Page 1

Global LCD Panel Exchange Center

ுழၴ ຝ ᐉு ߡۥ ދป

ขጥ

吳

柏 勳

TFT LCD Approval Specification

MODEL NO.:M156B1-C01

www.panelook.com

Issued Date: Jul. 16, 2009

Model No.: M156B1-C01

Approval

Customer :

Approved by :

Note :

2009-08-11

17:49:41

MTR

2009.08.11

Director Accept

/19

1

Version 2.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 2

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: Jul. 16, 2009

Model No.: M156B1-C01

Approval

- CONTENTS -

REVISION HISTORY ------------------------------------------------------- 3

1. GENERAL DESCRIPTION ------------------------------------------------------- 4

1.1 OVERVIEW

1.2 FEATURES

1.3 APPLICATION

1.4 GENERAL SPECIFICATIONS

2. ABSOLUTE MAXIMUM RATINGS ---------------------------------------------- 5

3. SUGGESTIVE DRIVING CONDITION ---------------------------------------------- 6

4. PANEL PIN DEFINITION ------------------------------------------------------- 7

5. OPTICAL CHARACTERISTICS ---------------------------------------------- 10

5.1 TEST CONDITIONS

5.2 OPTICAL SPECIFICATIONS

6. PACKAGING --------------------------------------------- 14

6.1 PACKING SPECIFICATIONS

6.2 PACKING METHOD

7. DEFINITION OF LABELS ---------------------------------------------- 16

8. PRECAUTIONS ---------------------------------------------- 17

8.1 ASSEMBLY AND HANDLING PRECAUTIONS

8.2 SAFETY PRECAUTIONS

9. RELIABILITY TEST ---------------------------------------------- 18

10. PANEL DRAWING ---------------------------------------------- 19

/19

2

Version 2.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 3

Global LCD Panel Exchange Center

www.panelook.com

REVISION HISTORY

Version Date Section Description

Issued Date: Jul. 16, 2009

Model No.: M156B1-C01

Approval

Ver. 2.0 Jul, 16 ’09

- M156B1-C01 approval specifications was first issued.

/19

3

Version 2.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 4

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: Jul. 16, 2009

Model No.: M156B1-C01

Approval

1. GENERAL DESCRIPTION

1.1 OVERVIEW

The M156B1-C01 is a 15.6-inch wide LCD cell with thin film transistors as active elements and contains

1366x768 pixels. Each pixel is divided into red, green and blue dot, which are arranged in vertical stripe.

The cell is normally white mode, and can be applied to the transmission type display. Backlight unit (BLU)

and circuit board for the cell are not built in.

1.2 FEATURES

- Response time 8ms

- WXGA (1366 x 768 pixels) resolution

1.3 APPLICATION

- TFT LCD Monitor

- TFT LCD TV

1.4 GENERAL SPECIFICATIONS

Item Specification Unit

Max Panel Dimension (TFT) 353.632 X 203.086 mm

Glass thickness( TFT/ CF ) 0.7/0.7 mm

Active Area 344.232 (H) x 193.536 (V) (15.6” diagonal) mm

Driver Element a-si TFT active matrix Pixel Number 1366X R.G.B X 768 pixel

Pixel Pitch 0.252 (H) X 0.252 (V) mm

Pixel Arrangement RGB vertical stripe Transmissive Mode Normally white Surface Treatment Hard coating (3H), AG (Haze 25%) Polarizer Type TAC -

Polarizer Dimension

Polarizer Thickness

Weight 297(typ.) g

TFT 350.43 X 199.44 mm

CF 350.43 X 199.44 mm

TFT 0.215 mm

CF 0.215 mm

/19

4

Version 2.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 5

Global LCD Panel Exchange Center

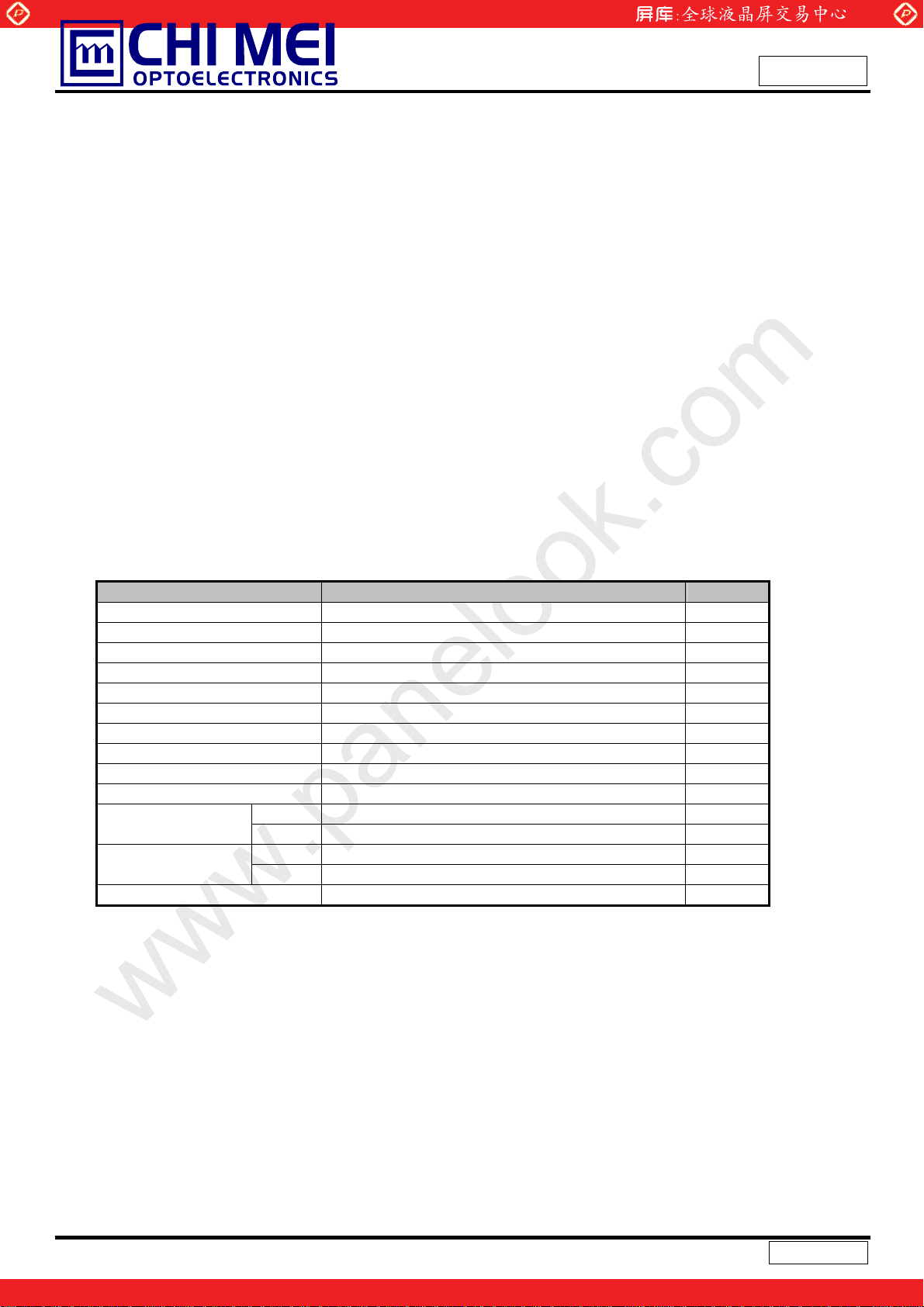

2. ABSOLUTE MAXIMUM RATINGS

Item Symbol

Storage Temperature TST -20 +60 ºC (1)

Operating Ambient Temperature TOP 0 +50 ºC (1), (2)

LCD Cell Life Time L

Relative Humidity (%RH)

100

80

90

www.panelook.com

Issued Date: Jul. 16, 2009

Model No.: M156B1-C01

Value

Min. Max.

50,000 - Hrs

CELL

Unit Note

Approval

MTBF

based

60

Operating Range

40

20

10

Storage Range

-20 40 0 20 -40

Temperature (

Note (1) Temperature and relative humidity range is shown in the figure below.

(a) 90% RH Max. (Ta Љ 40 ºC).

(b) Wet-bulb temperature should be 39 ºC Max. (Ta > 40 ºC).

(c) No condensation.

Note (2) The temperature of panel surface should be 0 ºC Min. and 60 ºC Max

C)

60

80

/19

5

Version 2.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 6

Global LCD Panel Exchange Center

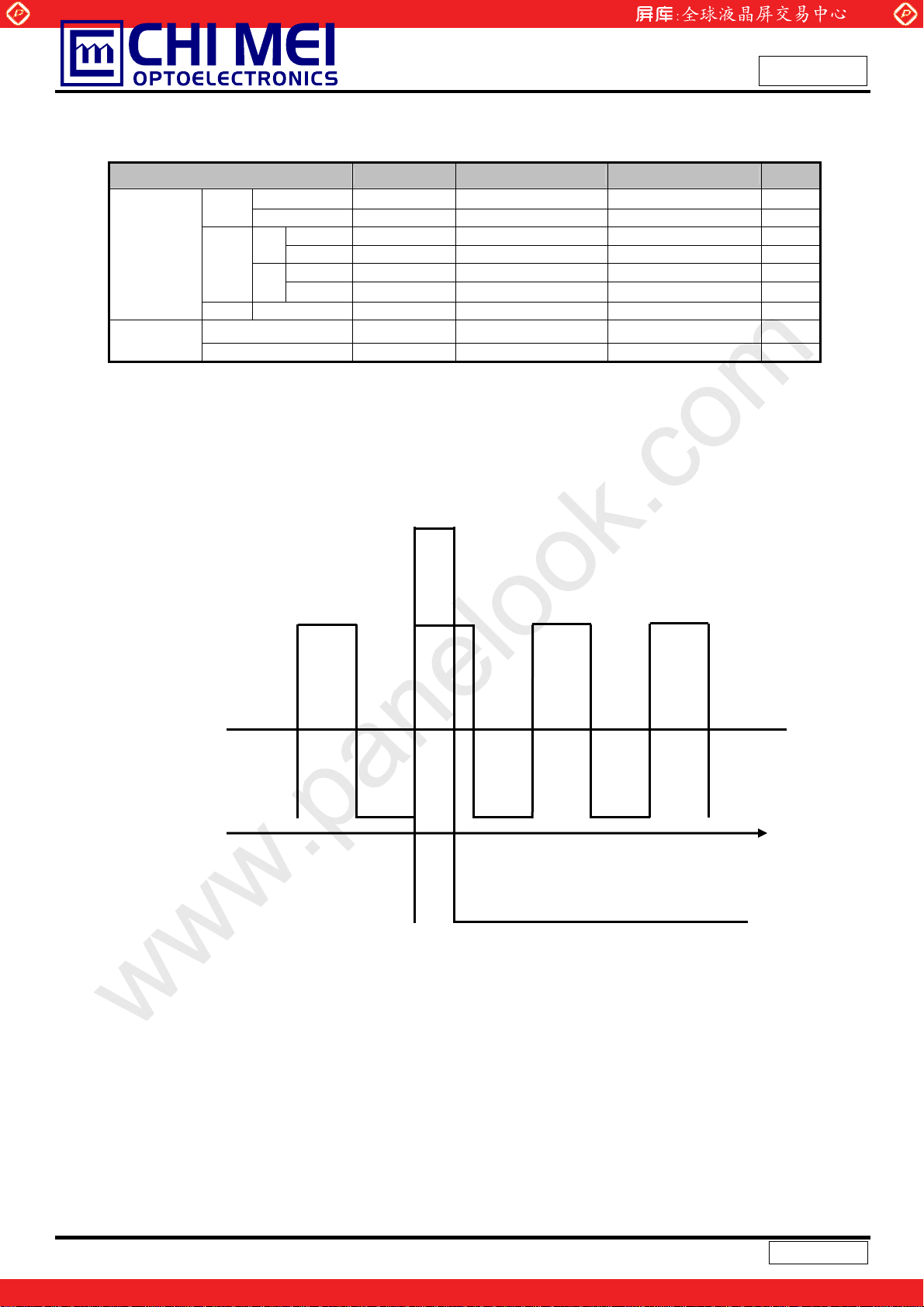

3. Suggestive Driving Condition

Item Min. Typ. Max. Unit

VG

Driving

Voltage

B: Black pattern

W: White pattern

Gamma Voltage : Gam1 > Gam2 > Gam3 > … > Gam10 GЦ: gate pulse falling edge

VD

V

GЦ-D offset

Charging time 15 - - us

On 20.13 20.83 21.53 V

Off -7.46 -6.86 -6.26 V

Gam1 10.275 10.475 10.675 V

B

Gam14 -0.1 0.1 0.3 V

Gam7 5.717 5.917 6.117 V

W

Gam8 5.185 5.385 5.585 V

Center 4.0 4.5 5.0 V

COM

www.panelook.com

Issued Date: Jul. 16, 2009

Model No.: M156B1-C01

Approval

2 - - us

DRIVING TIMING DIAGRAM

VG

VD

V

COM

/19

6

Version 2.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 7

Global LCD Panel Exchange Center

www.panelook.com

4. PANEL PIN DEFINITION

4.1 DATA PIN DEFINE

Pin number TAB1 TAB2~5 TAB6

1 dummy dummy dummy

2 dummy dummy dummy

3 dummy dummy dummy

4 dummy dummy dummy

5 dummy dummy dummy

6 dummy dummy dummy

7 dummy dummy dummy

8 LR dummy dummy

9 XAO dummy dummy

10 OE dummy dummy

11 CPV dummy dummy

12 STV1 dummy dummy

13 STV2 dummy dummy

14 VSS dummy dummy

15 VSS dummy dummy

16 VDD dummy dummy

17 VDD dummy dummy

18 Vee dummy dummy

19 Vgl dummy dummy

20 Vgl dummy dummy

21 Vgl dummy dummy

22 dummy dummy dummy

23 Vgh dummy dummy

24 Vgh dummy dummy

25 Vgh dummy dummy

26 Vcom Vcom Vcom

27 Vst dummy dummy

28 Vst dummy dummy

29 Vcom Vcom Vcom

30 dummy dummy dummy

31 OUT_1 OUT_1 OUT_1

32 OUT_2 OUT_2 OUT_2

33 OUT_3 OUT_3 OUT_3

34 OUT_4 OUT_4 OUT_4

35 OUT_5 OUT_5 OUT_5

36 OUT_6 OUT_6 OUT_6

37 OUT_7 OUT_7 OUT_7

38 OUT_8 OUT_8 OUT_8

39 OUT_9 OUT_9 OUT_9

.... ʳ ʳ ʳ

372 OUT_342 OUT_342 OUT_342

373 dummy dummy dummy

…. dummy dummy dummy

408 dummy dummy dummy

409 OUT_343 OUT_343 OUT_343

.... ʳ ʳ ʳ

729 OUT_663 OUT_663 OUT_663

730 OUT_664 OUT_664 OUT_664

Issued Date: Jul. 16, 2009

Model No.: M156B1-C01

Approval

/19

7

Version 2.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 8

Global LCD Panel Exchange Center

731 OUT_665 OUT_665 OUT_665

732 OUT_666 OUT_666 OUT_666

733 OUT_667 OUT_667 OUT_667

734 OUT_668 OUT_668 OUT_668

735 OUT_669 OUT_669 OUT_669

736 OUT_670 OUT_670 OUT_670

737 OUT_671 OUT_671 OUT_671

738 OUT_672 OUT_672 OUT_672

739 OUT_673 OUT_673 OUT_673

740 OUT_674 OUT_674 OUT_674

741 OUT_675 OUT_675 OUT_675

742 OUT_676 OUT_676 OUT_676

743 OUT_677 OUT_677 OUT_677

744 OUT_678 OUT_678 OUT_678

745 OUT_679 OUT_679 dummy

746 OUT_680 OUT_680 dummy

747 OUT_681 OUT_681 dummy

748 OUT_682 OUT_682 dummy

749 OUT_683 OUT_683 dummy

750 OUT_684 OUT_684 dummy

751 dummy dummy dummy

752 dummy dummy dummy

753 Vcom Vcom Vcom

754 dummy dummy Vst

755 dummy dummy Vst

756 dummy dummy G_gate(Vgl)

757 dummy dummy G1-Vcom

758 dummy dummy G2-Vcom

759 dummy dummy dummy

760 dummy dummy dummy

761 Vcom Vcom Vcom

762 Vcom Vcom Vcom

763 dummy dummy dummy

764 dummy dummy dummy

765 dummy dummy dummy

766 dummy dummy dummy

767 dummy dummy dummy

www.panelook.com

Issued Date: Jul. 16, 2009

Model No.: M156B1-C01

Approval

Note: 1. Test pin is recommend for floating

2. LR default value is Vss (ground)

/19

8

Version 2.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 9

Global LCD Panel Exchange Center

4.2 SCAN PIN DEFINE

www.panelook.com

Issued Date: Jul. 16, 2009

Model No.: M156B1-C01

Approval

Scan1~3

DUMMY

XAO 154 165 166 VEE

VDD 153 167 168 VEE

LR 152 169 170 VGH

TEST 151 171 172 VGH

ʳ 173 174 PASS1

ʳ 175 Dummy PAD

DUMMY 150 176 OUT264

. ʳ 177 OUT263

. ʳ ʳ .

ʳ ʳ .

ʳ ʳ .

. ʳ ʳ .

. ʳ ʳ .

. ʳ ʳ .

. ʳ ʳ .

. ʳ ʳ OUT136

. ʳ ʳ OUT135

. ʳ ʳ .

ʳ ʳ OUT129

ʳ ʳ OUT128

ʳ ʳ .

. ʳ ʳ .

. ʳ ʳ .

. ʳ ʳ .

. ʳ ʳ .

. ʳ ʳ .

DUMMY 15 439 OUT1

ʳ 440 OUT0

ʳ 441 Dummy PAD

PASS3 14 442 443 PASS1

LR 13 444 445 VGH

VSS 12 446 447 VGH

XAO 11 448 449 VEE

ʳ 450 451 VEE

10 9 8 7 6 5 4 3 2 1

155 156 157 157 159 160 161 162 163 164

OE

CPV

PASS2

STV2

VSS

MODE2

VDD

VEE

VEE

G(1,1)

G(1, 128)

G(1, 129)

G(1,256)

DUMMY

OE

CPV

PASS2

STV1

VSS

MODE1

VDD

VEE

VEE

/19

9

Version 2.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 10

Global LCD Panel Exchange Center

5. OPTICAL CHARACTERISTICS

5.1 TEST CONDITIONS

Item Symbol Value Unit

Ambient Temperature Ta

Ambient Humidity Ha

Gamma voltage - Refer to Item 3 driving condition V

Vcom - most suitable Vcom V

5.2 OPTICAL SPECIFICATION

ITEM Symbol Condition MIN. TYP. MAX. UNIT NOTE

Contrast Ratio CR

Response Time

(Black/White)

Center point Transmittance T%

Transmittance uniformity

(13pts)

Horizontal x

Viewing

Angle

Color

Coordinate

at center

point

(y=0± )

Verti ca l y

(x=0± )

Red

Green

Blue

White

www.panelook.com

Issued Date: Jul. 16, 2009

Model No.: M156B1-C01

Approval

o

ms

ms

-

C

%RH

5,1,8

2,3,1,8

2,0

25±2

50±10

=0° , θY

θ

x

=0°

CS-1000T,

CMO BLU

Tr x=y=0±

Tf x=y=0±

=0° , θY

θ

x

=0°

CS-1000T,

CMO BLU

ӬT%

Right

Left

Up

Down

Rcx 0.641 Rcy 0.329 Gcx 0.274 Gcy 0.585 Bcx 0.150 -

Bcy 0.106 Wcx 0.308 Wcy

x=y=0± - 1.4 1.5 - 6,1

CR≥10

USB2000

=0° , θY

θ

x

=0°

CS-1000T

Standard

light source

“C”

350 500

- 2 4

- 6 12

10.5 11 - % 7,1,8

40 45

40 45

15 20

40

Typ

-0.03

45

0.346

- % 4,1,8

- Deg

- Deg

- Deg

- Deg

Typ

+0.03

Note (0)

Light source is the standard light source “C” which is defined by CIE and driving voltages are based on

suitable gamma voltages. The calculating method is as followingΚ

1. Measure Module’s and BLU’s spectrums. White is without signal input and R, G, B are with signal input.

BLU is supplied by CMO. Light source is the BLU with DBEF-D2.

2. Calculate cell’s spectrum.

3. Calculate cell’s chromaticity by using the spectrum of standard light source “C”

/19

10

Version 2.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 11

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: Jul. 16, 2009

Model No.: M156B1-C01

Approval

Note (1)

Light source is the BLU, which is supplied by CMO, and driving voltages are based on suitable gamma

voltages. White is without signal input and R, G, B are with signal input. SPEC is judged by CMO’s golden sample.

Note (2): Measurement setup:

The LCD module should be stabilized at given temperature for 20 minutes to avoid abrupt temperature

change during measuring. In order to stabilize the luminance, the measurement should be executed after lighting

backlight for 20 minutes in a windless room.

LCD Module

LCD Panel

USB2000

Center of the Screen

500 mm

CS-1000T

Field of View = 2º

Light Shield Room

(Ambient Luminance < 2 lux)

/19

11

Version 2.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 12

Global LCD Panel Exchange Center

Note (3): Definition of viewing angle (x ,y):

www.panelook.com

Issued Date: Jul. 16, 2009

Model No.: M156B1-C01

Approval

Note (4): Definition of Contrast Ratio (CR):

Ratio of gray max (Gmax), gray min (Gmin), at the center point of panel.

Luminance with all pixel white (Gmax)

CR =

Luminance with all pixel Black (Gmin)

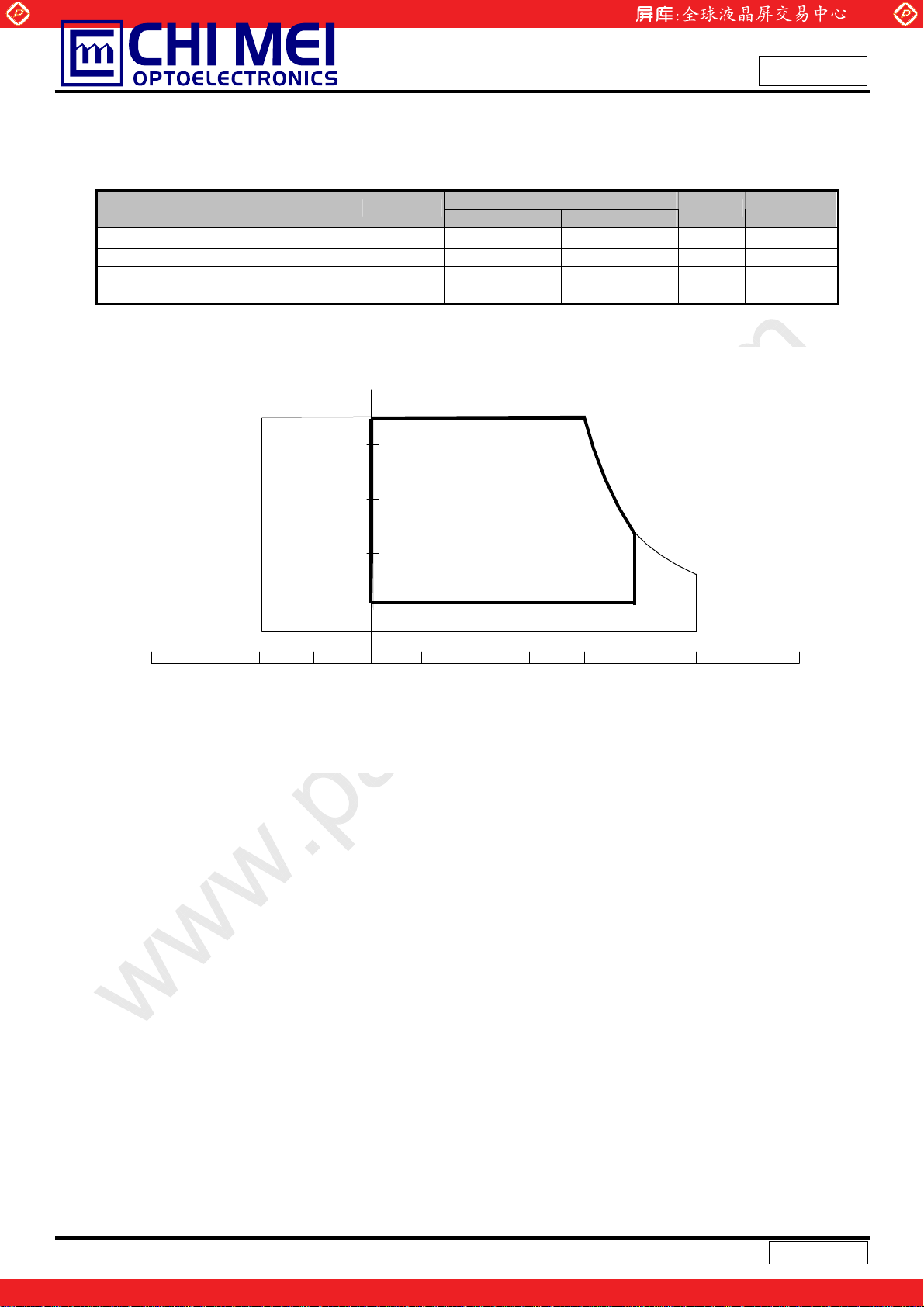

Note (5): Definition of Response Time (T

100%

90%

Optical

Response

10%

0%

Gray Level 255

R, TF):

T

R

Gray Level 0

Gray Level 255

Time

T

F

66.67ms

/19

12

66.67ms

Version 2.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 13

Global LCD Panel Exchange Center

A

Note (6): Definition of Transmittance Variation (δT%):

Measure the transmittance at 13 points

T% =

δ

Maximum [T%(1), T%(2), … T%(13)]

Minimum [T%(1), T%(2), … T%(13)]

www.panelook.com

Issued Date: Jul. 16, 2009

Model No.: M156B1-C01

Approval

˄˃

ˉ

˛˂ˇ

˛˂ˇ˛˂ˇ

˛

Vertical Line Number

Note (7) : Definition of Transmittance(T%):

Module is without signal input.

˛˂ˇ

ˌ

˄˄

˄˃

Horizontal Line Number

˅

ˇ

˄˃

˪˂ˇ ˪˂ˇ

ˊ

˄

˄˅

˪˂ˇ

˪

ctive Area

ˋ

ˆ

˄˃

X

ΚTest Point

XЈ1 to 13

ˈ

˄ˆ

˄˃

˪˂ˇ

BLU is supplied by CMO .

Transmittance

Luminance of LCD module

=

Luminance of backlight

Ϡ 100%

Note (8): Under suggestive driving condition (see Section 3).

/19

13

Version 2.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 14

Global LCD Panel Exchange Center

6. PACKAGING

6.1. PACKING SPECIFICATION

1. 22 pcs LCD panel / 1 Dense Pack Box

2. Dense Box Dimensions: 462 (L) X 273.5 (W) X 119.5(H) mm

3. Weight: Approximately 15.5Kg (44 cells per bag)

6.2 PACKING METHOD

www.panelook.com

Issued Date: Jul. 16, 2009

Model No.: M156B1-C01

Approval

Figure. 6-1 Packing method

]

/19

14

Version 2.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 15

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: Jul. 16, 2009

Model No.: M156B1-C01

Approval

Figure. 6-2 Packing method

/19

15

Version 2.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 16

Global LCD Panel Exchange Center

7. DEFINITION OF LABEL

1. Mode Name: M156B1- C01

2. Panel Type: version control

3. Quantity: 22pcs / PP box

4. Case ID: serial number.

5. Note: Notification, if necessary.

6. Barcode: Case ID in code39 format

www.panelook.com

Issued Date: Jul. 16, 2009

Model No.: M156B1-C01

Approval

Figure. 7-1 Carton Label

/19

16

Version 2.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 17

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: Jul. 16, 2009

Model No.: M156B1-C01

Approval

8. PRECAUTIONS

8.1 ASSEMBLY AND HANDLING PRECAUTIONS

1. Do not apply rough force such as bending or twisting to the cell during assembly.

2. To assemble or install cell into customer’s module can be only in clean working areas. The dust and

oil may cause electrical short or worsen the polarizer.

3. It is not permitted to have pressure or impulse on the module because the LCD panel and Backlight

will be damaged.

4. Use a soft dry cloth without chemicals for cleaning, because the surface of polarizer is very soft and

easily scratched.

5. It is dangerous that moisture come into or contacted the LCD panel, because moisture may damage

TFT circuit.

6. High temperature or humidity may reduce the performance of cell. Please store LCD cell within the

specified storage conditions.

8.2 SAFETY PRECAUTIONS

1. If the liquid crystal material leaks from the panel, it should be kept away from the eyes or mouth. In

case of contact with hands, skin or clothes, it has to be washed away thoroughly with soap.

/19

17

Version 2.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 18

Global LCD Panel Exchange Center

9. RELIABILITY TEST

www.panelook.com

Issued Date: Jul. 16, 2009

Model No.: M156B1-C01

Approval

Environment test conditions are listed as following table.

Items Required Condition Note

Temperature Humidity Bias (THB)

High Temperature Operation (HTO)

Low Temperature Operation (LTO)

High Temperature Storage (HTS)

Low Temperature Storage (LTS)

Packing Vibration

Thermal Shock Test (TST)

Note (1) The tests are done with CMO LCD modules (M156B1-L01).

Note (2) The test is done with a package shown in Section 6.

Ta= 5 0 к , 80%RH, 240hours

Ta= 5 0 к , 50%RH , 240hours

Ta= 0 к , 240hours

Ta= 6 0 к , 240hours

Ta= - 2 0 к , 240hours

1.14Grms

Random, Frequency Range: 1 – 200 Hz

Top & Bottom: 30 minutes (+Z), 10 min (-Z)

Right & Left: 10 minutes (X)

Back & Forth 10 minutes (Y)

-20к/30min , 60к / 30min , 100 cycles

(1)

(2)

(1)

/19

18

Version 2.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 19

Loading...

Loading...