Page 1

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 2

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: Aug.31, 2005

Model No.: N150X3 - L09

Approval

- CONTENTS -

REVISION HISTORY ------------------------------------------------------- 3

1. GENERAL DESCRIPTION ------------------------------------------------------- 4

1.1 OVERVIEW

1.2 FEATURES

1.3 APPLICATION

1.4 GENERAL SPECIFICATIONS

1.5 MECHANICAL SPECIFICATIONS

2. ABSOLUTE MAXIMUM RATINGS ------------------------------------------------------- 5

2.1 ABSOLUTE RATINGS OF ENVIRONMENT

2.2 ELECTRICAL ABSOLUTE RATINGS

2.2.1 TFT LCD MODULE

2.2.2 BACKLIGHT UNIT

3. ELECTRICAL CHARACTERISTICS ------------------------------------------------------- 6

3.1 TFT LCD MODULE

3.2 BACKLIGHT UNIT

3.3 EDID DATA

4. BLOCK DIAGRAM ------------------------------------------------------- 13

TFT LCD MODULE w/ INVERTER

5. INPUT TERMINAL PIN ASSIGNMENT ------------------------------------------------------- 13

5.1 TFT LCD MODULE

5.2 TIMING DIAGRAM OF LVDS INPUT SIGNAL

5.3 COLOR DATA INPUT ASSIGNMENT

6. INTERFACE TIMING ------------------------------------------------------- 16

6.1 INPUT SIGNAL TIMING SPECIFICATIONS

6.2 POWER ON/OFF SEQUENCE

7. OPTICAL CHARACTERISTICS ------------------------------------------------------- 18

7.1 TEST CONDITIONS

7.2 OPTICAL SPECIFICATIONS

8. PRECAUTIONS ------------------------------------------------------- 22

8.1 ASSEMBLY AND HANDLING PRECAUTIONS

8.2 SAFETY PRECAUTIONS

9. DEFINITION OF LABELS ------------------------------------------------------- 23

9.1 CMO MODULE LABEL

9.2 Dell LABEL

10.2.1 MAL PPID LABEL

10.2.2 CARTON LABEL

10.2.3 PALLET LABEL

10. PACKING ------------------------------------------------ 24

10.1 CARTON

10.2 PALLET

2 / 27

Version 2.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 3

Global LCD Panel Exchange Center

Version Date

Ver 1.0

Ver 2.0

Ver 2.1

Jan.31 ‘05

May.23 ’05

Aug.31 ‘05

Page

(New)

All

9

25

Section Description

All

3.3

10

www.panelook.com

Issued Date: Aug.31, 2005

Model No.: N150X3 - L09

Approval

REVISION HISTORY

Perminaliary specification was first issued

Added EDID code

Modified Carton & pallet

3 / 27

Version 2.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 4

Global LCD Panel Exchange Center

1. GENERAL DESCRIPTION

1.1 OVERVIEW

N150X3- L09 is a 15.0” TFT Liquid Crystal Display module. This module supports 1024 x 768 XGA mode

and can display 262,144 colors. The optimum viewing angle is at 6 o’clock direction.

1.2 FEATURES

- Thin and Light Weight

- XGA (1024 x 768 pixels) resolution

- DE only mode

- 3.3V LVDS (Low Voltage Differential Signaling) interface with 1 pixel/clock

- SPWG (Standard Panel Working Group) Style B compatible

- Single CCFL

www.panelook.com

Issued Date: Aug.31, 2005

Model No.: N150X3 - L09

Approval

1.3 APPLICATION

- TFT LCD Notebook

1.4 GENERAL SPECIFICATI0NS

Item Specification Unit Note

Active Area 304.1 (H) x 228.1 (V) (15.0” diagonal) mm

Bezel Opening Area 307.8 (H) x 231.6 (V) mm

Driver Element a-si TFT active matrix - Pixel Number 1024 x R.G.B. x 768 pixel Pixel Pitch 0.297 (H) x 0.297 (V) mm Pixel Arrangement RGB vertical stripe - Display Colors 262,144 color Transmissive Mode Normally white - Surface Treatment Hard coating (3H), Anti-glare (Haze 25) - -

1.5 MECHANICAL SPECIFICATIONS

Item Min. Typ. Max. Unit Note

Horizontal(H) 316.8 317.3 317.8 mm (1)

Module Size

Note (1) Please refer to the attached drawings for more information of front and back outline dimensions.

Vertical(V) 241.5 242 242.5 mm (1)

Depth(D) - 5.7 6.0 mm (1)

Weight - 550 565 g -

(1)

4 / 27

Version 2.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 5

Global LCD Panel Exchange Center

2. ABSOLUTE MAXIMUM RATINGS

2.1 ABSOLUTE RATINGS OF ENVIRONMENT

Item Symbol

Storage Temperature TST -20 +60 ºC (1)

Storage Humidity HST 10 90 %RH (1)

Operating Ambient Temperature TOP 0 +50 ºC (1), (2)

Operating Ambient Humidity HOP 20 90 %RH (1)

Shock (Non-Operating) S

Vibration (Non-Operating) V

Note (1) (a) 90 %RH Max. (Ta Љ 40 ºC).

(b) Wet-bulb temperature should be 39 ºC Max. (Ta > 40 ºC).

(c) No condensation.

Note (2) The temperature of panel surface should be 0к min. and 50 к max.

Note (3) Condition for 50/18 G/ms is Rectangle Wave. Condition for 220/2 G/ms is Half Since Wave.

www.panelook.com

Issued Date: Aug.31, 2005

Model No.: N150X3 - L09

Approval

Value

Min. Max.

-

NOP

- 1.5/10-200 G/Hz (4), (5)

NOP

50/18

220/2

Unit Note

G/ms (3), (4), (5)

Note (4) The fixing condition is shown as below:

Side Mount Fixing Screw

Note (5) At testing Vibration and Shock, the fixture in holding the module has to be hard and rigid enough

so that the module would not be twisted or bent by the fixture.

gap=2mm

Bracket

LCD Module

Side Mount Fixing Screw

Stage

5 / 27

Version 2.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 6

Global LCD Panel Exchange Center

2.2 ELECTRICAL ABSOLUTE RATINGS

2.2.1 TFT LCD MODULE

Item Symbol

Power Supply Voltage VCC -0.3 +4.0 V

Logic Input Voltage VIN -0.3 VCC+0.3 V

2.2.2 BACKLIGHT UNIT

Item Symbol

Lamp Voltage VL - (2.5K) V

Lamp Current IL 2.0 6.5 mA

Lamp Frequency FL 50 80 KHz

Note (1) Permanent damage to the device may occur if maximum values are exceeded. Function operation

should be restricted to the conditions described under Normal Operating Conditions.

www.panelook.com

Value

Min. Max.

Value

Min. Max.

Unit Note

Unit Note

Issued Date: Aug.31, 2005

Model No.: N150X3 - L09

Approval

(1)

(1), (2), IL = 6.0 mA

RMS

RMS

(1), (2)

Note (2) Specified values are for lamp (Refer to 3.2 for further information).

3. ELECTRICAL CHARACTERISTICS

3.1 TFT LCD MODULE Ta = 25 ± 2 ºC

Parameter Symbol

Min. Typ. Max.

Power Supply Voltage Vcc 3.0 3.3 3.6 V Ripple Voltage VRP - 100 - mV Rush Current I

Power Supply Current

White - 300 350 mA (3)a

Black

- - 1.5 A (2)

RUSH

Lcc

- 350 400 mA (3)b

“H” Level VIL - - +100 mV - Logical Input Voltage

(LVDS)

“L” Level V

-100 - - mV -

IH

Terminating Resistor RT - 100 - Ohm Power per EBL WG P

- 3.176 - W (4)

EBL

Note (1) The module should be always operated within above ranges.

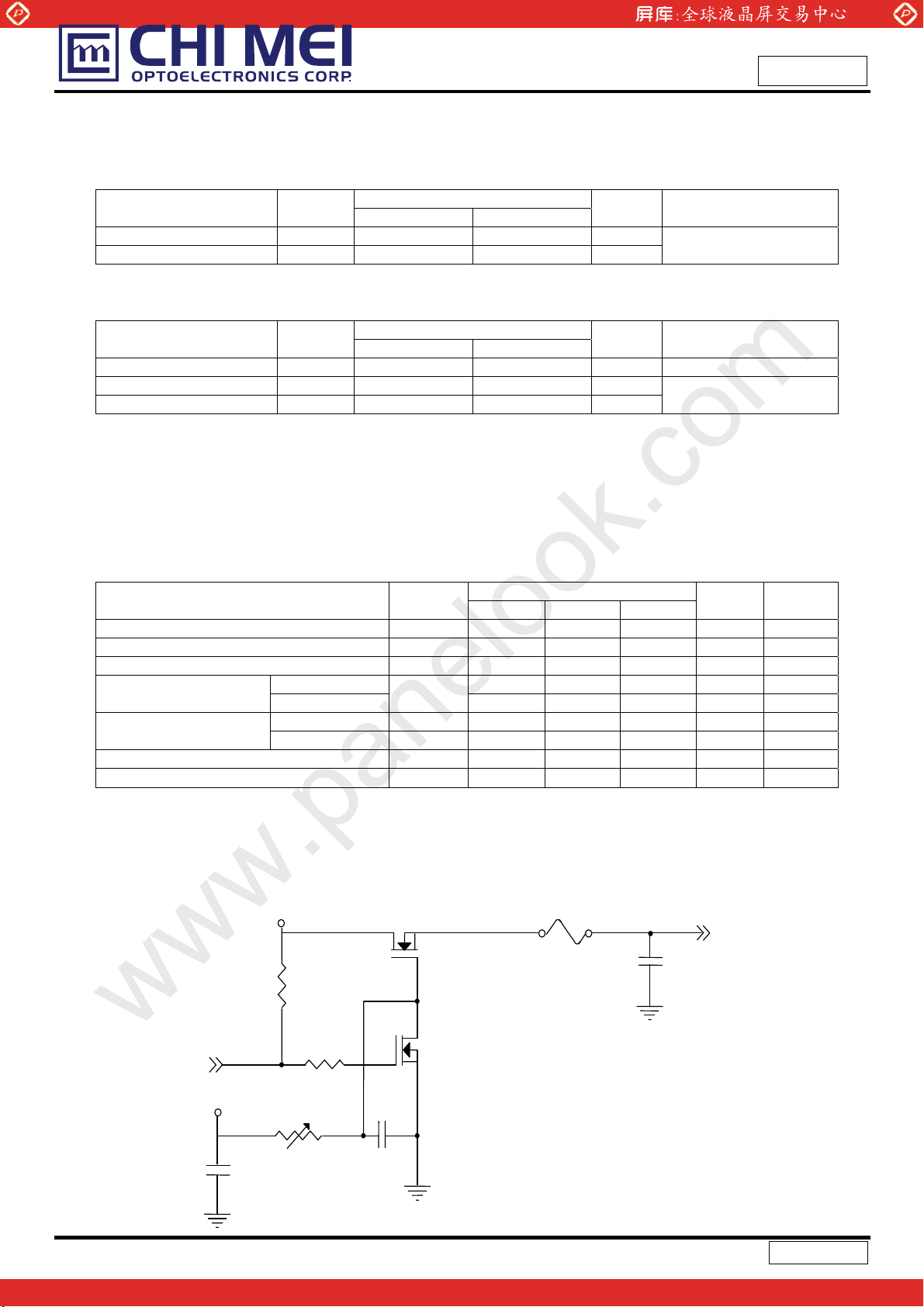

Note (2) Measurement Conditions:

+3.3V

Q1 2SK1475

R1

47K

(High to Low)

(Control Signal)

SW

+12V

C1

1uF

VR1

R2

1K

47K

0.01uF

Q2

2SK1470

C2

Value

FUSE

C3

1uF

Unit Note

Vcc

(LCD Module Input)

6 / 27

Version 2.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 7

Global LCD Panel Exchange Center

Vcc rising time is 470μs

0.1Vcc

GND

www.panelook.com

Issued Date: Aug.31, 2005

Model No.: N150X3 - L09

Approval

+3.3V

0.9Vcc

470μs

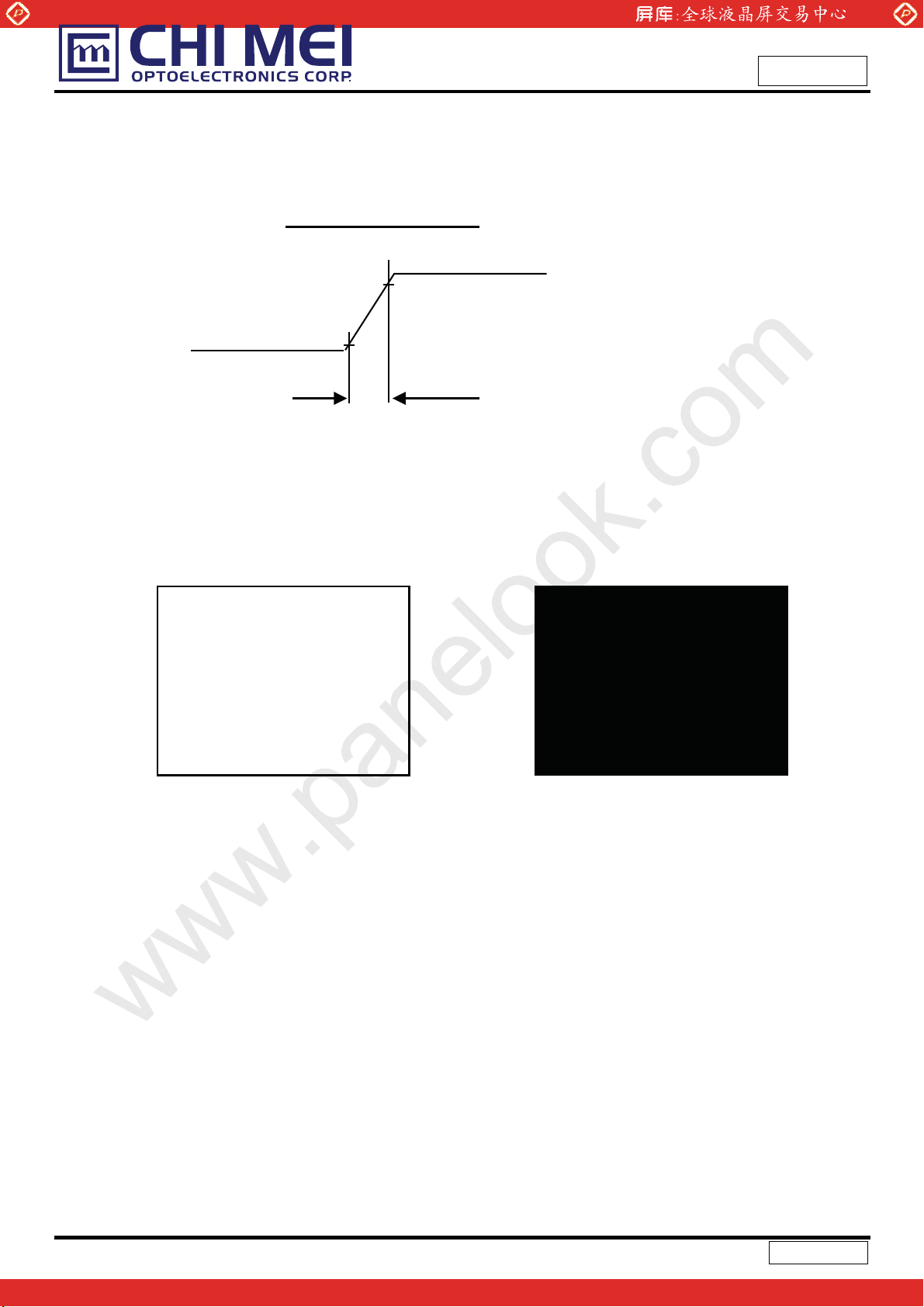

Note (3) The specified power supply current is under the conditions at Vcc = 3.3 V, Ta = 25 ± 2 ºC, f

Hz, whereas a power dissipation check pattern below is displayed.

Note (4) The specified power are the sum of LCD panel electronics input power and the inverter input

a. White Pattern

Active Area

power. Test conditions are as follows.

(a) Vcc = 3.3 V, Ta = 25 ± 2 ºC, f

(b) The pattern used is a black and white 32 x 36 checkerboard, slide #100 from the VESA file

= 60 Hz,

v

b. Black Pattern

Active Area

= 60

v

“Flat Panel Display Monitor Setup Patterns”, FPDMSU.ppt.

(c) Luminance: 60 nits.

(d) The inverter used is provided from O2Micro (www.o2micro.com). Please contact O2Mirco for detail

information. CMO doesn’t provide the inverter in this product.

7 / 27

Version 2.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 8

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: Aug.31, 2005

Model No.: N150X3 - L09

Approval

3.2 BACKLIGHT UNIT Ta = 25 ± 2 ºC

Parameter Symbol

Min. Typ. Max.

Lamp Input Voltage VL 627 660 693 V

Lamp Current IL 2.0 6.0 6.5 mA

Lamp Turn On Voltage VS

--- --- 1165 (25

--- --- 1400 (0

Operating Frequency FL 50 --- 80 KHz (3)

Lamp Life Time LBL 15,000 - Hrs (5)

Power Consumption PL - 3.96 - W (4), IL = 6.0 mA

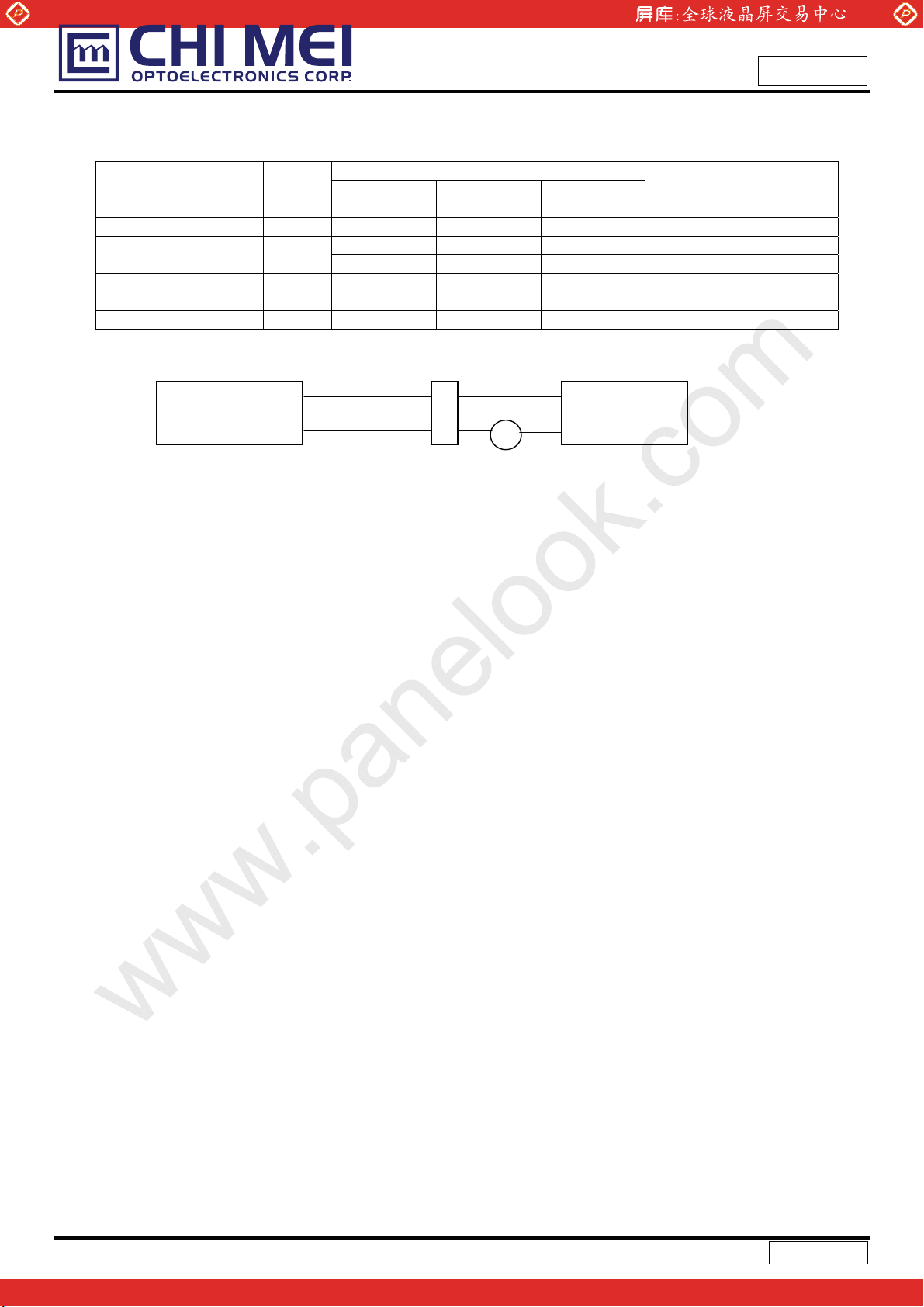

Note (1) Lamp current is measured by utilizing a high frequency current meter as shown below:

Value

o

C) V

o

C) V

Unit Note

I

RMS

RMS

(2)

RMS

(2)

RMS

= 6.0 mA

L

(1)

LCD

Module

HV (White)

LV (Black)

1

2

Current Meter

Inverter

A

Note (2) The voltage shown above should be applied to the lamp for more than 1 second after startup.

Otherwise the lamp may not be turned on.

Note (3) The lamp frequency may produce interference with horizontal synchronous frequency from the

display, and this may cause line flow on the display. In order to avoid interference, the lamp

frequency should be detached from the horizontal synchronous frequency and its harmonics as far

as possible.

Note (4) P

= IL VL

L

Note (5) The lifetime of lamp can be defined as the time in which it continues to operate under the condition

Ta = 25 2

o

C and IL = 6.0 mArms until one of the following events occurs:

(a) When the brightness becomes or lower than 50% of its original value.

(b) When the effective ignition length becomes or lower than 80% of its original value. (Effective

ignition length is defined as an area that has less than 70% brightness compared to the

brightness in the center point.)

Note (6) The waveform of the voltage output of inverter must be area-symmetric and the design of the

inverter must have specifications for the modularized lamp. The performance of the Backlight,

such as lifetime or brightness, is greatly influenced by the characteristics of the DC-AC inverter for

the lamp. All the parameters of an inverter should be carefully designed to avoid producing too

much current leakage from high voltage output of the inverter. When designing or ordering the

inverter please make sure that a poor lighting caused by the mismatch of the Backlight and the

inverter (miss-lighting, flicker, etc.) never occurs. If the above situation is confirmed, the module

should be operated in the same manners when it is installed in your instrument.

8 / 27

Version 2.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 9

Global LCD Panel Exchange Center

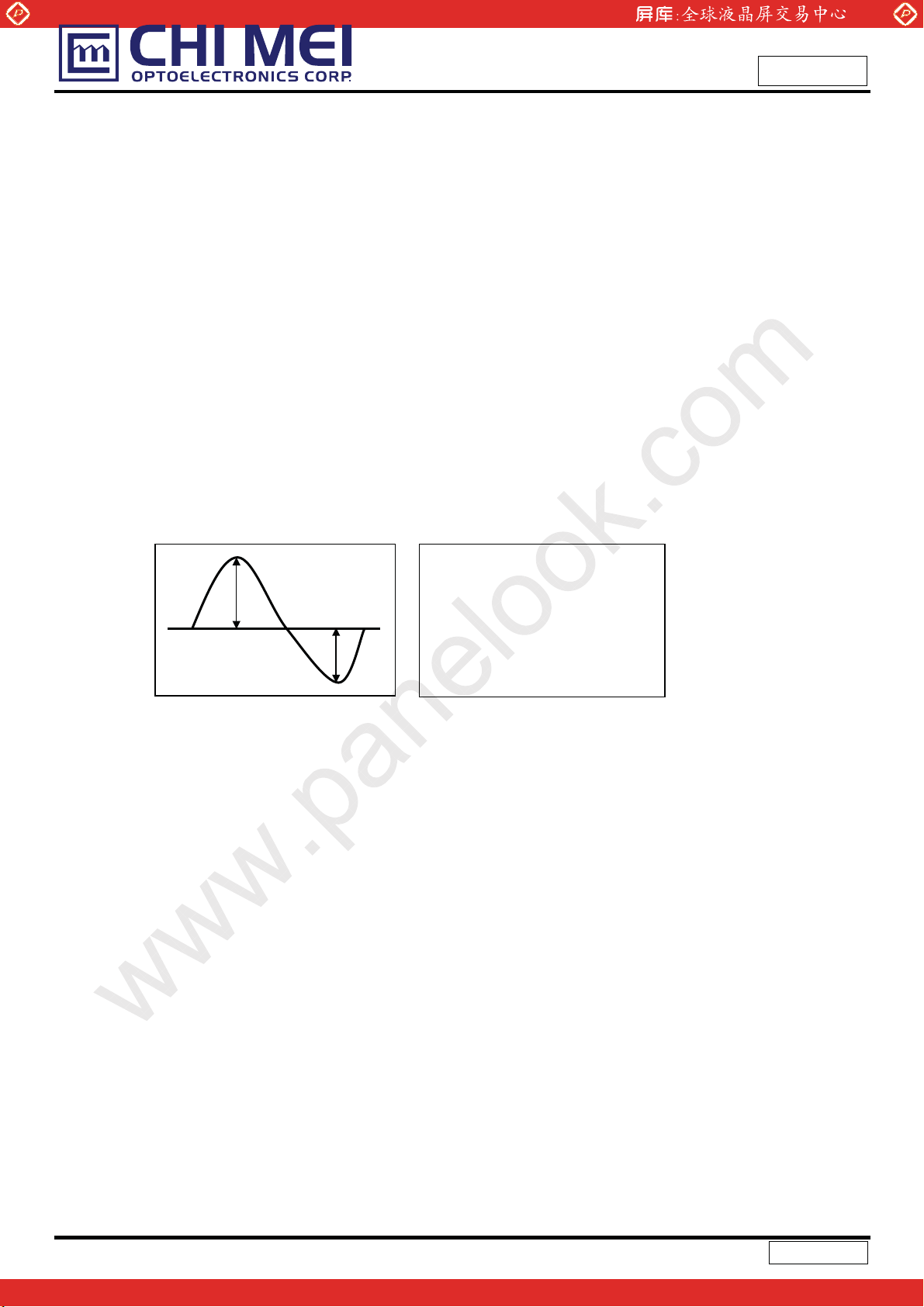

The output of the inverter must have symmetrical (negative and positive) voltage waveform and

symmetrical current waveform.(Unsymmetrical ratio is less than 10%) Please do not use the inverter

which has unsymmetrical voltage and unsymmetrical current and spike wave. Lamp frequency may

produce interface with horizontal synchronous frequency and as a result this may cause beat on the

display. Therefore lamp frequency shall be as away possible from the horizontal synchronous

frequency and from its harmonics in order to prevent interference.

Requirements for a system inverter design, which is intended to have a better display performance, a

better power efficiency and a more reliable lamp. It shall help increase the lamp lifetime and reduce its

leakage current.

a. The asymmetry rate of the inverter waveform should be 10% below;

b. The distortion rate of the waveform should be within Ѕ2 ± 10%;

www.panelook.com

Issued Date: Aug.31, 2005

Model No.: N150X3 - L09

Approval

The ideal sine wave form shall be symmetric in positive and negative polarities.

I p

I -p

* Asymmetry rate:

| I

* Distortion rate

I

– I –p | / I

p

(or I –p) / I

p

rms

rms

* 100%

9 / 27

Version 2.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 10

Global LCD Panel Exchange Center

3.3 EDID DATA

The following data is based on VESA Enhanced EDID proposal.

www.panelook.com

Issued Date: Aug.31, 2005

Model No.: N150X3 - L09

Approval

Byte # Byte Value Value

(decimal) (hex)

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

0 Header

1 Header

2 Header

3 Header

4 Header

5 Header

6 Header

7 Header

8 EISA ID manufacturer name (“CMO”)

9 EISA ID manufacturer name (Compressed ASCII)

0A ID product code

0B ID product code

0C ID S/N (fixed “0”)

0D ID S/N (fixed “0”)

0E ID S/N (fixed “0”)

0F ID S/N (fixed “0”)

10 Week of manufacture (fixed week code)

11 Year of manufacture (fixed year code)

12 EDID structure version # (“1”)

13 EDID revision # (“3”)

14 Video I/P definition (“digital”)

15 Max H image size (“30.4128 cm”)

16 Max V image size (“22.8096 cm”)

17 Display Gamma (Gamma = ”2.2”)

18 Feature support (“Active off, RGB Color”)

Field Name and Comments

(hex) (binary)

00 00000000

FF 11111111

FF 11111111

FF 11111111

FF 11111111

FF 11111111

FF 11111111

00 00000000

0D 00001101

AF 10101111

13 00010011

15 00010101

00 00000000

00 00000000

00 00000000

00 00000000

00 00000000

00 00000000

01 00000001

03 00000011

80 10000000

1E 00011110

17 00010111

78 01111000

0A 00001010

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

19 Red/Green (Rx1, Rx0, Ry1, Ry0, Gx1, Gx0, Gy1, Gy0)

1A Blue/White (Bx1, Bx0, By1, By0, Wx1, Wx0, Wy1, Wy0)

1B Red-x (Rx = “0.626”)

1C Red-y (Ry = “0.355”)

1D Green-x (Gx = ”0.294”)

1E Green-y (Gy = ”0.589”)

1F Blue-x (Bx = ”0.144”)

20 Blue-y (By = ”0.097”)

21 White-x (Wx = ”0.309”)

22 White-y (Wy = ”0.329”)

23 Established timings 1

24 Established timings 2

25 Manufacturer’s reserved timings

26 Standard timing ID # 1

27 Standard timing ID # 1

28 Standard timing ID # 2

29 Standard timing ID # 2

10 / 27

77 01110111

F1 11110001

A0 10100000

5A 01011010

4B 01001011

96 10010110

24 00100100

18 00011000

4F 01001111

54 01010100

00 00000000

08 00001000

00 00000000

01 00000001

01 00000001

01 00000001

01 00000001

Version 2.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 11

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: Aug.31, 2005

Model No.: N150X3 - L09

Approval

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

2A Standard timing ID # 3

2B Standard timing ID # 3

2C Standard timing ID # 4

2D Standard timing ID # 4

2E Standard timing ID # 5

2F Standard timing ID # 5

30 Standard timing ID # 6

31 Standard timing ID # 6

32 Standard timing ID # 7

33 Standard timing ID # 7

34 Standard timing ID # 8

35 Standard timing ID # 8

36 Detailed timing description # 1 Pixel clock (“65 MHz”)

37 # 1 Pixel clock (hex LSB first)

38 # 1 H active (“1024”)

39 # 1 H blank (“320”)

3A # 1 H active : H blank (“1024 : 320”)

3B # 1 V active (”768”)

3C # 1 V blank (”38”)

3D # 1 V active : V blank (”768 : 38”)

3E # 1 H sync offset (”24”)

3F # 1 H sync pulse width (”136”)

40 # 1 V sync offset : V sync pulse width (”3 : 6”)

# 1 H sync offset : H sync pulse width : V sync offset : V

41

sync width (”24 : 136 : 3 : 6”)

42 # 1 H image size (”304.128 mm”)

43 # 1 V image size (”228.096 mm”)

44 # 1 H image size : V image size (”304 : 228”)

45 # 1 H boarder (”0”)

46 # 1 V boarder (”0”)

# 1 Non-interlaced, Normal, no stereo, Separate sync,

47

H/V pol Negatives

48 Detailed timing description # 2

49 # 2 Flag

4A # 2 Reserved

# 2 FE (hex) defines ASCII string (Model Name

4B

“N150X3-L09”, ASCII)

4C # 2 Flag

4D # 2 1st character of name (“N”)

4E # 2 2nd character of name (“1”)

4F # 2 3rd character of name (“5”)

50 # 2 4th character of name (“0”)

51 # 2 5th character of name (“X”)

52 # 2 6th character of name (“3”)

01 00000001

01 00000001

01 00000001

01 00000001

01 00000001

01 00000001

01 00000001

01 00000001

01 00000001

01 00000001

01 00000001

01 00000001

64 01100100

19 00011001

00 00000000

40 01000000

41 01000001

00 00000000

26 00100110

30 00110000

18 00011000

88 10001000

36 00110110

00 00000000

30 00110000

E4 11100100

10 00010000

00 00000000

00 00000000

18 00011000

00 00000000

00 00000000

00 00000000

FE 11111110

00 00000000

4E 01001110

31 00110001

35 00110101

30 00110000

58 01011000

33 00110011

83

84

85

86

53 # 2 7th character of name (“-”)

54 # 2 8th character of name (“L”)

55 # 2 9th character of name (“0”)

56 # 2 10th character of name (“9”)

2D 00101101

4C 01001100

30 00110000

39 00111001

11 / 27

Version 2.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 12

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: Aug.31, 2005

Model No.: N150X3 - L09

Approval

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

(If <13 char, then terminate with ASCII code 0Ah, set

57

remaining char = 20h)

(If <13 char, then terminate with ASCII code 0Ah, set

58

remaining char = 20h)

(If <13 char, then terminate with ASCII code 0Ah, set

59

remaining char = 20h)

5A Detailed timing description # 3

5B # 3 Flag

5C # 3 Reserved

5D # 3 FE (hex) defines ASCII string (Vendor “CMO”, ASCII)

5E # 3 Flag

5F # 3 1st character of string (“C”)

60 # 3 2nd character of string (“M”)

61 # 3 3rd character of string (“O”)

(If <13 char, then terminate with ASCII code 0Ah, set

62

remaining char = 20h)

(If <13 char, then terminate with ASCII code 0Ah, set

63

remaining char = 20h)

(If <13 char, then terminate with ASCII code 0Ah, set

64

remaining char = 20h)

(If <13 char, then terminate with ASCII code 0Ah, set

65

remaining char = 20h)

(If <13 char, then terminate with ASCII code 0Ah, set

66

remaining char = 20h)

(If <13 char, then terminate with ASCII code 0Ah, set

67

remaining char = 20h)

(If <13 char, then terminate with ASCII code 0Ah, set

68

remaining char = 20h)

(If <13 char, then terminate with ASCII code 0Ah, set

69

remaining char = 20h)

(If <13 char, then terminate with ASCII code 0Ah, set

6A

remaining char = 20h)

(If <13 char, then terminate with ASCII code 0Ah, set

6B

remaining char = 20h)

6C Detailed timing description # 4

6D # 4 Flag

6E # 4 Reserved

# 4 FE (hex) defines ASCII string (Model

6F

Name“N150X3-L09”, ASCII)

70 # 4 Flag

71 # 4 1st character of name (“N”)

72 # 4 2nd character of name (“1”)

73 # 4 3rd character of name (“5”)

74 # 4 4th character of name (“0”)

75 # 4 5th character of name (“X”)

76 # 4 6th character of name (“3”)

77 # 4 7th character of name (“-”)

78 # 4 8th character of name (“L”)

79 # 4 9th character of name (“0”)

7A # 4 10th character of name (“9”)

(If <13 char, then terminate with ASCII code 0Ah, set

7B

remaining char = 20h)

0A 00001010

20 00100000

20 00100000

00 00000000

00 00000000

00 00000000

FE 11111110

00 00000000

43 01000011

4D 01001101

4F 01001111

0A 00001010

20 00100000

20 00100000

20 00100000

20 00100000

20 00100000

20 00100000

20 00100000

20 00100000

20 00100000

00 00000000

00 00000000

00 00000000

FE 11111110

00 00000000

4E 01001110

31 00110001

35 00110101

30 00110000

58 01011000

33 00110011

2D 00101101

4C 01001100

30 00110000

39 00111001

0A 00001010

12 / 27

Version 2.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 13

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: Aug.31, 2005

Model No.: N150X3 - L09

Approval

124

125

126

127

(If <13 char, then terminate with ASCII code 0Ah, set

7C

remaining char = 20h)

(If <13 char, then terminate with ASCII code 0Ah, set

7D

remaining char = 20h)

7E Extension flag

7F Checksum

20 00100000

20 00100000

00 00000000

0E 00001110

13 / 27

Version 2.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 14

Global LCD Panel Exchange Center

4. BLOCK DIAGRAM

TFT LCD MODULE

Rxin0(+/-)

Rxin1(+/-)

(JAE-FI-XB30SL-HF10)

INPUT CONNECTOR

www.panelook.com

LVDS INPUT /

TIMING CONTROLLER

Issued Date: Aug.31, 2005

Model No.: N150X3 - L09

SCAN DRIVER IC

TFT LCD PANEL

(1024xR.G.B.x768)

Approval

Rxin2(+/-)

CLK(+/-)

Vcc

GND

DC/DC CONVERTER &

REFERENCE VOLTAGE

GENERATOR

5. INPUT TERMINAL PIN ASSIGNMENT

5.1 TFT LCD MODULE

Pin Symbol Description Polarity Remark

1 Vss Ground

2 Vcc Power Supply +3.3 V (typical)

3 Vcc Power Supply +3.3 V (typical)

4 NC Non-Connection

5 NC Non-Connection

6 NC Non-Connection

7 NC Non-Connection 8 Rxin0- LVDS Differential Data Input Negative

9 Rxin0+ LVDS Differential Data Input Positive

10 Vss Ground

11 Rxin1- LVDS Differential Data Input Negative

12 Rxin1+ LVDS Differential Data Input Positive

13 Vss Ground

14 Rxin2- LVDS Differential Data Input Negative

15 Rxin2+ LVDS Differential Data Input Positive

16 Vss Ground

17 CLK- LVDS Clock Data Input Negative

18 CLK+ LVDS Clock Data Input Positive

19 Vss Ground

20 NC Non-Connection

21 NC Non-Connection

22 Vss Ground

23 NC Non-Connection

24 NC Non-Connection

DATA DRIVER IC

R0~R5,G0

-

G1~G5,B0,B1

-

B2~B5,DE,Hsync,Vsync

LVDS Level Clock

14 / 27

Version 2.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 15

Global LCD Panel Exchange Center

25 Vss Ground

26 NC Non-Connection

27 NC Non-Connection

28 Vss Ground

29 NC Non-Connection

30 NC Non-Connection

Note (1) Connector Part No.: JAE-FI-XB30SL-HF10 or equivalent

Note (2) User’s connector Part No: JAE-FI-X30C2L or equivalent

Note (3) The first pixel is even.

5.2 TIMING DIAGRAM OF LVDS INPUT SIGNAL

www.panelook.com

Issued Date: Aug.31, 2005

Model No.: N150X3 - L09

Approval

CLK+

Rxin2

Rxin1

Rxin0

T/7

IN20 IN19 IN18 IN17 IN16 IN15 IN14

DE B5 B4 B3 B2 Vsync Hsync

IN13 IN12 IN11 IN10 IN9 IN8 IN7

B1 G4 G3 G2 G1 B0 G5

IN6 IN5 IN4 IN3 IN2 IN1 IN0

G0 R3 R2 R1 R0 R5 R4

Signal for 1 DCLK Cycle (T)

15 / 27

Version 2.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 16

Global LCD Panel Exchange Center

5.3 COLOR DATA INPUT ASSIGNMENT

The brightness of each primary color (red, green and blue) is based on the 6-bit gray scale data input for

the color. The higher the binary input, the brighter the color. The table below provides the assignment of

color versus data input.

Color

R5 R4 R3 R2 R1 R0 G5 G4 G3 G2 G1 G0 B5 B4 B3 B2 B1 B0

Black

Red

Green

Basic

Colors

Gray

Scale

Of

Red

Gray

Scale

Of

Green

Gray

Scale

Of

Blue

Note (1) 0: Low Level Voltage, 1: High Level Voltage

Blue

Cyan

Magenta

Yellow

White

Red(0)/Dark

Red(1)

Red(2)

:

:

Red(61)

Red(62)

Red(63)

Green(0)/Dark

Green(1)

Green(2)

:

:

Green(61)

Green(62)

Green(63)

Blue(0)/Dark

Blue(1)

Blue(2)

:

:

Blue(61)

Blue(62)

Blue(63)

0

0

1

1

0

0

0

0

0

0

1

1

1

1

1

1

0

0

0

0

0

0

:

:

1

1

1

1

1

1

0

0

0

0

0

0

:

:

0

0

0

0

0

0

0

0

0

0

0

0

:

:

0

0

0

0

0

0

www.panelook.com

Issued Date: Aug.31, 2005

Model No.: N150X3 - L09

Approval

Data Signal

Red Green Blue

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

0

0

0

0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

0

0

0

0

0

0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

0

0

0

0

0

0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

0

0

0

0

0

0

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

1

1

0

1

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

0

0

0

0

1

1

1

1

0

1

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

0

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

0

0

0

0

0

0

0

0

0

0

1

1

1

1

0

1

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

16 / 27

Version 2.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 17

Global LCD Panel Exchange Center

6. INTERFACE TIMING

6.1 INPUT SIGNAL TIMING SPECIFICATIONS

The input signal timing specifications are shown as the following table and timing diagram.

Signal Item Symbol Min. Typ. Max. Unit Note

DCLK Frequency 1/Tc 50 65 68 MHz -

Frame Time Cycle TV 771 806 850 TH -

DE

Note (1) Because this module is operated by DE only mode, Hsync and Vsync input signals should be set

to low logic level or ground. Otherwise, this module would operate abnormally.

Vertical Active Display Period TVD 768 768 768 TH -

One Line Scanning Time Cycle TH 1200 1344 1600 Tc -

Horizontal Active Display Period THD 1024 1024 1024 Tc -

www.panelook.com

Issued Date: Aug.31, 2005

Model No.: N150X3 - L09

Approval

DE

DCLK

TC

DE

DATA

6.2 POWER ON/OFF SEQUENCE

Power Supply

for LCD, Vcc

- Interface Signal

(LVDS Signal of

Transmitter), V

- Power for Lamp

0V

0V

I

10%

INPUT SIGNAL TIMING DIAGRAM

Power On

90%

t1

Valid Data

ONOFF OFF

Power Off

90%

t6 t5

50%50%

HD

T

Restart

10%

t3 t2

t4

17 / 27

Version 2.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 18

Global LCD Panel Exchange Center

Timing Specifications:

0.47 < t1 Љ 10 msec

0 < t2 Љ 50 msec

0 < t3 Љ 50 msec

t4 Њ 500 msec

t5 Њ 200 msec

t6 Њ 200 msec

Note (1) Please avoid floating state of interface signal at invalid period.

Note (2) When the interface signal is invalid, be sure to pull down the power supply of LCD Vcc to 0 V.

Note (3) The Backlight inverter power must be turned on after the power supply for the logic and the

interface signal is valid. The Backlight inverter power must be turned off before the power supply

for the logic and the interface signal is invalid.

www.panelook.com

Issued Date: Aug.31, 2005

Model No.: N150X3 - L09

Approval

18 / 27

Version 2.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 19

Global LCD Panel Exchange Center

7. OPTICAL CHARACTERISTICS

7.1 TEST CONDITIONS

Item Symbol Value Unit

Ambient Temperature Ta

Ambient Humidity Ha

Supply Voltage VCC 3.3 V

Input Signal According to typical value in "3. ELECTRICAL CHARACTERISTICS"

Inverter Current IL 6.0 mA

Inverter Driving Frequency FL 61 KHz

Inverter Sumida H05 4915

The relative measurement methods of optical characteristics are shown in 6.2. The following items

should be measured under the test conditions described in 6.1 and stable environment shown in Note (6).

www.panelook.com

25r2

50r10

Issued Date: Aug.31, 2005

Model No.: N150X3 - L09

Approval

o

C

%RH

7.2 OPTICAL SPECIFICATIONS

Item Symbol Condition Min. Typ. Max. Unit Note

Red

Green

Color

Chromaticity

Blue

White

Center Luminance of White L

Contrast Ratio CR

Response Time

White Variation

Horizontal

Viewing

Angle

Vertical

Rx 0.589 ---

Ry 0.338 ---

Gx 0.316 ---

Gy 0.532 ---

Bx 0.152 ---

T

=0q, TY =0q

By 0.129 ---

x

CS-1000T

TYP

-0.03

TYP

+0.03

(1), (5)

Wx 0.313 ---

Wy

C

0.329

170 200 --- cd/m2(4), (5)

---

200 300 --- --- (2), (6)

TR --- 5 10 ms

T

F

GW

Tx+

T

-

x

TY+

-

T

Y

=0q, TY =0q

T

x

T

=0q, TY =0q

x

CA-210

CRt10

CA-210

--- 11 16 ms

--- 1.25 1.40 --- (5), (6)

40 45 ---

40 45 ---

Deg.

15 20 ---

40 45 ---

(3)

(1), (2)

(5)

19 / 27

Version 2.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 20

Global LCD Panel Exchange Center

Note (1) Definition of Viewing Angle (Tx, Ty):

www.panelook.com

Issued Date: Aug.31, 2005

Model No.: N150X3 - L09

Approval

TX- = 90º

x-

6 o’clock

T

y- = 90º

y-

Note (2) Definition of Contrast Ratio (CR):

The contrast ratio can be calculated by the following expression.

Normal

Tx = Ty = 0º

Ty- Ty

Tx

Tx

y+

12 o’clock direction

T

y+ = 90º

x+

TX+ = 90º

Contrast Ratio (CR) = L63 / L0

L63: Luminance of gray level 63

L 0: Luminance of gray level 0

CR = CR (5)

CR (X) is corresponding to the Contrast Ratio of the point X at Figure in Note (7).

Note (3) Definition of Response Time (T

100%

90%

Optical

Response

Gray Level 63

10%

0%

, TF):

R

R

Gray Level 0

Gray Level 63

T

FT

Time

20 / 27

Version 2.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 21

Global LCD Panel Exchange Center

A

A

www.panelook.com

Issued Date: Aug.31, 2005

Model No.: N150X3 - L09

Approval

Note (4) Definition of Luminance of White (L

Measure the luminance of gray level 63 at center point

LC = L (5)

L (x) is corresponding to the luminance of the point X at Figure in Note (6).

Note (5) Definition of Cross Talk (CT):

CT = | Y

– YA | / YA u 100 (%)

B

Where:

Y

= Luminance of measured location without gray level 0 pattern (cd/m2)

A

Y

= Luminance of measured location with gray level 0 pattern (cd/m2)

B

(0, 0)

ctive Area

Y

(D/8,W/2)

A, L

Gray 32

Y

(D/2,7W/8)

A, D

Y

A, U

Y

A, R

(D,W)

):

C

(D/2,W/8)

(7D/8,W/2)

(D/4,W/4)

Y

(D/8,W/2)

B, L

Y

(D/2,7W/8)

B, D

(0, 0)

ctive Area

Gray 0

Gray 32

Y

B, U

Y

B, R

(3D/4,3W/4)

(D,W)

(D/2,W/8)

(7D/8,W/2)

Note (6) Measurement Setup:

The LCD module should be stabilized at given temperature for 20 minutes to avoid abrupt

temperature change during measuring. In order to stabilize the luminance, the measurement

should be executed after lighting Backlight for 20 minutes in a windless room.

LCD Module

LCD Panel

Center of the Screen

500 mm

BM-5A

CS-1000T

Field of View = 2º

Light Shield Room

(Ambient Luminance < 2 lux)

21 / 27

Version 2.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 22

Global LCD Panel Exchange Center

Note (7) Definition of White Variation (GW):

Measure the luminance of gray level 63 at 5 points

GW = Maximum [L (1), L (2), L (3), L (4), L (5)] / Minimum [L (1), L (2), L (3), L (4), L (5)]

www.panelook.com

Issued Date: Aug.31, 2005

Model No.: N150X3 - L09

Approval

W

W/4

W/2

Vertical Line

3W/4

Note (8) Definition of color gamut (C.G%):

C.G%= 'R G B /'R

R

R, G, B

'R

, G0, B0 : color coordinates of red, green, and blue defined by NTSC, respectively.

0

: color coordinates of module on 255 gray levels of red, green, and blue, respectively.

0 G0 B0

: area of triangle defined by R0, G0, B0

0 G0 B0

'R G B: area of triangle defined by R, G, B

Horizontal Line

D

D/4 D/2 3D/4

12

5

3

Active Area

,

X

: Test Point

X=1 to 5

4

˖˜˘ʳ˄ˌˆ˄

˃ˁˌ

˃ˁˋ

˃ˁˊ

˃ˁˉ

˃ˁˈ

˃ˁˇ

˃ˁˆ

˃ˁ˅

˃ˁ˄

˃

˃ ˃ˁ˅ ˃ˁˇ ˃ˁˉ ˃ˁˋ

G

0

G

R

0

R

B

B

0

22 / 27

Version 2.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 23

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: Aug.31, 2005

Model No.: N150X3 - L09

Approval

8. PRECAUTIONS

8.1 ASSEMBLY AND HANDLING PRECAUTIONS

(1) Do not apply rough force such as bending or twisting to the module during assembly.

(2) To assemble or install module into user’s system can be only in clean working areas. The dust and oil

may cause electrical short or worsen the polarizer.

(3) It’s not permitted to have pressure or impulse on the module because the LCD panel and Backlight will

be damaged.

(4) Always follow the correct power sequence when LCD module is connecting and operating. This can

prevent damage to the CMOS LSI chips during latch-up.

(5) Do not pull the I/F connector in or out while the module is operating.

(6) Do not disassemble the module.

(7) Use a soft dry cloth without chemicals for cleaning, because the surface of polarizer is very soft and

easily scratched.

(8) It is dangerous that moisture come into or contacted the LCD module, because moisture may damage

LCD module when it is operating.

(9) High temperature or humidity may reduce the performance of module. Please store LCD module within

the specified storage conditions.

(10) When ambient temperature is lower than 10ºC may reduce the display quality. For example, the

response time will become slowly, and the starting voltage of CCFL will be higher than room

temperature.

8.2 SAFETY PRECAUTIONS

(1) The startup voltage of Backlight is approximately 1000 Volts. It may cause electrical shock while

assembling with inverter. Do not disassemble the module or insert anything into the Backlight unit.

(2) If the liquid crystal material leaks from the panel, it should be kept away from the eyes or mouth. In

case of contact with hands, skin or clothes, it has to be washed away thoroughly with soap.

(3) After the module’s end of life, it is not harmful in case of normal operation and storage.

23 / 27

Version 2.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 24

Global LCD Panel Exchange Center

9. DEFINITION OF LABELS

9.1 CMO MODULE LABEL

The barcode nameplate is pasted on each module as illustration, and its definitions are as following

explanation.

N150X3 - L09 Rev. XX

CHI MEI

OPTOELECTRONICS

(a) Model Name: N150X3 - L09

(b) Revision: Rev. XX: WS, ES : A1, A2, A3,…, etc.

www.panelook.com

MADE IN TAIWAN

X X X X X X X Y M D L N N N N

Issued Date: Aug.31, 2005

Model No.: N150X3 - L09

Approval

E207943

MADE IN TAIWAN

CS & MP : C1, C2, C3,…,etc.

Note: It will happen that revision code changed without product changed in developing duration because

of CMO internal stage change, for example: AX Æ B1, BX Æ C1.

(c) Serial ID: X X

Serial ID includes the information as below:

(a) Manufactured Date: Year: 0 ~ 9, for 2000 ~ 2009.

X X X X X Y M D L N N N N

Month: 1 ~ 9, A ~ C, for Jan. ~ Dec.

Day: 1 ~ 9, A ~ Y, for 1

Serial No.

Product Line

Year, Month, Date

CMO Internal Use

Revision

CMO Internal Use

st

to 31st, exclude I, O and U.

(b) Revision Code: cover all the changes.

(c) Serial No.: Manufacturing sequence of product.

(d) Product Line: 1 -> Line1, 2 -> Line 2, …etc.

24 / 27

Version 2.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 25

Global LCD Panel Exchange Center

10.PACKING

10.1 CARTON

www.panelook.com

Issued Date: Aug.31, 2005

Model No.: N150X3 - L09

Approval

10.2 PALLET

25 / 27

Version 2.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 26

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 27

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Loading...

Loading...