CML J350 Instruction Manual

I

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

ModelJ350

Multi blade wood cutting machine

I

Mod

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

el

J350

Multi blade wood curling machine

. 1

Li

st of co

Mach ine identification

Warranty

Technical specifications

Phonometric survey

Individual sulety protection

- correct use

- residual risks

Installation:

Suction

ElectricaJ

Control

nt

wiring

panel

ents:

01

the machine and unrecommended operations

Ulting

Positioning.

Testing

Page

1

3

4

4

5

6

7

8

9

11

Instructions for use

Wooden boards

Blades

Safety

User security and residual risks

Possible anomaJies: iden

Maintenance and cleaning

Lubrication

Electric diagrams

Spares

Enclosures

measures

ti

fication and counter meas u

Electric diagram

Motor position diagram

Salety positioning diagram

Lubrication diagram

Drawing

Drawing 1

Pressure group

Main spindle

Sprocket axe

Free axe

Blade screw

Pressure group screw

res

12

15

16

17

19

19

21

21

22

22

IN

srnUCTIO

N M

ANUAL

Model

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

Multi blad9

J350

wood

culling machine

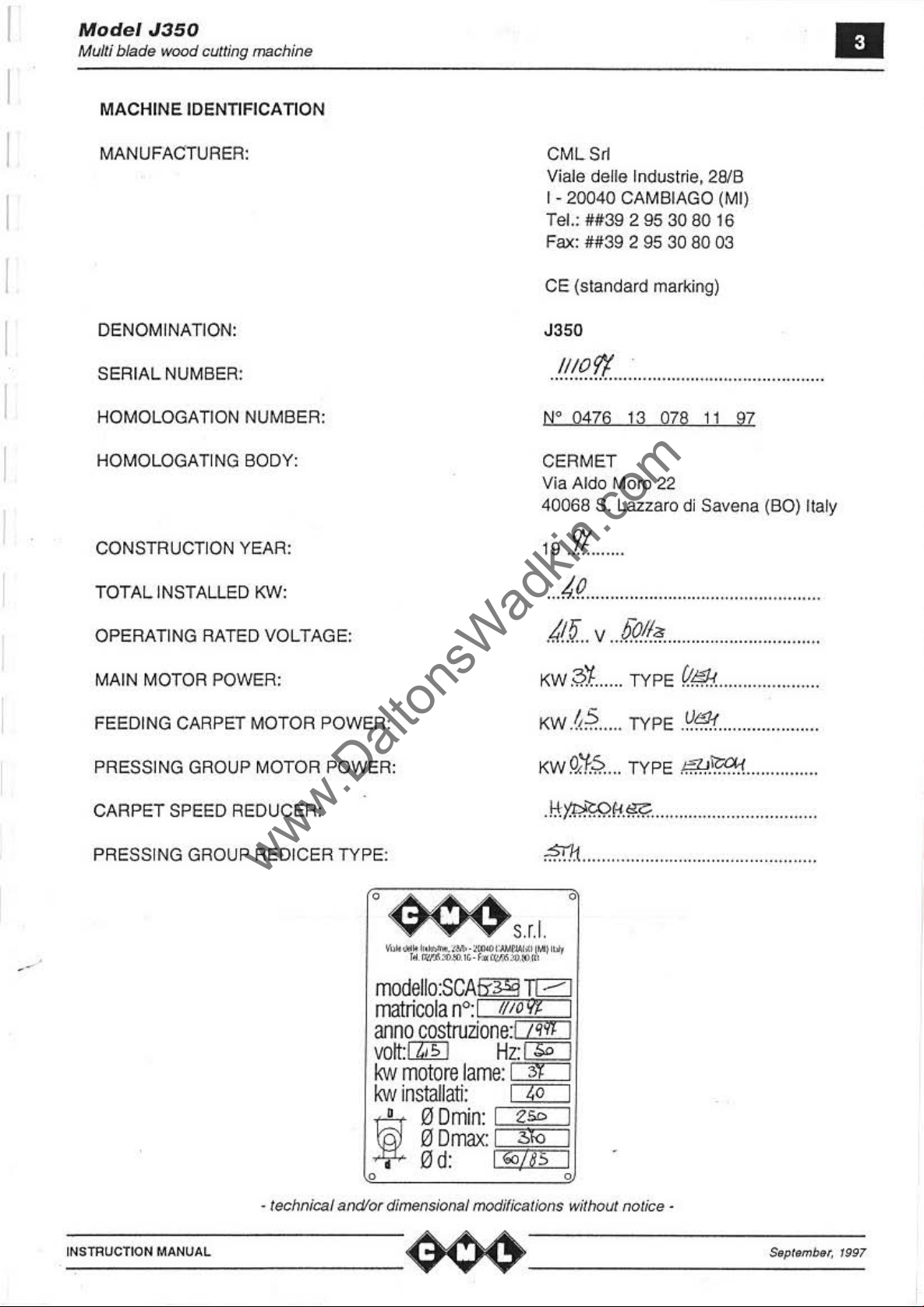

MACHINE

MANUFACTURER:

DENOMINATION:

SERIAL NUMBER:

HOMOLOGATION NUMBER:

HOMOLOGATING

CONSTRUCTI

IDENTIFICATION

BODY:

ON

YEAR:

CML

Sri

Viale delle Industria,

I - 20040 CAMBIAGO (MI)

Tel.: ##39 2 95

Fax: ##39 2 95 30

CE

(standard marking)

J350

.

/!!.

P.

f'!. ...

.....

...........................

W 04

CERMET

Via Aldo Moro

40068 S. Lazzaro di Savena (BO) Italy

19

76

.'!f. ...

..

13

078 11 97

22

.

30

80

80

281B

16

03

.......

.

TOTAL

OPERATING RATED VOLTAGE:

MAIN MOTOR

FEEDING CARPET MOTOR POWER:

PRESSING GROUP MOTOR POWER:

CARPET

PRESSING GROUP REDICER TYPE:

INSTALLED KW:

POWER :

SPEED REDUCER:

...

4q ....

.

4W

KW

.'9.

KW

A:? .....

Kw9"''1:~

.H~f:i

2'1J

s.r

J

.....................

..

V

...

&II

•...............................

'/:..

....

TYPE

TYPE

.... TYPE @.~ ......... ..... .

.~

...............................................

Vl:{/;!.

.~

..

................................

.................

..

..

...................

.................... .

. .

.

.

.

. 19Chnical and/or dirmmsional modifications without

_,,_'"'

__

,_"_O_,_"_,_"_,_,

________________

~

--------------------

notice·

~c'

c~--

~

-,-'~

__

;

Mod

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

el

J3S0

MultllMdcl weed cutting machine

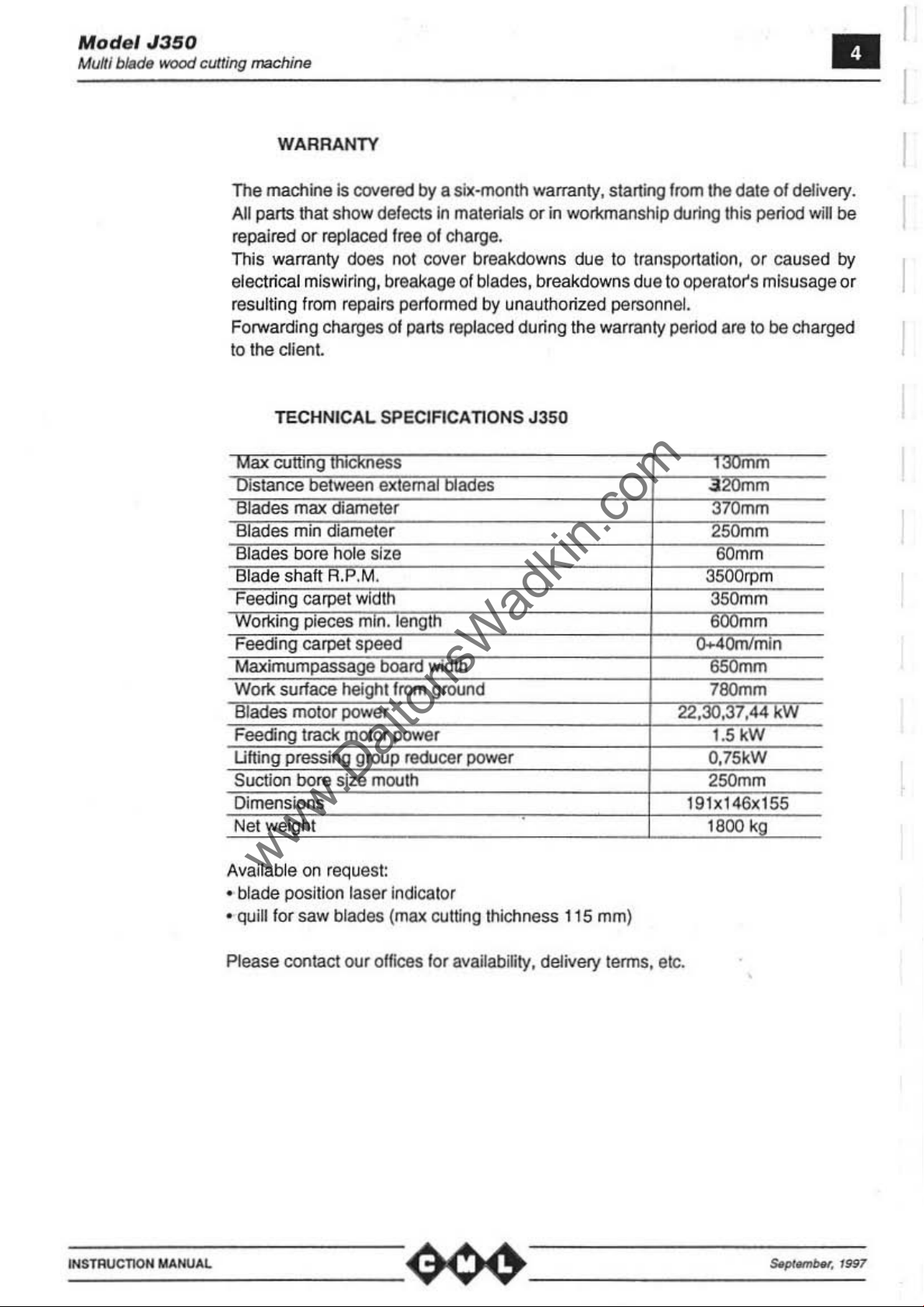

WARRANTY

The machine

All

parts that show

repaired

This warranty

electricat miswiring, breakage olblades, breakdowns dueto operator's mlsusageor

re$ulting from

FOlWarding

10

the client.

TE

i$

covered

defect$1n

Of

replaced Iree

ooes

repairs performed

charges

CHNIC

AL

SPECIFICATIONS J

by

a six-mooth warranty, starting from

materials

01

charge.

not

cover breakdowns due

01

pans replaced during Ihe warranty period

Of

in

worlanan$hlp during

10

transportation, or caused

by

unauthorized personnel.

350

the date of delivery.

thiS

are

period

10

will

be

by

be charged

Available

• blade

• quill for saw blad

Plea$e contact

on

request:

position laser Indicator

es

(max cutting

our olfice$ lor availability, de!ive!)' lenns,

thictmess

115

mm)

etc

.

Model

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

Multi blade wood cutting machine

J350

Phonometric

The phonometric survey

proofing materials in respect ISO 7960.

For survey data, see attached.

··Acoustlc equivalent pondered pressure PA 95

~Instant

• Instant sound pressure >130 db

··Ambient correction factor K 1,9 db

NOTE: the noise

they

sound

do

not necessariy represent sale operating levels.

survey

was

performed on a machine equipped with sound·

power

values shown must

100

db

(A)

be

regarded as admiSSion levels; therefore,

db

(A)

lNST1'lUCl10N MAN

UAL

Model

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

MuIIl

J350

blade wood cutling machine

. '

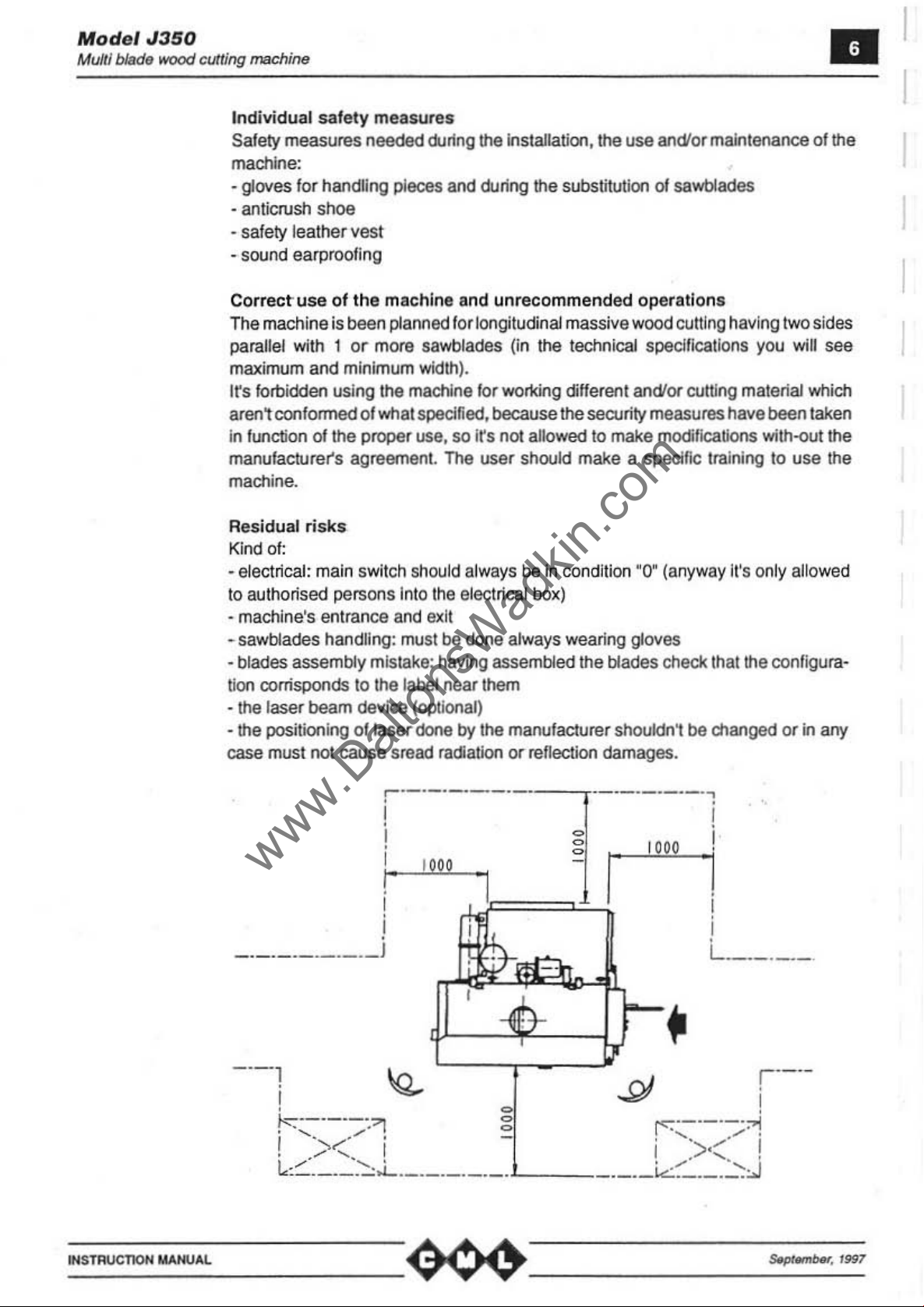

Individual safe

Safety

machine:

-

- anticrush shoe

•

- sound earproofing

Co

The

parallel with t

maximum and

Irs

measures

gloves for handling pieces and

safety leather vesl

rrect

use

madline

lolbidden

aren' conlormed

in

function of the proper use, so I

manufaChJrer's

machine.

sid

ual risks

Re

Kind of :

-

electrical: main switch should always

to authorised persons Into

- machine's entrance and

• sawblades hoodling: must be

- blades assembly mistake: having assembled the blades check that the conliguration COfrisponds to the label near them

- the laser beam device (optional)

- the positioning of

must

case

ly meas

needed

01

the

is been planned lorlongitudinal masSive wood cutting having two sides

or

minimum width).

using t

01

agreement

not

cause sread radiation

ure

s

IiIrlng

machin

more

laser

sawbtades (in the technical specmcatlons you wilt see

ne

machine

what specified, because the

e~1t

done by the manufacturer shouldn't be d"langed

the inslallation, !he use

e a

lilriog

nd

Ior

the

substlMion

unrecommended

worIdng different

S8O.Irity

rs

not allowed to make modillcations with-out the

The user should make a

be

in condition "0" (anyway It's only allowed

the

electrical bo

done

)!"

)

always wearing gtoves

or

reflection damages.

anCVor

of

sawblades

opera

and'or

measures have been taken

spedllc

miUltenance

tions

cutting material which

training

to

use the

or

01

the

in any

Model

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

Multi blade wood culling machine

J350

IN

STA

LLATI

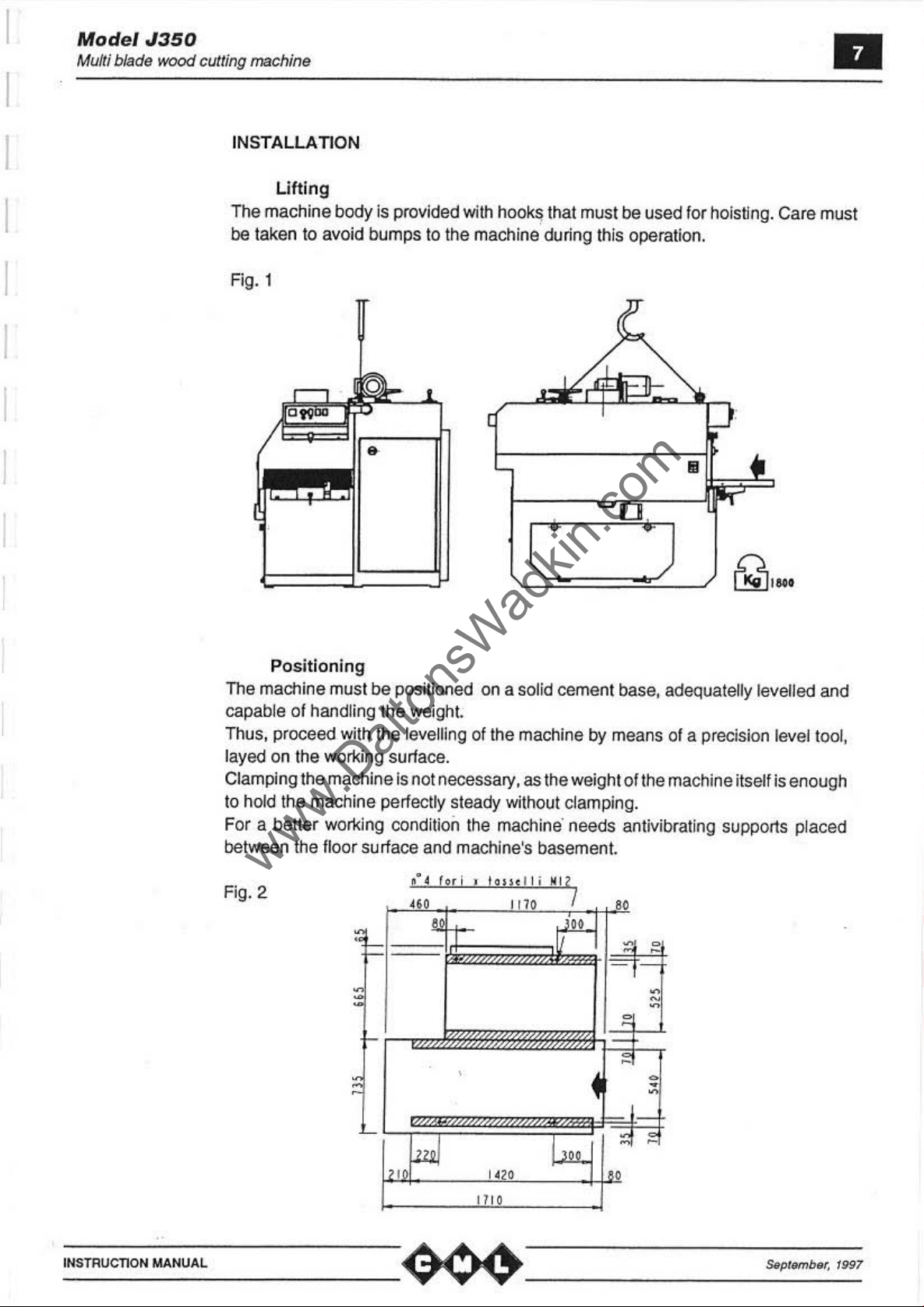

Lifting

The

machine

be taken to avoid bumps to the machine during this operation.

Fig. 1

ON

body is provided wilh

hoo~

that must be used for hoisting . Care must

:

Positioning

The machine must

capable of

Thus, proceed

layed on the working surface.

Clamping the machine is not necessary, as the weight

to hold t

For a better working condition the machine' needs antivibrating supports placed

between the floor surface and

Fig. 2

handling the weight.

he

machine perfectly steady without

be

positioned on a solid cement base, adequatelly levelled and

with the levelling of the machine by means

of

the machine itself is enough

damping

machine's basement.

.

of

a precision level tool,

"

INSTRUCTION

MANUA

L

Model

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

Multi

bIIlde

J350

wood I;utting tna<:hi"..

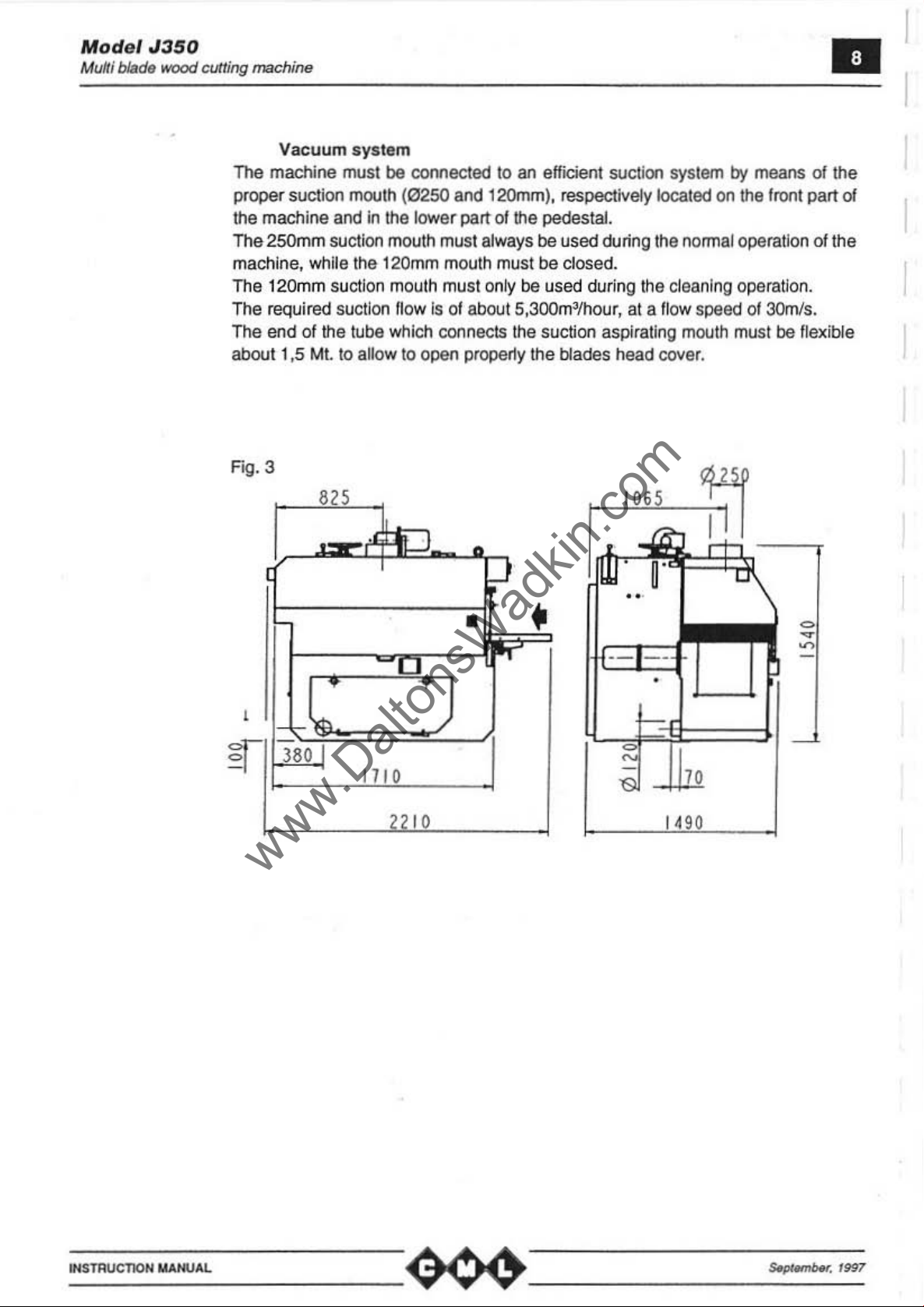

Vacuum system

The

machine

proper suction mouth (0 250 and l2Omm), respectively located on the froot part

the

machine

The2SOmm

machine, while the 120mm mouth must 00 closed.

The 120mm suction mou

The required suc tion

The ood of the lube which connects Ihe suction aspirating mouth must be flexible

about 1,5 M

Ftg.3

must be connected

and

in

the lower part

suction mouth must always

th

must only be used during the deaning operation.

fl

ow

Is

of

t.

to allow

815

10

open property the blades head cover.

to

of

about 5,3OOm'lhour, at a flow speed

an

effiCient suction system by means

the pedestal.

be

used during the (I(lrmal operation of

of

3OmIs.

. J

of

the

cA

the

,

~.

380

-

,

,J

•

•

-ft'i'

J

1110

1110

Model

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

Multi blade wood culling machine

J350

•

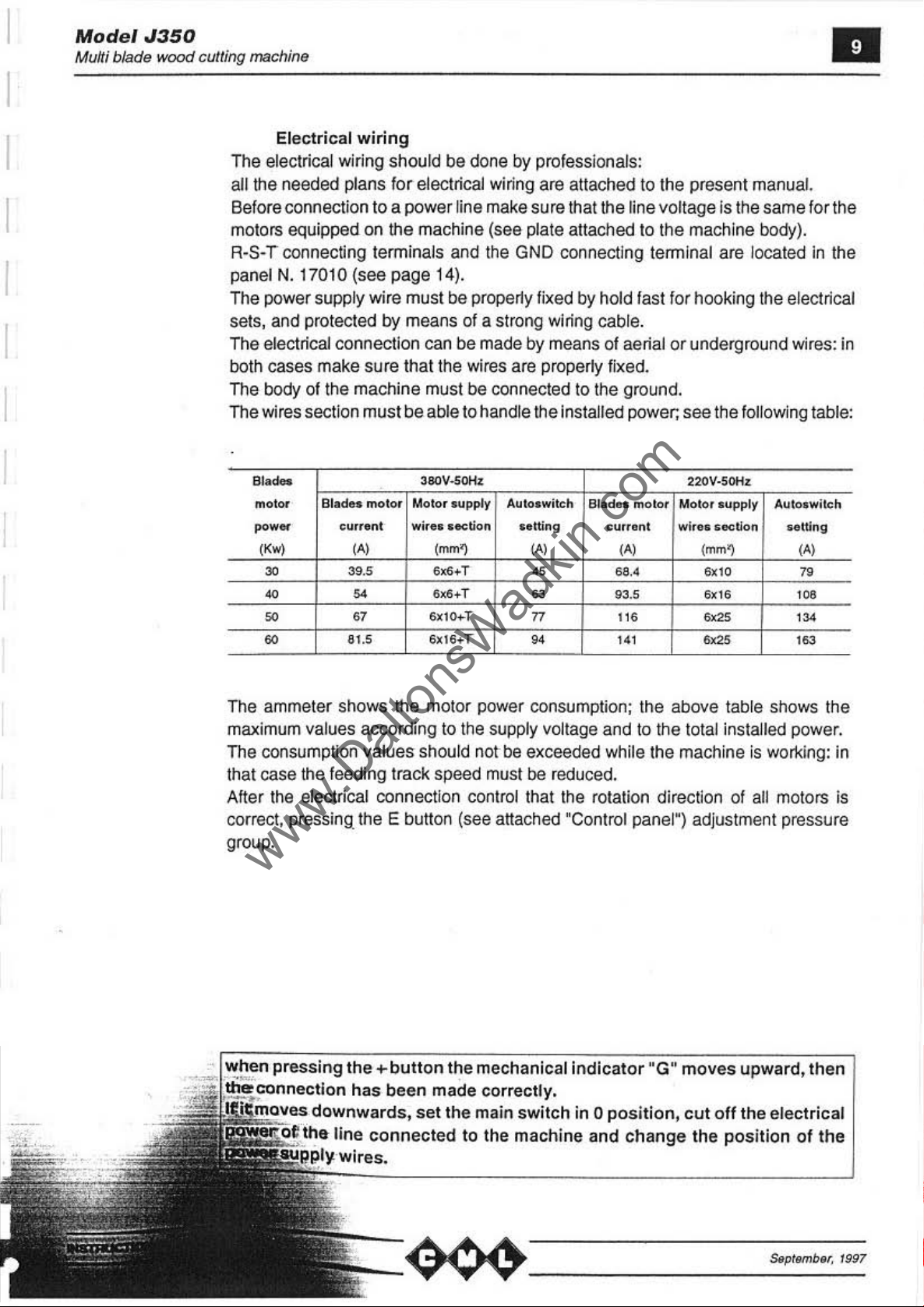

Electrical

The electrical wiring should

all

ttJe

needed plans for electrical wiring are attached

Beforeconnection

motors equipped on

A-S-T connecting

panel

The power suppfy wire must be properly fixed by hold fast f

sets, and protected

The electrical connection can

both cases make sure that the wires are properly fixed.

The body of the machine must be connected to the ground.

The wires section must be able

.~

molo<

~.

<

,.,

N.

t 7010 (see page 14).

•

•

"

•

wiring

be

done

by professionals:

to

a power line make sure Ihat Ihe line voltage is Ihe same

ttJe

machine (see plale attached

lerminals and the GND connecting terminal are located

by

means of a strong wiring cable.

be

made by means of aerial

to

handle the Installed power; see the following table:

J80V-SolU 220V·5OHJ:

BI

.des

molo< Molor ouppjy Autoowitch IIIod

wireo

ourro

'"

39.5

~

"

&1.5

nl

o..,tion

(mm')

6><6+T

~.,

t\lrl0

6><16<-

..

T

T

ooffing

'"

~

~

n

"

10

to

..

molet

curronl

'"

'"

93

.5

'"

'"

the present manual.

Ihe machine body).

or

forthe

in

or

hooking the electrical

underground wires:

Molor oupply Autoowitch

wl

..

o •

...,~o

~

...

lIlng

(m

m')

6, IQ

6,16

~

~

ro

'"

,

~

,.

,~

the

in

The ammeter shows the

maximum

The consumption values should not be exceeded while the machine

that case the feeding track speed must

After the electrical connection

correct, pressing. the E

group.

values according to the supply voaage and to the total installed power.

pressing

the

has

li

ne

connected

motor

power consumption; the above table shows the

be reduced.

cOl1trol

buttoo (see attached "Control panel") adjustment pressure

been made correctly.

main

to

that the rotation direcUon of

the

switch

machine

in 0

and

position,

change

~

m~'

~'~

cut

the

.;,

;;;p.;;d,

off

position

is

worldng: in

all

motors is

the

electrical

of

the

Model

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

Mulli blacJ. wood cutting machilJ8

J350

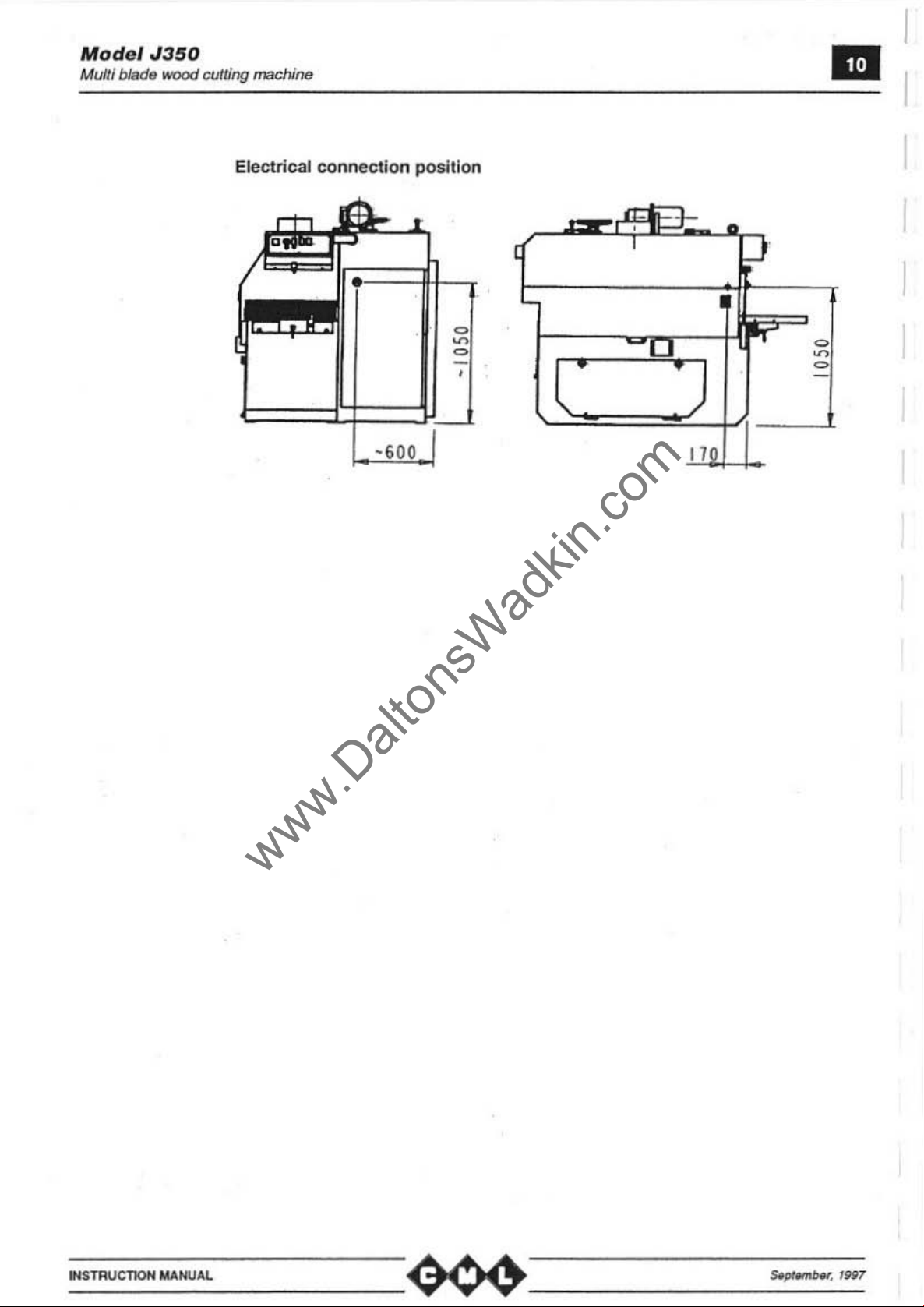

I

Electric

al

connection position

I

I

Model

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

Mulll

~

J350

wood cuI/ing

machilWl

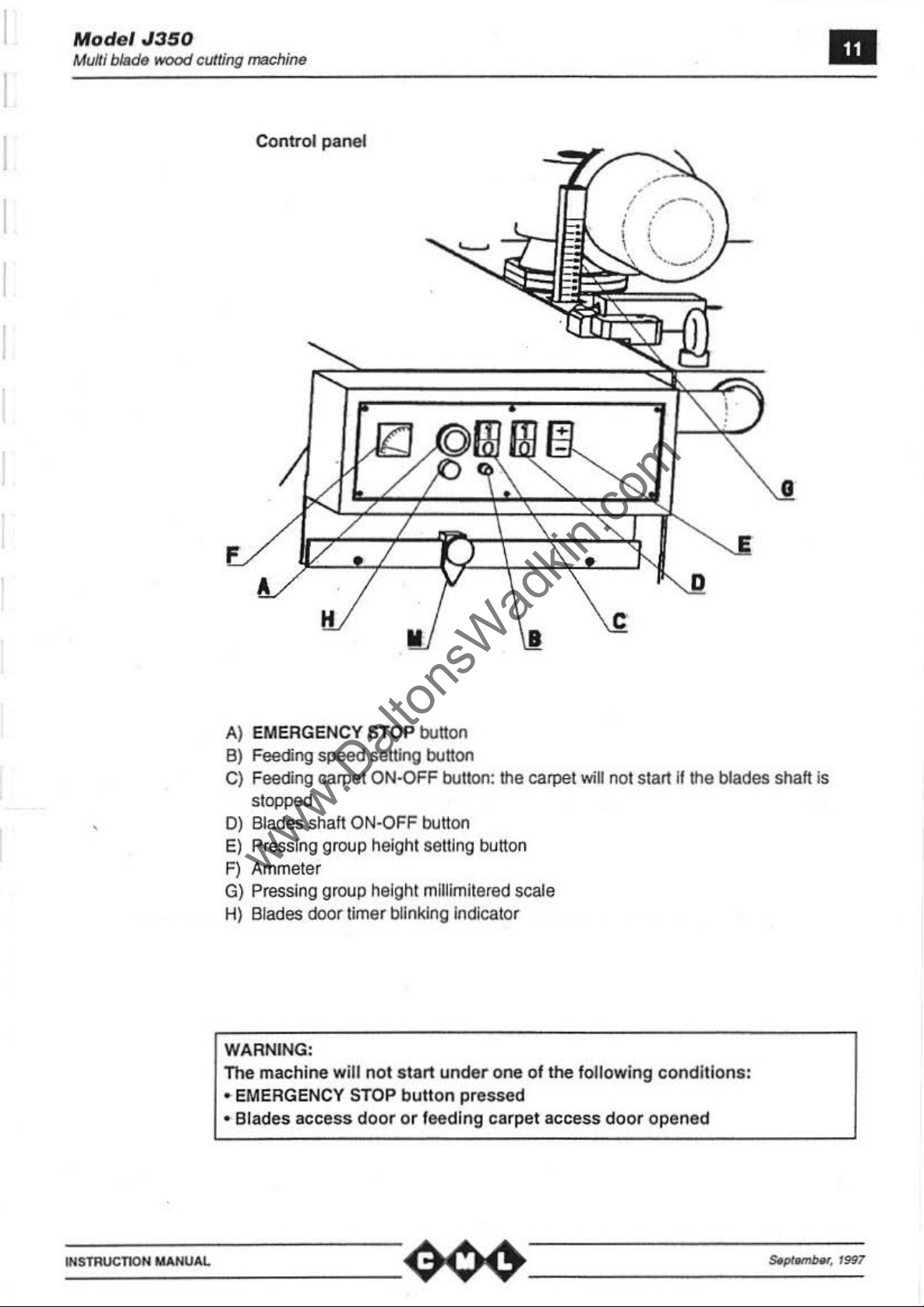

Control panel

III

A) EMERGENCY STOP button

8) Feeding speed setting button

C)

Feeding carpel ON-OFF bullon: ltIe carpet

stopped

D)

Blades shalt ON-OFF button

E)

Pressing group height

F)

Ammeter

Pressing group height mlllimitered scale

G)

H) Blades

WARNING:

The

machine will not

• EMERGENCY STOP

• Blades access door or feeding carpet acce

door timer blinking Indicator

sta

butt

seWrlg

rt

button

under one of the follo wing

on press

ed

wi~

not start if ltIe blades shaft is

condi

tions:

ss doo

r opened

Mod

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

el

J350

Multi blade wood cutting machine

INSTRUC

When

machine

Following

operate the machine,

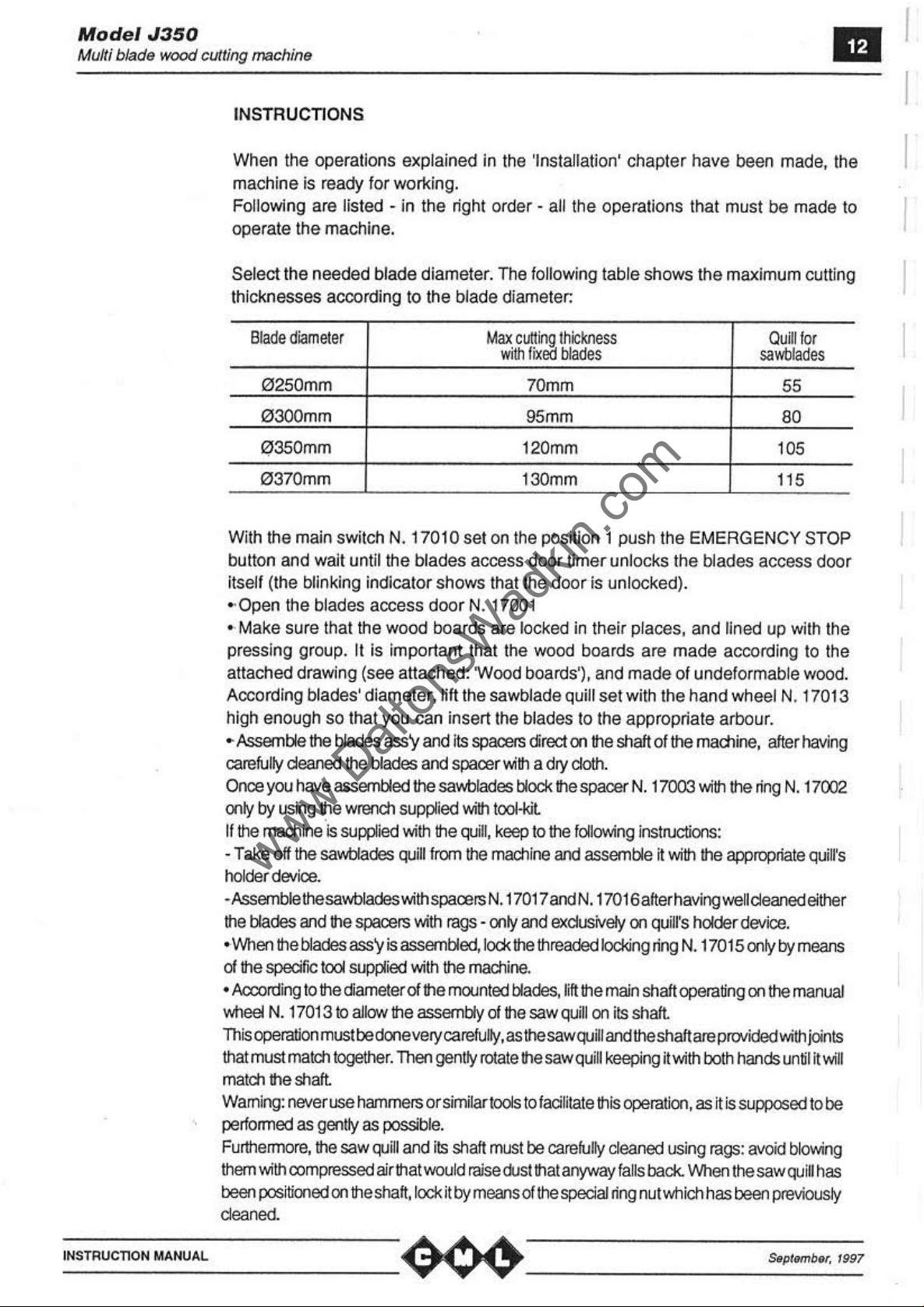

Select

th

icknesses according to the blade diameter.

Bladed~meler

Cl250mm

Cl300mm

Cl350mm

Cl370mm

Wi

th

button

itself (the blinking indicator shows that

"Open

• Make sure that

pressing group.

attached drawing

According

high enough

•

Assernt:Oe

carefully

OnceyouhaveassetrbledthesaYAJlades tlIodIthespacerN.

cnly

by

If

the

machine

-

Take

hok'Jerdevice.

·Assernblethesawbtadeswithspaoo

the

tJades

•

'Nhen

cA

the

spOOfic

•

Aoo::lrding

wheel N.

ThiSoperaIionmustbedorleverycareluly,aslhesawquiUandtheshahareprcMdedwill1jOOts

that

must

matdl

W

arning:

parforrned

Furthermore,

them

with

been positioned(Jl

TION

S

the operations explained

is

ready for working.

are

listed -

the needed blade diameter.

the main switch N. 17010

and

wait until

lt1e

blades access door N.

blades' diameter, lift the sawblade quill set w

so

that

the btades ass'y and

cleaned

using

off

the

lI1e

1701310

mald1

the

shalt

neveruse

as

corn;:xessed

the blades and

~

wrench

Is

supplied

sa\\t:llades

and

the

btadesao;sy

toot

SLqJIied

10

the

diameterrithe

aIow the

togeiher

gently

the

saw quill

th

in

the

lt1e

blades access door timer unlocks the blades access door

lt1e

wood

11

is

(see

you

spacers

is

hamnl6!S orsimilartods to

as

possible

airthal

eshaft,

ooards

important that

attached: Wood boards'

can insert

supp'ted

with

lI1

qui.

lrom the madline and

v-ith

assembled,

v-ith

assembly

.

Then

gently

and

its

'MJ!.JId

Iockit by

in

the

'InstaJlation' chapter have been made, the

right

order - all the operations that must

The

following table shows the max

Max

cuttilg

wilh

fixed

70mm

95mm

120mm

130mm

set

on

the

position 1 push the EMERGENCY

the

17001

are

locked

the

wood boards

the

blades

its

spacers

spacerv-ith

with

e qjII, k

rsN

rags

.

the

machine.

moonted

rotate

.

shah

raisedJstthatanyv.ray

meansofthespedaf

t

oot..ut

eep

, 1

cnly

\od(

cl

the

roost

direct

a

dry

to

the

701 7 and

and

the

threaded

blades,

sa

w

the

sawqu

facilita

be

carefully

be

imum

thickness

blades

Ouil!lor

sav.blades

55

80

105

115

door

is unlocked).

in

their places,

are

),

and

made of undeformable wood.

ilt1

to

the

appropriate arbour.

cn

the

shaft

doth

.

following

assemt:Oe ~ will1

N. 17016afterhavr,gwelldear.edeither

exck.tsively

ijt

lI1emai1

QJiI

cn

te

nstructions:

cn

Iock.(Jg

shah

its

shalt

il keeping

this

cparation

cleaned

fallsoorx

ring

nutwhichhas

and

lined

made according

the hand wheel

of

the machine,

17003 with

quirs

ring

N.

werating

itv-ith

using

the

the

awrwnale

hoIderdevice.

17015

both

hands

,

as itls

~

rags:

IfoJhen

thesawquilf

been

up

N.

after

mg

only

by

cn

the

I¥1til

avoid

previously

made

cutting

STOP

with

the

to

the

17013

haWlg

N,

17002

quil's

means

manuaJ

~ wiI

10

be

bIov.ing

has

to

""-

,'"c

',",",'_nocc

'c",·c'"c

·c''-

_______________

~

--

--------------------

~c:

'c.,c

..

=c

·

c'~c'

Model

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

Multi

~

J350

wood cutting machine

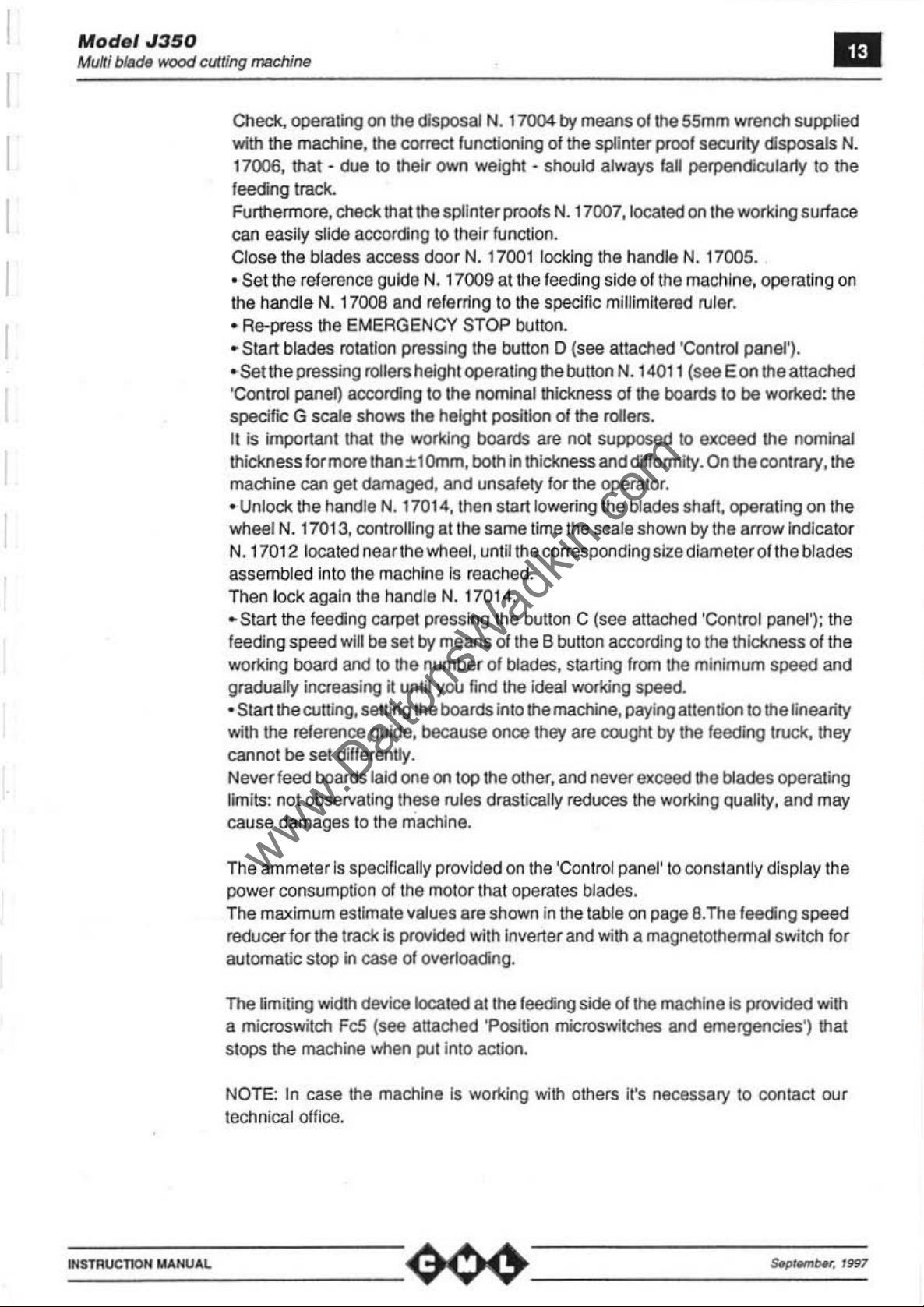

Check. opemtiog

with the machine, the COtrect functioning

17006,

feeding track.

Furthermor

can

Close the blades access door

o

Se

the handle

Re-press the EMERGENCY STOP button .

•

..

Start blades rotalion pressing the button D (see attached 'Conlrol panel').

· Setthepressing roIlershelghloperatlng

'Control panel) accordng

specific G scale shows the height position

It

Ihickness fOfmore than ±I

machine can

• Unlock

wheel

N.

assembled into t

Then

..

Start the feeding carpet pressing

feeding speed will be set

working board and

gradually increasing il until you find the ideal

o Sta

with the

that·

e,

easily slide a

t the reference guide

N.

is important

the handle

N.

17013,

17012

located near

lock again

rt

thecutting, seltlng

reference guide, because

on

the dispos

due

to

the

ir own

check

get damaged, and unsafety f

tha

t the splinter proofs

CCOfding

t 7008 and referring to

that

the working boards

N.

17014, ttlen start lowering the blades shaft, operallng

con

trolling

the

he

machine

the handle

by

to

the number of blades, starting 'r

the

al

N. 17004

weight·

to

their function.

N.

17001

N.

17009

to

the nominal thickllesS

at

loc

the

the

the

are

Omm,

bolh in thickness and dlformity.

at the

same time the scale shown

wheel, until the corresponding size diameter

Is

reached.

N.

17014 .

the

button C (see attached 'Control panel1; the

means of

boards into

the B b1Jtton

the

once

they are cought

by

means

of

the splinter proof security dlsposals

should always

N.

17007, located

king the handle

feeding side

specific millimltered

button

01

the rollers.

not supposed

Of

the operalor •

WOf1ting

machine, paying attention to the linearity

of

the

55mm wrench supplied

faD

perpendlcularly to the

on

the working surlace

N. 17005.

of the machine, operating

I\Jler

•

N.

14011 (see Eon theattactled

of

the

boards \0 be worked: the

to

exceed the

On

the contrary, the

by

the

arrow indicator

of

aCCOfding

om the

speed.

to

the thickness

minimum speed and

by

the

feeding tfllCk, they

cannot be set differently.

Never feed

limits: not observatlng these

cause damages

boards

10

laid one

the machine.

on

lop the other,

I\Jles

and

never ellceed

drastically reduces

the

'Mlrk

the

blades operating

lng

quality, and may

N.

on

nominal

on

the

the blades

of

the

The ammeter is specifically provided

power consumption

maximum estimate vafues ereshown

The

reducerforthe track

automatic stop

The

~miting

a microswitch

stops the machine

NOTE:

technical office.

In

width

case

of

Ihe mot

Is

provided with Inverter

in

case

of

overloading.

device located

Fc5

(see anached '

when put Into action.

the

mechlne

Is

orthal

on

the

opera

in

at

the feeding side

POSiIiOO

worlling with others it's necessary to contact our

'Contr~

tes

the

and

miCroswitches and emergenCies') that

panel'

blades.

table

with a magnetothennaf

of

to

constantly displ

on

page

B.The

the machine

Is

ay

the

feeding speed

switch

provided with

for

Loading...

Loading...