Page 1

DUBAI • HOUSTON • NEWCASTLE • SINGAPORE • SHANGHAI • PUSAN • PERTH

TECHNICAL DATA

CABLE GLAND TYPE : A2FFC

INGRESS PROTECTION : IP66, NEMA 4X

PROCESS CONTROL SYSTEM : BS EN ISO 9001

ISO/IEC 80079-34:2011

INSTALLATION INSTRUCTIONS FOR

A2FFC CONDUIT GLAND

HAZARDOUS AREA CLASSIFICATION

ATEX CERTIFICATION No : SIRA06ATEX1097X, SIRA07ATEX4326X

ATEX CERTIFICATION CODE : II 2/3 GD Ex d IIC, Ex e II, Ex nR II, Ex tD A21 IP66 - Equipment Zone 1, 2, 21 & 22,

IEC Ex CERTIFICATION No : IEC Ex SIR.06.0040X

IEC Ex CERTIFICATION CODE : Ex d IIC / Ex e II / Ex nR II, Ex tD A21 IP66

CSA CERTIFICATION No : 1211841

CSA CERTIFICATION CODE : Ex d IIC / Ex e II, Enclosure Type 4x

INSTALLATION INSTRUCTIONS

Installation should only be performed by a competent person using the correct tools. Spanners should be used for tightening. Read all instructions

before beginning installation.

SPECIAL CONDITIONS FOR SAFE USE

• The A2FFC shall only be used where the temperature, at the point of entry, is between -60°C and +130°C.

• The entry component threads may need additional sealing to maintain the ingress protection rating as applicable to the associated equipment to

which it will be attached.

• The A2FFC is only suitable for flexible conduit installations. Cables must be effectively clamped to prevent pulling or twisting.

able

C

Connector

Size

20S16 M20 X 1.5 15.0 29.0 17.0 3.2 4.3 5.1 9.8 20S16A2FFC1RAC000 0.044

20S16 M20 X 1.5 15.0 29.0 17.0 3.2 5.8 6.8 9.0 20S16A2FFC1RA001 0.048

20S16 M20 X 1.5 15.0 29.0 17.0 3.2 6.6 7.8 11.6 20S16A2FFC1RAC004 0.05

20S16 M20 X 1.5 15.0 29.0 17.0 3.2 8.0 9.1 13.9 20S16A2FFC1RAC009 0.05

20S16 M20 X 1.5 15.0 29.0 17.0 3.2 8.1 9.5 13.0 20S16A2FFC1RAC010 0.05

20S16 M20 X 1.5 15.0 29.0 17.0 3.2 8.1 10.2 14.0 20S16A2FFC1RAC020 0.054

20S16 M20 X 1.5 15.0 29.0 17.0 3.2 8.1 10.9 15.9 20S16A2FFC1RAC025 0.054

20S16 M20 X 1.5 15.0 29.0 17.0 3.2 8.1 11.7 15.9 20S16A2FFC1RAC030 0.056

20S M20 X 1.5 15.0 29.0 17.0 6.1 9.9 10.9 15.9 20SA2FFC1RAC025 0.057

20S M20 X 1.5 15.0 29.0 17.0 6.1 11.7 13.0 16.0 20SA2FFC1RAC040 0.057

20S M20 X 1.5 15.0 29.0 17.0 6.1 11.7 13.9 18.9 20SA2FFC1RAC045 0.059

20S M20 X 1.5 15.0 29.0 17.0 6.1 11.7 14.7 18.7 20SA2FFC1RAC060 0.061

20 M20 X 1.5 15.0 34.0 21.0 6.5 14.0 13.0 16.0 20A2FFC1RAC040 0.057

20 M20 X 1.5 15.0 34.0 21.0 6.5 13.1 15.6 21.0 20A2FFC1RAC050 0.082

20 M20 X 1.5 15.0 34.0 21.0 6.5 14.0 16.9 20.5 20A2FFC1RAC066 0.086

20 M20 X 1.5 15.0 34.0 21.0 6.5 14.0 18.0 21.0 20A2FFC1RAC070 0.09

20 M20 X 1.5 15.0 34.0 21.0 6.5 14.0 18.7 24.0 20A2FFC1RAC075 0.09

20 M20 X 1.5 15.0 34.0 21.0 6.5 14.0 20.0 23.5 20A2FFC1RAC080 0.095

20 M20 X 1.5 15.0 34.0 51.0 6.5 14.0 20.5 27.0 20A2FFC1RAC085 0.095

25 M25 X 1.5 15.0 44.0 25.0 11.1 15.3 17.6 25.0 25A2FFC1RAC100 0.115

25 M25 X 1.5 15.0 44.0 25.0 11.1 18.7 20.7 26.0 25A2FFC1RAC105 0.115

25 M25 X 1.5 15.0 44.0 25.0 11.1 20.0 22.3 26.5 25A2FFC1AC110 0.115

25 M25 X 1.5 15.0 44.0 25.0 11.1 20.0 23.7 30.8 25A2FFC1RAC115 0.124

25 M25 X 1.5 15.0 44.0 25.0 11.1 20.0 25.1 29.0 25A2FFC1RAC120 0.124

25 M25 X 1.5 15.0 44.0 25.0 11.1 20.0 26.5 34.0 25A2FFC1RAC180 0.124

32 M32 X 1.5 15.0 45.5 29.0 17.0 26.0 28.1 32.0 32A2FFC1RAC250 0.182

32 M32 X 1.5 15.0 45.5 29.0 17.0 26.3 30.4 38.0 32A2FFC1RAC280 0.188

32 M32 X 1.5 15.0 45.5 29.0 17.0 26.3 35.0 43.0 32A2FFC1RAC290 0.188

40 M40 X 1.5 15.0 50.0 30.0 23.5 32.2 36.4 44.0 40A2FFC1RAC300 0.23

40 M40 X 1.5 15.0 50.0 30.0 23.5 32.2 40.0 48.0 40A2FFC1RAC380 0.23

50S M50 X 1.5 15.0 50.0 30.0 31.0 38.2 46.5 58.7 50SA2FFC1RAC450 0.3

50S M50 X 1.5 15.0 50.0 30.0 31.0 38.2 51.2 60.0 50SA2FFC1RAC500 0.3

50 M50 X 1.5 15.0 50.0 30.0 35.6 44.1 51.2 60.0 50A2FFC1RAC550 0.34

I, the undersigned, hereby declare that the equipment referred to herein conforms to the requirements of the ATEX Directive 94/9/EC and the following standards:-

EN 60079-0:2006, EN 60079-1:2007, EN 60079-7:2007, EN 60079-15:2005, BS 6121:1989, EN 50262:1998 (Amd 2001), EN 61241-0:2004, EN 61241-1:2004.

Entry

hread

T

“C”

Metric ID OD ID OD

Min Entry

Thread

ength “E”

L

Gas Groups IIA, IIB & IIC

ax

M

Envelope

Diameter

“

Protrusion

ength

L

D”

“F”

All dimensions in millimeters

Diameter Of Cable

A”

“

Typical Diameter Of

rmour Conduit

A

B”

“

Ordering

eference

R

(Brass Metric)

Cable

Connector

Weight

Kgs)

(

CONDUIT GLAND FOR USE WITH UNARMOURED AND BRAID ARMOURED CABLES

INCORPORATING EC DECLARATION OF CONFORMITY TO DIRECTIVE 94/9/EC

CONDUIT

CONDUIT

GLAND

GLAND

TYPE

TYPE

A2FFC

A2FFC

Cable Connector Selection Table

CMP Document No. FI412 Issue 6 1012

Dr Geof Mood - Technical Director - (Authorised Person)

Registered Office: Glasshouse Street • St. Peters • Newcastle upon Tyne • NE6 1BS

0518

Notified Body: Sira Certification Service, Rake Lane, Chester CH4 9JN, England.

E-Mail: cmp@cmp-products.co.uk • Web: www.cmp-products.com

www.cmp-products.com

Tel: +44 191 265 7411 • Fax: +44 191 265 0581

Logo’s shown for illustration purposes only. Please check certification for details

Page 2

DUBAI • HOUSTON • NEWCASTLE • SINGAPORE • SHANGHAI • PUSAN • PERTH

INSTALLATION INSTRUCTIONS FOR CMP CONDUIT GLAND TYPE A2F-FC

www.cmp-products.com

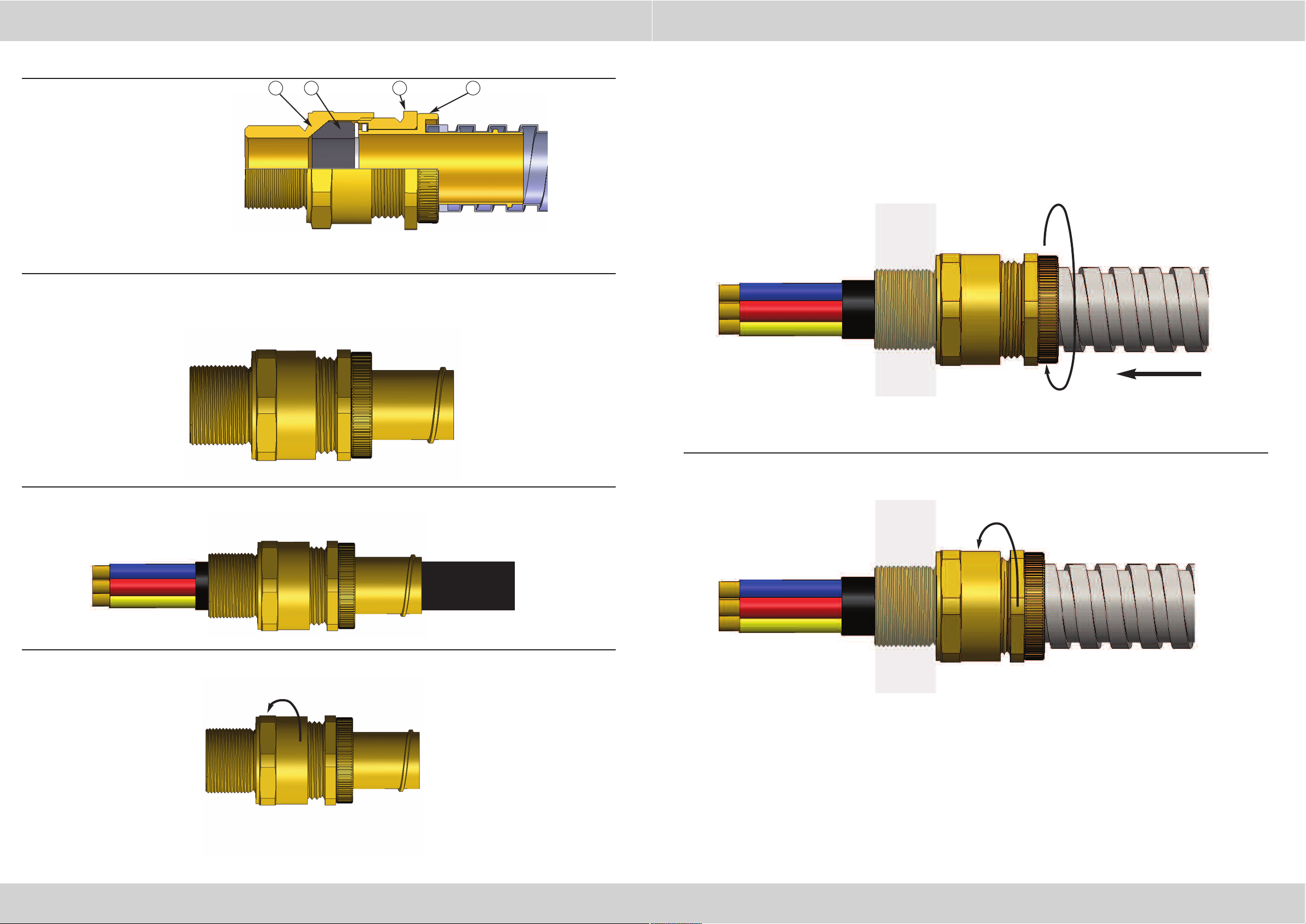

CONDUIT GLAND COMPONENTS

1. Entry Item

2. Seal

3. Seal Nut

4. Conduit Anchor

PLEASE READ ALL INSTRUCTIONS CAREFULLY BEFORE BEGINNING THE INSTALLATION

4321

There is no need to disassemble the gland in order to fit it to the conduit.

1. Slacken the seal nut (3) to relax the seal.

4. Bring the conduit into engagement with the conduit anchor (4) and then screw the anchor into

the conduit until it is fully engaged

2. Pass enough cable through the seal (2) to suit the installation.

3. Fit the gland into the equipment and fully tighten the entry item (1).

5. Tighten the seal nut (3) by hand until resistance is felt (when the seal engages the cable) and

then tighten further one full turn with a spanner.

www.cmp-products.com

DUBAI • HOUSTON • NEWCASTLE • SINGAPORE • SHANGHAI • PUSAN • PERTH

Loading...

Loading...