Page 1

Chapter

Chapter

Chapter

SyStem Setup ScreenS

5

5

5

In This Chapter...

Introduction ...................................................................................................................5-2

Accessing the System Setup Screens ............................................................................5-3

With no project loaded ������������������������������������������������������������������������������������������������5-3

With project loaded������������������������������������������������������������������������������������������������������5-4

Using RHMI USB Remote ����������������������������������������������������������������������������������������������5-5

System Setup Screens – Enable Password in Software ................................................5-7

System Setup Screens Flowchart ................................................................................5-13

Main Menu...................................................................................................................5-14

Information Menu .......................................................................................................5-15

Setting Menu ...............................................................................................................5-19

Test Menu ....................................................................................................................5-25

Memory Menu .............................................................................................................5-35

Page 2

Chapter 5 - System Setup Screens

Introduction

1

2

3

4

5

6

7

8

9

10

11

The C-more EA9-RHMI includes a series of built-in System Setup Screens that allow

the user to view detailed information about the HMI; adjust certain features; configure

communications; test various functions of the HMI; backup and restore firmware, recipe, log

and project memory; clear memory and reset all values and conditions back to the original

factory defaults.

The four Main Menu selections are:

Information

The information tabs display details about the HMI model; the HMI’s

name; version information for the hardware, boot loader and firmware;

clock source, and beeper status. Other tabs display details on the

HMI’s internal memory and the status of any external memory devices.

Communication port details are available in this area, as well as an error log to help in

troubleshooting the system

Setting

This is the area for (1) making adjustments to the internal clock,

(2) setting the IP addresses (3) adjusting (calibrating) a connected touch

screen, (4) enabling or disabling the internal beep, and (5) enabling or

disabling a mouse pointer.

Test Menu

From this sub menu, the user can (1) test the a connected touch

screen, (2) test a connected display, (3) test the user LED (4) test the

communication ports, and (5) test both the internal beeper. A WAV

sound file is system provided for the audio output test.

12

13

14

A

B

C

D

5-2

Memory

Select the Memory menu item to either backup or restore your project,

log data, recipe data and/or system memory. Selections can be made to

backup to optional SD card memory or USB pen drive memory. The

menu selections also give the user the ability to clear the memory, and

there is also a selection to reset all of the HMI settings back to the original factory defaults.

®

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

Page 3

Accessing the System Setup Screens

There are three ways to access the System Setup Screens in the EA9-RHMI.

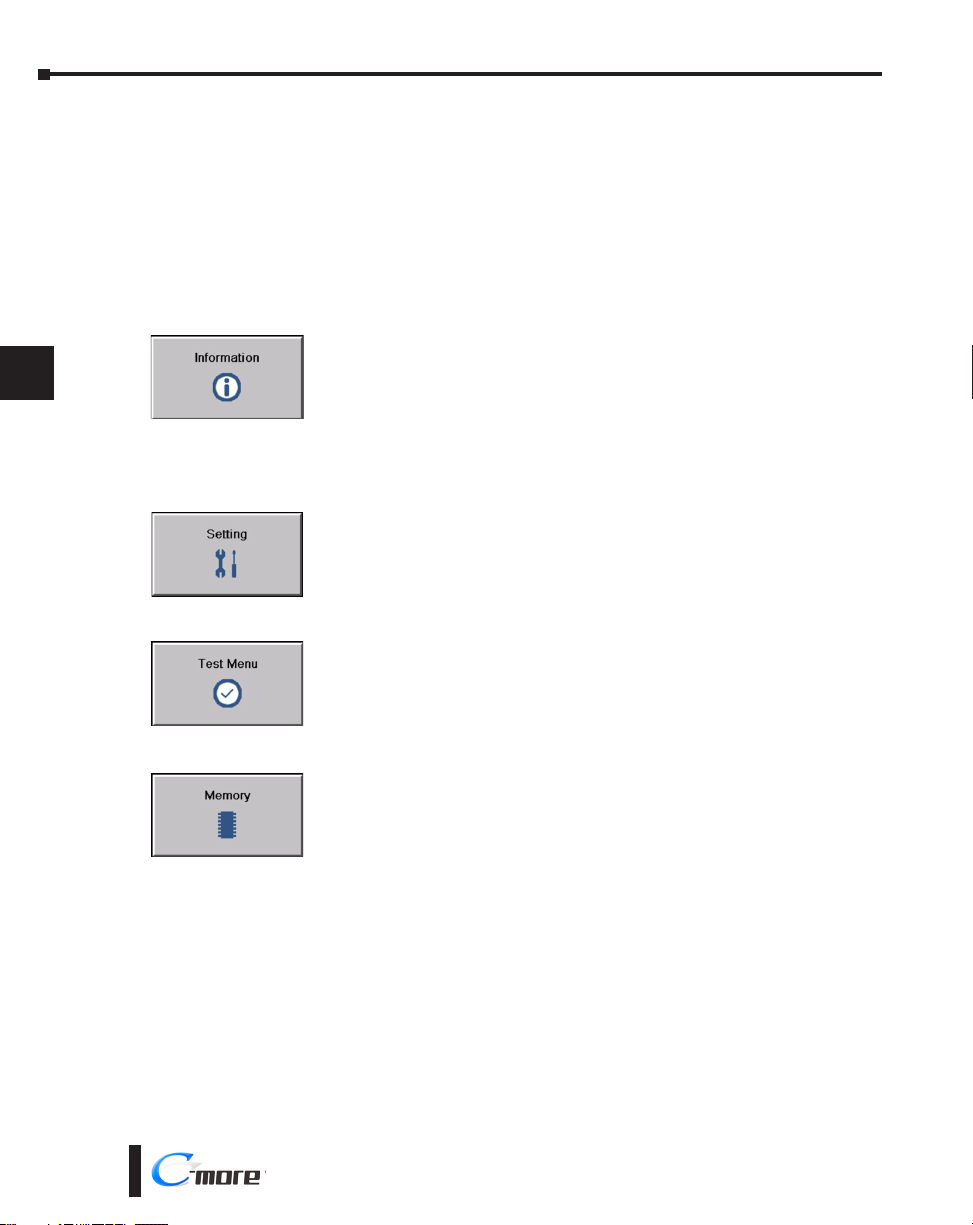

1) On the HMI by moving the RUN/STOP switch to the STOP position

2) From a connected compatible touch screen using the Key Button Object

3) From the C-more Software and using the RHMI USB Remote utility

With no project loaded

To access the Main Menu of the HMI System Setup Screens prior to downloading a project,

move the RUN/STOP switch to the STOP position as shown below. If a display is attached

to the EA9-RHMI, the Main Menu will be displayed.

Chapter 5 - System Setup Screens

1

2

3

4

5

6

7

8

9

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

10

11

12

13

14

A

B

C

D

®

5-3

Page 4

Chapter 5 - System Setup Screens

With project loaded

To access the Main Menu of the EA9-RHMI System Setup Screens with a project loaded into

1

memory, move the RUN/STOP switch to the STOP position.

2

3

4

5

6

7

8

9

10

11

12

13

14

A

B

C

If the RUN/STOP Switch is not accessible, a Key Button Object can be added to a screen

in the C-more HMI project to access the System Screens. See the C-more Programming

Software Help File Topic, “Key Button Object” for more information.

If the Key Button is used and no system screen password is enabled, the following

WARNING dialog box will appear on the connected screen:

• Pressing OK will display the system setup screen.

See the WARNING below!

System Screen Called

Activating System Screen will stop the

WARNING: This will STOP the PLC driver and therefore all communications between the EA9-RHMI

and PLC will cease. In addition, moving the RUN / STOP switch to the STOP position does not

display this warning. This is why it is strongly recommended that the password system tag “SYS

SYSTEMSCREENPW” be enabled to add a safeguard step in accessing the system setup screens. See

the next section for an overview of how to set the System Tags in the Event Manager Database.

Panel Run Mode.

Do you want to continue?

CancelOK

• Pressing Cancel will take you back to the project screen.

• Communication with the PLC is active while the

Warning is displayed.

• The dialog box will close if no action is taken for 60

seconds.

• The dialog box will not display if the HMI does not have

a project loaded.

• The dialog box will display after a valid password is

entered if the System Screen password is enabled.

D

5-4

®

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

Page 5

Chapter 5 - System Setup Screens

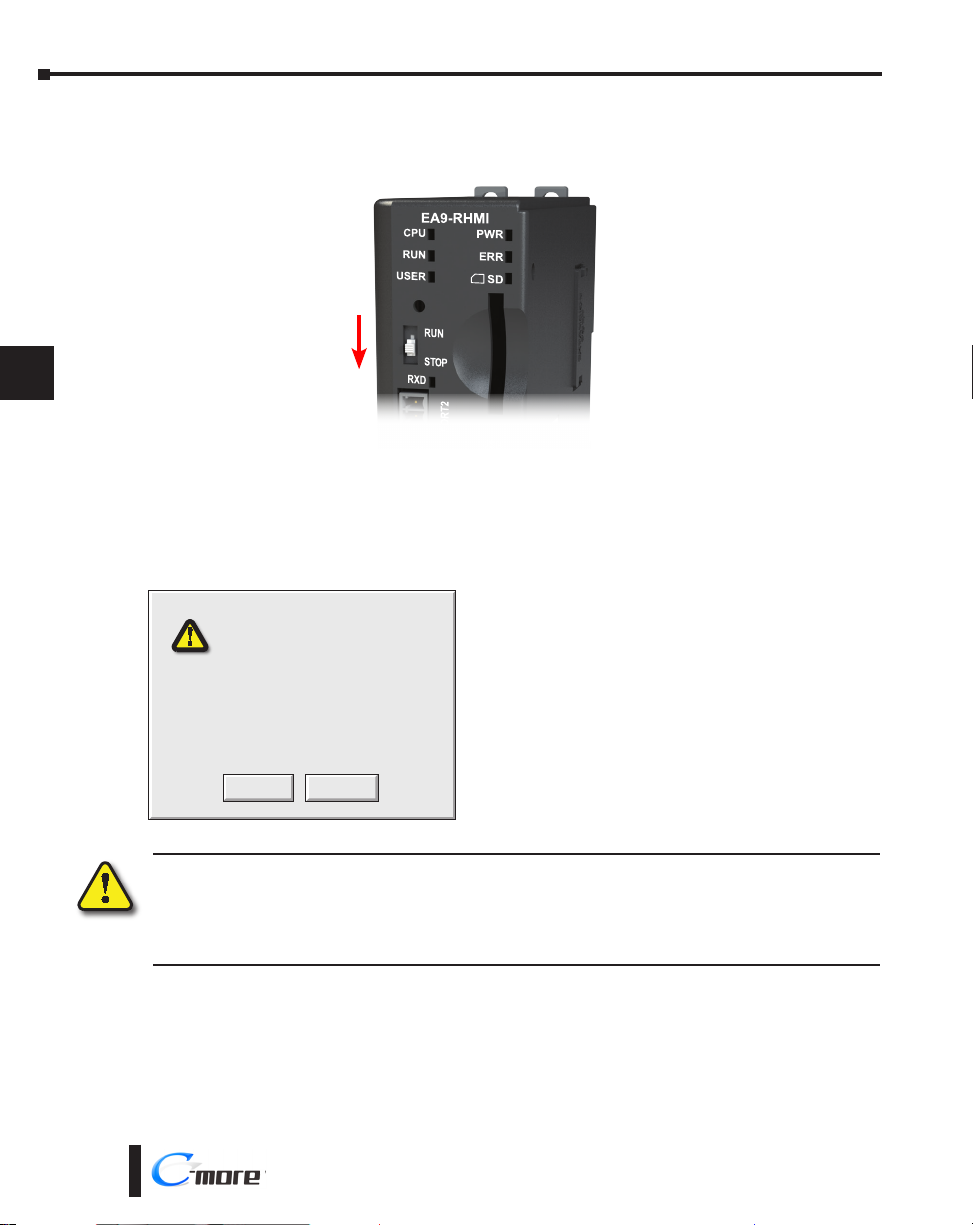

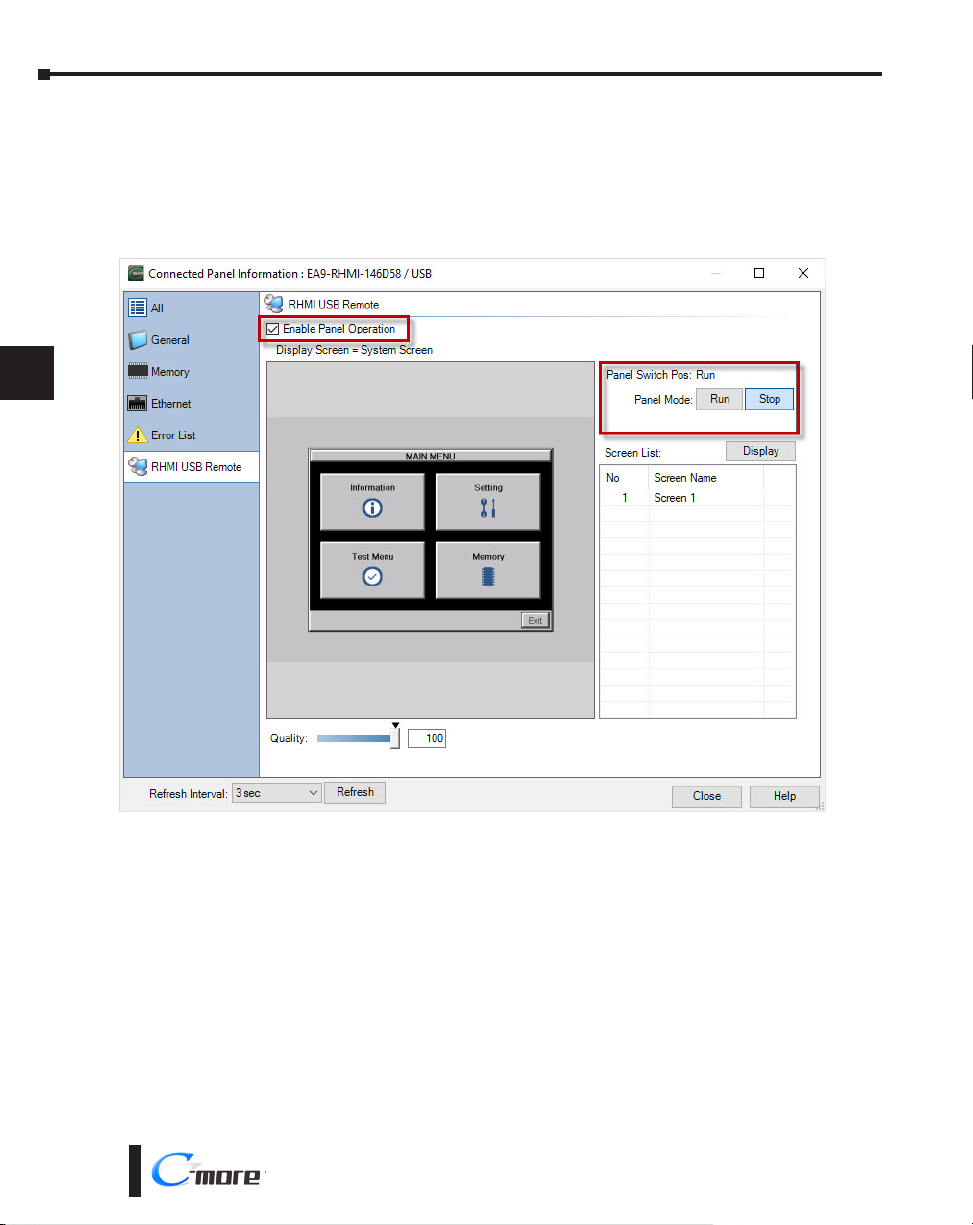

Using RHMI USB Remote

Another option for seeing the System Screens is through a PC connected by USB to the

EA9-RHMI.

In the C-more programming software, double click Panel Information in the Panel tab on the

navigation window as shown below or select Panel Information in the Panel menu.

1

2

3

4

5

6

7

8

Select RHMI USB Remote. The RHMI USB Remote displays the same screen that is shown

on a connected HMI monitor.

NOTE: The RHMI USB Remote selection is only available if the panel is connected to the PC by a USB cable.

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

®

5-5

9

10

11

12

13

14

A

B

C

D

Page 6

Chapter 5 - System Setup Screens

Select Enable Panel Operation. This allows the screens to be clicked with a mouse and

operated as if you were touching a touch screen connected to the HMI.

1

2

If the HMI’s RUN/STOP Switch is in the RUN position, you can select STOP under Panel

Switch Position to see the System Screen. If the Switch is in the STOP position already, the

System Screen will already be displayed.

For more information see the Help File topic Panel Tab - Panel Information.

3

4

5

6

7

8

9

10

11

12

13

14

A

B

C

D

5-6

®

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

Page 7

Chapter 5 - System Setup Screens

System Setup Screens

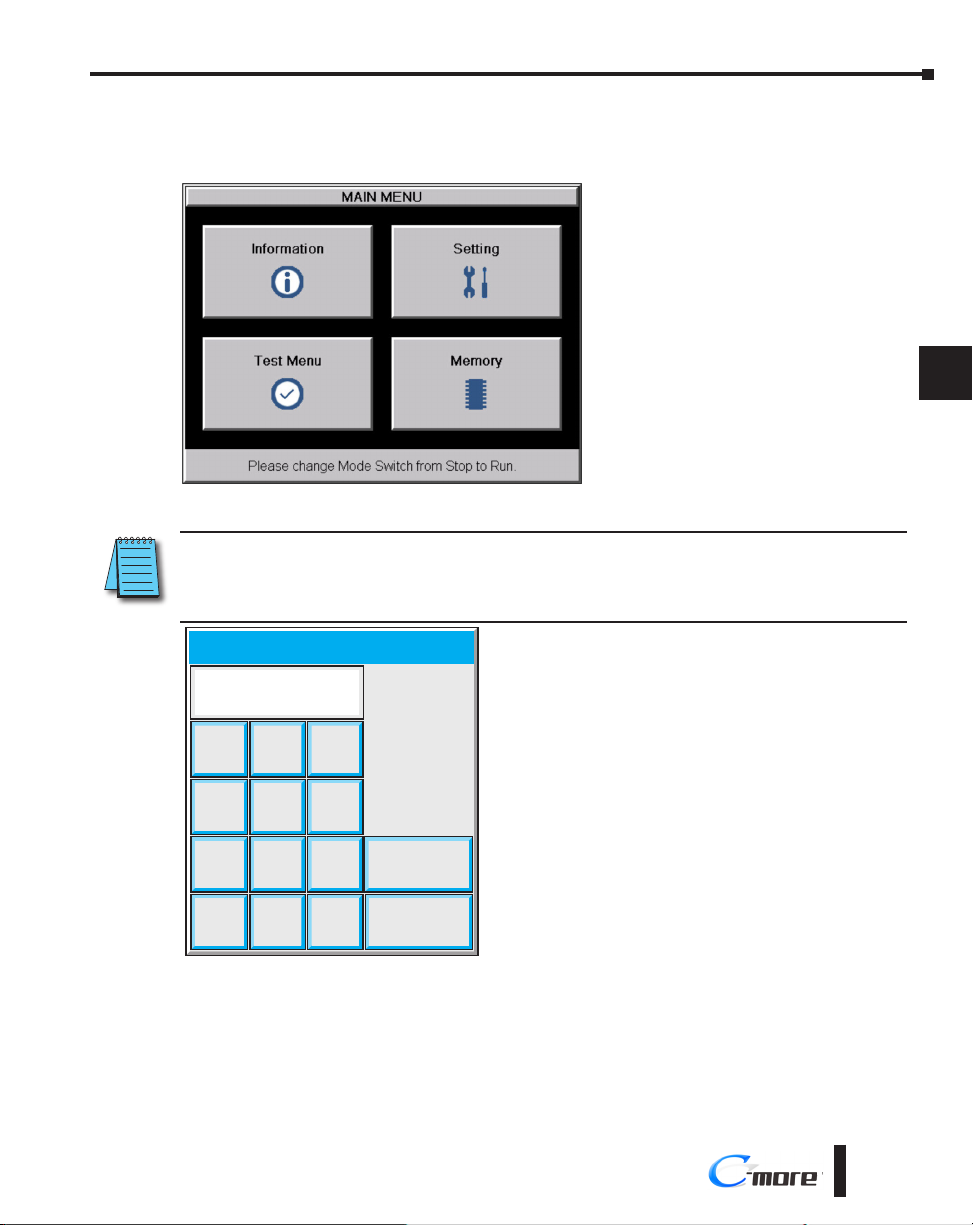

Clicking the OK button will open the Main Menu as shown below. You can then proceed to

the other system setup screens.

1

2

3

4

5

6

Password Protecting System Screen Access

NOTE: If the password system tag SYS SYSTEMSCREENPW is enabled, the Enter Security Code keypad shown

below will open. The procedure to enable the SYS SYSTEMSCREENPW is detailed below.

Entering the correct password will display the HMI Run Mode warning dialog described previously. PLC

communications continue while the keypad is displayed. The keypad will timeout after 60 seconds.

Enter Security Code

987

654

321

CL0–

Enter

Cancel

7

8

9

10

11

12

13

14

A

B

C

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

D

®

5-7

Page 8

Chapter 5 - System Setup Screens

System Setup Screens – Enable Password in Software

1

2

3

4

5

6

7

8

9

10

11

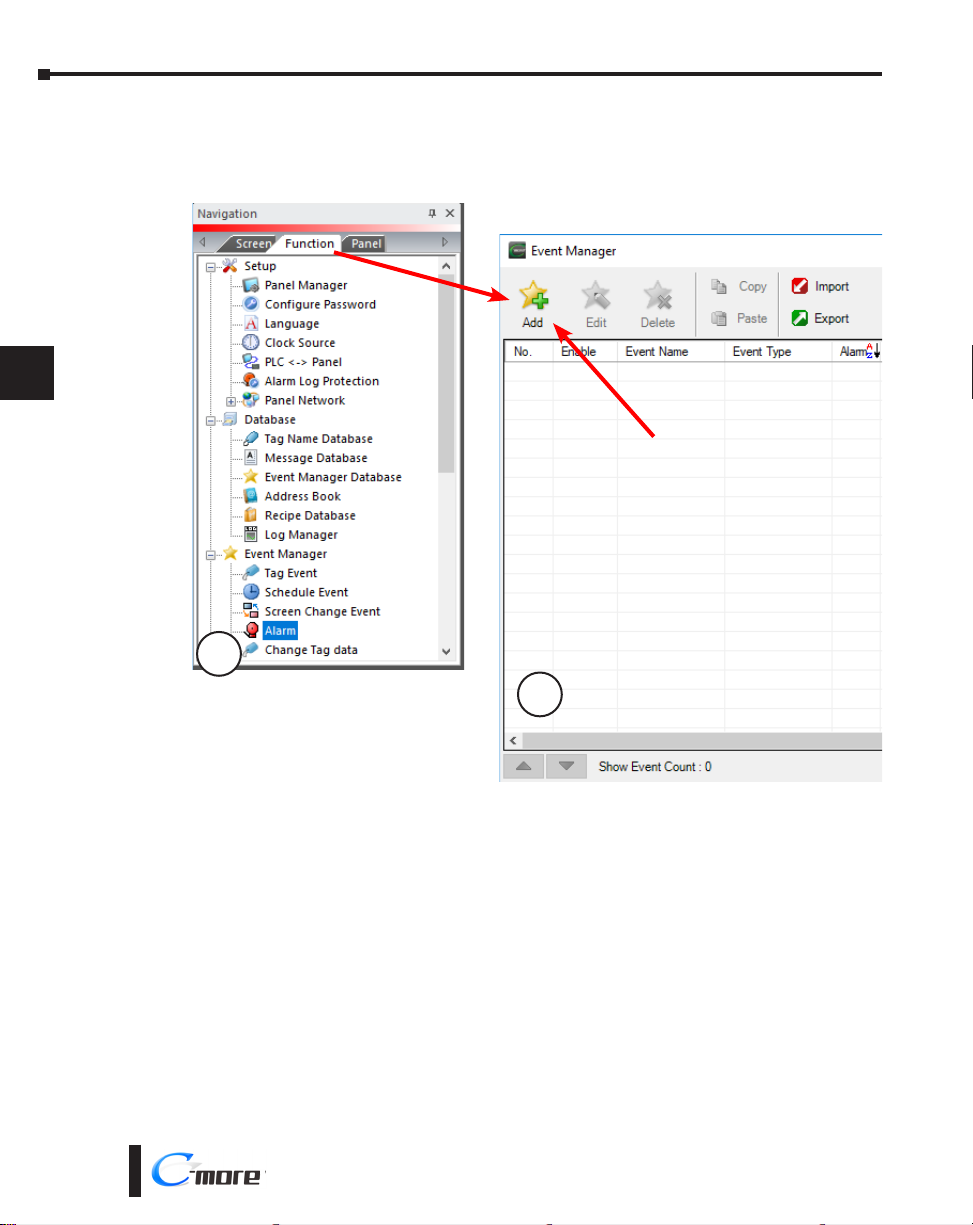

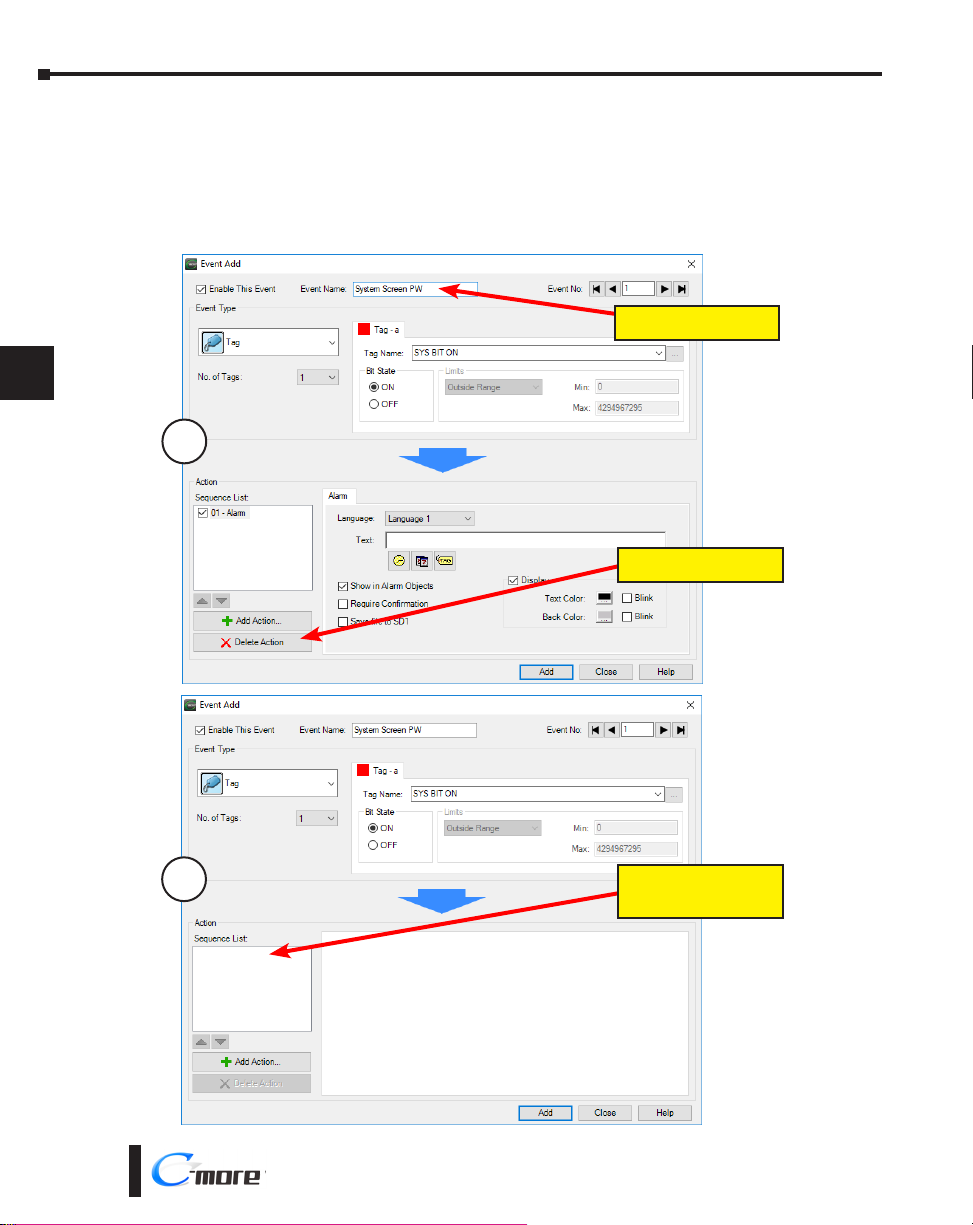

Under the C-more Programming Software’s Navigation window, select the Function tab, then

double click on “Alarm Action” to display the Event Manager Database shown below:

Click on the Add button

to add an event to the

database that will be used

to enable the System

Screen Password.

1

2

12

13

14

A

B

C

D

5-8

®

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

Page 9

Chapter 5 - System Setup Screens

System Setup Screens – Enable Password (cont’d)

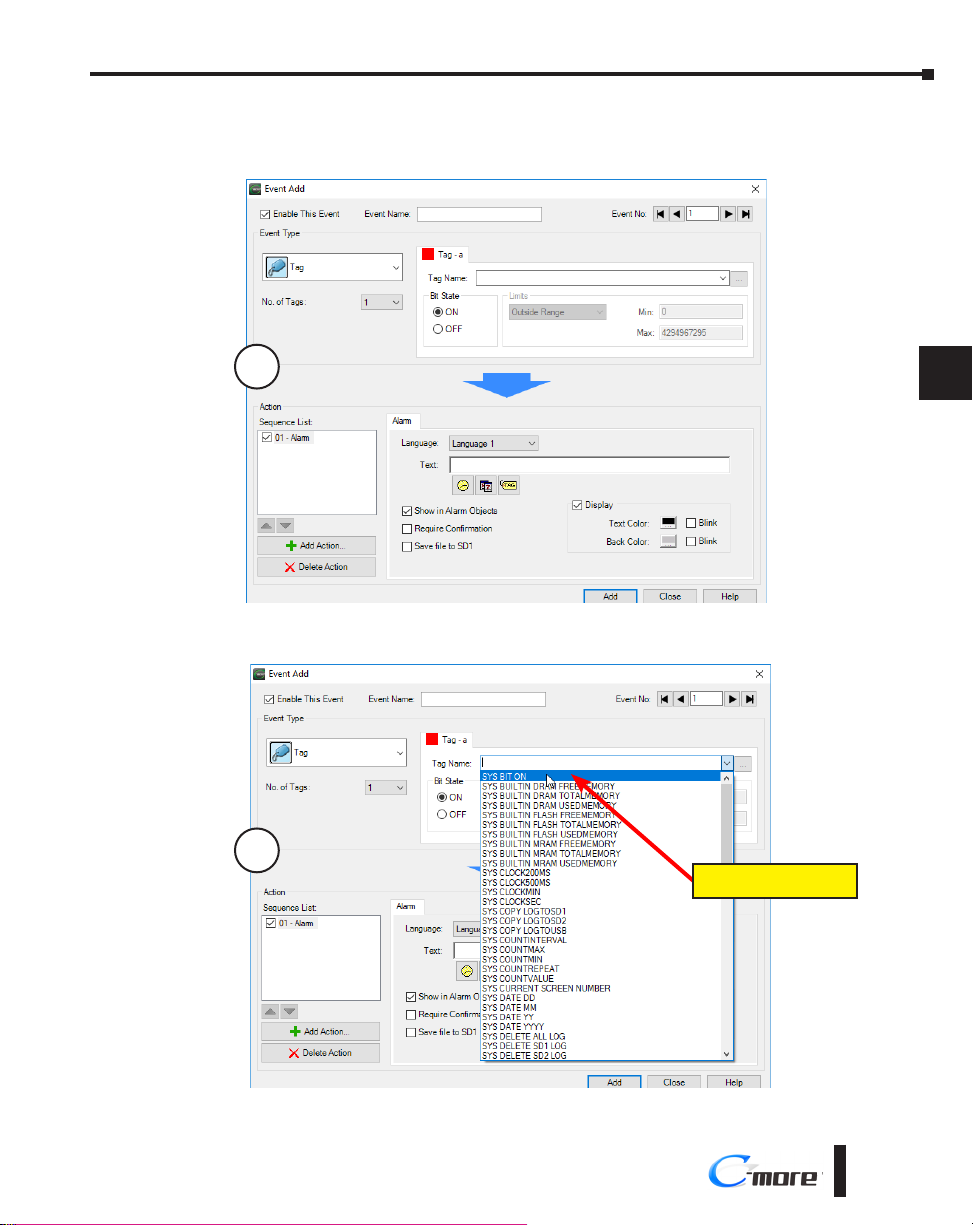

The Event Add dialog box will be displayed as shown.

1

2

3

4

Click on the Tag Name: pull down menu and select the internal System Bit On

(SYS BIT ON) tag as shown. This will force the tag event type to be continuously active.

3

4

Tag Name: SYS BIT ON

5

6

7

8

9

10

11

12

13

14

A

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

B

C

D

®

5-9

Page 10

Chapter 5 - System Setup Screens

System Setup Screens – Enable Password (cont’d)

1

2

3

4

5

6

7

8

9

10

11

Use the Event Name: text box to document the event as “System Screen PW” for record

keeping This is optional.

In the Action box, click once on the displayed 01-Alarm under the Sequence List: so that

01-Alarm is highlighted. Then click the Delete Action button to remove the 01-Alarm.

Event Name:

5

Delete Action

12

13

14

A

B

C

D

5-10

6

The Sequence List will

now be cleared out.

®

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

Page 11

Chapter 5 - System Setup Screens

System Setup Screens – Enable Password (cont’d)

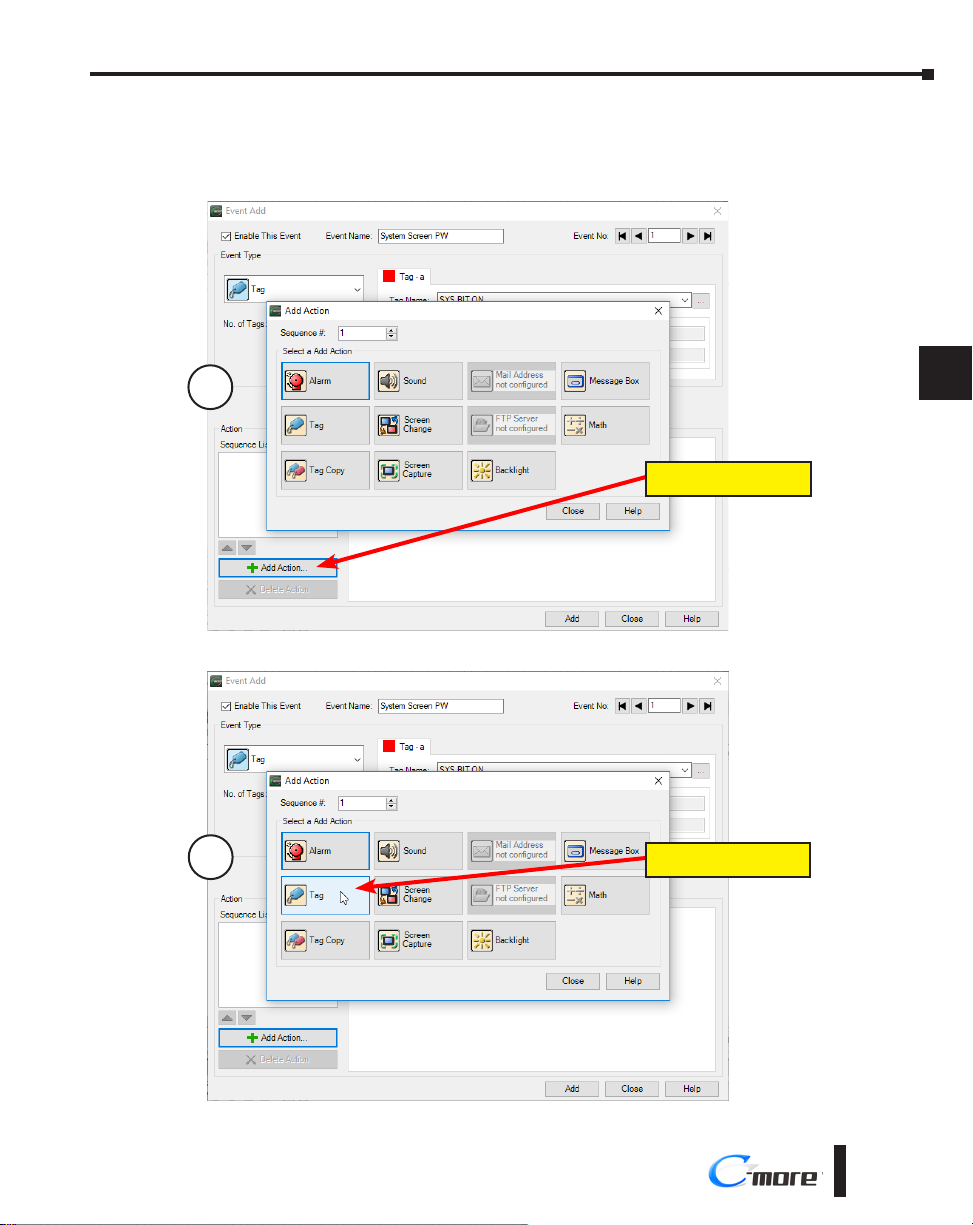

In the Action box, click on the Add Action... button. This will bring up the Add Action

dialog box as shown below:

1

2

3

4

7

Click on the Tag button.

8

Add Action

Tag

5

6

7

8

9

10

11

12

13

14

A

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

®

B

C

D

5-11

Page 12

Chapter 5 - System Setup Screens

System Setup Screens – Enable Password (cont’d)

1

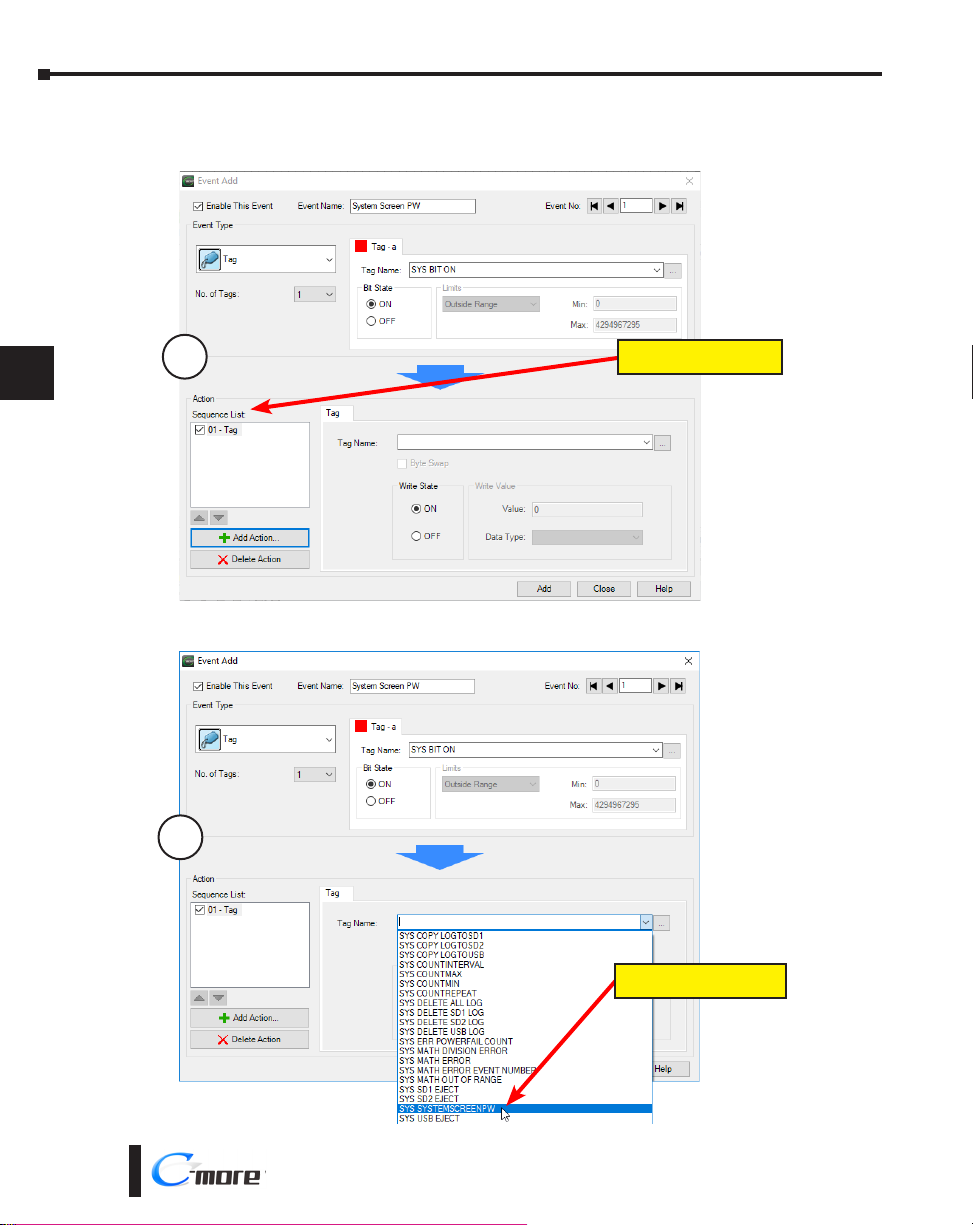

A 01-Tag action item will then be added to the Sequence List.

2

3

4

9

5

6

7

8

9

Click on the Tag Name: pull down list down arrow in the Action box’s Tag tab, select

10

SYS SYSTEMSCREENPW from the list, and click OK.

01-Tag

11

12

13

14

A

B

C

D

5-12

10

SYS SYSTEMSCREENPW

®

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

Page 13

Chapter 5 - System Setup Screens

System Setup Screens – Enable Password (cont’d)

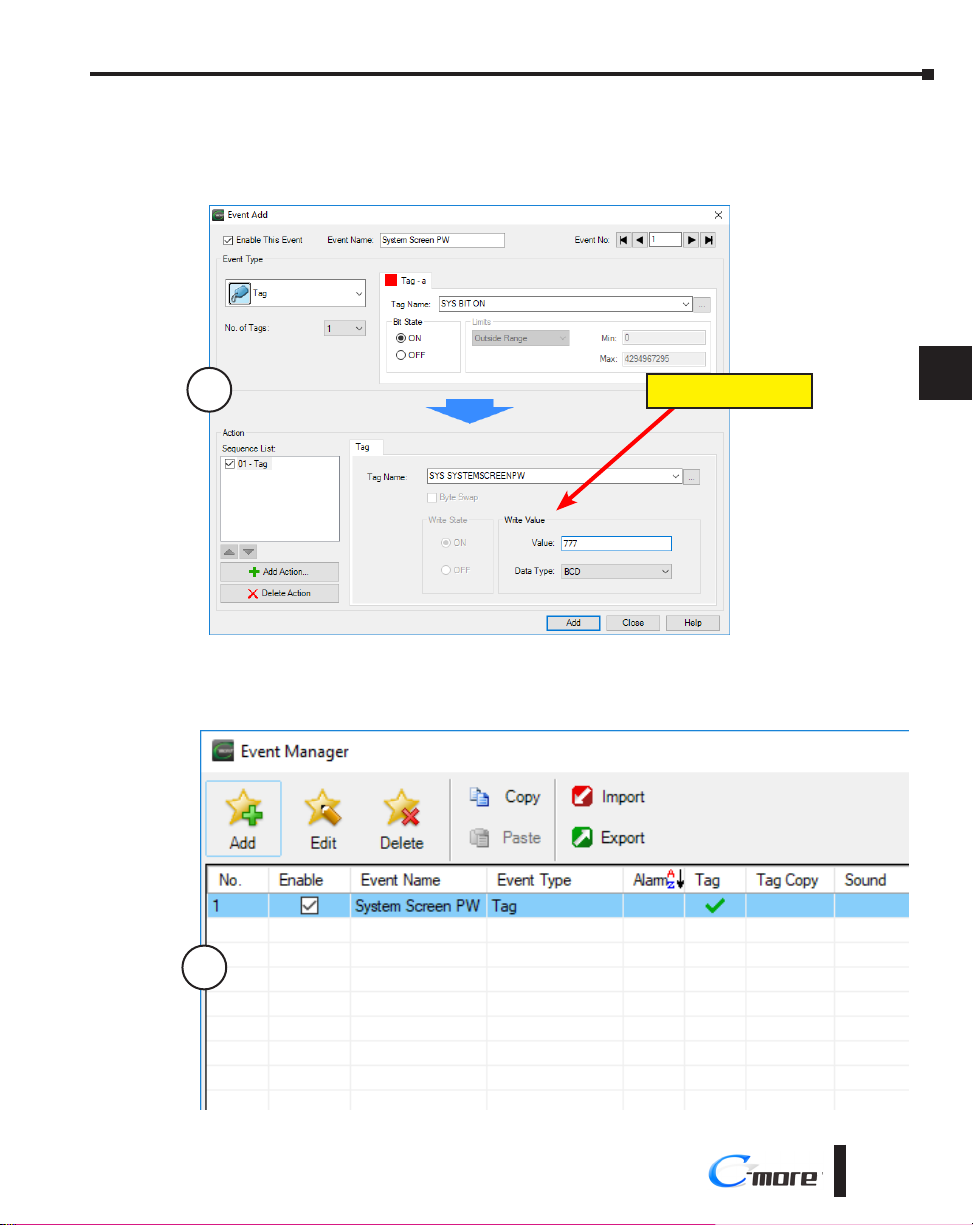

Enter a numeric value into the Value: box, such as “777”. This value becomes the Password

code to access the System Setup Screen’s Main Menu.

11

Click the Add button in the Event Add dialog box and then the Close button to return to

the Event Manager Database. You now will see that the first event in the database is for the

System Screen Password and it is enabled.

Password Value – 777

1

2

3

4

5

6

7

8

9

10

11

12

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

®

12

13

14

A

B

C

D

5-13

Page 14

Chapter 5 - System Setup Screens

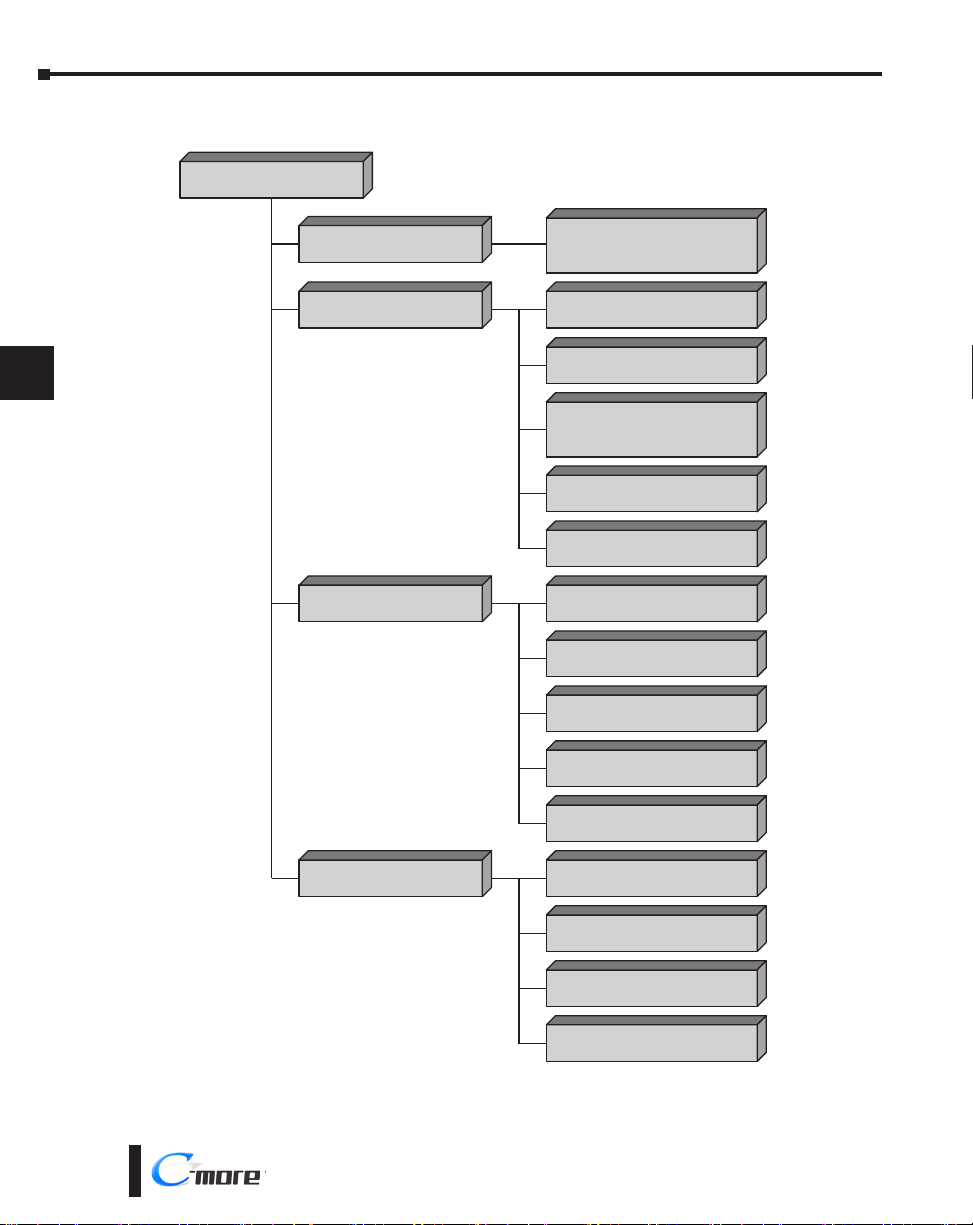

System Setup Screens Flowchart

1

2

3

4

5

6

7

8

9

10

11

Main Menu

Information

Setting Adjust Clock

Test Menu

General/Memory/Ethernet/

Error

IP Address Setting

Adjust Touch Panel

(Touch Screen Calibration)

Beep

Mouse

Test Touch Panel

Test Display

Test User LED

12

13

14

A

B

C

D

5-14

Test Communication Port

Test Beep/Sound

Memory

®

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

Backup

Restore

Clear Memory

Reset to Factory Default

Page 15

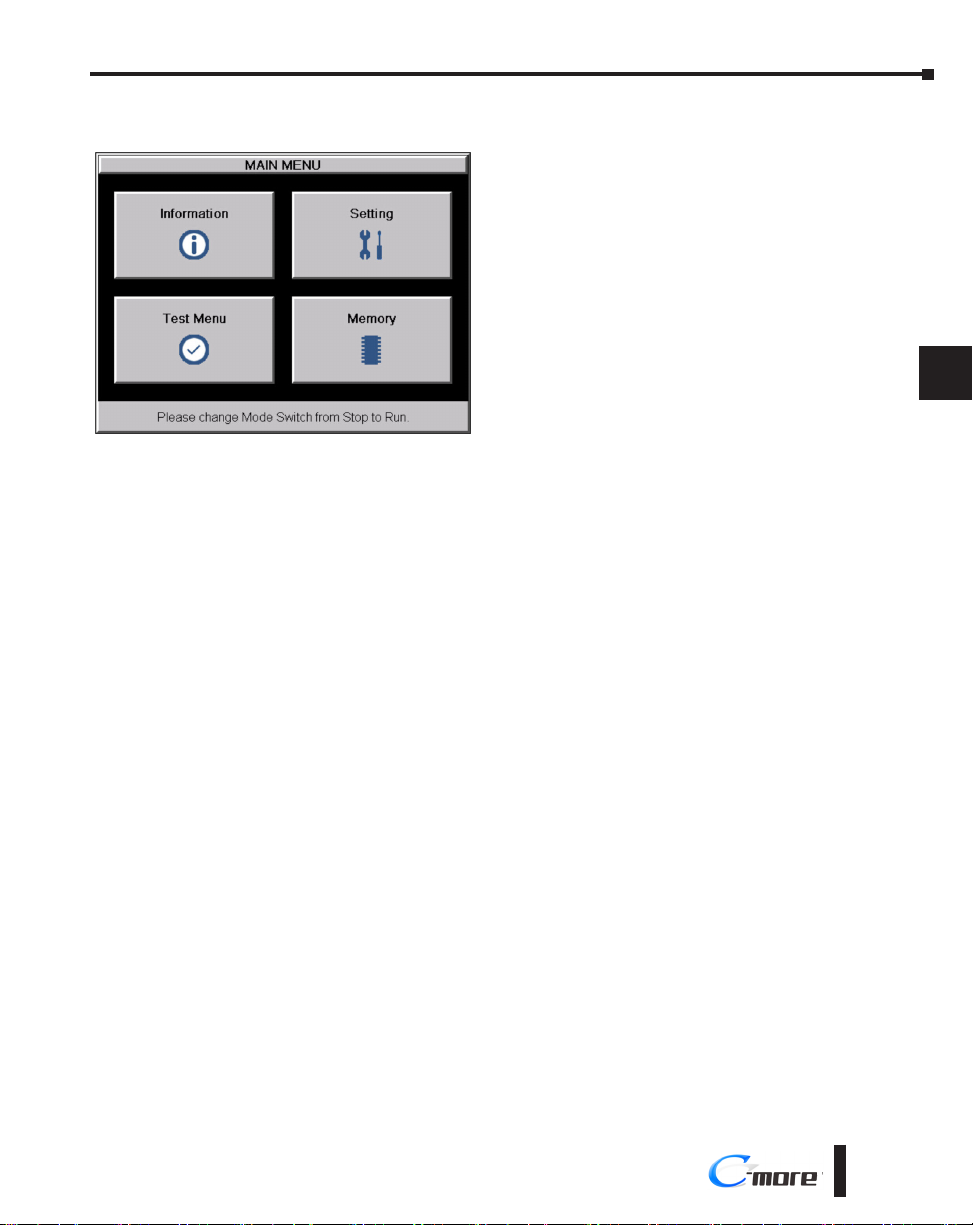

Main Menu

Chapter 5 - System Setup Screens

The Main Menu system setup screen is the top layer in

the menu structure.

1

2

3

4

5

6

7

8

9

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

®

10

11

12

13

14

A

B

C

D

5-15

Page 16

Chapter 5 - System Setup Screens

Information Menu

1

2

3

4

5

6

7

8

9

10

11

12

13

14

A

B

C

D

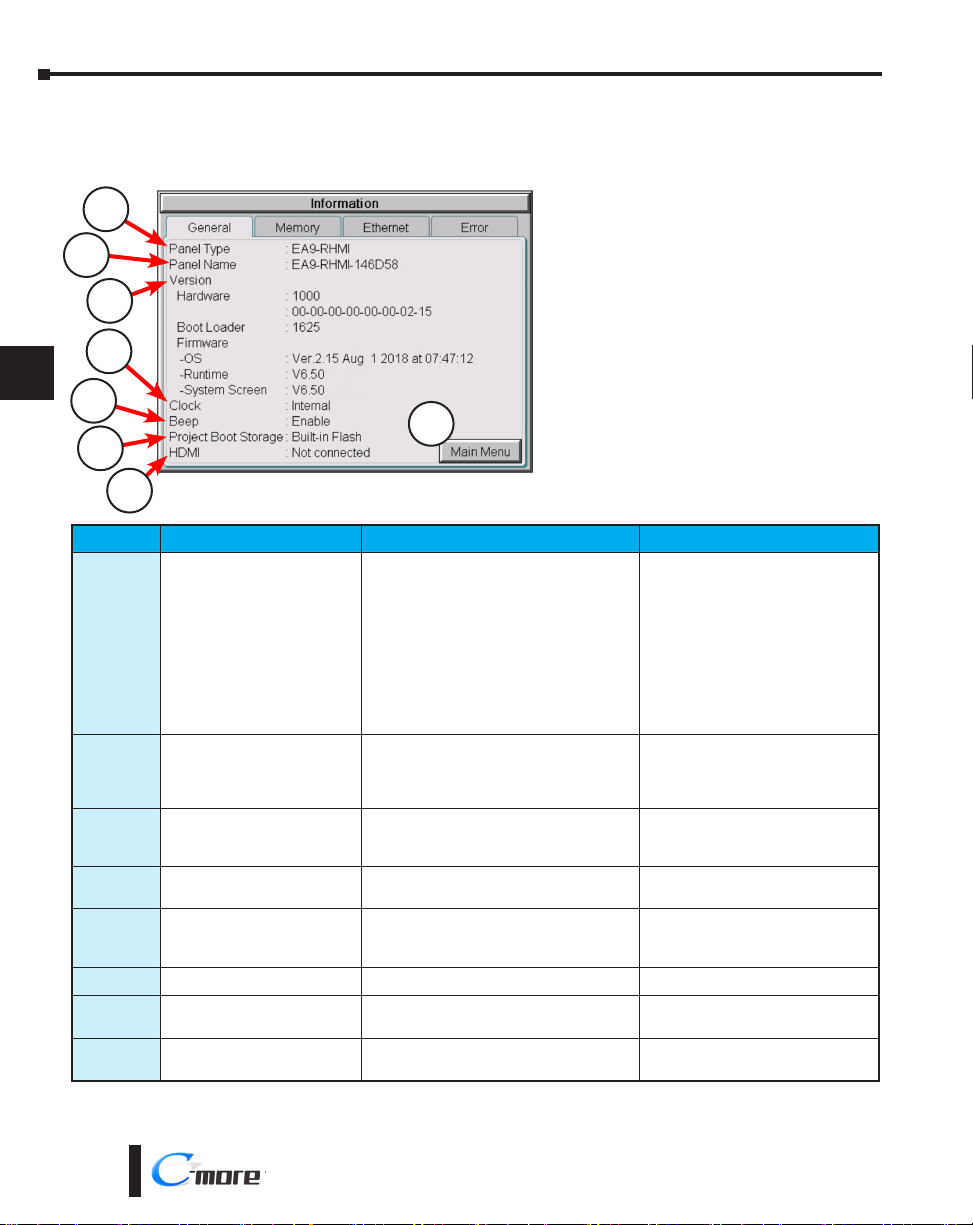

Information - General tab

1

2

The General tab under the Information

menu provides detailed information about

the C-more HMI.

3

4

5

8

6

7

Item No. Function Description Comments

EA9-T6CL-R

EA9-T6CL

EA9-T7CL-R

EA9-T7CL

EA9-T8CL

1 Panel Type

2 Panel Name

3 Version

4 Clock

5 Beep

6 Project Boot Storage

7 HDMI

8 Main Menu

EA9-T10CL

EA9-T10WCL

EA9-T12CL

EA9-T15CL-R

EA9-T15CL

EA9-RHMI

The panel name is configured in the

programming software and saved with a

project.

The version identifications provide

information on the components and

firmware in the panel

Internal/External clock selection.

Status of the internal beeper.

The location of the current project. Built-in flash, SD1

HDMI connection to an external screen.

Only models with HDMI port

Press to return to the Main Menu screen.

Model Number

The default panel name is the model

number plus the lower three bytes

of the panel MAC address, i.e. EA9T8CL-0022C4.

Files reside in the C-more HMI’s

memory.

Configured in the C-more

Programming Software.

Configurable in the Setting Menu –

Beeper shown on page 5-23 or in

the C-more Programming Software.

Connected, Not connected

Main Menu shown on previous

page.

5-16

®

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

Page 17

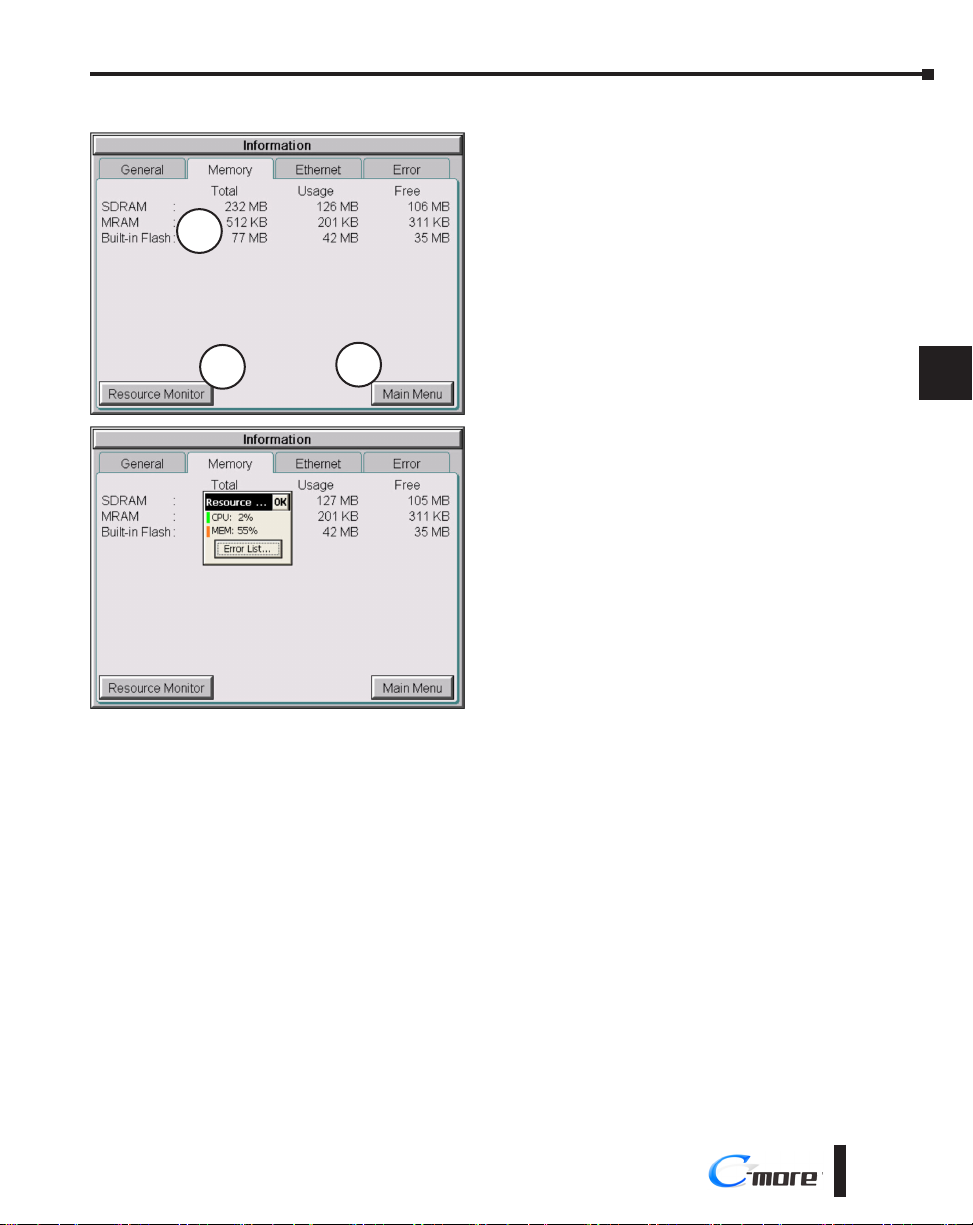

Information - Memory tab

1

Chapter 5 - System Setup Screens

1. Memory components - Status of each memory

component - SDRAM, MRAM and Built-in Flash

are internal memory components. When external

memory devices are installed in the panel they will be

included in this list : SD and USB.

1

2

3

4

2

3

2. Resource Monitor - Selecting Resource Monitor

displays the CPU and runtime memory usage

percentage. This window will remain open after

exiting from the system screen. This allows for

monitoring the panel resources while the project

is running. Pressing the Error List button expands

the window to show the PLC communication error

list in real time. Press OK once to remove the Error

List. Press OK again to close the Resource Monitor

window.

3. Main Menu - Press to return to the Main Menu

screen - Main Menu shown previously

5

6

7

8

9

10

11

12

13

14

A

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

®

B

C

D

5-17

Page 18

Chapter 5 - System Setup Screens

Information - Ethernet tab

1

2

3

4

5

6

7

8

9

10

11

12

13

14

1

3

2 4

Item No. Function Description Comment

Ethernet Settings:

MAC Address: 00 D0 7C XX XX XX

Ethernet

1

(Link: Online)

2 Option Unit

Option

3

(Link Online)

4 Main Menu

Address Type: DHCP/Static

IP Address:

Subnet Mask:

Default Gateway:

DNS: 1) Automatically

2) Use Designated Address

Opens Ethernet settings for optional

EA-ECOM if connected.

Ethernet Settings:

MAC Address: 00 D0 7C XX XX XX

Address Type: DHCP/Static

IP Address:

Subnet Mask:

Note: Option Unit uses the same Default

Gateways as Item 1 - Ethernet

Press to return to the Main Menu screen.

Configurable in the Setting Menu

– IP Address Setting shown in

this section or in the C-more

Programming Software.

A

B

C

D

5-18

®

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

Page 19

Information - Error tab

Chapter 5 - System Setup Screens

21 3 4 5

Error message format

Navigation buttons

6 7 8

21 3 4

Error Message Format:

Item No. Function Description Comment

Order of error message functions:

Error Number, Date, Time, Error Port, Device Name, Error Type, PLC Address, Access Bytes, Error Message

1 Date

2 Time

3 Error Port

4 Device Name

5 Error Type

6 PLC Address

7 Access Bytes

8 Error Message

Error Message navigation buttons:

Format: MM/DD/YY Date error occurred.

Format: HH/MM/SS Time error occurred.

PLC Serial Communications Port:

Ethernet:

The name of the device reporting the error.

RD: Read

WT: Write

The assigned address of the PLC that caused

the error.

The number of access bytes.

The error message is the same as the

message displayed in the upper left of the

C-more HMI’s connected display.

Device names are configured in the

programming software, Panel Manager

A list of Error Massages is shown in

Appendix A

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Item No. Function Description Comment

1 Clear

2 Page Down

3 Page Up

4 Main Menu

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

Press to clear all error messages. This

button is grayed out when there are no error

messages to display.

Press to go to the next page. This button is

grayed out when there is no error messages

on the next page.

Press to go to the previous page. This

button is grayed out when there is no error

messages on the previous page.

Press to return to the Main Menu screen.

Errors are also cleared with firmware is

updated on the panel. Errors are not cleared

on power cycle or project transfer.

®

A

B

C

D

5-19

Page 20

Chapter 5 - System Setup Screens

Setting Menu

1

2

3

1

4

The Setting Menu is used to adjust the time & date,

adjust the contrast or brightness of the display, enter

the IP address settings, adjust (calibrate) the connected

touch screen, enable or disable the internal beep and

turn on and off the mouse cursor .

2

5

6

7

8

9

10

11

12

13

14

A

3 4

5

6

Item No. Function Description Comments

1 Adjust Clock

2 IP Address

3 Adjust Touch Panel

4 Beep

5 Mouse

6 Main Menu

Press to go to the Adjust Clock screen.

Press to go to the IP Address screen

Press to go to the Adjust Touch Panel screen.

Press to go to the Beep screen.

Press to go to the Mouse screen.

Press to return to the Main Menu screen.

The IP Address can also be set from

the programming software or by the

project.

B

C

D

5-20

®

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

Page 21

Setting – Adjust Clock

1

2

3

Chapter 5 - System Setup Screens

1

2

3

4

4

Item No. Function Description Comments

1 Select

2 Up

3 Down

4 OK

5 Cancel

NOTE: The function buttons used to adjust the clock settings on the panel’s setup screen are disabled if an

External clock source is selected in the C-more programming software. The choice of an internal or external clock

source is available by selecting Clock Source in the C-more programming software under the Main Menu drop

down function Setup.

NOTE: The panel’s clock can also be adjusted from the C-more programming software. The Adjust Clock function

can be accessed in the software by selecting Adjust Clock under the Main Menu drop down function Panel or

selecting Adjust Clock under the Panel tab in the software’s Navigation window.

5

Time: Each press of the Select button will

cycle thru the following settings.

1) No Selection to Hours

2) Hours to Minutes

3) Minutes to Seconds

4) Seconds back to Hours

Date: Each press of the Select button will

cycle thru the following settings.

1) Month to Day

2) Day to Year

3) Year back to Month

Press to increment the value by “1” with

each press.

Press to decrement the value by “1” with

each press.

Press to accept the changes.

Press to return to the Setting Menu screen

without accepting the changes.

5

6

7

8

9

10

11

12

13

14

A

B

C

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

®

D

5-21

Page 22

Chapter 5 - System Setup Screens

Setting – Adjust Touch Panel

A compatible touch screen can be attached to the EA9-RHMI through the USB Type A port.

1

2

This procedure is used to calibrate a connected touch screen to ensure accuracy of the touch

areas. There are three points on the touch screen that the calibration is based around. The

adjustment relies on very narrow areas for the calibration points.

3

4

5

6

7

8

9

10

11

12

13

3a

1

2

Item No. Function Description Comment

1 Start Calibration

2 Cancel

3 Points 3a thru 3c

Press to begin the touch screen calibration

Press to return to the Setting Menu screen.

The touch screen calibration crosshairs will

appear individually in the order of point 3a

thru 3c respectively as each proceeding

crosshair is pressed.

Once all three points are touched,

select Accept, Redo or Cancel.

3c

3b

14

A

B

C

D

5-22

®

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

Page 23

Setting – Beep

Chapter 5 - System Setup Screens

This system setup screen function is used to enable or

disable the HMI’s internal beep function.

1

2

1

2

Item No. Function Description Comments

1 Enable Beep

2 OK

3 Cancel

NOTE: The project settings in the C-more programming software Panel Manager will override the HMI’s internal

setting upon initial download.

3

Check to enable the internal beep.

Press to accept the changes.

Press to return to the Setting Menu screen

without accepting the changes.

3

4

5

6

7

8

9

10

11

12

13

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

®

14

A

B

C

D

5-23

Page 24

Chapter 5 - System Setup Screens

Setting – Mouse

1

2

3

4

This system setup screen function is used to enable/

disable the arrow mouse cursor on the connected screen.

It may be valuable to display the mouse cursor, for

example, when an external USB keyboard is connected

to the panel. The mouse cursor is enabled by default

when the EA9-RHMI panel is the panel used for a

project.

5

6

7

8

9

10

11

12

13

14

A

5

NOTE: The project settings in the C-more programming software Panel Manager will override the HMI’s internal

setting upon initial download.

B

C

D

5-24

®

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

Page 25

Setting – IP Address Setting

1

3

Chapter 5 - System Setup Screens

1

2

3

2

4

5

7

6

Item No. Function Description Comment

“DHCP” is enabled as the default when this

1 DHCP

2 IP Address

IP Address

3

Subnet Mask

Default Gateway

4 Keypad

5 IP Address (Option unit)

6 OK

7 Cancel

system setup screen is first selected.

All of the other selections on this screen are

dimmed when “DHCP” is selected and are

not available.

The “Use the following IP Address” setting is

selected when its radio button is pressed.

Use the numerical keypad to assign the IP

address.

Select the field that needs to be assigned by

touching the entry value and use the keypad

to enter the desired address.

The keypad is used to enter the Address:

Use the numeric keys to enter the address,

e.g: 192.168.10.1

“CL” = Clear value entered

Opens Ethernet settings for optional

EA-ECOM if connected.

Press to accept the changes and return to the

Setting Menu screen.

Press to return to the Setting Menu screen

without accepting the changes.

Note: If an Ethernet cable is not

connected to the HMI from an

active Ethernet device, then the IP

Address will show as 0.0.0.0.

Each field can be independently

assigned.

4

5

6

7

8

9

10

11

12

13

14

NOTE: The project settings in the C-more programming software Panel Manager will override the HMI’s internal

setting upon initial download.

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

®

A

B

C

D

5-25

Page 26

Chapter 5 - System Setup Screens

Test Menu

1

2

The Test Menu gives the user the ability to test the

operation of a connected touch screen, test the LCD

display, test the various communication ports, and also

test the internal beeper.

3

4

5

6

7

8

9

10

11

12

13

1

4

2

5

3

6

Item No. Function Description Comments

1 Test Touch Panel

2 Test Display

3 Test User LED

4 Test Communication Port

5 Test Beep/Sound

6 Main Menu

Press to go to the Test Touch Panel screen.

Press to go to the Test Display screen.

Tests the user configurable LED on the front

of the panel.

Refer to the online help file for details on the

configuration of this LED.

Press to go to the Test Communication Port

screen.

Press to go to the Test Beep/Sound screen.

Press to return to the Main Menu screen.

14

A

B

C

D

5-26

®

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

Page 27

Test Menu – Test Touch Panel

1

2

Chapter 5 - System Setup Screens

Using this test, normal or unusual

operation of the connected analog touch

screen can be determined.

Testing:

If an area of the touch screen is suspected

to be inoperable, touch that area of the

screen while in the Test Touch Panel

screen mode. The screen pixels should

turn black in that area. If the screen pixels

do not turn black when touched, then

the touch screen is defective or needs to

be calibrated. See Setting - Adjust Touch

Screen

1

2

3

4

5

6

7

Item No. Function Description Comments

1 Touch area

2 Cancel

NOTE: The touch screen driver is designed to respond to a single touch. If it is touched at multiple points at the

same time, an unexpected object may be activated.

Touch to turn on pixels on the screen.

Press to return to the Test Menu screen.

Both the title bar (Test Touch Panel)

and Cancel button can be drawn

across to test the touch operation.

8

9

10

11

12

13

14

A

B

C

D

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

®

5-27

Page 28

Chapter 5 - System Setup Screens

Test Menu – Test Display

1

2

3

4

5

6

7

8

9

10

11

12

13

14

A

B

1) Test LCD

There are two different test patterns that may be run on the display to allow the user to check

for display screen defects. If an attached touch screen is not touched or a connected mouse is

not clicked within 3 seconds of Test Pattern 1 being displayed, then Test Pattern 2 will be

displayed until the screen is touched or a connected mouse is clicked, otherwise Test Pattern

1 will remain until cancelled.

Test Pattern 1 displays a test pattern of 16 grayscale graduations and RGB colors.

1

2

C

D

5-28

®

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

Page 29

Chapter 5 - System Setup Screens

Test Pattern 2 will follow the pattern as shown in the following chart with the color wiping

across the screen in the direction indicated by the arrows, then repeats:

Color 1st Time 2nd Time 3rd Time 4th Time

1

RED

3

GREEN

BLUE

Item No. Function Description Comments

Touch the Test Display

1

screen

2 Cancel (Test Pattern 1)

Touch Anywhere

3

(Test Pattern 2)

Test Results: If any pixels on the screen do not appear the same color as the surrounding

pixels, the screen may be defective.

2) Check Available Resolutions on External HDMI Display

This selection performs a check through the HDMI port and attempts to negotiate with a

connected display and determine all available resolutions.

NOTE: If the display is connected through a signal converter such as an HDMI-DVI converter, the negotiations may

not be sucessful and the available resolutions may not be correct.

Press the screen anywhere except the

Cancel button and the shown Test Pattern 1

remains.

Press to return to the Test Menu screen.

Touch the sceen anywhere during Test

Pattern 2 and return to the Test Menu

screen.

If the Test Display screen is not

touched, then in three seconds the

display will move to Test Pattern 2.

2

3

4

5

6

7

8

9

10

11

12

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

®

13

14

A

B

C

D

5-29

Page 30

Chapter 5 - System Setup Screens

1

15

15-pin D-sub

(male)

2

3

TXD

RXD

7

8

CTS

RTS

RS-232 Loop-back Connector

Wiring Diagram

1

15

15-pin D-sub

(male)

7

8

CTS

RTS

9

11

RXD+

TXD+

10

12

RXD–

TXD–

RS-422/485 Loop-back Connector

Wiring Diagram

Test Menu – Test Communication Ports: Serial Ports

1

2

1

3

4

The following test can be used to check the operation

of the serial communication ports, with the use of

a loop back connector and can also check the serial

2

communications to any connected and configured PLC.

5

6

7

8

9

10

11

12

13

14

A

3

Item No. Function Description Comments

The loop back test may be performed

on Serial Port 1 or Serial Port 3. Each

tab shows diagrams to assist the user

in building the loop back connector.

The PLC must be configured for

the selected port in the C-more

programming software Panel

Manager and transferred to the HMI

before attempting the PLC Enquiry

test.

1 Loop Back Test

2 PLC Enquiry Test

3 Cancel

Serial Port 1

The loop back test checks the hardware

components of the selected port for proper

operation.

This function allows the ability to select any

PLC that that may be connected to the HMI

via a serial connection and checks to see if

the communications are working correctly.

Press to return to the Test Menu screen.

B

C

D

5-30

®

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

Page 31

Chapter 5 - System Setup Screens

Test Menu – PLC Serial Comm Port – Loop Back Test

Test Results

1.) Bytes Sent:

The number of bytes sent after a test is started.

2.) Receive Counts:

The number of bytes which are received after the test is started.

3.) Error Counts:

The number of bytes which have not been received after the test is started.

4.) RTS/CTS Test: Pass/Fail

RTS is turned on and if CTS receives the signal then the test shows “Pass,” otherwise the

test shows “Fail.”

NOTE: The test will continue to run until the Cancel button is pressed. If there are any error counts, check the loop

back connector.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

A

B

C

D

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

®

5-31

Page 32

Chapter 5 - System Setup Screens

Test Menu – PLC Enquiry Test: Serial Connection

1

2

3

4

5

6

PLC Enquiry Test

7

Four test packets are sent to the selected PLC. The test result with return either Pass or Fail.

8

9

This function allows the ability to select any PLC that

may be connected to the HMI through the selected

serial comm port connection and checks to see if the

communications are working correctly.

NOTE: The communications protocol for the PLC

being selected must be configured the same as the

C-more HMI. The HMI’s PLC serial communications

are configured using the C-more Programming

Software’s Panel Manager.

10

11

12

13

14

A

B

C

D

5-32

®

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

Page 33

Chapter 5 - System Setup Screens

Test Menu – Test Communication Ports: Ethernet

The following test feature can be used to check the

operation of the Ethernet communication port by

indicating if an Ethernet link has been established

2

1

3

Item No. Function Description Comments

This area displays information on whether

or not an Ethernet link has been established

1 Ethernet Connected

2 PLC Enquiry Test

3 Cancel

Example of displayed message when the HMI’s Ethernet port

is not connected. Note that the address resets to 0.0.0.0

even if it has previously been entered.

for the HMI’s Ethernet comm port. Displays

panel’s IP address and shows whether it is

static or assigned by a DHCP server.

This function allows the ability to select

any PLC configured in the project that may

be connected to the HMI via an Ethernet

connection and checks to see if the

communications are working correctly.

Press to return to the Test Menu screen.

or not. It can also check the status of the Ethernet

communications to any connected PLC.

Base featured models (-R) do not include an Ethernet

port. Therefore, this check is not displayed on -R

models.

NOTE: The communications protocol for the PLC

being selected must be configured the same as the

C-more HMI. The HMI’s PLC serial communications

are configured using the C-more Programming

Software’s Panel Manager...

The PLC must be configured for

the selected port in the C-more

programming software Panel

Manager and transferred to the panel

before attempting the PLC Enquiry

test.

1

2

3

4

5

6

7

8

9

10

11

12

Typical Ethernet connection

with Ethernet switch

CLICK PLC

Ethernet CAT5

Cable

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

Stride™

Ethernet Switch

10/100 Base-T

(such as SE2-SW5U)

EA9-RHMI

Auto MDI / MDI-X

Ethernet Port

C-more

®

13

14

A

B

C

D

5-33

Page 34

Chapter 5 - System Setup Screens

Test Menu – PLC Enquiry Test: Ethernet Connection

1

2

3

2

1

4

This function allows the ability to select any PLC

configured in the project that may be connected to the

HMI through an Ethernet port connection and checks

to see if the communications are working correctly.

NOTE: The communications protocol for the PLC

being selected must be configured the same as the

C-more HMI. The HMI’s PLC serial communications

are configured using the C-more Programming

Software’s Panel Manager.

5

6

7

8

9

10

11

12

13

14

A

3

PLC Enquiry Test

Following are the steps that the Ethernet PLC Enquiry Test performs:

1) Ping the network 4 times for the PLC selected.

2) Four of the test read packets are sent to the selected PLC.

The test result will either be Pass or Fail. However, if the result of pinging the network shows

an error, the test is stopped.

B

C

D

5-34

®

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

Page 35

Test Menu – Test Beep/Sound

Chapter 5 - System Setup Screens

The internal Beeper can be tested from this system

setup screen whether the Beeper is enabled or disabled.

After the Beep Test button is pressed and released, the

Beeper will sound for 500 msec.

1

2

1

2

3

4

5

6

7

8

9

10

11

12

13

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

®

14

A

B

C

D

5-35

Page 36

Chapter 5 - System Setup Screens

Memory Menu

1

2

3

1

4

2

The user’s project, Firmware and OS, log and recipes

files can be backed up to or restored from an SD

memory card or a USB memory device. From this menu

the user can also clear the project log files. The user also

has the ability to clear the memory within the C-more

HMI.

5

6

7

8

9

10

11

12

13

14

A

B

C

D

3

4

5

Item No. Function Description Comments

Any USB 2.0 pen drive.

SD formats SD and SDHC are

supported. Capacity up to 32GB.

Backup project, Firmware and OS, log &

1 Backup

2 Restore

3 Clear Memory

4 Reset to Factory Default

5 Main Menu

NOTE: The Project is RESTORED to the panel from an external memory device. A project can be TRANSFERRED

to an SD card or USB memory from the programming software to be RESTORED to a panel that is not connected

to the programming software. This file has the .eas9 extension NOT the .eap9 extension of a projects SAVED from

the software.

recipe files to the following memory devices:

USB port - Type A: USB pen drive

SD Card Slot: SD card

Restore project, Firmware and OS, log &

recipe files to the internal memory from one

of the following memory devices:

USB port - Type A: USB pen drive

SD Card Slot: SD card

Clear selected data files from the memory

of the following internal memory or external

memory devices:

Built-in FLASH Memory

USB port - Type A: USB pen drive

SD Card Slot: SD card

The HMI’s internal memory is set to the

original factory defaults.

Press to return to the Main Menu screen.

The backup data files are created and

copied to a folder on the memory device

named “EA_Memory Copy.”

The project file is named

StartupStorage.eas9

“Log” and “Recipe” folders with the

appropriate data files are also created on

the memory device.

A folder on the memory device named

“EA_Memory Copy” must exist

containing a file named “StartupStorage.

eas9”. The project data file is stored

in this file, and if the system data file

was backed up, it also will be stored in

this file. Any backed up log or recipe

data files will be located under the

appropriate “Log” or “Recipe” folders.

Can only clear project, log and recipe

data files of the Built-in FLASH memory.

Can clear entire contents or individual

data files of external memory devices.

Clears all project memory.

5-36

®

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

Page 37

Chapter 5 - System Setup Screens

Project Executed from SD Card Slot 1

If the Project Storage/Boot Location is set to Auto or SD1 in the C-more software Panel

Manager, and an SD memory card is located in the SD Card Slot 1 at the time a project is

transferred to the panel, the project will be stored on the SD card and the Internal Project

Memory will be cleared.

If Slot 1 contains an SD memory card with a project and the HMI’s power is cycled, then the

project file stored on the SD card is loaded into the HMI’s internal memory and executed.

Any project in the internal FLASH memory is cleared.

1

2

3

WARNING: During power up with an SD memory card plugged into an SD card slot, do not remove the

memory card from the slot. Damage to the SD memory card and possibly the HMI may result.

WARNING: After a firmware update, the project files which are located in either the HMI’s internal

FLASH memory or an SD memory card plugged into an SD card slot are cleared. The programming

software will need to be used to transfer the project file back into the panel. If you wish to retain the

project on the SD memory card, power down the HMI and remove the SD card before performing a

firmware upgrade.

Increasing Project Memory Size using an SD memory card:

If a project is transferred to the panel with an SD memory card in SD slot 1, the Font and

Recipe data files are not included in the 82MB project size. Therefore using an SD memory

card can allow a project to be loaded that is larger than 82MB if the excessive size is caused by

Fonts and/or Recipe Sheets.

4

5

6

7

8

9

10

11

12

13

14

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

®

A

B

C

D

5-37

Page 38

Chapter 5 - System Setup Screens

Memory – Backup

1

2

3

4

5

The Memory - Backup selection allows you to backup

the panel’s Project, Log files, Recipe files or even

the Firmware files to either an SD memory card or

USB pen drive. The available memory devices will be

displayed with their total and free memory.

If the device is not available, it will be grayed out. The

Next button is grayed out until a device is selected.

The Cancel button can be pressed at any time to return

to the Memory Menu screen.

6

7

8

9

10

11

12

13

14

A

B

This is an example of selecting a USB memory device to

write the backed up files to.

The selected device is highlighted. Pressing again

deselects it.

Even if there is only one available memory device, it still

needs to be highlighted in order to go to the next step.

Press the Next button to continue to Step 2.

Please read the explanation for the availability of SD1 under different conditions that follow:

C

D

5-38

®

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

Page 39

Memory – Backup (cont’d)

Chapter 5 - System Setup Screens

SD Card Slot1 Availability Explanation:

SD1 may be unavailable (grayed out) if there is no card

in SD Slot 1 or the card in SD slot 1 has the project

currently running on the panel stored on it.

The project will exist on SD1 if the SD card

was installed in SD1 when the project was

TRANSFERRED to the panel by the C-more

programming software.

If the panel is powered up or rebooted with an SD card

inserted into SD1 Slot, then the SD1 button’s Total

and Free memory will be displayed.

1

2

3

4

5

6

7

8

9

10

11

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

®

12

13

14

A

B

C

D

5-39

Page 40

Chapter 5 - System Setup Screens

Memory – Backup (cont’d)

NOTE: The following definitions are for the various file types that can be backed up:

1

2

3

4

Project data – consists of the actual developed project data that is created in the C-more programming software

and includes all functionality, objects, screens, tag names, labels, comments, graphics, etc. Included in backup file

name StartupStorage.eas9.

Recipe data – consists of all the data values and labels that have been created for the various recipe sheets.

Includes all recipe sheets loaded to the panel. Only recipe sheets used in the project are loaded to the panel.

Firmware – consists of the operating system, firmware and run time files. Included in backup file name

StartupStorage.eas9.

Log data – consists of the Alarm Log, Message Log and Trend Data Logging files.

Select the data file(s) to be backed up by pressing the appropriate data file button. The

selection will be highlighted.

5

6

7

8

9

10

11

12

13

14

A

B

Pressing the highlighted data file button again will

turn it off.

The Next >> button will stay grayed out until at least

one data file is selected.

Any file type not available will be grayed out.

The Next >> button is now enabled.

Pressing Cancel will return to the previous menu.

Press the Next button to continue.

NOTE: In the case of the Project and Firmware files, these can be Restored later to another panel.

Recipe files can be edited externally from the panel and then Restored to the panel.

The Log files are for viewing purposes only.

See Memory - Restore later in this chapter for instructions on Restoring the Project, Firmware and/or Recipe files to

a Panel.

C

D

5-40

®

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

Page 41

Memory – Backup (cont’d)

Chapter 5 - System Setup Screens

Backup Data Files Naming and Organization

The following graphic shows how the various data files are organized on the memory device

when doing a Backup and also the file naming convention that is used when viewed in

Windows® File Explorer on a PC.

Folders

Removable Disk (F:)

EA_MemoryCopy

StartupStorage.eas

EAS File

160 KB

Log

Alarm_080131.txt

Text Document

1 KB

Screen1.jpg

320 x 240

JPEG Image

Recipe

Steel.csv

Microsoft Office Excel Comma ...

1 KB

X

Backup memory device

Project & Firmware

backup file

Log backup files

Recipe Sheet backup

files

1

2

3

4

5

6

7

8

9

10

11

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

®

12

13

14

A

B

C

D

5-41

Page 42

Chapter 5 - System Setup Screens

Memory – Backup (cont’d)

1

2

3

4

5

6

The next system setup screen allows the verification of

the data file selections. When the OK button is pressed,

the backup begins.

The user can return to the previous screen by pressing

the << Prev button.

7

8

9

10

11

12

13

14

A

B

C

This message is displayed during the Backup copying

process. Press the Cancel button to abort the backup.

The following text is shown in the copying progress

message box:

Copy to USB Memory:

“Please do not Power Off and Remove USB”

Copy to SD1:

“Please do not Power Off and Remove SD”

WARNING: During the copying process do

not power off the HMI or remove the memory

device.

This message is displayed to indicate the Backup is

complete. Press the OK button to return to the previous

menu selection.

D

5-42

®

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

Page 43

Memory – Backup (cont’d)

Chapter 5 - System Setup Screens

Warning Messages

If the destination does not have enough space to store

the selected memory size, then the message shown here

will be displayed. Press the OK button to clear the

warning message.

The warning message will read “There is not enough

storage memory in %Device%.”

%Device% will show either “SD1” or “USB.”

This warning message will be displayed if the backup

Memory device fails or is removed during the backup.

Press the OK button to clear the warning message.

The warning message will read “Backup Failed.

“%Device% cannot be found.”

%Device% will show either “SD1” or “USB.”

Refer to Chapter 8: Troubleshooting for additional

help.

1

2

3

4

5

6

7

8

9

10

11

For any other reason the backup fails, then this warning

message will be displayed. Press the OK button to clear

the warning message.

The warning message will read “Backup Failed.”

Refer to Chapter 8: Troubleshooting for additional

help.

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

®

12

13

14

A

B

C

D

5-43

Page 44

Chapter 5 - System Setup Screens

Memory – Restore

1

2

3

4

5

6

7

8

9

10

11

12

13

The Memory - Restore function is used to:

1.) Restore a project previously backed up on an SD

card or USB pen drive memory device to the same

panel. See Memory - Backup previously in this

chapter.

2.) Copy a project from one panel to another panel

using a memory device to physically transport the data

files.

3.) Restore a project into the panel that was

transferred to an “External Memory Device” using the

C-more Programming Software.

4.) Restore Recipe Sheet(s) previously backed up to a

memory device or copied to the memory device using

a PC.

The available memory devices will be displayed

showing the total and free available memory for that

device. If the device is not available, it will be grayed

out. The Next button is grayed out until a device is

selected.

The Cancel button can be pressed at any time to

return to the Memory Menu screen.

This is an example of a USB memory device selected

to be the source for restoring the data file(s).

The selected device is highlighted. Pressing again

deselects it.

Even if there is only one available memory device, it

needs to be highlighted in order to go to the next step.

Press the Next button to continue to Step 2.

14

A

B

C

D

5-44

NOTE: If you have a memory device inserted into the proper port on the HMI, but it doesn’t show up as highlighted

in Step 1 of the Backup setup screen, then try a different device to determine if the memory device is defective or if

there is a possible problem with the memory device connection. It may not be compatible with the panel. Some USB

pen drives are not USB 2.0 compatible and will not work with C-more HMIs. Some USB pen drives may take several

minutes before they are recognized by the panel.

SD cards must be formatted using the SD formatter provided by SDcard.org

®

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

Page 45

Chapter 5 - System Setup Screens

Memory – Restore (cont’d)

Please read the explanation for the availability of SD1 under different conditions as shown on

this page and the next.

1

SD1 Availability Explanation:

SD1 may be unavailable (grayed out) if there is no

card in SD Slot 1 or the card in SD slot 1 has the

project currently running on the panel stored on it.

The project will exist on SD1 if the SD card

was installed in SD1 when the project was

TRANSFERRED to the panel by the C-more

programming software.

If the panel is powered up or rebooted with an SD

card inserted into SD1 Slot, then the SD1 button’s

Total and Free memory will be displayed.

2

3

4

5

6

7

8

9

10

11

12

NOTE: The following definitions are for the various file types that can be restored:

Project data – consists of the actual developed project data that is created in the C-more programming software

and includes all functionality, objects, screens, tag names, labels, comments, graphics, etc. Included in backup file

name StartupStorage.eas9.

Recipe data – consists of all the data values and labels that have been created for the various recipe sheets.

Includes all recipe sheets loaded to the panel. Only recipe sheets used in the project are loaded to the panel.

Firmware – consists of the operating system, firmware and run time files. Included in backup file name

StartupStorage.eas9.

Log data – consists of the Alarm Log, Message Log and Trend Data Logging files.

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

®

5-45

13

14

A

B

C

D

Page 46

Chapter 5 - System Setup Screens

Memory – Restore (cont’d)

1

2

3

4

5

6

7

Select the data file(s) to be restored by pressing the

appropriate data file button. The selection will be

highlighted. The data file can be either the Project,

Firmware and/or Recipe files. The selected data is

restored to the internal built-in memory if there is no

SD card inserted into the SD1 slot.

Pressing the highlighted data file again will turn it off.

The Next >> button will stay grayed out until at least

one data file is selected.

Any file type not available will be grayed out.

8

9

10

11

12

13

14

A

B

C

D

This is an example of a file selected to restore.

The selected file is highlighted.

The Next >> button is now enabled.

Pressing Cancel will return to the previous menu.

Press the Next button to continue.

NOTE: The following definitions are for the various file types that can be restored:

Project data – consists of the actual developed project data that is created in the C-more programming software

and includes all functionality, objects, screens, tag names, labels, comments, graphics, etc. Included in backup file

name StartupStorage.eas9.

Recipe data – consists of all the data values and labels that have been created for the various recipe sheets.

Includes all recipe sheets loaded to the panel. Only recipe sheets used in the project are loaded to the panel.

Firmware – consists of the operating system, firmware and run time files. Included in backup file name

StartupStorage.eas9.

Log data – consists of the Alarm Log, Message Log and Trend Data Logging files.

5-46

®

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

Page 47

Memory – Restore (cont’d)

Chapter 5 - System Setup Screens

The data selected to restore is checked. If the data is

good, then the OK button can be pressed to start the

restore.

If there is a problem with the data, the OK button

will remain grayed out and the user can return to the

previous screen by pressing the << Prev button.

The problem could be caused by a corrupted data file.

See Chapter 8: Troubleshooting for additional help.

This message is displayed during the Restore process.

Press the Cancel button to abort the backup.

The following text is shown in the copying progress

message box:

Copy to USB Memory:

“Please do not Power Off and Remove USB”

Copy to SD1:

“Please do not Power Off and Remove SD card”

WARNING: During the copying process. Do

not power off the HMI or remove the memory

device.

1

2

3

4

5

6

7

8

9

10

11

This message is displayed to indicate the Restore

is complete. Press the OK button to return to the

previous menu selection.

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

®

12

13

14

A

B

C

D

5-47

Page 48

Chapter 5 - System Setup Screens

Memory – Restore (cont’d)

1

2

3

4

5

6

7

8

9

10

11

Warning Messages:

If the system memory does not have enough space to

restore the selected memory size, then the message

shown here will be displayed. Press the OK button to

clear the warning message.

The warning message will read “Not enough Memory

Space in System Memory.”

The Project size must be less than 40 MB.

This warning message will be displayed if the restore

Memory device fails or is removed during the backup.

Press the OK button to clear the warning message.

The warning message will read “Restore Failed.

“%Device% cannot be found.”

%Device% will show show “SD1” or “USB.”

Try using a different device with known good data in

the same connector or using the device that is causing

the error in a different connector.

12

13

14

A

B

C

D

5-48

For any other reason the restore fails, then this

warning message will be displayed. Press the OK

button to clear the warning message.

®

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

Page 49

Memory – Clear Memory

Chapter 5 - System Setup Screens

This function is used to clear individually selected

data files, or all data files, within the panel’s Built-in

Memory or any installed memory device such as a

USB pen drive or an SD card.

Select the memory device to clear. If the device is not

available, it will be grayed out.

The Next button is grayed out until a device is

selected.

1

2

3

4

5

6

The selected device is highlighted. Pressing again

deselects it.

When there are more than two available backup

devices, the one selected will be highlighted. If

another is selected, then the highlight will change to

the last one pressed. Only one device can be selected

at a time.

Press the Next button to continue.

7

8

9

10

11

12

13

14

A

B

C

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

®

D

5-49

Page 50

Chapter 5 - System Setup Screens

Memory – Clear Memory (cont’d)

1

2

3

4

5

6

Select the data file(s) to be cleared.

This is an example of an SD card or USB memory

that was selected in Clear Memory - Step-1.

The selected file will be highlighted. Pressing again

deselects it.

The Next >> button will stay grayed out until file(s)

are selected.

Selecting Clear All will erase all files located on the

memory device.

This is an example of USB Memory that was selected

in Clear Memory - Step-1.

Notice the ability to select either the Project file, Log

files, Recipe files, or the System files.

7

8

9

10

11

12

13

14

A

B

C

NOTE: Firmware files cannot be cleared from internal memory.

This is an example of the Project data file being

selected for clearing.

The selected memory area is highlighted. Pressing

again deselects it.

The Next >> button is now enabled.

Pressing Cancel will deselect the file(s).

Press the Next button to continue.

D

5-50

®

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

Page 51

Memory – Clear Memory (cont’d)

Chapter 5 - System Setup Screens

The data file(s)selected to clear are checked. If the

data file is good, then the OK button can be pressed

to start the clear procedure.

If there is a problem with the data file, the OK button

will remain grayed out and the user can return to the

previous screen by pressing the << Prev button.

1

2

3

4

Press the OK button to continue.

This message is displayed during the clearing process.

Press the Cancel button to abort the clearing.

The following text is shown in the clearing progress

message box:

Clearing Built-in Memory:

“Please do not Power Off”

Clearing USB Memory:

“Please do not Power Off or Remove USB”

Clearing SD1

“Please do not Power Off or Remove SD”

WARNING: During the clearing process, do not power off the HMI or remove the memory device.

The following message is displayed when the clearing

process is complete:

“%Device% cleared”

%Device% will show either “SD1,” “SD2,” or “USB.”

Press the OK button to return to the Memory Menu

screen.

5

6

7

8

9

10

11

12

13

14

A

B

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

®

C

D

5-51

Page 52

Chapter 5 - System Setup Screens

Memory – Clear Memory (cont’d)

1

The following is an example of Clear All selected for

clearing.

2

3

4

5

6

7

8

9

10

11

12

The selected device is highlighted.

The Next >> button is now enabled.

Pressing Cancel will deselect the Clear All.

NOTE: If Clear All is selected, all files will be erased from the memory device, even those not related to the C-more

HMI.

The data file(s)selected to clear are verified. If the data

file is good, then the OK button can be pressed to

start the clear procedure.

If there is a problem with the data file, the OK button

will remain grayed out and the user can return to the

previous screen by pressing the << Prev button.

Press the OK button to continue.

13

14

A

B

C

D

5-52

The warning message shown here will be displayed to

give the user the opportunity to decide if they want to

proceed or not.

Press the OK button to continue.

The Clear All process will start with a warning

message as seen in the first example and continue until

a message saying the device is cleared or a warning

message as shown on the next page appears.

®

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

Page 53

Memory – Clear Memory (cont’d)

Chapter 5 - System Setup Screens

The warning message shown here will be displayed if

the clearing process fails.

“Clear Failed.”

Press the OK button to return to the Clear Memory

screen and try again.

If the selected memory still fails to clear, then refer to

Chapter 8: Troubleshooting for additional help.

1

2

3

4

5

6

7

8

9

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

®

10

11

12

13

14

A

B

C

D

5-53

Page 54

Chapter 5 - System Setup Screens

Memory – Reset to Factory Default

1

2

3

4

5

6

WARNING: As a precaution, it is recommended to create a backup file to an SD card or USB storage

7

device using the Memory Backup function before resetting to factory defaults.

After pressing the Reset to Factory Default button

from the Memory Menu, the message box shown

will be displayed.

Resetting to the Factory Defaults produces the

following actions:

1.) The project file is cleared.

2.) The log, recipe & WAV files are cleared.

4.) The IP address is set to DHCP.

8

9

10

11

12

13

14

A

B

C

D

The message shown here is displayed once the Factory

Default values have been stored into the system

memory.

Press OK to continue.

5-54

®

EA9-RHMI-USER-M Hardware User Manual, 1st Ed. Rev. G

Loading...

Loading...