Page 1

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 2

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: Sep.20, 2005

Model No.: N154I1-L09

Approval

- CONTENTS -

REVISION HISTORY

1. GENERAL DESCRIPTION

1.1 OVERVIEW

1.2 FEATURES

1.3 APPLICATION

1.4 GENERAL SPECIFICATIONS

1.5 MECHANICAL SPECIFICATIONS

2. ABSOLUTE MAXIMUM RATINGS

2.1 ABSOLUTE RATINGS OF ENVIRONMENT

2.2 ELECTRICAL ABSOLUTE RATINGS

2.2.1 TFT LCD MODULE

2.2.2 BACKLIGHT UNIT

3. ELECTRICAL CHARACTERISTICS

3.1 TFT LCD MODULE

3.2 BACKLIGHT UNIT

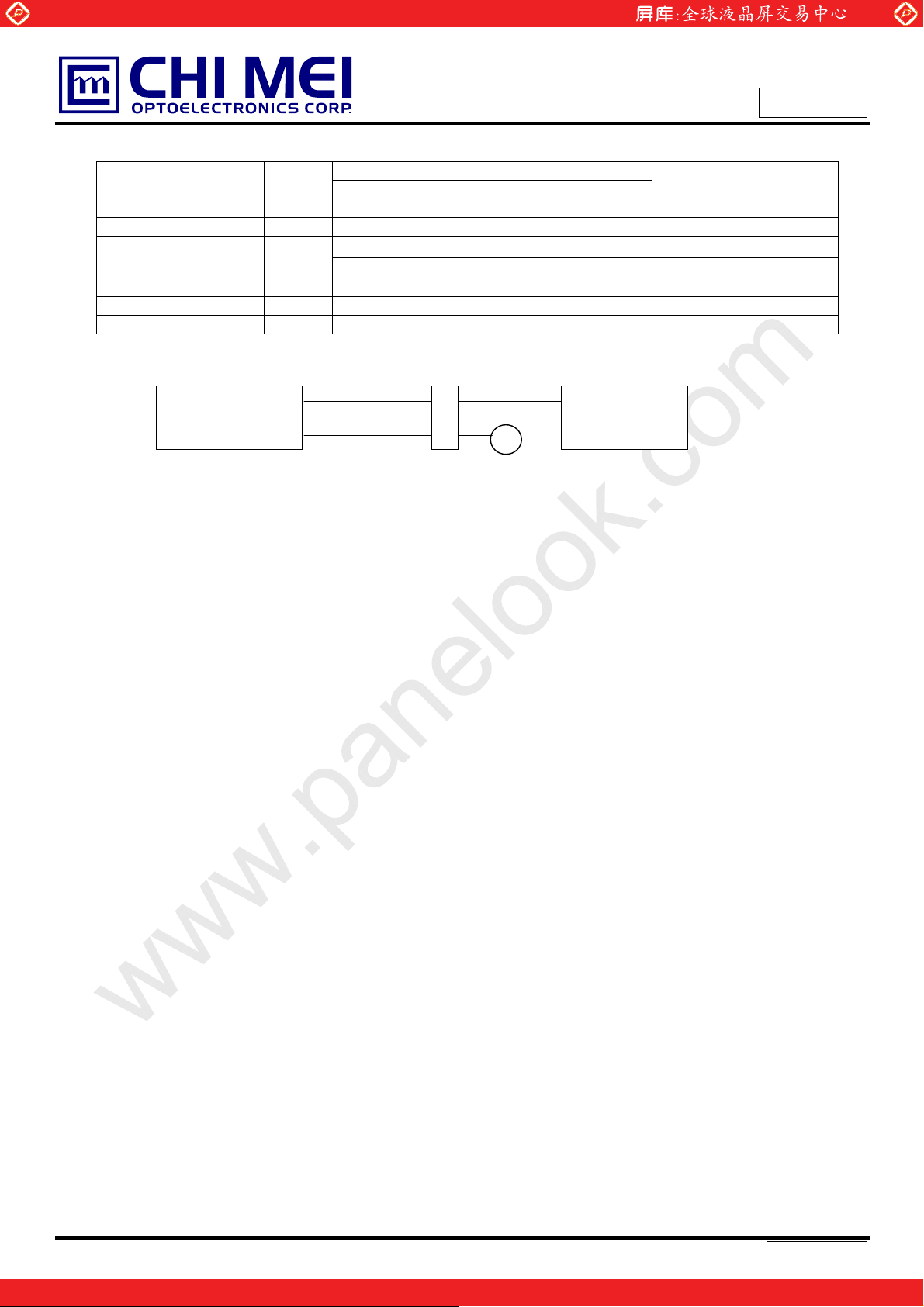

4. BLOCK DIAGRAM

4.1 TFT LCD MODULE

4.2 BACKLIGHT UNIT

5. INPUT TERMINAL PIN ASSIGNMENT

5.1 TFT LCD MODULE

5.2 BACKLIGHT UNIT

5.3 TIMING DIAGRAM OF LVDS INPUT SIGNAL

5.4 COLOR DATA INPUT ASSIGNMENT

5.5 EDID DATA STRUCTURE

5.6 EDID SIGNAL SPECIFICATION

6. INTERFACE TIMING

6.1 INPUT SIGNAL TIMING SPECIFICATIONS

6.2 POWER ON/OFF SEQUENCE

7. OPTICAL CHARACTERISTICS

7.1 TEST CONDITIONS

7.2 OPTICAL SPECIFICATIONS

8. PRECAUTIONS

8.1 HANDLING PRECAUTIONS

8.2 STORAGE PRECAUTIONS

8.3 OPERATION PRECAUTIONS

9. PACKING ------------------------------------------------------- 26

9.1 CARTON

9.2 PALLET

10. DEFINITION OF LABELS

10.1 CMO MODULE LABEL

10.2 CARTON LABEL

------------------------------------------------------- 3

------------------------------------------------------- 4

------------------------------------------------------- 5

------------------------------------------------------- 7

------------------------------------------------------- 10

------------------------------------------------------- 11

------------------------------------------------------- 19

------------------------------------------------------- 21

------------------------------------------------------- 25

------------------------------------------------------- 28

2 / 29

Version 3.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 3

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: Sep.20, 2005

Model No.: N154I1-L09

Approval

Version Date

Ver 3.0 Sep. 20, 05’

Page

(New)

All

REVISION HISTORY

Section Description

All

Approval specification first issued.

3 / 29

Version 3.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 4

Global LCD Panel Exchange Center

1. GENERAL DESCRIPTION

1.1 OVERVIEW

N154I1 -L09 is a 15.4” TFT Liquid Crystal Display module with single CCFL Backlight unit and 30 pins

LVDS interface. This module supports 1280 x 800 Wide-XGA mode and can display 262,144 colors. The

optimum viewing angle is at 6 o’clock direction. The inverter module for Backlight is not built in.

1.2 FEATURES

- Thin and light weight

- WXGA (1280 x 800 pixels) resolution

- 3.3V LVDS (Low Voltage Differential Signaling) interface with 1 pixel/clock

- Meet RoHS requirement.

www.panelook.com

Issued Date: Sep.20, 2005

Model No.: N154I1-L09

Approval

1.3 APPLICATION

- TFT LCD Notebook

1.4 GENERAL SPECIFICATI0NS

Item Specification Unit Note

Active Area 331.2 (H) x 207.0 (V) (15.4” diagonal) mm

Bezel Opening Area 335.0 (H) x 210.7 (V) mm

Driver Element a-si TFT active matrix - Pixel Number 1280 x R.G.B. x 800 pixel Pixel Pitch 0.2588 (H) x 0.2588 (V) mm Pixel Arrangement RGB vertical stripe - Display Colors 262,144 color Transmissive Mode Normally white - Surface Treatment Hard coating (3H), Anti-glare (Haze 25) - -

1.5 MECHANICAL SPECIFICATIONS

Item Min. Typ. Max. Unit Note

Horizontal(H) 343.5 344.0 344.5 mm

Module Size

Note (1) Please refer to the attached drawings for more information of front and back outline dimensions.

Vertical(V) 221.5 222.0 222.5 mm

Depth(D) - 6.2 6.5 mm

Weight - 600 620 g -

(1)

(1)

4 / 29

Version 3.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 5

Global LCD Panel Exchange Center

A

2. ABSOLUTE MAXIMUM RATINGS

2.1 ABSOLUTE RATINGS OF ENVIRONMENT

Item Symbol

Storage Temperature TST -20 +60 ºC (1)

Operating Ambient Temperature TOP 0 +50 ºC (1), (2)

Shock (Non-Operating) S

Vibration (Non-Operating) V

Note (1) Temperature and relative humidity range is shown in the figure below.

(a) 90 %RH Max. (Ta Љ 40 ºC).

(b) Wet-bulb temperature should be 39 ºC Max. (Ta > 40 ºC).

(c) No condensation .

www.panelook.com

Issued Date: Sep.20, 2005

Model No.: N154I1-L09

Approval

Value

Min. Max.

- 220 G (3), (5)

NOP

- 1.5 G (4), (5)

NOP

Unit Note

Note (2) The temperature of panel surface should be 0 ºC Min. and 50 ºC Max.

Note (3) 2ms, half sine wave, 1 time for ± X, ± Y, ± Z.

Relative Humidity (%RH)

100

90

80

60

Operating Range

40

20

Storage Range

5

Temperature (ºC)

8060 -20 400 20-40

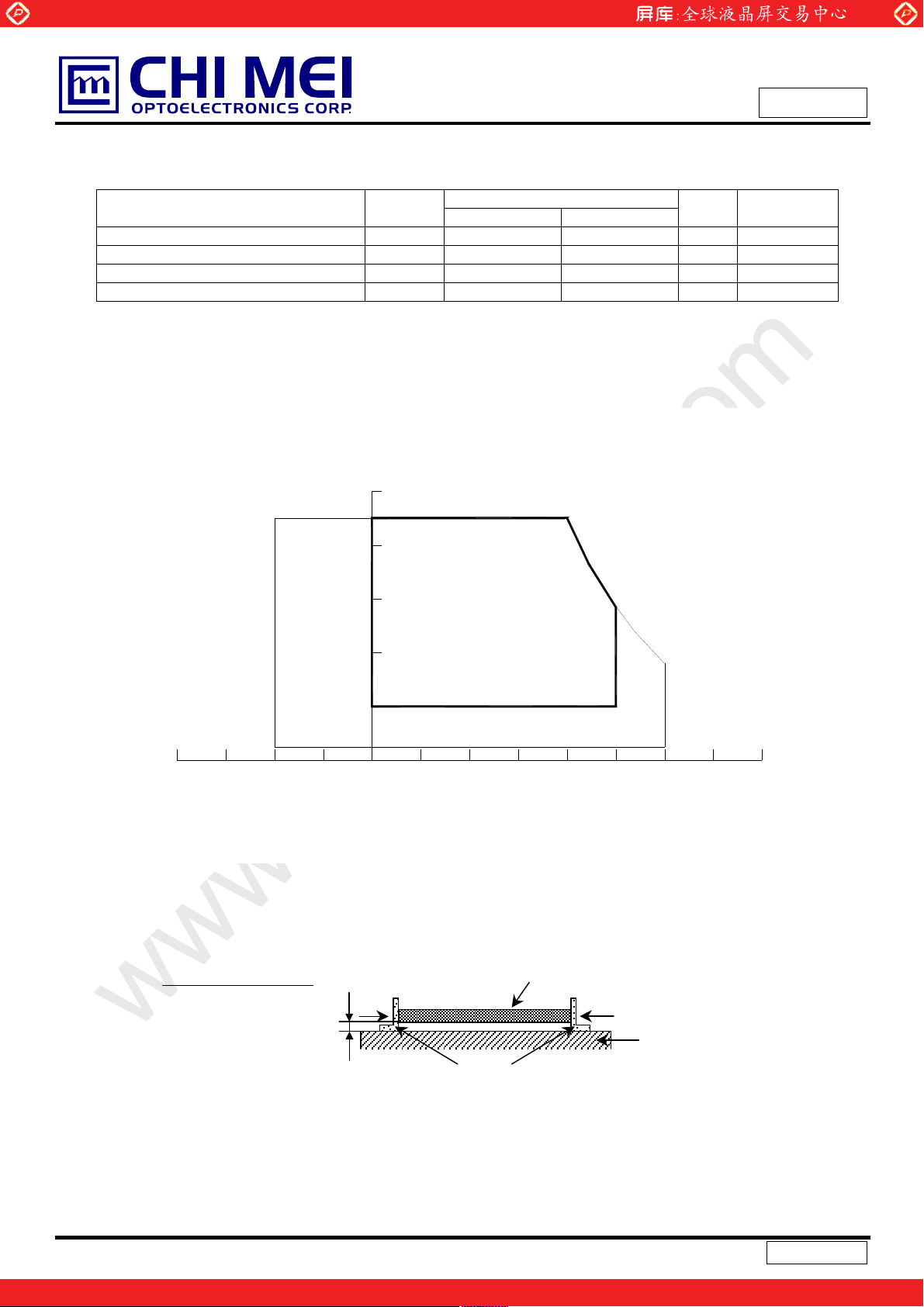

Note (4) 10 ~ 200 Hz, 0.5 Hr / Cycle, 1 cycles for each X, Y, Z. The fixing condition is shown as below:

Note (5) At testing Vibration and Shock, the fixture in holding the module has to be hard and rigid enough

t Room Temperature

Side Mount Fixing Screw

Gap=2mm

so that the module would not be twisted or bent by the fixture.

Bracket

LCD Module

Side Mount Fixing Screw

Stage

5 / 29

Version 3.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 6

Global LCD Panel Exchange Center

2.2 ELECTRICAL ABSOLUTE RATINGS

2.2.1 TFT LCD MODULE

Item Symbol

Power Supply Voltage Vcc -0.3 +4.0 V

Logic Input Voltage VIN -0.3 Vcc+0.3 V

2.2.2 BACKLIGHT UNIT

Item Symbol

Lamp Voltage VL - 2.5K V

Lamp Current IL - 7.0 mA

Lamp Frequency FL - 80 KHz

Note (1) Permanent damage to the device may occur if maximum values are exceeded. Function operation

should be restricted to the conditions described under Normal Operating Conditions.

www.panelook.com

Value

Min. Max.

Value

Min. Max.

Unit Note

Unit Note

Issued Date: Sep.20, 2005

Model No.: N154I1-L09

Approval

(1)

(1), (2), IL = 6.5 mA

RMS

RMS

(1), (2)

Note (2) Specified values are for lamp (Refer to Section 3.2 for further information).

3. ELECTRICAL CHARACTERISTICS

3.1 TFT LCD MODULE Ta = 25 ± 2 ºC

FUSE

Value

C3

1uF

Unit Note

Vcc

(LCD Module Input)

Parameter Symbol

Min. Typ. Max.

Power Supply Voltage Vcc 3.0 3.3 3.6 V Ripple Voltage VRP - - 100 mV Rush Current I

- - 1.5 A (2)

RUSH

White - 580 mA (3)a

Power Supply Current

Black - 650 mA (3)b

Vertical Stripe

lcc

- 650 mA (3)c

“H” Level VIH - - +100 mV - Differential Input Voltage for

LVDS Receiver Threshold

“L” Level V

-100 - - mV -

IL

Terminating Resistor RT - 100 - Ohm -

Note (1) The module should be always operated within above ranges.

Note (2) Measurement Conditions:

+3.3V

Q1 2SK1475

R1

47K

(High to Low)

(Control Signal)

SW

+12V

C1

1uF

VR1

R2

1K

47K

0.01uF

Q2

2SK1470

C2

6 / 29

Version 3.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 7

Global LCD Panel Exchange Center

Vcc rising time is 470us

0.1Vcc

GND

www.panelook.com

Issued Date: Sep.20, 2005

Model No.: N154I1-L09

Approval

+3.3V

0.9Vcc

470us

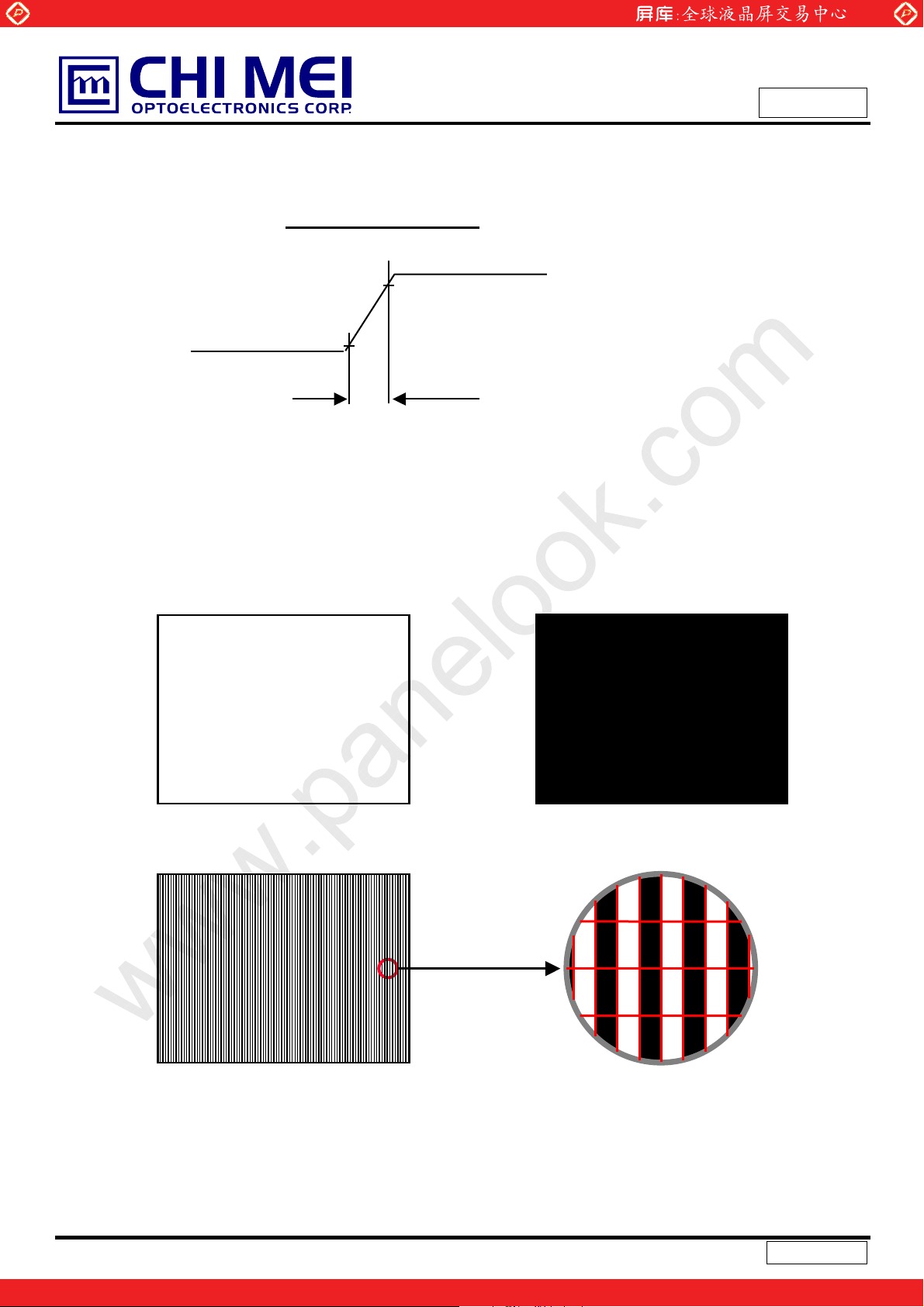

Note (3) The specified power supply current is under the conditions at Vcc = 3.3 V, Ta = 25 ± 2 ºC, DC

Current and f

a. White Pattern

c. Vertical Stripe Pattern

= 60 Hz, whereas a power dissipation check pattern below is displayed.

v

b. Black Pattern

Active Area

Active Area

R

G

B

R

G

B

R

Active Area

B

R

B

R R

G

G

G

B

B

B

R

R

G

G

G

B

B

B

7 / 29

Version 3.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

R

R

www.panelook.com

Page 8

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: Sep.20, 2005

Model No.: N154I1-L09

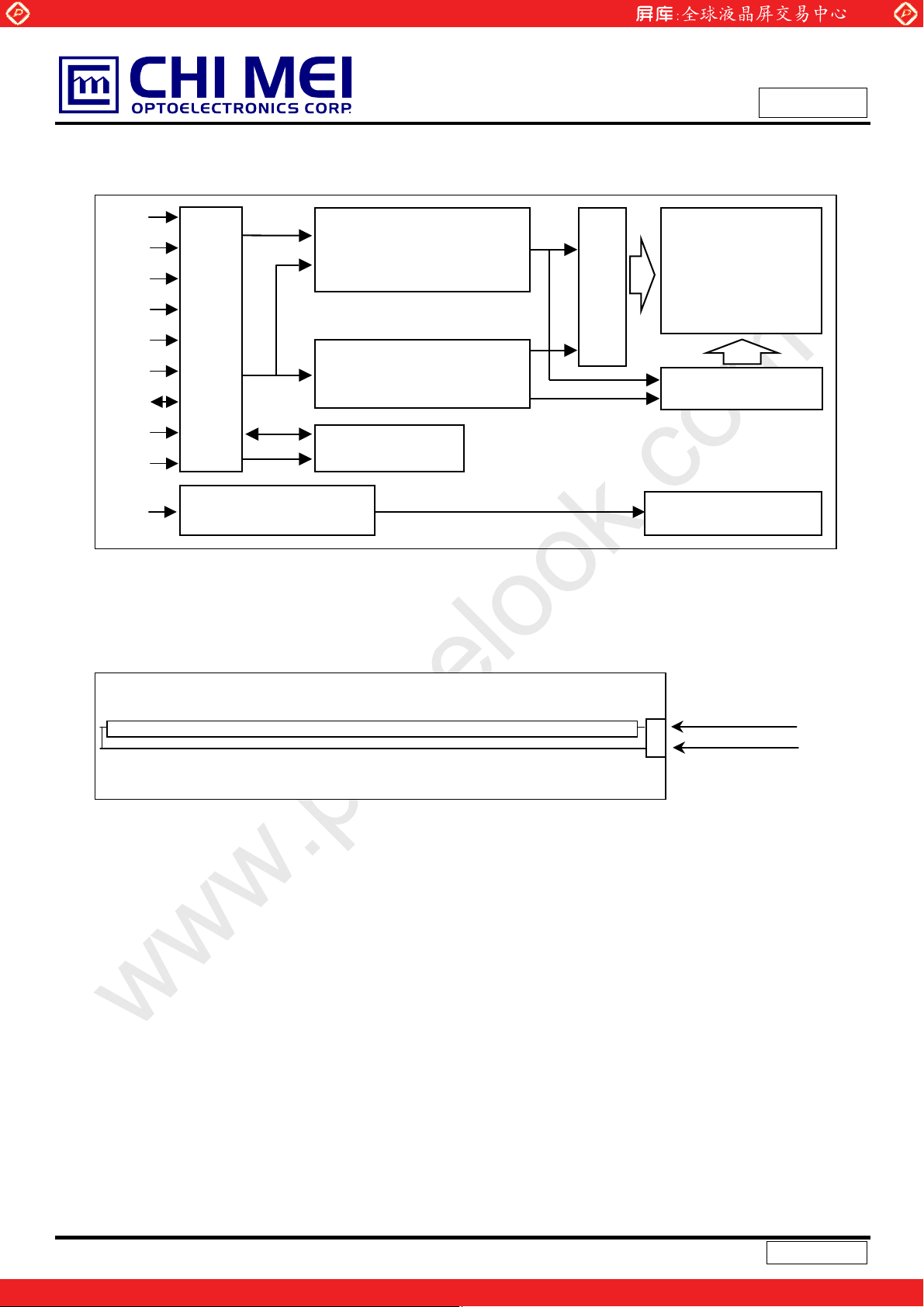

3.2 BACKLIGHT UNIT Ta = 25 ± 2 ºC

Parameter Symbol

Min. Typ. Max.

Lamp Input Voltage VL 585 650 715 V

Lamp Current IL 2.0 6.5 7.0 mA

Lamp Turn On Voltage VS

- -

- Operating Frequency FL 50 - 80 KHz (3)

Lamp Life Time LBL 10,000 - - Hrs (5)

Power Consumption PL - 4.22 - W (4), IL = 6.5 mA

Note (1) Lamp current is measured by utilizing a high frequency current meter as shown below:

Value

1230, 25

1530, 0к

Unit Note

IL = 6.5 mA

RMS

(1)

RMS

V

(2)

RMS

(2)

V

RMS

Approval

LCD

Module

HV (Pink)

LV (Black)

1

2

Current Meter

Inverter

A

Note (2) The voltage shown above should be applied to the lamp for more than 1 second after startup.

Otherwise the lamp may not be turned on.

Note (3) The lamp frequency may generate interference with horizontal synchronous frequency from the

display, and this may cause line flow on the display. In order to avoid interference, the lamp

frequency should be detached from the horizontal synchronous frequency and its harmonics as far

as possible.

Note (4) P

= IL VL

L

Note (5) The lifetime of lamp is defined as the time when it continues to operate under the conditions at Ta

= 25 2

o

C and IL = 6.5 mA

until one of the following events occurs:

RMS

(a) When the brightness becomes Љ 50% of its original value.

(b) When the effective ignition length becomes Љ 80% of its original value. (Effective ignition

length is defined as an area that the brightness is less than 70% compared to the center point.)

Note (6) The waveform of the voltage output of inverter must be area-symmetric and the design of the

inverter must have specifications for the modularized lamp. The performance of the Backlight,

such as lifetime or brightness, is greatly influenced by the characteristics of the DC-AC inverter for

the lamp. All the parameters of an inverter should be carefully designed to avoid generating too

much current leakage from high voltage output of the inverter. When designing or ordering the

inverter please make sure that a poor lighting caused by the mismatch of the Backlight and the

inverter (miss-lighting, flicker, etc.) never occurs. If the above situation is confirmed, the module

should be operated in the same manners when it is installed in your instrument.

8 / 29

Version 3.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 9

Global LCD Panel Exchange Center

)

4. BLOCK DIAGRAM

4.1 TFT LCD MODULE

www.panelook.com

Issued Date: Sep.20, 2005

Model No.: N154I1-L09

Approval

Rxin0(+/-)

Rxin1(+/-)

Rxin2(+/-)

CLK(+/-)

Vcc

(JAE-FI-XB30SL-HF10)

GND

Data

CLK

V

EDID

EDID

EDID

VL

LAMP CONNECTOR

4.2 BACKLIGHT UNIT

INPUT CONNECTOR

(JST-BHSR-02VS-1)

TIMING CONTROLLER

DC/DC CONVERTER &

REFERENCE VOLTAGE

LVDS INPUT /

GENERATOR

EDID

EEPROM

SCAN DRIVER IC

TFT LCD PANEL

(1280x3x800)

DATA DRIVER IC

BACKLIGHT UNIT

1 HV (Pink)

2 LV (Black

9 / 29

Version 3.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 10

Global LCD Panel Exchange Center

5. INPUT TERMINAL PIN ASSIGNMENT

5.1 TFT LCD MODULE

Pin Symbol Description Polarity Remark

1 Vss Ground 2 Vcc Power Supply +3.3 V 3 Vcc Power Supply +3.3 V 4 V

5 NC - - 6 CLK

7 Data

8 Rxin0- LVDS Differential Data Input Negative

9 Rxin0+ LVDS Differential Data Input Positive

10 Vss Ground

11 Rxin1- LVDS Differential Data Input Negative

12 Rxin1+ LVDS Differential Data Input Positive

13 Vss Ground

14 Rxin2- LVDS Differential Data Input Negative

15 Rxin2+ LVDS Differential Data Input Positive

16 Vss Ground

17 CLK- LVDS Clock Data Input Negative

18 CLK+ LVDS Clock Data Input Positive

19 Vss Ground

20 NC - - 21 NC - - 22 NC - - 23 NC - - 24 NC - - 25 NC - - 26 NC - - 27 NC - - 28 NC - - 29 NC - - 30 NC - - -

Note (1) Connector Part No.: JAE-FI-XB30SL-HF10 or equivalent

DDC +3.3 V

EDID

DDC Clock

EDID

DDC Data

EDID

www.panelook.com

Issued Date: Sep.20, 2005

Model No.: N154I1-L09

Approval

-

R0~R5,G0

-

G1~G5,B0,B1

-

B2~B5,Hsync,Vsync,DE

LVDS Level

Note (2) User’s connector Part No: JAE-FI-X30C2L or equivalent

10 / 29

Version 3.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 11

Global LCD Panel Exchange Center

5.2 BACKLIGHT UNIT

Pin Symbol Description Color

1 HV High Voltage Pink

2 LV Ground Black

Note (1) Connector Part No.: JST-BHSR-02VS-1 or equivalent

Note (2) User’s connector Part No.: JST-SM02B-BHSS-1-TB or equivalent

5.3 TIMING DIAGRAM OF LVDS INPUT SIGNAL

CLK+

Rxin2

Rxin1

Rxin0

T/7

IN20 IN19 IN18 IN17 IN16 IN15 IN14

DE B5 B4 B3 B2 Vsync Hsync

IN13 IN12 IN11 IN10 IN9 IN8 IN7

B1 G4 G3 G2 G1 B0 G5

IN6 IN5 IN4 IN3 IN2 IN1 IN0

G0 R3 R2 R1 R0

R5

www.panelook.com

Issued Date: Sep.20, 2005

Model No.: N154I1-L09

Approval

R4

Signal for 1 DCLK Cycle (T)

11 / 29

Version 3.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 12

Global LCD Panel Exchange Center

5.4 COLOR DATA INPUT ASSIGNMENT

The brightness of each primary color (red, green and blue) is based on the 6-bit gray scale data input for

the color. The higher the binary input the brighter the color. The table below provides the assignment of

color versus data input.

Color

R5 R4 R3 R2 R1 R0 G5 G4 G3 G2 G1 G0 B5 B4 B3 B2 B1 B0

Black

Red

Green

Basic

Colors

Gray

Scale

Of

Red

Gray

Scale

Of

Green

Gray

Scale

Of

Blue

Note (1) 0: Low Level Voltage, 1: High Level Voltage

Blue

Cyan

Magenta

Yellow

White

Red(0)/Dark

Red(1)

Red(2)

:

:

Red(61)

Red(62)

Red(63)

Green(0)/Dark

Green(1)

Green(2)

:

:

Green(61)

Green(62)

Green(63)

Blue(0)/Dark

Blue(1)

Blue(2)

:

:

Blue(61)

Blue(62)

Blue(63)

0

0

1

1

0

0

0

0

0

0

1

1

1

1

1

1

0

0

0

0

0

0

:

:

1

1

1

1

1

1

0

0

0

0

0

0

:

:

0

0

0

0

0

0

0

0

0

0

0

0

:

:

0

0

0

0

0

0

www.panelook.com

Issued Date: Sep.20, 2005

Model No.: N154I1-L09

Approval

Data Signal

Red Green Blue

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

0

0

0

0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

0

0

0

0

0

0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

0

0

0

0

0

0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

0

0

0

0

0

0

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

1

1

0

1

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

0

0

0

0

1

1

1

1

0

1

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

0

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

0

0

0

0

0

0

0

0

0

0

1

1

1

1

0

1

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

12 / 29

Version 3.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 13

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: Sep.20, 2005

Model No.: N154I1-L09

Approval

5.5 EDID DATA STRUCTURE

The EDID (Extended Display Identification Data) data formats are to support displays as defined in the VESA

Plug & Display and FPDI standards.

˕˸ʳʶʳ

ʻ˷˸˶˼˴˿ʼʳ

˃ʳ˃ʳ

˄ʳ ˄ʳ

˅ʳ ˅ʳ

ˆʳ ˆʳ

ˇʳ ˇʳ

ˈʳ ˈʳ

ˉʳ ˉʳ

ˊʳ ˊʳ

ˋʳ ˋʳ

ˌʳ ˌʳ

˄˃ʳ ˃˔ʳ

˄˄ʳ ˃˕ʳ

˄˅ʳ ˃˖ʳ

˄ˆʳ ˃˗ʳ

˄ˇʳ ˃˘ʳ

˄ˈʳ ˃˙ʳ

˄ˉʳ ˄˃ʳ

˄ˊʳ ˄˄ʳ

˄ˋʳ ˄˅ʳ

˄ˌʳ ˄ˆʳ

˅˃ʳ ˄ˇʳ

˅˄ʳ ˄ˈʳ

˅˅ʳ ˄ˉʳ

˅ˆʳ ˄ˊʳ

˅ˇʳ ˄ˋʳ

˅ˈʳ ˄ˌʳ

˅ˉʳ ˄˔ʳ

˅ˊʳ ˄˕ʳ

˅ˋʳ ˄˖ʳ

˅ˌʳ ˄˗ʳ

ˆ˃ʳ ˄˘ʳ

ˆ˄ʳ ˄˙ʳ

ˆ˅ʳ ˅˃ʳ

ˆˆʳ ˅˄ʳ

ˆˇʳ ˅˅ʳ

ˆˈʳ ˅ˆʳ

ˆˉʳ ˅ˇʳ

ˆˊʳ ˅ˈʳ

ˆˋʳ ˅ˉʳ

ˆˌʳ ˅ˊʳ

˕˸ʳʶʳ

ʻ˻˸ʼʳ ˙˼˸˿˷ʳˡ˴˸ʳ˴˷ʳ˖˸ʳ

Header

Header

Header

Header

Header

Header

Header

Header

EISA ID manufacturer name (“CMO”)

EISA ID manufacturer name (Compressed ASCII)

ID product code 04

ID product code 15

ID S/N (fixed “0”)

ID S/N (fixed “0”)

ID S/N (fixed “0”)

ID S/N (fixed “0”)

Week of manufacture (fixed week code)

Year of manufacture (fixed year code)

EDID structure version # (“1”)

EDID revision # (“3”)

Video I/P definition (“digital”)

Max H image size (“33.12cm”)

Max V image size (“20.70 cm”)

Display Gamma (Gamma = ”2.2”)

Feature support (“Active off, RGB Color”)

Red/Green (Rx1, Rx0, Ry1, Ry0, Gx1, Gx0, Gy1, Gy0)

Blue/White (Bx1, Bx0, By1, By0, Wx1, Wx0, Wy1, Wy0)

Red-x (Rx = “0.585”)

Red-y (Ry = “0.355”)

Green-x (Gx = ”0.299”)

Green-y (Gy = ”0.584”)

Blue-x (Bx = ”0.154”)

Blue-y (By = ”0.135”)

White-x (Wx = ”0.313”)

White-y (Wy = ”0.329”)

Established timings 1

Established timings 2

Manufacturer’s reserved timings

Standard timing ID # 1

Standard timing ID # 1

˩˴˿˸ʳ

ʻ˻˸ʼʳ

00 00000000

FF 11111111

FF 11111111

FF 11111111

FF 11111111

FF 11111111

FF 11111111

00 00000000

0D 00001101

AF 10101111

00 00000000

00 00000000

00 00000000

00 00000000

24 00100100

0E 00001110

01 00000001

03 00000011

80 10000000

21 00100001

15 00010101

78 01111000

0A 00001010

CA 11001010

A5 10100101

95 10010101

5B 01011011

4C 01001100

95 10010101

27 00100111

22 00100010

50 01010000

54 01010100

00 00000000

00 00000000

00 00000000

01 00000001

01 00000001

˩˴˿˸ʳ

ʻ˵˼˴ʼʳ

00000100

00010101

13 / 29

Version 3.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 14

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: Sep.20, 2005

Model No.: N154I1-L09

Approval

ˇ˃ʳ ˅ˋʳ

ˇ˄ʳ ˅ˌʳ

ˇ˅ʳ ˅˔ʳ

ˇˆʳ ˅˕ʳ

ˇˇʳ ˅˖ʳ

ˇˈʳ ˅˗ʳ

ˇˉʳ ˅˘ʳ

ˇˊʳ ˅˙ʳ

ˇˋʳ ˆ˃ʳ

ˇˌʳ ˆ˄ʳ

ˈ˃ʳ ˆ˅ʳ

ˈ˄ʳ ˆˆʳ

ˈ˅ʳ ˆˇʳ

ˈˆʳ ˆˈʳ

ˈˇʳ ˆˉʳ

ˈˈʳ ˆˊʳ

ˈˉʳ ˆˋʳ

ˈˊʳ ˆˌʳ

ˈˋʳ ˆ˔ʳ

ˈˌʳ ˆ˕ʳ

ˉ˃ʳ ˆ˖ʳ

ˉ˄ʳ ˆ˗ʳ

ˉ˅ʳ ˆ˘ʳ

ˉˆʳ ˆ˙ʳ

ˉˇʳ ˇ˃ʳ

ˉˈʳ ˇ˄ʳ

ˉˉʳ ˇ˅ʳ

ˉˊʳ ˇˆʳ

ˉˋʳ ˇˇʳ

ˉˌʳ ˇˈʳ

ˊ˃ʳ ˇˉʳ

ˊ˄ʳ ˇˊʳ

ˊ˅ʳ ˇˋʳ

ˊˆʳ ˇˌʳ

ˊˇʳ ˇ˔ʳ

ˊˈʳ ˇ˕ʳ

ˊˉʳ ˇ˖ʳ

ˊˊʳ ˇ˗ʳ

ˊˋʳ ˇ˘ʳ

ˊˌʳ ˇ˙ʳ

ˋ˃ʳ ˈ˃ʳ

ˋ˄ʳ ˈ˄ʳ

ˋ˅ʳ ˈ˅ʳ

ˋˆʳ ˈˆʳ

Standard timing ID # 2

Standard timing ID # 2

Standard timing ID # 3

Standard timing ID # 3

Standard timing ID # 4

Standard timing ID # 4

Standard timing ID # 5

Standard timing ID # 5

Standard timing ID # 6

Standard timing ID # 6

Standard timing ID # 7

Standard timing ID # 7

Standard timing ID # 8

Standard timing ID # 8

Detailed timing description # 1 Pixel clock (“71 MHz”)

# 1 Pixel clock (hex LSB first)

# 1 H active (“1280”)

# 1 H blank (“160”)

# 1 H active : H blank (“1280 : 160”)

# 1 V active (”800”)

# 1 V blank (”23”)

# 1 V active : V blank (”800 :23”)

# 1 H sync offset (”48”)

# 1 H sync pulse width ("32”)

# 1 V sync offset : V sync pulse width (”3 : 6”)

# 1 H sync offset : H sync pulse width : V sync offset : V sync width

(”48: 32 : 3 : 6”)

# 1 H image size (”331 mm”)

# 1 V image size (”207 mm”)

# 1 H image size : V image size (”331 : 207”)

# 1 H boarder (”0”)

# 1 V boarder (”0”)

# 1 Non-interlaced, Normal, no stereo, Separate sync, H/V pol

Negatives

Detailed timing description # 2

# 2 Flag

# 2 Reserved

# 2 FE (hex) defines ASCII string (Model Name “N154I1-L09”, ASCII)

# 2 Flag

# 2 1st character of name (“N”)

# 2 2nd character of name (“1”)

# 2 3rd character of name (“5”)

# 2 4th character of name (“4”)

# 2 5th character of name (“I”)

# 2 6th character of name (“1”)

# 2 7th character of name (“-”)

01 00000001

01 00000001

01 00000001

01 00000001

01 00000001

01 00000001

01 00000001

01 00000001

01 00000001

01 00000001

01 00000001

01 00000001

01 00000001

01 00000001

BC 10111100

1B 00011011

00 00000000

A0 10100000

50 01010000

20 00100000

17 00010111

30 00110000

30 00110000

20 00100000

36 00110110

00 00000000

4B 01001011

CF 11001111

10 00010000

00 00000000

00 00000000

18 00011000

00 00000000

00 00000000

00 00000000

FE 11111110

00 00000000

4E 01001110

31 00110001

35 00110101

34 00110100

49 01001001

31 00110001

2D 00101101

14 / 29

Version 3.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 15

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: Sep.20, 2005

Model No.: N154I1-L09

Approval

ˋˇʳ ˈˇʳ

ˋˈʳ ˈˈʳ

ˋˉʳ ˈˉʳ

ˋˊʳ ˈˊʳ

ˋˋʳ ˈˋʳ

ˋˌʳ ˈˌʳ

ˌ˃ʳ ˈ˔ʳ

ˌ˄ʳ ˈ˕ʳ

ˌ˅ʳ ˈ˖ʳ

ˌˆʳ ˈ˗ʳ

ˌˇʳ ˈ˘ʳ

ˌˈʳ ˈ˙ʳ

ˌˉʳ ˉ˃ʳ

ˌˊʳ ˉ˄ʳ

ˌˋʳ ˉ˅ʳ

ˌˌʳ ˉˆʳ

˄˃˃ʳ ˉˇʳ

˄˃˄ʳ ˉˈʳ

˄˃˅ʳ ˉˉʳ

˄˃ˆʳ ˉˊʳ

˄˃ˇʳ ˉˋʳ

˄˃ˈʳ ˉˌʳ

˄˃ˉʳ ˉ˔ʳ

˄˃ˊʳ ˉ˕ʳ

˄˃ˋʳ ˉ˖ʳ

˄˃ˌʳ ˉ˗ʳ

˄˄˃ʳ ˉ˘ʳ

˄˄˄ʳ ˉ˙ʳ

˄˄˅ʳ ˊ˃ʳ

˄˄ˆʳ ˊ˄ʳ

˄˄ˇʳ ˊ˅ʳ

˄˄ˈʳ ˊˆʳ

˄˄ˉʳ ˊˇʳ

˄˄ˊʳ ˊˈʳ

˄˄ˋʳ ˊˉʳ

˄˄ˌʳ ˊˊʳ

˄˅˃ʳ ˊˋʳ

˄˅˄ʳ ˊˌʳ

˄˅˅ʳ ˊ˔ʳ

˄˅ˆʳ ˊ˕ʳ

˄˅ˇʳ ˊ˖ʳ

˄˅ˈʳ ˊ˗ʳ

˄˅ˉʳ ˊ˘ʳ

˄˅ˊʳ ˊ˙ʳ

# 2 8th character of name (“L”)

# 2 9th character of name (“0”)

# 2 9th character of name (“9”)

# 2 Padding with “Blank” character

# 2 Padding with “Blank” character

# 2 Padding with “Blank” character

Detailed timing description # 3

# 3 Flag

# 3 Reserved

# 3 FE (hex) defines ASCII string (Vendor “CMO”, ASCII)

# 3 Flag

# 3 1st character of string (“C”)

# 3 2nd character of string (“M”)

# 3 3rd character of string (“O”)

# 3 New line character indicates end of ASCII string

# 3 Padding with “Blank” character

# 3 Padding with “Blank” character

# 3 Padding with “Blank” character

# 3 Padding with “Blank” character

# 3 Padding with “Blank” character

# 3 Padding with “Blank” character

# 3 Padding with “Blank” character

# 3 Padding with “Blank” character

# 3 Padding with “Blank” character

Detailed timing description # 4

# 4 Flag

# 4 Reserved

# 4 FE (hex) defines ASCII string (Model Name“N154I1-L09”, ASCII)

# 4 Flag

# 4 1st character of name (“N”) 4E

# 4 2nd character of name (“1”) 31

# 4 3rd character of name (“5”) 35

# 4 4th character of name (“4”) 34

# 4 5th character of name (“I”) 49

# 4 6th character of name (“1”) 31

# 4 7th character of name (“-”) 2D

# 4 8th character of name (“L”) 4C

# 4 9th character of name (“0”)

# 4 9th character of name (“9”)

# 4 New line character indicates end of ASCII string

# 4 Padding with “Blank” character

# 4 Padding with “Blank” character

Extension flag

Checksum

4C 01001100

30 00110000

39 00111001

0A 00001010

20 00100000

20 00100000

00 00000000

00 00000000

00 00000000

FE 11111110

00 00000000

43 01000011

4D 01001101

4F 01001111

0A 00001010

20 00100000

20 00100000

20 00100000

20 00100000

20 00100000

20 00100000

20 00100000

20 00100000

20 00100000

00 00000000

00 00000000

00 00000000

FE 11111110

00 00000000

30 00110000

39 00111001

0A 00001010

20 00100000

20 00100000

00 00000000

71 01110001

01001110

00110001

00110101

00110100

01001001

00110001

00101101

01001100

15 / 29

Version 3.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 16

Global LCD Panel Exchange Center

5.6 EDID SIGINAL SPECIFICATION

(1) EDID Power

Parameter Symbol Test Condition Min. Typ. Max. Unit

Power supply

voltage

Vcc — 2.7 — 5.5 V

www.panelook.com

Issued Date: Sep.20, 2005

Model No.: N154I1-L09

Approval

(2) DC characteristics

Parameter Symbol Test Condition Min Typ Max Unit

Supply current Vcc=5.0V Icc READ at 100kHz — 0.4 1.0 mA

Supply current Vcc=5.0V Icc WRITE at 100kHz — 2.0 3.0 mA

Standby Current ISB Vin=Vcc or Vss — 1.6 4.0 μA

Input Leakage Current ILI Vin=Vcc or Vss — 0.1 3.0 μA

Onput Leakage Current ILO Vout=Vcc or Vss — 0.05 3.0 μA

Input Low Level VIL — -1.0 — Vcc x 0.3 V

Input High Level VIH — Vcc x 0.7 — Vcc+0.5 V

Output Low Level Vcc=1.8V VOL1 IOL=0.15mA — — 0.2 V

Output Low Level Vcc=3.0V VOL2 IOL=2.1mA — — 0.4 V

16 / 29

Version 3.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 17

Global LCD Panel Exchange Center

(3) AC characteristics (VCC=2.5~5.5V standard operation mode)

Parameter Symbol Min Max Unit

Clock Frequency, SCL FSCL — 100 kHz

www.panelook.com

Issued Date: Sep.20, 2005

Model No.: N154I1-L09

Approval

Clock Pulse Width Low TLOW 4.7 —

Clock Pulse Width High THIGH 4.0 —

Noise Suppression Time TI — 100 ns

Clock Low to Data Out Valid TAA 0.1 4.5

Time the bus must be free

BUF 4.7 —

before a new transmission

can start

Start Hold Time THD.STA 4.0 —

Start Set-up Time TSU.STA 4.7 —

Data in Hold Time THD.DAT 0 —

Data in Set-up Time TSU.DAT 200 — ns

Inputs Rise Time TR — 1.0

T

Ӵs

Ӵs

Ӵs

Ӵs

Ӵs

Ӵs

Ӵs

Ӵs

Inputs Fall Time TF — 300 ns

Stop Set-up Time TSU.STO 4.7 —

Data Out Hold Time TDH 100 — ns

Write Cycle Time TWR — 10 ms

Ӵs

17 / 29

Version 3.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 18

Global LCD Panel Exchange Center

6. INTERFACE TIMING

6.1 INPUT SIGNAL TIMING SPECIFICATIONS

The input signal timing specifications are shown as the following table and timing diagram.

Signal Item Symbol Min. Typ. Max. Unit Note

Frequency 1/Tc - 71 80 MHz -

Clock

Data

Vsync Frequency Frequency Vsync - 60 - Hz

Hsync Frequency Frequency Hsync - 49.4 - KHz

Data Enable Pulse width TDEP 100 - - clocks (1)

Data Enable Setup Time TES 3.5 4.0 - nsec (1)

Frame Frequency Cycle TV 810 823 2000 lines Vertical Active Display Term Display Period TVD 800 800 800 lines One Line Scanning Time Cycle TH 1360 1440 2000 clocks (2)

Horizontal Active Display Term Display Period THD 1280 1280 1280 clocks -

Note (1) Because this module is operated by DE only mode, Hsync and Vsync input signals should be set

Setup Time TDS 4 - - nsec -

www.panelook.com

Issued Date: Sep.20, 2005

Model No.: N154I1-L09

Approval

High Time TCH 13 - - nsec -

Low Time T

Hold Time T

CL 13 - - nsec -

DH 4 - - nsec -

to low logic level or ground. Otherwise, this module would operate abnormally.

Note (2) The duration of DE signal must be longer than 1 clock period at every horizontal sync. period.

INPUT SIGNAL TIMING DIAGRAM

DE

DCLK

DE

DATA

SIGNAL

TC

TCH

Valid display data (1280 pixels)

TC

TCL

THD

DCLK

DISPLAY

DATA

DE

TDS

TES

TDH

50%

50%

50%

18 / 29

Version 3.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 19

Global LCD Panel Exchange Center

6.2 POWER ON/OFF SEQUENCE

www.panelook.com

Issued Date: Sep.20, 2005

Model No.: N154I1-L09

Approval

Power Supply

for LCD, Vcc

- Interface Signal

(LVDS Signal of

Transmitter), V

- Power for Lamp

Timing Specifications:

0.5 < t1 Љ 10 msec

0 < t2 Љ 45 msec

0 < t3 Љ 45 msec

Restart

t7

10%

10%

t4

Power On

90%

0V

0V

I

10%

t1

Valid Data

ONOFF OFF

Power Off

90%

t3 t2

t6 t5

50%50%

t4 Њ 400 msec

t5 Њ 200 msec

t6 Њ 200 msec

Note (1) Please avoid floating state of interface signal at invalid period.

Note (2) When the interface signal is invalid, be sure to pull down the power supply of LCD Vcc to 0 V.

Note (3) The Backlight inverter power must be turned on after the power supply for the logic and the

interface signal is valid. The Backlight inverter power must be turned off before the power supply

for the logic and the interface signal is invalid.

Note (4) Sometimes some slight noise shows when LCD is turned off (even backlight is already off). To

avoid this phenomenon, we suggest that the Vcc falling time had better to follow

t7 Њ 5 msec

19 / 29

Version 3.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 20

Global LCD Panel Exchange Center

7. OPTICAL CHARACTERISTICS

7.1 TEST CONDITIONS

Item Symbol Value Unit

Ambient Temperature Ta

Ambient Humidity Ha

Supply Voltage VCC 3.3 V

Input Signal According to typical value in "3. ELECTRICAL CHARACTERISTICS"

Inverter Current IL 6.5 mA

Inverter Driving Frequency FL 55 KHz

Inverter Sumida-H05-4915

The measurement methods of optical characteristics are shown in Section 7.2. The following items

should be measured under the test conditions described in Section 7.1 and stable environment shown in

Note (6).

www.panelook.com

25r2

50r10

Issued Date: Sep.20, 2005

Model No.: N154I1-L09

Approval

o

C

%RH

7.2 OPTICAL SPECIFICATIONS

Item Symbol Condition Min. Typ. Max. Unit Note

Contrast Ratio CR - 350 - - (2), (6)

Response Time

Central Luminance of White L

White Variation

Cross Talk CT - - 4 % (5), (6)

Red

Color

Chromaticity

Green

Blue

White

Horizontal

Viewing Angle

Vertica l

TR - 10 30 ms

T

- 20 50 ms

F

150 175 - cd/m2(4), (6)

AVE

GW

Rx

Ry

Gx

Gy

Bx

By

=0q, TY =0q

T

x

Viewing Normal Angle

- - 1.4 - (6), (7)

0.571 0.601 0.631

0.305 0.335 0.365

0.290 0.320 0.350

0.501 0.531 0.561

0.126 0.156 0.186

0.103 0.133 0.163

Wx 0.283 0.313 0.343 Wy

Tx+

T

x

TY+

T

Y

CRt10

-

0.299 0.329 0.359 -

- 45 -

- 45 -

- 15 -

Deg. (1), (6)

- 35 -

(3)

-

-

-

(1), (6)

-

-

20 / 29

Version 3.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 21

Global LCD Panel Exchange Center

Note (1) Definition of Viewing Angle (Tx, Ty):

www.panelook.com

Issued Date: Sep.20, 2005

Model No.: N154I1-L09

Approval

TX- = 90º

x-

6 o’clock

T

y- = 90º

y-

Note (2) Definition of Contrast Ratio (CR):

The contrast ratio can be calculated by the following expression.

Normal

Tx = Ty = 0º

Ty- Ty

Tx-

Tx+

y+

12 o’clock direction

T

y+ = 90º

x+

TX+ = 90º

Contrast Ratio (CR) = L63 / L0

L63: Luminance of gray level 63

L 0: Luminance of gray level 0

CR = CR (5)

CR (X) is corresponding to the Contrast Ratio of the point X at Figure in Note (7).

Note (3) Definition of Response Time (T

100%

90%

Optical

Response

10%

0%

R

T

R

, TF):

Time

T

F

21 / 29

Version 3.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 22

Global LCD Panel Exchange Center

A

A

www.panelook.com

Issued Date: Sep.20, 2005

Model No.: N154I1-L09

Approval

Note (4) Definition of Average Luminance of White (L

Measure the luminance of gray level 63 at 5 points

L

= [L (1)+ L (2)+ L (3)+ L (4)+ L (5)] / 5

AVE

L (x) is corresponding to the luminance of the point X at Figure in Note (7).

Note (5) Definition of Cross Talk (CT):

CT = | Y

– YA | / YA u 100 (%)

B

Where:

Y

= Luminance of measured location without gray level 0 pattern (cd/m2)

A

Y

= Luminance of measured location with gray level 0 pattern (cd/m2)

B

(0, 0)

ctive Area

Y

(D/8,W/2)

A, L

Gray 32

Y

(D/2,7W/8)

A, D

(D,W)

Y

(D/2,W/8)

A, U

Y

(7D/8,W/2)

A, R

AVE

):

(D/4,W/4)

Y

(D/8,W/2)

B, L

Y

(D/2,7W/8)

B, D

(0, 0)

ctive Area

Gray 0

Gray 32

Y

B, U

Y

B, R

(3D/4,3W/4)

(D,W)

(D/2,W/8)

(7D/8,W/2)

Note (6) Measurement Setup:

The LCD module should be stabilized at given temperature for 20 minutes to avoid abrupt

temperature change during measuring. In order to stabilize the luminance, the measurement

should be executed after lighting Backlight for 20 minutes in a windless room.

LCD Module

LCD Panel

Center of the Screen

500 mm

Photometer

(TOPCON BM-5A)

Field of View = 2º

Light Shield Room

(Ambient Luminance < 2 lux)

22 / 29

Version 3.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 23

Global LCD Panel Exchange Center

Note (7) Definition of White Variation (GW):

Measure the luminance of gray level 63 at 5 points

GW = Maximum [L (1), L (2), L (3), L (4), L (5)] / Minimum [L (1), L (2), L (3), L (4), L (5)]

www.panelook.com

Issued Date: Sep.20, 2005

Model No.: N154I1-L09

Approval

W

W/4

W/2

3W/4

Vertical Line

Horizontal Line

D

D/4 D/2 3D/4

12

X

: Test Point

X=1 to 5

3

5

4

Active Area

23 / 29

Version 3.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 24

Global LCD Panel Exchange Center

8. PRECAUTIONS

8.1 HANDLING PRECAUTIONS

(1) The module should be assembled into the system firmly by using every mounting hole. Be careful not

to twist or bend the module.

(2) While assembling or installing modules, it can only be in the clean area. The dust and oil may cause

electrical short or damage the polarizer.

(3) Use fingerstalls or soft gloves in order to keep display clean during the incoming inspection and

assembly process.

(4) Do not press or scratch the surface harder than a HB pencil lead on the panel because the polarizer is

very soft and easily scratched.

(5) If the surface of the polarizer is dirty, please clean it by some absorbent cotton or soft cloth. Do not use

Ketone type materials (ex. Acetone), Ethyl alcohol, Toluene, Ethyl acid or Methyl chloride. It might

www.panelook.com

Issued Date: Sep.20, 2005

Model No.: N154I1-L09

Approval

permanently damage the polarizer due to chemical reaction.

(6) Wipe off water droplets or oil immediately. Staining and discoloration may occur if they left on panel for

a long time.

(7) If the liquid crystal material leaks from the panel, it should be kept away from the eyes or mouth. In

case of contacting with hands, legs or clothes, it must be washed away thoroughly with soap.

(8) Protect the module from static electricity, it may cause damage to the C-MOS Gate Array IC.

(9) Do not disassemble the module.

(10) Do not pull or fold the lamp wire.

(11) Pins of I/F connector should not be touched directly with bare hands.

8.2 STORAGE PRECAUTIONS

(1) High temperature or humidity may reduce the performance of module. Please store LCD module within

the specified storage conditions.

(2) It is dangerous that moisture come into or contacted the LCD module, because the moisture may

damage LCD module when it is operating.

(3) It may reduce the display quality if the ambient temperature is lower than 10 ºC. For example, the

response time will become slowly, and the starting voltage of lamp will be higher than the room

temperature.

8.3 OPERATION PRECAUTIONS

(1) Do not pull the I/F connector in or out while the module is operating.

(2) Always follow the correct power on/off sequence when LCD module is connecting and operating. This

can prevent the CMOS LSI chips from damage during latch-up.

(3) The startup voltage of Backlight is approximately 1000 Volts. It may cause electrical shock while

assembling with inverter. Do not disassemble the module or insert anything into the Backlight unit.

24 / 29

Version 3.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 25

Global LCD Panel Exchange Center

9. PACKING

9.1 CARTON

LCD Module

Anti-static Bag

www.panelook.com

Issued Date: Sep.20, 2005

Model No.: N154I1-L09

Approval

Box dimensions:422(L)x337(W)x345(H)mm

Weight:Appox. 7.5kg(10 module per 1 box)

PE Foam(Cover)

Carton

Drier

Packing testing criteria :

(1) Packing drop : 1 corner, 3 edges, 6 faces, each direction for one time, follow ISTA standard.

(2) Packing vibration : Random, follow ISTA standard.

Carton Label

25 / 29

Version 3.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 26

Global LCD Panel Exchange Center

9.2 PALLET

www.panelook.com

Issued Date: Sep.20, 2005

Model No.: N154I1-L09

Approval

26 / 29

Version 3.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 27

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: Sep.20, 2005

Model No.: N154I1-L09

Approval

10. DEFINITION OF LABELS

10.1 CMO MODULE LABEL

The barcode nameplate is pasted on each module as illustration, and its definitions are as following explanation.

01A

N141X5 - L03 Rev.XX

-

X X X X X X X Y M D L N N N N

C P 1 3 5 4 4 8 - 0 1

Rev. XX

(a) Model Name: N154I1 - L09

(b) Revision: Rev. XX, for example: C1, C2 …etc.

(c) Serial ID: X X

X X X X X Y M D L N N N N

E207943

MADE IN TAIWAN

Serial No.

Product Line

Year, Month, Date

CMO Internal Use

Revision

CMO Internal Use

Serial ID includes the information as below:

(a) Manufactured Date: Year: 1~9, for 2001~2009

Month: 1~9, A~C, for Jan. ~ Dec.

Day: 1~9, A~Y, for 1

(b) Revision Code: cover all the change

(c) Serial No.: Manufacturing sequence of product

st

to 31st, exclude I , O and U

27 / 29

Version 3.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 28

Global LCD Panel Exchange Center

10.2 CARTON LABEL

www.panelook.com

Issued Date: Sep.20, 2005

Model No.: N154I1-L09

Approval

28 / 29

Version 3.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 29

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Loading...

Loading...