Page 1

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 2

Global LCD Panel Exchange Center

www.panelook.com

DCC No.:1402Y128

Issued Date:Nov.22,2002

Model No.: M150X4-T05

Approval

- CONTENTS -

REVISION HISTORY

1. GENERAL DESCRIPTION

1.1 OVERVIEW

1.2 FEATURES

1.3 APPLICATION

1.4 GENERAL SPECIFICATIONS

1.5 MECHANICAL SPECIFICATIONS

2. ABSOLUTE MAXIMUM RATINGS

2.1 ABSOLUTE RATINGS OF ENVIRONMENT

2.2 ELECTRICAL ABSOLUTE RATINGS

2.2.1 TFT LCD MODULE

2.2.2 BACKLIGHT UNIT

3. ELECTRICAL CHARACTERISTICS

3.1 TFT LCD MODULE

3.2 BACKLIGHT UNIT

4. BLOCK DIAGRAM

4.1 TFT LCD MODULE

4.2 BACKLIGHT UNIT

5. INPUT TERMINAL PIN ASSIGNMENT

5.1 TFT LCD MODULE

5.2 BACKLIGHT UNIT

5.3 COLOR DATA INPUT ASSIGNMENT

6. INTERFACE TIMING

6.1 INPUT SIGNAL TIMING SPECIFICATIONS

6.2 POWER ON/OFF SEQUENCE

7. OPTICAL CHARACTERISTICS

7.1 TEST CONDITIONS

7.2 OPTICAL SPECIFICATIONS

8. PRECAUTIONS

8.1 HANDLING PRECAUTIONS

8.2 STORAGE PRECAUTIONS

8.3 OPERATION PRECAUTIONS

9. PACKAGING ------------------------------------------------------- 22

9.1 PACKING SPECIFICATIONS

9.2 PACKING METHOD

10. INCOMING INSPECITION DAY ------------------------------------------------------- 24

11. DEFINITION OF SHIPPING LABEL ON MODULE ------------------------------------------------------- 25

------------------------------------------------------- 3

------------------------------------------------------- 5

------------------------------------------------------- 6

------------------------------------------------------- 8

------------------------------------------------------- 11

------------------------------------------------------- 12

------------------------------------------------------- 14

------------------------------------------------------- 17

------------------------------------------------------- 20

2 / 26

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 3.0

www.panelook.com

Page 3

Global LCD Panel Exchange Center

www.panelook.com

DCC No.:1402Y128

Issued Date:Nov.22,2002

Model No.: M150X4-T05

Approval

Version Date

Ver 0.0

Ver 0.1

Ver 0.2

Ver 1.0

Ver 1.1

Jun.26,’2002

Aug.12,’2002

Sep.12,’2002

Oct.28,’2002

Nov.20,’2002

Page

(New)

All

7

14

16

17

19

24

6

9

12

17

24

17

18

19

5

REVISION HISTORY

Section Description

Tentative Specification was first issued.

All

Rush Current I

3.1

6.1

6.2

7.2

7.2

11

2.2.2

3.2

5.2

7.2

11

7.2

1.4

Power Supply Current White I

Power Supply Current Black I

DCLK Pixel clock Frequency 65(Typ.)/80(Max.)Æ32.5(Typ.)/40(Max.).

DCLK Pixel clock periodÆ

12.5(Min.)/15(Typ.)/20(Max.)Æ25(Min.)/30(Typ.)/40(Max.).

DE Horizontal period 1100(Symbol)ÆThp(Symbol).

Interface SignalΚLVDS Signal of TransmitterÆInput Signal.

Luminance of White 230(Typ.)Æ250(Typ.).

Add Item White Variation.

Color Chromaticity Blue Bx (0.111)(Min.)/(0.141)(Typ.)/(0.171)(Max.)Æ

(0.114)(Min.)/(0.144)(Typ.)/(0.174)(Max.).

Color Chromaticity White Wx 0.290(Min.)/0.310(Typ.)/0.340(Max.)Æ

0.283(Min.)/0.313(Typ.)/0.343(Max.).

Color Chromaticity White Wy 0.300(Min.)/0.330(Typ.)/0.360(Max.)Æ

0.299(Min.)/0.329(Typ.)/0.359(Max.).

Revised Note (5).

Revised DEFINITION OF LABELS.

Modify Note I

Modify Lamp Input Voltage V

Modify Lamp Turn On Voltage V

Modify Lamp Life Time L

Modify Power Consumption P

Modify Pin 2 Æ Pin 3.

Response Time T

Response Time T

Viewing Angle Vertical T

Revised DEFINITION OF LABELS.

White Variation ӬWΚ(1.35)(Max.)Æ1.40(Max.)

Color Chromaticity Red RxΚ(0.597)(Min.)/(0.627)(Typ.)/(0.657)(Max.)

Æ0.603(Min.)/0.633(Typ.)/0.663(Max.)

Color Chromaticity Green GxΚ(0.265)(Min.)/(0.295)(Typ.)/(0.325)(Max.)

Æ0.270(Min.)/0.300(Typ.)/0.330(Max.)

Color Chromaticity Green GyΚ(0.559)(Min.)/(0.589)(Typ.)/(0.619)(Max.)

Æ0.556(Min.)/0.586(Typ.)/0.616(Max.)

Color Chromaticity Blue BxΚ(0.114)(Min.)/(0.144)(Typ.)/(0.174)(Max.)

Æ0.112(Min.)/0.142(Typ.)/0.172(Max.)

Note (2)ΚCR=CR(5)ÆCR=CR(1).

Note (4)Κ20 minutesÆ15 minutes

Modify Active Area Specification

RUSH (TBD)(Max.)Æ2.0(Max.).

CC (TBD)(Typ.)Æ450(Typ.).

CC (TBD)(Typ.)Æ700(Typ.).

L= (8.0) mA.

LΚ(522)(Min.)/(580)(Typ.)/(638)(Max.).

SΚ(1150)(25к)(Max.)/(1360)(0к)(Max.).

BLΚ(40000)(Min.).

LΚ(9.28)(Typ.).

RΚ (5)(Typ.)Æ(6)(Typ.)/(10)(Max.).

FΚ (12)(Typ.)Æ(17)(Typ.)/(25)(Max.).

+ Κ(45)(Min.)/(50)(Typ.)Æ (30)(Min.)/(45)(Typ.).

Y

3 / 26

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 3.0

www.panelook.com

Page 4

Global LCD Panel Exchange Center

www.panelook.com

DCC No.:1402Y128

Issued Date:Nov.22,2002

Model No.: M150X4-T05

Approval

Version Date

Ver 1.1

Ver 3.0

Nov.20,’2002

Nov.22,’2002

Page

(New)

5

7

10

all

REVISION HISTORY

Section Description

Modify Horizontal (H)Κ320.5(Min.)/321.5(Max.)

1.5

Modify Vertical (V)Κ244.9(Min.)/245.9(Max.)

Modify Depth (D)Κ10(Max.)

2.2.2

Lamp Voltage V

Lamp Current I

Lamp Frequency F

3.2

Lamp Input Voltage V

Lamp Current I

Lamp Turn On Voltage VsΚ(1150)(25к)(Max.)/(1360)(0к)(Max.)

Æ1180( 25к)(Max.)/1350(0к)(Max.)

Operating Frequency F

Power Consumption P

I

L=(8) mA Æ IL=8.0 mA

all

approval specification was issued.

LΚ603(Min.)/737(Max.)Æ -(Min.)/2.5K(Max.)

LΚ2.0(Min.)/(9)(Max.)Æ -(Min.)/8.5(Max.)

LΚ30(Min.)Æ -(Min.)

LΚ(580)(Typ.)/(638)(Max.)Æ 585(Typ.)/644(Max.)

LΚ(8)(Typ.)/(9)(Max.)Æ 8.0(Typ.)/8.5(Max.)

LΚ30(Min.)/(45)(Typ.)Æ 40(Min.)/50(Typ.)

LΚ(9.28)(Typ.)Æ9.36(Typ.)

4 / 26

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 3.0

www.panelook.com

Page 5

Global LCD Panel Exchange Center

1. GENERAL DESCRIPTION

1.1 OVERVIEW

M150X4-T05 is a 15.0” TFT Liquid Crystal Display module with 2 CCFL Backlight units and 60 pins TTL

interface. This module supports 1024 x 768 XGA mode and can display 262,144 colors. The optimum

viewing angle is at 6 o’clock direction. The inverter module for Backlight is not built in.

1.2 FEATURES

- XGA (1024 x 768 pixels) resolution

- DE(Data Enable) only mode

- TTL Interface with 2pixels/clock

1.3 APPLICATION

www.panelook.com

DCC No.:1402Y128

Issued Date:Nov.22,2002

Model No.: M150X4-T05

Approval

- Desktop monitors

1.4 GENERAL SPECIFICATI0NS

Item Specification Unit Note

Active Area 304.128(H) x 228.096(V) (15.0” diagonal) mm

Bezel Opening Area 307.5(H) x 231.4(V) mm

Driver Element a-Si TFT active matrix - Pixel Number 1024 x R.G.B. x 768 pixel Pixel Pitch 0.297(H) x 0.297(W) mm Pixel Arrangement RGB vertical stripe - Display Colors 262,144 color Transmissive Mode Normally white - -

1.5 MECHANICAL SPECIFICATIONS

Item Min. Typ. Max. Unit Note

Horizontal(H) 320.5 321.0 321.5 mm

Module Size

Note (1) Please refer to the attached drawings for more information of front and back outline dimensions.

Note (2) The depth is without connector.

Vertical(V) 244.9 245.4 245.9 mm

Depth(D) - 9.7 10 mm (1)(2)

Weight - - 930 g -

(1)

(1)

5 / 26

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 3.0

www.panelook.com

Page 6

Global LCD Panel Exchange Center

2. ABSOLUTE MAXIMUM RATINGS

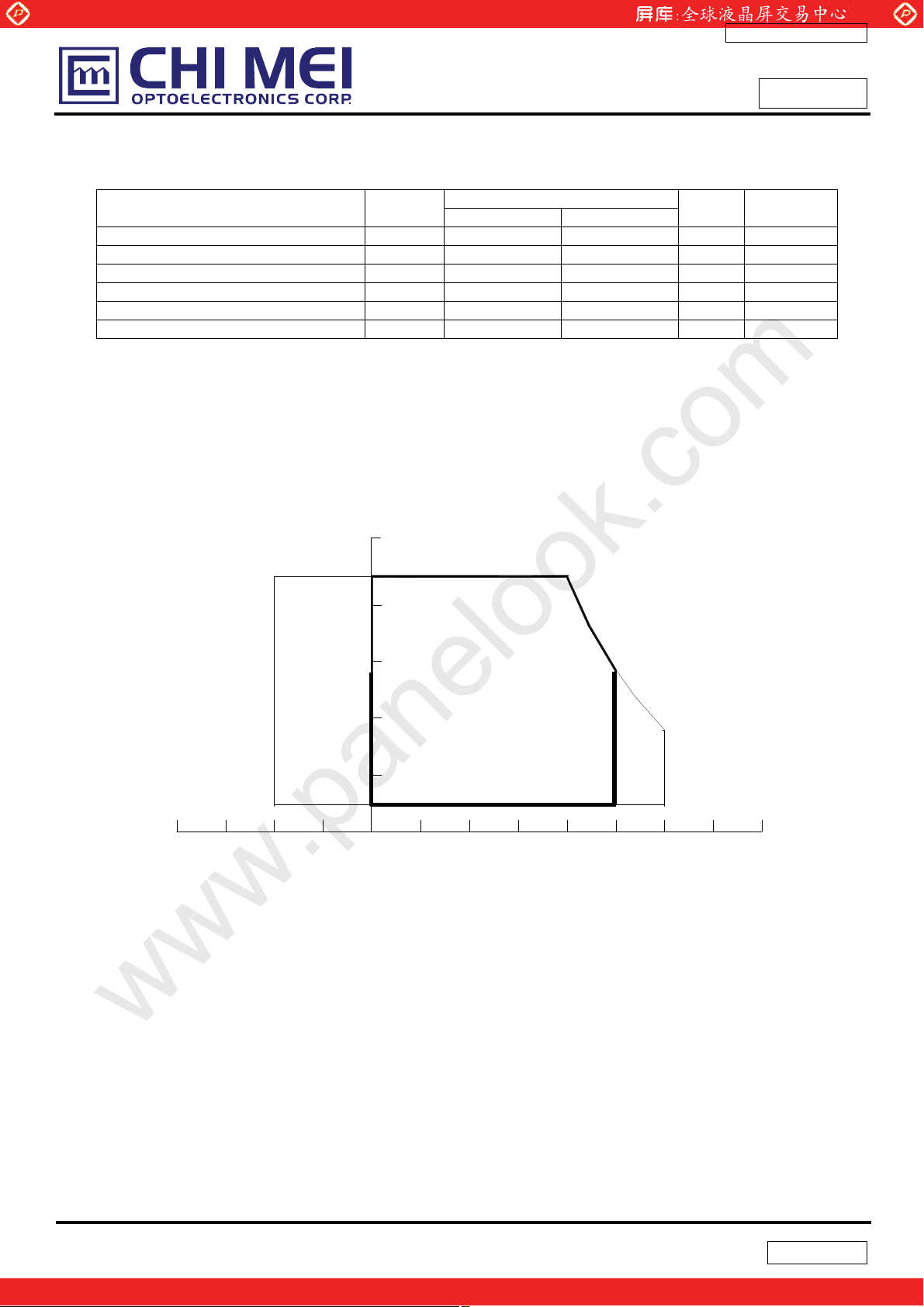

2.1 ABSOLUTE RATINGS OF ENVIRONMENT

Item Symbol

Storage Temperature TST -20 +60 ºC (1)

Operating Ambient Temperature TOP 0 +50 ºC (1), (2)

Storage Humidity HST 10 90 % Operation Humidity HOP 10 90 % Shock (Non-Operating) S

Vibration (Non-Operating) V

Note (1) Temperature and relative humidity range is shown in the figure below.

(a) 90 %RH Max. (Ta d 40 ºC).

(b) Wet-bulb temperature should be 39 ºC Max. (Ta > 40 ºC).

(c) No condensation of water.

www.panelook.com

DCC No.:1402Y128

Issued Date:Nov.22,2002

Model No.: M150X4-T05

Approval

Value

Min. Max.

- 50 G (3), (5)

NOP

- 1.5 G (4), (5)

NOP

Unit Note

Relative Humidity (%RH)

100

90

80

60

Operating Range

40

Storage Range

20

10

8060 -20 400 20-40

Temperature (ºC)

Note (2) The temperature of panel surface should be 0 ºC Min. and 60 ºC Max.

Note (3) 11ms, 1 time each rX,rY and rZ directions

Note (4) 10 ~ 500 Hz, 1 cycle/20min. 1.5mm max, 1 hour each X, Y and Z directions

Note (5) At testing Vibration and Shock, the fixture in holding the module has to be hard and rigid enough

so that the module would not be twisted or bent by the fixture.

6 / 26

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 3.0

www.panelook.com

Page 7

Global LCD Panel Exchange Center

2.2 ELECTRICAL ABSOLUTE RATINGS

2.2.1 TFT LCD MODULE

Item Symbol

Power Supply Voltage VDD -0.3 4.0 V

2.2.2 BACKLIGHT UNIT

Item Symbol

Lamp Voltage VL - 2.5k V

Lamp Current IL - 8.5 mA

Lamp Frequency FL - 80 KHz

Note (1) Permanent damage to the device may occur if maximum values are exceeded. Function operation

should be restricted to the conditions described under Normal Operating Conditions.

www.panelook.com

Value

Min. Max.

Value

Min. Max.

Unit Note

Unit Note

DCC No.:1402Y128

Issued Date:Nov.22,2002

Model No.: M150X4-T05

Approval

(1), (2), IL = 8.0 mA

RMS

RMS

(1), (2)

Note (2) Specified values are for lamp (Refer to Section 3.2 for further information).

7 / 26

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 3.0

www.panelook.com

Page 8

Global LCD Panel Exchange Center

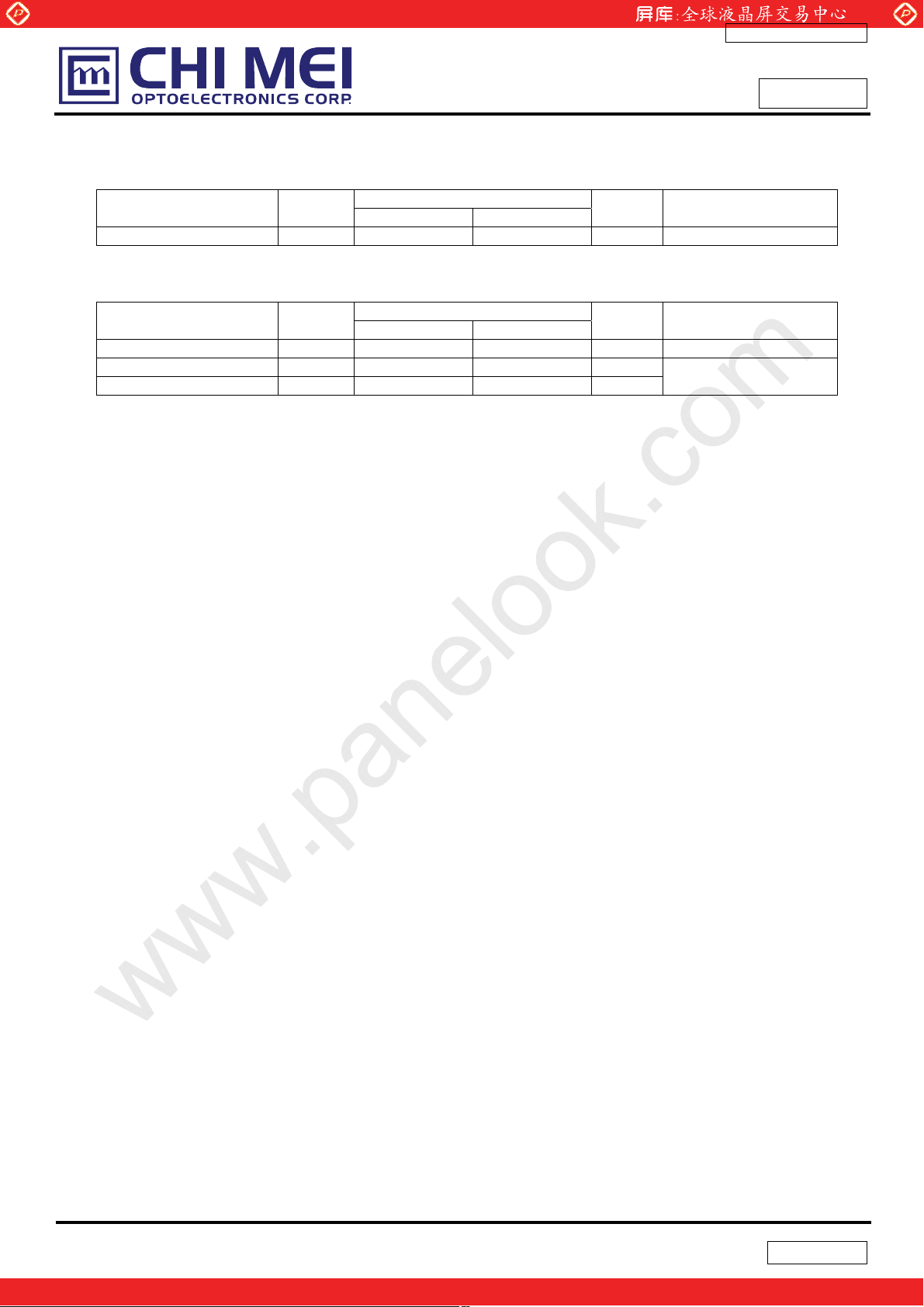

3. ELECTRICAL CHARACTERISTICS

3.1 TFT LCD MODULE

Parameter Symbol

Power Supply Voltage VDD 3.0 3.3 3.6 V Rush Current I

Power Supply Current

Input voltage

Note (1) The module should be always operated within above ranges.

Note (2) Measurement Conditions:

White - 450 - mA (3)a

Black

“H” Level VIH 2.4 - 3.6 V “L” Level V

www.panelook.com

Min. Typ. Max.

- - 2.0 A (2)

RUSH

lcc

0 - 0.9 V -

IL

- 700 - mA (3)b

Value

DCC No.:1402Y128

Issued Date:Nov.22,2002

Model No.: M150X4-T05

Approval

Unit Note

+3.3V

R1

47K

Q1 2SK1475

FUSE

C3

1uF

VDD

(LCD Module Input)

(High to Low)

(Control Signal)

SW

+12V

C1

1uF

VR1

R2

1K

47K

0.01uF

Q2

2SK1470

C2

+3.3V

0.9 V

DD

0.1 VDD

GND

470Ӵs

8 / 26

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 3.0

www.panelook.com

Page 9

Global LCD Panel Exchange Center

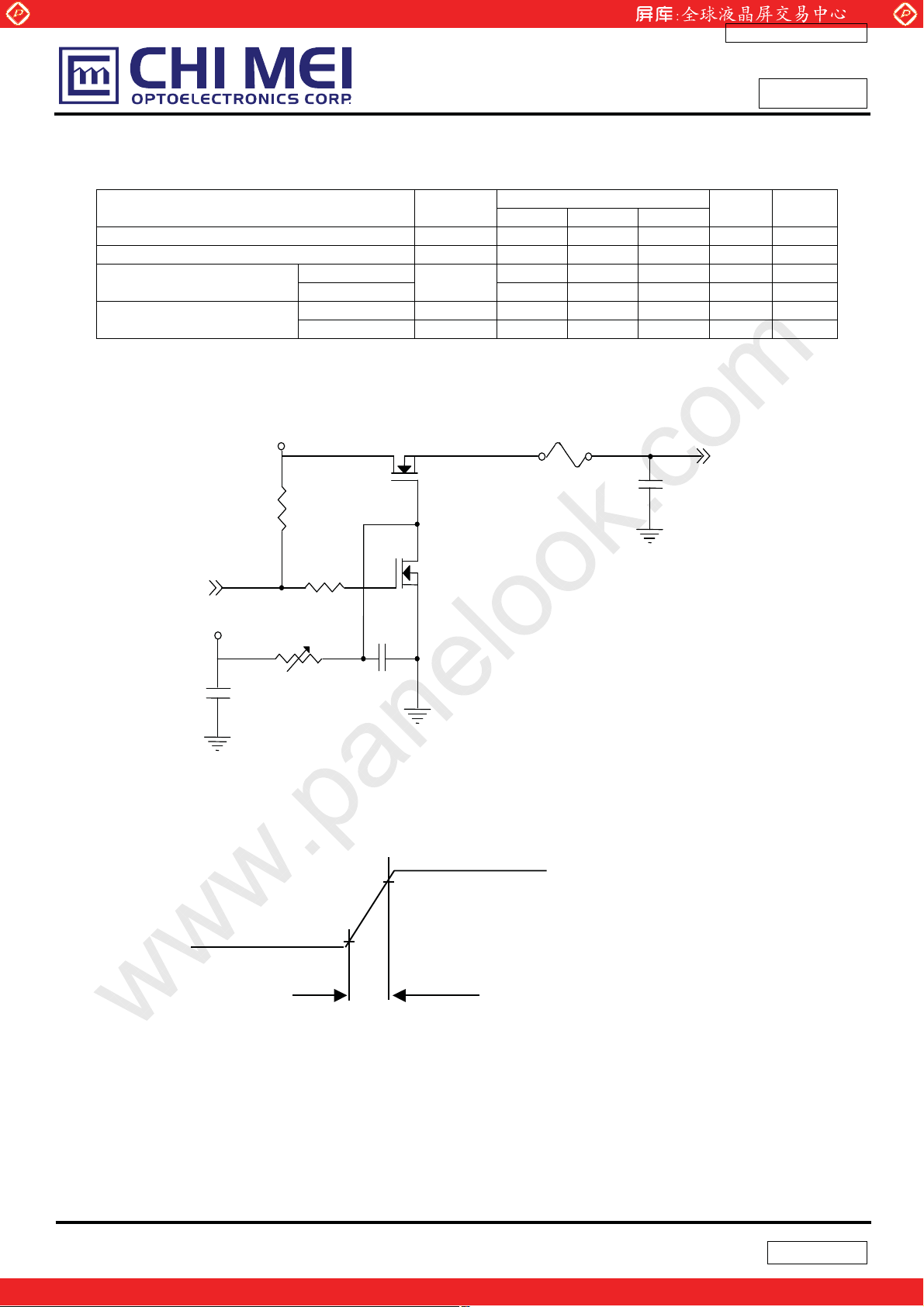

Note (3) The specified power supply current is under the conditions at VDD =3.3V, Ta = 25 r 2 ºC, DC

www.panelook.com

DCC No.:1402Y128

Issued Date:Nov.22,2002

Model No.: M150X4-T05

Approval

Current and f

a. White Pattern

= 60 Hz, whereas a power dissipation check pattern below is displayed.

v

b. Black Pattern

Active Area

Active Area

9 / 26

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 3.0

www.panelook.com

Page 10

Global LCD Panel Exchange Center

www.panelook.com

DCC No.:1402Y128

Issued Date:Nov.22,2002

Model No.: M150X4-T05

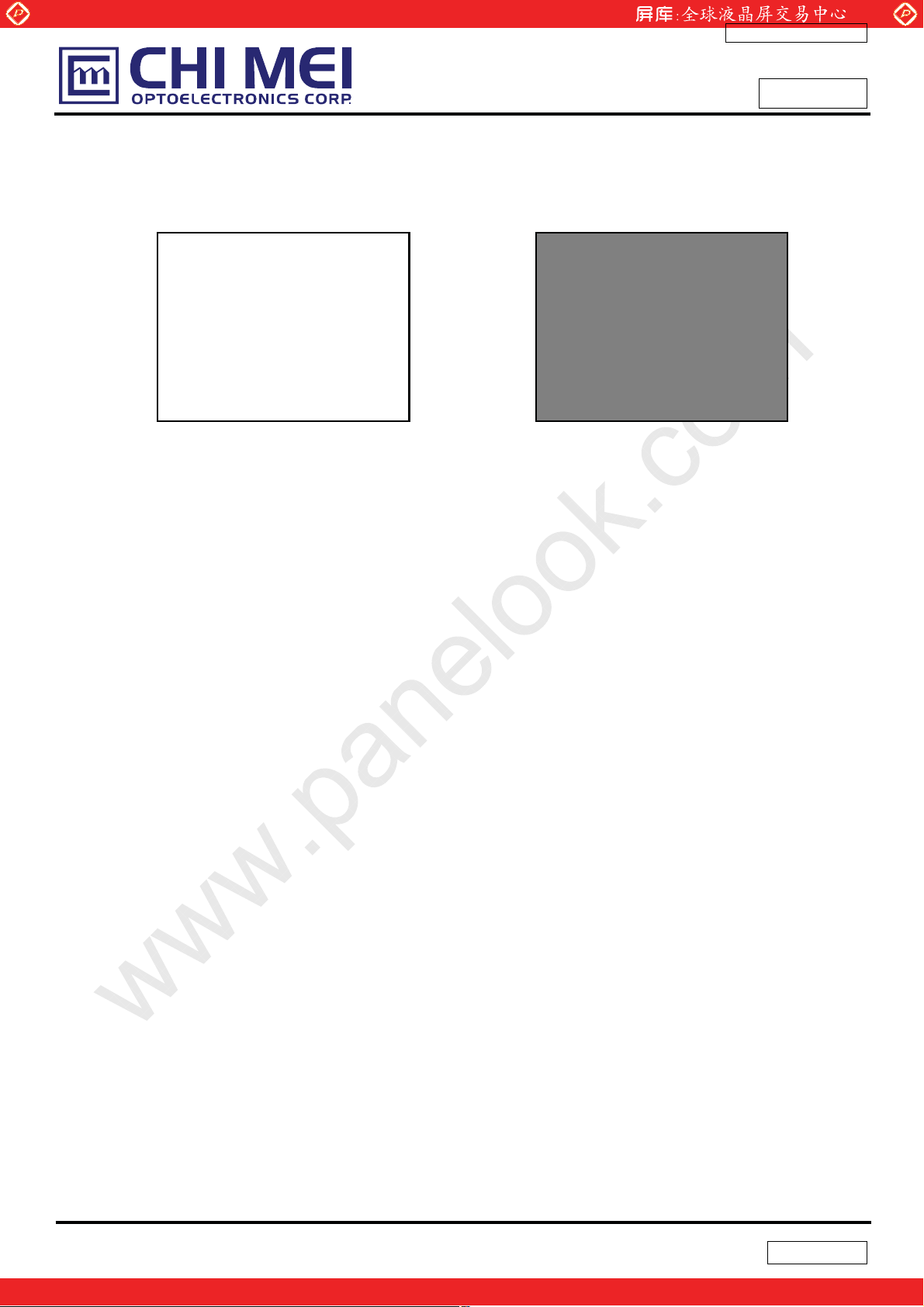

3.2 BACKLIGHT UNIT Ta = 25 r 2 ºC

Parameter Symbol

Min. Typ. Max.

Lamp Input Voltage VL 522 585 644 V

Lamp Current IL 2.0 8.0 8.5 mA

Lamp Turn On Voltage VS

- - 1180 (25

- - 1350 (0

Operating Frequency FL 40 50 80 KHz (3)

Lamp Life Time LBL 40000 - - Hrs (5)

Power Consumption PL - 9.36 - W (4), IL =8.0 mA

Note (1) Lamp current is measured by utilizing a high frequency current meter as shown below:

Value

o

C) V

o

C) V

Unit Note

I

RMS

(1)

RMS

(2)

RMS

(2)

RMS

= 8.0mA

L

Approval

LCD

Module

HV (Pink/ Blue)

LV (White/ Black)

1

3

Current Meter

Inverter

A

Note (2) The voltage shown above should be applied to the lamp for more than 1 second after startup.

Otherwise the lamp may not be turned on.

Note (3) The lamp frequency may generate interference with horizontal synchronous frequency from the

display, and this may cause line flow on the display. In order to avoid interference, the lamp

frequency should be detached from the horizontal synchronous frequency and its harmonics as far

as possible.

Note (4) P

= IL X VL

L

Note (5) The lifetime of lamp is defined as the time when it continues to operate under the conditions at Ta

= 25 r2

o

C and IL =8.0mA

until one of the following events occurs:

RMS

(a) When the brightness becomes d 50% of its original value.

(b) When the effective ignition length becomes d 80% of its original value. (Effective ignition length

is defined as an area that the brightness is less than 70% compared to the center point.)

Note (6) The waveform of the voltage output of inverter must be area-symmetric and the design of the

inverter must have specifications for the modularized lamp. The performance of the Backlight,

such as lifetime or brightness, is greatly influenced by the characteristics of the DC-AC inverter for

the lamp. All the parameters of an inverter should be carefully designed to avoid generating too

much current leakage from high voltage output of the inverter. When designing or ordering the

inverter please make sure that a poor lighting caused by the mismatch of the Backlight and the

inverter (miss-lighting, flicker, etc.) never occurs. If the above situation is confirmed, the module

should be operated in the same manners when it is installed in your instrument.

10 / 26

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 3.0

www.panelook.com

Page 11

Global LCD Panel Exchange Center

)

)

)

)

4. BLOCK DIAGRAM

4.1 TFT LCD MODULE

www.panelook.com

DCC No.:1402Y128

Issued Date:Nov.22,2002

Model No.: M150X4-T05

Approval

ENAB

DCLK

GND

VDD

RO0~RO5

GO0~GO5

BO0~BO5

RE0~RE5

GE0~GE5

BE0~BE5

(M0lex 52760-0600)

LAMP CONNECTOR

4.2 BACKLIGHT UNIT

INPUT CONNECTOR

(JST-BHR-03VS-1)

TTL INPUT /

TIMING CONTROLLER

DC/DC CONVERTER &

REFERENCE VOLTAGE

GENERATOR

SCAN DRIVER IC

TFT LCD PANEL

(1024x3x768)

DATA DRIVER IC

BACKLIGHT UNIT

1 HV (Pink

3 LV (White

1 HV (Pink

3 LV (White

11 / 26

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 3.0

www.panelook.com

Page 12

Global LCD Panel Exchange Center

5. INPUT TERMINAL PIN ASSIGNMENT

5.1 TFT LCD MODULE

Pin

No.

1 GND - Ground 31 GE1 I Green even data 1

2 RO0 I Red odd data 0 32 GE2 I Green even data 2

3 RO1 I Red odd data 1 33 GE3 I Green even data 3

4 RO2 I Red odd data 2 34 GE4 I Green even data 4

5 RO3 I Red odd data 3 35 GE5 I Green even data 5

6 RO4 I Red odd data 4 36 GND - Ground

7 RO5 I Red odd data 5 37 BE0 I Blue even data 0

8 GND - Ground 38 BE1 I Blue even data 1

9 GO0 I Green odd data 0 39 BE2 I Blue even data 2

10 GO1 I Green odd data 1 40 BE3 I Blue even data 3

11 GO2 I Green odd data 2 41 BE4 I Blue even data 4

12 GO3 I Green odd data 3 42 BE5 I Blue even data 5

13 GO4 I Green odd data 4 43 GND - Ground

14 GO5 I Green odd data 5 44 NC - Must be floating

15 GND - Ground 45 NC - Must be floating

16 BO0 I Blue odd data 0 46 ENAB I Data enable signal

17 BO1 I Blue odd data 1 47 GND - Ground

18 BO2 I Blue odd data 2 48 GND - Ground

19 BO3 I Blue odd data 3 49 DCLK I Dot clock signal

20 BO4 I Blue odd data 4 50 GND - Ground

21 BO5 I Blue odd data 5 51 GND - Ground

22 GND - Ground 52 NC - Must be floating

23 RE0 I Red even data 0 53 NC - Must be floating

24 RE1 I Red even data 1 54 GND - Ground

25 RE2 I Red even data 2 55 GND - Ground

26 RE3 I Red even data 3 56 GND - Ground

27 RE4 I Red even data 4 57 VDD - +3.3V Power supply

28 RE5 I Red even data 5 58 VDD - +3.3V Power supply

29 GND - Ground 59 VDD - +3.3V Power supply

30 GE0 I Green even data 0 60 VDD - +3.3V Power supply

Connector Part No.: 52760-0600(Molex)

Symbol I/O Function Pin

www.panelook.com

DCC No.:1402Y128

Issued Date:Nov.22,2002

Model No.: M150X4-T05

Approval

Symbol I/O Function

No.

User’s connector Part No: 53475-0609(Molex)

12 / 26

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 3.0

www.panelook.com

Page 13

Global LCD Panel Exchange Center

www.panelook.com

DCC No.:1402Y128

Issued Date:Nov.22,2002

Model No.: M150X4-T05

Correspondence between Data and Display Position

S0001 S0002 S0003 S0004 S0005 S0006 S0007 S0008 S3071 S3072

C001 RE

0001

C768 RE

0001

GE

0001

GE

0001

BE

0001

BE

0001

RO

0002

RO

0002

GO

0002

GO

0002

BO

0002

BO

0002

RE

0003

RE

0003

GE

0003

GE

0003

GO

1024

GO

1024

BO

1024

BO

1024

Approval

5.2 BACKLIGHT UNIT

Pin Symbol Description Color

1 HV1 High Voltage Pink/ Blue

3 LV Ground White/ Black

Note (1) Connector Part No.: BHR-03VS-1 (JST) or equivalent

Note (2) Matching Connector Part No.: SM02B-BHS-1-TB (JST) or equivalent

13 / 26

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 3.0

www.panelook.com

Page 14

Global LCD Panel Exchange Center

5.3 COLOR DATA INPUT ASSIGNMENT

The brightness of each primary color (red, green and blue) is based on the 6-bit gray scale data input for

the color. The higher the binary input the brighter the color. The table below provides the assignment of

color versus data input.

Basic

Colors

Gray

Scale

Of

Red

Gray

Scale

Of

Green

Gray

Scale

Of

Blue

Color

R5 R4 R3 R2 R1 R0 G5 G4 G3 G2 G1 G0 B5 B4 B3 B2 B1 B0

Black

Red

Green

Blue

Cyan

Magenta

Ye ll ow

White

Red(0) / Dark

Red(1)

Red(2)

:

:

Red(61)

Red(62)

Red(63)

Green(0) / Dark

Green(1)

Green(2)

:

:

Green(61)

Green(62)

Green(63)

Blue(0) / Dark

Blue(1)

Blue(2)

:

:

Blue(61)

Blue(62)

Blue(63)

Note (1) 0: Low Level Voltage, 1: High Level Voltage

0

1

0

0

0

1

1

1

0

0

0

:

:

1

1

1

0

0

0

:

:

0

0

0

0

0

0

:

:

0

0

0

www.panelook.com

DCC No.:1402Y128

Issued Date:Nov.22,2002

Model No.: M150X4-T05

Approval

Data Signal

Red Green Blue

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

0

0

0

0

0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

0

0

0

0

0

0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

0

0

0

0

0

0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

0

0

0

0

0

0

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

1

1

1

0

1

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

0

0

0

0

0

1

1

1

1

0

1

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

0

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

0

1

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

14 / 26

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 3.0

www.panelook.com

Page 15

Global LCD Panel Exchange Center

6. INTERFACE TIMING

6.1 INPUT SIGNAL TIMING SPECIFICATIONS

The input signal timing specifications are shown as the following table and timing diagram.

Signal Parameter Symbol Min Typ Max Unit Remarks

Pixel clock Frequency fck - 32.5 40 MHz

Pixel clock period Tck 25 30 40 ns

DCLK

DATA

DE

Duty ratio (%Tch) - 45 50 55 % Tch/Tck

High time Tckh 5 - - ns

Low time Tfckl 5 - - ns

Setup time Tsd 4 - - ns

Hold time Thd 4 - - ns

Rise time Trd 4 - - ns

Fall time Tfd 4 - - ns

Setup time Tsde 4 - - ns

Hold time Thde 4 - - ns

Vertical Frequency Fv - 60 75 Hz

Vertical period Tvp 769 806 - Thp

Vertical display blank period Tvdb 1 38 - Thp

Vertical display active period Tvda 768 768 768 Thp

Horizontal period Thp 550 672 900 Tck

Horizontal display blank period Thdb 38 160 388 Tck

Horizontal display active

period

www.panelook.com

DCC No.:1402Y128

Issued Date:Nov.22,2002

Model No.: M150X4-T05

Approval

Thda 512 512 512 Tck

Note (1) Because this module is operated by DE only mode, Hsync and Vsync input signals should be set

to low logic level or ground. Otherwise, this module would operate abnormally.

15 / 26

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 3.0

www.panelook.com

Page 16

Global LCD Panel Exchange Center

www.panelook.com

DCC No.:1402Y128

Issued Date:Nov.22,2002

Model No.: M150X4-T05

Approval

INPUT SIGNAL TIMING DIAGRAM

Tvp

Tvdb

Tvda

DE

768

1

2

768

Thp

DE

Thdb

Thda

DCLK

DATA

Valid display data (512Tck)

Invalid Valid

Tck h

Tck l

Tch

DCLK

DATA

Tck

0.7VDD

0.3VDD

Thd Tsd

0.7VDD

0.3VDD

DE

Tsde

Thde

0.7VDD

16 / 26

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 3.0

www.panelook.com

Page 17

Global LCD Panel Exchange Center

6.2 POWER ON/OFF SEQUENCE

Power On

90%

www.panelook.com

Power Off

90%

DCC No.:1402Y128

Issued Date:Nov.22,2002

Model No.: M150X4-T05

Approval

Restart

t4

Power Supply

for LCD, VDD

- Interface Signal

(Input Signal), V

0V

0V

I

10%

t1

Valid Data

t6 t5

10%

t3 t2

10%

- Power for Lamp

ONOFF OFF

Timing Specifications:

0 < t1 d ( 10 ) msec

0 < t2 d ( 50 ) msec

0 < t3 d ( 50 )msec

t4 t ( 1 ) sec

t5 t ( 100 ) mesc

t6 t ( 100 )msec

Note (1) Please avoid floating state of interface signal at invalid period.

Note (2) When the interface signal is invalid, be sure to pull down the power supply of LCD V

to 0 V.

DD

Note (3) The Backlight inverter power must be turned on after the power supply for the logic and the

interface signal is valid. The Backlight inverter power must be turned off before the power supply

for the logic and the interface signal is invalid.

17 / 26

Version 3.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 18

Global LCD Panel Exchange Center

7. OPTICAL CHARACTERISTICS

7.1 TEST CONDITIONS

Item Symbol Value Unit

Ambient Temperature Ta

Ambient Humidity Ha

Supply Voltage VDD 3.3 V

Input Signal According to typical value in "3. ELECTRICAL CHARACTERISTICS"

Inverter Current IL 8.0 mA

The measurement methods of optical characteristics are shown in Section 7.2. The following items

should be measured under the test conditions described in Section 7.1 and stable environment shown in

Note (4).

7.2 OPTICAL SPECIFICATIONS

Item Symbol Condition Min. Typ. Max. Unit Note

Contrast Ratio CR 200

Response Time

Luminance of White

(Center point)

White Variation

Red

Color

Chromaticity

Viewing Angle

Green

Blue

White

Horizontal

Ver t ical

www.panelook.com

DCC No.:1402Y128

Issued Date:Nov.22,2002

Model No.: M150X4-T05

Approval

o

25r2

50r10

350

TR -

-

T

F

6

17

- - (2), (4)

10 ms

25 ms

L 200 250 - cd/m

GW

Rx 0.603 0.633 0.663 Ry 0.327 0.357 0.387 -

T

=0q, TY =0q

x

Viewing Normal Angle

- 1.25 1.40 - (4),(5)

Gx 0.270 0.300 0.330 Gy 0.556 0.586 0.616 -

Bx 0.112 0.142 0.172 -

By 0.064 0.094 0.124 Wx 0.283 0.313 0.343 Wy

Tx+

T

x

TY+

T

Y

CRt10

-

0.299 0.329 0.359 50 60 50 60 30 40 50 60 -

C

%RH

Deg.

2

(3)

(4),(5)

(1), (4)

18 / 26

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 3.0

www.panelook.com

Page 19

Global LCD Panel Exchange Center

T

Note (1) Definition of Viewing Angle (Tx, Ty):

www.panelook.com

DCC No.:1402Y128

Issued Date:Nov.22,2002

Model No.: M150X4-T05

Approval

TX- = 90º

x-

6 o’clock

T

y- = 90º

y-

Note (2) Definition of Contrast Ratio (CR):

The contrast ratio can be calculated by the following expression.

Contrast Ratio (CR) = L63 / L0

Normal

Tx = Ty = 0º

Ty- Ty

Tx-

Tx

12 o’clock direction

y+

T

y+ = 90º

x+

TX+ = 90º

L63: Luminance of gray level 63

L 0: Luminance of gray level 0

CR = CR (1)

CR (X) is corresponding to the Contrast Ratio of the point X at Figure in Note (5).

Note (3) Definition of Response Time (T

100%

90%

Optical

Response

Gray Level 63

10%

0%

, TF):

R

Gray Level 63

Gray Level 0

ime

T

R

T

F

19 / 26

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 3.0

www.panelook.com

Page 20

Global LCD Panel Exchange Center

Note (4) Measurement Setup:

The LCD module should be stabilized at given temperature for 15 minutes to avoid abrupt

temperature change during measuring. In order to stabilize the luminance, the measurement

should be executed after lighting Backlight for 15 minutes in a windless room

LCD Module

www.panelook.com

DCC No.:1402Y128

Issued Date:Nov.22,2002

Model No.: M150X4-T05

Approval

LCD Panel

Center of the Screen

Field of View = 2º

500 mm

Note (5) Definition of luminance measured points:

Measure the luminance of gray level 63 at point L(1)

Definition of White Variation (GW):

Measure the luminance of gray level 63 at 9 points

Maximum [L (1), L (6), L (7), L (8), L (9), L (10), L (11), L (12), L (13)]

GW =

Minimum [L (1), L (6), L (7), L (8), L (9), L (10), L (11), L (12), L (13)]

Photometer

(TOPCON BM-5A)

Light Shield Room

(Ambient Luminance < 2 lux)

D/10

Horizontal Line

D

D/4 D/2 3D/4

9D/10

W/10

W/4

6

23

7

8

: Test Point

W

W/2

9

1

10

Vertical Line

3W/4

9W/10

4

11 12 13

5

X

X=1 to 13

Active Area

20 / 26

Version 3.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 21

Global LCD Panel Exchange Center

8. PRECAUTIONS

8.1 HANDLING PRECAUTIONS

(1) The module should be assembled into the system firmly by using every mounting hole. Be careful not

to twist or bend the module.

(2) While assembling or installing modules, it can only be in the clean area. The dust and oil may cause

electrical short or damage the polarizer.

(3) Use fingerstalls or soft gloves in order to keep display clean during the incoming inspection and

assembly process.

(4) Do not press or scratch the surface harder than a HB pencil lead on the panel because the polarizer is

very soft and easily scratched.

(5) If the surface of the polarizer is dirty, please clean it by some absorbent cotton or soft cloth. Do not use

Ketone type materials (ex. Acetone), Ethyl alcohol, Toluene, Ethyl acid or Methyl chloride. It might

www.panelook.com

DCC No.:1402Y128

Issued Date:Nov.22,2002

Model No.: M150X4-T05

Approval

permanently damage the polarizer due to chemical reaction.

(6) Wipe off water droplets or oil immediately. Staining and discoloration may occur if they left on panel for

a long time.

(7) If the liquid crystal material leaks from the panel, it should be kept away from the eyes or mouth. In

case of contacting with hands, legs or clothes, it must be washed away thoroughly with soap.

(8) Protect the module from static electricity, it may cause damage to the C-MOS Gate Array IC.

(9) Do not disassemble the module.

(10) Do not pull or fold the lamp wire.

(11) Pins of I/F connector should not be touched directly with bare hands.

8.2 STORAGE PRECAUTIONS

(1) High temperature or humidity may reduce the performance of module. Please store LCD module within

the specified storage conditions.

(2) It is dangerous that moisture come into or contacted the LCD module, because the moisture may

damage LCD module when it is operating.

(3) It may reduce the display quality if the ambient temperature is lower than 10 ºC. For example, the

response time will become slowly, and the starting voltage of lamp will be higher than the room

temperature.

8.3 OPERATION PRECAUTIONS

(1) Do not pull the I/F connector in or out while the module is operating.

(2) Always follow the correct power on/off sequence when LCD module is connecting and operating. This

can prevent the CMOS LSI chips from damage during latch-up.

(3) The startup voltage of Backlight is approximately 1000 Volts. It may cause electrical shock while

assembling with inverter. Do not disassemble the module or insert anything into the Backlight unit.

21 / 26

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 3.0

www.panelook.com

Page 22

Global LCD Panel Exchange Center

9. PACKAGING

9.1 PACKING SPECIFICATIONS

(1) 10 LCD modules / 1 Box

(2) Box dimensions : 511(L) X 420(W) X 360(H) mm

www.panelook.com

DCC No.:1402Y128

Issued Date:Nov.22,2002

Model No.: M150X4-T05

Approval

(3) Weight : approximately 11Kg ( 10 modules per box)

9.2 PACKING Method

Figures 9-1and 9-2 are the packing method.

Figure. 9-1 Packing method

22 / 26

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 3.0

www.panelook.com

Page 23

Global LCD Panel Exchange Center

www.panelook.com

DCC No.:1402Y128

Issued Date:Nov.22,2002

Model No.: M150X4-T05

Approval

Figure. 9-2 Packing method

23 / 26

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 3.0

www.panelook.com

Page 24

Global LCD Panel Exchange Center

www.panelook.com

DCC No.:1402Y128

Issued Date:Nov.22,2002

Model No.: M150X4-T05

Approval

10. INCOMING INSPECTION DAY

The Supplier should be acquainted the inspection results (acceptance or rejection) by Customer, and the results

are in accordance with the incoming inspection standard within 30 days after the date of the bills of lading.

Should Customer fail to so notify the Supplier within the said 30 days period. The Customer’s right to reject the

LCMS shall then lapse, and the said LCMS shall be deemed to have been accepted by the customer.

24 / 26

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 3.0

www.panelook.com

Page 25

Global LCD Panel Exchange Center

11. DEFINITION OF LABELS

11.1 CMO MODULE LABEL

The barcode nameplate is pasted on each module as illustration, and its definitions are as following

explanation.

www.panelook.com

DCC No.:1402Y128

Issued Date:Nov.22,2002

Model No.: M150X4-T05

Approval

CMO TAIWAN M150X4 -T05

CHI MEI

OPTOELECTRONICS

TN M XXXXX XXXNNNNN YYMMDD

M150X4 -T05 Rev. XX

X X X X X X X Y M D X N N N N

E207943

MADE IN TAIWAN

(a) Model Name: M150X4 –T05

(b) Revision: Rev. XX, for example: C1, C2 …etc.

(c) BenQ’s definition

Serial ID: TN

M XXXXX X X X NNNNN YYMMDD

Year , Month , Date

Serial No.

Module Line Code

Revision Code

FAB Code

CMO Internal Use

Supplier Code

Location Code

(d) CMO’s definition

Serial ID: X X

X X X X X Y M D X N N N N

Serial No.

CMO Internal Use

Year, Month, Date

CMO Internal Use

Product Line

Revision

CMO Internal Use

25 / 26

Version 3.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 26

Global LCD Panel Exchange Center

Serial ID includes the information as below:

(a) Manufactured Date: Year: 01~99, for 2001~2099

Month: 01~12 , for Jan. ~ Dec.

Day: 01~31, for 1

(b) Serial No.: Manufacturing sequence of product

(c) CMO Internal Use: 1 -> Line1, 2 -> Line 2, …etc.

(d) Revision Code: cover all the change

www.panelook.com

(e) Supplier Code : CMO

(f)

Location Code : Tainan

st

to 31st, exclude I and O

DCC No.:1402Y128

Issued Date:Nov.22,2002

Model No.: M150X4-T05

Approval

26 / 26

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 3.0

www.panelook.com

Page 27

www.panelook.com

www.panelook.com

Global LCD Panel Exchange Center

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Page 28

www.panelook.com

E207943

www.panelook.com

Global LCD Panel Exchange Center

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Loading...

Loading...