Page 1

Chapter

Chapter

Chapter

GettinG Started

1

1

1

In This Chapter...

Introduction ...................................................................................................................1-2

The Purpose of This Manual �����������������������������������������������������������������������������������������1-2

Supplemental Manuals �������������������������������������������������������������������������������������������������1-2

Technical Support ��������������������������������������������������������������������������������������������������������1-2

Conventions Used ..........................................................................................................1-3

Key Topics for Each Chapter �����������������������������������������������������������������������������������������1-3

Product Overview ..........................................................................................................1-4

Quick Start Steps ...........................................................................................................1-5

Step 1 – Unpack and Inspect ����������������������������������������������������������������������������������������1-5

Step 2 – Install Optional Hardware Accessories �������������������������������������������������������������1-6

Step 3 – Become Familiar with Available Communication Ports ������������������������������������1-7

Step 4 – Install the Programming Software and Develop a Project �������������������������������1-8

Step 5 – Connect HMI to Computer ����������������������������������������������������������������������������1-9

Step 6 – Provide Power to the HMI ����������������������������������������������������������������������������1-10

Step 7 – Access the EA9-RHMI Setup Screens �������������������������������������������������������������1-13

Step 8 – Choose HMI to Device Cable������������������������������������������������������������������������1-14

Step 9 – Connect HMI to PLC ������������������������������������������������������������������������������������1-17

Page 2

Chapter 1 - Getting Started

Introduction

1

2

3

4

5

6

7

8

9

10

11

12

13

14

The Purpose of This Manual

Thank you for purchasing our C-more® human-machine interface (HMI) family of products.

This manual describes AutomationDirect.com’s C-more headless HMI, its specifications,

included components and available accessories and provides you with important information

for installation, connectivity and setup. The manual shows you how to install, wire and use

the product. It also helps you understand how to interface the HMI to other devices in a

control system.

This user manual contains important information for personnel who will install the HMI

and accessories and for the personnel who will be programming the HMI. If you understand

control systems that make use of operating interfaces such as the C-more RHMI, our user

manuals will provide all the information you need to get and keep your system up and

running.

Supplemental Manuals

If you are familiar with industrial control type devices, you may be able to get up and running

with just the aide of the Quick Start Guide that is included with each HMI. You should also

refer to the On-line help that is available in the C-more programming software for more

information about programming the panel.

Technical Support

We strive to make our manuals the best in the industry. We rely on your feedback to let

us know if we are reaching our goal. If you cannot find the solution to your particular

application, or, if for any reason you need technical assistance, please call us at:

770–844–4200

Our technical support group will work with you to answer your questions. They are available

Monday through Friday from 9:00 A.M. to 6:00 P.M. Eastern Time. We also encourage you

to visit our web site where you can find technical and non-technical information about our

products and our company.

http://c-more.automationdirect.com

A

B

C

D

1-2

®

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

Page 3

Conventions Used

Chapter 1 - Getting Started

1

When you see the “notepad” icon in the left-hand margin, the paragraph to its immediate right will be a special note.

The word NOTE: in boldface will mark the beginning of the text.

When you see the “exclamation mark” icon in the left-hand margin, the paragraph to its immediate

right will be a warning. This information could prevent injury, loss of property, or even death (in

extreme cases). The word Warning: will mark the beginning of the text.

Key Topics for Each Chapter

The beginning of each chapter will list the key topics

that can be found in that chapter.

Getting Started

In This Chapter...

General Information

.................................................................1-2

...........................................................................1-4Specifications

CHAPTER

2

3

4

5

6

7

8

9

1

10

11

12

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

13

14

A

B

C

D

®

1-3

Page 4

Chapter 1 - Getting Started

Product Overview

1

2

3

4

5

6

7

8

9

10

11

12

13

Some of the features designed into the product to provide excellent hardware and software are

listed below.

• Drivers for ELO Single Touch Resistive/SAW, EETI eGalax Single Touch Resistive and singletouch Protected Capacitive touch screens that can be used with many touch capable industrial touch

monitors

• Plenty of memory and methods to get data in/out of the panel

• Overlapping active devices on the screen

• 65,536 colors for enhanced graphics

• HDMI Video Output supporting several resolutions including 720p (60Hz) and Audio

• Built-in FTP client/server, E-mail client, and Web server

• User configurable LED on the front of the unit

• Built-in project simulation; test on PC while developing

• Ethernet 10/100 Base-T communications

• 15-pin serial port with RS-232, RS422/485

• 3-wire terminal block RS-485 port

• Programming via USB or Ethernet

• Animation of bitmaps and objects

• Thousands of built-in symbols and Windows fonts

• PID face plate, trending, alarming and a recipe database

• Trend Data Logging

• Event Manager to trigger actions based on assigned state changes, schedules, PLC tag names, etc. set

up in a database environment. The event can also trigger a sound byte, initiate a screen capture, send

a data file (FTP), send an E-mail, etc.

• Internet Remote Access

14

A

B

C

D

1-4

®

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

Page 5

Quick Start Steps

Chapter 1 - Getting Started

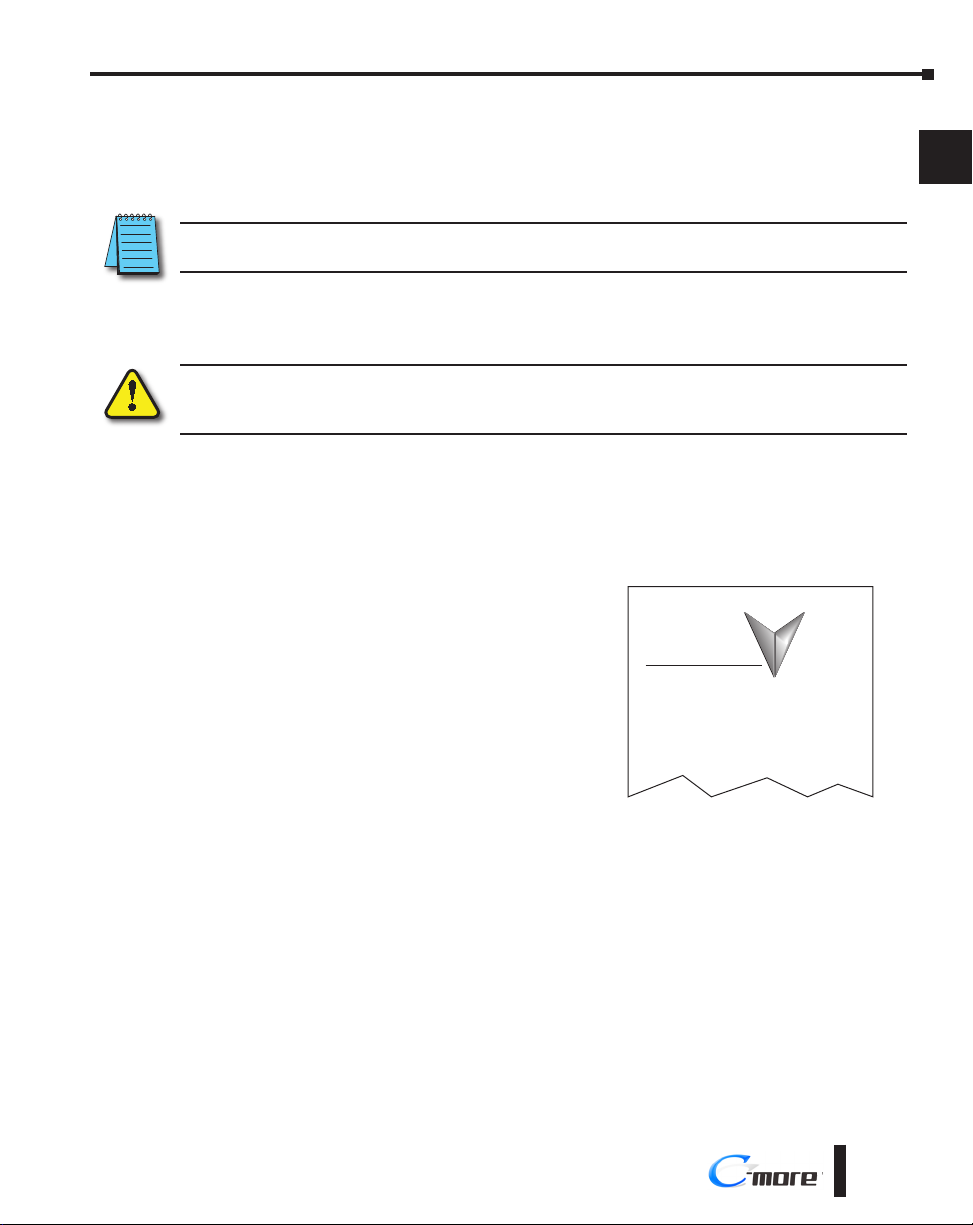

Step 1 – Unpack and Inspect

a.) Unpack the C-more RHMI from its shipping carton. A Quick Start Guide is included in

the carton.

b.) Unpack any accessories that have been ordered, such as programming cable,

communications cable, etc.

c.) Inspect all equipment for completeness. If anything is missing or damaged, immediately

call the AutomationDirect® returns department @ 1-800-633-0405.

Optional Accessories

1

2

3

4

5

6

7

8

9

10

11

12

Communication

Expansion Module

EA-ECOM

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

SD Memory Card

EA-SD-CARD

USB Pen Drive

USB-FLASH

DSUB Port Adapter

EA-COMCON-3A

®

13

14

A

B

C

D

1-5

Page 6

Chapter 1 - Getting Started

Step 2 – Install Optional Hardware Accessories

1

2

3

4

5

6

7

8

9

10

11

12

EA-SD-CARD

USB-FLASH

EA-ECOM

Ethernet Communication

Module

C-more EA9-RHMI

EA-COMCON-3A

13

14

A

B

C

D

1-6

®

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

Page 7

Chapter 1 - Getting Started

Step 3 – Become Familiar with Available Communication Ports

Pin Signal

1 Frame GND

TXD (232C)

2

RXD (232C)

3

N.C.

4

5 Logic GND

Port 2

Serial Communication

RS-485

Logic Ground

–

+

EA9-3TB

Port 1

PLC Serial Communications

RS-232C / RS-422 / RS-485

8 1

15 9

Pin Signal Pin Signal

6 LE (for DH485)

CTS (232C)

7

RTS (232C)

8

RXD+ (422/485)

9

10 RXD– (422/485)

11 TXD+ (422/485)

TXD– (422/485)

12

Term. Resistor

13

N.C.

14

15 N.C.

HDMI Port Video Out

SD Card Slot

Expansion Port

(Right Side)

USB Port - Type A

USB Device Options

Pin Signal

4

1 Vbus

3

21

Ethernet 10/100 Base-T

PLC Communications,

Programming/Download

Pin Signal

1 TD+

2

3

4

2

3

4

USB Port - Type B

Programming

Pin Signal

1 N.C.

2

3

4

TD–

RD+

do not use

D–

D+

GND

ShieldSHELL

D–

D+

GND

ShieldShell

Pin Signal

2

3

1 8

5 Do not use

RD–

6

N.C.

7

N.C.

8

1

2

3

4

5

6

7

1

4

8

9

10

11

12

NOTE: See Chapter 6: PLC Communications for additional details on the available communication ports, protocols

and cables.

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

®

13

14

A

B

C

D

1-7

Page 8

Chapter 1 - Getting Started

Step 4 – Install the Programming Software and Develop a Project

1

2

3

4

5

6

7

8

9

10

11

Download the latest version of the C-more Programming Software, p/n EA9-PGMSW,

from the Automationdirect website. Alternately, if the C-more Programming Software CD is

available, you may install from the software CD. Refer to the AutomationDirect website for

current minimum system requirements for installation.

For software download installation, follow the screen prompts to download and install the

C-more Programming Software.

For CD installation, insert the supplied CD into the PC’s CD drive and navigate to the CD

drive location on the PC. Double-click on EA_Setup.exe and follow the instructions. If you

need assistance during the software installation, call the AutomationDirect Technical Support

team @ 770-844-4200.

NOTES: Regarding Ethernet access to a C-more panel.

If you intend to take advantage of the methods of remote access to the panel, including the web server, PC remote

access, FTP, iOS or Android app, you need to consider the security exposure in order to minimize the risks to your

process and your C-more panel.

Security measures may include password protection, changing the ports exposed on your network, including a VPN

in your network, and other methods. Security should always be carefully evaluated for each installation. Refer to

Appendix C - Security Considerations for Control Systems Networks.

12

13

14

A

B

C

D

1-8

®

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

Page 9

Step 5 – Connect HMI to Computer

• Connect a USB Programming Cable, such as p/n USB-CBL-AB15, from a USB type A port on the

PC to the USB type B programming port on the C-more HMI.

• Or connect the C-more EA9-RHMI and PC together either directly or via an Ethernet switch and

CAT5 Ethernet cables

PC

Chapter 1 - Getting Started

C-more

EA9-RHMI

1

2

3

PC

PC

USB

Port

Stride™

Ethernet Switch

10/100 Base-T

(such as SE2-SW5U)

Ethernet

Port

Ethernet

Port

USB-CBL-ABxx

USB Cable

Ethernet CAT5

Cable

Ethernet CAT5

Cable

USB

Port

C-more

EA9-RHMI

Auto MDI / MDI-X

Ethernet Port

C-more

EA9-RHMI

4

5

6

7

8

9

10

11

12

13

14

A

Auto MDI / MDI-X

Ethernet Port

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

B

C

D

®

1-9

Page 10

Chapter 1 - Getting Started

Step 6 – Provide Power to the HMI

• Connect a dedicated 12-24 VDC Class 2 power supply to the DC connector on the front of the

1

2

3

C-more EA9-RHMI. Make sure to connect the ground terminal to a proper equipment ground.

• Then turn on the power source and check the LED status indicators on the front of the C-more

EA9-RHMI for proper indication (see next page).

NOTE: A dedicated power supply is recommended. If the power supply also feeds inductive loads such as

solenoids or relays, the transients caused by these loads can affect the operation of or cause damage to HMI

components.

4

5

6

7

8

9

10

11

12

13

14

A

DC Power Wiring

Recommended Fuse

Rating ADC part number

2.5 A MDL2-5

Equipment

Ground

0V

12- 24 VDC

Tightening Torque

Power supply cable torque 32-35 oz-in (0.22-0.25 Nm)

Warning: Use 60/75 °C copper conductors only.

C0-4TB

Terminal Block

B

C

D

1-10

®

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

Page 11

Step 6 – Provide Power to the HMI (cont’d)

C-more LED Status Indicators

System Status LEDs

- CPU Green/Red/Orange

- RUN Green/Red/Orange

- USER Green/Red/Orange

Reset Button

Chapter 1 - Getting Started

System Status LEDs

- PWR Green

- ERR Red

SD Status Green

1

2

3

RUN / STOP Switch

Receive Green

Port 2 Serial Port

Transmit Green

Receive Green

Port 1 Serial Port

Transmit Green

System Status LEDs

State

LED

Status Loading OS

CPU Running Normal

Project Loaded and Running

No User Project

Password Required

Errors Power Loss Detection

Memory Error

OS Error

Watch Dog Time Out

No Log Storage Found

General Error*

Warning*

Mode Recovery Mode

Safe Mode

*Note - See Chapter 8 - Troubleshooting for General Error and Warning explanations.

CPU RUN ERR

Blinking Green (0.5s) OFF OFF

Green – OFF

– Green –

– Orange –

– Blinking Orange (0.5s) Blinking Red (0.5s)

Blinking Orange (0.2s) – –

Red OFF Red

Blinking Orange (0.5s) OFF Red

Blinking Red (0.5s) – Red

– Blinking Orange (0.5s) Blinking Red (0.5s)

– Red (0.5s) Blinking Red (0.5s)

– Blinking Orange (0.5s) Blinking Red (0.5s)

Blinking Orange (0.5s) OFF OFF

Orange OFF Red

USB Status Green

4

5

6

7

8

9

10

11

12

13

14

A

B

C

D

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

®

1-11

Page 12

Chapter 1 - Getting Started

EA9-RHMI Beep

1

2

3

4

5

6

Function Beep Pattern

Boot 1-long, 2-short

Boot Error* 3-long

HDMI Connected 3-short

Reset to Factory Defaults 14 short beeps progressively closer together followed by 1-long beep.

Blink Screen 5-long

*Boot Errors

Multiple Projects

Write Protected SD Card

No Log Storage Found

System Screen (RUN/STOP switch in STOP position)

Password Protected

Beep Functions

7

8

9

10

11

12

13

14

A

B

C

D

Reset Button

Reset Button

Push Action Behavior Note

Push for <15 seconds Reboot the EA9-RHMI

Push for >15 seconds Reset to factory default The project is cleared and all settings are initialized.

While holding down the

reset button, power on the

EA9-RHMI and continue

holding the button for

>15 seconds

RUN / STOP switch

Position Behavior Note

RUN

STOP

Power on the EA9-RHMI

while in the STOP position

System recovery mode

RUN / STOP Switch

Project will run if present and the

RUN LED will be green

The project and any logging

stops and the System Screen is

displayed.

The System Screen is displayed A System Screen password is ignored.

The CPU LED will blink ORANGE. See “No System

Found” in Chapter 8 - Troubleshooting

If no project is loaded in the HMI, the

message “No User Program” will be displayed

on a connected display. The RUN LED will be

orange.

If a password has been set up for the System

Screen, the RUN LED will blink orange.

User Defined LED

The user defined LED on the EA9-RHMI can be controlled from the project to illuminate

red, green or orange. It can also be configured to blink these colors. Refer to the online help

file provided with the programming software for details.

1-12

®

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

Page 13

Step 7 – Access the EA9-RHMI Setup Screens

• Access the Main Menu of the EA9-RHMI System Setup Screens by changing the selector switch on

the front of the unit to STOP.

• Adjust the time and date for the panel by pressing the Setting button on the Main Menu. Then

press the Adjust Clock button on the Setting screen.

• Use the right-pointing arrows for the time or date display to select the unit to change. Use the up

and down arrows to increment or decrement the value for the selected unit.

• Press OK when done to accept the changes to the time and date in the HMI or press Cancel to exit

the Adjust Clock setup screen without making any changes.

• Press the Main Menu button on the Setting screen and then the Exit button on the Main Menu

screen to return to the application screen.

• Change the selector switch on the front of the unit to RUN.

Chapter 1 - Getting Started

1

2

3

4

5

6

7

8

9

NOTE: For more information on EA9-RHMI setup screens, see Chapter 5 - System Setup Screens.

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

®

10

11

12

13

14

A

B

C

D

1-13

Page 14

Chapter 1 - Getting Started

Step 8 – Choose HMI to Device Cable

The table below shows the PLCs, controllers and protocols supported by the EA9-RHMI.

1

2

Model Protocols

Ensure your controller and protocol are supported.

3

4

5

6

7

8

9

10

AutomationDirect

11

12

13

14

A

B

C

D

PLC Protocol Table

Productivity Series

Do-more

(BRX)

CLICK

DL05/DL06

DL105 all K-Sequence

DL205

DL305

DL405

H2-WinPLC (Think & Do) Live V5.2 or later and Studio any version Think & Do Modbus RTU (serial port)

H2-WinPLC (Think & Do) Live V5.5.1 or later and Studio V7.2.1 or later Think & Do Modbus TCP/IP (Ethernet port)

GS Drives

SOLO Temperature Controllers (models with serial communications) SOLO Temperature Controller

all

all

H0-ECOM/H0-ECOM100

D2-230 K-Sequence

D2-240

D2-250/D2-250-1/D2-260/D2-262

D2-240/D2-250-1/D2-260

Using DCM

H2-ECOM/H2-ECOM100

D3-330/330P (Requires the use of a Data Communications Unit)

D3-340

D3-350

D3-350 DCM

D4-430

D4-440

D4-450/D4-454

All with DCM

H4-ECOM/H4-ECOM100

Productivity Serial

Productivity Ethernet

Do-more Serial

Do-more Ethernet

Modbus (CLICK addressing)

Modbus TCP (CLICK addressing)

K-Sequence

Direct NET

Modbus (Koyo addressing)

Direct LOGIC Ethernet

K-Sequence

Direct NET

K-Sequence

Direct NET

Modbus (Koyo addressing)

Direct NET

Modbus (Koyo addressing)

Direct LOGIC Ethernet

Direct NET

Direct NET

K-Sequence

Direct NET

Modbus (Koyo addressing)

Direct NET

Modbus (Koyo addressing)

K-Sequence

Direct NET

K-Sequence

Direct NET

K-Sequence

Direct NET

Modbus (Koyo addressing)

Direct NET

Modbus (Koyo addressing)

Direct LOGIC Ethernet

GS Drives Serial

GS Drives TCP/IP (GS-EDRV)

1-14

®

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

Page 15

Chapter 1 - Getting Started

Step 8 – Choose HMI to Device Cable (cont’d)

Model Protocols

MicroLogix 1000, 1100, 1200, 1400, 1500, SLC 5-01/02/03 DH485/AIC/AIC+

MicroLogix 1000, 1100, 1200, 1400 and 1500

ControlLogix™, CompactLogix™, FlexLogix™

PLC-5 DF1 Full Duplex

ControlLogix, CompactLogix, FlexLogix - Tag Based DF1 Half Duplex; DF1 Full Duplex

Allen-Bradley

Modbus RTU

Modbus TCP/IP

GE

Mitsubishi

Modicon

Omron

Siemens

ControlLogix, CompactLogix, FlexLogix - Generic I/O Messaging EtherNet/IP Server

ControlLogix, CompactLogix, FlexLogix - Tag Based

MicroLogix 1100, 1400 and SLC 5/05, via native Ethernet port

MicroLogix 1000, 1100, 1200, 1400, 1500, SLC 5-03/04/05, all via ENI adapter

Micro 800 Series

Micro 800 Series - Tag Based

Modbus RTU devices Modbus RTU

Modbus TCP/IP devices Modbus TCP/IP

90/30, 90/70, Micro 90, VersaMax Micro SNPX

90/30, Rx3i SRTP Ethernet

FX Series FX Direct

Q02, Q02H, Q06H, Q12H, Q25H Q CPU

Q, QnA Serial QnA Serial

Q, QnA Ethernet QnA Ethernet

984 CPU, Quantum 113 CPU, AEG Modicon Micro Series 110 CPU: 311-xx, 411-xx,

512-xx, 612-xx

Other devices using Modicon Modbus addressing

C200 Adapter, C500 Host Link

CJ1/CS1 Serial

CJ1/CS1 Ethernet

S7-200 CPU, RS-485 Serial PPI

S7-200 CPU, S7-300 CPU, S7-400, S7-1200 CPU

Ethernet

PLC Protocol Table (cont’d)

DF1 Half Duplex; DF1 Full DuplexSLC 5-03/04/05

EtherNet/IP Client

Modbus RTU

Modbus TCP

DF1 Full Duplex

EtherNet/IP Client

Modbus RTU

Modbus RTU

TUModbus TCP/IP

FINS

Ethernet ISO over TCP

1

2

3

4

5

6

7

8

9

10

11

12

13

14

A

B

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

®

C

D

1-15

Page 16

Chapter 1 - Getting Started

Step 8 – Choose HMI to Device Cable (cont’d)

Available cables to connect from PLC to C-more serial Port 1

1

2

To use Serial communication through Port 1 of the EA9-RHMI, consult the chart below for

the proper cable. See Chapter 6: PLC Communications for wiring diagrams of additional user

contructed cables.

3

4

5

6

7

8

9

10

11

12

13

Cable

Description

Communication cable, 15-pin D-shell male to 6-pin RJ12, 9.8ft/3m cable length. For use with

C-more or C-more Micro panel and AutomationDirect PLCs with RJ12 ports.

Communication cable, 15-pin D-shell male to 15-pin D-sub HD15 male, 3m/9.8ft cable length.

For use with C-more or C-more Micro panel and a DL06, D2-250(-1), D2-260 or D2-262 (bottom

port) CPU.

Communication cable, 15-pin D-shell male to 6-pin RJ11, 3m/9.8ft cable length. For use with

C-more or C-more Micro panel and a D3-340 CPU top or bottom port.

Communication cable, 15-pin D-shell male to 15-pin D-shell male, 3m/9.8ft cable length. For use

with C-more or C-more Micro panel and a DL405 (top port) CPU.

Communication cable, 15-pin D-shell male to 25-pin D-shell male, 3m/9.8ft cable length. For

use with C-more or C-more Micro panel and a D2-DCM, D3-232-DCU, D3-350 (bottom port) or

DL405 (bottom port) CPU.

Communication cable, 15-pin D-shell male to 8-pin mini DIN male, 3m/9.8ft cable length. For use

with C-more or C-more Micro panel and an Allen-Bradley Micrologix CPU.

Communication cable, 15-pin D-shell male to 9-pin D-shell female, 3m/9.8ft cable length. For use

with C-more or C-more Micro panel and an Allen-Bradley SLC 5/03, 5/04 or 5/05 CPU with DF-1

port.

Communication cable, 15-pin D-shell male to 25-pin D-shell male, 3m/9.8ft cable length. For use

with C-more or C-more Micro panel and an Allen-Bradley PLC-5 CPU with a DF1 port.

Communication cable, 15-pin D-shell male to 6-pin RJ45, 3m/9.8ft cable length. For use with

C-more or C-more Micro panel and an Allen-Bradley SLC 5/01, 5/02 or 5/03 CPU with a DH485

port cable.

Communication cable, 15-pin D-shell male to 15-pin D-shell male, 3m/9.8ft cable length. For use

with C-more or C-more Micro and GE Fanuc Series 90/30 or 90/70 serial port.

Communication cable, 15-pin D-shell male to 25-pin D-shell male, 3m/9.8ft cable length. For use

with C-more or C-more Micro panel and a Mitsubishi FX Series CPU.

Communication cable, 15-pin D-shell male to 8-pin mini DIN male, 3m/9.8ft cable length. For use

with C-more or C-more Micro panel and a Mitsubishi FX Series CPU.

Communication cable, 15-pin D-shell male to 25-pin D-shell male, 3m/9.8ft cable length. For use

with C-more or C-more Micro panel and an Omron C200 or C500 CPU.

Cable

Part Number

EA-2CBL

EA-2CBL-1

EA-3CBL

EA-4CBL-1

EA-4CBL-2

EA-MLOGIX-CBL

EA-SLC-232-CBL

EA-PLC5-232-CBL

EA-DH485-CBL

EA-90-30-CBL

EA-MITSU-CBL

EA-MITSU-CBL-1

EA-OMRON-CBL

14

A

B

C

D

1-16

NOTE: The above list of pre-made communications cables may be purchased. See Chapter 6: PLC

Communications for wiring diagrams of additional user constructed cables. Chapter 6 also includes wiring diagrams

for the pre-made cables.

Pre-made cable

examples

®

EA-2CBL

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

EA-2CBL-1

Page 17

Chapter 1 - Getting Started

Step 9 – Connect HMI to PLC

• Connect the serial communications cable between the C-more EA9-RHMI and the PLC

• Or connect the C-more EA9-RHMI and PLC together either directly or via an Ethernet switch and

CAT5 Ethernet cables.

For further information on setting up communications between the EA9-RHMI and a PLC, see the

C-more programming help file topic CM129: Creating a New Project.

Serial

C-more

DL-06 PLC

EA9-RHMI

1

2

3

4

Port 2

Ethernet via Switch

CLICK PLC

Ethernet CAT5

Cable

Ethernet

CLICK PLC

Serial Port

EA-2CBL-1

Stride™

Ethernet Switch

10/100 Base-T

(such as SE2-SW5U)

C-more

EA9-RHMI

EA9-RHMI

Auto MDI / MDI-X

Ethernet Port

C-more

5

6

7

8

9

10

11

12

13

14

A

Ethernet CAT5

Cable

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

Auto MDI / MDI-X

Ethernet Port

®

B

C

D

1-17

Page 18

Loading...

Loading...