Page 1

Global LCD Panel Exchange Center

MODEL NO.: V216B1

www.panelook.com

PRODUCT SPECIFICATION

ϭʳ Tentative Specification

ϭʳ Preliminary Specification

Ϯʳ Approval Specification

SUFFIX: P14

Customer:

APPROVED BY SIGNATURE

Name / Title

Note

Please return 1 copy for your confirmation with your

signature and comments.

Approved By Checked By Prepared By

Chao-Chun Chung Roger Huang Carlos Lee

Version 2.0 1 DateΚ15 Jun 2010

The copyright belongs to CHIMEI InnoLux. Any unauthorized use is prohibited

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 2

Global LCD Panel Exchange Center

www.panelook.com

PRODUCT SPECIFICATION

CONTENTS

1. GENERAL DESCRIPTION......................................................................................................................................................... 5

1.1 OVERVIEW...........................................................................................................................................................5

1.2 CHARACTERISTICS...........................................................................................................................................5

1.3 MECHANICAL SPECIFICATIONS .....................................................................................................................5

2. ABSOLUTE MAXIMUM RATINGS.......................................................................................................................................... 6

2.1 ABSOLUTE RATINGS OF ENVIRONMENT (BASED ON CMI MODULE V216B1-L04)....................................6

2.2 ABSOLUTE RATINGS OF ENVIRONMENT (OPEN CELL) ...............................................................................7

2.3 ELECTRICAL ABSOLUTE RATINGS ..................................................................................................................7

2.3.1 TFT LCD MODULE ....................................................................................................................................7

3. ELECTRICAL CHARACTERISTICS......................................................................................................................................... 8

3.1 TFT LCD MODULE ..............................................................................................................................................8

4. BLOCK DIAGRAM OF INTERFACE...................................................................................................................................... 11

4.1 TFT LCD MODULE ............................................................................................................................................11

5. INPUT TERMINAL PIN ASSIGNMENT................................................................................................................................ 12

5.1 TFT LCD Module Input ......................................................................................................................................12

5.2 LVDS INTERFACE .............................................................................................................................................13

5.3 COLOR DATA INPUT ASSIGNMENT ..............................................................................................................14

6. INTERFACE TIMING................................................................................................................................................................ 15

6.1 INPUT SIGNAL TIMING SPECIFICATIONS.....................................................................................................15

6.2 POWER ON/OFF SEQUENCE...........................................................................................................................18

7. OPTICAL CHARACTERISTICS .............................................................................................................................................. 19

7.1 TEST CONDITIONS ...........................................................................................................................................19

7.2 OPTICAL SPECIFICATIONS..............................................................................................................................20

8. DEFINITION OF LABELS ........................................................................................................................................................ 23

8.1 OPEN CELL LABEL............................................................................................................................................23

8.2 CARTON LABEL................................................................................................................................................23

9. PACKAGING ............................................................................................................................................................................. 24

9.1 PACKAGING SPECIFICATIONS.......................................................................................................................24

Version 2.0 2 DateΚ15 Jun 2010

The copyright belongs to CHIMEI InnoLux. Any unauthorized use is prohibited

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 3

Global LCD Panel Exchange Center

www.panelook.com

PRODUCT SPECIFICATION

9.2 PACKAGING METHOD....................................................................................................................................24

10. PRECAUTIONS........................................................................................................................................................................ 26

10.1 ASSEMBLY AND HANDLING PRECAUTIONS.............................................................................................26

10.2 SAFETY PRECAUTIONS..................................................................................................................................26

11. MECHANICAL CHARACTERISTIC .................................................................................................................................... 27

Version 2.0 3 DateΚ15 Jun 2010

The copyright belongs to CHIMEI InnoLux. Any unauthorized use is prohibited

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 4

Global LCD Panel Exchange Center

Version Date Page(New) Section Description

Ver. 2.0 Jun 15, 2010 All All The specification was first issued.

www.panelook.com

PRODUCT SPECIFICATION

REVISION HISTORY

Version 2.0 4 DateΚ15 Jun 2010

The copyright belongs to CHIMEI InnoLux. Any unauthorized use is prohibited

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 5

Global LCD Panel Exchange Center

The mounting inclination of the connector makes

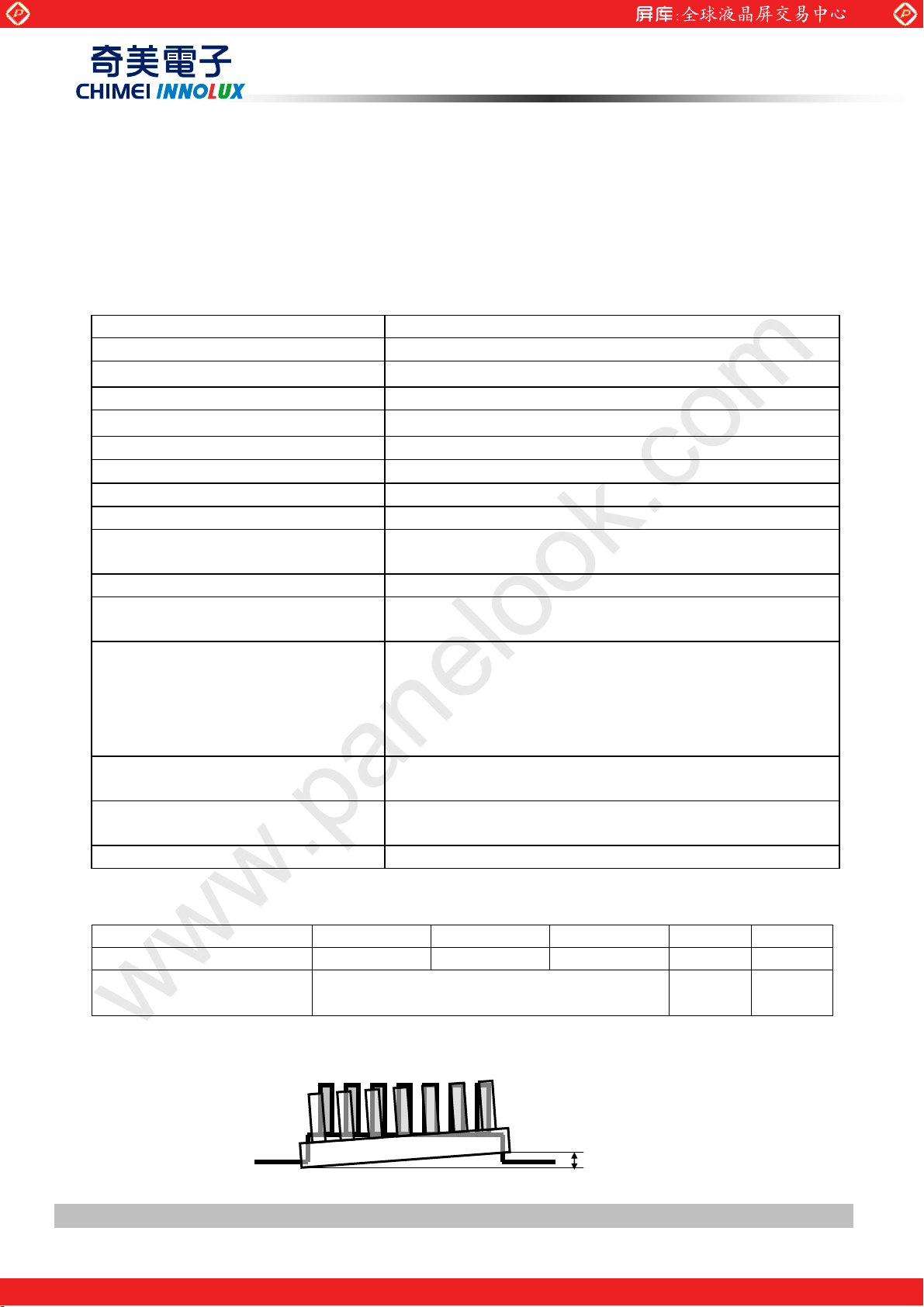

1. GENERAL DESCRIPTION

1.1 OVERVIEW

V216B1- P14 is a 21.6-inch TFT LCD cell with driver ICs and a 30pin 1ch-LVDS interface. This module supports

1366 x 768 (16:9 wide screen) formats and can display 16.7M colors (6-bit + Hi-FRC colors). The backlight unit is

not built in.

1.2 CHARACTERISTICS

CHARACTERISTICS ITEMS SPECIFICATIONS

Screen Diagonal [in] 21.6

Pixels [lines] 1366 × 768

Active Area [mm] 477.417 × 268.416

Sub -Pixel Pitch [mm] 0.1165 (H) × 0.3495 (V)

Pixel Arrangement RGB vertical stripe

Weight [g] TYP. 593

Physical Size [mm] 488.917(W) x 279.916(H) x 1.83(D) Typ.

Display Mode TN, Normally White

Contrast Ratio 800:1 Typ.

Glass thickness (Array/CF) [mm] 0.7 / 0.7

Viewing Angle (CR>10) +85/-85(H), +80/-80(V) Typ.

Color Chromaticity R=0.6883, 0.3115

www.panelook.com

PRODUCT SPECIFICATION

(Typical value measured at CMI’s module)

(Typical value measured at CMI’s module)

G=0.3347, 0.5615

B=0.1974, 0.1237

W=0.3203, 0.3595

*Please refer to “color chromaticity” on chapter 7.2

Cell Transparency [и] 7.1%Typ.

(Typical value measured at CMI’s module)

Polarizer (CF side) Anti-Glare coating (Haze 25%)

484.4(H) x 275.8(w), Hardness: 3H

Polarizer (TFT side) 484.4(H) x 275.8 (w)

1.3 MECHANICAL SPECIFICATIONS

Item Min. Typ. Max. Unit Note

Weight 564 593 622 g

I/F connector mounting

position

Note (1) Connector mounting position

the screen center within ±0.5mm as the horizontal.

+/- 0.5mm

(1)

Version 2.0 5 DateΚ15 Jun 2010

The copyright belongs to CHIMEI InnoLux. Any unauthorized use is prohibited

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 6

Global LCD Panel Exchange Center

www.panelook.com

PRODUCT SPECIFICATION

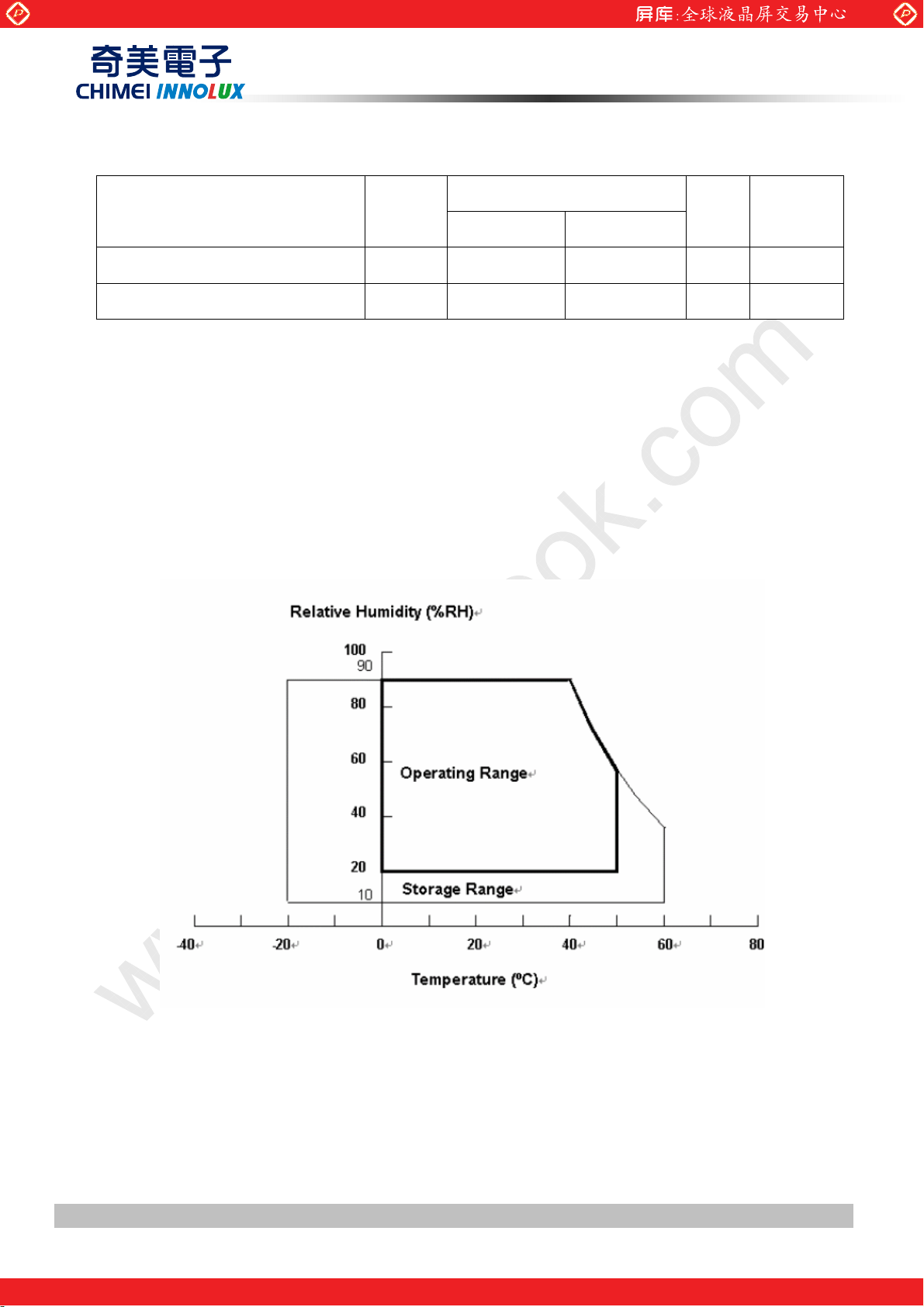

2. ABSOLUTE MAXIMUM RATINGS

2.1 ABSOLUTE RATINGS OF ENVIRONMENT (BASED ON CMI MODULE V216B1-L04)

Value

Item Symbol

Min. Max.

Storage Temperature TST -20 +60 ºC (1)

Operating Ambient Temperature TOP 0 +50 ºC (1) (2)

Note (1) Temperature and relative humidity range is shown in the figure below.

(a) 90 %RH Max. (Ta Љ 40 ºC).

(b) Wet-bulb temperature should be 39 ºC Max. (Ta > 40 ºC).

(c) No condensation.

Note (2) The maximum operating temperature is based on the test condition that the surface temperature of

Unit Note

display area is less than or equal to 65 ºC with LCD module alone in a temperature controlled chamber.

Thermal management should be considered in final product desig n to prevent the surface temperature

of display area from being over 65 ºC. The range of operating temperature may degra de in case of

improper thermal management in final product design.

Version 2.0 6 DateΚ15 Jun 2010

The copyright belongs to CHIMEI InnoLux. Any unauthorized use is prohibited

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 7

Global LCD Panel Exchange Center

www.panelook.com

PRODUCT SPECIFICATION

2.2 ABSOLUTE RATINGS OF ENVIRONMENT (OPEN CELL)

Storage Condition: With shipping package.

Storage temperature range: 25±5 к

Storage humidity range: 50±10%RH

Shelf life: a month

2.3 ELECTRICAL ABSOLUTE RATINGS

2.3.1 TFT LCD MODULE

Value

Item Symbol

Min. Max.

Power Supply Voltage VCC -0.3 6.0 V

Logic Input Voltage VIN -0.3 3.6 V

Unit Note

(1)

Note (1) Permanent damage to the device may occur if maximum values are exceeded. Function operation

should be restricted to the conditions described under Normal Operating C onditions.

Version 2.0 7 DateΚ15 Jun 2010

The copyright belongs to CHIMEI InnoLux. Any unauthorized use is prohibited

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 8

Global LCD Panel Exchange Center

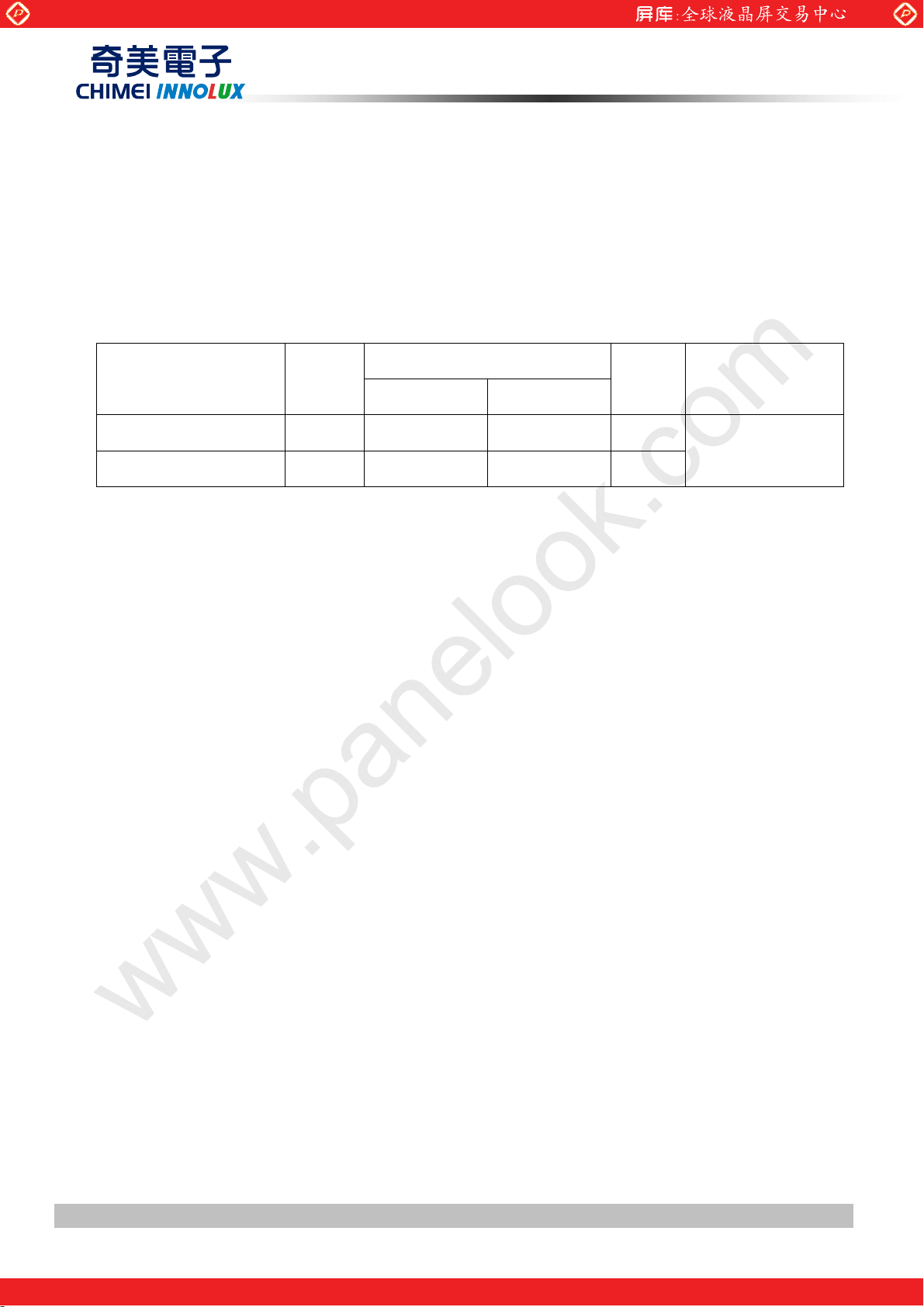

3. ELECTRICAL CHARACTERISTICS

3.1 TFT LCD MODULE

(Ta = 25 ± 2 ºC)

Parameter Symbol

Power Supply Voltage VCC 4.5 5.0 5.5 V (1)

www.panelook.com

PRODUCT SPECIFICATION

Value

Unit Note

Min. Typ. Max.

Rush Current I

White

Power Supply Current

Black

Vertical Stripe

Differential Input High

Threshold Voltage

Differential Input Low

Threshold Voltage

V

V

RUSH

I

CC

LVTH

LVTL

ЁЁ

Ё

Ё

Ё

+100

0.40

0.53 0.61 A

0.50

ЁЁ

ЁЁ

LVDS

interface

CMOS

interface

Common Input Voltage VCM 1.0 1.2 1.4 V

Differential input voltage |VID| 200

Terminating Resistor R

T

Ё

Input High Threshold Voltage VIH 2.7

Input Low Threshold Voltage V

0

IL

Ё

100

Ё

Ё

Note (1) The module should be always operated within the above ranges.

Note (2) Measurement condition:

3.0 A (2)

Ё

A

(3)

Ё

A

mV

-100 mV

(4)

600 mV

Ё

ohm

3.3 V

0.7 V

Version 2.0 8 DateΚ15 Jun 2010

The copyright belongs to CHIMEI InnoLux. Any unauthorized use is prohibited

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 9

Global LCD Panel Exchange Center

www.panelook.com

PRODUCT SPECIFICATION

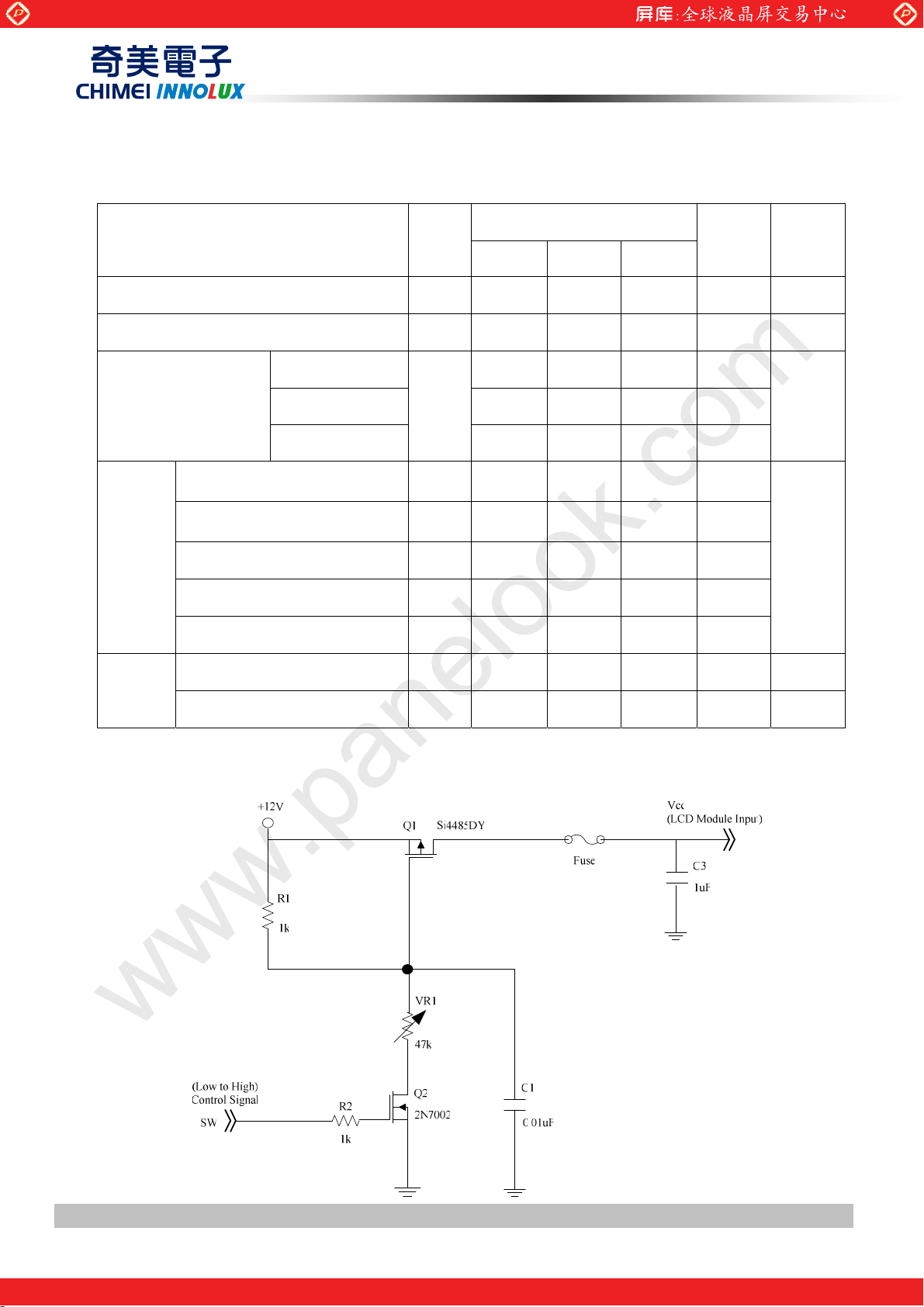

Vcc rising time is 470us

Vcc

0.9Vcc

0.1Vcc

GND

470us

Note (3) The specified power supply current is under the conditions at Vcc = 5 V, Ta = 25 ± 2 ºC, f

whereas a power dissipation check pattern below is displayed.

b. Black Pattern

Active Area

a. White Pattern

Active Area

c. Horizontal Pattern

= 60 Hz,

v

Version 2.0 9 DateΚ15 Jun 2010

The copyright belongs to CHIMEI InnoLux. Any unauthorized use is prohibited

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 10

Global LCD Panel Exchange Center

Note (4) The LVDS input characteristics are as follows:

www.panelook.com

PRODUCT SPECIFICATION

Version 2.0 10 DateΚ15 Jun 2010

The copyright belongs to CHIMEI InnoLux. Any unauthorized use is prohibited

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 11

Global LCD Panel Exchange Center

4. BLOCK DIAGRAM OF INTERFAC E

4.1 TFT LCD MODULE

www.panelook.com

PRODUCT SPECIFICATION

TFT LCD PANEL

(1366x3x768)

BACKLIGHT UNIT CONNECTOR

CP0404S0000(CviLux)

X BOARD

LVDS SIGNAL INPUT

Connector Part No.: JAE: FI-X30SSL-HF or P-TWO 187053-30091 or equivalent

Version 2.0 11 DateΚ15 Jun 2010

The copyright belongs to CHIMEI InnoLux. Any unauthorized use is prohibited

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 12

Global LCD Panel Exchange Center

Pin No.

Symbol

Description

Note

1NC No connection

(2)

2NC No connection

(2)

3NC No connection

(2)4GND

Ground

5

RX0- Negative tra nsmission data of pixel 0

6

RX0+

Positive tra

nsmission data of pixel 0

7

GND

Ground

8

RX1- Negative tra nsmission data of pixel 1

9

RX1+

Positive transmission data of pixel 1

10

GND

Ground

11

RX2- Negative tra nsmission data of pixel 2

12

RX2+

Positive transmission data of pixel

2

13

GND

Ground

14

RXCLK

-

Negative of clock

15

RXCLK+

Positive of clock

16

GND

Ground

17

RX3- Negative tra nsmission data of pixel 3

18

RX3+

Positive transmission data of pixel 3

19

GND

Ground

20NC No connection

(2)

21

SEL

LVDS

Select LVDS data format

(3)

22NC No connection

(2)

23

GND

Ground

24

GND

Ground

25

GND

Ground

26

VCC

Power supply: +5V

27

VCC

Power supply: +5V

28

VCC

Power supply: +5V

29

VCC

Power supply: +5V

30

VCC

Power supply: +5V

5. INPUT TERMINAL PIN ASSIGNMENT

5.1 TFT LCD Module Input

www.panelook.com

PRODUCT SPECIFICATION

Note (1) Connector part no.: JAE FI-X30SSL-HF or P-TWO 187053-30091 or equivalent

LVDS connector pin order defined as follows

Note (2) Reserved for internal use. Please leave it open.

Note (3) High or OPEN: Normal, Ground: JEIDA LVDS format

Please refer to chapter 5.2 LVDS INTERFACE.

Version 2.0 12 DateΚ15 Jun 2010

The copyright belongs to CHIMEI InnoLux. Any unauthorized use is prohibited

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 13

Global LCD Panel Exchange Center

5.2 LVDS INTERFACE

SELLVDS = H or Open (VESA)

www.panelook.com

PRODUCT SPECIFICATION

SELLVDS = L (JEIDA)

R0~R7: Pixel R Data (7; MSB, 0; LSB)

G0~G7: Pixel G Data (7; MSB, 0; LSB)

B0~B7: Pixel B Data (7; MSB, 0; LSB)

DE : Data enable signal

Notes (1) RSVD (reserved) pins on the transmitter shall be “H” or “L”.

Version 2.0 13 DateΚ15 Jun 2010

The copyright belongs to CHIMEI InnoLux. Any unauthorized use is prohibited

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 14

Global LCD Panel Exchange Center

5.3 COLOR DATA INPUT ASSIGNMENT

The brightness of each primary color (red, green and blue) is based on the 8-bit gray scale data input for the color.

The higher the binary input, the brighter the color. The table below provides the assignment of the color versus

data input.

Color

R7 R6 R5 R4 R3 R2 R1 R0 G7 G6 G5 G4 G3 G2 G1 G0 B7 B6 B5 B4 B3 B2 B1 B0

Black

Red

Green

Basic

Colors

Gray

Scale

Of

Red

Gray

Scale

Of

Green

Gray

Scale

Of

Blue

Note (1) 0: Low Level Voltage, 1: High Level Voltage

Blue

Cyan

Magenta

Yellow

White

Red (0) / Dark

Red (1)

Red (2)

:

:

Red (253)

Red (254)

Red (255)

Green (0) / Dark

Green (1)

Green (2)

:

:

Green (253)

Green (254)

Green (255)

Blue (0) / Dark

Blue (1)

Blue (2)

:

:

Blue (253)

Blue (254)

Blue (255)

0

0

0

1

1

1

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

1

0

0

0

0

:

:

1

1

1

0

0

0

:

:

0

0

0

0

0

0

:

:

0

0

0

0

0

0

0

0

:

:

:

:

1

1

1

1

1

1

0

0

0

0

0

0

:

:

:

:

0

0

0

0

0

0

0

0

0

0

0

0

:

:

:

:

0

0

0

0

0

0

www.panelook.com

PRODUCT SPECIFICATION

Data Signal

Red Green Blue

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

0

0

0

0

0

0

0

0

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

0

0

0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

1

0

0

0

0

:

:

:

:

:

:

:

:

:

:

:

:

:

:

1

1

1

0

1

0

0

0

1

1

1

1

0

0

0

0

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

:

:

:

:

:

:

:

:

:

:

:

:

:

:

0

0

0

0

0

1

1

1

0

0

0

0

0

1

1

1

0

0

0

0

0

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

:

:

:

:

:

:

:

:

:

:

:

:

:

:

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

0

0

1

1

0

0

1

1

1

1

0

0

0

0

0

0

:

:

:

:

:

:

0

0

0

0

0

0

0

0

0

0

0

0

:

:

:

:

:

:

1

1

1

1

1

1

0

0

0

0

0

0

:

:

:

:

:

:

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

0

0

0

1

1

1

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

1

0

0

0

0

0

0

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

1

0

1

0

0

0

0

0

1

1

0

0

0

0

0

0

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

0

0

0

1

1

1

1

1

0

0

0

1

1

1

1

1

0

0

0

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

:

:

:

:

:

:

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

0

1

0

:

:

:

:

:

:

1

0

1

1

1

0

1

1

1

Version 2.0 14 DateΚ15 Jun 2010

The copyright belongs to CHIMEI InnoLux. Any unauthorized use is prohibited

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 15

Global LCD Panel Exchange Center

6. INTERFACE TIMING

6.1 INPUT SIGNAL TIMING SPECIFICATIONS

(Ta = 25 ± 2 ºC)

The input signal timing specifications are shown as the following table and timing diagram.

www.panelook.com

PRODUCT SPECIFICATION

Signal Item Symbol

F

clkin

(=1/TC)

T

clkin_mod

F

LVDS

Receiver

Clock

Frequency

Input cycle to

cycle jitter

Spread spectrum

modulation range

Spread spectrum

modulation

F

SSM

frequency

LVDS

Setup Time Tlvsu 600

Receiver

Data

Hold Time Tlvhd

Fr5 47 50 53 Hz

Frame Rate

Vertical

Active

Display

Term

Total Tv 778 806 1050 Th

Display Tvd 768 768 768 Th

F

Blank Tvb 10 38 282 Th

Min. Typ. Max. Unit Note

60 76 82 MHz

rcl

ЁЁ

F

clkin

-2%

Ё

ЁЁ

ЁЁ

600

57 60 63 Hz

r6

ЁЁ

200 ps (3)

F

+2% MHz

clkin

200 KHz

ps

ps

(4)

(5)

Tv=Tvd+Tvb

Horizontal

Active

Display

Term

Total Th 1442 1560 1936 Tc

Display Thd 1366 1366 1366 Tc

Blank Thb 76 194 570 Tc

Th=Thd+Thb

“Enlarging Vtotal from Max 888Th to 1050Th is OK, provided that both pixel clock & Htotal are within the

specified range in the spec.”

Note (1) Please make sure the range of pixel clock has follow the below equationΚ

Fclkin(max) Њ Fr6 Ѽ Tv Ѽ Th

Fr5 Ѽ Tv Ѽ Th Њ Fclkin(min)

Note (2) This module is operated in DE only mode and please follow the input signal timing diagram belowΚ

ʳ

Version 2.0 15 DateΚ15 Jun 2010

The copyright belongs to CHIMEI InnoLux. Any unauthorized use is prohibited

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 16

Global LCD Panel Exchange Center

DE

h

T

DCLK

T

c

DE

www.panelook.com

PRODUCT SPECIFICATION

INPUT SIGNAL TIMING DIAGRAM

T

v

vd

T

Thd

Thb

T

vb

DATA

Note (3) The input clock cycle-to-cycle jitter is defined as below figures. Trcl = I T1 – T I

Note (4) The SSCG (Spread spectrum clock generator) is defined as below figures.

Valid display data (1366 clocks)

Version 2.0 16 DateΚ15 Jun 2010

The copyright belongs to CHIMEI InnoLux. Any unauthorized use is prohibited

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 17

Global LCD Panel Exchange Center

www.panelook.com

PRODUCT SPECIFICATION

Note (5) The LVDS timing diagram and setup/hold time is defined and showing as the following figures.

LVDS RECEIVER INTERFACE TIMING DIAGRAM

Tc

RXCLK+/-

RXn+/-

Tlvsu

Tlvhd

1T

14

3T

14

5T

14

7T

14

9T

14

11T

14

13T

14

Version 2.0 17 DateΚ15 Jun 2010

The copyright belongs to CHIMEI InnoLux. Any unauthorized use is prohibited

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 18

Global LCD Panel Exchange Center

Љ

Љ

Љ

Љ

Љ

P

Љ

Љ

Љ

www.panelook.com

PRODUCT SPECIFICATION

6.2 POWER ON/OFF SEQUENCE

To prevent a latch-up or DC operation of LCD module, the power on/off sequence should be as the diagram

below.

cc

0.1V

T4

0.5ЉT1Љ10ms

0

T

2

50ms

0

T

3

50ms

1s

T

4

LVDS Signals

0V

0V

0.1V

CC

Power On

T

3T1

2

T

VALID

0ЉT7ЉT2

8

T3

T

0

T7

8

T

Option Signals

(SELLVDS)

Backlight (Recommended)

500msЉT

100ms

5

T6

50%

5

T

50%

T

6

Power ON/OFF Sequence

Note (1) The supply voltage of the external system for the module input should follow the definition of Vcc.

Note (2) Apply the lamp voltage within the LCD operation range. When the backlight turns on before the LCD

operation or the LCD turns off before the backlig ht turns off, the display may momentarily beco me

abnormal screen.

Note (3) In case of Vcc is in off level, please keep the level of input signals on the low or high impedance. If T2<0,

that maybe cause electrical overstress failure.

Note (4) T4 should be measured after the module has been fully discharged between power off and on period.

Note (5) Interface signal shall not be kept at high impedance when the power is on.

Version 2.0 18 DateΚ15 Jun 2010

The copyright belongs to CHIMEI InnoLux. Any unauthorized use is prohibited

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 19

Global LCD Panel Exchange Center

7. OPTICAL CHARACTERISTICS

7.1 TEST CONDITIONS

Item Symbol Value Unit

www.panelook.com

PRODUCT SPECIFICATION

Ambient Temperature Ta

Ambient Humidity Ha

Supply Voltage VCC 5.0 V

Input Signal According to typical value in "3. ELECTRICAL CHARACTERISTICS"

Lamp Current IL 7 mA

Oscillating Frequency (Inverter) F

Vertical Frame Rate Fr 60 Hz

The LCD module should be stabilized at given temperature for 1 hour to avoid abrupt temperature change

during measuring. In order to stabilize the lum ina nce, the mea surement should be executed after lighting

backlight for 1 hour in a windless room.

W

25 ± 2ʳ

50 ± 10

66 ± 3

к

%RH

KHz

Version 2.0 19 DateΚ15 Jun 2010

The copyright belongs to CHIMEI InnoLux. Any unauthorized use is prohibited

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 20

Global LCD Panel Exchange Center

7.2 OPTICAL SPECIFICATIONS

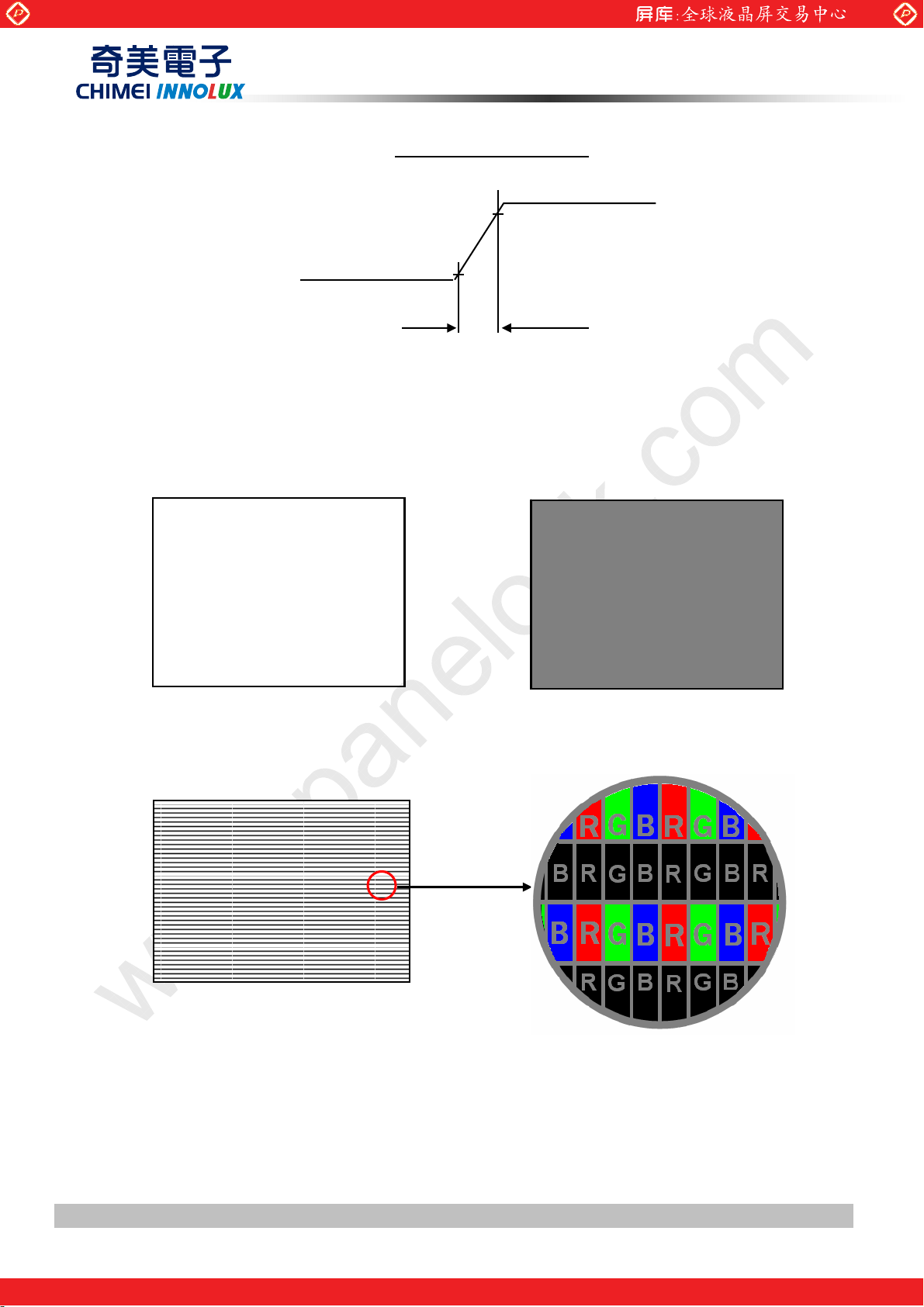

The relative measurement methods of optica l characteristics are shown in 7.2. The following items should be

measured under the test conditions described in 7.1 and stable environment shown in 7.1.

www.panelook.com

PRODUCT SPECIFICATION

Item Symbol

Rcx

Condition Min. Typ. Max. Unit Note

0.6883

Red

Color

Chromaticity

Green

Blue

Rcy

Gcx

Gcy

Bcx

Bcy

Wcx

=0°, θY =0°

θ

x

Viewing Angle at

Normal Direction

Standard light source

“C”

---

0.3115

0.3347

0.5615

0.1974

0.1237

0.3203

---

(0) (5)

White

Wcy

Center Transmittance T% --- 7.1 --- % (1) (7)

Contrast Ratio CR

Response Time

White Variation

TR --T

with CMI Module@60Hz

F

δW

θ

+

x

=0°, θY =0°

θ

x

with CMI module

θ

=0°, θY =0°

x

=0°, θY =0°

θ

x

with CMI module

--- 800

---

--- --- 1.3

--- 80 ---

0.3595

1.3 ---

3.7 ---

--- (1) (3)

ms

(4)

ms

(1) (6)

Horizontal

-

Viewing

Angle

Vertical

θ

x

θ

+

Y

θ

-

Y

CR≥10

With CMI module

--- 80 --Deg. (1) (2)

--- 80 ---

--- 70 ---

Note (0) Light source is the standard light source ”C” which is defined by CIE and driving voltage are based on

suitable gamma voltages. The calculating method is as following:

1. Measure Module’s and BLU’s spectrum. White is without signal input and R, G, B are with signal input.

BLU (for V216B1-L04) is supplied by CMI.

2. Calculate cell’s spectrum.

3. Calculate cell’s chromaticity by using the spectrum of standard light source “C ”.

Note (1) Light source is the BLU which is supplied by CMI and driving voltage are based on suitable gamma

voltages.

Version 2.0 20 DateΚ15 Jun 2010

The copyright belongs to CHIMEI InnoLux. Any unauthorized use is prohibited

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 21

Global LCD Panel Exchange Center

T

Note (2) Definition of Viewing Angle (θx, θy):

Viewing angles are measured by Autronic Conoscope Cono-80.

www.panelook.com

PRODUCT SPECIFICATION

Normal

θx = θy = 0º

X- = 90º

θ

6 o’clock

θ

y- = 90º

x-

y-

Note (3) Definition of Contrast Ratio (CR):

The contrast ratio can be calculated by the following expression.

Contrast Ratio (CR) = L255 / L0

L255: Luminance of gray level 255

L0: Luminance of gray level 0

CR = CR (5),

θy- θ

y+

θx−

θx+

12 o’clock direction

y+

θ

y+ = 90º

x+

X+ = 90º

θ

where CR (X) is corresponding to the Contrast Ratio of the point X at the figure in Note (6).

Note (4) Definition of Response Time (T

Gray Level 255

100%

90%

Optical

Response

10%

0%

T

, TF):

R

Gray Level 255

Gray Level 0

R

T

F

ime

Version 2.0 21 DateΚ15 Jun 2010

The copyright belongs to CHIMEI InnoLux. Any unauthorized use is prohibited

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 22

Global LCD Panel Exchange Center

Note (5) Measurement Setup:

The LCD module should be stabilized at given temperature for 1 hour to avoid abrupt temperature

change during measuring. In order to stabilize the luminance, the measurement should be

executed after lighting Backlight for 1 hour in a windl e ss room.

www.panelook.com

PRODUCT SPECIFICATION

Note (6) Definition of White Variation (δW):

Measure the luminance of gray level 255 at 5 points

δW = Maximum [L (1), L (2), L (3), L (4), L (5)] / Minimum [L (1), L (2), L (3), L (4), L (5)]

W/4

W/2

W

Vertical Line

3W/4

Horizontal Line

D

D/4 D/2 3D/4

1 2

5

3 4

X

Active Area

: Test Point

X=1 to 5

Note (7) Definition of Transmittance (T%) :

Module is without signal input.

Luminance of LCD module

Transmittance = x 100%

Luminance of backlight

Version 2.0 22 DateΚ15 Jun 2010

The copyright belongs to CHIMEI InnoLux. Any unauthorized use is prohibited

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 23

Global LCD Panel Exchange Center

www.panelook.com

PRODUCT SPECIFICATION

8. DEFINITION OF LABELS

8.1 OPEN CELL LABEL

The barcode nameplate is pasted on each open cell as illustration for CMI internal control.

V216B1-P14 Rev.

XXXXXXXXXXXXXXX

8.2 CARTON LABEL

The barcode nameplate is pasted on each box as illustration, and its definitions are as following explanation.

P.O. NO.

Parts ID.

Carton ID.

XXXXXXXXXXXXXX

Made in Taiwan

P.O. NO.

Parts ID.

Carton ID.

XXXXXXXXXXXXXX

Quantities 27

Quantities 27

Made in China

(a) Model Name: V216B1– P14

(b) Carton ID: CMI internal control

(c) Quantities: 27

Version 2.0 23 DateΚ15 Jun 2010

The copyright belongs to CHIMEI InnoLux. Any unauthorized use is prohibited

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 24

Global LCD Panel Exchange Center

e

9. PACKAGING

9.1 PACKAGING SPECIFICATIONS

(1) 27 PCS LCD TV Panels / 1 Box

(2) Box dimensions : 640 (L) X 490 (W) X 320 (H)

(3) Weight : approximately 24 Kg

9.2 PACKAGING METHOD

Figures 9- 1 and 9-2 are the packing method.

LCD Panel

www.panelook.com

PRODUCT SPECIFICATION

The design packing top layer for empty tray

LCD Panel

LCD Panel

Carton

Carton Lab

Figure.9-1 packing method

Version 2.0 24 DateΚ15 Jun 2010

The copyright belongs to CHIMEI InnoLux. Any unauthorized use is prohibited

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 25

Global LCD Panel Exchange Center

Film

www.panelook.com

PRODUCT SPECIFICATION

PE Sheet

PE Sheet

Film

Carton Label

PE Sheet

PP Belt

PP Belt

PP Belt

Film

Carton Label

Figure.9-2 packing method

Film

Carton Label

Version 2.0 25 DateΚ15 Jun 2010

The copyright belongs to CHIMEI InnoLux. Any unauthorized use is prohibited

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 26

Global LCD Panel Exchange Center

www.panelook.com

PRODUCT SPECIFICATION

10. PRECAUTIONS

10.1 ASSEMBLY AND HANDLING PRECAUTIONS

(1) Do not apply rough force such as bending or twisting to the product during assembly.

(2) To assemble ba cklig ht or insta ll module in to user’s sys tem can be onl y in clean w orking a reas. The dust

and oil may cause electrical short or worsen the polarizer.

(3) It is not permitted to have pressure or impulse on the module because the LCD panel will be damaged.

(4) Always follow the correct power sequence when the product is connecting and operating. This can

prevent damage to the CMOS LSI chips during latch-up.

(5) Do not pull the I/F connector in or out while the module is operating.

(6) Use a soft dry cloth without chemicals for cleaning, because the surface of polarizer is very soft and

easily scratched.

(7) It is dangero us that moisture come into or contacted the product, because moisture may damage the

product when it is operating.

(8) High temperature or humidity may reduce the performance of module. Please store this product within

the specified storage conditions.

(9) When ambient temperature is lower than 10ºC may reduce the display quality. For example, the

response time will become slowly.

10.2 SAFETY PRECAUTI ONS

(1) If the liquid crystal material leaks from the panel, it should be kept away from the eyes or mouth. In

case of contact with hands, skin or clothes, it has to be washed away thoroughly with soap.

(2) After the product’s end of life, it is not harmful in case of norma l operation and storage.

Version 2.0 26 DateΚ15 Jun 2010

The copyright belongs to CHIMEI InnoLux. Any unauthorized use is prohibited

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 27

Global LCD Panel Exchange Center

&+ ,0(,

11. MECHANICAL CHARACTERISTIC

www.panelook.com

PRODUCT SPECIFICATION

Version 2.0 27 DateΚ15 Jun 2010

The copyright belongs to CHIMEI InnoLux. Any unauthorized use is prohibited

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Loading...

Loading...