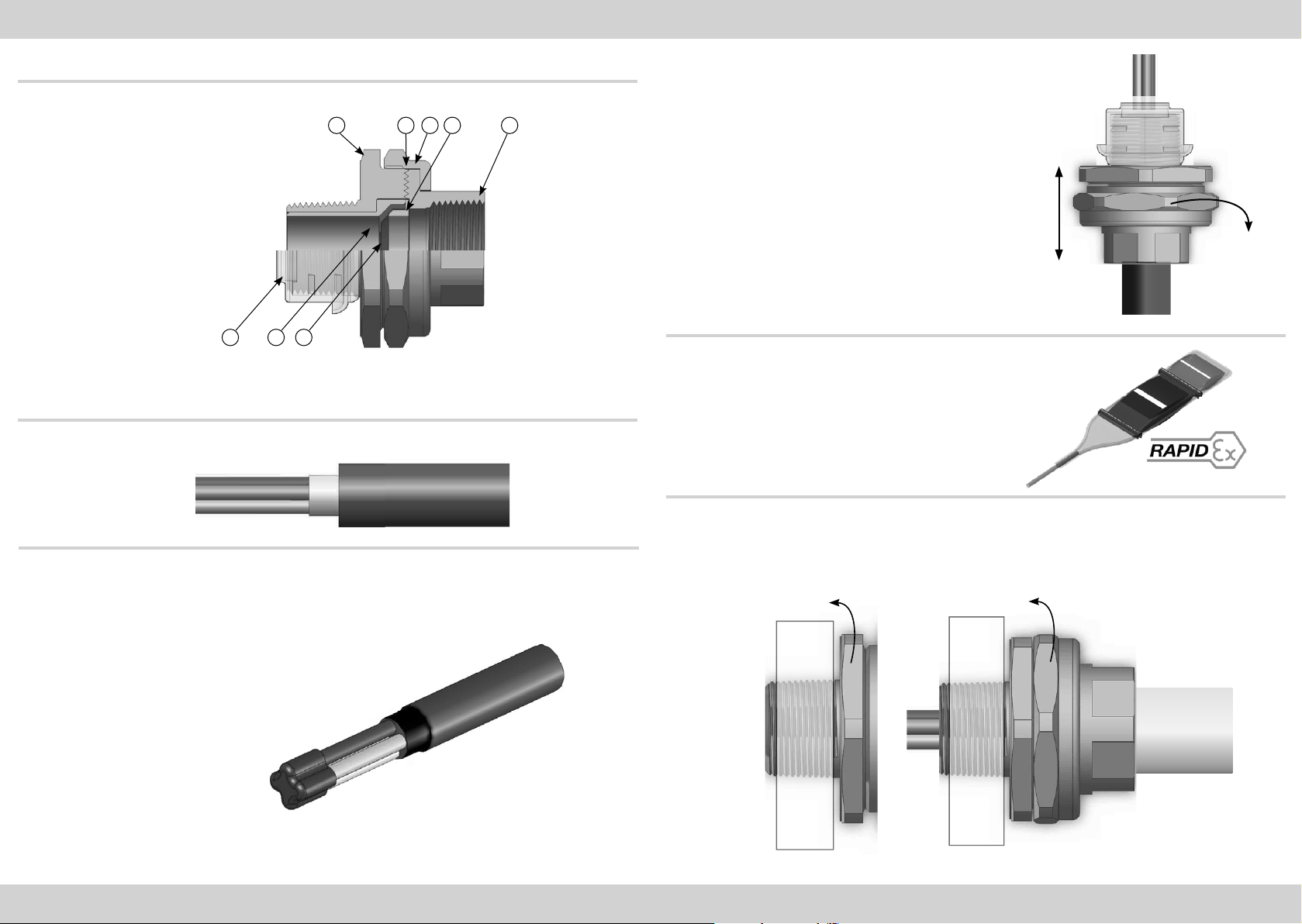

INSTALLATION INSTRUCTIONS FOR CMP CABLE UNION PX780REX

UNION COMPONENTS - It is not necessary to dismantle the union any further than illustrated below

1 2 3 4

1. Entry Item

2. Serrated Flamepath

3. Nut

4. Conduit Connector

5. Washer

6. Resin Dam

7. Compound Tube

8. Thread Shield

678

NOTE: THERE IS NO NEED TO DISSASSEMBLE THE UNION

PLEASE READ ALL INSTRUCTIONS CAREFULLY BEFORE BEGINNING THE INSTALLATION

1. Prepare the cable by removing the outer sheath from the cores so that they are exposed within

the Compound Tube when finally assembled.

5

3. Feed the cables/cores through the union.

If the installation uses only cores (i.e. no cable sheath) then

electrical tape must be wrapped around the cores at the position

at which it will engage the resin dam.

Use the length of the union as a guide to position the tape as

shown above (guide length “L”)

L

4. Mix the Resin and apply as per RapidEx instructions.

2. Remove any bedding or fillers from around the cable cores. If the cable cores have screens,

these should be unwound and then twisted together to form a single core.

This single core and/or any drain wires present should be sleeved with some heat shrink tubing.

Electrical tape MUST be wrapped around the tips of the

cable cores. This is to ensure the cable cores are

together and also to cover any sharp edges that could

potentially tear the Resin Dam during installation.

5.1 When the Resin has cured the Entry Item (1) should be removed from the assembly and fully tightened into the

apparatus.

5.2 Tighten the Conduit Connector (4) onto the conduit and then tighten to the Entry Item (1) using the Nut (3) to

complete the installation.

www.cmp-products.comwww.cmp-products.com

Loading...

Loading...