Page 1

S-D2

OPERATOR’S MANUAL

650132 Lev A

Page 2

Operator’s

316 E. 9th St.

Owensboro, KY 42303

866-835-0690

Fax: 270 -685-6268

www.alcoholtest.com

S-D2

Manual

No part of this work covered by the copyrights hereon may

be reproduced or copied in any form or by any means—

graphical, electronic, mechanical, including photocopying, taping

or information storage and retrieval systems—without

© 2002 by CMI, Inc.

written permission of CMI, Inc.

Page 3

INTOXILYZER® S-D2 Operator’s Manual

INTRODUCTION . . . . . . . . . . . . . . . . . . . 1

PRINCIPLES OF OPERA TION . . . . . . . . . 2

• Instrument Features . . . . . . . . . . . . . 3

Mouthpiece

Sampling Port

“SET” Button

“READ” Button

Alcohol Level Display

Calibration Control

Breath Sampling Lights

Battery

Leather Case

SUBJECT BREATH TEST . . . . . . . . . . . . 7

• Ambient T emperature . . . . . . . . . . . . 7

• Preliminary . . . . . . . . . . . . . . . . . . . . 8

• Detailed Procedure . . . . . . . . . . . . . . 8

Ready Check

SET

Attach Mouthpiece

Instruct the Subject

Take Sample

Observe Display

Discard Mouthpiece

Reset and Wait

CALIBRA TION REQUIREMENTS: USE OF

THE DRY GAS STANDARD . . . . . . . . . . 14

TABLE OF

CONTENTS

Page 4

INTOXILYZER® S-D2 Operator’s Manual

• The Alcohol Standard . . . . . . . . . . . . 14

• The Gas Standard . . . . . . . . . . . . . . . 15

• Using a Dry Gas Standard

at High Altitude . . . . . . . . . . . . . . . . 15

• Altitude Correction Chart . . . . . . . . . . 16

• Use of a Wet-Bath Simulator . . . . . . . 17

CALIBRA TION CHECK PROCEDURE . . . 18

• Detailed Procedure . . . . . . . . . . . . . . 18

Ready Check

SET

Sample the Dry Gas Standard

Read the Display

Reset and Wait

CALIBRATION ADJUSTMENT . . . . . . . . . 21

• The Calibration Control . . . . . . . . . . . 21

• The Dry Gas Calibration Value . . . . . . 21

• Detailed Procedure . . . . . . . . . . . . . . 22

Preliminary

Ready Check

SET

Sample the Dry Gas Standard

Adjust the Display to the Value of the

Dry Gas Standard

Reset and Wait

ROUTINE FIELD SERVICE CHECKS . . . . 27

• Battery Check & Replacement . . . . . . 27

• Sampling System Check . . . . . . . . . 28

• Breath Sampling Light Check . . . . . . . 29

• Test Fuel Cell Switch . . . . . . . . . . . . 31

• Fuel Cell Replacement . . . . . . . . . . . 31

POINTS TO REMEMBER . . . . . . . . . . . . . 32

• Test Procedure . . . . . . . . . . . . . . . . . 32

• Mouthpiece . . . . . . . . . . . . . . . . . . . . 33

• Smoking . . . . . . . . . . . . . . . . . . . . . . 33

• Food and Drink . . . . . . . . . . . . . . . . . 33

• Storage Between Tests . . . . . . . . . . . 33

• Radio Transmitters . . . . . . . . . . . . . . 34

• Physical Shock . . . . . . . . . . . . . . . . 34

INTOXILYZER® S-D2 SPECIFICA TIONS . . 35

Page 5

INTOXILYZER® S-D2 Operator’s Manual

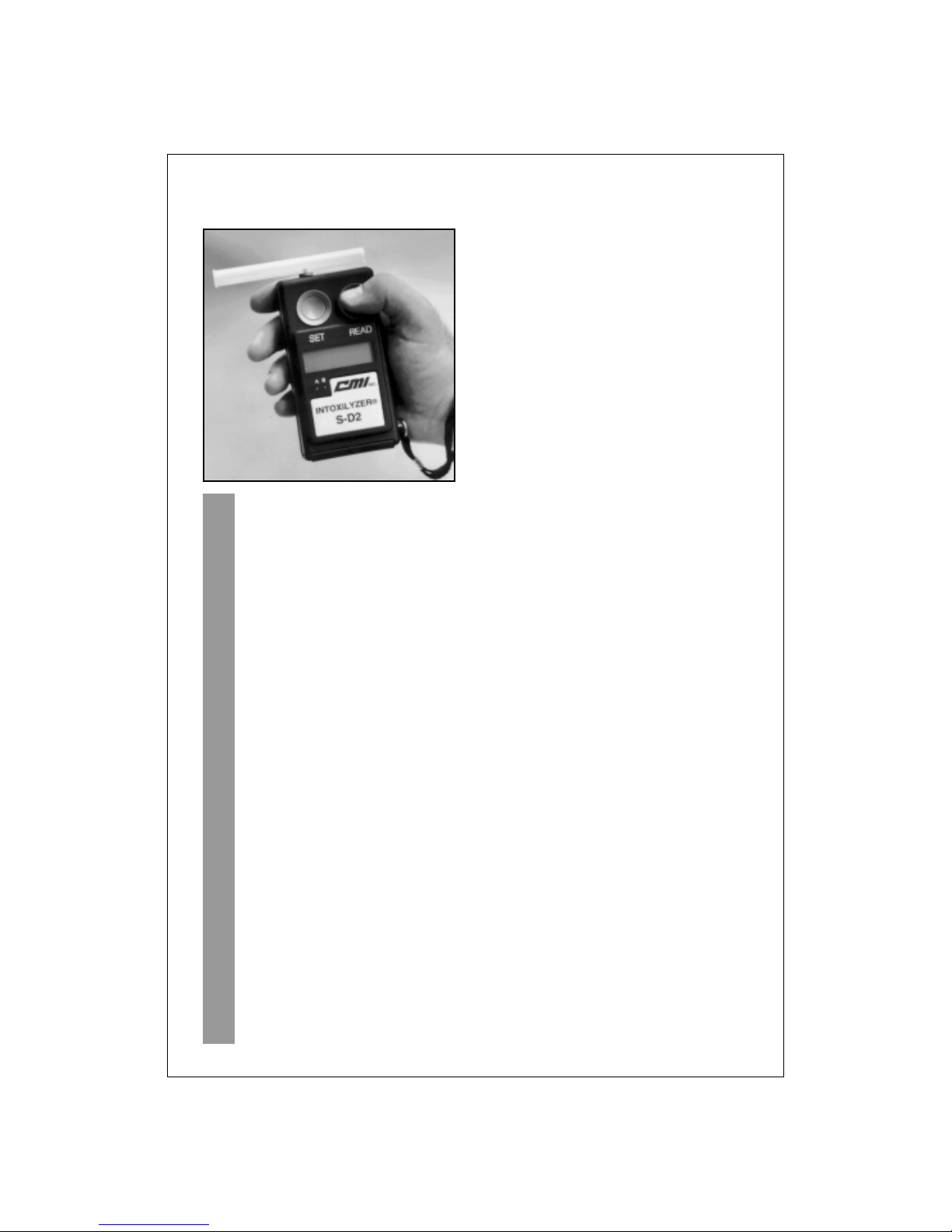

workplace safety applications. The S-D2 is just

one of the range of instruments manufactured by

CMI, Inc. for these purposes.

The Intoxilyzer® S-D2 is accurate and reliable,

allowing a complete breath test procedure to be

conducted in about one minute.

INTRODUCTION

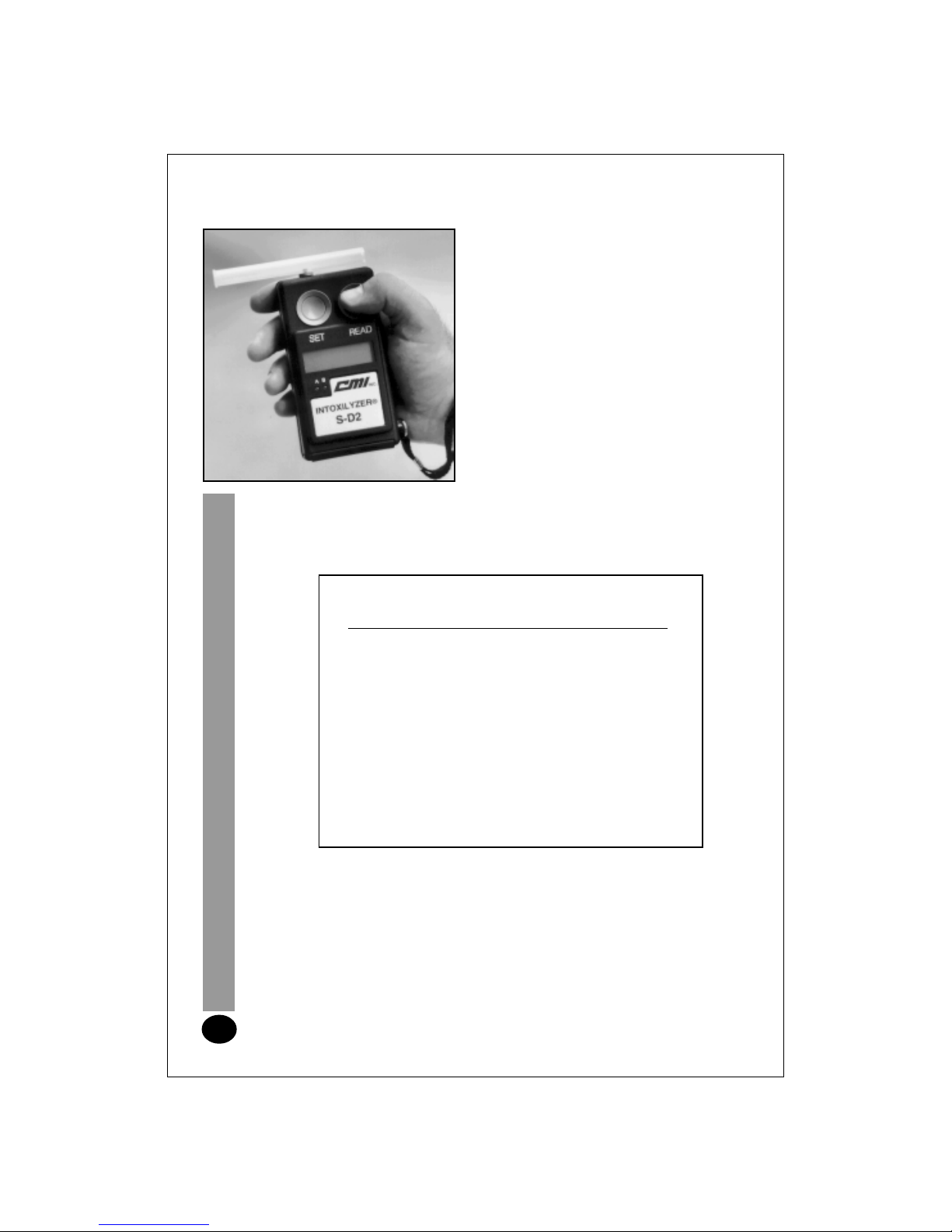

The Intoxilyzer® S-D2

represents a well established

concept in breath alcohol

testing analysis. It is used

worldwide in law enforcement, transportation and

This manual describes the operation,

maintenance, calibration check, and calibration

adjustment of the S-D2. This manual should be

read completely and fully understood by each

operator prior to testing a subject. It is further

recommended that operators practice the breath

testing process before giving an actual “in the

field” test.

The information contained in this manual concerning operational

procedures, protocols, accuracy verification schedules and

techniques is presented solely for the purpose of establishing a

general knowledge of the instrument and its operation. CMI

recognizes that many law enforcement customers have

agencies responsible for specifying instrument procedures,

protocols and techniques based upon their individual needs,

current laws and pre-existing administrative rules. Therefore, if

any such procedure, protocol, schedule or technique described

in this manual conflicts with the rules set forth by a recognized

1

governing agency, CMI defers to those authorized entities.

Page 6

INTOXILYZER® S-D2 Operator’s Manual

PRINCIPLES OF

OPERATION

The Intoxilyzer® S-D2

uses an electrochemical

fuel cell, containing two

platinum electrodes, to

detect and measure the

concentration of alcohol vapor in expired breath.

When breath is drawn into this fuel cell, by means

of the sampling system, a small voltage is

generated in proportion to its breath alcohol

concentration. This fuel cell is fed to an electronic

amplifier and displayed on a digital meter (liquid

crystal).

The S-D2 incorporates two breath sampling lights,

controlled by an interlinked pressure switch and

timer system. The sampling lights show the

operator if the subject is blowing correctly , and

when he has provided a suitable sample of breath

for analysis.

The instrument is simple to operate and may be

used as often as required, provided that a suitable

delay is allowed between successive tests. This

time delay allows the fuel cell to clear itself of

alcohol and prevents the possibility of additive

readings. If no alcohol is present in a test, a

second test may be analyzed immediately , since

the fuel cell voltage is already at zero. Unless the

breath alcohol level of the subject is very high,

2

Page 7

INTOXILYZER® S-D2 Operator’s Manual

the instrument will generally be clear enough to receive

and analyze the second sample in less than two minutes.

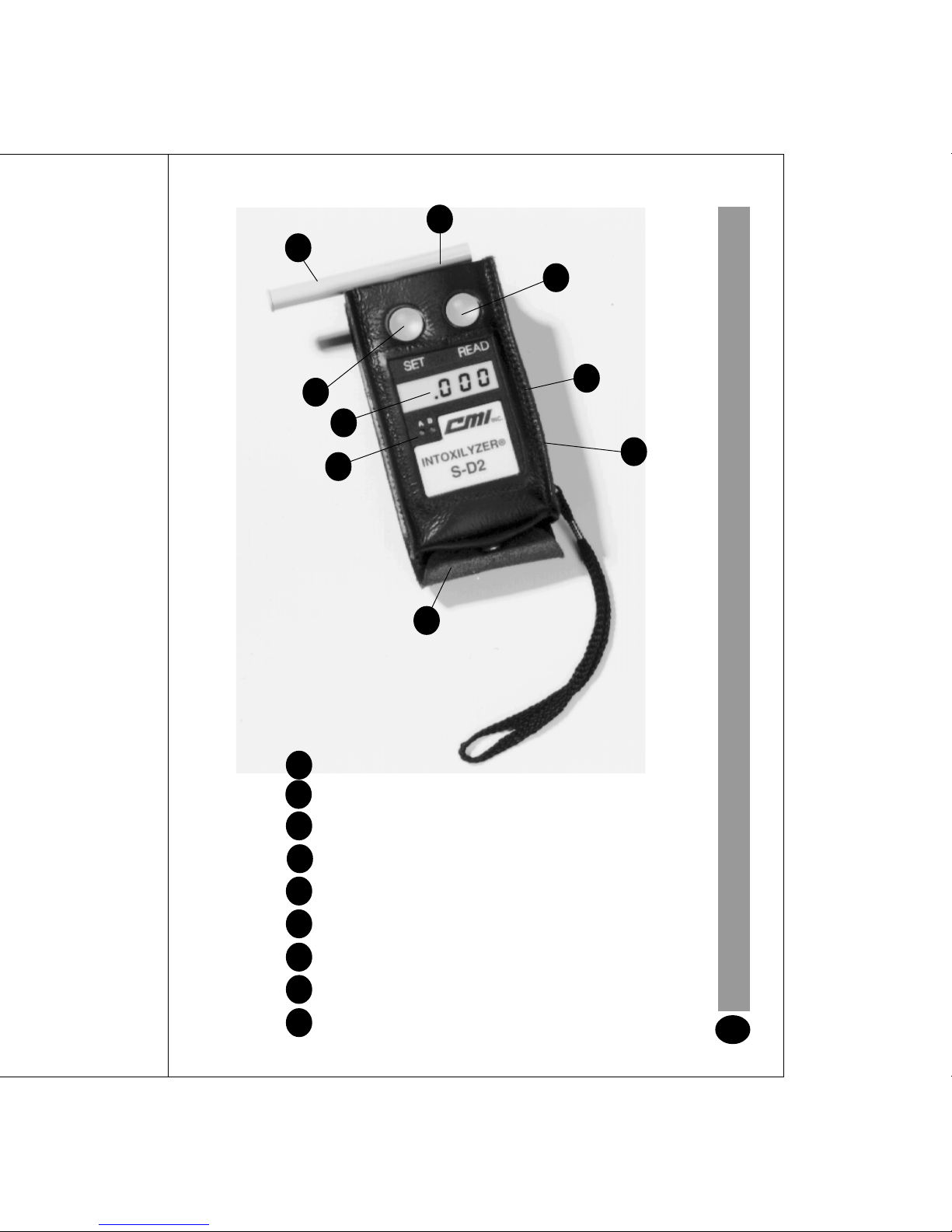

INSTRUMENT FEA TURES

1) Mouthpiece

This is attached to the sampling port. For

hygenic reasons, mouthpieces are supplied

separately packed and are disposable. A new

mouthpiece must be used for each breath test.

This minimizes health concerns and prevents

cross-sample alcohol contamination.

2) Sampling Port

This forms the entrance to the fuel cell detector.

When inserted into the small hole in the side of

the mouthpiece, it allows a small portion of

breath to be drawn into the instrument for

analysis.

3) ‘SET’ Button

This button forms part of the sampling system.

When fully depressed, the button locks to set

the instrument ready for sampling. When the

‘SET’ button rises, the sample to be analyzed

is drawn directly into the fuel cell detector.

4) ‘READ’ Button

This button has two functions:

1) to release the ‘SET’ button and take

the sample,

2) to switch on the amplifier and display

systems

3

Page 8

INTOXILYZER® S-D2 Operator’s Manual

2

1

4

3

5

7

8

INSTRUMENT

FEATURES

1 Mouthpiece

2 Sampling Port

3 ‘SET’ Button

6

9

4 ‘READ’ Button

5 Alcohol Level Display

6 Calibration Control (on side)

7 Breath Sampling Lights

8 Battery (on bottom)

9 Leather Case

4

Page 9

INTOXILYZER® S-D2 Operator’s Manual

The ‘READ’ button is spring loaded.

Momentary depression will take the breath

sample. Constant pressure is required to

switch on the amplifier and display systems.

5) Alcohol Level Display

This three digit, liquid crystal display shows

the breath alcohol concentration of the subject.

The display has built-in illumination and is

activated by depressing the ‘READ’ button.

If the figure on the left shows ‘L ’ when the

‘READ’ button is depressed, the battery needs

to be replaced.

6) Calibration Control

This screw control, located on the right side of the

case, is used for periodic calibration adjustments

with either a dry gas standard or wet bath

simulator.

7) Breath Sampling Lights

Light ‘A’ illuminates to indicate that the subject

is blowing hard enough to obtain a proper breath

sample. Light ‘B’ illuminates when the subject

has blown long enough and indicates when the

‘READ’ button should be pressed. In other

words, light ‘B’ illuminates when the subject has

provided a suitable sample for breath analysis.

8) Battery

The battery is located directly behind the sliding

base on the bottom of the S-D2. It powers the

amplifier, digit al display and sampling lights and

5

Page 10

should be replaced when the letter ‘L’ appears on

the left side of the display .

9) Leather Case

The S-D2 is supplied in a leather protective case.

The unit should be kept inside the case at all

times, except when calibrating, changing the

battery or during maintenance.

INTOXILYZER® S-D2 Operator’s Manual

6

Page 11

INTOXILYZER® S-D2 Operator’s Manual

basic steps. These should be understood and

followed to insure maximum efficiency of operation.

OPERATION CHECK LIST

SUBJECT

BREATH

TEST

The operating sequence for

testing a subject with the

Intoxilyer® S-D2 is simple,

consisting of the following

1. Ready Check

2. Set

3. Attach Mouthpiece

4. Instruct the Subject

5. Take Sample

6. Observe Reading

7. Remove and Discard Mouthpiece

8. Reset and Wait

AMBIENT TEMPERA TURE

The Intoxilyzer

32-104° degrees Fahrenheit (0-40° Celsius) temperature

range. Keeping the instrument within this range insures

minimum condensation of alcohol and water from the

®

S-D2 is designed primarily for use in the

7

Page 12

INTOXILYZER® S-D2 Operator’s Manual

breath and permits both accurate and rapid breath alcohol

measurements.

It is recommended that in very cold weather the

instrument is stored in a pocket (preferably inside a coat)

and returned there after use.

PRELIMINARY

Ask the subject when he/she last took anything by mouth.

Some foods and even “non-alcoholic” drinks may contain

traces of alcohol, which the subject may later claim

affected the result of the test through a “mouth alcohol”

effect. To prevent this, wherever possible, insure that a

delay of about 20 minutes has elapsed since the subject

took anything by mouth—even medicines which may

contain alcohol.

Do not even allow the subject a glass of water prior to the

test since this will cool the mouth and dilute the saliva,

temporarily reducing the amount of alcohol in the breath,

and, consequently , the instrument reading.

Insure that no radio transmitter is currently being used in

the immediate vicinity of the test.

DET AILED PROCEDURE

This section describes in detail how the Intoxilyzer

®

S-D2 is used in a breath test and examines what is

actually happening at each stage of the operation. These

instructions are also given in the form of a checklist on the

card which accompanies the instrument as well as in the

“Introduction” section of this operator’s manual.

1) READY CHECK

The instrument should first be checked to insure it is

ready to receive a sample. This is accomplished by

8

Page 13

INTOXILYZER® S-D2 Operator’s Manual

checking to insure the fuel cell is discharged and free of

alcohol from any previous sample. Elimination of alcohol

from the fuel cell should take no longer than two

minutes—except in unusual cases—depending on how

much alcohol was actually present in the last sample.

To conduct a READY CHECK, depress the ‘READ’ button

and hold it down for at least ten seconds. This

will release the ‘SET’ button and switch on the amplifier

and display circuits. Observe the display; it should not

exceed .002 after ten seconds. If the display does not

show .002 or less during the ten second READY CHECK,

the fuel cell may have traces of residual alcohol from a

previous sample. If this occurs after a previous test,

depress the ‘SET’ button to lock and wait one minute

before repeating the READY CHECK. If the left digit

shows ‘L’, replace the battery.

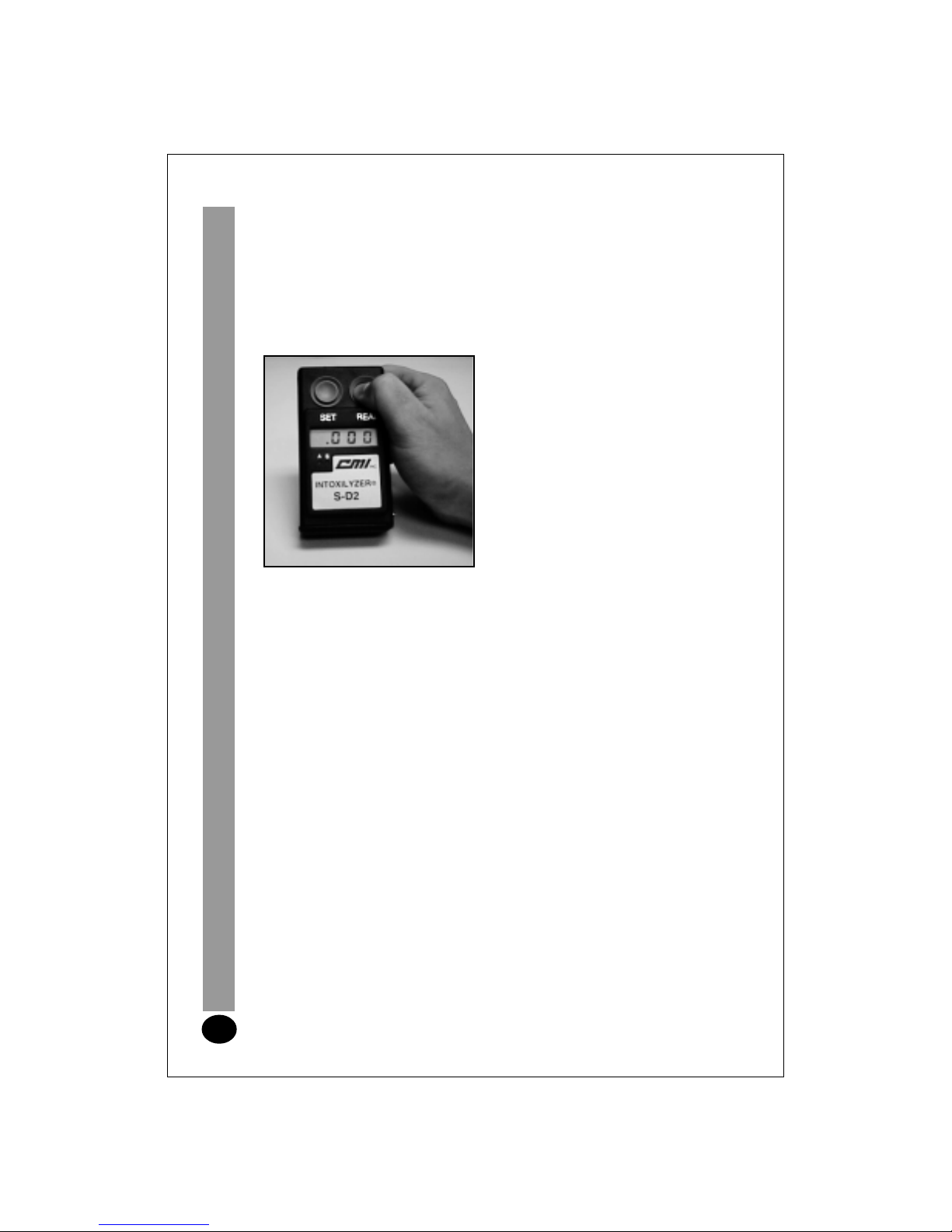

To complete the READY

CHECK, depress the

‘READ’ button for at least

ten seconds.

2) SET

Once the READY CHECK is complete, the sampling

system must now be SET to prepare it to draw a breath

sample into the fuel cell for analysis. Press down the

‘SET’ button until it locks. This pushes down the

diaphragm and holds it against a spring-loaded catch.

This action also places a short-circuit across the fuel cell,

9

which accelerates its inter-sample recovery time.

Page 14

INTOXILYZER® S-D2 Operator’s Manual

Press the ‘SET’

button until it

locks.

3) ATTACH MOUTHPIECE

Attach a mouthpiece to the sampling port on the top of the

S-D2. This sampling port forms the entrance to the fuel

cell and pressure switch and it is essential that the

mouthpiece is pushed fully onto it.

The subject must be offered the wide-bore, lipped end of

the mouthpiece to blow through. If the subject blows into

the other end, the pressure switch will not be activated

and the sampling lights will not operate. The instrument

Firmly

attach

a new

mouthpiece

to the

sampling

port.

10

Page 15

INTOXILYZER® S-D2 Operator’s Manual

is now ready to receive a breath sample from the subject

for analysis.

A WORD ABOUT MOUTHPIECES...

The S-D2’s sampling port is designed specifically

for the particular S-D2 mouthpieces sold by CMI,

Inc. It is strongly recommended that

mouthpieces for the S-D2 be ordered from CMI

at 1-866-835-0690.

4) INSTRUCT THE SUBJECT

Instruct the subject exactly what must occur to provide a

suitable sample of breath for analysis. Tell the subject to

take a deep breath, blow strong enough to bring on light ‘A’

and keep blowing at that pressure long enough to bring on

light ‘B’. The subject must then continue blowing until

told to stop and you have taken the sample by pressing the

‘READ’ button. Warn the subject that if both sampling

lights fail to come on, there will not be a suitable sample of

breath for analysis.

11

If the subject blows too hard then he/she may run out of

breath before the ‘B’ light comes on: just a moderate

breath flow rate is required.

Finally , the subject should keep hands away from the

instrument. If the subject clasps it, your view of the

sampling lights or your operation of the sampling

mechanism could be obstructed .

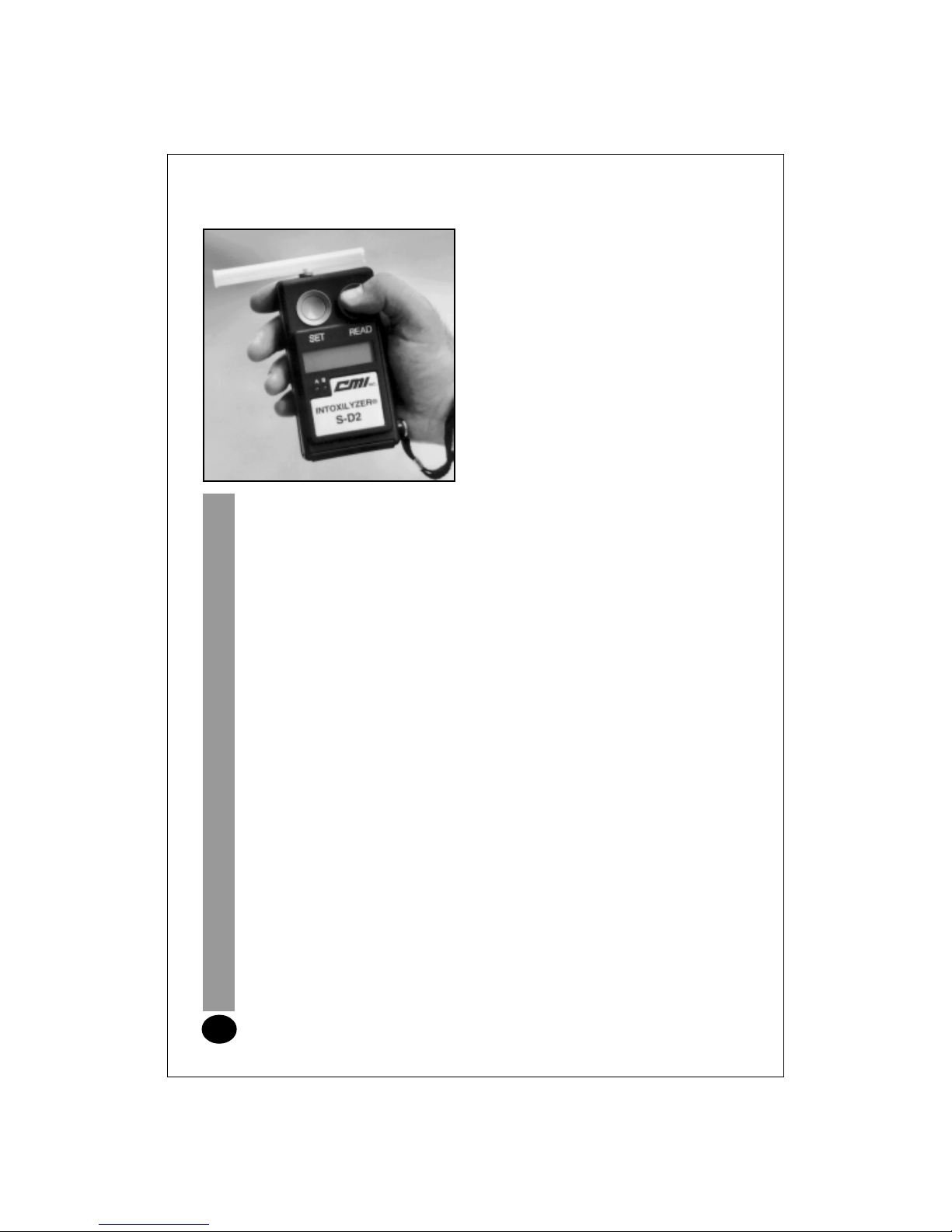

5) TAKE SAMPLE

T ell the subject to t ake a deep breath and blow through the

wide-bore, lipped end of the mouthpiece. The subject

must blow strongly enough to bring on sampling light ‘A’

and then continue to blow at this pressure until the ‘B’ light

is activated. At this point, the subject will have expelled

top lung air so that deep lung air is now being blown

Page 16

INTOXILYZER® S-D2 Operator’s Manual

The subject

blows until light

‘B’ is activated.

The operator

then pushes the

‘READ’ button.

through the mouthpiece. Press the ‘READ’ button to

release the catch holding down the ‘SET’ button,

allowing it to rise. This pulls up the diaphragm, drawing

a small portion of breath from the mouthpiece directly

into the fuel cell detector.

It is imperative that the subject is still blowing when the

sample is taken. Both sampling lights must be on when

the sample is taken. The subject must, therefore,

continue blowing until told to stop. If the subject stops

blowing prematurely , the sampling lights will go out.

6) OBSERVE DISPLAY

Withdraw the instrument from the subject and continue

to hold down the ‘READ’ button. The fuel cell now

develops its signal, which takes about 30 seconds to

complete from the time of sampling. The maximum

sample reached is a measure of the amount of alcohol in

the breath sample.

As the fuel cell charges, it will cause the display reading

to rise. The final value will be displayed after 20-30

seconds and is the alcohol concentration of the subject.

If the ‘READ’ button is accidentally released during this

time, the fuel cell signal will not be affected as long as the

‘SET’ button is not depressed. Simply re-press the

12

Page 17

INTOXILYZER® S-D2 Operator’s Manual

0

20

30

The fuel cell will

take 20-30 seconds

to reach its

maximum voltage

and produce a final

reading.

‘READ’ button within the 30 second signal development

time to continue reading the alcohol level on the digital

display .

It is important that the ‘SET’ button is not touched

during the reading development time. This would

flush the alcohol from the cell and partly discharge its

voltage and reduce the alcohol level.

13

7) DISCARD MOUTHPIECE

Having completed the test and observed the alcohol

reading, you should now remove and discard the

mouthpiece. Never use the same mouthpiece for

subsequent tests, on either the same or different subjects.

8) RESET AND WAIT

The instrument must now be RESET so it will be ready for

another test. This RESET is done by depressing the ‘SET’

button until it locks. This flushes out the fuel cell and shortcircuits its electrodes, allowing its voltage to return more

quickly to zero.

If the display shows .003 or higher as a result of the test, it

may take several minutes before a satisfactory READY

CHECK can be obtained before re-use of the S-D2.

Page 18

INTOXILYZER® S-D2 Operator’s Manual

CALIBRATION

REQUIREMENTS:

USE OF THE

DRY GAS

STANDARD

The Intoxilyzer® S-D2 uses an electrochemical fuel

cell to detect and measure the concentration of

alcohol in expired breath. The sensitivity of the

instrument changes slowly with time, due to aging

of the platinum electrode within the fuel cell. This

change in sensitivity is very slight and calibration

will not normally change significantly over a six

month or longer period.

Monthly calibration checks are recommended to

determine when calibration adjustment is needed.

Either a dry gas standard or wet-bath simulator

may be used to generate the standard alcohol

vapor required.

THE ALCOHOL STANDARD

Calibration checks and adjustments can be

conveniently done using a dry gas standard. This

consists of a mixture of alcohol in air or nitrogen.

The quantity of alcohol in the gas is accurately

known and is shown on the label. Therefore, when

14

Page 19

INTOXILYZER® S-D2 Operator’s Manual

the instrument is calibrated using a dry gas standard,

subsequent breath tests will indicate the subject’s blood

alcohol concentration (BAC).

Dry gas standards are supplied in one of three ranges,

each range based around a legal limit which is in wide use:

.045% BAC, .085% BAC and .105% BAC.

THE GAS ST ANDARD

The gas canister is a high-pressure, disposable cylinder

fitted with a regulator. It cont ains enough gas for

approximately 300 calibration checks or adjustments.

The label on each cylinder is marked with an expiration

date. The gas should not be used after that time due to

deviation of alcohol concentration of the gas mixture

outside the analytical specifications of the instrument. The

value shown on the label is within 2% of the true value of

the gas mixture.

15

When the cylinder is empty or time-expired, the regulator

can be safely unscrewed from the cylinder and retained for

use with a new cylinder. The old cylinder can then be

disposed or recycled.

USING A DR Y GAS STANDARD AT HIGH AL TITUDE

The concentration of alcohol in the dry gas standard is

calculated and carefully controlled to give the correct vapor

concentration when the cylinder is used at sea level at

normal atmospheric pressure. At lower atmospheric

pressures, the concentration of alcohol in the vapor leaving

the cylinder will be less. The change in alcohol

concentration due to normal atmospheric pressure changes

at sea level is so small as to be negligible, but if the dry gas

standard was used at a high altitude, significant errors

would result if suitable corrections were not made.

It should be emphasized that the sensitivity of the S-D2

Page 20

INTOXILYZER® S-D2 Operator’s Manual

ALTITUDE CORRECTION CHART

Elevation from Sea Level Correction Factor

0 1.000

500 .981

1000 .962

1500 .943

2000 .925

2500 .907

3000 .889

3500 .872

4000 .854

4500 .837

5000 .820

5500 .804

6000 .787

6500 .771

7000 .755

7500 .740

8000 .724

16

Page 21

INTOXILYZER® S-D2 Operator’s Manual

itself to alcohol is not affected by changes in atmospheric

pressure; it is only the concentration of the alcohol in the

vapor from the dry gas standard that is affected.

The Altitude Correction Chart on the preceding page gives

the correction factors which should be applied to the stated

dry gas value when calibration checks or adjustments are

made at various altitudes above sea level.

Correction factor sample:

Suppose the dry gas standard you are using

has a value of .045% BAC at sea level, but

it is being used at an altitude of 500 feet.

Using the chart on page 16, the correction

factor would be (0.981). Therefore, the

corrected value of the dry gas standard

would now be (.045 x .981 = .044% BAC).

17

USE OF A WET BATH SIMULA TOR

If required, a wet bath simulator can be used instead of a

dry gas standard to perform calibration checks and

adjustments on the S-D2.

A wet bath simulator should be used according to its own

instructions. Pay particular attention to the alcoholic

strength and temperature of the solution used.

A mouthpiece should be attached to the simulator outlet for

direct attachment to the sampling port on the instrument.

A flow rate of air of about 1.5-2 liters per second should be

used. Any higher rate may result in the formation of an

aerosol and lead to excessive cooling of the solution itself.

The simulator vapor must be allowed to pass through the

mouthpiece for at least ten seconds before the sample is

taken for analysis.

Page 22

INTOXILYZER® S-D2 Operator’s Manual

CALIBRATION

CHECK

PROCEDURE

The calibration check

procedure insures that the

Intoxilyzer® S-D2 is

reading alcohol levels

correctly and alerts the operator that a calibration

adjustment is needed.

CALIBRATION CHECK

CHECKLIST

1. Ready Check

2. Set

3. Sample the Standard

4. Read the Display

5. Reset and Wait

DET AILED PROCEDURE

It is recommended that a calibration check be

performed at least once every month.

To insure that the instrument’s fuel cell is at its

optimum sensitivity , there should be no breath tests

done on the unit in the previous ten minutes before

a calibration check is done.

18

Page 23

INTOXILYZER® S-D2 Operator’s Manual

1) READY CHECK

This insures that the instrument is ready to take a sample

of the dry gas standard and tests whether the fuel cell is

completely discharged and free of alcohol from a previous

sample. It also insures that the battery has sufficient power

to drive the electronic circuitry .

Press the ‘READ’ button and hold down for at least ten

seconds. This will release the ‘SET’ button and activate

the electronics. During these ten seconds, the display

should not read more than .002. A higher reading shows

that alcohol may still be present in the fuel cell. If this

occurs, depress the ‘SET’ button to lock, wait one minute

and repeat the ten-second READY CHECK.

If the letter ‘L’ is displayed, replace the unit’s battery.

2) SET

19

Assuming the READY CHECK has been completed,

depress the ‘SET’ button to lock. This prepares the

instrument to sample the dry gas standard.

3) SAMPLE THE DRY GAS STANDARD

Follow the procedure below to sample the standard:

a) Use a new mouthpiece and attach its

lipped end to the outlet on the regulator

button.

b) Insert the S-D2’s sampling port into the hole

on the mouthpiece.

c) Hold the instrument with your thumb

near the ‘READ’ button.

d) Depress the regulator button so that gas

begins flowing through the mouthpiece.

e) After about five seconds of continuous gas

flow, AND WHILE GAS IS STILL

Page 24

INTOXILYZER® S-D2 Operator’s Manual

FLOWING, press the ‘READ’ button which

draws a sample of gas into the unit.

Continue to hold down the ‘READ’ button.

f) When the sample has been taken, release

the regulator button to stop the gas flow.

IT IS ESSENTIAL THAT THE GAS IS STILL

FLOWING WHEN THE ‘READ’ BUTTON IS

PUSHED.

4) READ THE DISPLAY

Disconnect the instrument from the mouthpiece—

continuing to hold down the ‘READ’ button—and observe

the display . The value shown on the S-D2 should rise

steadily and then stop, about 20-30 seconds from the time

the sample was initially “taken”.

If the final reading is within ±.005% BAC of the known value

of the gas standard, the instrument is calibrated properly

and no adjustments are needed.

If the maximum reading displayed shows a deviation from

the value of the standard, then calibration adjustment is

required, which is outlined in the next section.

5) RESET AND WAIT

After the final alcohol reading is noted, depress the ‘SET’

button to lock. This allows the fuel cell to clear itself of

alcohol before using the instrument for more tests. This will

take approximately two minutes.

20

Page 25

INTOXILYZER® S-D2 Operator’s Manual

calibration compensates for any change in sensitivity of

the fuel cell detector over a period of time. Calibration

adjustment should not normally be required more than

two or three times per year.

It is very important that this section be read and

understood completely before attempting to recalibrate

the S-D2.

CALIBRATION

ADJUSTMENT

Calibration adjustment is

required when a calibration

check indicates the S-D2 has

deviated from a known

standard of alcohol vapor .

Adjusting the S-D2’s

21

THE CALIBRA TION CONTROL

Calibration is done by using the small screw adjustment

located on the right side of the instrument. It is

accessed through a hole in the S-D2’s outer case.

Turning the control clockwise decreases the reading on

the alcohol level display in response to the sampling of

the gas standard.

THE DRY GAS CALIBRA TION V ALUE

Since the fuel cell detector responds linearly to the

concentration of alcohol vapor in the standard, the actual

value of the dry gas standard used for calibration is not

important, provided that the instrument is actually

calibrated to this value.

Page 26

INTOXILYZER® S-D2 Operator’s Manual

CALIBRA TION ADJUSTMENT

CHECKLIST

1. Preliminary

2. Ready Check

3. Set

4. Sample the Dry Gas Standard

5. Adjust the Display to the Value of

the Dry Gas Standard

6. Reset and Wait

DET AILED PROCEDURE

The calibration adjustment process assumes three

conditions:

• The instrument has not analyzed more than

two samples containing alcohol within the

previous hour or any sample within the

previous ten minutes,

• The instrument is in its normal operating

temperature range, and

• The battery does not need replacement.

1) PRELIMINARY

The instrument must first be removed from its protective

leather pouch. Remove the wrist strap by detaching the

split ring from the metal pillar . Then, insert the

screwdriver included with the S-D2 into the hole in the

pouch and ease the leather upwards taking care to

prevent the pillar from catching on the pouch. At the

same time, push the instrument upwards from the

bottom of the pouch, easing the pillar under the edges of

the hole.

22

Page 27

INTOXILYZER® S-D2 Operator’s Manual

2) READY CHECK

This insures that the instrument is ready to take a sample

of the dry gas standard and tests whether the fuel cell is

completely discharged and free of alcohol from a previous

sample. It also insures that the battery has sufficient power

to drive the electronic circuitry .

Press the ‘READ’ button and hold down for at least ten

seconds. This will release the ‘SET’ button and activate

the electronics. During these ten seconds, the display

should not read more than .002. A higher reading shows

that alcohol may still be present in the fuel cell. If this

occurs, depress the ‘SET’ button to lock, wait one minute

and repeat the ten-second READY CHECK.

If the letter ‘L’ is displayed, replace the unit’s battery.

3) SET

23

Assuming the READY CHECK has been completed,

depress the ‘SET’ button to lock. This prepares the

instrument to sample the dry gas standard.

Perform a

READY

CHECK and

then SET the

instrument.

0

10

20

Page 28

INTOXILYZER® S-D2 Operator’s Manual

Sample the dry gas standard.

4) SAMPLE THE DRY GAS STANDARD

Follow the procedure below to sample the standard:

a) Use a new mouthpiece and attach its

lipped end to the outlet on the regulator

button.

b) Insert the S-D2’s sampling port into the

hole on the mouthpiece.

c) Hold the instrument with your thumb

near the ‘READ’ button.

d) Depress the regulator button so that gas

begins flowing through the mouthpiece.

e) After about five seconds of continuous gas

flow, AND WHILE GAS IS STILL

FLOWING, press the ‘READ’ button

which draws a sample of gas into the unit.

Continue to hold down the ‘READ’ button.

f) When the sample has been taken, release

the regulator button to stop the gas flow.

IT IS ESSENTIAL THAT THE GAS IS STILL

FLOWING WHEN THE ‘READ’ BUTTON IS

PUSHED.

24

Page 29

INTOXILYZER® S-D2 Operator’s Manual

5) ADJUST THE DISPLAY TO THE VALUE OF THE

DRY GAS STANDARD

Continue to hold down the ‘READ’ button and turn the

calibration control screw on the right side of the S-D2

counter-clockwise until, after about ten seconds, the

display reading exceeds the value of the dry gas

standard. As the display rises still further, due to

continued charging of the fuel cell, turn the control

clockwise to maintain the display at the dry gas

standard value. As the fuel cell reaches its peak

voltage, the control will require no further adjusting.

The instrument is now calibrated. Do not turn the

control to increase the reading once the display (fuel

cell voltage) has passed its peak reading.

0

10

20

25

Adjust the

display slightly

counterclockwise to

exceed the dry

gas standard

value.

0

20

30

Turn the screw

slightly clockwise

to hold the

display at the dry

gas standard

value.

Page 30

INTOXILYZER® S-D2 Operator’s Manual

If the display reading cannot be brought up to the

dry gas standard value, the fuel cell has reached the

end of its life and should be replaced. See the next

section for more information.

6) RESET AND WAIT

After the final alcohol reading is noted, depress the ‘SET’

button to lock. This allows the fuel cell to clear itself of

alcohol before using the instrument for more tests. This

will take approximately two minutes.

26

Page 31

INTOXILYZER® S-D2 Operator’s Manual

the following checks at monthly intervals will insure that

your S-D2 is in proper working order with regard to its

other functional systems.

BA TTERY CHECK AND REPLACEMENT

ROUTINE

FIELD SERVICE

CHECKS

Although the calibration check

procedure shows whether the

instrument reads the dry gas

standard correctly , performing

27

If, when the ‘READ’ button is depressed fully down, the

left digit on the display shows the letter ‘L’, then the

battery is low in voltage and must be replaced. The

battery compartment is at the base of the instrument,

Insure that the

new 9-volt

battery is

correctly

connected to

the contacts.

Page 32

INTOXILYZER® S-D2 Operator’s Manual

which must be removed from its protective pouch to

change its battery . The S-D2 requires one 9-volt battery.

First, remove the wrist strap by detaching the split ring from

the metal pillar . Then, insert the screwdriver included with

the S-D2 into the hole in the pouch and ease the leather

upwards as to prevent the pillar from catching on the

pouch. At the same time, push the instrument upwards

from the bottom of the pouch, easing the pillar under the

edges of the hole. Access to the battery is obtained by

sliding away the cover at the base of the instrument. When

replacing the battery , be sure to separate the contact

carefully and insure that the replacement battery is securely

connected and fitted inside its compartment inside the

instrument. After the battery is in place, the cover and

protective pouch can be reinstalled.

SAMPLING SYSTEM CHECK

A simple routine check on the operating ef ficiency of the

sampling system may be done by the following steps:

a) Press the ‘SET’ button to lock in the down

position and place a forefinger tightly over

the sampling port forming an airtight seal.

b) Press the ‘READ’ button fully down and

observe the ‘SET’ button. It should not rise

since air cannot be drawn into the system.

If the ‘SET’ button DOES rise at this time,

then there is probably a leak in the system,

and a qualified technician should be

consulted. Remove your finger from the

sampling port and the ‘SET’ button should

immediately rise. If the ‘SET’ button rises

slowly after you remove your finger from the

sampling port, the sampling system may

be blocked, and the instrument should be

returned to a qualified technician.

DO NOT , FOR ANY REASON, COVER THE SAMPLING

PORT AND FORCE DOWN THE ‘SET’ BUTT ON FROM

28

Page 33

INTOXILYZER® S-D2 Operator’s Manual

ITS UP POSITION. THIS WOULD RUPTURE THE

SAMPLING DIAPHRAGM OR FUEL CELL

ELECTRODE AND NECESSITA TE THE

REPLACEMENT OF EITHER OR BOTH OF THESE

P ARTS.

Check the

S-D2’s sampling

system by 1)

pressing the

‘SET’ button to

the locked

position and

placing a

forefinger over

the sampling

port. 2) Press

the ‘READ’

button down

and observe the

‘SET’ button,

which should

not rise.

BREA TH SAMPLING LIGHT CHECK

This procedure checks the operation of the breath

pressure switch and the timing and operation of the

breath sampling lights:

29

Page 34

INTOXILYZER® S-D2 Operator’s Manual

a) Insure that the ‘SET’ button is in the

locked down position.

b) Place a forefinger over the sampling port

and apply continuous pressure to the

‘SET’ button. This should activate the

pressure switch and cause sampling

light ‘A’ to illuminate, followed by light

‘B’ approximately 2½ seconds later .

Check the S-D2’s

sampling lights

by 1) locking the

0

SECONDS

‘SET’ button,

and then 2)

placing a

forefinger over

the sampling

port and

applying

continuous

pressure to the

‘SET’ button.

The ‘A’ light

should activate,

followed about

2½ seconds later

by the ‘B’ light.

SECONDS

0

2½

30

Page 35

INTOXILYZER® S-D2 Operator’s Manual

TEST FUEL CELL SWITCH

When an alcohol sample has been taken, the reading

is cleared from the display and fuel cell recovery is

accelerated by depressing the ‘SET’ button. This

short circuits the fuel cell electrodes and accelerates its

discharge; immediate discharge is not generally

possible since alcohol will still be present on the

electrode surface.

To test and insure that this circuiting switch is working

properly , the following procedure should be done:

a) Take a sample of dry gas standard into

the S-D2.

b) Hold down the ‘READ’ button and

observe the display as it starts to

increase to the standard value. While

still holding down the ‘READ’ button,

press the ‘SET’ button fully down—you

will be holding both buttons down

at the same time. This should cause the

display to reset to .000.

c) Allow the instrument to clear before using

for further breath tests.

31

If the fuel cell reset switch test fails, the instrument

should be returned to an authorized agent for

inspection and repair .

FUEL CELL REPLACEMENT

When the fuel cell has reached the end of its working

life, as seen by the inability to calibrate the instrument

(see previous section), the complete instrument should

be returned to the manufacturer for a replacement fuel

cell to be fitted.

Page 36

INTOXILYZER® S-D2 Operator’s Manual

POINTS

TO

REMEMBER

The following

information, if applied to

the operation of your SD2, will help prevent any

problems.

TEST PROCEDURES

Learn the operating sequence thoroughly , and with a

little practice, you will soon be completing tests in a

little more than one minute:

1. Ready Check

2. Set

3. Attach Mouthpiece

4. Instruct the Subject

5. Take Sample

6. Observe Display

7. Discard Mouthpiece

8. Reset and Wait

READY CHECK

Each breath test must be preceded by a satisfactory

READY CHECK.

MOUTH ALCOHOL

Twenty (20) minutes should p ass between the

32

Page 37

INTOXILYZER® S-D2 Operator’s Manual

consumption of alcohol and a breath test using the

S-D2. This period allows for any “mouth alcohol” to be

dispersed.

MOUTHPIECE

Use a new mouthpiece for every test and insure that the

subject blows through the lipped edge, wide-bored end.

It is strongly recommended that only mouthpieces from

CMI, Inc. be used.

SMOKING

Smoking just prior to a breath test will not influence the

result, but tobacco smoke should not be blown through

a mouthpiece attached to the instrument. Tobacco

smoke could damage the fuel cell.

FOOD AND DRINK

33

Do not allow the subject to eat or drink before a breath

test. Although this will not generally af fect the result of

the analysis, certain cough drops may contain alcohol.

A subject could later claim that the cof fee to calm his

nerves was laced with something stronger causing a

high blood alcohol concentration.

STORAGE BETWEEN TESTS

Always store the S-D2 with the ‘SET’ button down.

This will keep the cell discharged so that the instrument

is always ready for a breath test, provided that a

satisfactory READY CHECK was obtained prior to

taking the sample.

Avoid storing the unit in temperature extremes.

Page 38

INTOXILYZER® S-D2 Operator’s Manual

RADIO TRANSMITTERS

Do not use the S-D2 in close proximity to radio

transmitters while they are transmitting.

PHYSICAL SHOCK

The S-D2 is rugged and reliable but should be treated

with respect. Normal physical shock encountered in the

field will be no problem, but a hard jolt like a drop on the

floor or ground could be damaging. If you suspect that

a drop may have damaged the unit, perform a

calibration check.

34

Page 39

INTOXILYZER® S-D2 Operator’s Manual

INTOXILYZER

®

S-D2

SPECIFICATIONS

MODEL: Intoxilyzer® S-D2

DETECTOR: Electrochemical fuel cell sensor

SPECIFICITY: Alcohol detector is unaffected by

acetone, paint and glue fumes,

foods, confectionery , methane

and practically any other

substance likely to be found

in breath (apart from those

which contain alcohol).

ACCURACY: Better than ±5% around the

BREA TH Aspirating sample system with

SAMPLING: subject blowing through

DISPLA Y: Illuminated three-digit liquid

35

calibrated level of a known

alcohol standard.

disposable mouthpiece.

crystal display giving direct

alcohol level readout.

Page 40

INTOXILYZER® S-D2 Operator’s Manual

ANAL YSIS TIME: Approximately one minute per

test.

CALIBRA TION: With dry gas standard or

“wet bath” simulator.

RECOMMENDED 32-104° degrees Fahrenheit

OPERA TING (0-40° Celsius).

TEMPERA TURE

POWER SUPPL Y : 9-volt battery with sufficient

power for at least 500 tests.

DIMENSIONS: 2¾” wide x 1½” deep x

5” high (in pouch).

WEIGHT: 7½ ounces (including pouch and

battery).

WARRANTY: 12 month warranty, excludes

damage caused by mishandling

or improper use. Please consult

CMI, Inc. or your local agent

for full details of the warranty .

36

Page 41

Loading...

Loading...