Page 1

c

COMBINATION BOILER

Heating and Instantaneous Domestic Hot Water

Fanned Flue system

Installation and Operating instructions

Manufactures N° Model Type Gas Council N°

200906827037.31 MX2 24 Nat 47 - 980 - 28

200906828037.31 MX2 30 Nat 47 - 980 - 29

GB

Unit 3A, Thornton Road Ind. Estate Off Hockney Road Bradford, BD8 9HQ

01274 488 388

Page 2

2

These instructions are suitable for the NC boilers :

Do not forget the Logbook!

Chaffoteaux & Maury supports Benchmark, the heating industry code to ensure the correct installation, commissioning and

servicing of domestic central heating systems.

To The Householder

Make sure you have a completed Logbook for your boiler. This provides a record of the commissioning of your boiler.

It contains important information about your particular installation that may be required by service engineers. The logbook will

also provide contact details for the installer should you need guidance in the use of this appliance or if there are any problems.

As with your car, your boiler will work more reliably and efficiently if regularly serviced. We recommend an annual service

check. The service history of the appliance will be recorded on the logbook.

In the unlikely event of any problems with your boiler or system you should first contact your installer. If your installer cannot

resolve the problem he should telephone our national service helpline.

A charge may be made if Chaffoteaux & Maury Service is called out to resolve a non-product related fault.

Your statutory rights are not affected.

CUSTOMER CARE

Chaffoteaux & Maury Ltd., as a leading manufacturer of domestic and commercial water heating appliances is committed to

providing high quality products and a high quality after sales service. If it is necessary to contact an engineer, then telephone

the national warranty helpline 0870 243 0224.

Advice on installation or servicing can also be obtained by contacting the Chaffoteaux Customer Services Department at

Telford.

CUSTOMER SERVICES DEPARTMENT

Tel: 01952 222288

Fax: 01952 260915

GUARANTEE

The manufacturer’s guarantee is for 12 months from the date of purchase. The guarantee is invalidated if the appliance is not

installed in accordance with the recommendations made herein or in a manner not approved by the manufacturer. To assist us

in providing you with an efficient after sales service, please return the guarantee registration card enclosed with the boiler

without delay.

STATUTORY REQUIREMENTS

The installation of this appliance must be carried out by a CORGI Registered person or other competent person and in

accordance with the requirements of the Gas Safety (Installation and Use) Regulations.

In addition, the installation must also comply with the current bylaws of Local Water Undertakings, Building Regulations, IEE

Wiring Regulations, Local Authority Building Standards (Scotland) Regulations and the Safety Document 635 The Electricity at

work Regulation. The appliance named below does not contain any asbestos or asbestos products, or mercury

derivatives. Additional CFC’s have not been used in this product.

The appliance does not contain any potential hazard in relation to the COSHH regulations.

It should also be carried out in accordance with current editions of the following British Standards Codes of practice: BS 6891,

BS 5440 parts 1 and 2, BS 5449 part 1, BS 7593, BS 6798, BS 5546, BS 4814, BS 7074 part 1 and 2, BS 7671 and BG DM2.

If there is a possibility of the incoming mains water pressure exceeding 10 bar then a suitable pressure limiting valve must be

fitted where pressures exceed 6 bars a pressure limiting is preferred.

Precautions: During servicing, keep the dust generation to a minimum and avoid inhaling any dust and contact with the skin

and eyes. Normal handling and use will not present any discomfort, although some people with a history of skin complaints

may be susceptible to irritation. When disposing of the ceramic lining, ensure that it is securely wrapped and wash hands after

contact.

TO CONTACT C&M SERVICE, PLEASE CALL THE NATIONAL WARRANTY HELPLINE ON:

0 870 243 0224

To The Installer

As part of the commissioning of this appliance it is vital that the Logbook is completed and given to the Householder. Please

ensure that your customer is aware of the importance of keeping the Logbook safe as a record of the installation and the

appliance service history.

Please ensure that your customer is aware of the correct operation of the system, boiler and controls.

Unit 3A, Thornton Road Ind. Estate Off Hockney Road Bradford, BD8 9HQ

01274 488 388

Page 3

3

Contents

CUSTOMER CARE

Page

Guarantee ............................................................................................................................................................2

Statutory Requirements .......................................................................................................................................2

Contents ...............................................................................................................................................................3

INSTALLER’S INSTRUCTION.............................................................................................................................5

1 DESCRIPTION ................................................................................................................................................5

2 DIMENSIONS .................................................................................................................................................6

3 HYDRAULIC DATA .........................................................................................................................................6

4 INSTALLATION REQUIREMENTS ................................................................................................................7

Location ...................................................................................................................................................7

Flue ..........................................................................................................................................................7

Ventilation ................................................................................................................................................7

Gas Supply .............................................................................................................................................7

Electrical Supply ....................................................................................................................................7

Showers ...................................................................................................................................................7

Flushing and Water Treatment ...............................................................................................................7

System Controls ......................................................................................................................................7

5 CONNECTING GAS INTAKE AND EXHAUST DUCTS ..................................................................................8

6 INSTALLING THE BOILER ...........................................................................................................................10

7 ELECTRICAL CONNECTIONS ....................................................................................................................11

8 OPERATING..................................................................................................................................................12

Pressurising ...........................................................................................................................................12

Settings ..................................................................................................................................................12

Burner gas output setting ......................................................................................................................13

9 FITTING THE CASING ..................................................................................................................................14

10 GAS CONVERSION ......................................................................................................................................15

11 INCORRECT FUNCTION .............................................................................................................................16

12 PARTICULAR CHARACTERISTICS ............................................................................................................17

Unit 3A, Thornton Road Ind. Estate Off Hockney Road Bradford, BD8 9HQ

01274 488 388

Page 4

4

USER’S INSTRUCTIONS

Page

13- CONTROL PANEL .......................................................................................................................................18

14- HOW TO USE ..............................................................................................................................................19

15 MAINTENANCE ............................................................................................................................................20

16 FLUE GAS SAFETY .....................................................................................................................................20

17 GUARANTEE ................................................................................................................................................20

18 PRACTICAL INFORMATION ........................................................................................................................20

19 TECHNICAL DATA .......................................................................................................................................21

20 INSTRUCTION FOR SETTING THE BUILT IN CLOCK................................................................................22

21 INCORRECT FUNCTION ..............................................................................................................................23

This instruction booklet is especially designed for appliances installed in United Kingdoms

INTRODUCTION

The

MX2 is a fully automatic, wall mounted, low water content combination boiler. It is a room sealed, fan

assisted, balanced flued appliance providing central heating and mains pressure domestic hot water on demand.

It has electronic ignition and is suitable for all modern electrical control systems. The boiler is designed for sealed

systems only and a circulating pump, expansion vessel together with a pressure gauge and safety valve are

included within the boiler.

The standard horizontal flue kit is suitable for lengths 300 mm minimum to 850 mm maximum and includes an

elbow adapter that can be rotated through 360 ° . The horizontal flue can extend up to 4 metres using 1 metre

flue extension kits. 45 ° and 90° flue bends are also available as accessories.

Unit 3A, Thornton Road Ind. Estate Off Hockney Road Bradford, BD8 9HQ

01274 488 388

Page 5

5

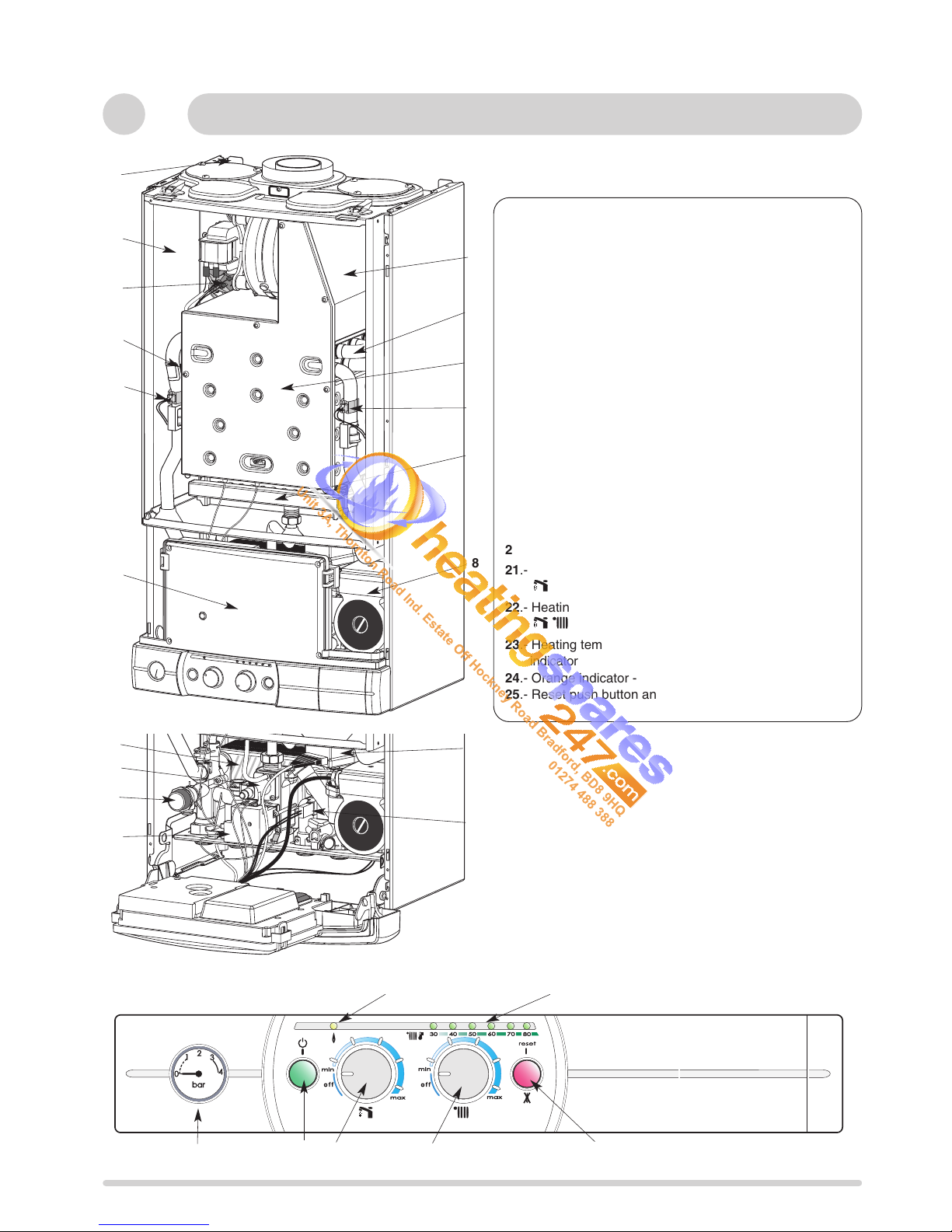

1

Description

INSTALLER’S INSTRUCTIONS

Fig.1

1

2

14

4

5

6

12

3

10

15

17

16

18

Fig.2

7

8

9

11

1.- Steel chassis complete with expansion vessel

2.- Sealed chamber

3.- Flue hood with fan

4.- Main heat exchanger

5.- Combustion chamber

6.- Multi- gas burner assembly comprising ignition and

ionisation electrodes

7.- Gas valve assembly

8.- Pump with automatic air separator and automatic vent

9.- Overheat safety cutout

10 - Main exchanger inlet thermistor

11.- Main exchanger outlet thermistor

12.- Electrical box

13.- Hot water flow sensor

14.- Air pressure switch

15.- Ignitor

16.- Central heating pressure relief valve

17.- Three way valve

18.- Secondary heat exchanger

19. - Pressure gauge

20. - On/off push button and power on indicator light

21.- Sanitary temperature setting and sanitary start button

22.- Heating temperature setting and heating start button

23.- Heating temperature indicator and operating faults

indicator

24.- Orange indicator - Burner ON

25.- Reset push button and red indicator locking light

13

20

21

23

25

22

24

19

Fig.3

c

Unit 3A, Thornton Road Ind. Estate Off Hockney Road Bradford, BD8 9HQ

01274 488 388

Page 6

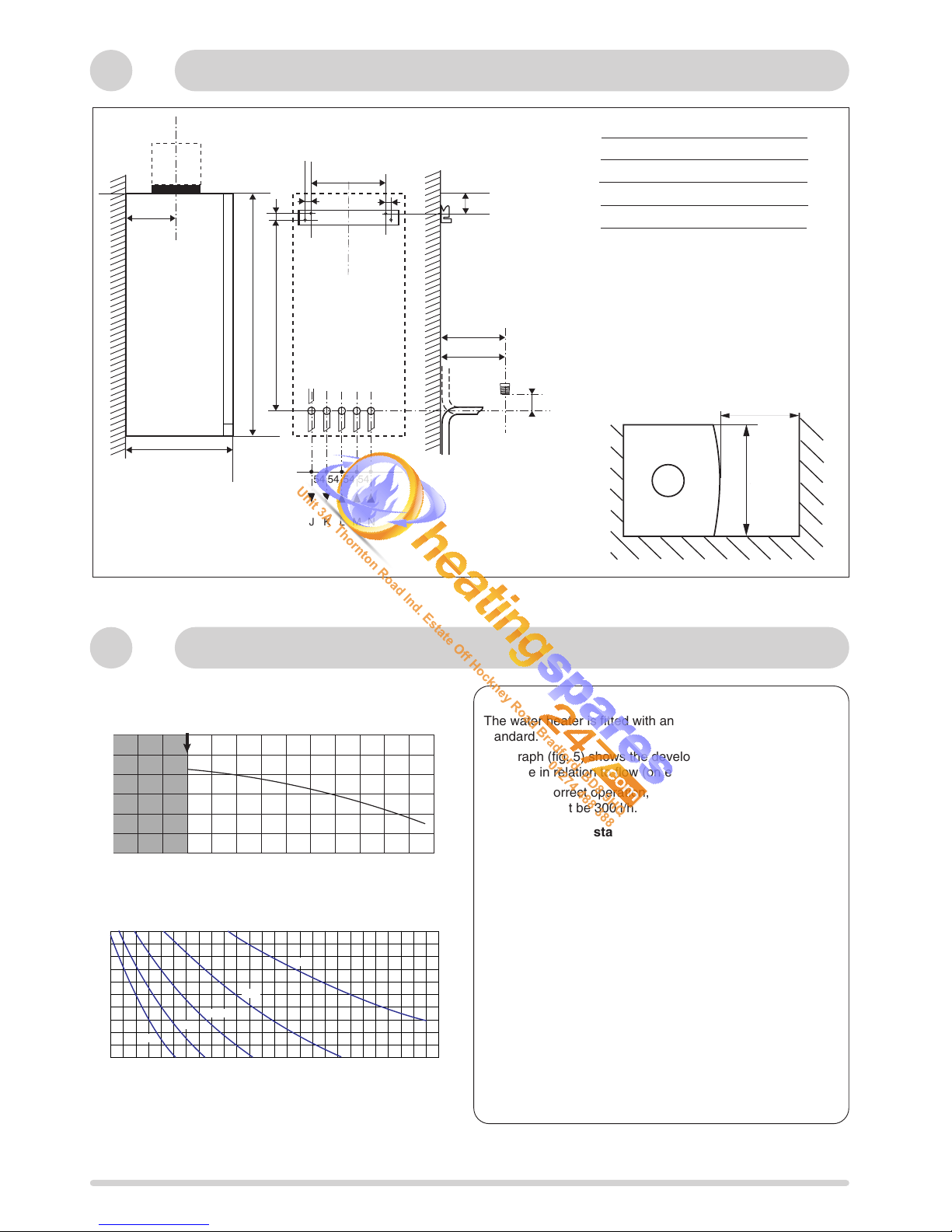

6

440

450 mini pour entretien

Fig. 4

2 Dimensions

54 54 54 54

JKLMN

I

JKLMN

32

296

141

289

15

21

720

652

121,5

I

172,5

18,5

18

All dimensions in mm

With packaging :

24 kW : 32 kg

30 kW : 33 kg

3

Hydraulic data

Fig. 5

Fig. 6

The water heater is fitted with an automatic by-pass as

standard.

The graph (fig. 5) shows the developmentof the pressure

available in relation to flow (on exit from the boiler).

To ensure correct operation, the minimum flow of the

appliance must be 300 l/h. (Thermostatic taps closed).

Capacity of the installation.

The water heater is fitted with a pressurised expansion

vessel.

Maximum. volume of expansion vessel: 6 litres.

Pressure: 1 bar.

The volume of the expansion vessel in a pressurised

appliance varies according to:

- the average operating temperature in °C

- the static height, which is the difference in metres between

the highest point of the appliance and the expansion vessel

axis).

The minimum cold filling pressure of the appliance is 1 bar

(recommended pressure between 1.2 and 1.7 bar).

The pressure of the expansion vessel should always be

greater than the static height (in metres) divided by 10.

0

4

3

2

1

5

6

100

200 800

700

600

500

400

300

900

1000

1100

1200

l/h

mCE

Débit mini (robinets thermostatiques fermés)

Pression disponible

20 40 60 80 100 120

Pf

140 160 180 200 220 240

1,0

1,1

1,2

1,3

1,4

1,5

1,6

1,7

1,8

1,9

2,0

Capacité maximale de l'installation (en litres)

260

Pression à froid pour le circuit chauffage (en bar)

280

40°C

50°C

60°C

70°C

80°C

390

minimum space required 450

I Safety valve C/H and condensate

J

Heating flow

K

D.H.W. flow

L

Gas supply

M

Cold water inlet

N

Heating return

C liter

Pump head chart available at the outlet of the boiler

System capacity chart

Pump head available

Minimum flow rate (with all heating thermostatic valves closed)

Central heating initial pressure when cold (in bar)

Diagramme de contenance en eau.

Unit 3A, Thornton Road Ind. Estate Off Hockney Road Bradford, BD8 9HQ

01274 488 388

Page 7

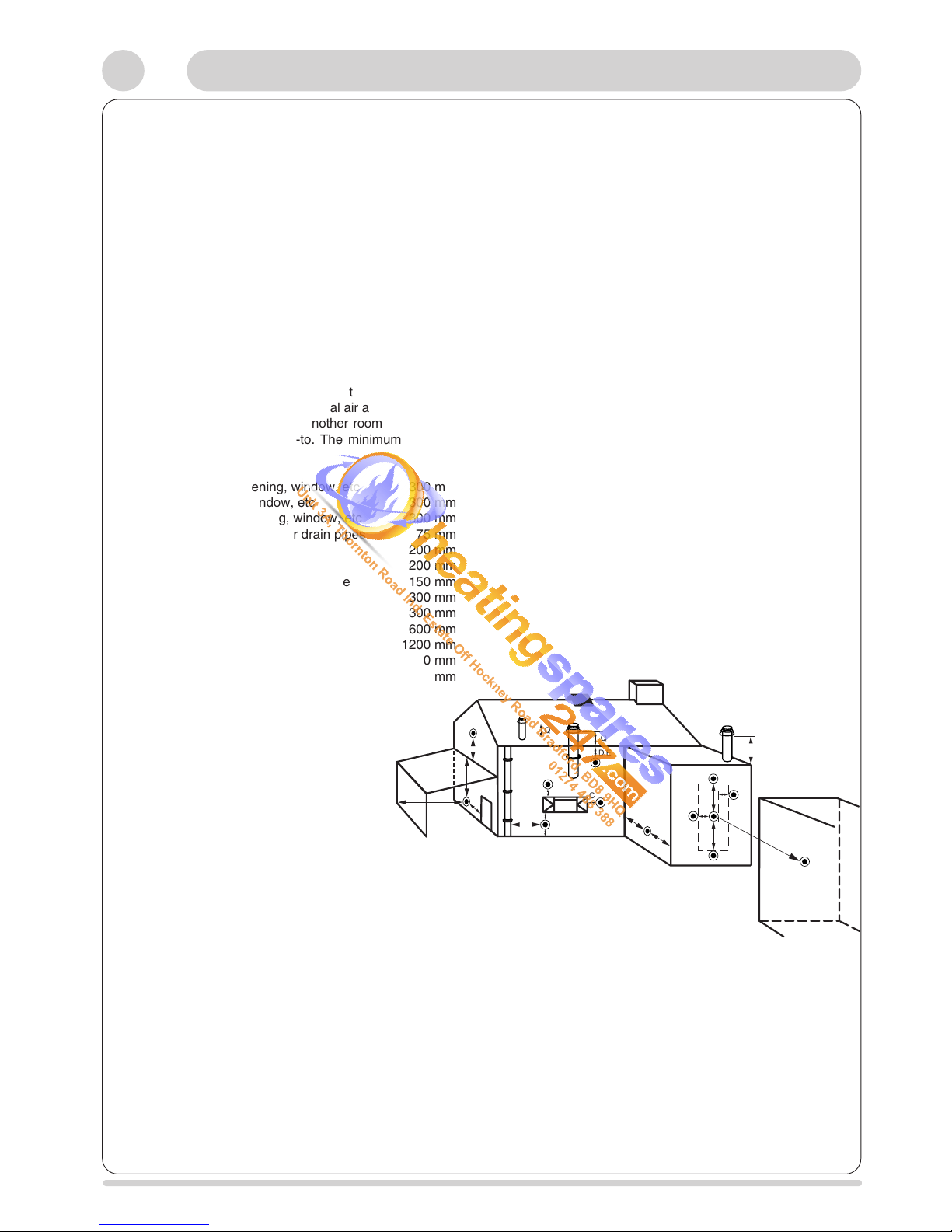

7

4 Installation requirements

Location

The boiler can be installed on any suitable internal wall.

Provision must be made to allow the correct routing of the flue

and siting of the terminal to allow the safe and efficient

removal of the flue products. A compartment or cupboard may

be used provided that it has been purpose-built or modified for

the purpose. It is not necessary to provide permanent

ventilation for cooling purposes. Detailed recommendations

are given in BS 5440 pt 2. If it is proposed that it is installed in

a timber framed building then reference must be made to

British Gas Document DM2, or advice sought from CORGI.

Avoid to install the boiler where the air inlet can be polluted

by chemical products such as chlorine (swimming pool aera),

or ammonia (hair dresser), or alcalin products (launderette)

Flue

Detailed information on flue assembly is contained in the

appropriate starter pack.

The boiler must be installed so that the flue terminal is

exposed to the free passage of external air at all times. It must

not be allowed to discharge into another room or space such

as an outhouse or closed lean-to. The minimum acceptable

clearances are shown below:

- A Directly below an opening, window, etc 300 mm

- B Above an opening, window, etc 300 mm

- C Horizontally to an opening, window, etc 300 mm

- D Below gutters, soils pipes or drain pipes 75 mm

- E Below eaves 200 mm

- F Below balconies or car port roof 200 mm

- G From a vertical drain pipe or soil pipe 150 mm

- H From an internal or external corner 300 mm

- I Above ground roof or balcony level 300 mm

- J From a surface facing the terminal 600 mm

- K From a terminal facing the terminal 1200 mm

- L From an opening in the car port into the dwelling 1200 mm

- M Vertically from a terminal on the same wall 1500 mm

- N Horizontally from a terminal on the same wall 300 mm

- Q Fixed by Ubbink Rolux 4 GM flue terminal

It may be necessary to protect the terminal with a

guard. Reference should be made to the Building

Regulations for guidance. Suitable guards may be

obtained from the following manufacturer:

Quinnel Barret & Quinnel Wireworks

Old Kent Road

London SE15 1NL

Tel: 0171 639 1357

Ventilation

The room in which the boiler is installed does not require specific

ventilation. If it is installed in a cupboard or compartment

permanent ventilation is not required for cooling purposes.

Gas Supply

The gas installation and soundness testing must be in

accordance with the requirements of BS 6891.The boiler

requires a 22 mm supply. Ensure that the pipe size is

adequate for demand including other gas appliances on the

same supply.

Electrical Supply

The appliance requires an earthed 230V - 50 Hz supply and

must be in accordance with current I.E.E. It must also be

possible to be able to completely isolate the appliance

electrically. Connection should be via a 3 amp fused doublepole isolating switch with contact separation of at least 3 mm

on both poles. Alternatively, a fused 3 Amp. 3 pin plug and

unswitched socket may be used, provided it is not used in a

room containing a bath or shower. It should only supply the

appliance.

The boiler is suitable for sealed systems only. The maximum

working pressure for the appliance is 10 bar. All fittings and

pipework connected to the appliance should be of the same

standard. If there is a possibility of the incoming mains

pressure exceeding 10 bar, particularly at night, then a

suitable pressure limiting valve must be fitted.

The boiler is designed to provide hot water on demand to

multiple outlets within the property. If there is a requirement

for greater demands, for example if the property has several

bathrooms and cloakrooms, a vented or unvented hot water

storage system may be used.

Showers

Any shower valves used with the appliance should be of a

thermostatic or pressure balanced type. Refer to the shower

manufacturer for performance guidance and suitability.

Flushing and Water Treatment

The performance of the appliance could be impaired by

system debris or the effects of corrosion. The system must

be flushed thoroughly to remove metal filings, solder,

machining oils and other fluxes and greases before

connecting the boiler. If it is an existing system, an

appropriate flushing and descaling agent should be used.

Refer to BS 7593 (1992) for guidance. For more information

on the use of corrosion inhibitors, flushing and descaling

agents, advice can be sought from the manufacturers of

water treatment products such as:

Betz Dearborn Ltd

Foundry Lane

Widnes

Cheshire

WA8 8UD

Tel: 0151 424 5351

Fernox Manufacturing

Britannica Works

Clavering

Essex

CB11 4QZ

Tel: 01799 550811

System Controls

The boiler is electrically controlled and is suitable for most

modern electronic time and temperature controls. The

addition of such external controls can be beneficial to the

efficient operation of the system. The boiler connections for

external controls are 24V and so only controls of 24V or that

have voltage free contacts should be used.

Fig. 7

A

B

G

H

J

C

L

M

N

K

I

D,E

F

Q

H

N

M

Q

Q

I

Unit 3A, Thornton Road Ind. Estate Off Hockney Road Bradford, BD8 9HQ

01274 488 388

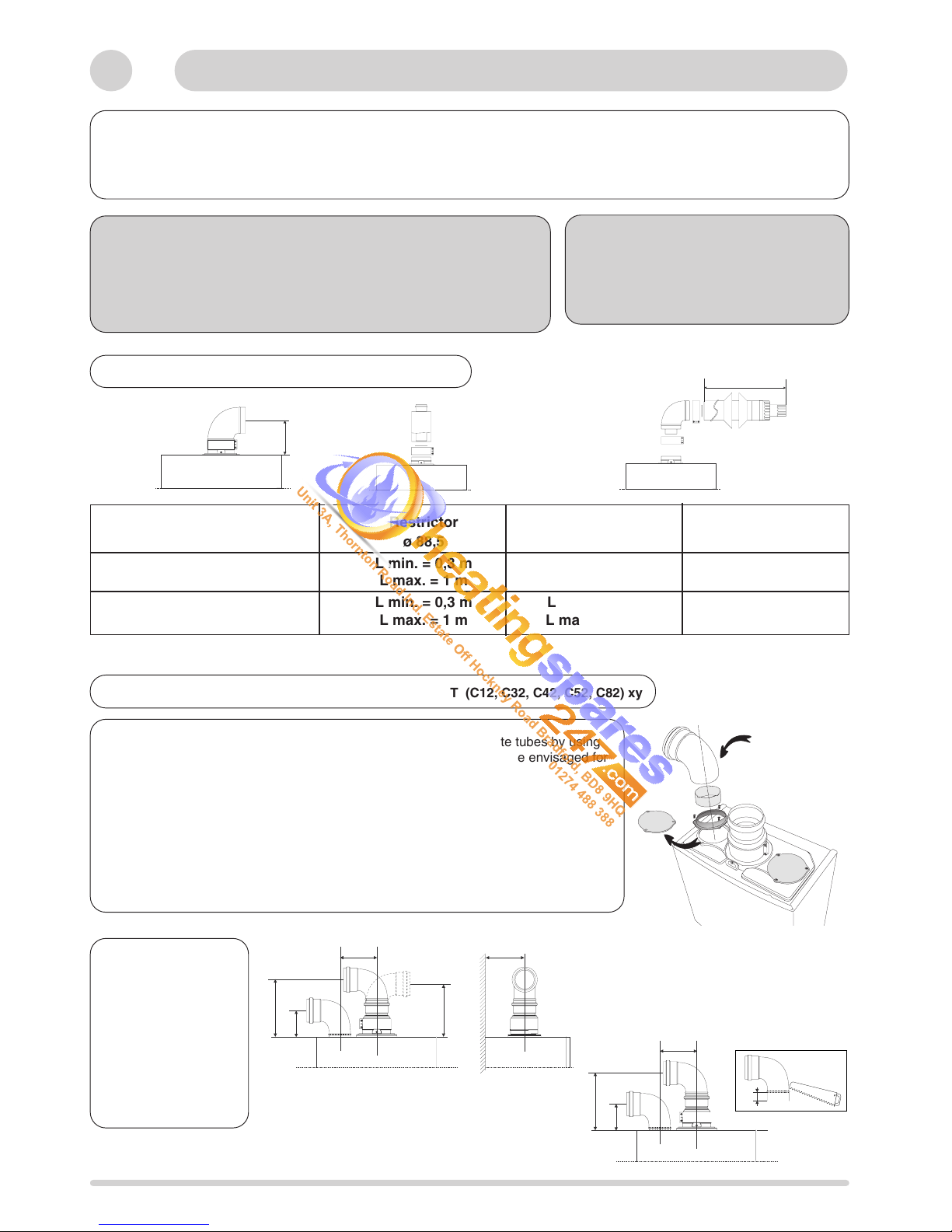

Page 8

8

5

Connecting gas intake and exhaust ducts

5.1 TYPE OF COAXIAL OUTLET (C12, C32, C42) xx

L max = 4 m

Ø 60/100 mm

136

The boiler should only be installed with a fresh air inlet and smoke outlet device supplied by the boiler manufacturer.

These kits are supplied separately to the appliance in order to respond to different installation solutions. For more information

with regard to the inlet/outlet accessories consult the accessory catalogue and the installation instructions contained in the kits.

The boiler is predisposed for the connection to a twin flow concentric gas intake and exhaust duct system

Warning

The exhaust gas ducts should not be in contact with or close to

inflammable material and should not pass through building structures or

walls made of inflammable material.

When replacing an old appliance, the gas intake and exhaust duct system

will also have to be changed.

Important

Ensure that the gas intake and exhaust

passages are not blocked.

Ensure that the exhaust gas ducts do not

have leaks

Concentric outlet Restrictor

60/100 ø 88,5 Without restrictor Max.length

24 kW

L min. = 0,3 m L min. = 1 m 4 m

L max. = 1 m L max. = 4 m /

30 kW

L min. = 0,3 m L min. = 1 m 4 m

L max. = 1 m L max. = 4 m /

There is also the possibility of using an exhaust gas duct with separate tubes by using

an adaptor on the outlet header and by inserting the tube in the air intake envisaged for

this purpose.

In order to use the air intake, you should:

1) Take the air intake cover off

2) Assemble the flange on the header supplied with the boiler

3) Assemble the membrane, if necessary, on the tube or the elbow

4) Insert the header on the tube or the elbow up until the lower stop

(you do not have to use the washer).

5) Insert the elbow/header in the boiler air intake hole and fasten it with screws

If the two elbows or in

the same lateral

direction and if you

need to reduce the

required space, the

minimum 230 mm

measurement can be

reduced by carefully

cutting the elbow below

the air inlet by 25 mm

123,5 135

230 MIN *

200

132

123,5

200

107

25

L = total length of gas intake and exhaust ducts.

5.2 TYPE OF TWIN FLOW CONCENTRIC EXHAUST DUCT (C12, C32, C42, C52, C82) xy

Unit 3A, Thornton Road Ind. Estate Off Hockney Road Bradford, BD8 9HQ

01274 488 388

Page 9

9

ø 100

60 mm

In the special case where the connection

is with separate tubes and with the boiler

installed at a minimum distance of 6 cm

from the wall, make a ø 10 cm hole, thus

enabling better assembly between the

fresh air elbow and the tube outside the

wall (see diagram).

The maximum development value L, mentioned in the table includes the exhaust gas/fresh air terminal and for the coaxial

system also takes into account an elbow. The C52 outlets should respect the following instructions:

1- Keep the same ø 80 mm for the gas intakes and exhaust gas ducts.

2- If you need to insert elbows in the gas intake and exhaust gas ducts, you should consider for each one the equivalent

length to be included in the calculation of developed length.

3- The exhaust gas duct should jut above the roof by at least 0.5 m.

4- The intake and exhaust gas ducts in C52 cannot be installed on opposite walls of the building

Diagram illustrating some coaxial and twin flow version installation

examples

For more detailed information concerning exhaust gas outlets and

fresh air inlets, consult our accessory catalogues

Warning

If the selected exhaust gas duct is planned

to be fitted with a membrane as indicated

in the corresponding tables, then the

installation of the membrane is compulsory

5.3 LAYING OF RESTRICTOR

Coaxial

Twin flow

Twin flow outlet Restrictor Restrictor Restrictor Without

24 kW ø 41 ø 46 ø 51 restrictor

C12, C32, C42 L min. > 0 m L min. > 2,5 m L min. > 12 m L max. > 19 m

80/80 L max. = 2,5 m L max. = 12 m L max. = 19 m L max. = 24 m

C52, C82 L min. > 0 m L min. > 10 m L max. > 29 m L max. > 35 m

80/80 L max. = 10 m L max. = 29 m L max. = 35 m L max. = 45 m

Air intake lenght 1 m.

L = total length of gas intake and exhaust ducts.

If the exhaust gas duct length is longer than 5,5 m, you will need a condensate sump

Twin flow outlet Restrictor Restrictor Without Without

30 kW ø 44 ø 50 restrictor restrictor

C12, C32, C42 L min. > 0 m L min. > 3 m L min. > 12 m L max. > 19 m

80/80 L max. = 3 m L max. = 12 m L max. = 30 m L max. = 24 m

C52, C82 L min. > 0 m L min. > 11,5 m L max. > 30 m L max. > 35 m

80/80 L max. = 11,5 m L max. = 30 m L max. = 60 m L max. = 45 m

Air intake lenght 1 m.

L = total length of gas intake and exhaust ducts.

If the exhaust gas duct length is longer than 7,5 m, you will need a condensate sump

Unit 3A, Thornton Road Ind. Estate Off Hockney Road Bradford, BD8 9HQ

01274 488 388

Page 10

10

- place the paper template in the selected position on the wall

- fit the hanging bracket

- bring the water pipes and the electrical connection to the locations shown on the fitting template

- unscrew the two clamp locking bolts A, which secure the front panel (fig. 7)

- remove the front panel

- offer the water heater up to its bracket and allow it to drop into position while pressing on it (fig. 8)

- fit the connectors and taps (fig. 9)

- connect the water and gas pipes with the various seals (rubber seal on the gas pipe)

The safety valve drain port 16 must be connected to a waste water pipe.

Fit an evacuation device according to the type of connection chosen, referring to the installation handbook supplied with the kit

Cleaning the appliance

Once the water has been connected, it is essential to clean the appliance with an appropriate product (dispersing agent) to

remove filings, solder, and various factory oils and greases.

The use of any solvent or aromatic agent (petrol, oil etc.) is forbidden.

It is advisable to treat the heating appliance completely in order to maintain a pH value of between 9 and 9.5.

6 Installing the boiler

Fig. 8

1

2

Fig. 7

Fig. 9

37

A

A

Unit 3A, Thornton Road Ind. Estate Off Hockney Road Bradford, BD8 9HQ

01274 488 388

Page 11

11

7 Electrical connections

Location of connections:

- the 230 V supply lead and room thermostat

inputs must be fitted on the wall at the height

specified on the fitting template

• the water heater is supplied with 230 V by a

twin and earth lead supplied with the appliance

• room thermostat : - allow at least 50 cm of

spare room thermostat lead for the wall input

Access to the water heater room thermostat

connection:

- the room thermostat is connected behind the

water heater control unit

Recommendation:

- to comply with regulations, a device that discon-

nects all poles with a contact opening gap of at

least 3 mm must be fitted when permanently installing the water heater

- the water heater must be connected to a fixed

boiler with the lead supplied

Fig. 10

B

C

S

T

D

J12

J1

J12

E

J1

230 V and earth connection via the lead provided at J1.

Important : If the supply cord is damaged, it must be replaced by the manufacturer or is service agent or similarly

person in order to avoid a hazard.

Room thermostat connection

Before it leaves the factory, the water heater is set to operate without a room thermostat: a shunt S is placed on connector D.

The room thermostat connection is made on this connector

- lower the electronic control unit by releasing the side locking pins P, to gain access to the reverse side

- remove screws B and remove cover C (fig. 10)

The room thermostat connection can then be accessed.

- remove connector D

- connect the thermostat in place of shunt S

- reconnect connector D

Connector J12 represented (fig. 11), is provided for connecting an optional programmer (see the relevant notice if necessary).

Fig. 11

Cable 230 V 2P + T

P

P

Unit 3A, Thornton Road Ind. Estate Off Hockney Road Bradford, BD8 9HQ

01274 488 388

Page 12

12

PRESSURISING (fig. 12)

Hot water circuit:

- open the cold water tap 34

- drain the appliance by opening the various hot water taps

Central Heating :

- Open flow and return valves on the boiler 31 and 35

- Open the automatic air vent

- Open filling taps 36 and 37, and vent radiators.

- Set system pressure, close filling taps 36, 37 and remove

filling loop 38.

- Check for leaks.

- Manually check pump is free to turn

Gas circuit

- open the gas tap 33

- flush the gas circuit

- check the sealing on the whole gas circuit

8 Operating

Fig. 12

31

33

34

35

16

SETTINGS

The water heater is supplied with all the setting buttons OFF (fig. 13) and the potentiometers turned fully anti-clockwise. It is

possible to adjust these settings if required.

In this case, it is necessary to open the electronic control unit.

Switch the water heater power on, remove the casing and open the control unit by pressing the two push buttons P (fig.

10). The setting buttons are on the circuit board behind the blanking cover E.(fig. 11)

- A1 allows the Heating Anti-cycle Timing to be set to 30 seconds or 3 minutes

HAT: period during which restarting the burner is prohibited during a heating regulation phase

- A2 allows the heating pump to be run at high or low speed

- A3 to fix the heating temperature setting to 40 °C whatever the heating temperature adjustment button position 22 (fig. 3)

- A4 enables operation either in modulating heating mode, or on/off mode

- B1 reserved

- B2 reserved

- B3 allows the hot water flowmeter timing to be adjusted to 0 or 1.5 seconds

- B4 enables operation in conjunction with a CELECTIC, in this case, switch off the flow limiter.

setting ON: the hot water setting is fixed at 65°C whatever the position of the domestic hot water temperature setting

button 21.(fig. 3)

Note: after a power cut-out or board reset, the HAT is cancelled for 3 minutes.

- P1: potentiometer to limit heating output within the setting limit made on P2 (see table on page 13)

- P2: potentiometer enabling ignition output factory set (12,7 kW - 24 FF, 16 kW - 30 FF)

- P3: reserved

Once adjustments have been made, replace blanking cover E, close the control unit cover and refit the casing.

36

37

38

Unit 3A, Thornton Road Ind. Estate Off Hockney Road Bradford, BD8 9HQ

01274 488 388

Page 13

13

P1

P2

ON OFF

A1

A2

A3

A4

B1

B2

B3

B4

P3

Pompe Grande VitessePompe Petite Vitesse

Anticycle 3 min

Fonctionnement Modulant

Tempo Débistat Sanitaire 1,5 sec Tempo Débistat Sanitaire 0 sec

Célectic

OFF

ON

Anticycle 30 s

Fonctionnement TOR

Consigne chauffage à 40 °C

Consigne chauffage variable de 35 à 85 °C

Factory setting

Fig. 13

MX2 24 FF

Gas : G20 PROPANE BUTANE

P. utile Inlet Inlet Inlet

(kW) Pressure Pressure Pressure

(mm CE) (mm CE) (mm CE)

10 18 67 47

12,7 33 111 81

16 53 172 129

20 82 258 195

24 114 352 268

Burner gas output setting

The values shown in the tables below are given for information purposes for a nominal gas distribution pressure, to allow any

adjustments to the water heater heating output according to the requirements of the appliance.

They cannot be used to calculate the precise regulated output of the water heater.

8 Operating (continued)

Célectic

Domestic flowmeter time 1.5 sec Domestic flowmeter time 0 sec.

AON operation Modulating operation

Heating setting 40 °C Variable heating setting between 35 to 85 °C

Low-speed pump High-speed pump

Anti-cycle 30 secs Anti-cycle 3 min

MX2 30 FF

Gas : G20 PROPANE BUTANE

P. utile Inlet Inlet Inlet

(kW) Pressure Pressure Pressure

(mm CE) (mm CE) (mm CE)

12 15 58 41

16 35 107 78

20 59 167 124

25 93 256 190

30 130 359 265

Unit 3A, Thornton Road Ind. Estate Off Hockney Road Bradford, BD8 9HQ

01274 488 388

Page 14

14

Fig. 15

Fitting the casing

Remove the protective film on the casing:

- offer the casing up (fig. 14)

- engage hooks N on the casing in notches R on the side panels M operation 1

- fit the top of the panel in place

- close the panel mounting clamps (fig. 15)

- screw in the two clamp locking bolts A

Note: it is essential to refit both locking bolts A

9 Fitting the casing

1

M

A

N

V

Fig. 14

R

Unit 3A, Thornton Road Ind. Estate Off Hockney Road Bradford, BD8 9HQ

01274 488 388

Page 15

15

When adapting to a gas different from the one for which the boiler is equipped, you should replace the parts delivered with the

transformation kit, as well the gas valve adjustments following the operational mode described below

Adjusting the nominal output

• take off the adjusting screws protective

cap (fig. 16).

• take off screw 2 and insert a tube

connected to a pressure tap gauge (fig. 16).

• start the boiler at maximum output (hot

water tap on).

• put pressure on nut 3 by using an 8

wrench (fig. 17) and adjust the pressure to

the value envisaged in the table

“nominal output table.”

Adjusting the minimum output

• disconnect a valve power supply cable (fig.

18)

• put pressure on screw 4 by using a 5

wrench, while holding net 3 (fig. 18) and

adjust the pressure to the value envisaged

in the table

“minimum output table.”

• adjustment finished, put screw 2 back

again and test the tightness.

• put the adjustment screws protective cab

back on.

Adjusting the minimum output

(see settings on page 12).

2

Fig. 16

3

Fig. 17

4

Fig. 18

mm CE G 20 G 30 G 31

24 kW FF 114 268 352

30 kW FF 130 265 359

Output nominal

Output mini

mm CE G 20 G 30 G 31

24 kW FF 18 47 67

30 kW FF 15 41 58

10

Gas conversion

Unit 3A, Thornton Road Ind. Estate Off Hockney Road Bradford, BD8 9HQ

01274 488 388

Page 16

16

11

Incorrect function

CODE FAULT INFORMATION

30 40 50 60 70 80

Overheating safety feature.

No flame detection.

Antifrost mode on (pump in operation).

Antifrost mode on (burner and pump in operation).

lack of water circulation.

Primary water circulation defect

Central heating inlet thermistor faulty (open circuit).

Central heating inlet thermistor faulty (short circuit).

Central heating oulet thermistor faulty (open circuit).

Central heating oulet thermistor faulty (short circuit).

Firing problem

Wiring problem (or fuse 1,25 A)

Fan on but does not activate air pressure switch.

Fan off but air pressure switch fails to return to off position.

Communication defect with the display PCB.

Communication defect with the main PCB.

If a fault occurs in the appliance, one or more LEDs (22) flash according to the fault type listed in the table below.

= LED off

= LED blinking

Unit 3A, Thornton Road Ind. Estate Off Hockney Road Bradford, BD8 9HQ

01274 488 388

Page 17

17

12

Particular characteristics

Flow rate controller assembly direction

By-pass valve assembly direction

Unit 3A, Thornton Road Ind. Estate Off Hockney Road Bradford, BD8 9HQ

01274 488 388

Page 18

18

USER’S INSTRUCTIONS

Control panel

(fig. 16)

19. - Pressure gauge

20. - On/off push button and power on indicator light

21.- Sanitary temperature setting and sanitary start button

22.- Heating temperature setting and heating start button

23.- Heating temperature indicator and operating faults

indicator

24.- Orange indicator - Burner ON

25.- Reset push button and red indicator locking light

Connecting bracket Taps shown in Open position

(fig. 17)

31 : Central heating flow isolating valve

32 : Domestic Hot Water outlet

33 : Gas service tap

34 : Water service tap

35 : Central heating return isolating valve

16 : Central heating pressure relief valve

13

Control panel

Fig.16

Fig. 17

31

32 33

34

35

16

20

21

23

25

22

24

19

c

Unit 3A, Thornton Road Ind. Estate Off Hockney Road Bradford, BD8 9HQ

01274 488 388

Page 19

19

14

Operation

Note:

In some circumstances, it is possible that the pipes (and possibly a radiator) heat up slightly after hot water is drawn. To

prevent this, simply close heating inlet tap 31 (fig. 17).

Remember to re-open it at the start of the heating season, when you switch the heating back on by pressing button 22 (fig. 16)

Starting up (fig. 17)

1. check that the appliance's general gas shut-off tap is open and that the water heater is supplied with power.

2. check that there is sufficient pressure in the heating circuit: the pressure gauge needles should be at a minimum of 1,2 bar

with 1,7 bar at maximum cold

3. open the gas inlet tap 33 (fig. 17)

Your water heater is now ready to operate.

Important

When the appliance is operated after a prolonged period of inactivity, the presence of air in the gas flues may hinder the first

attempts at igniting the gas

See section 18 “Operating faults”

To obtain hot water and heating :

To obtain hot water and heating:

Press On/Off button 20; it lights up green when power is supplied

- turn button 21 to authorise water heating ignition if water is being drawn.This button allows you to adjust the hot water

temperature. While hot water is being drawn, LEDs 23 light up two by two.

- turn button 22 to authorise heating ignition. This button enables you to adjust the water temperature in the heating

circuit according to seasonal requirements. Indicator light 23 displays this temperature

• Turn button 22 :

- to Max in cold weather,

- to Min in mild weather,

Furthermore, if your home is fitted with a room thermostat, set it to the desired indoor temperature.

- orange indicator light 24 lights up each time the burner operates

Stopping the heating

- Turn button 22 to «off » position. The water heater then produces only hot water.

Stand by mode

- Turn buttons 21 and 22 to «off »position, button 20 (fig. 16) remains lit. The function remains active unless the boiler freezes.

Turn off the water heater completely

- press push button 20 , the indicator light turns off

- turn off the electricity supply to the water heater.

- turn off the gas by turning inlet tap 33 (fig. 17)

Unit 3A, Thornton Road Ind. Estate Off Hockney Road Bradford, BD8 9HQ

01274 488 388

Page 20

20

This water heater is equipped with a flue gas extraction flow detection system which authorises operation of the burner.

If the flow is insufficient for a prolonged period of time, the water heater shuts down for safety reasons, and indicators (23) 40,

60 and 80 flash.

Important: this flue gas checking device must not be removed, or have untimely work carried out on it. If it needs to be

replaced, only original parts may be used.

16

Flue gas safety

18

Practical information

The manufacturer`s guarantee is for 12 months from the date of purchase. The guarantee is voidable if the appliance is not

installed in accordance with the recommendations made herein or in a manner not approved by the manufacturer. To assist us

in providing you with an efficient after sales service, please return the guarantee registration card enclosed with the boiler

without delay.

17

Guarantee

As with your car, your boiler will work more reliably and efficiently if regularly serviced. We recommend an annual service

check. The service history of the appliance will be marked on the logbook.

15

Maintenance

Pump anti-sticking device

When the boiler is switched on (indicator light 20 lit), the circulation pump operates for 1 minute after the water heater has

been out of operation for more than 23 hours, whatever the operation of the water heater, to prevent the pump jamming.

Precautions to take in freezing conditions

We recommend that you contact your gas fitter or After-Sales service, who will advise you of the measures to take according

to your circumstances.

Hot water circuit

The hot water circuit is drained after closing the appliance's water counter and cold water tap:

- open a hot water tap

- unscrew the cold water connection union nut

Heating circuit

Take one of the following steps:

- 1) drain the circuit of the heating appliance

- 2) protect the heating appliance with an anti-freeze product. Periodically checking the level of protection provided by this

anti-freeze is an additional guarantee requirement.

- 3) allow your appliance to run at low load by setting the room thermostat to the "anti-freeze" position (between 5 and

10°C).

- 4) leave the power to the water heater on. It is fitted with an anti-freeze device which activates the circulation pump, then

the burner.

Unit 3A, Thornton Road Ind. Estate Off Hockney Road Bradford, BD8 9HQ

01274 488 388

Page 21

21

19

Technical data

This appliance is suitable for Natural gas or LPG. A gas conversion must be made by a competent person.

Model MX2 24 FF MX2 30 FF

Appliance Category ............................................................. II 2H3+ II 2H+3+

Heat output C/H ......................................................Pn 10 to 24 kW 12 to 30 kW

Heat output DHW ...........................................Pn max 24 kW 30 kW

DHW flow rates (∆T: 30 K) ...............................................D 11,4 I/min. 14,3 I/min.

Minimum DHW operating flow rate...................................... 2 l/mn 2 l/mn

Minimum DHW working pressures .................Pw min 0,1bar 0,1bar

Maximum DHW working pressures ...............Pw max 10 bar 10 bar

C/H circuit pressure max operating ...............Pw max 3 bar 3 bar

Supply ................................................................................. 230 volts mono - 50 Hz

Consumption ....................................................................... 150 W

Protection ............................................................................ IP X4D

Natural gas G20

Gas rate max....................................................................... 2,75 m

3

/h 3,44 m3/h

Gas rate mini ....................................................................... 1,27 m

3

/h 1,50 m3/h

Nominal inlet pressure......................................................... 20 mbar 20 mbar

Burner injector dialeter in 1/100 of mm ............................... 135 130

Butane LPG G30

Gas rate max....................................................................... 2,05 kg/h 2,56 kg/h

Gas rate mini ....................................................................... 0,95 kg/h 1,12 kg/h

Nominal inlet pressure......................................................... 28 mbar 28 mbar

Burner injector dialeter in 1/100 of mm ............................... 80 80

Propane LPG G31

Gas rate max....................................................................... 2,02 kg/h 2,52 kg/h

Gas rate mini ....................................................................... 0,93 kg/h 1,10 kg/h

Nominal inlet pressure......................................................... 37 mbar 37 mbar

Burner injector dialeter in 1/100 of mm ............................... 80 80

Unit 3A, Thornton Road Ind. Estate Off Hockney Road Bradford, BD8 9HQ

01274 488 388

Page 22

22

3

6

9

12

Fig. 18

20

Instruction for setting the built in clock (if fittied)

1. General layout

The mechanical clock covers a 24 hour period. Each tappet

represents 15 minutes A (fig. 19). An override switch is

located on the clock B (fig 19).

2. To set the time

To set the time of day, grasp the outer edge of the dial and

turn slowly clockwise until the correct time is lined up with

the arrow C (fig. 19).

3. To Set the "On" and "Off" times

The clock uses a 24hours system. e.g. 8 =8.00 am and

18 = 6.00 pm "ON" periods are set by sliding all tappets

between the "ON" time and the "OFF" time to the outer edge

of the dial.The tappets remaining at the centre of the dial are

the "OFF" periods.

4. To select function mode

Put the selector switch B to symbol to control the boiler

by the clock. Put the switch B to «I» to select permanent

operation or to «0» to turn heating off permanently.

Fig. 19

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18

18

19

19

20

20

21

21

22

22

23

23

24

24

9

9

6

6

12

12

I

A

C

B

Unit 3A, Thornton Road Ind. Estate Off Hockney Road Bradford, BD8 9HQ

01274 488 388

Page 23

23

21

Incorrect function

If these solutions do not cure the fault, call a qualified professional

Fault

The boiler doesn’t start

Red indicator alight

Noises in CH system

Radiators rise in temperature During

summer season

Cause

No gas, no water or no electricity

Air in the gas pipe

Room thermostat switched off

Air presence in CH system or.

Insufficient pressure

Gravity effect in the CH system

Solution

Control gas, water and electrical

supply, fuses…

Follow procedure in chapter 7

Set up the room thermostat

Wait for a few minutes

Press on reset button 25 (fig.16) the red

led turn off and the boiler attempts to relight.

If red indicator alight too frequently,

please call your localfaîtes service

centre.

Purge of air the system and rise up the

system pressure (chapter 7)

Close the heating flow isolating valve.

Don’t forget to open itagain when you

will start heating.

Unit 3A, Thornton Road Ind. Estate Off Hockney Road Bradford, BD8 9HQ

01274 488 388

Page 24

1313374a - 10/2003

Chaffoteaux & Maury are continuously improving their products and therefore reserve the right to change specifications without

prior notice and accepts no liability for any errors or omission in the information contained in this document.

Manufacturer: Chaffoteaux & Maury - France

Commercial subsidiary: MTS (GB) Limited

MTS Building

Hughenden Avenue

High Wycombe

Bucks HP13 5FT

Telephone: (01494) 755600

Fax: (01494) 459775

internet: www.chaffoteaux.co.uk

E-mail: info@mtsgb.ltd.uk

Technical Support Help Line: (01952) 222288

Unit 3A, Thornton Road Ind. Estate Off Hockney Road Bradford, BD8 9HQ

01274 488 388

Loading...

Loading...