Page 1

CMI | SOP003_rev1.0

1

CMI STANDARD OPERATING

PROCEDURE

Confocal Raman Microscope

Physiology Ground floor research lab

CONTACT

Peter Owens: 091 494036 (office) Peter.owens@nuigalway.ie

Jennifer Connolly: Jennifer.connolly@nuigalway.ie

REQUIREMENTS FOR EQUIPMENT USAGE:

1. CMI user

2. Completion and signing of Microscope Safety Checklist

3. Certification by Peter Owens or Jennifer Connolly

REVISION LOG

INFORMATION:

CMI document ID: SOP003

Revision

1.0

Date

12/5/14

1. Purpose

1.1. This document specifies the work instructions for the CMI Witec Confocal Raman microscope located in

the ground floor Physiology lab, Quadrangle building. If you see an area where more clarification is

needed, if additional information is needed, or if you have suggestions on how to make this guide more

1.2. Note that this document is not a detailed instrument manual and does not intend to be one. For

useful in the lab, please contact the CMI.

detailed questions or if anything unusual happens with the system, please refer to the manuals

present in the lab, or ask CMI personnel for help.

Author

P. Owens

Changes

Initial draft

Page 2

CMI | SOP003_rev1.0

2

2. Scope

These work instructions are applicable to all work that is carried out using the Witec raman microscope.

3. Important notes

3.1 Laser safety guidelines

PLEASE LEAVE ALL HARDCOPIES IN THE LAB

The WITec microscopes uses class 4 633 and 785 nm laser sources during operation. The

safe use of lasers requires that all laser users, and everyone near the laser systems, are aware of the

dangers involved.

CAUTION: Direct eye contact with the output beam from a laser will cause serious damage and possibly

blindness. The 785 nm laser has a high power output, extreme care is needed here when operating the

system.

3.1.1 Make sure the enclosure remains closed during laser scanning and measurement

3.1.2 Always close the laser shutter before opening the door of enclosure

3.1.3 Always wear the safety laser goggle when you want to open the door with laser on for

alignment procedure.

3.1.4 Participation in a Laser safety course is strongly recommended for operating this system.

3.2. Witec Alpha 500 manual (hardcopy in the lab, soft copy on the instrument PC), and training notes

3.3 The CMI access policy, available online at

http://imaging.nuigalway.ie/access%20policy/cmi_access_policy_1.6.pdf

3.4 This manual was developed to assist in the training process of users. Be aware that only the basic

operation details will be presented. Please contact the CMI staff for more assistance if required.

3.5 Changes may occur when a new software version or patch is installed. Please contact the CMI

staff if you are not sure about new features and functions.

3.6 Do not forget to sign in to the log book before you start your measurement.

3.7 Turn on the laser power when you begin, use laser shutter in-between measurements.

Responsibilities

4.

Operators of this equipment are responsible for the following:

4.1 Complying with all safety regulations.

4.2 Compliance with procedures and specifications contained in this document.

4.3 Reporting misuse of the instruments, or in a manner inconsistent with this specification, by any

Page 3

CMI | SOP003_rev1.0

3

personnel, to the supervising CMI staff.

4.4 Maintaining a clean workspace. Food and drink are NOT allowed!

4.5 Reporting any and all maintenance issues/concerns to the supervising CMI staff member

5 Raman overview

Raman spectroscopy is a characterization technique that is widely used in scientific field in recent years. It

actually utilizes the unique Raman spectra for different components as a spectral “finger print” to identify

unknown samples or even further analysis based on the information from the spectra. Raman spectra can be

obtained from various kinds of materials from bulk solids such as paper and cellphone, to nanomaterials such

as thin films and nanoconstructs.

Raman Spectroscopy has many advantages among many characterization techniques, and therefore it is quite

welcome in scientists and laboratory workers. Typically, the samples need little preparation before

characterization and analysis can be carried out through many containers. Raman Spectroscopy is usually not

destructive to samples unless you use too much laser power and focus high-energy laser on a point of the

sample, leading great amount of heat in that small area and thus burning your sample.

In addition, Raman Spectroscopy is typically a fast characterization technique that can perform real-time scan.

It can acquire a Raman spectrum of most substances in seconds via Charge Coupled Device detectors (CCDs)

that have a wide dynamic range for users to select the appropriate exposure time for their sample. Depending

on the raman cross section of the sample of interest, a high resolution scan can be finished in minutes using

the system.

Raman Spectroscopy can do both qualitative and quantitative analysis. Quantitative analysis of the sample is

typically performed by measuring the relative intensities of each peak in the Raman spectrum that are directly

proportional to the relative concentrations of the compounds. Alternatively, chemometric methods can be

used for detailed information and accurate calculation. These quantitative analyses are very sensitive that can

be performed on samples with high concentrations ranging from 90-100% material of interest down to

concentration determination at parts per billion (PPB) levels.

This instruction will guide you to run a Raman spectroscopy scanning step by step and help you obtain your

first Raman spectrum/ image from the WITec Raman Spectroscopy Instrument. It can also be used as a manual

book for laboratory users in case of operational problems and troubleshooting. This instruction is separated

into sections for instrument overview, step by step alignment and calibration check, acquisition, imaging, and

troubleshooting. Readers should follow the procedures in this instruction in order to operate the Raman

instrument properly.

DANGER: Class 4 laser radiation involved during the procedure!

immediately.

Page 4

CMI | SOP003_rev1.0

4

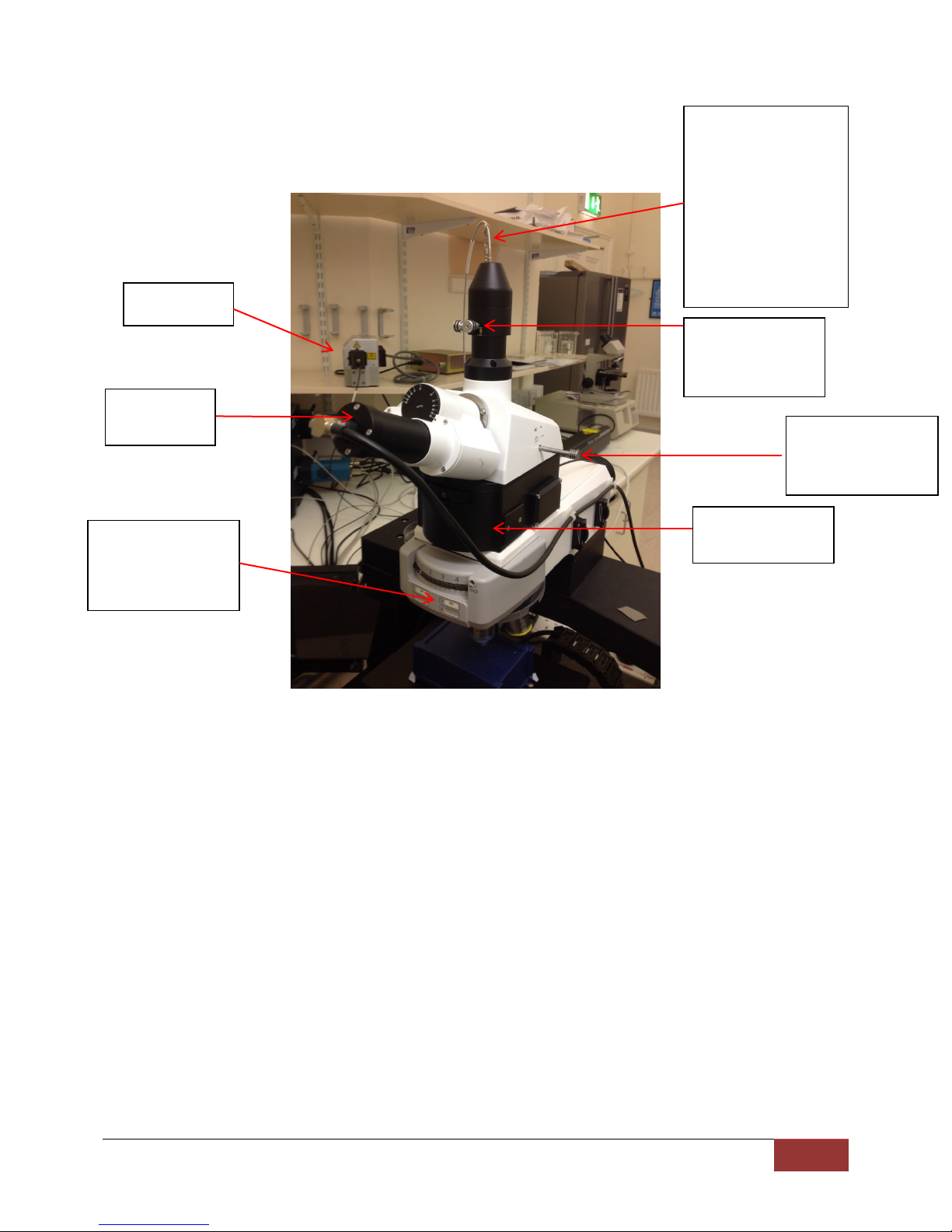

Fibre to detection

Adjustment

alignment

Push/pull rod for

Laser coupler

and filter wheel

Eye piece

camera

785nm laser

Brightfield/DIC/Ra

6 System Overview

man imaging

selection

system. Use 50 micron

fibre for 633 nm, 100

micron fibre for 785nm

excitation, fibre

diameter is part of the

serial number taped on

fibre. Extreme care

needed when handling

screws for

eyepiece/detector

The witec confocal raman microscope consists of the following devices:

6.1 Instrument Control PC, 64 bit running witec control and project software (version 1.6)

6.2 Controller unit.

6.3 Upright microscope with led light source for brightfield work.

6.4 Objectives including a 40x water dipping lens and 100 x air

6.5 Andor CCD cameras

6.6 Witec diffraction gratings for either vis or NIR operation.

6.7 Motorised stage for xyz control

6.8 Fibre optic cable for 633nm use: 50micron diameter

6.9 Fibre optic cable for 785 nm use : 100 micron diameter

Familiarise yourself with the system folders, located on the shelf above the equipment.

7 Start Up Procedure

7.1 Book equipment on CMI web booking system.

7.2 Turn on lasers or individual laser, if only one is to be used. For the 633 laser, turn on the key. For

the 785 nm laser, turn on power first and wait until the green led stops flashing. Then switch the

laser key to ‘on’ and again wait until the green led stops flashing and both yellow and green leds

Page 5

CMI | SOP003_rev1.0

5

are continuously on.

633nm laser

785 nm laser

Modulate

intensity

Diffraction grating

Diffraction grating

CCD camera VIS

CCD camera NIR

Power sockets for

Power to controller

tower

shutter

shutter

7.3 Turn on power to controller if not already on.

7.4 Turn on power to camera(s). Turn on only the one you are planning to use :

for visible spectrum

for NIR spect

camera, inner plug is

for NIR camera

7.5 Turn on PC, login password is ‘biophotonics119’.

7.6 Both the lasers have to be warmed up for at least 30 mins before acquisition; while warming up

alignment of the microscope can be done.

7.7 Click on the ‘Witec Project Control’ to start the raman software interface

laser

Page 6

CMI | SOP003_rev1.0

6

Laser coupler

Filter turret

imaging, spectra

8 Calibration

8.1 Use the silicon wafer for calibration (accepted Raman peak at 521 wavenumbers)

8.2 Choose objective to use and switch to brightfield mode (with edge filter and dichroic mirror off);

beam splitter should be in Bright Field (BF) mode (Pos 1)

Position 1: Brightfield

imaging

Slide rightwards(follow

arrow direction)

Options are block:

Position 2: DIC for

water dipping lens

Position 3: DIC for all

other lenses

Position 4: Raman

8.3 Set the detector knob, at the side of binocular, to the eyepiece mode (and not the camera mode)

8.4 Set the brightness to 100% in the software (‘Illumination’). Make sure to see some intensity

changes in the video image; check it by opening and closing the aperture stop (A) at the

microscope. Typically keep this just slightly open, unless for dim samples/dic imaging.

Open:

Either open , block for

633nm and 785 nm

can be chosen. All

other positions have

no filter , used for

brightfield.

Page 7

CMI | SOP003_rev1.0

7

Push/Pull rod

Eyepiece camera

Aperture stop

Field stop

Up/down: toggle

stage control

X Y Stage controls

Z Stage controls

Speed control :

Changing fibres: gently slide

the cover over the fibre and

rest on side of stand , ensuring

no kinks in fibre, unscrew the

fibre and change to the other

one. Align the raised edge on

the fibre coupling with the slot

on the fixed end then tighten

(hand tight-do not

overtighten)

Replace the black cover

Fully out : light directed to

detector system

Fully in : light directed to

eyepiece camera

8.5 Close the field stop and focus to bring the stage up

applies to either xy

or z. rotate white

circle anticlockwise

to reinitiate control

and increase by

rotating clockwise

8.6 With the remote, select ‘Microscope Z’ control and adjust the focus (in ‘z’); when in focus

between z control, xy

+Z : stage moves

away from objective

-Z: stage moves

towards objective

position, the image of the field stop is sharp in the video control window.

8.7 Fine tune the focus with remote observing the image of the field stop again.

8.8 Then open the field stop to observe the silicon sample.

Page 8

CMI | SOP003_rev1.0

8

8.9 Select the correct Video Viewer (objective) in the Video Control Window and calibrate (using

‘Video Calibration’ button). The rotation should be within -1 and +1 degree. If not, rotate the

camera in the binocular and redo the calibration. Hint: center a piece of dirt or scratch in the

video viewer window and try calibration again if having trouble getting the rotation below 1.

8.10 Turn the roller (at the Raman coupler) to needed laser wavelength (with edge filter off) and

switch on the shutter of the respective laser with minimum power. Adjust the laser power until

the laser spot can be seen in the video image. Move the microscope in ‘z’ to focus the laser until

the laser spot is sharp.

8.11 Select ‘Probe position’ on the laser spot.

8.12 Make sure the correct spectrometer is connected with the camera fibre and the right laser is

selected using the ‘Configuration’ in the taskbar

50 micron fibre : 633nm use

100 micron fibre : 785nm use

It is recommended to calibrate with silicon , if switching between wavelengths, but can be

possible as a quick check just to swap in the fibre cables. Note: Take extreme care when

handling the fibre cables as they can be damaged very easily. Ensure that the raised edge on

the fibre end lines up with slot on the connector before tightening.

8.13 Switch the coupler to laser wavelength with edge filter on.

8.14 Pull out the knob to ‘Camera mode’ (the light propagates through the detection fibre now).

8.15 Remove the beam splitter (set to either position 4) (not BF nor DIC or position 2 (extra DIC optics

filters in that position).

8.16 Start ‘Oscilloscope’, and adjust the power of the laser to get maximum intensity of the 1

Raman band of Silicon at ≈520 rel.cm

-1

st

order

8.17 Adjust fine focus.

8.18 Using the X and Y fibre knob (on top of the laser coupler), get the maximum intensity of the

Raman band; then again adjust the Z focus with objective.

8.19 Redo the above steps till maximum intensity is obtained.

8.20 Record the spectrum for silicon , say 0.5 integration time , verify that the peak intensity is as

expected and in the right place ie 520 rel wavenumbers.

8.21 Close the laser shutter and stop the oscilloscope. Alignment of the microscope is now completed.

Page 9

CMI | SOP003_rev1.0

9

Configuration

Project window all

Video

mode

Probe position

indicator

Data processing drag

Indication of z

Turn on

illumination

Hardware status window

Check

xy stage

Calibrate

button

Set probe

button

and click auto

brightness

speed of

9 Raman Measurements:

position

window

brightfield

display

video image

operations

performed during

the course of this

instance of the

software are stored

here. Rename all

files to meaningfull

names rather than

system generated

control conditions

only – doesn’t do

much

and drop operations

9.1 For in-vitro samples, the cells can be imaged with 633 nm laser and the nanoparticles with 785

nm laser. Saliva, to date has been recorded using 785 nm excitation.

9.2 After point scan or line scan to confirm the SERS signal from Raman reporter, an area of interest

is marked in the bright-field image.

9.3 Using ‘Sum’ filters, a spectrum region of interest can be marked; images specific to that range

will then be mapped by the WITec software. More than one range can be selected, and thus

more than one large area scan images can be constructed from a single large area scan. Eg, For

cells, vibrational bands of C-H stretching around 700 and 1000 wavenumbers can be used for

mapping.

9.4 After selecting the large area scan images with better contrast (between cells and nanoparticles),

data analysis – background correction, cosmic ray removal, basis analysis – can be performed on

large area scan data.

Page 10

CMI | SOP003_rev1.0

10

10 Troubleshooting

10.1 If you cannot see the laser spot – Check if the laser is turned on. Check if the shutter is open.

10.2 If you cannot see the white light – Check if the white light source is turned on (Illumination in

software. If it is turned on, then check if the microscope is set in Raman Mode. If it is in Raman

mode then change it to the eye-camera mode.

10.3 If you see the spectra with full of noise signal – Check for the CCD temperature. It should be

o

C .

-60

Procedure

Shut Down

11

11.1 You can save the experiment parameters for your own scanning recipe by clicking “Save

Project’ in ‘File’.

11.2 Close the laser shutter, switch off the laser power supply.

11.3 Using the remote control, move the sample away from the objective.

11.4 Open the doors. Remove the sample from the stage

11.5 Discard cover slips and glass sides in the red sharps container. This includes BioHazard material.

11.6 CLEAN UP the workplace, and leave it better than you found it.

11.7 Close the software, it will take several minutes to warm up the CCD before the software

fully closes. Log-off the computer. Log out from computer, complete log book.

Page 11

CMI | SOP003_rev1.0

11

12. APPENDIX A - CERTIFICATION: DEMONSTRATION OF SKILLS

Name:

Operation:

Date:

Tested by:

Pass:

Fail:

DEMONSTRATION of SKILLS

Demonstrate system/ software start up and configuration

Demonstrate loading a sample on the microscope

Demonstrate finding the sample, optimizing acquisition and taking spectra

Demonstrate changing the fibre cable during the measurement session

Demonstrate finishing and shutting down system

Where are cover slips, glass slides discarded?

Where are biological samples discarded?

Correct use of lasers and proper handling procedures?

Certification:

SAFETY

VALIDATION

Pass Fail

Trainee Certified by:

Date:

Loading...

Loading...