Hardware User Manual

EA1-MG6-USER-M

®

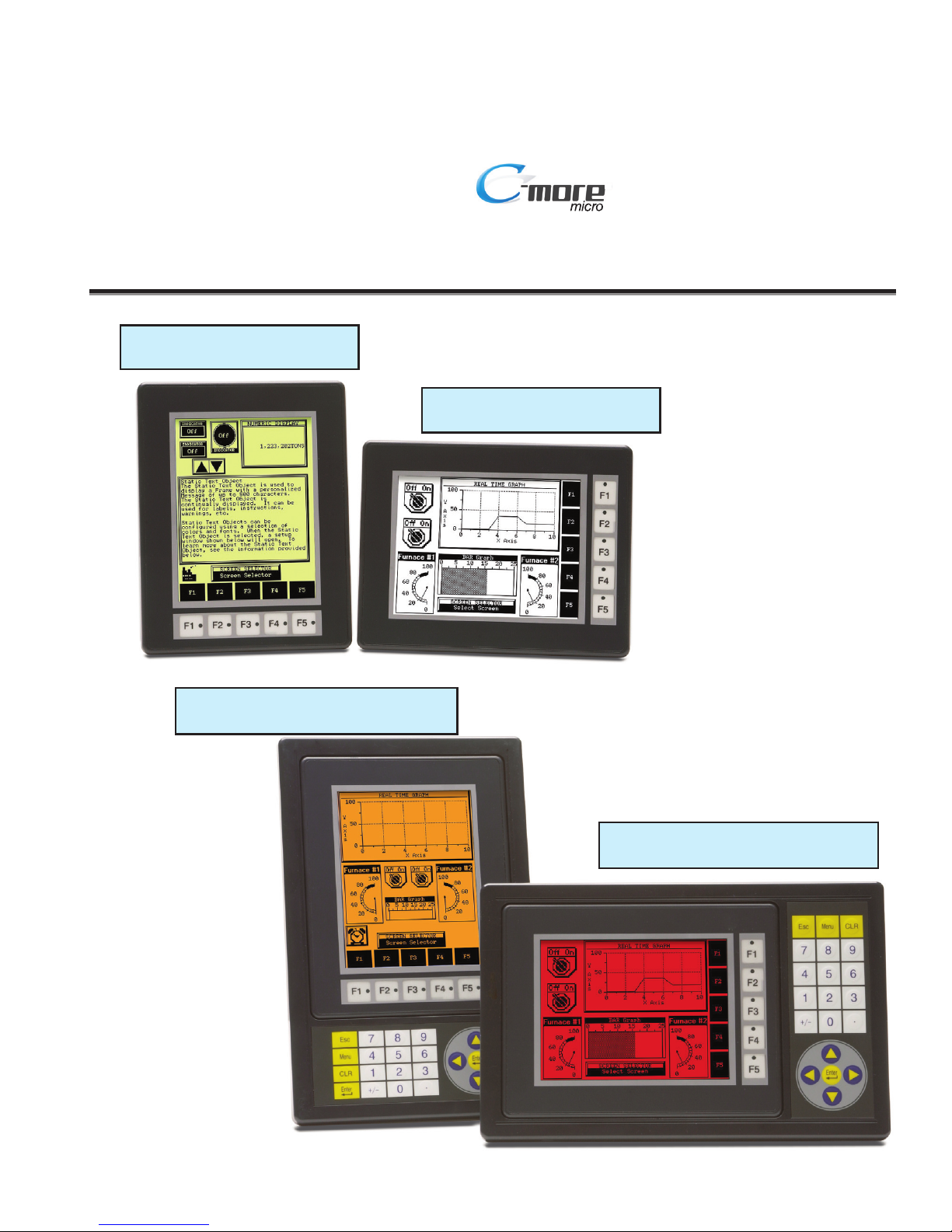

6-inch Micro-Graphic Panel

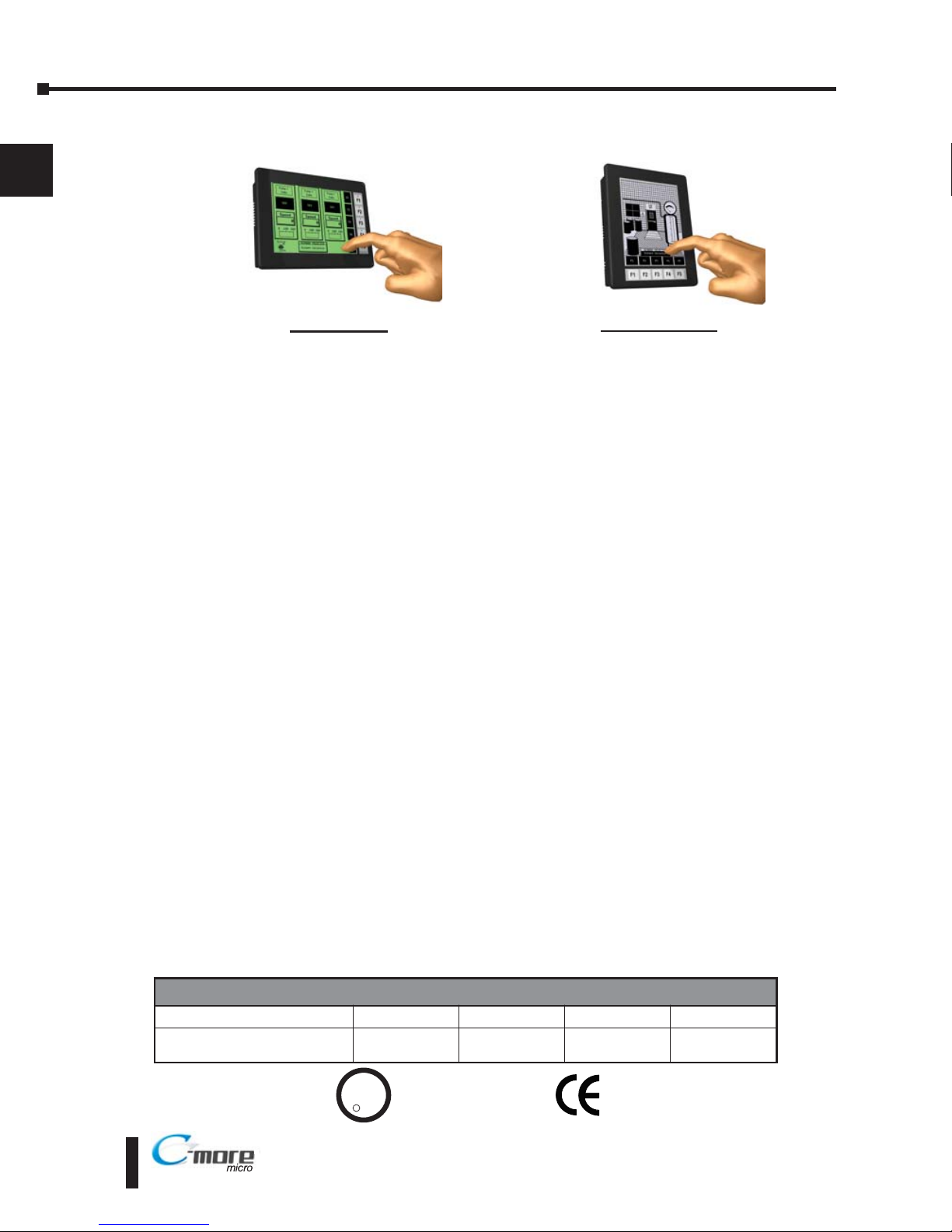

C-more 6” Micro-Graphic Panel

EA1-S6MLW - shown in Landscape Mode

C-more 6” Micro-Graphic Panel Installed in a

20-button Landscape Keypad Bezel EA-MG6-BZ2

C-more 6” Micro-Graphic Panel

EA1-S6ML - shown in Portrait Mode

C-more 6” Micro-Graphic Panel Installed in a

21-button Portrait Keypad Bezel EA-MG6-BZ2P

Graphic Panel - 6 Inch

HARDWARE USER MANUAL

Please include the Manual Number and the Manual Issue, both shown below,

when communicating with Technical Support regarding this publication.

Manual Number: EA1-MG6-USER-M

Issue: 1st Edition Rev C.

Issue Date: 09/10

Publication History

Issue Date Description of Changes

1st Edition 07/08 Original issue

Rev. A 10/08 Added CLICK PLC.

Rev. B 10/08 Added Mitsubishi Q / QnA

Rev. C 09/10 Added Allen Bradley PLC DF1 imformation and made minor corrections

®

WARNING

Thank you for purchasing automation equipment from Automationdirect.com®, doing business as,

AutomationDirect. We want your new automation equipment to operate safely. Anyone who installs or

uses this equipment should read this publication (and any other relevant publications) before installing or

operating the equipment.

To minimize the risk of potential safety problems, you should follow all applicable local and national codes

that regulate the installation and operation of your equipment. These codes vary from area to area and

usually change with time. It is your responsibility to determine which codes should be followed, and to

verify that the equipment, installation, and operation is in compliance with the latest revision of these

codes.

At a minimum, you should follow all applicable sections of the National Fire Code, National Electrical

Code, and the codes of the National Electrical Manufacturer's Association (NEMA). There may be local

regulatory or government offices that can also help determine which codes and standards are necessary for

safe installation and operation.

Equipment damage or serious injury to personnel can result from the failure to follow all applicable codes

and standards. We do not guarantee the products described in this publication are suitable for your

particular application, nor do we assume any responsibility for your product design, installation, or

operation.

Our products are not fault-tolerant and are not designed, manufactured or intended for use or resale as online control equipment in hazardous environments requiring fail-safe performance, such as in the

operation of nuclear facilities, aircraft navigation or communication systems, air traffic control, direct life

support machines, or weapons systems, in which the failure of the product could lead directly to death,

personal injury, or severe physical or environmental damage ("High Risk Activities"). AutomationDirect

specifically disclaims any expressed or implied warranty of fitness for High Risk Activities.

For additional warranty and safety information, see the Terms and Conditions section of our catalog. If

you have any questions concerning the installation or operation of this equipment, or if you need

additional information, please call us at 770-844-4200.

This publication is based on information that was available at the time it was printed. At

AutomationDirect we constantly strive to improve our products and services, so we reserve the right to

make changes to the products and/or publications at any time without notice and without any obligation.

This publication may also discuss features that may not be available in certain revisions of the product.

Trademarks

This publication may contain references to products produced and/or offered by other companies. The

product and company names may be trademarked and are the sole property of their respective owners.

AutomationDirect disclaims any proprietary interest in the marks and names of others.

Copyright 2006-2010, Automationdirect.com®Incorporated

All Rights Reserved

No part of this manual shall be copied, reproduced, or transmitted in any way without the prior, written

consent of Automationdirect.com

®

Incorporated. AutomationDirect retains the exclusive rights to all

information included in this document.

ADVERTENCIA

Gracias por comprar equipo de automatización de Automationdir ect.com®. Deseamos que su nuevo equipo de

automatización opere de manera segura. Cualquier persona que instale o use este equipo debe leer esta

publicación (y cualquier otra publicación pertinente) antes de instalar u operar el equipo.

Para reducir al mínimo el riesgo debido a problemas de seguridad, debe seguir todos los códigos de seguridad

locales o nacionales aplicables que regulan la instalación y operación de su equipo. Estos códigos varian de área

en área y usualmente cambian con el tiempo. Es su responsabilidad determinar cuales códigos deben ser

seguidos y verificar que el equipo, instalación y operación estén en cumplimiento con la revisión mas reciente

de estos códigos.

Como mínimo, debe seguir las secciones aplicables del Código Nacional de Incendio, Código Nacional

Eléctrico, y los códigos de (NEMA) la Asociación Nacional de Fabricantes Eléctricos de USA. Puede haber

oficinas de normas locales o del gobierno que pueden ayudar a determinar cuales códigos y normas son

necesarios para una instalación y operación segura.

Si no se siguen todos los códigos y normas aplicables, puede resultar en daños al equipo o lesiones serias a

personas. No garantizamos los productos descritos en esta publicación para ser adecuados para su aplicación en

particular, ni asumimos ninguna responsabilidad por el diseño de su producto, la instalación u operación.

Nuestros productos no son tolerantes a fallas y no han sido diseñados, fabricados o intencionados para uso o

reventa como equipo de control en línea en ambientes peligrosos que requieren una ejecución sin fallas, tales

como operación en instalaciones nucleares, sistemas de navegación aérea, o de comunicación, control de tráfico

aéreo, máquinas de soporte de vida o sistemas de armamentos en las cuales la falla del producto puede resultar

directamente en muerte, heridas personales, o daños físicos o ambientales severos ("Actividades de Alto Riesgo").

Automationdirect.com específicamente rechaza cualquier garantía ya sea expresada o implicada para

actividades de alto riesgo.

Para información adicional acerca de garantía e información de seguridad, vea la sección de Términos y

Condiciones de nuestro catálogo. Si tiene alguna pregunta sobre instalación u operación de este equipo, o si

necesita información adicional, por favor llámenos al número 770-844-4200 en Estados Unidos.

Esta publicación está basada en la información disponible al momento de impresión. En

Automationdirect.com nos esforzamos constantemente para mejorar nuestros productos y servicios, así que

nos reservamos el derecho de hacer cambios al producto y/o a las publicaciones en cualquier momento sin

notificación y sin ninguna obligación. Esta publicación también puede discutir características que no estén

disponibles en ciertas revisiones del producto

.

Marcas Registradas

Esta publicación puede contener referencias a productos producidos y/u ofrecidos por otras compañías. Los nombres de las

compañías y productos pueden tener marcas registradas y son propiedad única de sus respectivos dueños. Automationdirect.com,

renuncia cualquier interés propietario en las marcas y nombres de otros.

PROPIEDAD LITERARIA 2006-2010, AUTOMATIONDIRECT.COM®INCORPORATED

Todos los derechos reservados

No se permite copiar, reproducir, o transmitir de ninguna forma ninguna parte de este manual sin previo consentimiento por escrito de

Automationdirect.com

®

Incorprated. Automationdirect.com retiene los derechos exclusivos a toda la información incluida en este

documento. Los usuarios de este equipo pueden copiar este documento solamente para instalar, configurar y mantener el equipo

correspondiente. También las instituciones de enseñanza pueden usar este manual para propósitos educativos.

AVERTISSEMENT

Nous vous remercions d'avoir acheté l'équipement d'automatisation de Automationdirect.com®, en faisant des

affaires comme, AutomationDirect. Nous tenons à ce que votre nouvel équipement d'automatisation fonctionne en

toute sécurité. Toute personne qui installe ou utilise cet équipement doit lire la présente publication (et toutes les

autres publications pertinentes) avant de l'installer ou de l'utiliser.

Afin de réduire au minimum le risque d'éventuels problèmes de sécurité, vous devez respecter tous les codes locaux et

nationaux applicables régissant l'installation et le fonctionnement de votre équipement. Ces codes diffèrent d'une

région à l'autre et, habituellement, évoluent au fil du temps. Il vous incombe de déterminer les codes à respecter et

de vous assurer que l'équipement, l'installation et le fonctionnement sont conformes aux exigences de la version la

plus récente de ces codes.

Vous devez, à tout le moins, respecter toutes les sections applicables du Code national de prévention des incendies,

du Code national de l'électricité et des codes de la National Electrical Manufacturer's Association (NEMA). Des

organismes de réglementation ou des services gouvernementaux locaux peuvent également vous aider à déterminer

les codes ainsi que les normes à respecter pour assurer une installation et un fonctionnement sûrs.

L'omission de respecter la totalité des codes et des normes applicables peut entraîner des dommages à l'équipement

ou causer de graves blessures au personnel. Nous ne garantissons pas que les produits décrits dans cette publication

conviennent à votre application particulière et nous n'assumons aucune responsabilité à l'égard de la conception, de

l'installation ou du fonctionnement de votre produit.

Nos produits ne sont pas insensibles aux défaillances et ne sont ni conçus ni fabriqués pour l'utilisation ou la revente

en tant qu'équipement de commande en ligne dans des environnements dangereux nécessitant une sécurité absolue,

par exemple, l'exploitation d'installations nucléaires, les systèmes de navigation aérienne ou de communication, le

contrôle de la circulation aérienne, les équipements de survie ou les systèmes d'armes, pour lesquels la défaillance du

produit peut provoquer la mort, des blessures corporelles ou de graves dommages matériels ou environnementaux

(«activités à risque élevé»). La société AutomationDirect nie toute garantie expresse ou implicite d'aptitude à

l'emploi en ce qui a trait aux activités à risque élevé.

Pour des renseignements additionnels touchant la garantie et la sécurité, veuillez consulter la section Modalités et

conditions de notre documentation. Si vous avez des questions au sujet de l'installation ou du fonctionnement de cet

équipement, ou encore si vous avez besoin de renseignements supplémentaires, n'hésitez pas à nous téléphoner au

770-844-4200.

Cette publication s'appuie sur l'information qui était disponible au moment de l'impression. À la société

AutomationDirect, nous nous efforçons constamment d'améliorer nos produits et services. C'est pourquoi nous

nous réservons le droit d'apporter des modifications aux produits ou aux publications en tout temps, sans préavis ni

quelque obligation que ce soit. La présente publication peut aussi porter sur des caractéristiques susceptibles de ne

pas être offertes dans certaines versions révisées du produit.

Marques de commerce

La présente publication peut contenir des références à des produits fabriqués ou offerts par d'autres entreprises. Les

désignations des produits et des entreprises peuvent être des marques de commerce et appartiennent exclusivement à

leurs propriétaires respectifs. AutomationDirect nie tout intérêt dans les autres marques et désignations.

Copyright 2006-2010, Automationdirect.com®Incorporated

Tous droits réservés

Nulle partie de ce manuel ne doit être copiée, reproduite ou transmise de quelque façon que ce soit sans le

consentement préalable écrit de la société Automationdirect.com

®

Incorporated. AutomationDirect conserve les

droits exclusifs à l'égard de tous les renseignements contenus dans le présent document.

TABL E OF CON TEN TS

Chapter 1: Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–2

Conventions Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–3

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–4

Agency Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–4

Part Number Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–5

Product Label Example: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–5

Serial Number and Date Code format: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–5

Quick Start Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–6

Step 1 – Unpack and Inspect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–6

Step 2 – Install Optional Hardware Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–7

Step 3 – Become Familiar with Available Communication Ports . . . . . . . . . . . . . . . .1–8

Step 4 – Install C-more 6” Micro-Graphic Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–9

Enclosure Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–10

Step 5 – Connect C-more 6” Micro-Graphic Panel to Computer . . . . . . . . . . . . . .1–11

Step 6 – Provide Power to the C-more 6” Micro-Graphic Panel . . . . . . . . . . . . . . .1–12

Step 7 – Accessing the C-more 6” Micro-Graphic Panel Setup Screens . . . . . . . . .1–13

Step 8 – Choose C-more 6” Micro-Graphic Panel to PLC Protocol & Cables . . . . .1–14

Step 9 – Install the Programming Software and Develop a Project . . . . . . . . . . . .1–15

Step 10 – Connect C-more 6” Micro-Graphic Panel to PLC . . . . . . . . . . . . . . . . . .1–16

Chapter 2: Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2–1

Available Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2–2

Model Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2–3

Panel Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2–5

Communications Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2–6

Chemical Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2–7

Chapter 3: Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3–1

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3–2

C-more Micro-Graphic Programming Software . . . . . . . . . . . . . . . . . . . . . . . . . . . .3–3

USB to RS-232 Programming Cable Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3–6

20-Button Landscape (Horizontal) Keypad Bezel . . . . . . . . . . . . . . . . . . . . . . . . . .3–8

21-Button Portrait (Vertical) Keypad Bezel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3–11

D-SUB 15-pin 90-degree Communication Port Adapter . . . . . . . . . . . . . . . . . . . .3–14

D-SUB 15-pin to Terminal Block Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3–14

Clear Screen Overlay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3–15

Chapter 4: Installation and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . .4–1

Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4–2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4–3

Panel Cutout Dimensions (all models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4–4

Wiring Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4–5

Chapter 5: System Setup Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–2

Accessing the System Setup Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–3

System Setup Screens Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–4

Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–5

Information Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–6

ii

Table of Contents

®

EA1-MG6-USER-M Hardware User Manual, 1st Ed. Rev C, 09/10

Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–6

Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–6

Extensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–6

Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–6

Setting Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–7

LCD Contrast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–7

Backlight, Model EA1-S6ML . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–8

Backlight, Model EA1-S6MLW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–9

Beep . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–10

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–11

Clear User Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–12

Reset to Factory Default . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–12

Hourglass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–13

Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–14

Test Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–15

Serial Port1 - Loop Back Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–15

Serial Port2 - Loop Back Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–16

PLC Enquiry Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–17

Buzzer Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–17

Touch Panel Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–18

Exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–18

Chapter 6: PLC Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6–1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6–2

Available PLC Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6–3

C-more 6” Micro-Graphic Communication Ports . . . . . . . . . . . . . . . . . . . . . . . . . . .6–4

DirectLOGIC PLCs Password Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6–6

PLC Compatibility and Connection Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6–6

AutomationDirect CLICK PLC: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6–6

Direct LOGIC PLCs RS-422A/RS-485A: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6–7

Allen-Bradley: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6–7

GE, Mitsubishi, Omron, Modicon and Siemens: . . . . . . . . . . . . . . . . . . . . . . . . . . . .6–7

How to use the PLC Compatibility and Connection Charts . . . . . . . . . . . . . . . . . . .6–8

Example: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6–8

Cables from AutomationDirect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6–15

Cables from AutomationDirect – Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . .6–17

iii

Table of Contents

EA1-MG6-USER-M Hardware User Manual, 1st Ed. Rev C, 09/10

®

User Constructed Cables – Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6–26

RS-422A/RS-485A Multi-Drop Wiring Diagram Examples . . . . . . . . . . . . . . . . . . .6–34

Chapter 7: Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7–1

Project Backup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7–2

Check Operating Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7–2

Check Operating Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7–2

Check Transmit and Receive Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7–3

Check Physical Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7–3

Run Tests under the System Setup Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7–4

Check Settings under the System Setup Screens . . . . . . . . . . . . . . . . . . . . . . . . . .7–5

Cleaning the Display Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7–5

Check Project Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7–6

Checks from the C-more Micro-Graphic Programming Software . . . . . . . . . . . . . .7–6

Chapter 8: Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8–1

C-more Micro-Graphic Panel does not Power up . . . . . . . . . . . . . . . . . . . . . . . . . . .8–2

Display is Blank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8–2

Display is Dim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8–3

No User Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8–3

Lost Firmware – Red ‘Update Mode’ Screen Displayed . . . . . . . . . . . . . . . . . . . . . .8–4

Updating Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8–4

No Communications between Panel and PC (Personal Computer) . . . . . . . . . . . .8–5

No Communications between Panel and PLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8–7

Panel & PLC Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8–8

C-more Micro-Graphic Panel Runtime Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8–9

Electrical Noise Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8–10

Chapter 9: Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9–1

Replacement Parts Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9–2

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9–2

iv

Table of Contents

®

EA1-MG6-USER-M Hardware User Manual, 1st Ed. Rev C, 09/10

Customizing the Function Keys Insert Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9–3

Appendix A: PLC Protocol Error Codes . . . . . . . . . . . . . . . . . . . . . . . .A–1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A–2

C-more Micro-Graphic Panel Error Code Table . . . . . . . . . . . . . . . . . . . . . . . . . . . .A–3

Modbus Protocols Error Code P499 Explanation . . . . . . . . . . . . . . . . . . . . . . . . . .A–4

AutomationDirect CLICK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A–4

AutomationDirect DirectLOGIC - Modbus (Koyo) . . . . . . . . . . . . . . . . . . . . . . . . . . .A–4

Modicon Modbus RTU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A–4

Entivity Modbus RTU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A–4

DirectLOGIC Error Code P499 Explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A–5

DirectLOGIC – K-Sequence PLC Error Code Table . . . . . . . . . . . . . . . . . . . . . . . . . .A–5

DirectLOGIC – DirectNET PLC Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A–5

Allen-Bradley Error Code P499 Explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A–6

Allen-Bradley DF1 Protocol – PLC Error Code Tables . . . . . . . . . . . . . . . . . . . . . . .A–7

Allen-Bradley DH485 Protocol – PLC Error Code Tables . . . . . . . . . . . . . . . . . . . . .A–9

GE Error Code P499 Explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A–11

GE SNPX Protocol – PLC Error Code Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A–12

Mitsubishi FX Protocol – PLC Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A–21

Mitsubishi Q / QnA and Q Series – PLC Error Codes . . . . . . . . . . . . . . . . . . . . . .A–21

Omron Error Code P499 Explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A–23

Omron Host Link Protocol – PLC Error Code Table . . . . . . . . . . . . . . . . . . . . . . . .A–24

Omron FINS Protocol – PLC Error Code Table . . . . . . . . . . . . . . . . . . . . . . . . . . . .A–25

Siemens Error Code P499 Explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A–28

Siemens PPI Protocol – PLC Error Code Table . . . . . . . . . . . . . . . . . . . . . . . . . . . .A–29

Appendix B: C-more Micro-Graphic Panel Runtime Errors . . . . . . . . .B–1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B–2

Runtime Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B–2

Index

v

Table of Contents

EA1-MG6-USER-M Hardware User Manual, 1st Ed. Rev C, 09/10

®

1

1

GETTING STARTE D

CH

CHAPTER

CHAPTER

In This Chapter...

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–2

Conventions Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–3

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–4

Agency Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–4

Part Number Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–5

Product Label Example: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–5

Serial Number and Date Code format: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–5

Quick Start Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–6

Step 1 – Unpack and Inspect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–6

Step 2 – Install Optional Hardware Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–7

Step 3 – Become Familiar with Available Communication Ports . . . . . . . . . . . . . . . .1–8

Step 4 – Install C-more 6” Micro-Graphic Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–9

Enclosure Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–10

Step 5 – Connect C-more 6” Micro-Graphic Panel to Computer . . . . . . . . . . . . . .1–11

Step 6 – Provide Power to the C-more 6” Micro-Graphic Panel . . . . . . . . . . . . . . .1–12

Step 7 – Accessing the C-more 6” Micro-Graphic Panel Setup Screens . . . . . . . . .1–13

Step 8 – Choose C-more 6” Micro-Graphic Panel to PLC Protocol & Cables . . . . .1–14

Step 9 – Install the Programming Software and Develop a Project . . . . . . . . . . . .1–15

Step 10 – Connect C-more 6” Micro-Graphic Panel to PLC . . . . . . . . . . . . . . . . . .1–16

Introduction

The Purpose of this Manual

Thank you for purchasing from our C-more®Micro-Graphic family of products. This manual

describes AutomationDirect.com’s C-more 6” Micro-Graphic panels, their specifications,

included components and available accessories and provides you with important information

for installation, connectivity and setup. The manual shows you how to install, wire and use the

products. It also helps you understand how to interface the panels to other devices in a control

system.

This user manual contains important information for personnel who will install the panels and

accessories, and for the personnel who will be programming the panel. If you understand

control systems making use of operating interfaces such as the C-more Micro-Graphic panels,

our user manuals will provide all the information you need to get, and keep, your system up and

running.

Supplemental Manuals

If you are familiar with industrial control type devices, you may be able to get up and running

with just the aide of the Quick Start Guide that is included with each panel. You may also refer

to the online help that is available in the C-more Micro-Graphic programming software.

Technical Support

We strive to make our manuals the best in the industry. We rely on your feedback to let us know

if we are reaching our goal. If you cannot find the solution to your particular application, or, if

for any reason you need technical assistance, please call us at:

770–844–4200

Our technical support group will work with you to answer your questions. They are available

Monday through Friday from 9:00 A.M. to 6:00 P.M. Eastern Time. We also encourage you to

visit our web site where you can find technical and non-technical information about our

products and our company.

http://www.automationdirect.com

If you have a comment, question or suggestion about any of our products, services, or manuals,

please fill out and return the ‘Suggestions’ card that was included with this manual.

EA1-MG6-USER-M Hardware User Manual, 1st Ed. Rev C, 09/10

1–2

Chapter 1: Getting Started

1

®

Conventions Used

When you see the “notepad” icon in the left-hand margin, the paragraph to its immediate right will be a

special note. The word NOTE: in boldface will mark the beginning of the text.

When you see the “exclamation mark” icon in the left-hand margin, the paragraph to its immediate

right will be a warning. This information could prevent injury, loss of property, or even death (in

extreme cases). The word WARNING: in boldface will mark the beginning of the text.

Key Topics for Each Chapter

The beginning of each chapter will list the key topics

that can be found in that chapter.

EA1-MG6-USER-M Hardware User Manual, 1st Ed. Rev C, 09/10

1–3

Chapter 1: Getting Started

1

®

Getting Started

CHAPTER

1

In This Chapter...

............................ ....................................1-2

...................................... ....................................1-4Spec fications

General Information

Product Overview

The C-more 6” Micro-Graphic panel has a 5.7-inch STN LCD monochrome 320 x 240 dot

display. Model EA1-S6ML has five selectable LED-driven backlight colors including Green,

Red, Amber, Yellow and Lime. Model EA1-S6MLW has five selectable LED-driven backlight

colors including White, Pink1, Pink2, Pink3 and Red. Both models feature five user-defined

function keys, each key with a user-defined red LED indicator. The panels can display up to 40

lines by 78 characters of static text and up to 40 lines by 40 characters of dynamic text with

embedded variables and phrases mixed with graphics at landscape orientation. Portrait

orientation can display 59 characters and 40 lines of static text and 40 lines by 40 characters of

dynamic text. Each model is rated NEMA 4/4X, IP-65 (when mounted correctly, for indoor use

only). The C-more 6” Micro-Graphic panels are powered from a 12-24 VDC power supply or

can operate in low-power mode when powered from the serial communications port of select

AutomationDirect PLCs.

Other features include:

• 1792 KB memory

• Built in RJ12 serial communications port (RS-232)

• Built in 15-pin serial communications port (RS-232/422/485)

• Adjustable contrast

• 2 optional keypad bezels, 20-button landscape and 21-button portrait mount

• Optional replaceable clear screen overlay

• Built in Alarm Control setup that activates beep, backlight flash, customized alarm banner, and red

LED blinking

• Up to 999 screens, limited only by memory usage

• 0 to 50 °C (32 to 122 °F) operating temperature range

• UL, cUL & CE agency approvals (see below for details)

• 2-year warranty from date of purchase

Agency Approvals

EA1-MG6-USER-M Hardware User Manual, 1st Ed. Rev C, 09/10

1–4

Chapter 1: Getting Started

1

®

EA1-S6ML

shown in Portrait (Vertical) mode

UL/CUL/CE Certification Numbers

Name UL/CUL UL508 CE ISO-9000

C-more Micro-Graphic Panels

& Accessories

E157382 E157382 EN61131-2 Yes

U

L

C

US

R

EA1-S6MLW

shown in Landscape (Horizontal) mode

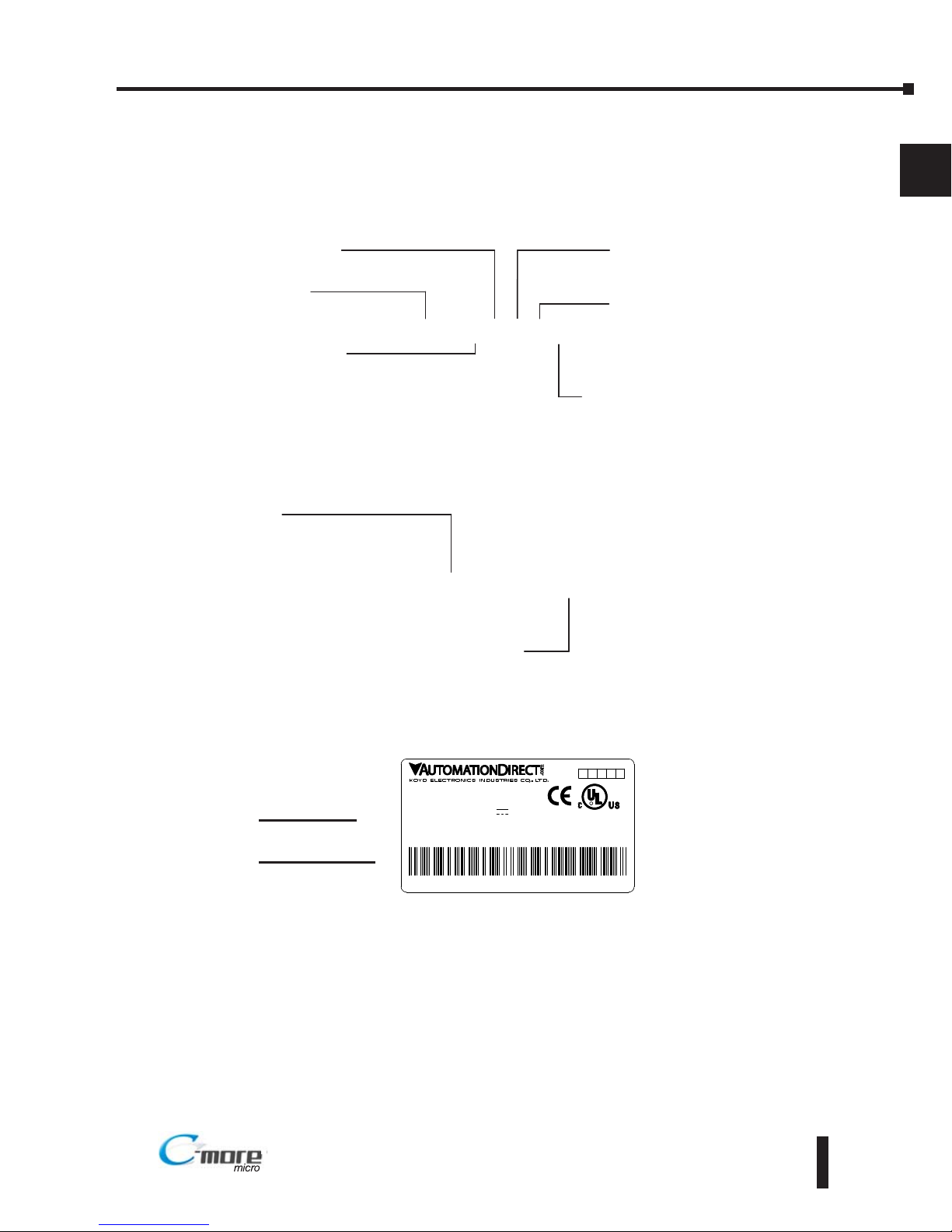

Part Number Key

Panel Part Number Key

The C-more 6” Micro-Graphic panel part numbers consist of the following:

Bezel Part Number Key

The optional C-more 6” Micro-Graphic keypad bezel part numbers consist of the following:

Product Label Example:

Serial Number and Date Code format:

EA1-MG6-USER-M Hardware User Manual, 1st Ed. Rev C, 09/10

1–5

Chapter 1: Getting Started

1

®

EA1-S6MLx

Display Type:

S: STN

Display Color:

M: Monochrome

Features:

blank: Green / Red backlight

W: White / Red backlight

Display Size:

6: 5.7”

Backlight Type:

L: LED

Series Name:

EA1: C more Micro Graphic

LISTED

7M17

Date code:****

5432

1

R01.

D

MADE IN CHINA

M

EA1-S6MLW + serial number

O S6

MODEL:EA1-S6MLW

4 5

INPUT:12-24V 6.5W

IND.CONT.EQ.

EA-MG6-XXXX

Module Type:

BZ2: 20 Key Bezel for landscape mode

BZ2P: 21 Key Bezel for portrait mode

Series Name:

EA MG6: C more 6” Micro Graphic

Bezel Option Module

EA1-S6ML

EA1-S6MLW

YYMF

YY: Year (07 99 --- e.g. 07 2007)

M: Month (1 9, X, Y, Z --- e.g. X Oct.)

DD: Day (1 31)

F: Manufacturing Site (0 9, A Z)

NNN: Sequence number for the date listed (000 999)

Serial Number =

[Part Number]+[YYMDDFNNN]

Date Code =

EA1-MG6-USER-M Hardware User Manual, 1st Ed. Rev C, 09/10

1–6

Chapter 1: Getting Started

1

®

Quick Start Steps

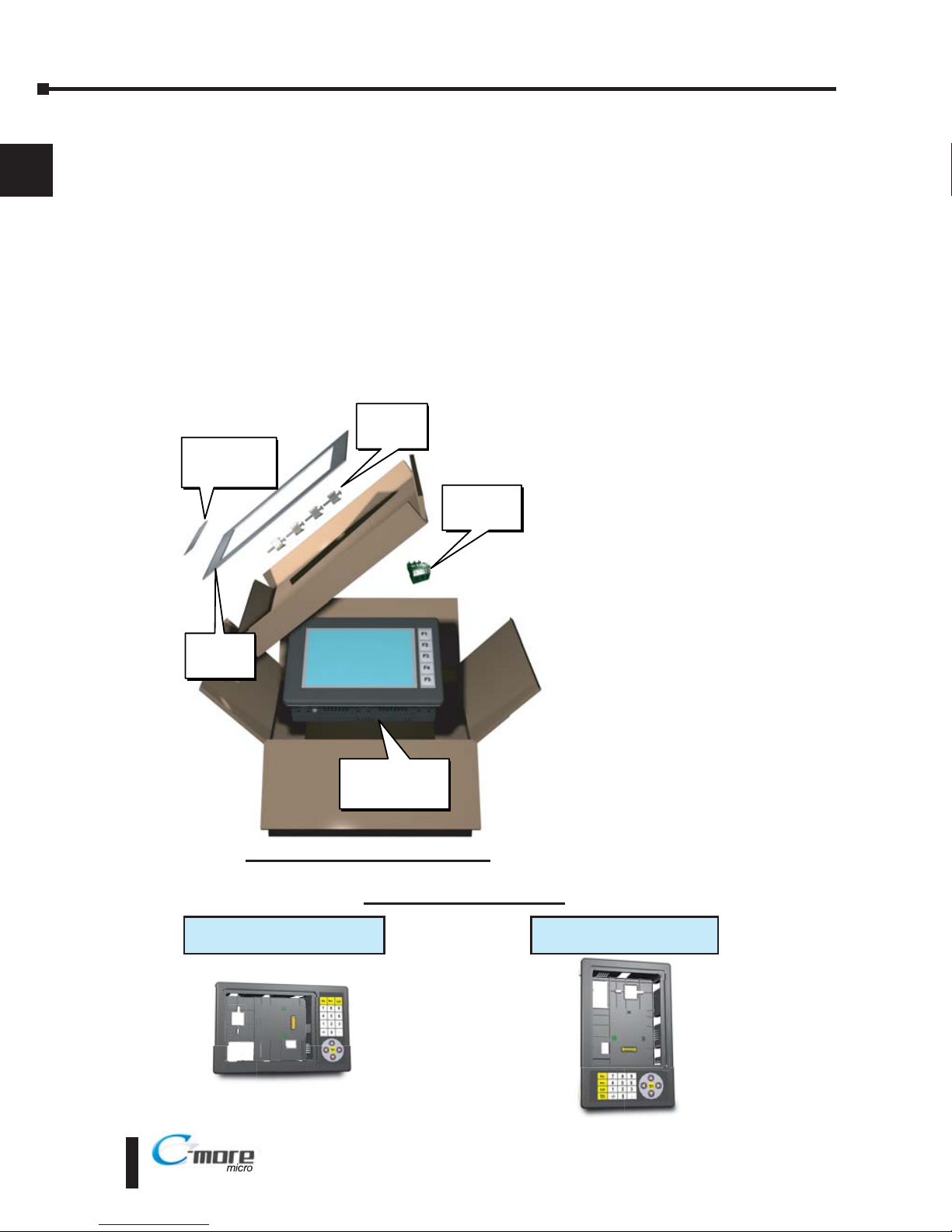

Step 1 – Unpack and Inspect

a.) Unpack the C-more 6” Micro-Graphic panel from its shipping carton. Included in the

carton are the following:

• C-more 6” Micro-Graphic panel (EA1-S6ML or EA1-S6MLW)

• DC power connector (EA-MG-DC-CON)

• cutout template

• mounting clips

• gasket

• function key label inserts

• Quick Start Guide

b.) Unpack any accessories that have

been ordered, such as:

Keypad Bezel, programming

cable, PLC communications

cable, etc.

c.) Inspect all equipment for

completeness. If anything is

missing or damaged,

immediately call the

AutomationDirect®returns

department @ 1-800-633-0405.

Shipping Carton Contents

20-Button Horizontal Keypad Bezel

EA-MG6-BZ2

21-Button Vertical Keypad Bezel

EA-MG6-BZ2P

Optional Accessories

Cutout

Template

Function Key

Label Inserts

Mounting

Clips

C-more 6 Inch

Micro-Graphic

Panel

DC Power

Connector

EA1-MG6-USER-M Hardware User Manual, 1st Ed. Rev C, 09/10

1–7

Chapter 1: Getting Started

1

®

Step 2 – Install Optional Hardware Accessories

Below is an example of a C-more 6” Micro-Graphic panel being assembled with an optional

EA-MG6-BZ2 20-button Keypad Bezel.

C-more 6 Inch

Micro-Graphic Panel

20 Button

Keypad Bezel

EA MG6 BZ2

1. Remove

Expansion

Connector

Protective

Cover from

rear of

panel.

2. Use the (4) Panel Mounting

Clips, EA-MG-BZ2-BRK,

that are supplied with the

panel, to secure panel to

keypad bezel and compress

the gasket between the

panel and the keypad bezel.

Tighten screws to a torque

of 21-28 oz-in [0.15-0.2 Nm].

3. Use (8) Bezel Mounting Clips,

EA-MG-BZ2-BRK, to secure keypad

bezel through enclosure cutout.

Tighten screws to a torque of

21-28 oz-in [0.15-0.2 Nm].

Function

Key Label

Insert

4. Peel Protective Film

from front of panel.

Clear Screen Overlay

EA-6-COV2

Optional Accessory

NOTE: Mounting clips for the panel and keypad bezels are included with the respective product.

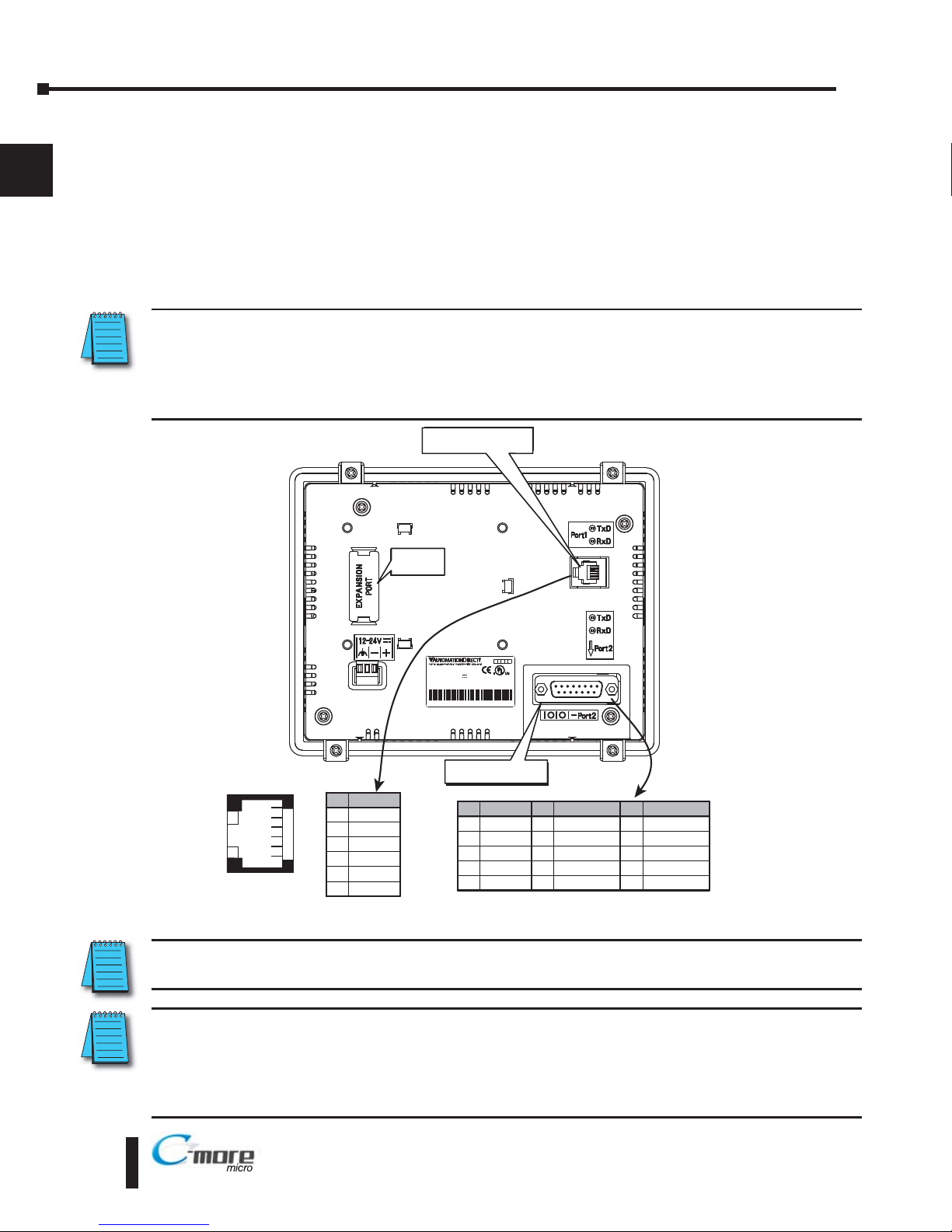

Step 3 – Become Familiar with Available Communication Ports

The C-more 6” Micro-Graphic panel includes a built-in RS-232 serial communications port

designated as Port1. This port uses an RJ12 type telephone jack to make connections to either

the EA-MG-PGM-CBL programming cable assembly or a communications cable, such as an

EA-2CBL, to interface with a PLC or controller. The panel can receive power through this port

from the serial communications port on AutomationDirect CLICK™ and select

Direct LOGIC PLCs. The other serial communications port designated as Port2 is a 15-pin Dsub connector that supports RS-232, RS-485 and RS-422.

NOTE: When the 6” panel is powered through Port1 from a connected PLC or PC, the screen brightness is

diminished because the panel is running in Low-Power Mode. For full brightness, connect an external

12-24 VDC power source to the panel’s power connection. Low-Power Mode is intended for initial

programming. For full brightness, connect an external 12-24 VDC power source when the panel is installed

in its application.

NOTE: See Chapter 2: Specifications and Chapter 6: PLC Communications for additional details on the

available communication ports, protocols and cables.

NOTE: The panel has a built-in RJ12 serial communications port (Port1 - RS-232) and a built in 15-pin serial

communications port (Port2 - RS-232/422/485). Only one of the ports can be used with a connected PLC.

The programming software allows the user to select either Port1 or Port2 under the Panel Manager dialog

box. When using Port2 to communicate with the connected PLC, Port1 can still be used with the EA-MGPGM-CBL Software Programming Cable Assembly to transfer projects between the PC and panel.

EA1-MG6-USER-M Hardware User Manual, 1st Ed. Rev C, 09/10

1–8

Chapter 1: Getting Started

1

®

IS EDIS ED

7M177M17

Date code:** *Date code:** *

5432

R01.R01.

MADE IN CH NAMADE IN CH NA

EA1-S6MLW + seral numberEA1-S6MLW + seral number

MODEL:EA1 S6MLWMODEL:EA1 S6MLW

NPUT:12 24V 6 5WNPUT:12 24V 6 5W

ND.CONTEQ.ND.CONTEQ.

6 5 4 3 2 1

Pin Signal

1 Logic GND

not used

RXD (232C)

TXD (232C)

2

3

4

5 +5 VDC

RJ12 serial

communications Port1

6 Logic GND

81

15

9

Pin Signal

1 Frame GND

TXD (232C)

RXD (232C)

Future

2

3

4

5 Logic GND

Pin Signal Pin Signal

6LE

CTS (232C)

RTS (232C)

RXD+ (422/485)

7

8

9

10 RXD (422/485)

11 TXD+ (422/485)

TXD (422/485)

Term Resistor

do not use

12

13

14

15 do not use

PLC 15-pin serial

communications Port2

RS-232 RS-232/422/485

Expansion

Connector

EA1-MG6-USER-M Hardware User Manual, 1st Ed. Rev C, 09/10

1–9

Chapter 1: Getting Started

1

®

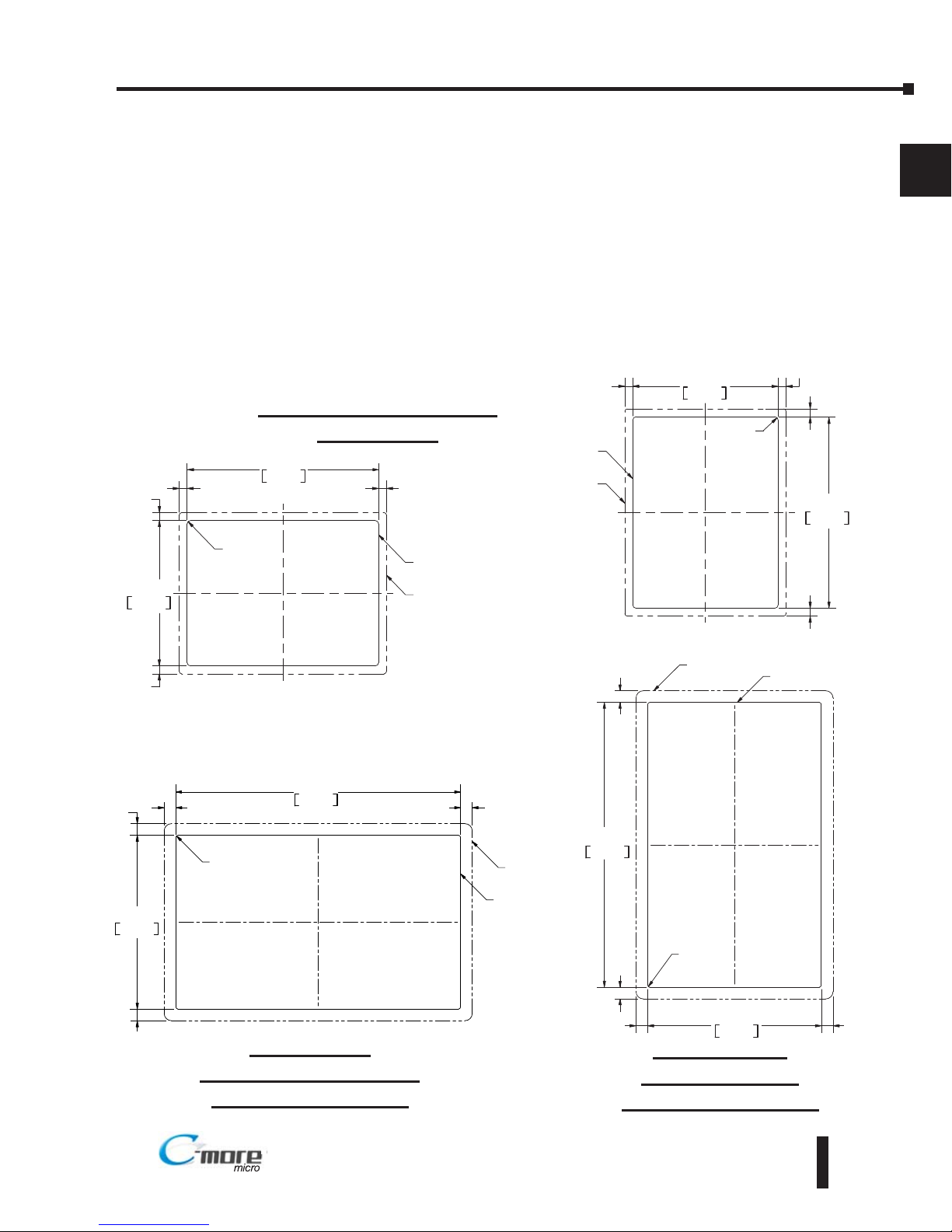

Step 4 – Install C-more 6” Micro-Graphic Panel

The C-more 6” Micro-Graphic panel can be mounted through a cutout in an enclosure by using

the template that is provided with the panel, or using the dimensions shown below. Cutout

dimensions for the 20-button landscape and 21-button portrait keypad bezel options are also

shown below. The keypad bezels also include a template that can be used. The enclosure

mounting thickness range for the panels and the keypad bezels is 0.04”–0.2” [1–5 mm].

The screw torque range for the screws used on the panel mounting clips and the keypad bezel

mounting clips is 21-28 oz-in [0.15-0.2 Nm].

See Chapter 2: Specifications for additional product dimensions.

Chapter 3: Accessories for accessory specifications and dimensions.

0 260

[6 6]

0 256

[6 5]

0 256

[6 5]

0 260

[6 6]

R 118 [R3]

CUTOUT

CUTOUT

OUTLINE

BEZEL

OUTLINE

122 2

+1

0

+0 04

0 00

4 811

161 0

+1

0

+0 04

0 00

6 339

Units Inches [mm]

0 382

[9 7]

0 382

[9 7]

0 382

[9 7]

0 382

[9 7]

143 0

+1

0

+0 04

0 00

5 630

CUTOUT

234 6

+1

0

+0 04

0 00

9 236

R0 59 [R1 5]

CUTOUT

OUTLINE

BEZEL

OUTLINE

EA1-S6ML & EA1-S6MLW

Panel Cutout

BEZEL

OUTLINE

0 382

[9 7]

0 382

[9 7]

0 382

[9 7]

0 382

[9 7]

143 0

+1

0

+0 04

0 00

5 630

CUTOUT

234 6

+1

0

+0 04

0 00

9 236

R0 59 [R1 5]

CUTOUT

OUTLINE

EA-MG6-BZ2

Landscape (Horizontal)

Keypad Bezel Cutout

EA-MG6-BZ2P

Portrait (Vertical)

Keypad Bezel Cutout

0 260

[6 6]

0 256

[6 5]

0 256

[6 5]

0 260

[6 6]

R 118 [R3]

CUTOUT

CUTOUT

OUTLINE

BEZEL

OUTLINE

122 2

+1

0

+0 04

0 00

4 811

161 0

+1

0

+0 04

0 00

6 339

Landscape Mode (Horizontal)

Portrait Mode (Vertical)

EA1-MG6-USER-M Hardware User Manual, 1st Ed. Rev C, 09/10

1–10

Chapter 1: Getting Started

1

®

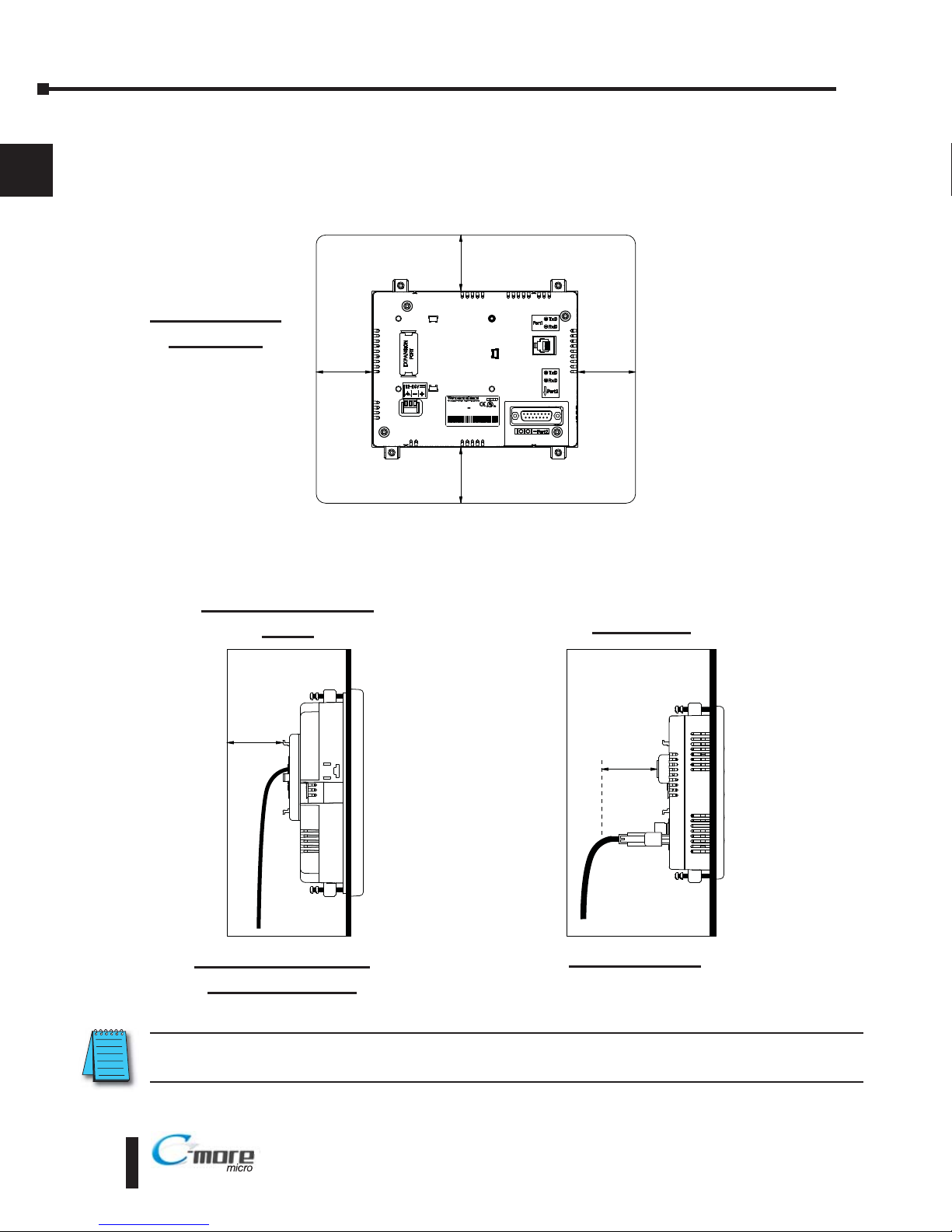

Enclosure Clearances

A 1.2” [30mm] minimum clearance is required inside an enclosure for proper ventilation of

the C-more Micro-Graphic panel.

1.2

[30.0]

1.2

[30.0]

Enclosure Enclosure

8 1

15

9

I T D

I T D

M 7

M 7

D te o e * **

D te o e* **

R01

R01

MAD IN HI A

MAD IN HI A

E 1 S6M W + se a num er

E 1 S6M W + se a num er

MODE : A1 S6M

MODE : A1 S6M W

N UT 12- 4V 6 5W

N UT 12- 4V 6 5W

NDC NT Q.

NDC NT Q.

1.2

[30.0]

1.2

[30.0]

1.2

[30.0]

1.2

[30.0]

Enclosure

units: inches [mm]

EA1-S6ML(W) with

EA-MG6-BZ2(P)

EA1-S6ML(W)

NOTE: Additional clearance inside the enclosure is required when connecting to the 15-pin serial

communications port (Port2).

EA1-S6ML(W)

Rear View

Panel with Keypad

Bezel

Panel only

EA1-MG6-USER-M Hardware User Manual, 1st Ed. Rev C, 09/10

1–11

Chapter 1: Getting Started

1

®

Step 5 – Install the Programming Software and Develop a Project

Following are the minimum system requirements for running C-more Micro-Graphic

Programming Software, EA-MG-PGMSW, on a PC:

• Personal Computer with a 333 MHz or higher processor (CPU) clock speed recommended;

(Windows® 2000 with Service Pack 4 or Windows® XP, 800 MHz or higher processor (CPU)

clock speed recommended (Windows® Vista (32 bit)); Intel® Pentium/Celeron family, or AMD®

K6/Athlon/Duron family, or compatible processor recommended

• Keyboard and Mouse or compatible pointing device

• Super VGA color video adapter and monitor with at least 800 x 600 pixels resolution

(1024 x 768 pixels recommended) 64K color minimum

• 150 MB free hard-disk space

• 128 MB free RAM (512 MB recommended); 512 MB free RAM (1GB recommended) for Vista

• CD-ROM or DVD drive for installing software from the CD, or internet access to download free

programming software

• USB port to use with an EA-MG-PGM-CBL, USB to RS232 Programming Cable Assembly for

project transfer from the programming software to the panel

• Operating System - Windows® XP Home / Professional Edition Service Pack 2, Windows® 2000

with Service Pack 4, or Windows® Vista (32 bit)

Insert the supplied CD-ROM into the PC’s CD-ROM drive and follow the instructions. If you

need assistance during the software installation, please refer to the supplied Software Installation

Guide or call the AutomationDirect Technical Support team at 770-844-4200.

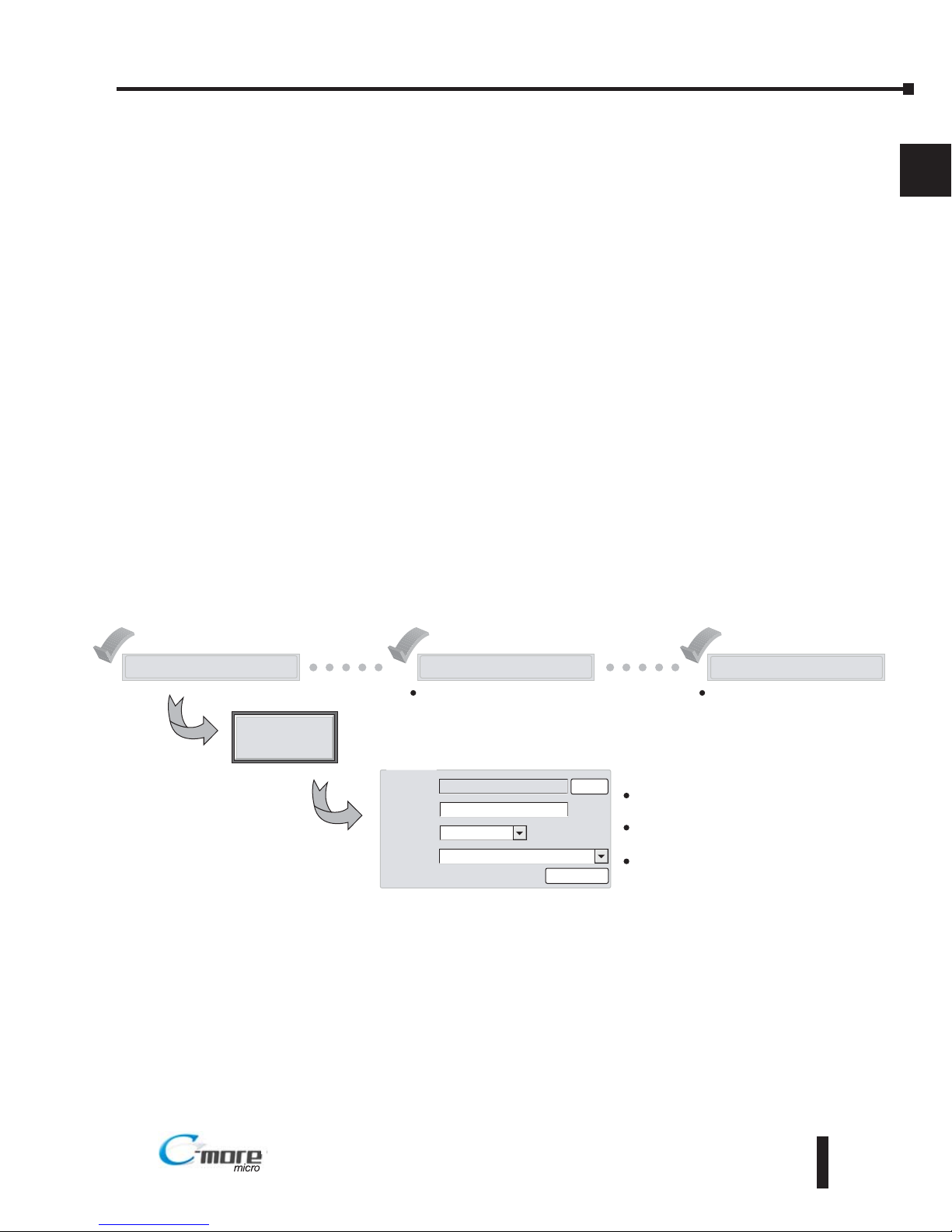

Start a Project

Simulate Project

Send Project to panel

Allows you to check the operation of

your project before downloading it to

the panel.

Download your project to the

connected panel.

Enter a name

for your project

Make a New Project

PLC Protocol

DirectLogic K Sequence

HMI Type

Project

Location

EA1 S6ML

MyProject

C \My Documents\C more Projects\

Select Project

Protocol Setup

Browse

Select the C-more

Micro-Graphic panel

Select the PLC Driver

EA1-MG6-USER-M Hardware User Manual, 1st Ed. Rev C, 09/10

Chapter 1: Getting Started

1

®

1–12

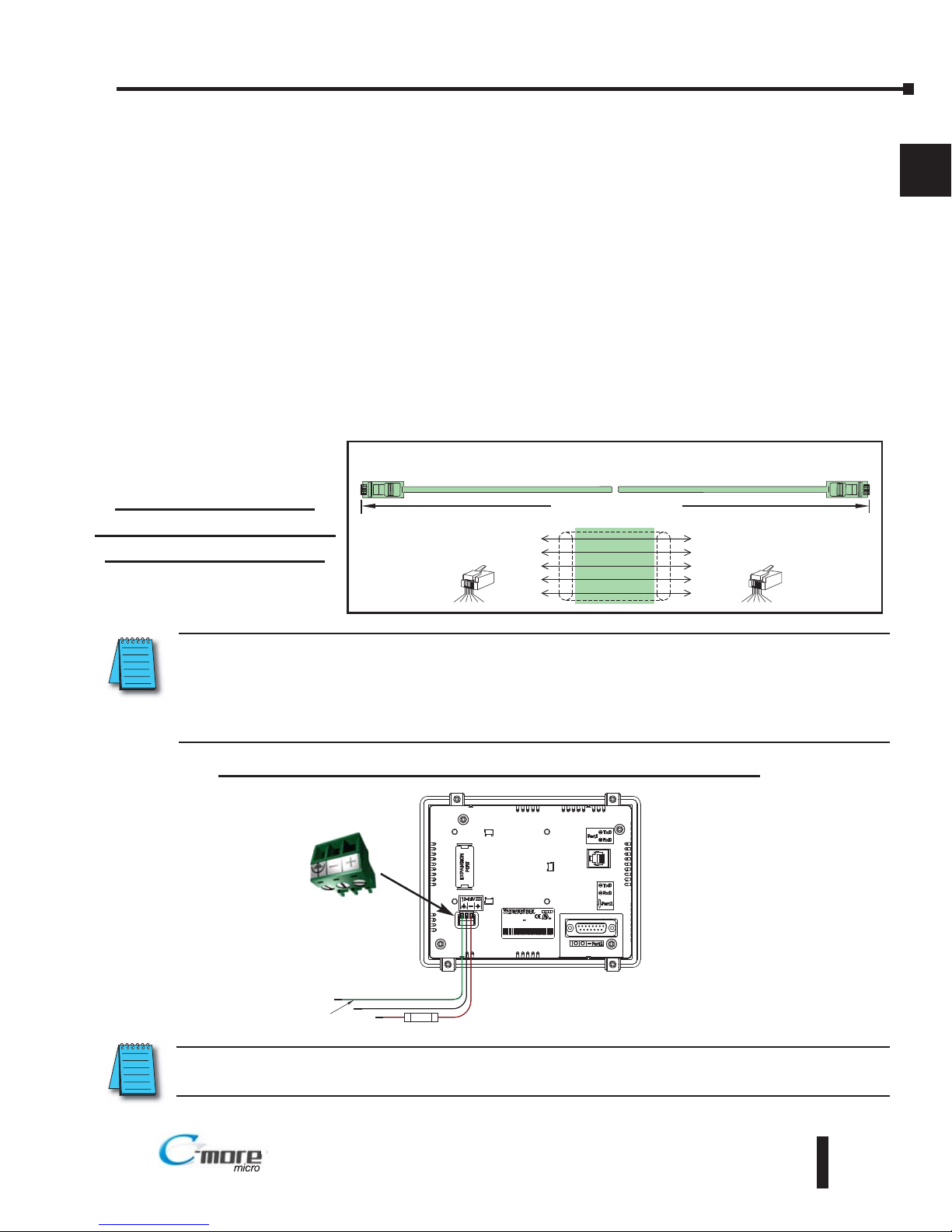

Step 6 – Connect C-more 6” Micro-Graphic Panel to Computer

NOTE: Install C-more Micro-Graphic Programming software before connecting the panel to the PC to ensure

the panel drivers install correctly.

Use an EA-MG-PGM-CBL, USB to RS-232 Programming Cable Assembly, from an USB

port type A on the project development PC, through the supplied converter, to the RJ12 RS232 programming/PLC serial communications port on the C-more Micro-Graphic panel as

shown below.

C-more 6 inch

Micro Graphic

Panel

USB

Cable

User PC

Serial

Cable

PC to Panel Programming

Cable Assembly

(Includes serial & USB cables)

EA MG PGM CBL

USB to RS232

Converter

USB to RS-232 Programming Cable Assembly

NOTE: When the panel is powered through Port1 from a connected PLC or PC, the screen brightness is

diminished because the panel is running in Low-Power Mode. For full brightness, connect an external

12-24 VDC power source to the panel’s power connection. Low-Power Mode is intended for initial

programming. For full brightness, connect an external 12-24 VDC power source when the panel is installed

in its application.

EA1-MG6-USER-M Hardware User Manual, 1st Ed. Rev C, 09/10

1–13

Chapter 1: Getting Started

1

®

Step 7 – Providing Power to the C-more 6” Micro-Graphic Panel

Power can be supplied to the C-more Micro-Graphic panel in one of three different ways.

1.) During operation, the panel functions in High-Power Mode when powered by a minimum 1 Amp

12 - 24 VDC power source. Recommended power supplies are AutomationDirect part number

PSP24-024S or PSP24-024C.

2.) The C-more Micro-Graphic panel is powered during programming from the PC through the USB

to RS-232 Programming Cable Assembly, EA-MG-PGM-CBL. The panel will operate in Lowpower mode when powered by the PC and result in a dim screen.

3.) Optionally, the C-more Micro-Graphic panel can function in Low-Power Mode powered from most

AutomationDirect PLC’s RJ12 serial communications port. Use a DV-1000CBL communications

cable, or a DV-1000CBL communications cable with a FA-15HD 15-pin HD DSub/RJ12 Adapter

connected to most AutomationDirect PLC’s 15-pin HD communications port (DL06, D2-250-1

& D2-260) PLCs for Low-Power operation. See Chapter 6: PLC Communications for additional

details. The panel will operate in low-power mode when powered by the PC.

Power Supplied to Panel through Cable from CLICK and Direct Logic PLC RJ12 port:

DL05, DL105, DL205, DL350, DL450, H2-WINPLC

RS-232C (p/n DV-1000CBL)

To PLC

RJ12 Port

To C more

Micro Graphic

Serial Port1

6

4

GND

TXD

1

3

GND

Wiring Diagram

3

RXD

2

+5 V

1 Sig GND

2 not used

3 RXD

4 TXD

5 +5 VDC

6 Sig GND

1 2 3 4 5 6

RJ12 6 pin

Phone Plug

(6P6C)

1

GND

6

GND

1 2 3 4 5 6

RJ12 6 pin

Phone Plug

(6P6C)

1 S g GND

2 +5 VDC

3 RXD

4 TXD

5 not used

6 S g GND

4

5

RXD

TXD

+5 V

10 feet [3.0 m] Maximum

L T D

L T D

M17

M17

ae od :

ae od :

R 1

R 1

ADE N CH NA

ADE N CH NA

EA - 6M W + e al umb r

EA - 6M W + e al umb r

MODEL A S6MLW

MODEL A S6MLW

NPUT:122 V . W

NPUT:122 V . W

I DCO T Q.

I DCO T Q.

81

15

9

Supply to Panel

1 A @ 12 24 VDC

(10 8 26 4 VDC)

+

–

GND

Equipment

Ground

Recommended

DC Supply Fuse

750 mA fast acting,

ADC p/n AGC 75

*Panel Powered from

AutomationDirect PLC via

Communications Cable

Panel Powered from a DC Power Source - Wiring Diagram

NOTE: Recommended DC power supply to power the C-more Micro Graphic Panel, AutomationDirect Part No.

PSP24-024S or PSP24-024C.

NOTE: When the 6” panel is powered through Port1 from a connected PLC or PC, the screen brightness is

diminished because the panel is running in Low-Power Mode. For full brightness, connect an external

12-24 VDC power source to the panel’s power connection. Low-Power Mode is intended for initial

programming. For full brightness, connect an external 12-24 VDC power source when the panel is installed

in its application.

EA1-MG6-USER-M Hardware User Manual, 1st Ed. Rev C, 09/10

1–14

Chapter 1: Getting Started

1

®

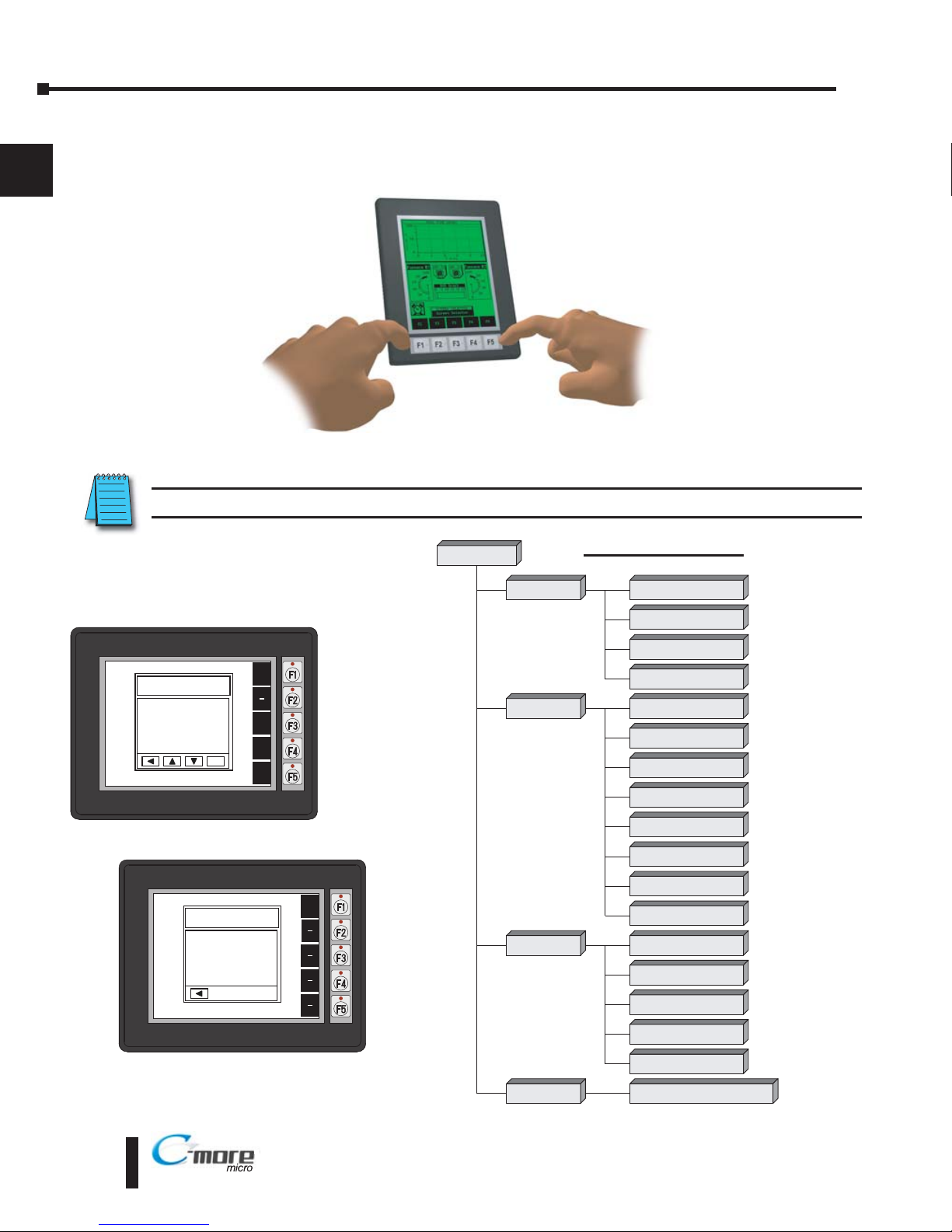

Step 8 – Accessing the C-more 6” Micro-Graphic Panel Setup Screens

To access the Setup Menu of the panel’s setup screens, press the the BAK [F1] and ENT [F5]

function keys simultaneously for three (3) seconds.

From the Setup Menu, information about the panel can be obtained, settings can be adjusted,

and panel functions can be tested.

NOTE: See Chapter 5: System Setup Screens for details on using the setup screen settings and functions.

BAK

1 Information >

2 Setting >

3 Test Menu >

4 Exit >

UP

DWN

ENT

ENT

SETUP MENU

BAK

Total

1835008 Bytes

Usage

26206 Bytes

Free

1808802 Bytes

MEMORY

Setup Menu

[pg 5 5]

1 Information

[pg 5 6]

1 Memory

[pg 5 6]

2 Setting

[pg 5 7]

1 LCD Contrast

[pg 5 7]

2 Backlight

[pg 5 8]

3 Beep

[pg 5 10]

4 Calibration

[pg 5 11]

5 Clear User Memory

[pg 5 12]

1 Serial Port1 Loop Back Test

[pg 5 15]

2

Ser al Port2 Loop Back Tes

t

[pg 5 16]

3 PLC Enquiry Test

[pg 5 17]

Do you want to exit from System Screen?

No[F1] / Yes[F5]

3 Test Menu

[pg 5 15]

4 Exit

[pg 5 18]

2 Protocol

[pg 5 6]

3 Extens ons

[pg 5 6]

4 Versions

[pg 5 6]

6 Reset to Factory Default

[pg 5 12]

7 Hourglass

[pg 5 13]

8 Rotation

[pg 5 14]

4 Buzzer Test

[pg 5 17]

5 Touch Panel Test

[pg 5 18]

Menu Flow Chart

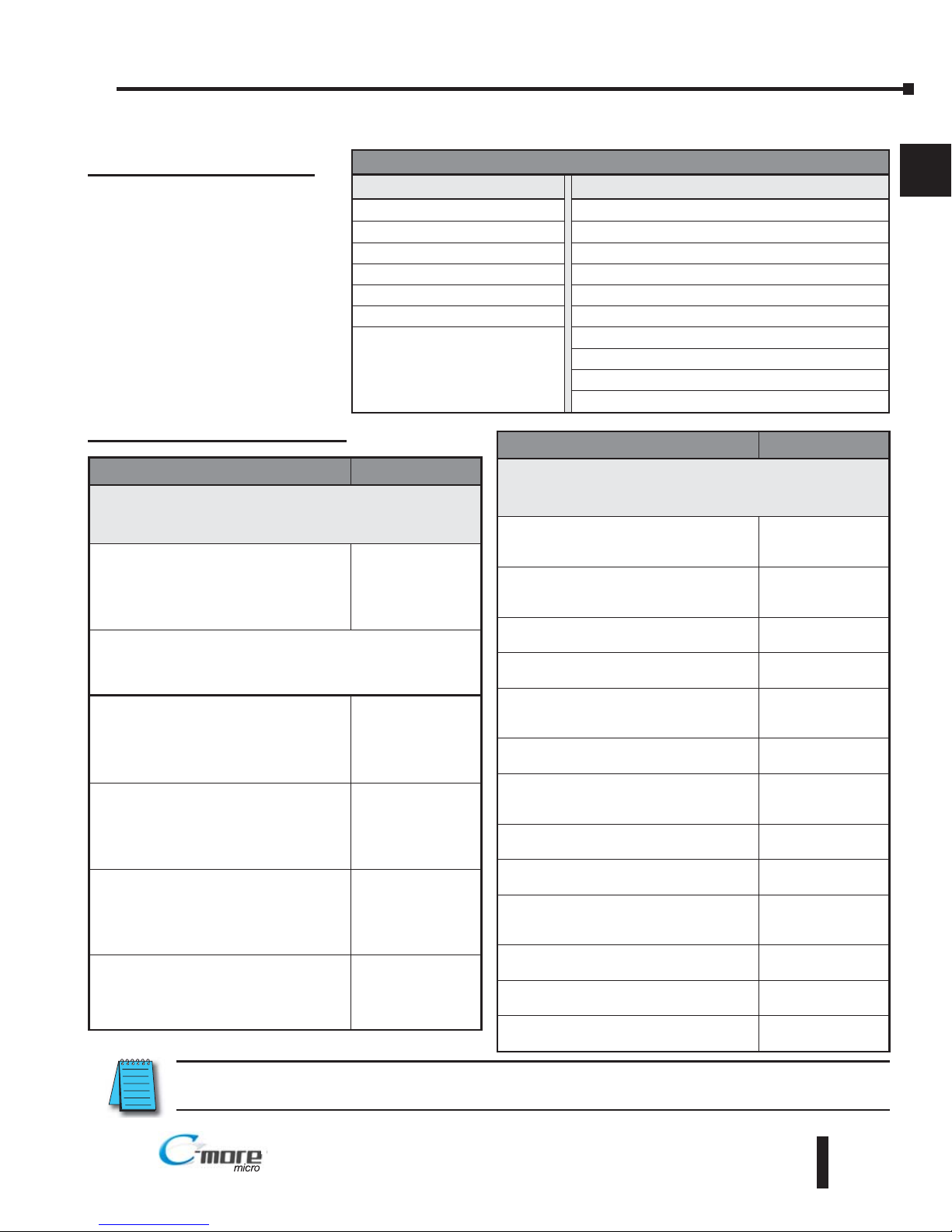

Step 9 – Choose C-more 6” Micro-Graphic Panel to PLC Protocol & Cables

Cable Description Cable Part No.

Cables used with serial Port1

AutomationDirect CLICK,

Direct

LOGIC

PLC RJ-12 port, DL05, DL06, DL105,

DL205, D3-350, D4-450 & H2-WinPLC

(RS-232C)

DV-1000CBL

Note: The PLC can provide 5 VDC through this cable. No

external 12-24 VDC souce is required, however,

screen brightness is diminished and the alarm beep

will not function.

Direct

LOGIC DL405 PLC 15-pin D-sub

port, DL405

(RS-232C)

D4-1000CBL

Direct

LOGIC (VGA Style) 15-pin port,

DL06, D2-250 (250-1), D2-260

(RS-232C)

Use with DV-1000CBL cable.

FA-15HD

Direct

LOGIC PLC 15-pin D-sub port,

DL405

(RS-232C).

FA-CABKIT

Direct

LOGIC PLC RJ-11 port, D3-340

(RS-232C).

OP-3CBL-1

EA1-MG6-USER-M Hardware User Manual, 1st Ed. Rev C, 09/10

1–15

Chapter 1: Getting Started

1

®

NOTE: See Chapter 6: PLC Communications for a detailed chart of PLC compatibility & cable connections.

Chapter 6 includes wiring diagrams for end user construction of certain cables.

Available purchased cables

Cable Description Cable Part No.

Cables used with serial Port2

AutomationDirect CLICK,

Direct

LOGIC PLC

RJ-12 port, DL05, DL06, DL105, DL205,

D3-350, D4-450 & H2-WinPLC (RS-232C)

EA-2CBL

Direct

LOGIC (VGA Style) 15-pin port,

DL06, D2-250 (250-1), D2-260

(RS-232C).

EA-2CBL-1

Direct

LOGIC PLC RJ-11 port, D3-340

(RS-232C).

EA-3CBL

Direct

LOGIC DL405 PLC 15-pin D-sub

port, DL405 (RS-232C).

EA-4CBL-1

Direct

LOGIC PLC 25-pin D-sub port,

DL405, D3-350, DL305 DCU and all DCM’s

(RS-232C).

EA-4CBL-2

Allen-Bradley MicroLogix 1000, 1100,

1200 & 1500 (RS-232C)

EA-MLOGIX-CBL

Allen-Bradley SLC 5-03/04/05,

ControlLogix, CompactLogix, FlexLogix

DF1 port (RS-232C)

EA-SLC-232-CBL

Allen-Bradley PLC-5 DF1 port

(RS-232C)

EA-PLC5-232-CBL

Allen-Bradley MicroLogix, SLC 5-01/02/03,

PLC5 DH485 port (RS-232C)

EA-DH485-CBL

GE 90/30, 90/70, Micro 90, Versamax

Micro (Port2) 15-pin D-sub port

(RS-422A)

EA-90-30-CBL

MITSUBISHI FX Series 25-pin port

(RS-422A)

EA-MITSU-CBL

MITSUBISHI FX Series 8-pin mini-DIN

(RS-422A)

EA-MITSU-CBL-1

OMRON Host Link (C200 Adapter, C500)

(RS-232C)

EA-OMRON-CBL

PLC Drivers

Serial - port1 or port2 Serial - port2 only

AutomationDirect CLICK Allen-Bradley DF1 Half Duplex

AutomationDirect K-sequence Allen-Bradley DF1 Full Duplex

AutomationDirect DirectNET Allen-Bradley PLC5 DF1

AutomationDirect Modbus Allen-Bradley DH485

Modicon Modbus RTU GE SNPX (90/30, 90/70, Micro 90, VersaMax Micro)

Entivity Modbus RTU Mitsubishi FX

Mitsubishi Q & QnA

Omron Host Link (C200 Adapter, C500)

Omron FINS Serial (CJ1, CS1)

Siemens PPI (S7-200 CPU)

Available PLC Protocols

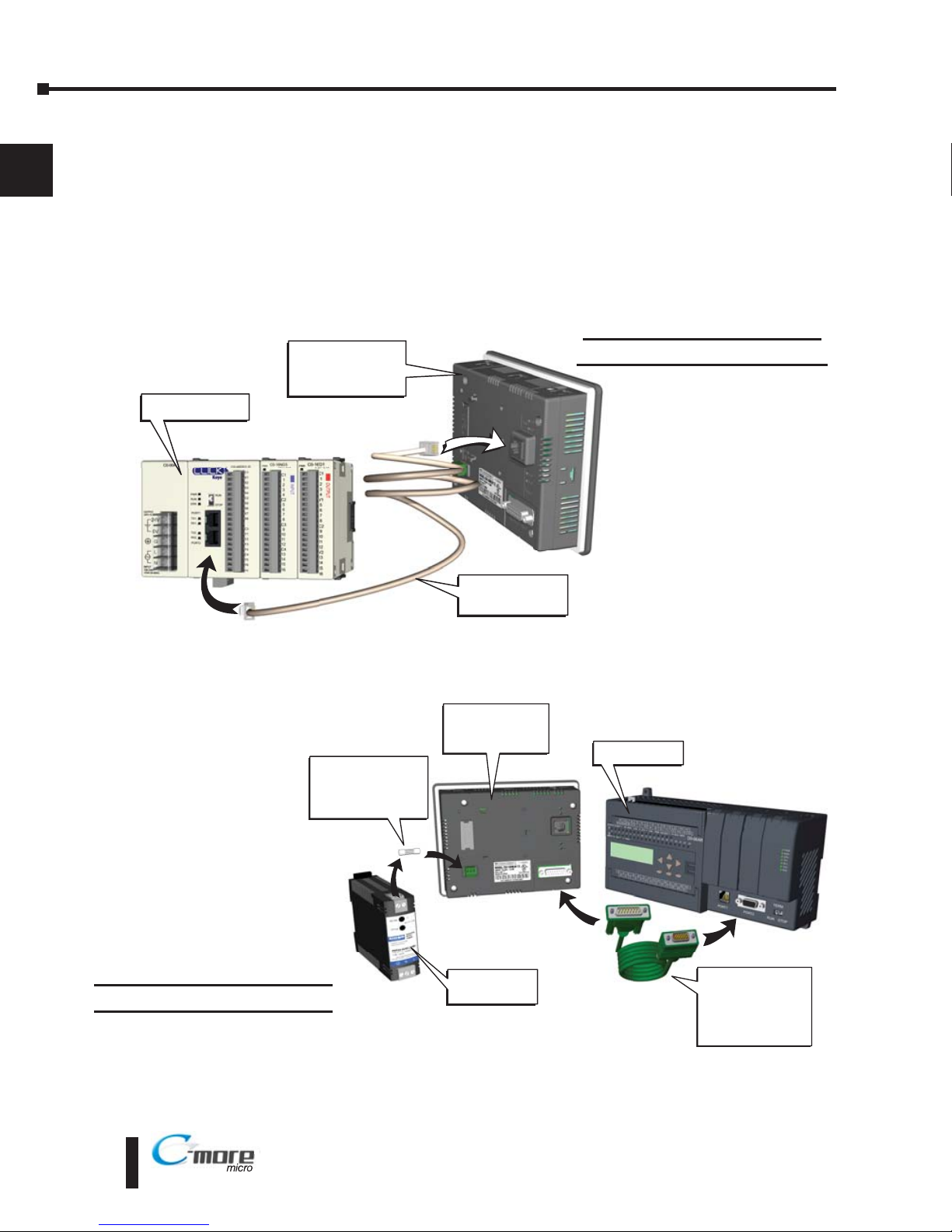

Step 10 – Connect C-more 6” Micro-Graphic Panel to PLC

Connect the serial communications cable between the C-more Micro-Graphic panel and the

PLC. The panel can be connected to the PLC via the panel’s built-in RJ12 serial

communications port (RS-232) or 15-pin serial communications port with either RS-232, RS422 or RS-485 communications.

EA1-MG6-USER-M Hardware User Manual, 1st Ed. Rev C, 09/10

1–16

Chapter 1: Getting Started

1

®

Port 1

Port 2

DV 1000CBL

serial cable

CLICK PLC

C-more 6 Inch

Micro-Graphic

Panel

Port

2

Port

2

C-more to

Direct LOGIC

VGA 15 pin port

serial cable

p/n EA 2CBL 1

DL-06 PLC

PSP-24-024S

Power Supply

Recommended

DC Supply Fuse

750 mA fast acting,

ADC p/n AGC-75

C-more 6 Inch

Micro-Graphic

Panel

Example of panel’s Port 1

connected to a CLICK PLC

Example of panel’s Port 2

connected to a DL06 PLC

Loading...

Loading...