Page 1

DUBAI • HOUSTON • NEWCASTLE • SINGAPORE • SHANGHAI • PUSAN • PERTH

TECHNICAL DATA

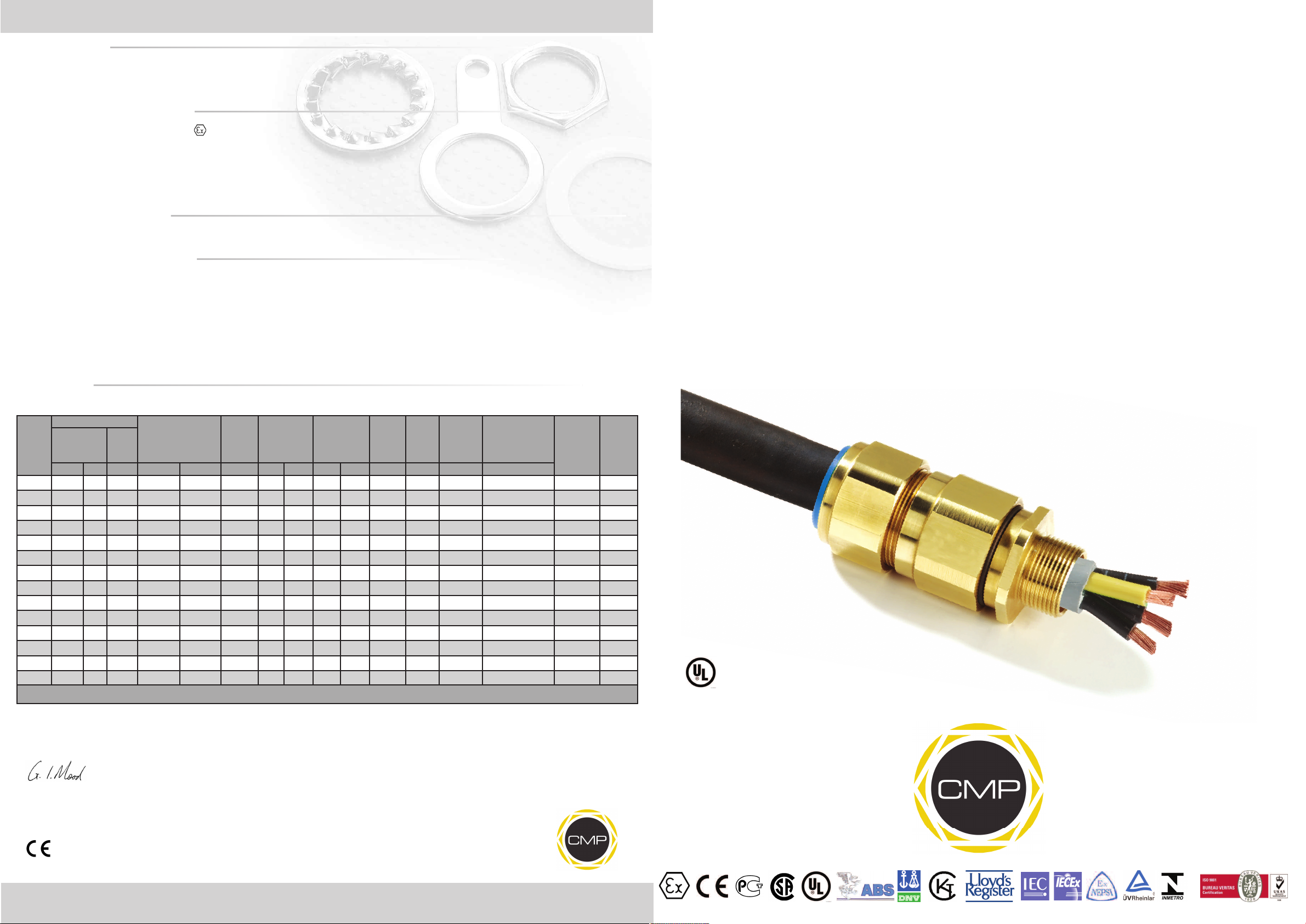

CABLE GLAND TYPE : C2KX

INGRESS PROTECTION : IP66, IP67, IP68

PROCESS CONTROL SYSTEM : BS EN ISO 9001

: ISO/IEC 80079-34:2011

HAZARDOUS AREA CLASSIFICATION

ATEX CERTIFICATION No : SIRA 06ATEX1097X

ATEX CERTIFICATION CODE : II 2 GD Ex e II / Ex tD A21 IP66

IEC Ex CERTIFICATION No : IEC Ex SIR.06.0042X

IEC Ex CERTIFICATION CODE : Ex e II / Ex tD A21 IP66

CSA CERTIFICATION No : 2367109

CSA CERTIFICATION CODE : Ex e II and Class I, Zone 1, AEx e II

UL CERTIFICATION FILE : E200163, E256367

UL CERTIFICATION CODE : Class I, Zone I AEx e II; TYPE 4X, OIL RES II

INSTALLATION INSTRUCTIONS

Installation should only be performed by a competent person using the correct tools. Spanners should be used for tightening. Read all instructions

before beginning installation.

SPECIAL CONDITIONS FOR SAFE USE

For ATEX & IEC Ex certification:

1. The cable gland ranges shall only be used where temperatures at the point of entry is between -60°C and +130°C.

2. C2KX cable glands are only suitable for fixed installations. Cables must be effectivelu clamped to prevent twisting and pulling

3. The entry component threads may need additional sealing to maintain the ingress protection rating as applicable to the associated equipment to

which it is attached

For American Ex certification:

1. C2KX cable glands are only suitable for fixed installations. Cables must be effectively clamped to prevent twisting and pulling.

2. According to C.E.C. and the N.E.C. wiring method for the types of cables that can be used in Class I, Zone 1and 2 Classified Areas, according

to 60079-14 installation wiring method restrictions.

3. Shipboard Cables are for use on Marine Platform and/or shipboards only and are subject to local authorities having jurisdiction on the installation.

INSTALLATION INSTRUCTIONS FOR

CMP CABLE GLAND TYPE C2KX

FOR TERMINATION OF CABLES WITH WIRE BRAID.

INCORPORATING EC DECLARATION OF CONFORMITY TO DIRECTIVE 94/9/EC

CABLE GLAND

CABLE GLAND

TYPE C2KX

TYPE C2KX

ACCESSORIES

The following accessories are available from CMP Products, as optional extras, to assist with fixing, sealing and earthing :-

Locknut | Earth Tag | Serrated Washer | Entry Thread (I.P.) Sealing Washer | Shroud *

Available Entry Threads

Cable

Connect

or Size

20S/16 1/2" 3/4" M20 0.630 0.591 0.461 0.240 0.453 0.006 0.020 0.945 1.021 2.303 20S16C2KX1RA531 PVC06 4.65

20S 1/2" 3/4" M20 0.630 0.591 0.461 0.374 0.626 0.006 0.020 0.945 1.021 2.303 20SC2KX1RA531 PVC06 4.65

20 1/2" 3/4" M20 0.630 0.591 0.551 0.492 0.823 0.008 0.020 1.201 1.112 2.382 20C2KX1RA531 PVC06 6.84

25S 3/4" 1 M25 0.669 0.591 0.787 0.551 0.866 0.008 0.024 1.476 1.594 2.657 25SC2KX1RA532 PVC09 10.78

25 3/4" 1" M25 0.669 0.591 0.787 0.717 1.031 0.008 0.024 1.476 1.594 2.657 25C2KX1RA531 PVC09 10.78

32 1" 1 1/4" M32 0.787 0.591 1.035 0.933 1.335 0.008 0.024 1.811 2.008 2.736 32C2KX1RA532 PVC11 16.49

40 1 1/4" 1 1/2" M40 0.787 0.591 1.268 1.098 1.591 0.008 0.031 2.165 1.956 3.071 40C2KX1RA534 PVC15 23.89

50S 1 1/2" 2" M50 0.787 0.591 1.504 1.386 1.839 0.008 0.031 2.362 2.338 2.972 50SC2KX1RA535 PVC18 26.43

50 2" 2 1/2" M50 0.906 0.591 1.736 1.591 2.091 0.012 0.031 2.756 2.827 3.169 50C2KX1RA536 PVC21 36.79

63S 2" 2 1/2" M63 0.906 0.591 1.969 1.795 2.339 0.012 0.031 2.953 3.189 3.602 63SC2KX1RA536 PVC23 37.85

63 2 1/2" 3" M63 0.984 0.591 2.205 2.150 2.594 0.012 0.031 3.150 3.402 3.622 63C2KX1RA537 PVC25 45.11

75S 2 1/2" 3" M75 0.984 0.591 2.441 2.323 2.839 0.012 0.031 3.504 3.784 3.898 75SC2KX1RA537 PVC28 65.55

75 3" 3 1/2" M75 1.417 0.591 2.677 2.262 3.091 0.012 0.031 3.898 4.209 4.016 75C2KX1RA538 PVC30 89.87

90 3 1/2" 4" M90 1.417 0.591 3.150 3.000 3.559 0.016 0.031 4.488 4.847 4.724 90C2KX1RA539 PVC32 128.63

NOTE: *CMP SOLO LSF Halogen Free Shrouds also available on request. # Other thread forms are available.

I, the undersigned, hereby declare that the equipment referred to herein conforms to the ATEX Directive 94/9/EC and the following standards:-

EN60079-0:2006, EN60079-1:2007, EN60079-7:2007, BS 6121:1989, EN50262:1998 (Amd 2001), EN61241-0:2004, EN61241-1:2004

Standard Option

Metric NPT NPT Actual NPT Min Metric Max Min Max Min Max Min Max Max Max

Thread Length

Cable

Bedding

Diameter

Dimensions are displayed in inches unless otherwise stated

Overall Cable

Diameter

Braid Wire

Diameter

Across

Flats

Across

Flats

Protrusion

Length

Ordering Reference

(NP Brass NPT)

PVC Shroud

Reference *

Connector

Weight

(Ozs)

LISTED MARINE

SHIPBOARD CABLE

FITTING

31YM

29NX

CMP Document No. FI425 Issue 3 01/13

Dr Geof Mood - Technical Director - (Authorised Person)

Glasshouse Street • St. Peters • Newcastle upon Tyne • NE6 1BS

0518

Notified Body: Sira Certification Service, Rake Lane, Chester CH4 9JN, England.

E-Mail: cmp@cmp-products.co.uk • Web: www.cmp-products.com

www.cmp-products.com

Tel: +44 191 265 7411 • Fax: +44 191 265 0581

Logo’s shown for illustration purposes only. Please check certification for details

Page 2

DUBAI • HOUSTON • NEWCASTLE • SINGAPORE • SHANGHAI • PUSAN • PERTH

www.cmp-products.com

INSTALLATION INSTRUCTIONS FOR CMP CABLE GLAND TYPE C2KX

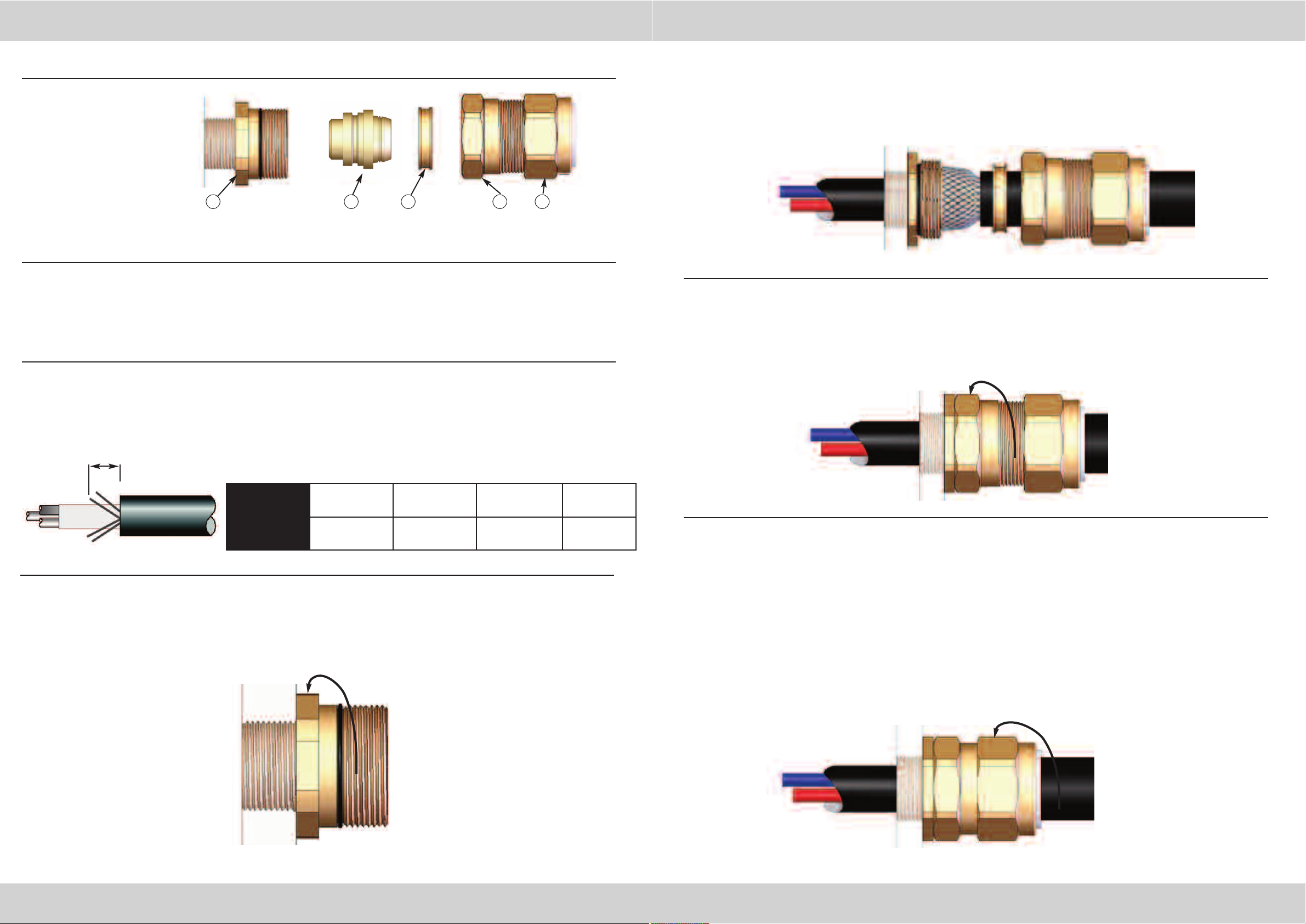

CABLE GLAND COMPONENTS

1. Entry Component

2. Detachable Armour Cone

3. AnyWay Clamping Ring

4. Body

5. Outer Seal Assembly

321

PLEASE READ ALL INSTRUCTIONS CAREFULLY BEFORE BEGINNING THE INSTALLATION

1. Slacken the Outer Seal Assembly (5), but do not remove it from the Body (4). Seperate the gland

components by removing the Body (4) and the Outer Seal Assembly (5) as one unit. (Note that the

Detachable Armour Cone (2) and AnyWay Clamping Ring (3) are loose items). Pass the Body (4), Outer

Seal Assembly (5) and AnyWay Clamping Ring (3) over the cable, Outer Seal Assembly (5) first.

4 5

4. Locate the Detachable Armour Cone (2) in the Entry Component (1). Pass the cable through the

Cone (2) and Entry Component (1), evenly spacing the braid around the Cone (2).

5. While continuing to gently push the cable forward to keep the braid in contact with the Cone (2),

tighten the Body (4) first by hand and then with a spanner until the Body (4) is fully tightened onto

the Entry Component (1) and no threads are visible.

2. Prepare the cable by stripping back the outer sheath and braid to suit the equipment. Expose the

braid or armour further so that it can be formed around the armour cone by cutting back the outer

sheath by a length “L”. This length varies slightly depending upon the cable diameter, but typical values

are shown below.

L

CABLE GLAND

SIZE

CABLE STRIP

LENGTH “L”

20S/16, 20S, 20 25S, 25, 32, 40 50S, 50, 63S, 63 75S, 75, 90

12 mm

(0.472 inches)

15 mm

(0.591 inches)

18 mm

(0.709 inches)

20 mm

(0.787 inches)

3. Secure the Entry Component (1) to the equipment by tightening with a spanner.

6. Tighten the Outer Seal Nut Assembly (5) until it comes to an effective stop.

This will occur when:-

A) The Outer Seal Nut Assembly (5) has clearly engaged the cable and cannot be further

tightened without the use of excessive force by the installer.

B) The Outer Seal Nut Assembly (5) has been fully tightened. (This will only happen if

the cable is at the bottom end of the range for the gland).

For Guidance:- The Outer Seal Assembly (5) is correctly fitted when it has been tightened until the

seal touches the cable sheath and then tightened a further one turn using a spanner.

www.cmp-products.com

DUBAI • HOUSTON • NEWCASTLE • SINGAPORE • SHANGHAI • PUSAN • PERTH

Loading...

Loading...