Page 1

Global LCD Panel Exchange Center

www.panelook.com

Doc. No.:14003226

Issue Date: Oct.03,2000

Model: M141X101

APPROVAL

1/28

Version 3.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 2

Global LCD Panel Exchange Center

CONTENTS

REVISION HISTORY

GENERAL DESCRIPTION

1. ABSOLUTE MAXIMUM RATINGS

2. ELECTRICAL SPECIFICATIONS

www.panelook.com

Doc. No.:14003226

Issue Date: Oct.03,2000

Model: M141X101

APPROVAL

3. INTERFACE SPECIFICATIONS

3.1 THE PIN ASSIGNMENT OF TTL INTERFACE CONNECTOR

3.2 INPUT SIGNAL TIMING SPECIFICATIONS

3.3 COLOR DATA INPUT ASSIGNMENT

3.4 POWER UP/DOWN SEQUENCE

4. OPTICAL SPECIFICATIONS

5. Reliability Test Item

6. MECHNICAL DRAWINGS

7. PRECAUTION

7.1 ASSEMBLY AND HANDLING PRECAUTION

7.2 SAFTY PRECAUTION

8. PACKAGING

8.1 PACKING SPECIFICATIONS

8.2 PACKING METHOD

9. INCOMING INSPECTION DAY

10. DEFINITION OF SHIPPING LABEL ON MODULE

2/28

Version 3.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 3

Global LCD Panel Exchange Center

A

VERSION Date DESCPIPTION

Ver 1.0

Sep.10’99

www.panelook.com

Doc. No.:14003226

Issue Date: Oct.03,2000

Model: M141X101

APPROVAL

REVISION HISTORY

Issue Preliminary Specification.

Ver 2.0

Nov.11’99

Page 6/28

- To revise the MECHANICAL SPECIFICATIONS

Page 7/28

- To Change the ABSOLUTE MAXIMUM RATINGS of Humidity

- To add Notes statement in ELECTRICAL SPECIFICATIONS

Page 11/28

- 3.2 INPUT SIGNAL TIMING SPECIFICATIONS is modified and

Page 12/28

- To revise the Tvdb interval in INPUT SIGNAL TIMING

Page 14/28

- The illustration of POWER UP/DOWN SEQUENCE is modify.

Page 15/28 ~ 23/28

- To revise the OPTICAL SPECIFICATIONS and modify the

Page 24/28

- Add the PRECAUTION statement.

Page 25/28~26/28

- Add the illustration of PACKAGING method

added the values which is TBD in version 1.0.

DIAGRAM.

Illustration of Notes.

Ver 2.1

Jan.31’00

Issue Approval Specification.

Page 6/28

- Add BLOCK DIAGRAM

dd “ Gap, panel surface with metal frame” spec. in

-

MECHANICAL SPECIFICATIONS.

Page 7/28

- Change the humidity condition in ABSOLUTE MAXIMUM

RATINGS.

Old ->Operation : 20% ~ 90% relative humidity

Non operation : 5% ~ 85% relative humidity

New ->Operation : 20% ~ 95% relative humidity, Ta≤40ºC

Storage: 5% ~ 95% relative humidity ,Ta≤40ºC

- Add Min./Max. value for “ Power Supply Current” in

ELECTRICAL SPECIFICATIONS ( MODULE).

- Add Min./Max. value for “ Power Consumption” in

ELECTRICAL SPECIFICATIONS ( BACKLIGHT).

3/28

Version 3.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 4

Global LCD Panel Exchange Center

VERSION Date DESCPIPTION

Ver 2.1

Jan.31’00

www.panelook.com

Doc. No.:14003226

Issue Date: Oct.03,2000

Model: M141X101

APPROVAL

REVISION HISTORY ( Continuation)

Page 12/28

- The following notes are attachment on INPUT SIGNAL TIMING

SPECIFICATIONS

1.Data is latched at falling edge of DCLK in the spec.

DCLK should appear during all blanking period.

2.VSYNC and HSYNC are negative polarity in the spec.

3.DE (Data Enable) should be positive polarity in the spec.

4.HSYNC should appear during blanking period of frame cycle.

Page 15/28

- Add Variation of Color and Cross Talk specifications

in OPTICAL SPECIFIACTIONS

Ver 2.2

Mar.1’00

Page 19/28

- Add Note 9 : Definition of Variation of Color

- Add Note 10: Definition of Cross Talk(CT)

Page 23/28

- Add 5.Reliability Test Item

Page 27/28

- Add 9. INCOMING INSPECTION DAY

Page 7/28

- Update the Lamp Voltage in 2. ELECTRICAL SPECIFICATIONS

Old : 640 (Typ.) ==> New : 560(Min.)/630(Typ.)/700(Max.)

- Update the Startup Volage in 2. ELECTRICAL

SPECIFICATIONS

Old : 985(25ºC)/1450(0ºC) ==> New : 1255(25ºC)/1385(0ºC)

Page 8/28

- To add the test pattern for Power Supply Current.

Page 15/28

- Update Brightness Uniformity spec.

Old : 1.0(Min.)/1.4(Typ.)/1.6(Max.)

New: 1.0(Min.)/1.2(Typ.)/1.35(Max.)

Page 19/28

- Update the illustration for Cross Talk Definition in Note (10).

- Add the note 11:definition of image sticking.

Page 20/28

- Add the note 12 for gamma values.

Page 23/28

- Add the Criterion after Reliability Test Item.

Ver 3.0

Mar.29’00

Page 15/28

- Update “Brightness Uniformity” to “Brightness Uniformity (VESA)”

- Add “TCO’99 Luminance Uniformity” spec.

- Add “TCO’99 Luminance Contrast” spec.

4/28

Version 3.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 5

Global LCD Panel Exchange Center

VERSION Date DESCPIPTION

Ver 3.0

Ver 3.1

Mar.29’00

Oct.03’00

www.panelook.com

Doc. No.:14003226

Issue Date: Oct.03,2000

Model: M141X101

APPROVAL

REVISION HISTORY ( Continuation)

Page 20/28

- Add Gamma Value in the table of Note 12.

Page 21/28

- Add Note 13 :Definition of TCO 99 Luminance Uniformity.

Page 22/28

- Add Note 14:Definition of TCO 99 Luminance Contrast.

Page 11/28

- To revise ”DATA” in 3.2 INPUT SIGNAL TIMING

SPECIFICATIONS.

Old setup time: -(Min.)/7.0(Typ.); New setup time: 5.0(Min.)/-(Typ.)

Old hold time: -(Min.)/7.0(Typ.); New hold time: 6.0(Min.)/-(Typ.)

Page 11/28

- Update ”DATA” in 3.2 INPUT SIGNAL TIMING

SPECIFICATIONS.

Old setup time: -(Min.)/7.0(Typ.); New setup time: 5.0(Min.)/-(Typ.)

Old hold time: -(Min.)/7.0(Typ.); New hold time: 6.0(Min.)/-(Typ.)

Page 15/28

- To correct Chromaticity on 4. OPTICAL SPECIFICATIONS.

: Old: 0.537(Min.)/ 0.557(Typ.)/ 0.577(Max.)

X

R

New: 0.560(Min.)/ 0.580(Typ.)/ 0.600(Max.)

Y

: Old: 0.309(Min.)/ 0.329(Typ.)/ 0.349(Max.)

R

New: 0.308(Min.)/ 0.328(Typ.)/ 0.348(Max.)

X

: Old: 0.276(Min.)/ 0.296(Typ.)/ 0.316(Max.)

G

New: 0.280(Min.)/ 0.300(Typ.)/ 0.320(Max.)

Y

: Old: 0.562(Min.)/ 0.582(Typ.)/ 0.602(Max.)

G

New: 0.542(Min.)/ 0.562(Typ.)/ 0.582(Max.)

Y

: Old: 0.112(Min.)/ 0.132(Typ.)/ 0.152(Max.)

B

New: 0.097(Min.)/ 0.117(Typ.)/ 0.137(Max.)

Page 28/28

- Add 10. Definition of Shipping Label on Module.

Change Attached Drawing form “M14114101F” to “M14114113A”.

5/28

Version 3.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 6

Global LCD Panel Exchange Center

p

(

)

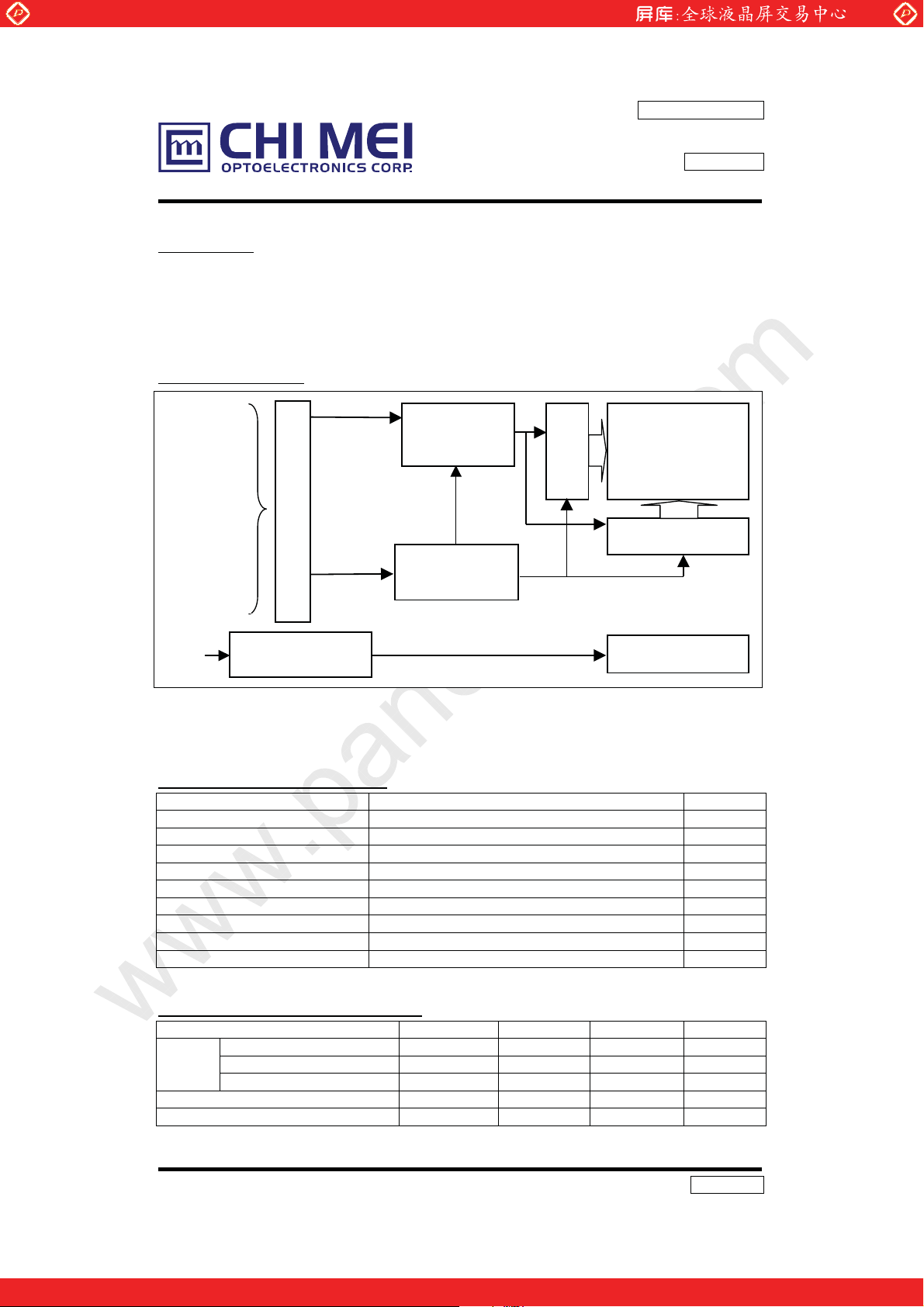

GENERAL DESCRIPTION

OVERVIEW

This product is a 14.1” TFT Liquid Crystal Display Module with a 2 lamps Backlight unit and 60

pins TTL interface. This module supports 1024 x 768 XGA mode and can display 262,144

colors. The inverter module for Backlight is not built in.

BLOCK DIAGRAM

In

HSYNC

VSYNC

ENAB

DCLK

RE0~5

GE0~5

BE0~5

RO0~5

GO0~5

Vcc

BO0~5

V

CC

GND

ut Connector

Molex- 52760-0600

www.panelook.com

Timing Control

ASIC

DC/DC Converter

& Reference

Voltage Generator

Doc. No.:14003226

Issue Date: Oct.03,2000

Model: M141X101

APPROVAL

Scan Driver IC

TFT-LCD Panel

(1024x768x3)

Data Driver IC

VL

Lamp Connector

( JST-BHR-03VS-1)

Backlight Unit

APPLICATION

-TFT-LCD Monitor

GENERAL SPECIFICATI0NS

Item Specifications Unit

Screen Size 14.1 Diagonal inch

Bezel opening area 289.8(W)x218.4(H) mm

Effective display area 285.7(W)x214.3(H) mm

Pixel number 1024 x R.G.Bx768 pixel

Pixel pitch 0.279(H)x0.279(V) mm

Pixel Arrangement R.G.B Vertical Stripe Display Color 6 bits, 262,144 color

Transmissive mode Normally white Surface treatments Hard coating(3H) and anti-glare -

MECHANICAL SPECIFICATIONS

ITEM MIN. TYP. MAX. Unit

Module

size

Gap, panel surface with metal frame - - 0.5 mm

Horizontal 329.5 330 330.5 mm

Vertical 254.5 255 255.5 mm

Depth - 17.0 17.5 mm

Weight - 1250 1300 g

6/28

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 3.1

www.panelook.com

Page 7

Global LCD Panel Exchange Center

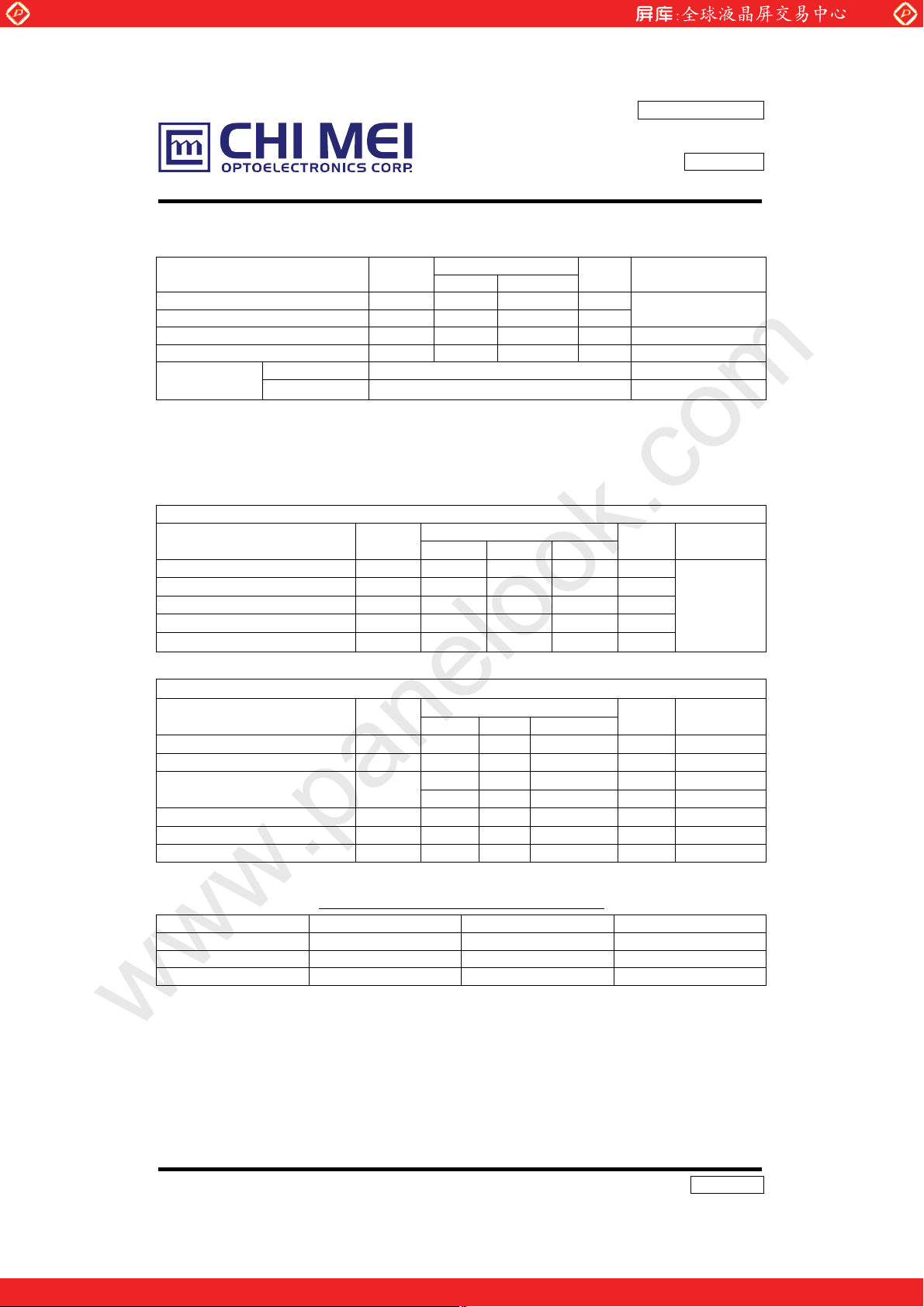

1. ABSOLUTE MAXIMUM RATINGS

www.panelook.com

Doc. No.:14003226

Issue Date: Oct.03,2000

Model: M141X101

APPROVAL

Parameter Symbol

Min. Max.

Values

Unit Remarks

Power supply voltage VCC -0.3 +6.0 V

Logic input voltage VIN -0.3 VCC+0.3 V

Ta=25ºC

Operating temperature Top 0 +50 ºC Module surface*

Storage temperature Tst -20 +60 ºC -

Operation 20%~95% relative humidity Ta<=40ºC

Humidity

Non operation 5%~95% relative humidity Ta<=40ºC

*Measure at the active display area

2. ELECTRICAL SPECIFICATIONS

MODULE

Parameter Symbol

Min. Typ. Max.

Power Supply Voltage VCC 4.5 5.0 5.5 V

Power Supply Current l

140 290 600 mA

CC

Ripple voltage VRP - 50 - mV

“H” level logical input voltage VIH 2 - Vcc V

“L” level logical input voltage VIL Vss - 1 V

Parameter Symbol

Min. Typ. Max.

Lamp Voltage VL 560 630 700 V

Lamp Current IL 1.0 6.0 8.0 mA (2)

Startup Voltage V

S

- - 1255 (25oC) V

- - 1385 (0 oC) V

Operating Frequency FL 30 50 70 KHz (4)

Power Consumption PL 6.8 7.6 8.4 W (5), IL=6.0mA

Lamp Life time LBL 50000 - - Hrs (6)

Value

Unit Notes

(1)

BACKLIGHT ( 2 Lamps) Ta=252oC

Value

Unit Notes

IL=6.0mA

RMS

(3)

RMS

(3)

RMS

The connector information of Black light unit.

Pin Symbol Description Remark

1 HV Lamp power input White

2 NC No connect

3 LV Ground Black

Connector Part No.: BHR-03VS-1 (JST)

User’s connector Part No.: SM02 (8.0) B-BHS-1-TB (JST)

7/28

Version 3.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 8

Global LCD Panel Exchange Center

R

G

R

GBR

G

R

G

R

GBR

G

R

G

R

GBR

G

R

G

R

GBR

G

R

G

R

GBR

G

R

G

R

GBR

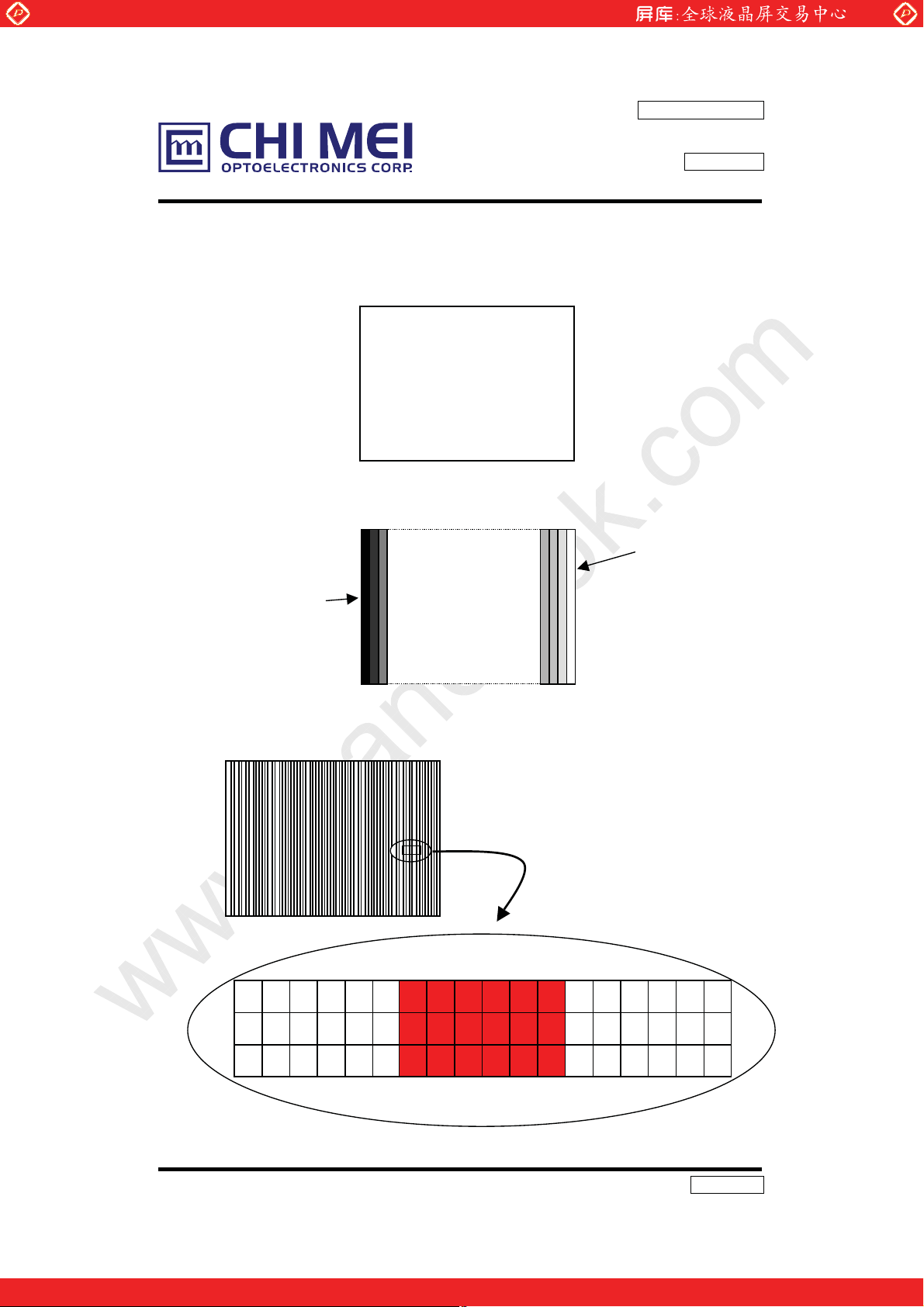

G

Note (1) Operating Temperature range : 0 ~ 50 ºC.

Power Supply Current specifications are tested by the following test pattern.

(a) Minimal value test pattern : White pattern

www.panelook.com

Doc. No.:14003226

Issue Date: Oct.03,2000

Model: M141X101

APPROVAL

Gray 63

(b)Typical value test pattern : 64 gray scale pattern

Gray 0

(C) Maximal value test pattern : Vertical 2 pixel white/black pattern

Gray 63

B

B

B

B

B

B

B

B

B

B

8/28

Version 3.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

B

B

www.panelook.com

Page 9

Global LCD Panel Exchange Center

Note (2) Lamp current is measured by utilizing a current meter for high frequency as shown

below:

LCD

Module

Note (3) The voltage shown above should be applied to the lamp for more than 1 second after

startup. Otherwise the lamp may not be turned on. And the start voltage at 0ºC is the

condition that stabilizes in the lamp, and it is the value that guarantees the lighting of

the lamp.

www.panelook.com

HV(Whit

LV(Black)

e)

1

2

Current meter

Doc. No.:14003226

Issue Date: Oct.03,2000

Model: M141X101

APPROVAL

A

Inverter

Note (4) The lamp frequency may produce interference with horizontal synchronous frequency

from the display, and this may cause line flow on the display. In order to avoid

interference the lamp frequency should be detached from the horizontal synchronous

frequency and its harmonics as far as possible.

.

Note (5) P

Note (6) The lifetime (Hr) of a lamp can be defined as the time in which it continues to operate

under the condition Ta = 252к and I

occurs:

Note (7) The waveform of the voltage output of inverter must be area-symmetric and the design

= I

L

(1) When the brightness becomes 50% or lower than its original,

(2) When the effective ignition length becomes 80% or lower than its original value.

of the inverter must have specifications for the modularized lamp. The performance of

the backlight, such as lifetime or brightness, is greatly influenced by the

characteristics of the DC-AC inverter for the lamp. All the parameters of an inverter

should be designed with care so as not to produce too much current leakage from

high-voltage output of the inverter. When designing or ordering the inverter, please

make sure that a poor lighting caused by the mismatch of the backlight and the

inverter (miss-lighting, flicker, etc.) never occurs. When the above situation is

confirmed, the module should be operated in the same manners as it is installed in

your instrument.

V

2.

L

L

= 6.0 mArms until one of the following event

L

(Effective ignition length is defined as an area that has less than 70% brightness

compared to the brightness in the center point.)

9/28

Version 3.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 10

Global LCD Panel Exchange Center

3. INTERFACE SPECIFICATIONS

3.1 THE PIN ASSIGNMENT OF TTL INTERFACE CONNECTOR.

www.panelook.com

Doc. No.:14003226

Issue Date: Oct.03,2000

Model: M141X101

APPROVAL

Pin

Symbol I/O Function

No.

1 GND - Ground 31 GE1 I Green even data 1

2 RO0 I Red odd data 0 32 GE2 I Green even data 2

3 RO1 I Red odd data 1 33 GE3 I Green even data 3

4 RO2 I Red odd data 2 34 GE4 I Green even data 4

5 RO3 I Red odd data 3 35 GE5 I Green even data 5

6 RO4 I Red odd data 4 36 GND - Ground

7 RO5 I Red odd data 5 37 BE0 I Blue even data 0

8 GND - Ground 38 BE1 I Blue even data 1

9 GO0 I Green odd data 0 39 BE2 I Blue even data 2

10 GO1 I Green odd data 1 40 BE3 I Blue even data 3

11 GO2 I Green odd data 2 41 BE4 I Blue even data 4

12 GO3 I Green odd data 3 42 BE5 I Blue even data 5

13 GO4 I Green odd data 4 43 GND - Ground

14 GO5 I Green odd data 5 44 VSYN I Vertical sync.

15 GND - Ground 45 HSYN I Horizontal sync.

16 BO0 I Blue odd data 0 46 ENAB I Data enable signal

17 BO1 I Blue odd data 1 47 GND - Ground

18 BO2 I Blue odd data 2 48 GND - Ground

19 BO3 I Blue odd data 3 49 DCLK I Dot clock signal

20 BO4 I Blue odd data 4 50 GND - Ground

21 BO5 I Blue odd data 5 51 GND - Ground

22 GND - Ground 52 NC - Must be floating

23 RE0 I Red even data 0 53 NC - Must be floating

24 RE1 I Red even data 1 54 GND - Ground

25 RE2 I Red even data 2 55 GND - Ground

26 RE3 I Red even data 3 56 GND - Ground

27 RE4 I Red even data 4 57 VDD - +5V Power supply

28 RE5 I Red even data 5 58 VDD - +5V Power supply

29 GND - Ground 59 VDD - +5V Power supply

30 GE0 I Green even data 0 60 VDD - +5V Power supply

Connector Part No.: 52760-0600(Molex)

User’s connector Part No: 53475-0600(Molex)

Pin

Symbol I/O Function

No.

10/28

Version 3.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 11

Global LCD Panel Exchange Center

3.2 INPUT SIGNAL TIMING SPECIFICATIONS

The specifications of input signal timing are as the following table and timing diagram.

Signal Parameter Symbol Min Typ Max Unit Remarks

Pixel clock Frequency fck 25 32.5 40 MHz

DCLK

DATA

VSYNC

HSYNC

Notes: 1.Data is latched at falling edge of DCLK in the spec. DCLK should appear during all

2. VSYNC and HSYNC are negative polarity in the spec.

3.DE (Data Enable) should be positive polarity in the spec.

4. HSYNC should appear during blanking period of frame cycle.

Pixel clock period Tck 40 30 25 ns

Duty ratio (%Tch) - 40 50 60 % Tch/Tck

Rise time Trck - 7.9 - ns

Fall time Tfck - 7.3 - ns

Setup time Tsd 5.0 - - ns

Hold time Thd 6.0 - - ns

Rise time Trd - 8.9 - ns

Fall time Tfd - 8.2 - ns

Setup time Tsde 4 5.8 - ns DE

Hold time Thde 4.5 6.2 - ns

Vertical Frequency fv 50 60 75 Hz

Vertical period Tvp 769 806 1000 Thp

Vertical display blank period Tvdb 1 38 232 Thp

Vertical display active period Tvda 768 768 768 Thp

Vertical sync. back porch Vbp 0 29 199 Thp

Vertical sync. front porch Vfp 0 3 199 Thp

Vertical sync. pulse width Vpw 1 6 200 Thp

Horizontal period Thp 575 672 806 Tck

Horizontal display blank period Thdb 63 160 294 Tck

Horizontal display active period Thda 512 512 512 Tck

Horizontal sync. back porch Hbp 52 53 281 Tck

Horizontal sync. front porch Hfb 0 35 281 Tck

Horizontal sync. pulse width Hpw 52 73 243 Tck

blanking period.

www.panelook.com

Doc. No.:14003226

Issue Date: Oct.03,2000

Model: M141X101

APPROVAL

11/28

Version 3.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 12

Global LCD Panel Exchange Center

VSYNC

HSYNC

www.panelook.com

INPUT SIGNAL TIMING DIAGRAM

pw

V

bp

V

vp

T

vda

vdb

T

T

Doc. No.:14003226

Issue Date: Oct.03,2000

Model: M141X101

APPROVAL

fp

V

DE

HSYNC

DE

DCLK

DATA

768

ch

T

768

ck

fp

H

Invalid Vali d

1

pw

H

bp

H

hdb

T

2

hp

T

hda

T

Valid display data (1024 Tck)

rck

T

fck

T

T

DCLK

sd

T

hd

T

DATA

rd / Tfd

T

T

sde

hde

T

DE

12/28

Version 3.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

90%

10%

90%

10%

90%

www.panelook.com

Page 13

Global LCD Panel Exchange Center

3.3 COLOR DATA INPUT ASSIGNMENT

Color

Basic

Colors

Gray

Scale

Of

Red

Gray

Scale

Of

Green

Gray

Scale

Of

Blue

Odd

Even

Black

Red

Green

Blue

Cyan

Magenta

Yellow

White

Red(0) / Dark

Red(1)

Red(2)

:

:

Red(61)

Red(62)

Red(63)

Green(0) / Dark

Green(1)

Green(2)

:

:

Green(61)

Green(62)

Green(63)

Blue(0) / Dark

Blue(1)

Blue(2)

:

:

Blue(61)

Blue(62)

Blue(63)

RO5 RO4 RO3 RO2 RO1 RO0 GO5 GO4 GO3 GO2 GO1 GO0 BO5 BO4 BO3 BO2 BO1 BO0

RE5 RE4 RE3 RE2 RE1 RE0 GE5 GE4 GE3 GE2 GE1 GE0 BE5 BE4 BE3 BE2 BE1 BE0

www.panelook.com

Doc. No.:14003226

Issue Date: Oct.03,2000

Model: M141X101

APPROVAL

Data Signal

Red Green Blue

0

0

0

0

0

0

0

1

1

0

0

0

1

1

1

0

0

0

:

:

1

1

1

0

0

0

:

:

0

0

0

0

0

0

:

:

0

0

0

1

1

0

0

0

0

0

0

1

1

1

1

1

1

0

0

0

0

0

0

:

:

:

:

1

1

1

1

1

1

0

0

0

0

0

0

:

:

:

:

0

0

0

0

0

0

0

0

0

0

0

0

:

:

:

:

0

0

0

0

0

0

1

0

0

0

0

0

0

1

1

1

1

1

1

0

0

0

0

0

1

:

:

:

:

0

1

1

1

1

1

0

0

0

0

0

0

:

:

:

:

0

0

0

0

0

0

0

0

0

0

0

0

:

:

:

:

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

0

0

0

0

0

0

0

1

1

1

1

1

0

0

0

0

0

0

1

1

1

1

1

1

1

1

1

1

1

1

1

0

0

0

0

1

0

:

:

1

0

1

0

0

0

:

:

0

0

0

0

0

0

:

:

0

0

0

0

0

0

0

0

0

0

:

:

:

:

0

0

0

0

0

0

0

0

0

0

0

0

:

:

:

:

1

1

1

1

1

1

0

0

0

0

0

0

:

:

:

:

0

0

0

0

0

0

0

0

0

0

0

:

:

:

:

:

:

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

:

:

:

:

:

:

1

1

0

1

1

1

1

1

1

0

0

0

0

0

0

0

0

0

:

:

:

:

:

:

0

0

0

0

0

0

0

0

0

0

1

0

0

1

1

1

0

1

1

0

1

1

0

0

0

0

0

0

:

:

:

:

0

0

0

0

0

0

0

0

1

0

0

0

:

:

:

:

1

0

0

0

1

0

0

0

0

0

0

0

:

:

:

:

1

0

1

0

1

0

0

0

0

0

0

0

0

0

1

1

1

0

1

0

0

0

:

:

0

0

0

0

0

0

:

:

0

0

0

0

0

0

:

:

1

1

1

0

0

0

0

0

1

1

1

1

1

1

0

0

1

1

0

0

0

0

0

0

:

:

:

:

0

0

0

0

0

0

0

0

0

0

0

0

:

:

:

:

0

0

0

0

0

0

0

0

0

0

0

0

:

:

:

:

1

1

1

1

1

1

0

0

0

0

0

0

1

1

1

1

1

1

0

0

1

1

0

0

0

0

0

0

:

:

:

:

0

0

0

0

0

0

0

0

0

0

0

0

:

:

:

:

0

0

0

0

0

0

0

0

1

0

0

1

:

:

:

:

1

0

0

1

1

1

13/28

Version 3.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 14

Global LCD Panel Exchange Center

Correspondence between Data and Display Position

S0001 S0002 S0003 S0004 S0005 S0006 S0007 S0008 S3071 S3072

C001 RE

GE

BE

www.panelook.com

RO

GO

BO

GE

Doc. No.:14003226

Issue Date: Oct.03,2000

Model: M141X101

APPROVAL

GO

BO

0001

0001

0001

0002

0002

0002RE0003

0003

1024

1024

C768 RE

0001

GE

0001

BE

0001

RO

0002

GO

0002

BO

0002RE0003

GE

0003

GO

1024

BO

1024

3.4 POWER UP/DOWN SEQUENCE

10%

t4

10%

Vcc

0V

Signals

0V

10%

90%

90%

t1

t3

t2

t5

t6

CCFL

Timing Specifications:

0 ≤ t1 ≤ 10mS

0 ≤ t2 ≤ 50mS

0 ≤ t3 ≤ 50mS

t4 ≥ 1S

t5 ≥ 170mS

t6 ≥ 200mS (min.)

Notes: 1. Please avoid floating state of interface signal at invalid period.

2. When the interface signal is invalid, be sure to pull down the power supply for

LCD Vcc to 0V.

14/28

Version 3.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 15

Global LCD Panel Exchange Center

4. OPTICAL SPECIFICATIONS

The following optical specifications shall be measured in a darkroom or equivalent state

(ambient luminance ≤1 lux, and at room temperature). The measurement must be taken after

backlight warming up for 20 minutes. The operation temperature is 25°C ± 2°C. The

measurement method is shown in Note (1).

Parameter Symbol Condition Min. Typ. Max. Unit Note

Central Luminance L Center,I

Contrast ratio CR Center 150 200 - - (1), (3)

Horizontal

Viewing Angle

Average Luminance L

Brightness Uniformity (VESA) Buni

Response Time

Chromaticity

Variation of Color

Cross Talk CT

Ver tical

Horizontal

Ver tical

Rising Tr - 20 35 ms

Falling Tf

www.panelook.com

Doc. No.:14003226

Issue Date: Oct.03,2000

Model: M141X101

APPROVAL

(1), (2),

=6.0mA 170 200 - cd/m

L

θx+

θx-

Center

CR ≥10

θy+

θy-

θx+

θx-

Center

CR ≥5

θy+

θy-

ave

IL = 6.0mA 150 180 - cd/m2 (1), (5)

θx = θy = 0

Center

θx = θy = 0

o

o

40 45 50

40 45 50

10 15 20

30 35 40

58 63 68

58 63 68

25 30 35

50 55 60

1.0 1.2 1.35 - (1), (6)

- 30 45 ms

Xw 0.290 0.310 0.330 Yw 0.310 0.330 0.350 -

XR 0.560 0.580 0.600 -

Center

YR 0.308 0.328 0.348 -

= θy = 0

θx

XG 0.280 0.300 0.320 -

o

YG 0.542 0.562 0.582 XB 0.136 0.156 0.176 -

Y

B

Δx/y

Center

θx = θy = 0

θx = θy = 0

0.097 0.117 0.137 -

o

o

- 0.02 0.03 - (1), (9)

- - 1.0 % (1), (10)

2

(4)

degree (1), (4)

(1), (7)

(1), (8)

Image Sticking Tis

Gamma Value -

TCO’99 Luminance Uniformity

(Angular-dependent)

TCO’99 Luminance Contrast

(Angular-dependent)

2hours, test pattern

L

R

C

m

- - 2 sec (11)

-

-

-

- - - - (12)

- - 1.7 - (13)

0.5 - - - (14)

15/28

Version 3.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 16

Global LCD Panel Exchange Center

y

y

Note (1) The method of optical measurement:

www.panelook.com

Field=2

º

Photometer

(TOPCON BM-5A)

cm

50

Doc. No.:14003226

Issue Date: Oct.03,2000

Model: M141X101

APPROVAL

TFT-LCD Module

Note (2) Definition of Central Luminance (L):

Central Luminance must be measured at the central point of the LCD module and at the

viewing angle of the θx

= θy = 0

o

(Note 4).

Note (3) Definition of Contrast Ratio (CR):

Contrast ratio measurement must be made at the viewing angle of the θx

= θy = 0

o

(Note 4)

and at the central point of the LCD module. The Luminance (Note 2) shall be measured with all

pixels in the viewing field set initially to be 63 gray level, then 0 gray level.

Luminance with all pixels in 63 gray

CR =

Luminance with all pixels in 0 gray level

Note (4) Definitions of Viewing Angle :

Normal

o

θx−

= 0

θx+

12 o’clock

y

direction

θX-

= 90

θx = θ

θy- θy+

o

x-

6 o’clock

-

θ

= 90

y-

o

x+

θX+

= 90

16/28

Version 3.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

o

www.panelook.com

Page 17

Global LCD Panel Exchange Center

b

b

b

b

Note (5) Definition of Average Luminance:

The Average Luminance is defined as arithmetic mean value of five spots across the LCD

surface at 63 gray level. The Luminance (Note 2) shall be measured with all pixels in the

viewing field at 63 gray level. The measuring spots must be taken at the locations shown in the

following figure, where a = b = 15mm.

www.panelook.com

Doc. No.:14003226

Issue Date: Oct.03,2000

Model: M141X101

APPROVAL

w

L

ave

a

1

11 12

a

L4 + L5 + L7 + L9 + L10

=

5

Luminance Measuring Points

d/4

d/2 3d/4

2

4

6

9

7

5

10

d

3

8

13

a

w/4

w/2

3w/4

a

17/28

Version 3.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 18

Global LCD Panel Exchange Center

Note (6) Definition of Brightness Uniformity (Buni):

www.panelook.com

Doc. No.:14003226

Issue Date: Oct.03,2000

Model: M141X101

APPROVAL

W/10

D/10

1

D/2

D/2

2

W/2

W

W/2

3

4

D

Buni =

Note (7) Definition of Response Time:

The Response Time is set initially by defining the “ Rising Time (Tr)” and the “ Falling Time

(Tf)” respectively. Tr and Tf are defined as following figure.

Maximum luminance of 5 points

Minimum luminance of 5 points

Data input:

100%

10%

90%

0%

63 gray level

Tr

0 gray level

18/28

63 gray level

Tf

Version 3.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 19

Global LCD Panel Exchange Center

A

(

)

A

(

)

(

)

Note (8) Definition of Chromaticity:

The color coordinates (Xw, Yw), (X

in the viewing field at white, red, green, and blue states, respectively.

Note (9) Definition of Variation of Color:

The variation of x and y values (Δx/y) in the CIE Color Coordinate by measuring 13 points

relative to central point, where a = b = 15 mm as shown in Note 5.

Note (10) Definition of Cross Talk (CT):

www.panelook.com

Doc. No.:14003226

Issue Date: Oct.03,2000

Model: M141X101

APPROVAL

R,YR), (XG,YG), and (XB,YB) are obtained with all pixels

ctive

Gray 32

– YA | / YA×100 (%),

B

Y

(512, 96)

A, U

Y

(896, 384)

A, R

1023, 767

(256, 192)

Y

(128, 384)

B, L

Y

(512, 672)

B, D

0, 0

ctive

Gray 0

Gray 32

Y

(128, 384)

A,L

Y

(512, 672)

A, D

(0, 0)

CT = | Y

where:

Y

= Luminance of measured location without 0 gray scale pattern (cd/m2)

A

Y

= Luminance of measured location with 0 gray scale pattern (cd/m2)

B

Note (11) Definition of Image Sticking:

The test pattern illustrated below is demonstrated for 2 hours. Then switch the test pattern

to a completely white pattern ( 63 gray level), and record the sustaining time (Tis) of the residual

image.

Gray 0

Gray 63

Y

(512, 96)

B,U

Y

(896, 384)

B,R

(768, 576)

1023, 767

Row 382 - 386

Row 510-514

19/28

Version 3.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 20

Global LCD Panel Exchange Center

Note (12) Gamma Values are measured at the center location. The luminance of each gray

scale level is measured at normal incidence. The maximum value of luminances of all different

gray scale levels is set to be 100%. The other luminance values relative to the maximum value

at each gray scale level can be obtained.

www.panelook.com

Doc. No.:14003226

Issue Date: Oct.03,2000

Model: M141X101

APPROVAL

Gray scale level

Average normalized Luminance (%)

0 0.42

4 0.73

8 ˄.43

˄2 2.69

˄6 4.68

20 8.27

24 ˄2.56

28 ˄6.89

32 20.65

36 26.˄7

40 32.65

44 40.08

48 48.˄7

52 58.47

56 72.48

60 90.04

63 ˄00.00

20/28

Version 3.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 21

Global LCD Panel Exchange Center

W

Note (13) Definition of TCO 99 Luminance Uniformity (Angular-dependent) (LR):

www.panelook.com

Doc. No.:14003226

Issue Date: Oct.03,2000

Model: M141X101

APPROVAL

D/2

W/2

R

W/2

0.1 D

L

0.1 D

D/2

C

D

Luminance is measured at the center measurement position “C” on the LCD panel. The

optical axis of the luminance meter shall be aligned with the normal of the panel surface. The

measuring distance between the photometer and the surface of the panel is defined as:

Md (cm) = diagonal of the panel (cm) X 1.5 with minimum distance 50 cm.

The panel is rotated around a vertical axis which passes the center of the display by

changing the azimuthal angle to +30°. The distance between the panel and the photometer

remains unchanged and the measured point is exact the same as the previous measured point.

The photometer is then rotated by changing its azimuthal angle with the fixed distance to

the panel. Luminances at points “L” and “R” are given:

LCD panel

L

min, +30

Md

L

max, +30

°

and L

L

min, +30

21/28

max, +30

°

L

30

°

R

C

°

°

Photometer

Version 3.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 22

Global LCD Panel Exchange Center

www.panelook.com

Doc. No.:14003226

Issue Date: Oct.03,2000

Model: M141X101

APPROVAL

The LCD panel is then rotated to another azimuthal angle to -30°; and L

max, -30

°

are obtained by using the same procedure.

R) is calculated as follow:

L

R

= ((L

max, +30

°

/ L

min, +30

°

)+( L

max, -30

°

/ L

min, -30

°

)) / 2.

L

The Luminance Uniformity (L

Note (14) Definition of TCO 99 Luminance Contrast (Angular-dependent) (Cm):

D/2

D/2

W/2

W

C

W/2

min, -3θ

°

and

D

Luminance contrast is measured at the center point of the LCD panel “C” along with the

normal of the display with the same distance described in Note 13. The display is then rotated

around the vertical axis by changing its azimuthal axis to +30°; and this gives :

LCD panel

L

63 G.L., +30

30

°

C

°

and L

0 G.L., +30

°

.

Photometer

22/28

Version 3.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 23

Global LCD Panel Exchange Center

www.panelook.com

Doc. No.:14003226

Issue Date: Oct.03,2000

Model: M141X101

APPROVAL

The LCD panel is then rotated to azimuthal angle to -30°; and L

°

are obtained by using the same procedure. The Luminance Contrast (Cm) is calculated:

-30

Cm = (L

For both +30° and -30°. The lower value for Cm is reported.

63

G. L.

- L

0 G.L.

)/ (L

63

G. L.

+ L

0 G.L

0 G. L., -30

)

°

and L

5. Reliability Test Item

No. Test Item Conditions

1.

2.

3.

4.

5.

High temperature

storage test

Low temperature

storage test

High temperature

and high humidity

operation test

High temperature

operation test

Low temperature

operation test

Ta = 60ºC , 500h (1), (2), (3), (4), (5)

Ta = -20ºC, 500h (1), (2), (3), (4), (5)

Ta = 40ºC, 95%RH 500h

( no condensation )

Ta = 55ºC, 500 h (1), (2), (3), (4), (5)

Ta = -5ºC, 48h (1), (2), (3), (4), (5)

Criterion

(Note)

(1), (2), (3), (4), (5)

63 G.L.,

6.

7.

Notes : The criterions are as following.

(1) The Contrast Ratio criterion after this test item are ӔCR ≤ 20% or CR > minimal

specification.

ӔCR is the contrast ratio variation which is measured before and after this test item.

(3) The module is functional work after this test item.

(4) The defect or mura are not increase after this test item.

(5) The mechanical outline is no abnormal change , for example, inflation, distortion or

metal frame shift.

Vibration test

( operating )

Mechanical shock

( non-operating )

(2) The module Power Supply Current ( Icc) ≤ Maximal Specification after this testing

item.

10 ~ 500 Hz, 1 G, 20 min./cycle, X,Y,Z,

each 3 times

50 G, 11 ms, half sine wave, X,Y,Z,

each 1 times

(3), (4), (5)

(3), (4), (5)

23/28

Version 3.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 24

Global LCD Panel Exchange Center

6. MECHNICAL DRAWING

Please refer to the attached drawings.

7. PRECAUTION

7. 1 ASSEMBLY AND HANDLING PRECAUTION

(1) Do not apply rough force such as bending or twisting to the module during assembly.

(2) To assemble or install module into user’s system can be only in clean working areas. The

dust and oil may cause electrical short or worsen the polarizer.

(3) It’s not permitted to have pressure or impulse on the module because the LCD panel and

backlight will be damaged.

(4) Always follow the correct power sequence when LCD module is connecting and operating.

This can prevent damage to the CMOS LSI chips during latchup.

(5) Do not pull the I/F connector in or out while the module is operating.

(6) Do not disassemble the module.

(7) Use a soft dry cloth without chemicals for cleaning, because the surface of polarizer is very

soft and easily scratched.

(8) It is dangerous that moisture come into or contacted the LCD module, because moisture

may damage LCD module when it is operating.

(9) High temperature or humidity may reduce the performance of module. Please store LCD

module within the specified storage conditions.

(10) When ambient temperature is lower than 10ºC may reduce the display quality. For example,

the response time will become slowly, and the starting voltage of CCFL will be higher than

room temperature.

www.panelook.com

Doc. No.:14003226

Issue Date: Oct.03,2000

Model: M141X101

APPROVAL

7.2 SAFTY PRECAUTION

(1) The startup voltage of backlight is approximately 1000 Volts. It may cause electrical shock

while assembling with inverter. Do not disassemble the module or insert anything into the

backlight unit.

(2) If the liquid crystal material leaks from the panel, it should be kept away from the eyes or

mouth. In case of contact with hands, skin or clothes, it has to be washed away thoroughly

with soap.

24/28

Version 3.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 25

Global LCD Panel Exchange Center

8. PACKAGING

8.1 PACKING SPECIFICATIONS

(1) 10 LCD modules / 1 Box

(2) Box dimensions : 443(L) X 433(W) X 388(H) mm

(3) Weight : approximately 14.5 Kg ( 10 modules per box)

8.2 PACKING Method

www.panelook.com

Doc. No.:14003226

Issue Date: Oct.03,2000

Model: M141X101

APPROVAL

The Figure. 8-1,2 show the packing method.

Figure. 8-1 Packing method

25/28

Version 3.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 26

Global LCD Panel Exchange Center

www.panelook.com

Doc. No.:14003226

Issue Date: Oct.03,2000

Model: M141X101

APPROVAL

Figure. 8-2 Packing method

26/28

Version 3.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 27

Global LCD Panel Exchange Center

9. INCOMING INSPECTION DAY

The Supplier should be acquainted the inspection results (acceptance or rejection) by

Customer, and the results are in accordance with the incoming inspection standard within 30

days after the date of the bills of lading.

Should Customer fail to so notify the Supplier within the said 30 days period. The

Customer’s right to reject the LCMS shall then lapse, and the said LCMS shall be deemed to

have been accepted by the customer.

www.panelook.com

Doc. No.:14003226

Issue Date: Oct.03,2000

Model: M141X101

APPROVAL

27/28

Version 3.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 28

Global LCD Panel Exchange Center

10. DEFINITION OF SHIPPING LABEL ON MODULE

The barcode nameplate is pasted on each module as illustration, and its

definitions are as following explanation.

www.panelook.com

Doc. No.:14003226

Issue Date: Oct.03,2000

Model: M141X101

APPROVAL

M 1 4 1 X 1 0 1 Rev. CX

CHI MEI OPTOELECTRONICS

(1) Model Name : M141X101

(2) Revision : Rev.XX, for example : C1, C2 …etc.

(3) Serial ID : 0 1

Serial ID include the information as list.

1. Manufactured Date : Year : 0~9, for 2000~2009

2. Revision Code : cover all the change

3. Model code

4. Serial No. : Manufacturing sequence of product

5. Product Line : 1 -> Line1, 2 -> Line 2 …,etc.

0 1 C 1 0 0 1 0 3 9 1 0 0 0 1

C 1 0 0 1 0 3 9 1 0 0 0 1

Month : 0~9, A~C, for Jan. ~ Dec.

Day : 0~9, A~Y, for 1

MADE IN TAIWAN

st

to 31st, exclude I and O

Serial No.

Product Line

Year, Month, Date

CMO Internal Use

CMO Internal Use

Revision

Model Code

28/28

Version 3.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 29

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 30

Global LCD Panel Exchange Center

www.panelook.com

E207943

Reating: 5Vdc 450mA

Model: M141X101

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Loading...

Loading...