CMC electronic MAI085MB User Manual

mAI085MB Actuator

Interface Technical Manual

Document No. 10856 Revision B

July 2007

1997-98-99, 2000 CMC Industrial Electronics Ltd.

Distributive Intelligence

Phone: (604) 421-4425 Toll-Free: (888) 421-4425 Fax: (604) 421-7734

CMC INDUSTRIAL ELECTRONICS LTD

info@cmciel.com www.cmciel.com

mAI085-MB Actuator Interface Technical Manual /i

Table of Contents

1. Overview..............................................................................................................................1

2. Description of the Keypad and Indicators.............................................................................3

3. External Connections...........................................................................................................5

3.1 Power and Communications .........................................................................................6

3.2 Optional Extended Data Network..................................................................................7

4. Using the Interface...............................................................................................................9

4.1 Selecting an Actuator Controller ...................................................................................9

4.2 Changing a Setpoint .....................................................................................................9

4.3 Opening the Actuators ..................................................................................................9

4.4 Closing the Actuators....................................................................................................9

4.5 Clearing the Setpoints.................................................................................................10

5. Configuration .....................................................................................................................11

5.1 Overview of System Configuration..............................................................................11

5.2 Configuration Keyboard Functions..............................................................................14

5.3 Configuration Menus...................................................................................................15

5.3.1 Main Menu...........................................................................................................16

5.3.2 Local Menu ..........................................................................................................18

5.3.3 Actuator Controller Menu .....................................................................................18

5.3.4 Modbus Interface Menu .......................................................................................21

5.3.5 Factory Values Menu...........................................................................................22

5.3.6 Diagnostics Menu ................................................................................................23

6. The Input / Output System .................................................................................................25

7. Controlling Conveying Systems .........................................................................................27

8. Using the Modbus Network Interface .................................................................................29

8.1 The Modbus Serial Interface .......................................................................................29

8.2 Register Assignments .................................................................................................29

8.2.1 Read Only Registers............................................................................................29

8.2.2 Read-Write Registers ..........................................................................................31

8.2.3 mAI085-MB Special Registers .............................................................................31

9. Specifications.....................................................................................................................33

10. Appendix 1 - Editing Controller Setup Tables on a PC ...................................................35

10.1

Setting up HyperTerminal........................................................................................35

10.2

Downloading the Configuration to the PC................................................................37

10.3

Uploading the Configuration to the mAI085MB........................................................40

11. Appendix 2 - Drawings ...................................................................................................43

Distributive Intelligence

CMC INDUSTRIAL ELECTRONICS LTD

mAI085-MB Actuator Interface Technical Manual /ii

Table of Figures

Figure 1 - Keypad and Indicators ................................................................................................3

Figure 2 - Terminal Blocks and Connectors ................................................................................5

Figure 3 - Recommended Network and Power Connections .......................................................6

Figure 4 - Extended Data Network ..............................................................................................7

Figure 5 - Configuration Keypad and Indicators ........................................................................14

Figure 6 - Conveying System Timing Diagram ..........................................................................28

Revision Notes

First Release August 14, 2006

Revision A, July 2, 2007

•

Add output relay contact ratings, update specifications and port descriptions

•

Add the Diagnostics and Upload/Download menu functions

Revision B, July 20, 2007

•

Add setup details for ASCII character delays to the upload/download instructions

•

Add notes describing the controller network expansion port

Distributive Intelligence

CMC INDUSTRIAL ELECTRONICS LTD

mAI085-MB Actuator Interface Technical Manual /1

1. Overview

The mAI085-MB Actuator Interface is an interface between the control room operator and a

network of Actuator Controllers. The interface is capable of controlling up to 100 actuators,

either on a single network of up to 31 controllers or through a series of network drops utilizing

RS485 repeaters. The interface allows for the pre-setting of setpoints for each of the actuators.

An open key opens all of the actuators to their preset setpoints. A close key closes all of the

actuators. A clear pushbutton sets all of the actuator setpoints to zero (fully closed).

The interface has optional features that allow the control of a conveying system. Timers are

provided which can delay the start of the actuator opening to allow a conveying system to start.

A second timer allows the conveying system to purge after closing all of the actuators.

Individual timers for each actuator allow for the distance between conveying system entry

points. The interface will open and close each actuator in sequence to provide superior

blending.

The interface communicates to the actuator controllers using the Modbus RS485 RTU protocol.

A Modbus RS232 RTU communications interface is provided for connection to a host computer

or PLC. The status information from all 100 actuators is available to the host computer or PLC

over this Modbus network. In addition, the interfaces front panel operators and enunciators are

mimicked over this network.

To facilitate configuration of the interface and the attached actuators a menu driven setup

system is provided. A table of parameters is saved for each actuator. The system allows the

retrieval and downloading of actuator parameters individually or for the entire network. A facility

is provided to backup the configuration to a TAB delimited file suitable for editing using Excel.

Distributive Intelligence

CMC INDUSTRIAL ELECTRONICS LTD

mAI085-MB Actuator Interface Technical Manual /2

This page intentionally left blank

Distributive Intelligence

CMC INDUSTRIAL ELECTRONICS LTD

mAI085-MB Actuator Interface Technical Manual /3

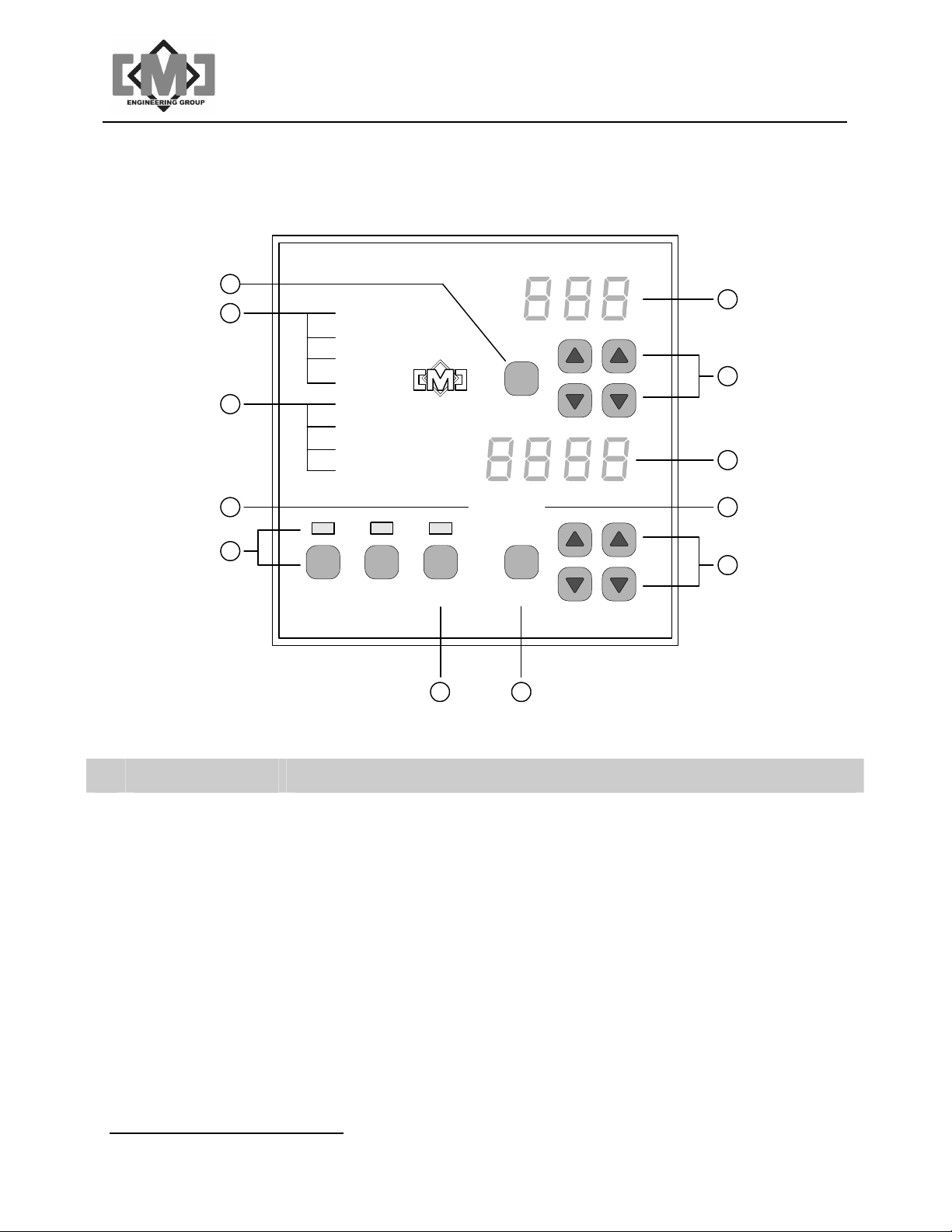

2. Description of the Keypad and Indicators

NDUSTRIAL ELECTRONICS

CMC I

12

11

10

OL

IDL

POS

FLT

MOV

OPN

CLS

EMP

SCAN

1

2

3

9

8

OPEN CLOSE CLEAR SET

PV

SV

A

CTUATOR INTERFACE

67

4

5

Figure 1 - Keypad and Indicators

ID Label Description of Operation

1 Upper Display Displays the name of the selected actuator.

2 Upper UP / DOWN Selects which actuator to view.

3 Lower Display Displays the process value or setpoint of the selected actuator.

4

Setpoint Value

Displaying the actuator setpoint

5 Lower UP /DOWN First press displays the setpoint of the selected actuator and each

subsequent press increases or decreases the setpoint value.

6 Set key

Saves the displayed setpoint only when SV is illuminated

Distributive Intelligence

CMC INDUSTRIAL ELECTRONICS LTD

mAI085-MB Actuator Interface Technical Manual /4

ID Label Description of Operation

7 Clear key and

lamp

8 Open / Close keys

and indicators

9

Process Value

10 Status Indicators

11 Fault Indicators

Clears all actuator setpoints. First press illuminates the lamp, the second

press clears the setpoints and turns off the lamp. The lamp will turn off

automatically after 10 seconds if the key is not pressed the second time

and the setpoints will not be cleared.

If the CLEAR lamp is illuminated continuously and the operator keyboard

does not function, the keyboard has been locked by the Modbus

interface. Pressing and holding the CLEAR key for 10 seconds will

unlock the keyboard. The CLEAR lamp will extinguish when the

keyboard is unlocked. The setpoints will not be cleared during this

operation.

Opens or closes the actuators to their pre-set values. The indicators

display which mode is active.

Displaying the actuator position

MOV - actuator is currently moving to setpoint

OPN – if configured, indicates the actuator is fully open

CLS - if configured, indicates the actuator is fully closed

EMP - if configured, indicates the bin served by the actuator is empty

OL – if configured, the actuator has faulted due to excess running current

IDL - if configured, the actuator has faulted due to excess idle current

POS – the actuator failed to reach the selected position

FLT – the actuator controller is not communicating or has a hardware

fault

12 Scan key Press once to scan through all controllers at 1 second intervals. Press

the SCAN key again to cancel scanning. Pressing the up or down

actuator selection keys also cancels scanning.

Table 1 - Description of Keys and Indicators

Distributive Intelligence

CMC INDUSTRIAL ELECTRONICS LTD

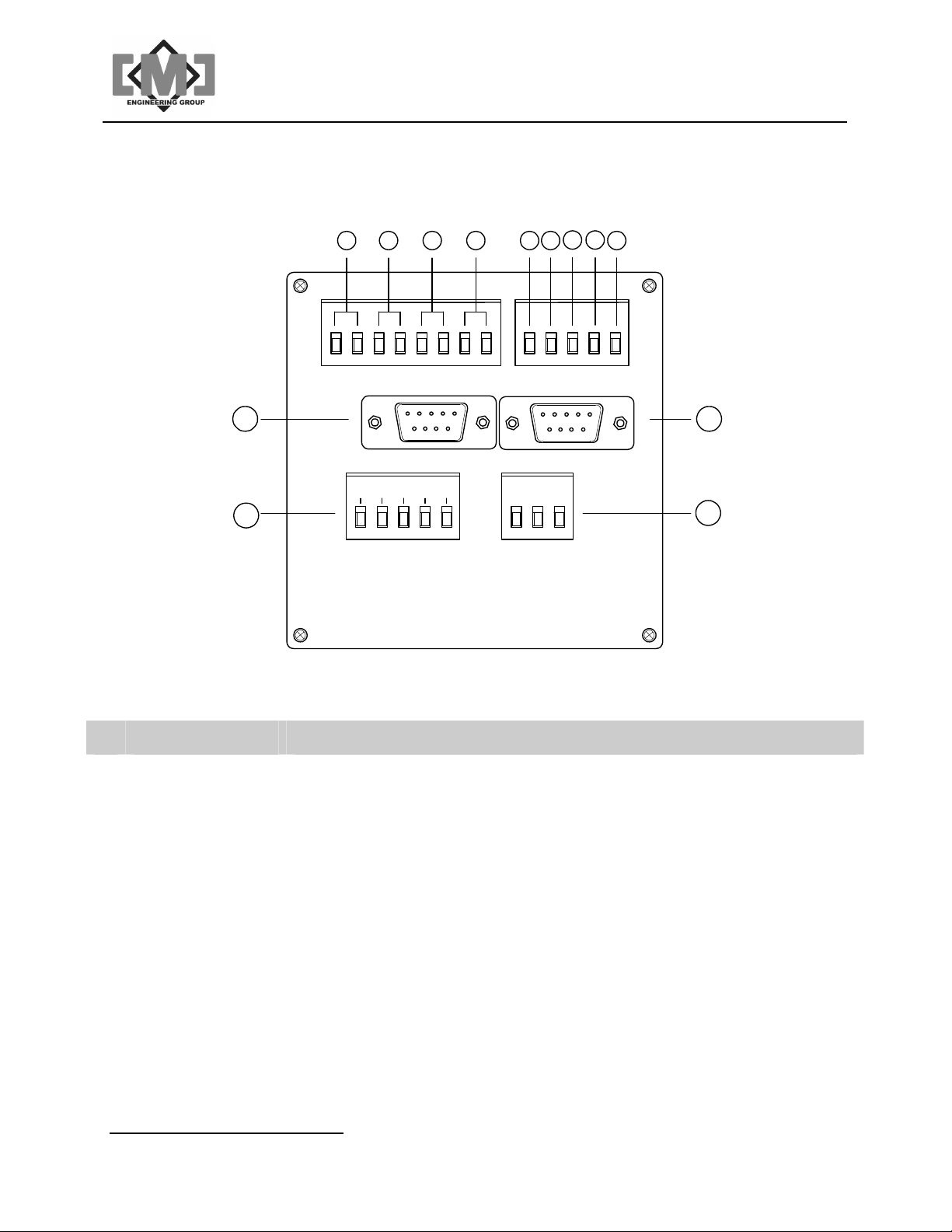

3. External Connections

mAI085-MB Actuator Interface Technical Manual /5

1 2 3 4 9

13

V- V+SHD_L D_H

12

V- V+G

7 8

65

10

11

Figure 2 - Terminal Blocks and Connectors

ID Label Description

1 Output 1 Contact will close if in open mode or to start the conveying system.

Maximum load 1A @24VDC, 0.5A@120VAC

2 Output 2 Contact will close if in close mode or to stop the conveying system.

Maximum load 1A @24VDC, 0.5A@120VAC

3 Output 3 Contact will close if all setpoints are at zero.

Maximum load 1A @24VDC, 0.5A@120VAC

4 Output 4 Contact will close if the interface has an internal fault.

Maximum load 1A @24VDC, 0.5A@120VAC

5 Inputs 1 Energizing will select open mode.

6 Inputs 2 Energizing will select close mode.

7 Inputs 3 Energizing will clear all setpoints to zero.

8 Inputs 4 Energizing will force all actuators closed without affecting open/close

mode selection. Blending timers are ignored during a force close.

Distributive Intelligence

CMC INDUSTRIAL ELECTRONICS LTD

mAI085-MB Actuator Interface Technical Manual /6

ID Label Description

9 Input Common Common connection for inputs. Inputs accept 8-32VDC of either polarity,

maximum load is 20mA.

10 Modbus Port Modbus network port - see Appendix for connections details, wired DCE

11 Input Power

Terminal

12 Output Power and

Network

Connections

13 Controller Network

Expansion

Download /

Upload Port

V+

G

V-

V+

D_H

SH

D_L

V-

22 -26 VDC @ 2.0A

Earth Ground

VDC Common

24 VDC fused at 1.75A

Data + (non inverted)

Shield

Data - (inverted)

VDC Common

RS232 connection for repeaters or fiber-optic cable drivers for the

controller network. Operates in parallel with the RS-485 port.

Port for exporting parameters to a comma delimited file - see Appendix B

for port wiring details, wired DTE

Table 2 - Description of Terminals and Connections

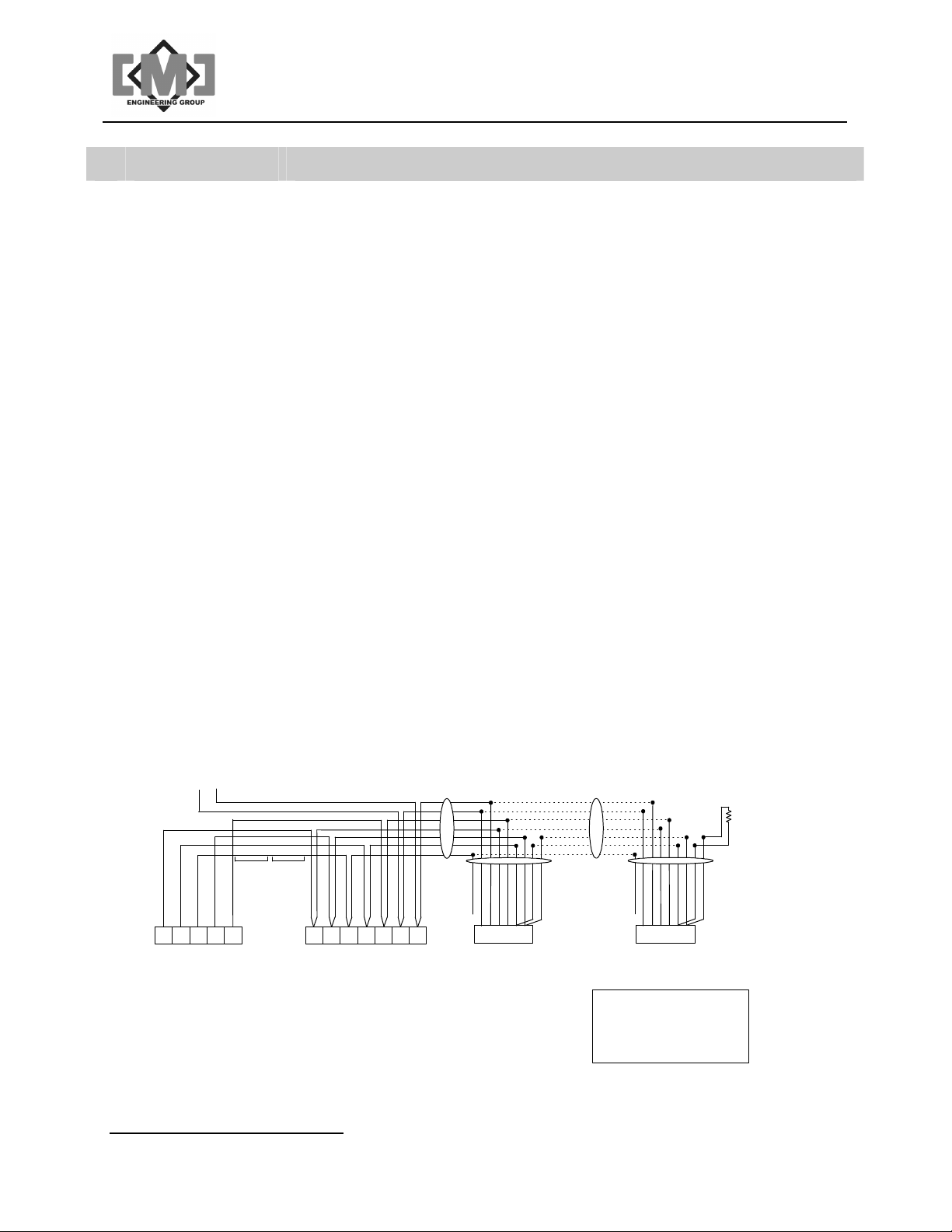

3.1 Power and Communications

A 2 or 3 pair shielded power and communication cable is utilized. Low capacitance twisted pair

cable is recommended. The cable should be sized to ensure voltage drop on the power

conductor does not exceed actuator controller input voltage specifications. The mAI085-MB

can accommodate up to a maximum of 31 actuator controllers. See drawing 10284 in the

Appendix for complete cabling details.

To force close

dry contact if used

GREEN

BLACK

RED

RED

BLACK

BLACK

WHITE

WHITE

BLACK

GREEN

SHIELD

SHIELD

2 Pair

3 Pair

Cables

Cables

WHT/BLU

SHIELD

WHT/ORG

ORG/WHT

24

5

DC Common

4321

Data -

Shield

Data +

24VDC Output

DC Common

D+SD-C

Data -

Shield

Data +

P1C

24VDC

Common

Input P1

X

mGP145-MB

Gate Positioner

BLU/WHT

WHT/BRN

BRN/WHT

WHT/GRN

GRN/WHT

654321

J2

SHIELD

WHT/ORG

X

mGP145-MB

Gate Positioner

WHT/BLU

WHT/BRN

BRN/WHT

WHT/GRN

ORG/WHT

GRN/WHT

654321

120 Ohm 1/

4W

Terminating

Resistor

BLU/WHT

J2

Data Cable

mAI085-MB

Actuator Interface

mAC185-MB

Actuator Controller

Pairs 20ga 22ga

2 9402 8723

3 9973 8777

Belden or equiv.

Figure 3 - Recommended Network and Power Connections

Distributive Intelligence

CMC INDUSTRIAL ELECTRONICS LTD

mAI085-MB Actuator Interface Technical Manual /7

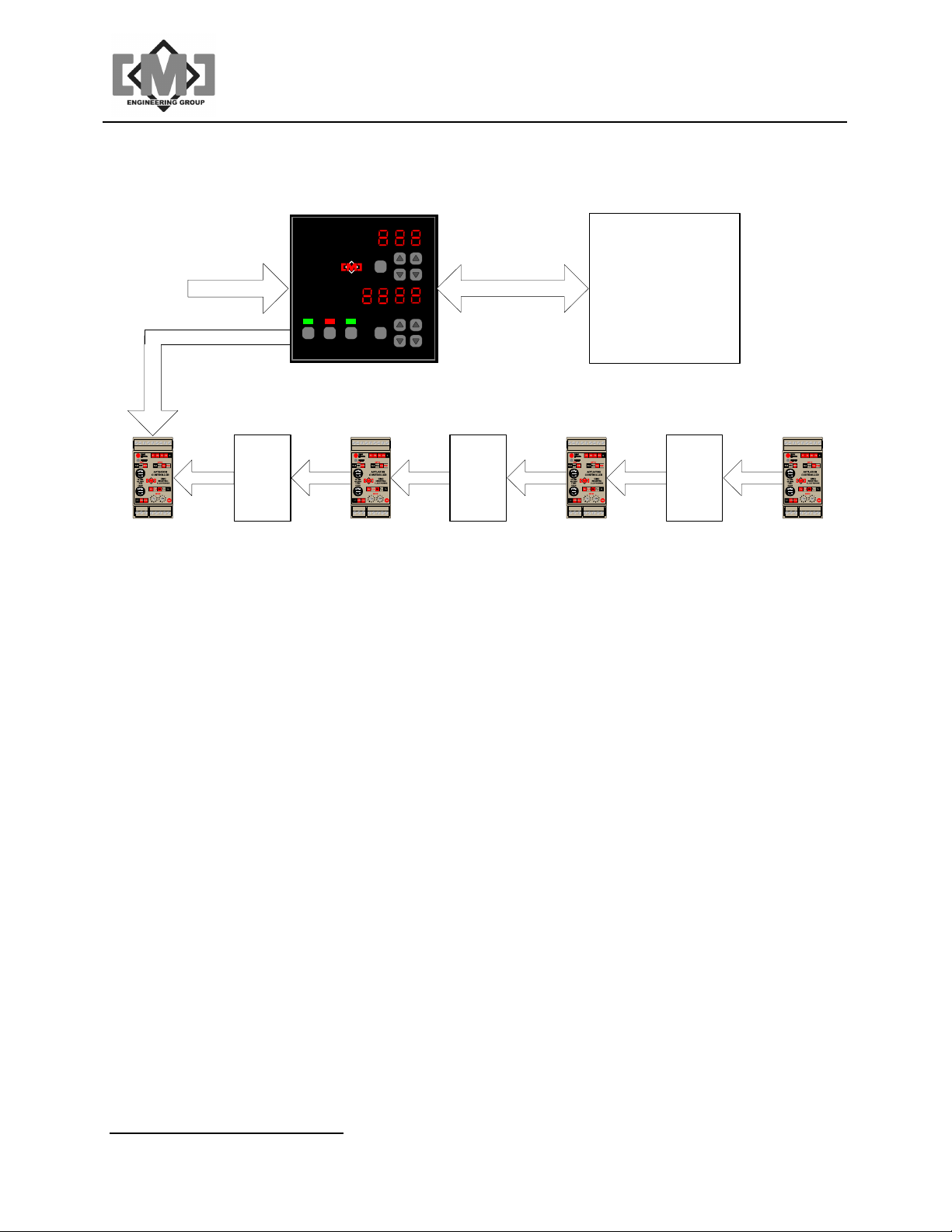

3.2 Optional Extended Data Network

CMC INDUSTRIAL ELECTRONICS

OL

IDL

POS

FLT

24VDC

1.25A

4 conductor

communications

cable RS-485

MOV

OPN

CLS

EMP

OPEN CLOSE CLEAR SET

PV

SCAN

SV

ACTUATOR INTERFACE

Modbus RTU

Host Computer

or PLC

RS-232

RS-485

repeater

Phoenix

Contact

2744429

Controller

91 - 100

Controller

1 - 30

RS-485

repeater

Phoenix

Contact

2744429

Controller

31-60

RS-485

repeater

Phoenix

Contact

2744429

Controller

61 - 90

Figure 4 - Extended Data Network

The interface can accommodate up to 100 actuator controllers if RS485 repeaters are used. A

typical repeater is the Phoenix Contact Part No. 2744429 optical isolated repeater. Up to 30

controllers can be on a single network segment (31 for the end of line). Using repeaters, a

linear network as shown above, or various forms of star or tee networks can be deployed as

required. The start of a branch on either a star or tee network must always begin with a

repeater.

A network expansion RS232 port is also provided. This port can connect directly to repeaters or

fiber-optic cable drivers. Controllers can be connected to both the standard RS485 port and the

expansion RS232 port. The port is designated J1 and is a female DB9 connector. It is wired

DTE.

Distributive Intelligence

CMC INDUSTRIAL ELECTRONICS LTD

mAI085-MB Actuator Interface Technical Manual /8

This page intentionally left blank

Distributive Intelligence

CMC INDUSTRIAL ELECTRONICS LTD

mAI085-MB Actuator Interface Technical Manual /9

4. Using the Interface

The controller has an easy to use keyboard for selecting and controlling the connected

actuators.

4.1 Selecting an Actuator Controller

Use the upper up or down keys to select the actuator. The right keys move between the

actuator one at a time. The left keys skip actuators at a time. The upper display indicates

which actuator is selected. The SCAN key allows the viewing of all connected actuators at one

second intervals. Pressing the SCAN key or any of the upper up/down keys can cancel scan.

4.2 Changing a Setpoint

The lower up/down keys change the setpoint for the selected actuator. The first press of any of

the up or down keys switches the lower display to the setpoint mode and the SV lamp will

illuminate. The right keys change the setpoint by 1. The left keys change the setpoint by 10.

The setpoint will not be saved and sent to the actuator until the SET key is pressed. If the SET

key is not pressed within 10 seconds, the display reverts to PV mode and the new setpoint is

discarded.

…Caution…

If it is required that all the actuators respond simultaneously to the

new setpoints, then first insure that the interface is in close mode

before making any changes to the setpoints.

The command to move the actuator is only sent when a setpoint has changed or the operating

mode is changed from closed to open. Pressing the SET key with the same setpoint value as

the previous move will not start a move operation.

4.3 Opening the Actuators

Pressing the OPEN key opens all actuators with a setpoint above 0. The OPEN indicator light

will illuminate. The STATUS display will indicate the status of the current open operation for the

selected actuator.

4.4 Closing the Actuators

Pressing the CLOSE key closes all actuators to a setpoint of 0. The CLOSE indicator light will

illuminate. The STATUS display will indicate the status of the current close operation for the

selected actuator.

Distributive Intelligence

CMC INDUSTRIAL ELECTRONICS LTD

mAI085-MB Actuator Interface Technical Manual /10

4.5 Clearing the Setpoints

The CLEAR key allows the clearing of all actuator setpoints. The first press of the CLEAR key

illuminates the CLEAR lamp. The second press of the key clears all actuator setpoints to 0. If

the key in not pressed a second time within 10 seconds, the lamp will extinguish and the

setpoints will not

Distributive Intelligence

CMC INDUSTRIAL ELECTRONICS LTD

mAI085-MB Actuator Interface Technical Manual /11

5. Configuration

The mAI085-MB Actuator Interface is configured using a menu driven interface. The operator

keyboard changes function during configuration. This section will describe the configuration of

the interface. The description will first define the keyboard functions, then describe the

configuration menus used.

5.1 Overview of System Configuration

Each actuator connected to the Interface has parameters that control its operation. These

parameters are stored in non-volatile memory at each actuator. These parameters can be

modified using the keyboard of the Interface. The Interface can also store in its internal nonvolatile memory, a copy of the parameters from each actuator.

The following table defines the steps used to set the actuator parameters and calibrate each

actuator controller.

Step Function Action at Interface Action at

Actuator Controller

1 Load Factory Default Values for the

Interface using the Factory Values

Menu..

2

Using the Controller Menu, set the iD

and adjust the parameters as required

for controller 1.

3

Using the Controller Menu, Snd the

adjusted parameters to controller 1.

4

From the Controller Menu, calibrate

controller 1, using the CAL function.

5 Test the configuration by exercising

controller 1

All internal Interface

no action

parameters are

overwritten with the

factory default values

Parameters for

no action

actuator controller 1

are adjusted in the

Interface parameter

table

no action Parameters at

actuator controller 1

are overwritten with

values from the

Interface

no action Calibration

parameters are

adjusted by the

actuator controller

Open and close the

gate to several

Controller will position

the gate

positions including fully

open and fully closed

and verify the limit

switch operation if

used

Distributive Intelligence

CMC INDUSTRIAL ELECTRONICS LTD

Loading...

Loading...