Page 1

OPERATING, MAINTENANCE

& PARTS MANUAL

ELECTRIC CHAIN HOIST

SHOPSTAR

SLC SERIES

SHOPHOIST

SLM SERIES

Before installing hoist, fill in the information below.

Model Number

Serial No.

Purchase Date

Follow all instructions and warnings for inspecting,

maintaining and operating this hoist.

The use of any hoist presents some risk of personal injury

or property damage. That risk is greatly increased if proper

instructions and warnings are not followed. Before using

this hoist, each operator should become thoroughly familiar

with all warnings, instructions and recommendations in this

manual. Retain this manual for future reference and use.

Forward this manual to the hoist operator. Failure to operate

equipment as directed in manual may cause injury.

Columbus McKinnon Corporation

205 Crosspoint Parkway

Getzville, NY 14068

P/N 192047138 Rev AA November 2017

Page 2

CM HOIST PARTS AND SERVICES ARE AVAILABLE IN THE UNITED STATES AND IN CANADA

As a CM Hoist and Trolley user you are assured of reliable repair and parts services through a network of Master Parts Depots and Service

Centers that are strategically located in the United States and Canada. These facilities have been selected on the basis of their demonstrated

ability to handle all parts and repair requirements promptly and efciently. To quickly obtain the name of the Master Parts Depot or Service

Center located nearest you, call (800) 888-0985. Fax: (716) 689-5644.

LAS PIEZAS Y REPARACIONES DE LOS POLIPASTOS DE CM

ESTÁN ASEGURADAS EN ESTADOS UNIDOS Y CANADÁ

Como usuario de un polipasto y carro de CM le aseguramos cualquier reparación o la disponibilidad de cualquier pieza de repuesto a

través de una red de almacenes de piezas de repuesto y centros de servicio situados estratégicamente en Estados Unidos y Canadá. Estas

instalaciones se han seleccionado en base a su capacidad demostrada en la reparación de equipos y suminstro de piezas de repuesto de

forma rápida y ecaz. Para obtener la dirección del almacén de piezas de repuesto o del centro de servicio más cercano, llame al teléfono

(800) 888-0985. Fax: (716) 689-5644 (sólo en Estados Unidos y Canadá).

LE SERVICE DE RÉPARATION ET DE PIÈCES POUR PALANS CM

EST DISPONIBLE AUX ÉTATS-UNIS ET AU CANADA

Soyez assurés qu'en temps d'utilisateur de palan et treuil CM, d'un service de réparation et de pièces able par l'entremise d'un réseau de

Centres de service et de Dépôts de pièces maîtresses qui sont stratégiquement situés aux États-Unis et au Canada. Ces établissements ont

été sélectionnés sur une base de leur habileté démontrée à s'occuper promptement et efcacement des besoins de réparation de pièces.

Appelez le (800) 888-0985, Fax: (716) 689-5644 pour obtenir rapidement le nom du dépôt de pièces maîtresses ou du centre de service situé

le plus près.

2

P/N 192047138 Rev AA November 2017

Page 3

Improper operation of a hoist can create a potentially

hazardous situation which, if not avoided, could result in

death or serious injury. To avoid such a potentially hazardous

situation, THE OPERATOR SHALL:

a. NOT operate a damaged, malfunctioning or unusually

performing hoist.

b. NOT operate the hoist until you have thoroughly read and

understood this Operating, Maintenance and Parts Manual.

c. NOT operate a hoist which has been modied.

d. NOT lift more than rated load for the hoist.

e. NOT use hoist with twisted, kinked, damaged, or worn load

chain.

f. NOT use the hoist to lift, support, or transport people.

g. NOT lift loads over people.

h. NOT operate a hoist unless all persons are and remain clear

of the supported load.

i. NOT operate unless load is centered under hoist.

j. NOT attempt to lengthen the load chain or repair damaged

load chain.

k. Protect the hoist’s load chain from weld splatter or other

damaging contaminants.

l. NOT operate hoist when it is restricted from forming a

straight line from hook to hook in the direction of loading.

m. NOT use load chain as a sling, or wrap chain around load.

n. NOT apply the load to the tip of the hook or to the hook

latch.

o. NOT apply the load unless load chain is properly seated in

the chain wheel(s) or sprocket(s).

p. NOT apply load if bearing prevents equal loading on all load

supporting chains.

q. NOT operate beyond the limits of the load chain travel.

r. NOT leave load supported by the hoist unattended unless

specic precautions have been taken.

s. NOT allow the load chain or hook to be used as an electrical

or welding ground.

t. NOT allow the load chain or hook to be touched by a live

welding electrode.

u. NOT remove or obscure the warnings on the hoist.

v. NOT operate a hoist on which the safety placards or decals

are missing or illegible.

w. NOT operate a hoist unless it has been securely attached to

a suitable support.

x. NOT operate a hoist unless load slings or other approved

single attachments are properly sized and seated in the

hook saddle.

y. Take up slack carefully - make sure load is balanced and

load holding action is secure before continuing.

z. Shut down a hoist that malfunctions or performs unusually

and report such malfunction.

aa. Make sure hoist limit switches function properly.

ab. Warn personnel of an approaching load.

Improper operation of a hoist can create a potentially

hazardous situation which, if not avoided, could result

in minor or moderate injury. To avoid such a potentially

hazardous situation, THE OPERATOR SHALL:

a. Maintain rm footing or be otherwise secured

when operating the hoist.

b. Check brake function by tensioning the hoist prior

to each lift operation.

c. Use hook latches. Latches are to retain slings, chains, etc.

under slack conditions only.

d. Make sure the hook latches are closed and not supporting

any parts of the load.

e. Make sure the load is free to move and will clear

all obstructions.

f. Avoid swinging the load or hook.

g. Make sure hook travel is in the same direction as shown

on the controls.

h. Inspect the hoist regularly, replace damaged or worn parts,

and keep appropriate records of maintenance.

i. Use factory parts when repairing the unit.

j. Lubricate load chain per hoist manufacturer’s

recommendations.

k. NOT use the hoist’s overload limiting clutch to measure

load.

l. NOT use limit switches as routine operating stops.

They are emergency devices only.

m. NOT allow your attention to be diverted from operating

the hoist.

n. NOT allow the hoist to be subjected to sharp contact with

other hoists, structures, or objects through misuse.

o. NOT adjust or repair the hoist unless qualied to perform

such adjustments or repairs.

SAFETY PRECAUTIONS

Each Shopstar Electric Hoist is built in accordance with the

specications contained herein and at the time of manufacture

complied with our interpretation of applicable sections of the National

Electrical Code (ANSI/NFPA 70). Installers are required to provide

current overload protection and grounding in keeping with the code.

Check each installation for compliance with the applicable sections of

the code as well as the National, State and Local Codes that may apply

to the installation. In addition, safety code requirements associated

with the operation of a hoist in the inverted (theatrical) position (chain

port up), as with any mechanical equipment, vary depending upon

locality. Therefore, before installing the hoist, the user should consult

his insurance company and/or local authority to see if a deviation is

required to permit the use of the hoist in this particular application.

The safety laws for elevators, lifting of people and for dumbwaiters

specify construction details that are not incorporated into

the hoists. For such applications, refer to the requirements of

applicable state and local codes, and the American National Safety

Code for elevators, dumbwaiters, escalators and moving walks

(ASME A17.1). We cannot be responsible for applications other

than those for which the equipment is intended.

* Copies of this standard can be obtained from ASME Order Department,

22 Law Drive, PO Box 2300, Faireld, NJ 07007- 2300, U.S.A.,

www.asme.org, 800-843-2763.

THIS SYMBOL POINTS OUT IMPORTANT SAFETY

INSTRUCTIONS WHICH IF NOT FOLLOWED COULD

ENDANGER THE PERSONAL SAFETY AND/OR PROPERTY

OF YOURSELF AND OTHERS. READ AND FOLLOW ALL

INSTRUCTIONS IN THIS MANUAL AND ANY PROVIDED

WITH THE EQUIPMENT BEFORE ATTEMPTING TO

OPERATE YOUR SHOPSTAR HOIST.

3

P/N 192047138 Rev AA November 2017

Page 4

HOIST SAFETY IS UP TO YOU...

DO NOT LIFT MORE THAN RATED LOAD.

CHOOSE THE RIGHT HOIST FOR THE JOB...

Choose a hoist with the capacity for

the job. Know the capacities of your

hoists and the weight of your loads.

Then match them.

The application, the size and type

of load, the attachments to be used

and the period of use must also be

taken into consideration in selecting

the right hoist for the job.

Remember, the hoist was

designed to ease our burden and

carelessness not only endangers the

operator, but in many cases, a valuable load.

DO NOT OPERATE DAMAGED OR MALFUNCTIONING HOIST.

DO NOT OPERATE WITH TWISTED, KINKED, OR DAMAGED CHAIN.

INSPECT

All hoists should be visually inspected

before use, in addition to regular, periodic

maintenance inspections.

Inspect hoists for operations warning notices

and legibility.

Deciencies should be noted and brought to the attention of

supervisors. Be sure defective hoists are tagged and taken out

of service until repairs are made.

Under no circumstances should you operate a malfunctioning hoist.

Check for gouged, twisted,

distorted links and foreign material.

Do not operate hoists with twisted,

kinked, or damaged chain links.

Load chain should be properly

lubricated.

Hooks that are bent, worn, or whose

openings are enlarged beyond

normal throat opening should not

be used. If latch does not engage

throat opening of hook, hoist should

be taken out of service.

Chains should be checked for

deposits of foreign material which

may be carried into the hoist

mechanism.

Check brake for evidence of slippage under load.

DO NOT PULL AT AN ANGLE. BE SURE HOIST AND LOAD ARE

IN A STRAIGHT LINE.

DO NOT USE LOAD CHAIN AS A SLING.

USE HOIST PROPERLY

Be sure hoist is solidly held in the uppermost part of the support

hook arc.

Be sure hoist and load are in a straight line.

Do not pull at an angle.

Be sure load is hooked securely. Do not tip load the hook. Do not

load hook latch. Hook latch is to prevent detachment of load under

slack chain conditions only.

Do not use load chain as a sling. Such usage damages the chain

and lower hook.

Do not operate with hoist head resting against any object. Lift the

load gently. Do not jerk it.

DO NOT LIFT PEOPLE OR LOADS OVER PEOPLE

LIFT PROPERLY

Do not lift co-workers with a

hoist.

Make sure everyone is clear of

the load when you lift.

Do not remove or obscure

operational warning notices.

MAINTAIN PROPERLY

CLEANING

Hoists should be kept clean and free of dust, dirt, moisture, etc.,

which will in any way affect the operation or safety of the equipment.

LUBRICATION

Chain should be properly lubricated.

AFTER REPAIRS

Carefully operate the hoist

before returning it to full service.

VIOLATIONS OF ANY OF THE WARNINGS LISTED MAY RESULT IN SERIOUS PERSONAL INJURY TO THE OPERATOR

OR NEARBY PERSONNEL BY NATURE OF RELEASED LOAD OR BROKEN HOIST COMPONENTS.

4

P/N 192047138 Rev AA November 2017

Page 5

FOREWORD

This manual contains important information to help you properly install, operate and maintain your hoist for maximum performance, economy

and safety.

Please study its contents thoroughly before putting your hoist into operation. By practicing correct operating procedures and by carrying out

the recommended preventive maintenance suggestions, you will experience long, dependable and safe service. After you have completely

familiarized yourself with the contents of this manual, we recommend that you carefully le it for future reference.

The information herein is directed to the proper use, care and maintenance of the hoist and does not comprise a handbook on the broad

subject of rigging.

Rigging can be dened as the process of lifting and moving heavy loads using hoists and other mechanical equipment. Skill acquired through

specialized experience and study is essential to safe rigging operations. For rigging information, we recommend consulting a standard

textbook on the subject.

TABLE OF CONTENTS

Master Parts Depots And Service Centers ........................................ 2

Safety Precautions ............................................................................. 3

Foreword ........................................................................................... 5

SPECIFICATIONS

Electric Chain Hoists .......................................................................... 6

Repair/Replacement Policy ................................................................ 6

Accessories ........................................................................................ 7

INSTALLATION

Unpacking .......................................................................................... 8

Mounting the Hoist ............................................................................. 8

Power Supply System ........................................................................ 8

Three Phase Hoists ............................................................................ 9

Checking for Adequate Voltage at Hoist ............................................ 9

OPERATION

General ............................................................................................. 10

MAINTENANCE

Inspection ......................................................................................... 11

Preventive Maintenance ................................................................... 11

Inspection Table ............................................................................... 12

Hook Inspection ............................................................................... 13

Hook Replacement Criteria .............................................................. 13

Inspecting The Load Chain .............................................................. 13

Lubrication ........................................................................................ 14

Electric Brake ................................................................................... 15

TROUBLESHOOTING

General ............................................................................................. 16

ELECTRICAL DATA

Open or Short Circuit in Electrical Components .............................. 17

WIRING

General ............................................................................................. 19

DISASSEMBLY-ASSEMBLY

General ............................................................................................. 23

Load Chain Removal/Installation...................................................... 23

Cutting Chain ................................................................................... 24

Testing .............................................................................................. 24

Repair Parts List ............................................................................... 25

ORDERING INSTRUCTIONS

General ............................................................................................. 25

RECOMMENDED SPARE PARTS

General ............................................................................................. 25

LIST OF TABLES

TABLE DESCRIPTION PAGE

1 Specications .................................................................... 6

2 Nominal Voltage ................................................................. 9

3 Start-up Voltage ................................................................. 9

4a-b Adequate Power Supply .................................................... 9

5 Electrical Data for Components ....................................... 18

6 Torque Settings ................................................................ 23

LIST OF ILLUSTRATIONS

FIG. DESCRIPTION PAGE

1 Chain Container ................................................................. 7

2 Latchlok Hook .................................................................... 7

3 632 Trolley .......................................................................... 7

4 UT Trolley ........................................................................... 7

5 CM Rocket Universal Pendant Control .............................. 7

6 Single Phase Systems ....................................................... 8

7 Three Phase Systems ........................................................ 8

8 Nameplate ......................................................................... 9

9 Hoist Components ............................................................. 9

10 Hook Inspection ...............................................................13

11 Chain Inspection .............................................................. 14

12 Chain Wear Areas ............................................................ 14

13 Chain Identication .......................................................... 14

14 Brake Field Assembly ...................................................... 15

15 Drive Shaft Assembly.......................................................15

16 Brake Assembly ............................................................... 15

17 110-1-50, 115-1-60 Hoists

without Contactor (Orange Control Station) .................... 19

18 110-1-50, 115-1-60 Hoists

with Contactor (Black Control Station) ............................ 19

19 220-1-50, 230-1-60 Hoists

with Contactor (Black Control Station) ............................ 20

20 220-3-50, 230-3-60 Hoists

with Contactor (Black Control Station) ............................ 20

21 380-3-50, 415-3-50, 460-3-60 Hoists

with Contactor (Black Control Station) ............................ 21

22 230-3-60, 400-3-50 PCB

(Printed Circuit Board) Unit .............................................. 21

23 575-3-60 Hoists with Contactor

(Black Control Station) ..................................................... 22

24 Main Frame ...................................................................... 23

25 Stator Installation ............................................................. 23

26 Chaining Hoist ................................................................. 23

27 Chaining Diagram ............................................................ 24

28 Chain Stop ....................................................................... 24

29 Cutting Chain by Nicking ................................................. 24

30 Cutting Chain with a Bold Cutter ..................................... 24

5

P/N 192047138 Rev AA November 2017

Page 6

SPECIFICATIONS

Standard features of the Electric Chain Hoist include:

• Alloy steel, oblique lay liftwheel that provides constant chain

speed and reduces chain wear.

• Hoistaloy® load chain for long and dependable service.

• Grease lubricated, hardened spur gears provide smooth and

quiet operation.

• Thermally protected, hoist duty motor.

• Forged steel upper and lower hooks with latch.

• ProtectorTM that prevents lifting dangerous overloads.

• D.C. disc type motor brake plus regenerative braking.

• 10 foot (3 M) lift. Longer lifts can be supplied on a per order basis.

• 6 foot (1.8 M) power cord with three prong plug for grounding on

115-1-50/60 units. 6 foot (1.8 M) power cord with provisions for

grounding is standard on 220-1-50 and three phase units.

• Rugged NEMA 4 (weatherproof) control station is suspended

on a TYPE SO cord six feet (2.8 M) below the bottom of the

hoist. Longer cords can be provided on a per order basis.

• Lightweight die cast aluminum frames and covers.

• Ball or needle bearings at all rotating points.

• Compact, yet rugged, design provides minimum headroom

and long, trouble-free service

• 220-1-50, 380 to 460-3-50/60, 220 to 240-3-50/60 and 575-3-60

units available. Lift speeds are based on 60 hertz power supply.

For 50 hertz power supply lift speeds will be 5/6 of those indicated.

• Speeds and capacities based on Table 1, below.

• UL and cUL listed.

• Lifetime Warranty.

Follow all instructions and warnings for inspecting, maintaining

and operating this hoist.

The use of any hoist presents some risk of personal injury or

property damage. That risk is greatly increased if proper instructions

and warnings are not followed. Before using this hoist, each operator

should become thoroughly familiar with all warnings, instructions,

and recommendations in this manual.

Retain this manual for future reference and use.

Forward this manual to the hoist operator. Failure to operate the

equipment as directed in the manual may cause injury. Before

putting hoist into service, ll in the information below. Refer to the

hoist identication plate.

REPAIR/REPLACEMENT POLICY

All Electric Chain Hoists are inspected and performance

tested prior to shipment. If any properly maintained hoist

develops a performance problem, due to a material or

workmanship defect, as veried by the factory, repair or

replacement of the unit will be made to the original purchaser

without charge. This repair/replacement policy applies only to

Shopstar Hoists installed, maintained and operated as outlined

in this manual, and specically excludes hoists subject to normal

wear, abuse, improper installation, improper or inadequate

maintenance, hostile environmental effects and unauthorized

repairs/modications.

We reserve the right to change materials or design if, in our opinion,

such changes will improve our product. Abuse, repair by an

unauthorized person, or use of non-factory replacement parts

voids the guarantee and could lead to dangerous operation.

All Shopstar Electric Chain Hoists are backed with a lifetime

warranty. Refer to the back cover for details and limitations.

Alterations or modication of hoist and use of non-factory repair

parts can lead to dangerous operation and injury.

TO AVOID INJURY:

• Do not alter or modify equipment.

• Do use only factory replacement parts.

Model Number

Serial No.

Purchase Date

Voltage

Rated Load

Table 1 - Specifications

Lift

fpm

6

8 fpm

12

fpm

13.3

fpm

16

fpm

250 lb x x x

300 lb x x x x

500 lb x x x x x

550 lb x

600 lb x x

1000 lb x x x

20

fpm

24

fpm

40

fpm

6

P/N 192047138 Rev AA November 2017

Page 7

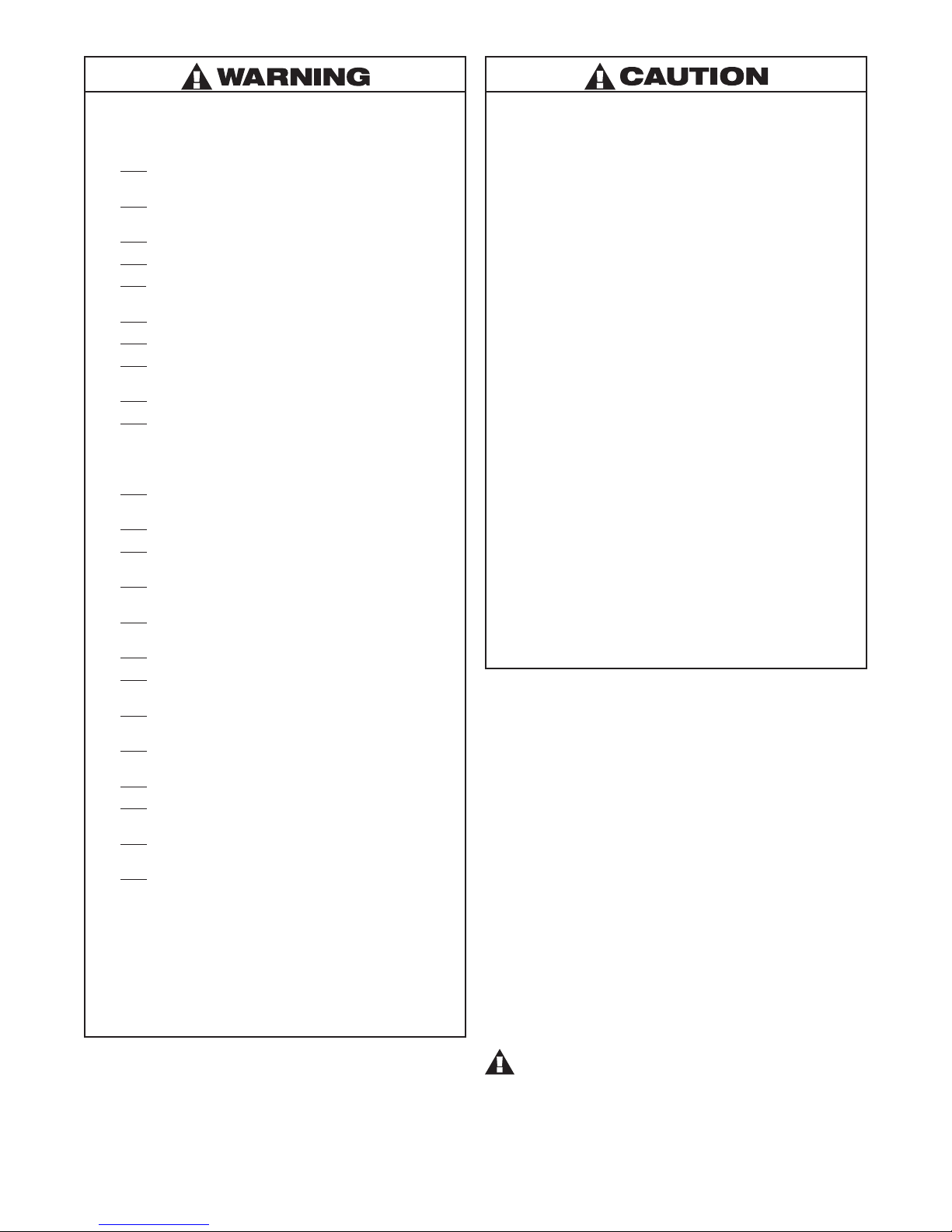

Figure 1 - Chain Container

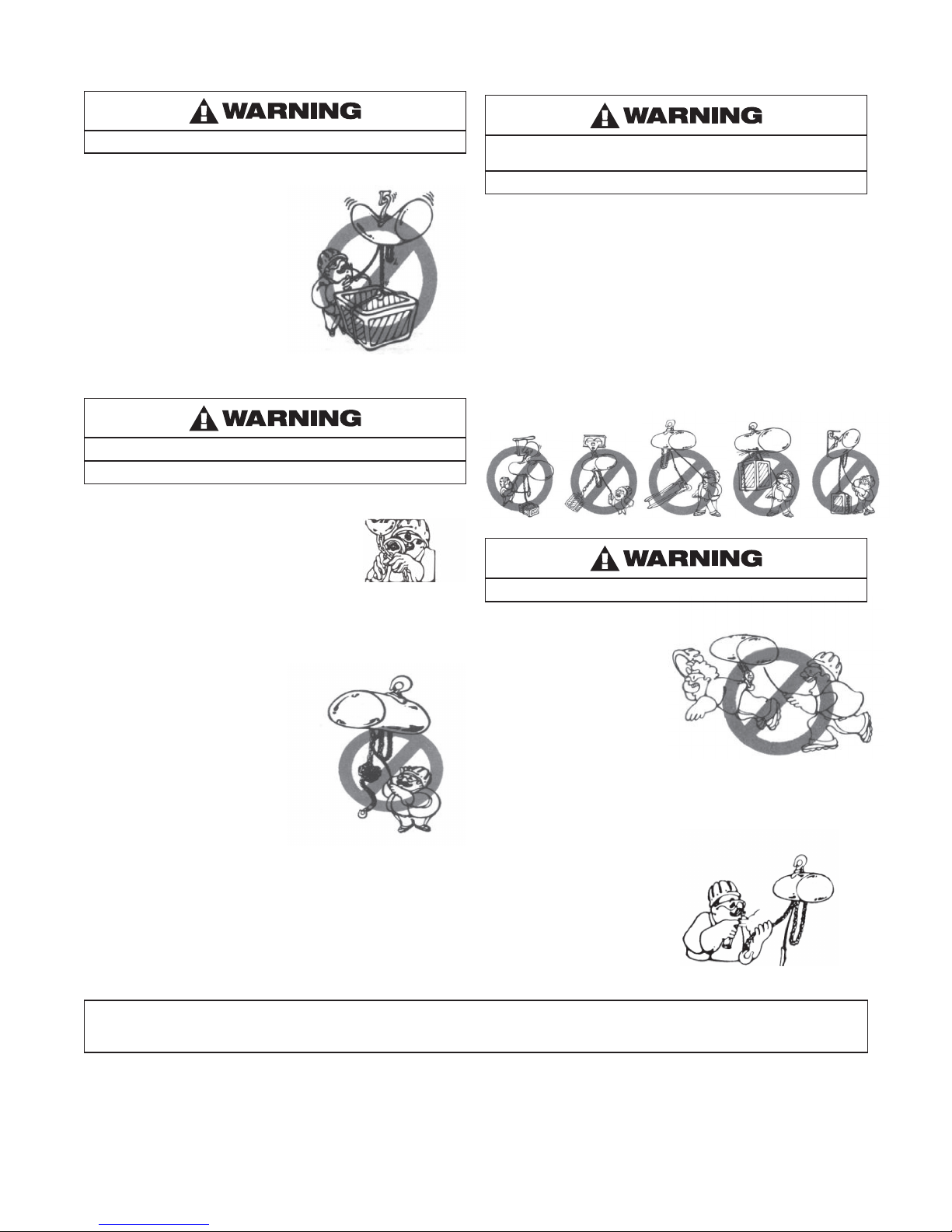

Figure 2 - Latchlok Hook

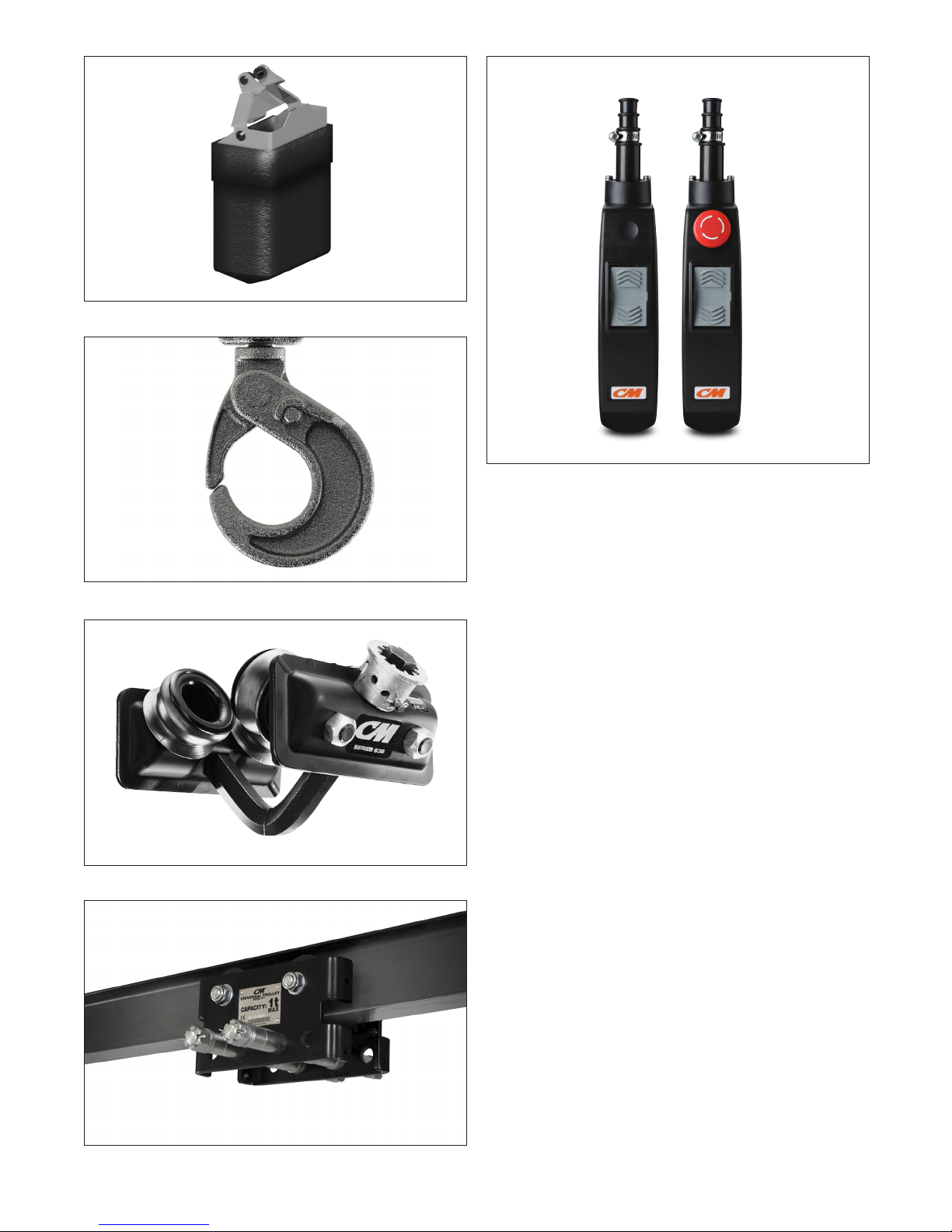

Figure 5 - CM® Rocket™ Universal Pendant Control

ACCESSORIES

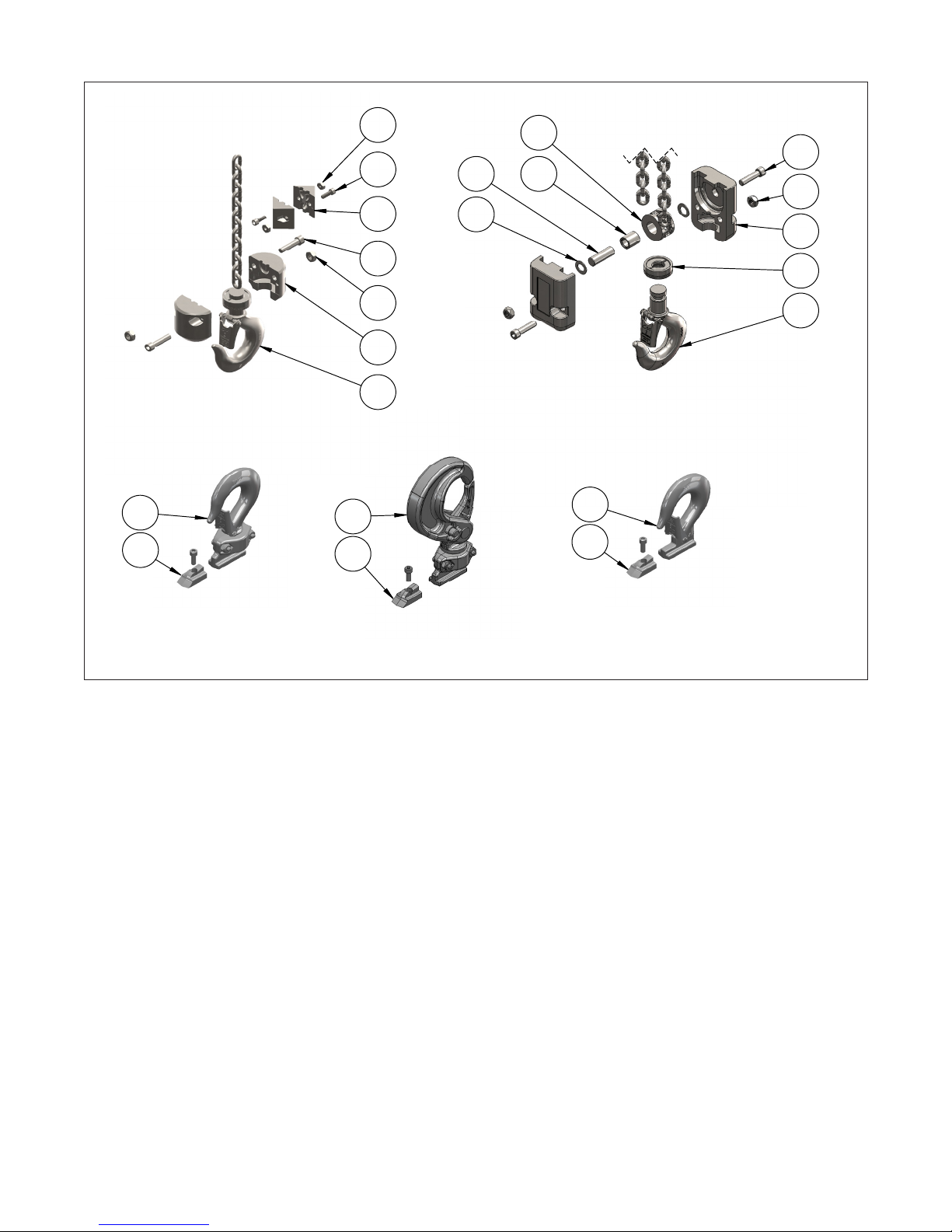

HOOK SUSPENSIONS

Swivel and rigid type hook suspensions are available for all Shopstar

Electric Hoists. However, swivel type hook suspensions are normally

recommended for most applications.

CHAIN CONTAINER

This accessory item (Figure 1) is used to hold the slack chain

and it is supplied with mounting hardware and instructions.

Chain containers are recommended for those applications where

slack chain will interfere with the load or drag on the oor as may

more often be the case with the double-reeved units (500, 600,

1,000lb - 226, 272, and 453kg). Chain containers are shipped

separately and can be furnished for units already in service.

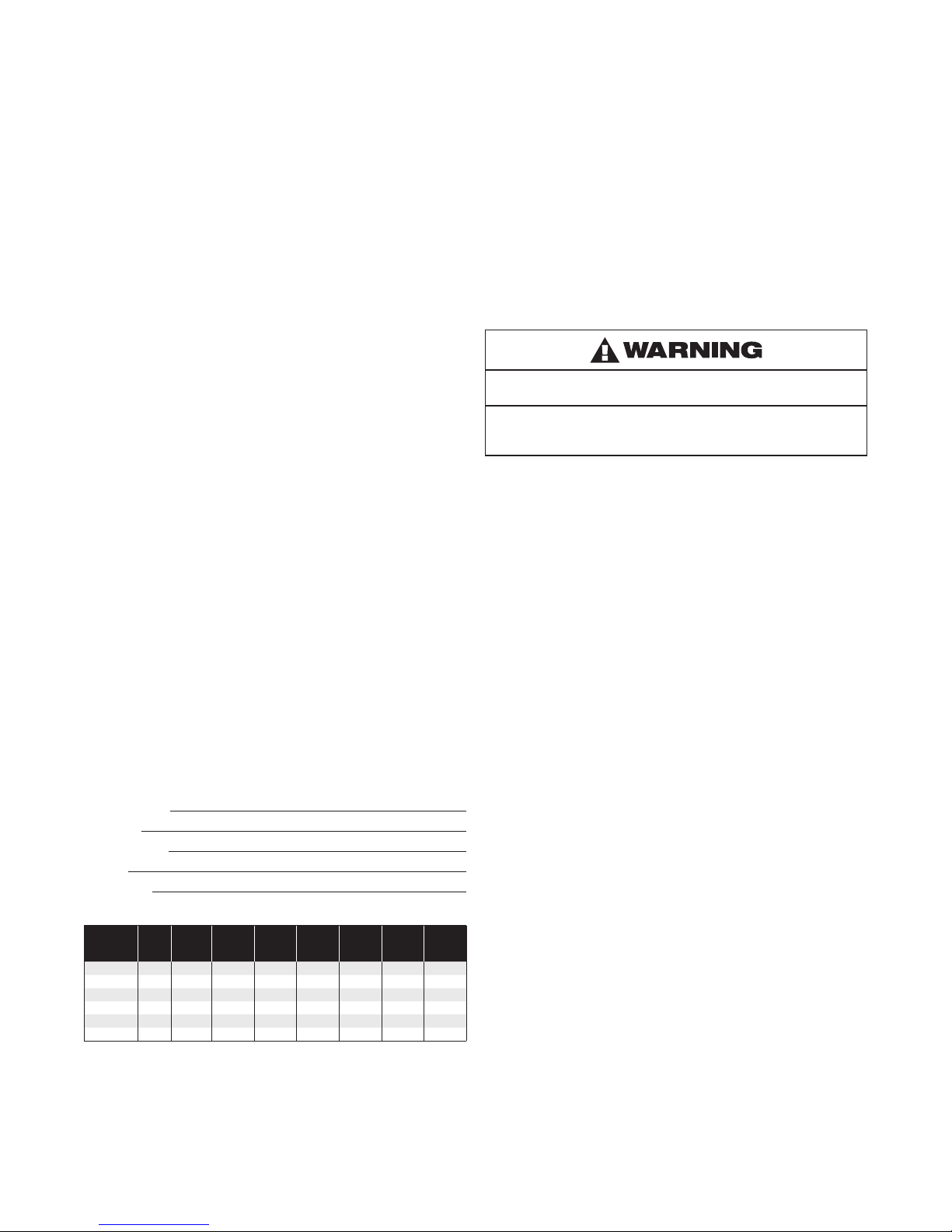

Figure 3 - 632 Trolley

Figure 4 - UT Trolley

LATCHLOK

®

HOOKS

CM’s Latchlok hooks are available (Figure 2) to replace the standard

upper and lower hooks used on the Shopstar Electric Hoists.

CM SERIES 632 TROLLEY

This lightweight, yet, rugged, manual push type trolley (Figure 3)

is designed to t a wide range of monorail beams and negotiate

tight curves. Provides mobility of your hoist.

CM UNIVERSAL (UT) TROLLEY

The CM Universal Trolley (UT) is designed to t virtually all

Columbus McKinnon powered chain hoists up to 3 ton capacities.

The rugged UT is available as a convertible plain unit, a geared unit

ideal for precise hoist positioning, and a motorized unit that’s perfect

for applications requiring high cycling and long distance hoist travel.

CM® ROCKET™ UNIVERSAL PENDANT CONTROL

The CM Rocket Pendant Control is engineered for maximum

operator comfort, while delivering the precision control your

application demands.

7

P/N 192047138 Rev AA November 2017

Page 8

INSTALLATION

UNPACKING

After opening the carton, carefully inspect the hoist frame, cords,

hooks, chain and control station for damage that may have occurred

during shipment. If there is damage, refer to the packing slip

envelope.

Make sure that the power supply to which the hoist is to be

connected is the same as that shown on the identication plate

located on bottom of hoist.

Operating a unit with obvious external damage may cause load to

drop and that may result in personal injury and/or property damage.

TO AVOID INJURY:

Carefully check unit for external damage prior to installation.

MOUNTING THE HOIST

Hang the hoist from its intended support. The structure used to

support the hoist must have sufcient strength to withstand several

times the load imposed. If in doubt consult a registered engineer

and local building codes.

Suspending the hoist from an inadequate support may allow the

hoist and load to fall and cause injury and/or property damage.

TO AVOID INJURY:

Make sure the attachment point has sufcient strength to hold

several times the hoist and its rated load. Using the upper hook,

hang the hoist from the support. Be sure hoist is solidly held

in the uppermost part of the hook arc and the latch is tightly

against the hook tip.

POWER SUPPLY SYSTEM

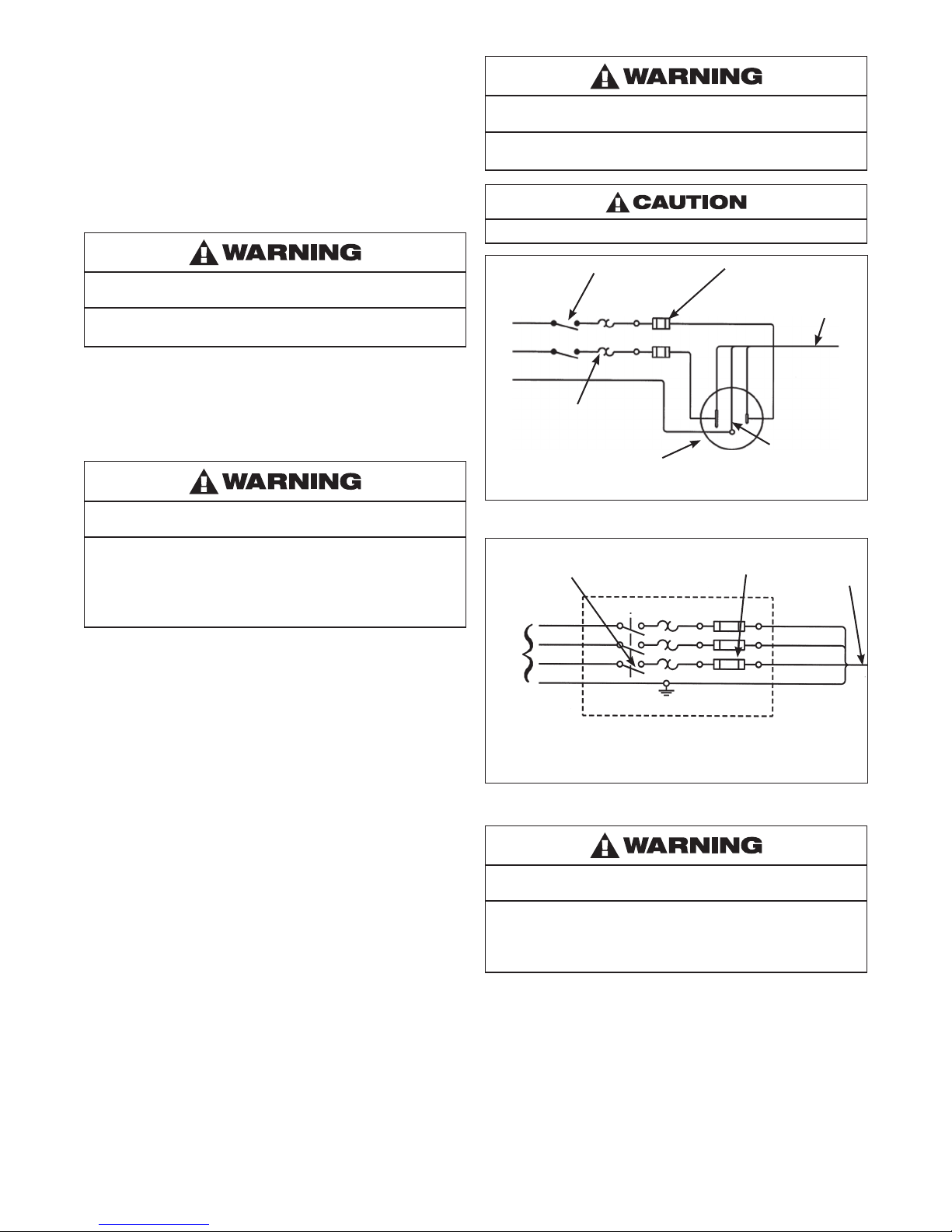

(Refer to Figure 6 or 7). To insure proper operation, to avoid damage

to hoist and electrical system and to reduce the risk of electric shock

or re, the branch circuit supplying power to the hoist must:

1. Have ample capacity to prevent excessive voltage drop during

starting and operation (refer to Figure 8). When determining

the size of branch circuit components and conductors,

special consideration should be given to the starting

current-amps (approximately three times that shown on the

hoist identication plate) and the length of the conductors.

As a minimum, the system should be rated for 15 amps and

it should have #16 AWG, or larger, wiring.

2. Be in accordance with the National Electrical Code (ANSI/

NFPA-70) and applicable National, State and Local Codes.

3. Effectively ground the hoist in accordance with National

Electrical Code and other applicable codes. Proper grounding

provides a path of least resistance for electric current to reduce

the risk of electric shock. The power cord of the hoist includes

a green-yellow wire for grounding the hoist to the external

power supply system. Be sure that the receptacle opening that

receives the longest prong is properly grounded. If grounding

is to be through the trolley trackwheels, each section of the

runway must be grounded to the building ground system

using metal to metal connections.

4. Include slow blow type fuses or inverse trip time circuit

breakers to permit the hoist to start and accelerate load.

5. Include a disconnecting means capable of being locked in the

“open” position.

Failure to properly ground the hoist presents the danger of

electric shock.

TO AVOID INJURY:

Permanently ground the hoist as instructed in this manual.

To reduce the risk of electric shock or injury, use indoors only.

Manual

Disconnect

Switch

Black

White

Ground

Thermal

Overload

Relay

Receptacle Rated for 15 amp Minimum (220-1-50 units do

not include Power Cord Plug). Wire Blue and Brown Wires to

Fuses or Circuit Breakers and Green-Yellow Wire to Ground.

Slow Blow Fuses or

Inverse Time Circuit

Breakers

Blue

Hoist Power

Cord

Brown

Green-Yellow

Figure 6 - Single Phase Systems

Manual

Disconnect

Switch

L1

L2

L3

Ground

Incoming Power

Must be per National Electrical Code and These Devices are

to be Supplied by the User.

Slow Blow Fuses or

Inverse Time Circuit

Breakers

Hoist Power

Cord

Black

Grey

Brown

Green-Yellow

Figure 7 - Three Phase Systems

Failure to provide a proper power supply system for the hoist may

cause hoist damage and offers the potential for a re.

TO AVOID INJURY:

Provide the hoist with a 15 amp, minimum, overcurrent protected

power supply per the National Electrical Code (ANSI/NFPA 70) and

applicable local codes as instructed in this manual.

8

P/N 192047138 Rev AA November 2017

Page 9

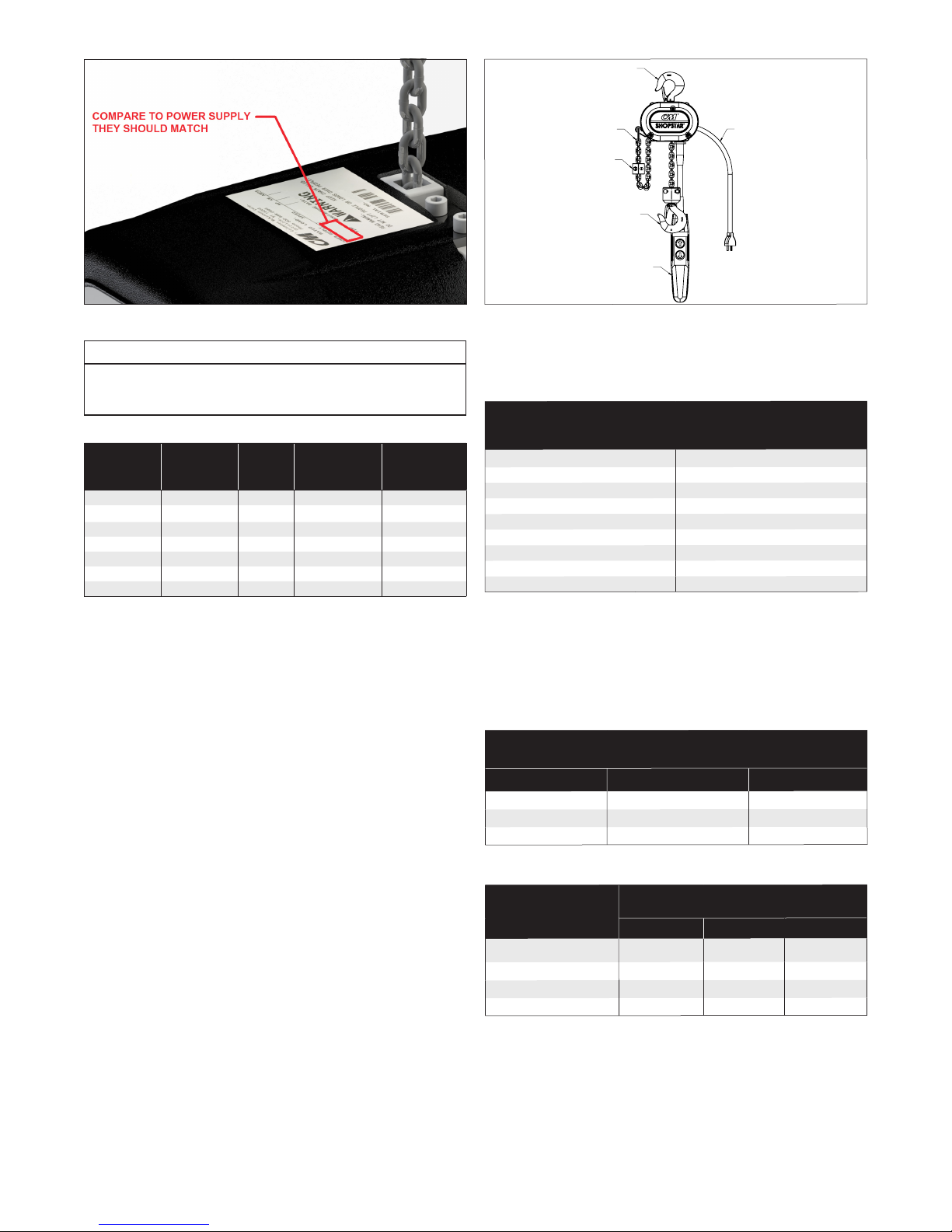

Figure 8 - Nameplate

UPPER HOOK

LOOSE END OF CHAIN

CHAIN STOP

LOWER HOOK

POWER

CORD

CONTROL STATION

Note

In this manual, nominal voltages are used when referring to power

supply systems. However, with no modication, the Shopstar

Hoist will operate on a range of voltages as indicated below:

Table 2 - Nominal Voltage

NOMINAL

VOLTAGE

VOLTAGE

RANGE

HERTZ

TRADITIONAL

CONTACTOR

230 208-240 60 AVAILABLE AVAILABLE

460 440-480 60 AVAILABLE NOT AVAILABLE

220 200-240 50 AVAILABLE AVAILABLE

380 365-395 50 AVAILABLE AVAILABLE

415 400-415 50 AVAILABLE AVAILABLE

430 415-430 50 AVAILABLE NOT AVAILABLE

575 550-600 60 AVAILABLE NOT AVAILABLE

THREE PHASE HOISTS

Since the motor in a three phase hoist can rotate in either direction,

depending on the manner in which it is connected to the power

supply, the direction of hook movement must be checked during

the original installation and each time hoist is moved to a new

location as follows:

1. Move the manual disconnect switch handle to the

“OFF” position.

2. Connect the BROWN, GREY AND BLACK wires of hoist

power cord to load side of disconnect switch. Connect

the GREEN-YELLOW wire of hoist power cord to power

supply ground.

3. Move the manual disconnect switch handle to the

“ON” position.

4. Depress the (up) control. If the hook moves in the up direction,

the hoist is ready for operation. If the hook lowers, move

the disconnect switch handle to the “OFF” position and

interchange the BLACK and BROWN leads at the disconnect

switch. Move the disconnect switch handle to the “ON”

position and the hoist is now ready for operation.

CHECKING FOR ADEQUATE VOLTAGE AT HOIST

The hoist must be supplied with adequate electrical power for proper

operation and to reduce problems that may result from insufcient

power (low voltage). These include:

• Noisy hoist operation due to brake and/or contactor chatter.

• Heating of the hoist motor and other internal components as well

as heating of wires and connectors in the circuit feeding the hoist.

• Failure of the hoist to lift the load due to motor stalling.

• Blowing fuses or tripping circuit breakers.

• Dimming of lights or slowing of motors connected to the

same circuit.

PRINTED

CIRCUIT BOARD

Figure 9 - Hoist Components

For proper operation and to avoid these low voltage problems,

voltage (measured at end of the power cord while lifting rated load)

should be as the following chart indicates.

Table 3 - Start-up Voltage

NOMINAL MINIMUM * MIN. VOLTAGE

POWER OPERATING AT INSTANT

SUPPLY VOLTAGE OF START

115-1-50/60 108

220-1-50 198

208-3-60 187

220-3-50 198

230-3-60 207

380-3-50 365

415-3-50 399

460-3-60 414

575-3-60 518

*The drop in voltage upon energizing the hoist should not be below the value listed.

Low voltage can also be caused by using an undersize extension

cord to supply power to the hoist. The following charts should be

used to determine the size wires in the extension cord in order to

minimize the voltage drop between the power source and the hoist.

115-1-50/60 units with contactor, 220-1-50 units and three phase

units (hoists with black control station)

Table 4a - Adequate Power Supply

MAXIMUM LENGTH OF EXTENSION CORD

Wire Size Single Phase Hoist Three Phase Hoist

#16 A.W.G. 135 ft (40m) 245 ft (73m)

#14 A.W.G. 220 ft (66m) 395 ft (120m)

#12 A.W.G. 354 ft (107m) 630 ft (192m)

115-1-50/60 units without contactor (hoists with orange control station)

Table 4b - Adequate Power Supply

LENGTH OF CONTROL

CORD ft(m)

MAXIMUM LENGTH OF EXTENSION CORD

BASED ON SIZE OF WIRE

#16 AWG #14 AWG #12 AWG

1.0 to 10.0 (0.3 to 3.0) 105ft (32m) 170ft (51m) 270ft (82m)

11.1 to 20.0 (3.1 to 6.0) 75ft (22m) 120ft (36m) 190ft (58m)

21.1 to 30.0 (6.1 to 9.0) 45ft (14m) 70ft (21m) 110ft (33m)

31.1 to 40.0 (9.1 to 12.0) 15ft (4.5m) 20ft (6m) 35ft (11m)

After the hoist is suspended from its support and you have made

sure the power supply complies with the above, the hoist is ready

for operation.

On the Double units, cut and discard the ties used to hold the two

strands of chain together. With no load on the lower hook, depress

the UP button in the control station and raise the lower hook

until it is about 2 feet below the bottom of the hoist. Check both

strands of chains for twists. Twists occur if the lower hook block

has been capsized between the strands of chain during packing,

shipment and/or handling. Reverse the capsize to remove twists.

9

P/N 192047138 Rev AA November 2017

Page 10

OPERATING INSTRUCTIONS

The hoist is equipped with a Protector™ that is designed to

allow the rst gear to slip on an excessive overload. An overload

is indicated when the hoist speed slows down, it raises the load in

a jerky manner or it will not lift the load at all. Also, some clutching

noise may be heard if the hoist is loaded beyond rated capacity.

Should this occur, immediately release the UP button to stop the

operation of the hoist. At this point, the load should be reduced to

the rated capacity or the hoist should be replaced with one of the

proper capacity. When the excessive load is removed, normal hoist

operation is automatically restored.

The Protector™ is susceptible to overheating and wear when slipped

for extended periods. Under no circumstance should the Protector

be allowed to slip for more than a few seconds.

Due to the above, the hoist is not recommended for use in any

application where there is a possibility of adding to an already

suspended load to the point of overload. This includes dumbwaiter

installations, containers that are loaded in mid-air, etc. Also, if the

hoist is used at unusual extremes of ambient temperatures, above

150º F (65ºC). or below 15ºF (-9ºC)., changes in lubricant properties

may permit the hoist to raise larger loads than under normal

operating conditions and present possibility of damage or injury.

On units without contactor (hoists with orange control station)

it is necessary to stop the hoist before changing direction.

Therefore, when lowering a load, the push button in the control

station must be released momentarily before the UP button is

depressed to raise the load. If this is not done, the hoist will

continue to operate in the down direction while the UP push

button is depressed, and it will continue to lower the load until

the control push button is released. As a result, the direction

must not be reversed quickly (plug reversed).

There are no electrical switches to stop the operation of the hoist

at the upper and lower limits of lift. As a result, it is necessary to

release the push button in the control station to stop the hoist

components from damage. However, continued, prolonged or

repeated slipping of the Protector will damage the Protector and

cause overheating of the internal hoist components.

Allowing the hook block to run into the hoist when raising a load or

allowing the chain stop to run into the hoist when lowering a load

may break the chain and allow the load to drop.

TO AVOID INJURY:

Do not allow the hook block or the chain stop to contact the hoist frame.

Hoist operation is controlled by depressing the control station push

buttons. Depressing the UP push button will move the load hook

toward the hoist head; depressing the DOWN push button will move

the load hook away from the hoist head.

The UP and DOWN buttons are momentary type and the hoist will

operate in the selected direction as long as the button is held in the

depressed position. Release the push button and the hoist will stop.

It is preferred that the load always be tied off with auxiliary chains or

cables before access to the area beneath the load is permitted. As

an alternative, the system may be designed such that malfunction or

failure of one hoist’s load bearing components does not cause load

loss and/or overloading of any other hoists in the system. Note that

in such a system, hoist performance and function must be monitored

visually or with the use of load cells. Check the supporting structure

to which the load hook is to be attached. Make sure the attachment

point as well as the structure have sufcient strength to withstand

several times the load imposed. If in doubt, consult a registered

engineer and local building codes.

10

P/N 192047138 Rev AA November 2017

Page 11

Attaching the load hook to an inadequate support may allow the

hoist and load to fall and cause injury and/or property damage.

TO AVOID INJURY:

Make sure the structure and the load hook attachment point have

sufcient strength to hold several times the hoist and rated load.

1. When preparing to lift a load, be sure that the attachments to

the load hook are rmly seated in hook saddle. Avoid off center

loading of any kind, especially loading on the point of the hook.

2. When lifting, raise the load only enough to clear the oor or

support and check to be sure that the attachments to the

hook and load are rmly seated. Continue lift only after you are

assured the load is free of all obstructions.

3. Do not load the hoist beyond the rated capacity shown on the

brake end cover. Overloading can cause immediate failure of

some load-carrying part or create a defect causing subsequent

failure at less than rated capacity. When in doubt, use the next

larger capacity of hoist.

4. Do not use this or any other overhead materials

handling equipment for lifting persons or allow people

on unsecured load.

5. Stand clear of all loads and avoid moving a load over heads

of other personnel. Warn personnel of your intention to move

a load in their area. Do not leave unsecured load over people.

6. Do not leave the load suspended in the air unattended.

7. Permit only qualied personnel to operate unit.

8. Do not wrap the load chain around the supporting structure and

hook onto itself as a choker chain. Doing this will result in:

1. The loss of the swivel effect of the load hook which could

mean twisted chain and a jammed liftwheel.

2. The chain could be damaged at the load hook.

9. On the Double-reeved hoists, check for twists in the load chain.

A twist can occur if the lower block has been capsized between

the strands of chain. Reverse the capsize to remove twist.

10. Do not allow a load to bear against the hook latch. The latch

is to help maintain the hook in position while the chain is slack

before taking up the slack chain.

11. Take up a slack load chain carefully and start load easily to

avoid shock and jerking of hoist chain. If there is any evidence

of overloading, immediately lower the load and remove the

excess load.

12. Do not allow the load to swing or twist while hoisting.

13. Never operate the hoist when ammable materials or vapors

are present. Electrical devices produce arcs or sparks that can

cause a re or explosion.

14. STAY ALERT! Watch what you are doing and use common

sense. Do not use the hoist when you are tired, distracted or

under the inuence of drugs, alcohol or medication causing

diminished control.

TO AVOID INJURY:

DO NOT Lift more than rated load.

DO NOT Operate with twisted, kinked or damaged chain.

DO NOT Operate damaged or malfunctioning hoist

DO NOT Lift people, loads over people, allow people on

unsecured load or leave unsecured load over people.

DO NOT Operate hoist when load hook is not centered overhoist.

DO NOT Permit load hook block to contact hoist frame or

chain container.

DO Replace damaged or malfunctioning hook latch.

DO Keep load chain well oiled.

DO Read ASME B30.16 Safety Code for Hoist and appropriate

operating instructions.

MAINTENANCE

INSPECTION

To maintain continuous and satisfactory operation, a regular

inspection procedure must be initiated to replace worn or damaged

parts before they become unsafe. Inspection intervals must be

determined by the individual application and are based on the type

of service to which the hoist will be subjected. The type of service to

which the hoist is subjected can be classied as “Severe”, “Normal”,

or “Stand by Service” per ANSI E1.6-2.

Severe Service: Hoist operates in excess of 200 days a year.

Normal Service: Hoist operates 200 or fewer days a year but

more than 25.

Stand by Service: Hoist operates 25 or fewer days per year

but at least once per year.

Two classes of inspection - frequent and periodic – must

be performed.

Frequent Inspections: Visual examination shall be performed by

a competent person following the items listed in the inspection table

Records of such inspections are recommended.

Periodic Inspections: Inspection shall be performed by a qualied

person following the items listed in inspection table. Records of

this inspection shall be recorded and retained for a minimum of 36

months after the hoist is taken out of service.

Lifting and lowering functions shall be tested under no-load

conditions. (Testing through complete rated lift length is

not required). Brake(s) operation shall be tested under

no-load conditions.

Any deciencies found during inspections are to be corrected

before the hoist is returned to service. Also, the external

conditions may show the need for disassembly to permit a

more detailed inspection, which, in turn, may require the use of

nondestructive type testing.

PREVENTIVE MAINTENANCE

In addition to the above inspection procedure, a preventive

maintenance program should be established to prolong the useful

life of the hoist and maintain its reliability and continued safe use.

The program should include the periodic and frequent inspections

with particular attention being paid to the lubrication of the various

components using the recommended lubricants (see page 15).

Note

To perform some of the periodic inspections, it is necessary to

partially disassemble the hoist. Refer to Disassembly - Assembly

starting on page 23.

Any deciencies noted must be corrected before the hoist is

returned to service. Also, the external conditions may show the

need for more detailed inspection which, in turn, may require the

use of nondestructive-type testing.

Any parts that are deemed unserviceable are to be replaced with

new parts before the unit is returned to service. It is very important

that the unserviceable parts be destroyed to prevent possible future

use as a repair item and properly disposed of.

Allowing a load to bear against the hook latch and/or hook tip can

result in loss of load.

TO AVOID INJURY:

Do not allow a load to bear against the hook latch and/or hook tip.

Apply load to hook bowl or saddle only

11

P/N 192047138 Rev AA November 2017

Page 12

Service Classifications

Severe Normal Stand By Rental

Frequent Inspections

Inspection Table

ITEM

Out of

Service

Hoist braking system for proper operation.

Hooks and attachment hardware for correct assembly,

damage, cracks, twists, excessive throat openings, latch

engagement, and latch operation.

Weekly to Monthly

Every 3 Months

Periodic Inspections

Monthly

Yearly

or Rental

Every 3 Months

Yearly

Prior to Next Use

Yearly

Load chain for adequate lubrication, signs of wear, damaged

links, corrosion, or foreign matter.

Load chain for proper reeving and twists.

Limit switches for function, if equipped

All items listed in Inspection Table for frequent inspections.

Evidence of loose screws, bolts or nuts.

Evidence of worn, corroded, cracked or distorted hook block

body, suspension screws, gears, bearings, chain dead end

and chain pin.

Evidence of damage or excessive wear of the lift wheel and

hook block sheave chain pockets.

Link by link inspection of the chain for evidence of excessive

interlink wear and damage.

Prior to Reintroduction into Service

Evidence of chain guide wear or damage where the chain

enters the hoist.

Evidence of excessive wear and/or damage of brake parts.

Proper brake adjustment.

If the hoist is equipped with a reversing contactor, inspect

contactors for functionality and free operation of the interlock.

Electrical cords, grommets, connectors, cables, and control

station enclosure (if applicable) for damage or wear.

Check bearings for excessive wear or damage.

Suspension components for damage, cracks, wear and

correct operation.

Evidence of lubricant leakage.

12

P/N 192047138 Rev AA November 2017

Page 13

HOOK INSPECTION

Hooks damaged from chemicals, deformations or cracks, or any

visibly apparent bend or twist from the plane of the unbent hook,

excessive opening or seat wear must be replaced. Also, hooks

that are opened and allow the latch to not engage the tip must be

replaced. Any hook that is twisted or has excessive throat opening

indicates abuse or overloading of the unit. Inspect other load

sustaining parts, hook block screws, load pins and hook block

bodies for damage.

On latch type hooks, check to make sure that the latch is not

damaged or bent and that it operates properly with sufcient spring

pressure to keep the latch tightly against the tip of the hook and

allow the latch to spring back to the tip when released. If the latch

does not operate properly, it should be replaced. See Figure 8 to

determine when the hook must be replaced.

Suspension bolts should be replaced any time the suspension

is removed from the hoist.

HOOK REPLACEMENT CRITERIA

Based on ASME B30.10, hooks shall be removed from service if

damage such as the following is visible and shall only be returned

to service when approved by a qualied person:

1. Missing or illegible rated load identication or illegible

hook manufacturers’ identication or secondary

manufacturer’s identication.

2. Excessive pitting or corrosion. Cracks, nicks, or gouges.

3. Wear--any wear exceeding 10% of the original section

dimension of the hook or its load pin.

4. Deformation--any visibly apparent bend or twist from the

plane of the unbent hook.

5. Throat opening-any distortion causing an increase in the

throat opening of 5% not to exceed 1/4” (6mm).

6. Inability to lock- any self-locking hook that does no lock.

7. Inoperative latch, any damaged latch or malfunctioning

latch that does not close the hook’s throat.

8. Thread wear, damage, or corrosion.

9. Evidence of excessive heat exposure or unauthorized welding.

10. Evidence of unauthorized alterations such as drilling,

machining, grinding, or other modications.

INSPECTING THE LOAD CHAIN

The chain must be inspected at regular intervals, with a minimum

of once annually. As the frequency of use increases, the time

Intervals between inspections must be reduced. During inspection,

the chain link must be examined along their entire length, including

the hidden parts. If the lifting equipment is frequently used with a

constant lifting distance or in other words the switch from upward to

downward often takes place in the same area, a particularly thorough

inspection and lubrication is required in that area. Worn chain can

also be an indication of worn hoist components. For this reason, the

hoist’s chain guides, hook blocks and liftwheel (sprocket) should be

examined for wear and replaced as necessary when replacing chain.

1. Check to see if chain is dirty or poorly lubricated.

2. Clean the chain with a non-caustic/non-acid type solvent

and make a link by link inspection for wear or cracks in the

links, twisted or deformed links. Chain with any one of these

defects must be replaced.

3. Slack the portion of the chain that normally passes over

the lift-wheel (sprocket) or idler sprocket on multi-reeved

hoist. Examine the chain links for wear. If the wire diameter

anywhere on the link measures less than 90% of the nominal

wire diameter, the chain must be replaced.

4. Based upon ASME B30.16, should also be checked for

elongation. Select an unworn, un-stretched length of the

chain (at the slack end for example). Suspend the chain

vertically under tension and using a knife blade caliper

type gauge, measure the outside length of any convenient

number of links, 11 is recommended. Measure the same

number of links in the used sections and calculate the

percentage in increased length. The chain should be

replaced if the length of the used portion is more than

1.5% longer than the unused portion of the chain. Also,

if the pitch of any individual link has elongated by more

than 5%, the chain should be replaced.

Figure 10 - Hook Inspection

Latch Type Hook Latchlok® Hook

“A” Max “B” Min “A” Max “B” Min

1.12” (28.5mm) .71” (18.0mm) 1.48” (37.7mm) .75” (18.8mm)

13

P/N 192047138 Rev AA November 2017

Page 14

Figure 11: Chain Inspection

Use only a “Knife-edge” caliper to eliminate possibility of false

reading by not measuring full pitch length.

Note that worn chain can be an indication of worn hoist

components. For this reason, the hoist’s chain guide, hook

block and liftwheel should be examined for wear and replaced

as necessary when replacing worn chain.

Also, these chains are specially heat treated and hardened and

should never be repaired.

IMPORTANT: Do not use replaced chain for other purposes such

as lifting or pulling. Load chain may break suddenly without visual

deformation. For this reason, cut replaced chain into short lengths

to prevent use after disposal.

CHAIN LUBRICATION

A small amount of lubricant will greatly increase the life of load

chain. Do not allow the chain to run dry.

Keep it clean and lubricate at regular intervals with Lubriplate®

Bar and Chain Oil 10-R (Fiske Bros. Rening Co.) or equal lubricant.

Normally, weekly lubrication and cleaning is satisfactory, but under

hot and dirty conditions, it may be necessary to clean the chain at

least once a day and lubricate it several times between cleaning.

When lubricating the chain, apply sufcient lubricant to obtain

natural run-off and full coverage, especially in the interlink area.

Used motor oils contain known carcinogenic materials.

Figure 12: Chain Wear Areas

Use only Star (H) grade load chain and factory replacement

parts. Use of other chain and parts may be dangerous and

voids factory warranty.

Figure 13: Chain Identification

Use only Star (*) grade load chain and original replacement

parts. Use of other chain and parts may be dangerous and

voids factory warranty.

IMPORTANT: Do not use replaced chain for other purposes such

as lifting or pulling. Load chain may break suddenly without visual

deformation. For this reason, cut replaced chain into short lengths

to prevent use after disposal.

Use of commercial or other manufactures’ chain and parts to repair

hoists may cause load loss.

TO AVOID INJURY:

Use only factory supplied replacement load chain and parts.

Chain and parts may look alike, but our chain and parts are made

of specic materials or processed to achieve specic properties.

TO AVOID HEALTH INJURIES

Never use used motor oils as a chain lubricant. Only use

Lubriplate® Bar and Chain Oil 10-R as a lubricant for the load

chain.

LUBRICATION

To assure extra long life and top performance, be sure to lubricate

the various parts of the Shopstar Hoist using the lubricants specied

below. If desired, these lubricants may be purchased from the

factory. Contact customer service for more information.

The lubricants used in and recommended for the Shopstar Hoist

may contain hazardous materials that mandate specic handling

and disposal procedures.

TO AVOID CONTACT AND CONTAMINATION:

Handle and dispose of lubricants only as directed in applicable

material safety data sheets and in accordance with applicable

local, state and federal regulations.

Part Number for Packaged Lubricants used

on the Shopstar Electric Chain Hoists

Lubricant Usage Type of Lubricant

Hoist Gears Grease (Special) 28605

Lower Hook Thrust

Bearing

*These oils are not furnished by CM in Packaged Quantities. When ordering lubricants, specify

the type of lubricant, part number and packages quantity required.

*Oil

GEARS

The Protector (620-111) should operate for the normal life of the

hoist without service. The device has been lubricated and calibrated

by the factory and should not be adjusted.

Part Numbers and Packaged

Quantity of Lubricants

Heavy Machine Oil obtain

locally

14

P/N 192047138 Rev AA November 2017

Page 15

The Protector™ is to be used with “Century Lubricants HB-11,

#3” grease. Do not use any other grease or the Protector will not

operate properly and parts could be damaged.

The gears and Protector are packed at assembly with grease and

should not need to be renewed unless the gears have been removed

from the housing and degreased.

Never degrease the Protector™ or attempt to disassemble this

device. Degreasing the Protector may damage parts and using a

device that has been degreased may cause erratic, inconsistent

operation. If the Protector has been degreased, it must be

replaced by a factory calibrated device.

Bra ke Asse mb ly

Brake Base Plate

First Pinio n

Sh a f t

Gap

Brake Field

A ssem b ly Inc lud es Co il

Brak e A rma tu re

Brak e Sp ring

CHAIN GUIDE, LIFTWHEEL AND SHEAVE WHEEL

When the hoist is disassembled for inspection and/or repair, the

chain guide, stripper, sheave wheel (on double chain unit) and

liftwheel must be lubricated with Lubriplate® Bar and Chain Oil

10-R (Fiske Bros. Rening Co.) prior to reassembly. The lubricant

must be applied in sufcient quantity to obtain natural runoff and full

coverage of these parts.

LOAD CHAIN

Refer to page 13 for lubrication of the load chain.

EXTERIOR FINISH

The exterior surface of the hoist has a durable, scratch resistant

baked powder coating. Normally, the exterior surfaces can be

cleaned by wiping with a cloth. However, if the nish is damaged,

compatible touch-up paint can be purchased from the factory. Refer

to page 19 for information on ordering the paint.

ELECTRIC BRAKE

The brake is non-adjustable with a nominal .004 inch (0.102 mm) air

gap and the brake disc must be replaced when the air gap reaches

.012 inch (0.305 mm). The brake spacer should be no more than

.012 inch (0.305 mm) thicker than the combined thickness of the

brake disc and armature plate. Refer to Figure 16.

Brak e D river

Bra k e D isc

Figure 14: Brake Field Assembly

Figure 15: Drive Shaft Assembly

If the gears are removed from the housing, wipe the excess grease

off the outside surfaces of the Protector with a soft cloth and

degrease the remaining gears and housings. Upon reassembly,

add 2 oz. of the above grease to gears and housing. Also, coat the

spline on the end of the rst pinion and shaft with a Molydisulphide

lubricant such as Moly-Duolube 67 (Hercules Packing Co.)

BEARINGS

Rotor bearings are pre-lubricated and require no lubrication. Needle

bearings) are packed at assembly with grease and should not need

to be relubricated. However, if the housings, liftwheel or sheave

wheel have been degreased, these bearings should be greased

using “Century Lubricants HB-11, #3” grease.

SEALS

When reassembling the unit, wipe the inside surface of the seals

with “Century Lubricants HB-11, #3” grease.

HOOK BLOCK

If the hook blocks are disassembled for inspection purposes, wipe

the grease from the hook knob and the hook knob cavities in the

hook blocks. At reassembly, coat the underside of the hook knob

and the knob bearing surfaces of cavities in the hook blocks with

Molykote BR-2-S (Dow Corning Corp.) grease or equivalent.

Figure 16: Brake Assembly

Failure to follow proper lockout/tagout procedures may present the

danger of electrical shock.

TO AVOID INJURY:

Disconnect power and lockout/tagout disconnecting means before

removing cover or servicing this equipment.

To inspect the brake gap, disconnect the hoist from power and

remove brake end cover.

1. Refer to Figure 16 and disassemble the brake. Depress and

hold the eld assembly while removing the four brake screws.

The eld assembly is under spring pressure and will spring-out

if not held. Examine the base plate, brake disc) and armature

for excessive wear, scoring or warpage. Make sure the brake

disc is not glazed, the coil rmly xed in the eld) and the

brake spring is not damaged. Worn, scored, warped, glazed or

damaged parts should be replaced before preceding.

2. Refer to Figure 16 and assemble the brake. Depress and hold

the eld assembly while installing the four brake screws through

the brake parts and mount the brake on the gear housing.

Tighten the four brake screws to 25 in.lb.

PROTECTOR™

The Protector should operate for the normal life of the hoist without

service. The device has been lubricated and calibrated and it should

not be adjusted. If the Protector is not operating properly (see

testing on page 13), it must be replaced with a properly calibrated

unit from the factory.

PREVENTATIVE MAINTENANCE

A preventative maintenance program should be established to

prolong the useful life of the hoist and maintain its reliability and

continued safe use. The program should include the periodic and

frequent inspections with particular attention being paid to the

lubrication schedule on page 12.

15

P/N 192047138 Rev AA November 2017

Page 16

TROUBLESHOOTING CHART

Always disconnect unit from the power supply system before removing hoist covers or the back cover of control station.

Symptom Possible Cause(s) Corrective Action

1. Hook does not respond to the control

station

A.) No voltage at hoist-main line or branch circuit switch open;

branch line fuse blown or circuit breaker tripped.

A.) Check for blown fuse or tripped circuit breaker

or open disconnect switch in main line or branch

circuit. Replace fuse, reset circuit breaker or

close switch.

B.) Open control circuit due to loose connections or broken wires in

circuit; motor thermal protector open; control station contacts

not closing; open or Shorted winding in transformer; transformer

thermal cut-out open; mechanical binding in contactor; open

or shorted winding in contactor coil or blown Printed Circuit

Board fuse.

C.) Wrong voltage or frequency. C.) Make sure that the power supply to hoist is the

D.) Low Voltage. D.) Check power supply system to make sure it

E.) Brake not releasing due to open or shorted coil, defective diodes

or brake disc binding.

F.) Excessive load. F.) Reduce load to capacity limit as indicated on

G.) Phase failure (single phasing-three phase units only) - open circuit,

grounded or faulty connection in one line of power supply system,

hoist wiring, contactor, motor leads or windings.

2.) Hook moves in the wrong direction. A.) Wiring connections reversed in control station or hoist. A.)Use wiring diagram and check wiring connections.

B.) Failure of cut-out device (single phase units only) to effect

dynamic braking at time of reversal.

C.) Phase reversal (three phase unit only). C.) See “Three Phase Hoists.”

3.) Hook lowers but will not raise. A.) Excessive load. A.) See item 1F.

B.) Hoisting circuit is OPEN due to loose connections or broken

wire in circuit; control station contacts are not making; open or

shorted winding in contactor coil.

C.) Motor cut-out device not operating. (single phase units only). C.) Check cut-out device and connections to same.

D.) Phase failure (three phase units only). D.) See item 1G.

4.) Hook raises but will not lower. A.) Lowering circuit is OPEN due to loose connections or broken

wire; control station contacts not closing; open or shorted

winding in contactor coil.

B.) Motor reversing switch not operating (single phase unit only). B.) See item 3C

C.) Phase reversal (three phase units only). C.) See item 2C

D.) Phase failure (three phase units only). D.) See item 1G.

5.) Hook does not stop promptly. A.) Brake slipping. A.) Check electric brake, especially the brake disc for

B.) Excessive load. B.) See item 1F.

B.) Check electrical continuity thru motor thermal

protector. If it is open, allow motor to cool. If this

does not correct the trouble, use wiring diagram to

check electrical continuity of wiring, transformer,

contactor and control station contacts. Repair

wiring or replace defective part. Check Printed

Circuit Board fuse & replace if needed.

same as that shown on identification plate on

button of hoist.

complies with the requirements listed under

“power supply system” starting on page 3.

E.) Check coil continuity, diodes and connections.

Make sure brake disc slides freely on brake driver

and brake spring is not broken. Replace coil (brake

field), repair connections, remove burrs from

brake driver so that brake disc slides freely and/or

replace brake spring.

identification and capacity labels on hoist.

G.) Check for electrical continuity and repair or

replace defective part.

B.) Check connections to cut-out device. Replace

damaged device or faulty capacitor

B.) Use wiring diagram to check electrical continuity

of wiring and control station contacts. Repair wiring

or replace defective part.

Repair connections and/or replace cut-out device.

A.) See item 1B.

wear or glazing and make sure brake spring is not

broken. Replace worn or glazed brake disc or replace

brake spring.

16

P/N 192047138 Rev AA November 2017

Page 17

Symptom Possible Cause(s) Corrective Action

6.) Hoist operates sluggishly. A.) Excessive load. A.) See item 1F.

B.) Low voltage. B.) See item 1D.

C.) Phase failure or unbalanced current in the phases

(three phase unit only).

D.) Brake dragging. D.) Check electric brake. Check to make sure brake

7.) Hoist operates sluggishly. A.Excessive load. A.) See item 1F.

B.) Low voltage. B.) See item 1D.

C.) Extreme external heat. C.) Above an ambient temperature of 104°F (40°C),

D.) Frequent starting or reversing. D.) Avoid excessive inching, jogging and reversing.

E.) Brake dragging. E.) See item 6C.

F.) Motor cut-out device not opening start winding circuit (single

phase units only).

G.) Phase failure or unbalanced current in phases (three phase units

only).

8. Hook fails to stop in either direction. A.) Brake not closing or ineffective. A.) Check electric brake, and armature for binding,

9. Hook lowers when up button is

depressed.

A.) Phase reversal (three phase units only). A.) See Item 2C.

C.) See item 1G.

disc is free to move on brake driver. Check for

warped or bent brake disc and base plate. Free-up

brake disc by removing burrs on driver. Replace

warped armature base plate or brake disc.

the frequency of hoist operation must be limited

to avoid overheating the motor. Special provisions

should be made to ventilate the space around the

hoist and shield it from radiant heat.

This type of operation drastically shortens motor

cut-out device, capacitor, control station and

contactor contact life and causes excessive

brake wear.

F.) See item 3C.

G.) See Item 1G.

broken brake spring, first pinion shaft broke, brake

driver worn, brake disc worn. Correct binding of

armature; replace broken or worn parts.

Failure to follow proper lockout/tagout procedures may present the

danger of electrical shock.

TO AVOID INJURY:

Disconnect power and lockout/tagout disconnecting means before

removing cover or servicing this equipment.

ELECTRICAL DATA

OPEN OR SHORT CIRCUIT IN ELECTRICAL

COMPONENTS

Open circuits in electrical components may be detected by isolating

the component and checking for continuity using an ohmmeter.

Short circuits are indicated by D.C. resistance substantially

below the nominal D.C. resistance. Motor current draw should be

measured at the end of the power cord while the hoist is raising

rated load. Check cut-out device (on single phase units only) by

measuring coil resistance (terminals 3 and 4) and making sure the

contact (terminals 2 and 4) is open.

17

P/N 192047138 Rev AA November 2017

Page 18

Table 5 - Electrical Data for Components

Stators

Volts-Phase-Hertz Full Load Current (amp)

110 to 120-1-50/60

2.7

Nominal DC

Resistance (ohm)

Yellow to Red: 7.7

Blue to Black: 6.2

Yellow to Red:

220-1-50 1.1

27.7 Blue to

Black: 24.2

220-3-50 1.1 White to Red:

26.8 White to

230-3-60 0.6

380-3-50 0.63

415-3-50 0.58

460-3-60 0.88

Black: 26.8

Red to Black: 26.8

White to Red: 72.6

White to Black: 72.6

Red to Black: 72.6

White to Red:

575-3-60 0.4

140.0 White to

Black: 140.0 Red

to Black: 140.0

Transformers

Primary 220/380v. 230/460v. 460v. 575v. 575v.

Secondary 48v. 115v. 48v. 115v. 48v.

Leads Nominal DC Resistance (ohm)

Black to Purple 11.7 71.0 11.9 73 98

White to Red 228.0 224.0

White to Yellow 614.0 902.0

Red to Yellow 384.0 682.0

To reduce the risk of electric shock or injury, use indoors only.

White to Orange 916.0 1100 1100

Coils

Nominal DC

Resistance

(ohm)

Contactor

Coils

Voltage

(V)

Current Draw (amp)

115 0.02 765

48 0.2 98.4

*115 - *272

Brake Field

**220 - 1120

***280 - 1608

Cut-out Device *115 0.1

Terminals 3 to

4: 0.3

*to measure 115 volt brake coil resistance, carefully cut and peel

back the shrink tubing on the brake coil leads to expose the diodes.

Trace the leads from the coil to the diodes. Connect the ohmmeter

leads at the coil side of the diodes (refer to the wiring diagram) and

measure the resistance. If coil is ok, reinsulate the brake coil leads

and diodes using electrical tape. Diodes are checked by connecting

the ohmmeter to the ends of the brake coil leads, checking for an

open or short circuit, reversing the connections to the ohmmeter and

again checking for an open or short circuit. If there is an indication of

an open or short circuit with the original and reversed connections,

diodes are defective and the brake eld, which includes the diodes,

must be replaced. Usable diodes are indicated by continuity with

the original connections and an open circuit when the connections

are reversed or, an open circuit with the original connection and

continuity with reversed connections.

** 220 volt brake coil is used on 220-1-50, 220-3-50/60, 380-3-50,

415-3-50 and 460-3-60 hoists.

***280 volt brake is used on 575-3-60 hoists.

18

P/N 192047138 Rev AA November 2017

Page 19

WIRING DIAGRAMS

The following wiring diagrams are representative. For actual wiring diagram, refer to the diagram supplied with the hoist. Note: for 575-3-60

units, refer to wiring diagram supplied with hoists.

Figure 17 - 110-1-50, 115-1-60 Hoists without Contactor (Orange Control Station)

Figure 18 - 110-1-50, 115-1-60 Hoists with Contactor (Black Control Station)

19

P/N 192047138 Rev AA November 2017

Page 20

WIRING DIAGRAMS

The following wiring diagrams are representative. For actual wiring diagram, refer to the diagram supplied with the hoist. Note: for 575-3-60

units, refer to wiring diagram supplied with hoists.

Figure 19 - 220-1-50, 230-1-60 Hoists with Contactor (Black Control Station)

Figure 20 - 220-3-50, 230-3-60 Hoists with Contactor (Black Control Station)

20

P/N 192047138 Rev AA November 2017

Page 21

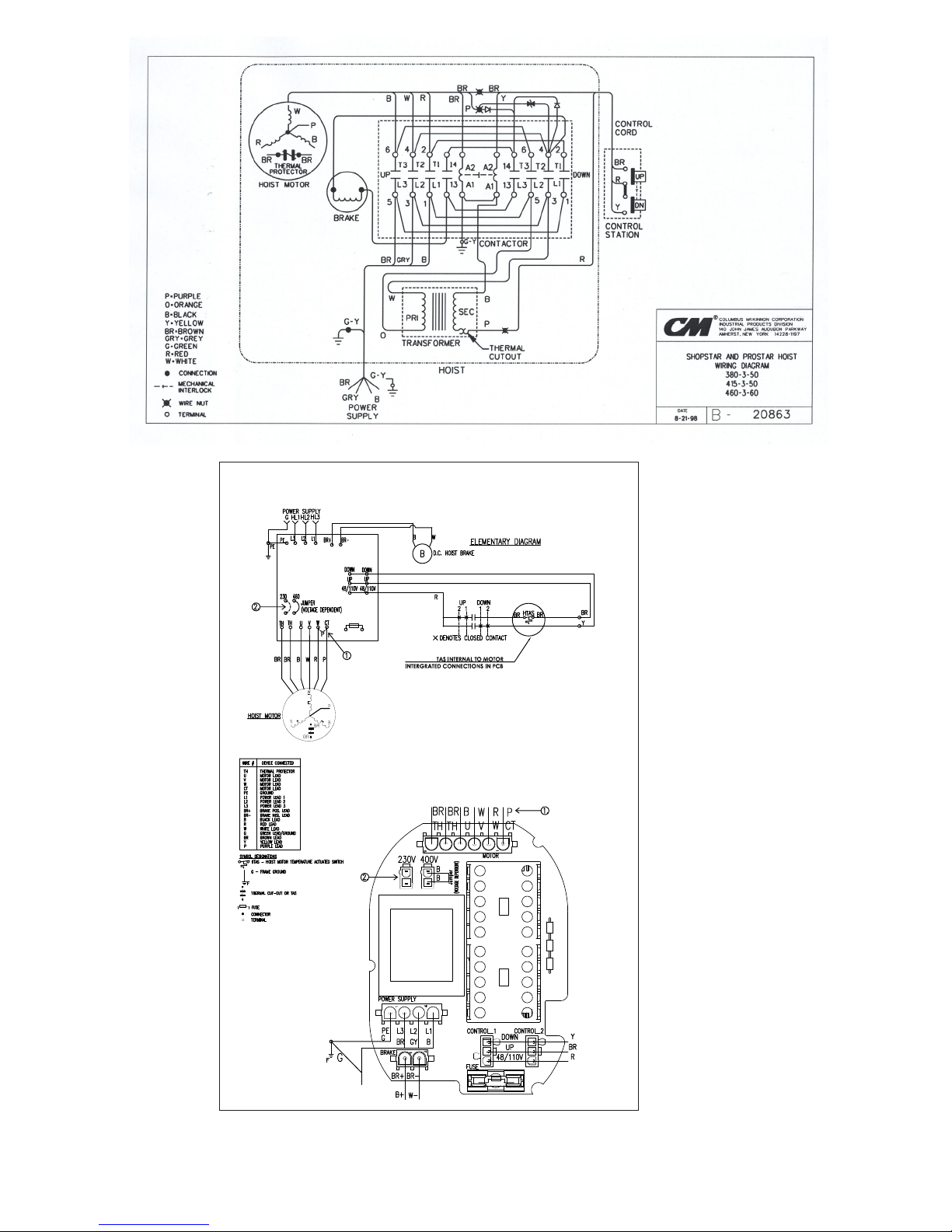

Figure 21 - 380-3-50, 415-3-50, 460-3-60 Hoists with Contactor (Black Control Station)

Figure 22 - 230-3-60, 400-3-50 PCB (Printed Circuit Board) Unit

21

P/N 192047138 Rev AA November 2017

Page 22

Figure 23 - 575-3-60 Hoists with Contactor (Black Control Station)

22

P/N 192047138 Rev AA November 2017

Page 23

DISASSEMBLY-ASSEMBLY

When disassembling and assembling the Shopstar Hoist, refer to

the exploded view and the parts list on pages 15 through 18.

These show the proper relationship of the parts, the names of the

parts and the required quantities of the parts. In addition, please

observe the following:

1. Needle bearings are pressed into the gear housing, main

frame, liftwheel and lower sheave wheel. Unless they are to

be replaced, do not attempt to remove these bearings.

2. A liftwheel seal is pressed into the main frame and a seal

is pressed into the end of the liftwheel shaft. Be careful

that these seals are not cut or damaged during disassembly

and reassembly.

Figure 24 - Main Frame

3. Refer to page 13 for disassembly, inspection, reassembly

and adjustment of the brake.

4. Do not attempt to disassemble the Protector™ - refer to

page 13.

5. Refer to page 14 for lubrication instructions.

6. See next section for load chain removal and installation.

7. Tighten the various screws as follows:

Table 6 - Torque Settings

Part Name

Pin Retainer Plate Screw 25 2.8

Motor Cover Screw 25 2.8

Gear Housing Screw 25 2.8

Brake End Cover Screw 25 2.8

Dead End Plate Screw 125 14.1

Hook Retainer Screw 10 1.1

Hook Block Screw, Double-reeved, 500,

600 and 1,000 lb (226, 272 and 453 kg)

Hook Block Screw, Single-reeved, 250,

300 and 500 lb (113, 136 and 226 kg)

Power Cord Ground Screw 20 2.2

8. When removing the stator , rst remove the brake end cover.

Disconnect stator leads from the wiring or contactor. At the

other end, remove the motor end cover. On single phase

units, use an insulated screw driver to short between the bare

terminals of the capacitor to discharge it. A spark may be

produced. Disconnect wiring to the capacitor and then remove

the capacitor. Remove the cut-out device and disconnect the

wires from it. Remove the rotor assembly and thrust washer.

Then slide the stator out of the main frame.

Seating

lb·in

Torque (N·m)

125 14.1

50 5.6

Pin Retainer Plate

Wire

Slot

Figure 25 - Stator Installation

9. To install the stator, (Refer to Figure 24) and make sure that the

pin retainer plate has been assembled to the main frame. On

single phase units slide jumpers “2” and “CAP” through the

wire slot in the main frame. Route these wires around the rotor

bearing boss in the main frame as shown in Figure 25. Attach

the brown and blue stator leads and “2” jumper to cut-out

device (refer to wiring diagram). Slide the cut-out device into

the cavity as shown. Push the cut-out device down until it sets

on the main frame. Place the capacitor on top of the cut-out

device and attach “CAP” jumper and the yellow stator lead to

it. Re-route jumpers “2” and “CAP”, if necessary to make sure

they clear the rotor bearing boss as shown in Figure 25. On all

units slide stator leads through wire slot. Align the slots in the

stator shell with the threaded holes in the main frame, as shown

in Figure 24. With the leads down, slide the stator into the main

frame. Slide the rotor, large bearing rst, into stator. Place

the rotor thrust washer on top of the exposed rotor bearing

and then assemble the motor end cover to the main frame.

Using wiring diagram, complete the wiring at the brake

end of the unit.

10. Properly install the upper hook as shown in Figure 27, then

slide the hook retainer into the cavity on top of the hoist and

secure it using hook retainer screw. Tighten screw to a seating

torque of 10 in. lbs. (1.1 NM).

LOAD CHAIN REMOVAL/INSTALLATION

1. If unit has a chain container, remove it from the chain guide.

2. Remove the chain stop. Depress DOWN button and run chain

out of hoist.

Figure 26: Chaining Hoist

23

P/N 192047138 Rev AA November 2017

Page 24

3. Feed a short length of soft wire through the opening in the

3. Feed a short length of soft wire through the opening in the

chain guide/stripper until it comes out of the hoist. Attach

“new” chain to end of the wire which is in the center of the

hoist. Position the chain so that the welds will be down and