Page 1

OPERATING, MAINTENANCE

& PARTS MANUAL

MANUAL DE FUNCIONAMIENTO,

MANTENIMIENTO Y PIEZAS

MANUEL D'ENTRETIEN,

D'OPÉRATION ET DE PIÈCES

HAND OPERATED LEVER HOIST

POLIPASTO MANUAL DE PALANCA

PALAN MANUEL À LEVIER

SERIES 653-A

LEVER HOIST

Before installing hoist, fill in the information below.

Antes de instalar el polipasto, rellene los datos siguientes.

Enregistrez les informations suivantes avant de faire l'installation.

Rated Load / Carga Nominal / Charge nominale

Serial No. / N° de Serie / No. de Ser.

Purchase Date / Fecha de Compra / Date d'achat

CAPACITIES:

3/4, 1, 1½, 2, 3 and 6 TON

(750, 1000, 1500, 2000,

3000 and 6000 kg.)

Follow all instructions and warnings

for inspecting, maintaining and

operating this hoist.

The use of any hoist presents some risk

of personal injury or property damage. That

risk is greatly increased if proper instructions

and warnings are not followed. Before using

this hoist, each operator should become

thoroughly familiar with all warnings,

instructions and recommendations

in this manual. Retain this manual for

future reference and use.

Forward this manual to operator.

Failure to operate equipment as

directed in manual may cause injury.

CAPACIDADES DE CARGA:

3/4, 1,1½, 2, 3 y 6 toneladas

(750, 1000, 1500, 2000, 3000 y

6000 kg.)

Siga todas las instrucciones y

advertencias para inspeccionar,

mantener y operar este polipasto.

El uso de cualquier polipasto presenta algunos

riesgos de daños a las personas o a las

cosas. Este riesgo se ve incrementado si no

se siguen correctamente las instrucciones

y advertencias. Antes de usar el polipasto

el operario debería estar familiarizado con

rodas las advertencias, instrucciones y

recomendaciones de este manual. Guarde

este manual para futuras consultas.

Entregue este manual al operario. Si el

equipo no se maneja tal y como se

recomienda en el presente manual, es

posible que se produzcan situaciones

de peligro que pueden resultar en

daños personales.

CHARGES NOMINALES:

3/4, 1,1½, 2, 3 et 6 TONNES

(750, 1000, 1500, 2000, 3000 et

6000 kg.)

Veuillez vous conformer à toutes les

instructions et avertissements d'inspection,

d'entretien et d'opération de ce palan.

L'utilisation de tout appareil de levage

comporte des risques de blessures ou

de dégâts matériels. Ces risques sont

de beaucoup accrus si les instructions

et avertissements ne sont pas suivis.

Tous les opérateurs devraient se

familiariser complètement avec toutes

les recommandations instructions et

avertissements de ce manuel avant d'utiliser

ce palan. Conservez ce manuel pour

utilisation et référence future.

Remettre ce manuel à l'opérateur.

L'utilisation de cet équipement contrairement

aux directives de ce manuel peut causer

des blessures.

P/N: 192065084 Rev AA March 2020

Page 2

WARRANTY

ENGLISH

LIMITATION OF WARRANTIES, REMEDIES AND DAMAGES

INDEMNIFICATION AND SAFE OPERATION

Buyer shall comply with and require its employees to comply with directions

set forth in instructions and manuals furnished by Seller and shall use

and require its employees to follow such instructions and manuals and

to use reasonable care in the use and maintenance of the goods and any

replacement parts. Buyer shall not remove or permit anyone to remove any

warning or instruction signs on the goods or replacement parts. In the event

of personal injury or damage to property or business arising from the use of

the goods or replacement parts, Buyer shall within 48 hours thereafter give

Seller written notice of such injury or damage. Buyer shall cooperate with

Seller in investigating any such injury or damage and in the defense of any

claims arising therefrom.

If Buyer fails to comply with this section or if any injury or damage is

caused, in whole or in part, by Buyer’s failure to comply with applicable

federal or state laws, rules or regulations safety requirements, Buyer shall

indemnify and hold Seller harmless against any claims, loss or expense

for injury or damage arising from the use of the goods and/or replacement

parts.

CMCO Warranty (HOISTS)

A. Columbus McKinnon Corporation (“Seller”) warrants to the original

end user (“Buyer”) that, for a period of one (1) year from the date of

Seller’s delivery of the goods (collectively, the “Goods”) to the carrier,

the Goods will be free from defects in workmanship and materials. (b)

for a period of three (3) years from the date of Seller’s delivery of the

Goods to the carrier, the brake discs on the Goods will be free from

defects in workmanship and materials; and (c) for the life of the Goods,

the mechanical components including, without limitation, the sidewinder

hoist lever, of the Goods (other than the brake discs on the Goods) will

be free from defects in workmanship and materials. . In addition, Seller

warrants to Buyer that, for a period of one (1) year from the date of their

delivery by Seller to the carrier, any aftermarket or replacement parts,

accessories or components purchased by Buyer with respect to any

Goods (collectively, “Replacement Parts”) will be free from defects in

workmanship and materials.

B. IN THE EVENT OF ANY BREACH OF ANY SUCH WARRANTY, SELLER’S

SOLE OBLIGATION SHALL BE EXCLUSIVELY LIMITED TO, AT THE

OPTION OF SELLER, REPAIR OR REPLACEMENT, F.O.B. SELLER’S

POINT OF SHIPMENT, OF ANY GOODS OR REPLACEMENT PARTS

THAT SELLER DETERMINES TO HAVE BEEN DEFECTIVE OR, IF

SELLER DETERMINES THAT SUCH REPAIR OR REPLACEMENT IS NOT

FEASIBLE, TO A REFUND OF THE PURCHASE PRICE UPON RETURN

OF THE GOODS OR REPLACEMENT PARTS TO SELLER. NO CLAIM

AGAINST SELLER FOR ANY BREACH OF (i) SUCH WARRANTY WITH

RESPECT TO THE ELECTRICAL COMPONENTS OF ANY GOOD OR

REPLACEMENT PARTS SHALL BE VALID OR ENFORCEABLE UNLESS

BUYER’S WRITTEN NOTICE THEREOF IS RECEIVED BY SELLER WITHIN

ONE (1) YEAR FROM THE DATE OF SELLER’S DELIVERY TO THE

CARRIER, (ii) SUCH WARRANTY WITH RESPECT TO THE BRAKE DISCS

OF ANY GOOD SHALL BE VALID OR ENFORCEABLE UNLESS BUYER’S

WRITTEN NOTICE THEREOF IS RECEIVED BY SELLER WITHIN THREE

(3) YEARS FROM THE DATE OF SELLER’S DELIVERY TO THE CARRIER

AND (iii) SUCH WARRANTY WITH RESPECT TO THE MECHANICAL

COMPONENTS, INCLUDING, WITHOUT LIMITATION, THE SIDEWINDER

HOIST LEVER, OF ANY GOOD (OTHER THAN THE BRAKE DISCS ON

ANY GOOD) SHALL BE VALID OR ENFORCEABLE UNLESS BUYER’S

WRITTEN NOTICE THEREOF IS RECEIVED BY SELLER WITHIN ONE (1)

YEAR FROM THE DATE ANY ALLEGED CLAIM ACCRUES. EXCEPT FOR

THE WARRANTIES SET FORTH ABOVE, SELLER MAKES NO OTHER

WARRANTIES WITH RESPECT TO THE GOODS OR ANY REPLACEMENT

PARTS, WHETHER EXPRESSED OR IMPLIED, INCLUDING ANY

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR

PURPOSE, QUALITY AND/OR THOSE ARISING BY STATUTE OR

OTHERWISE BY LAW OR FROM ANY COURSE OF DEALING OR USE OF

TRADE, ALL OF WHICH ARE HEREBY EXPRESSLY DISCLAIMED.

C. IN NO EVENT SHALL SELLER BE LIABLE TO BUYER OR ANY THIRD

PARTY WITH RESPECT TO ANY GOOD OR REPLACEMENT PART,

WHETHER IN CONTRACT, TORT OR OTHER THEORY OF LAW, FOR

LOSS OF PROFITS OR LOSS OF USE, OR FOR ANY INCIDENTAL,

CONSEQUENTIAL, SPECIAL, DIRECT OR INDIRECT DAMAGES,

HOWSOEVER CAUSED. SELLER’S MAXIMUM LIABILITY TO BUYER

WITH RESPECT TO THE GOODS OR ANY REPLACEMENT PART

SHALL IN NO EVENT EXCEED THE PRICE PAID BY BUYER FOR THE

GOODS OR REPLACEMENT PART THAT ARE THE SUBJECT OF THE

APPLICABLE CLAIM.

D. Seller shall not be liable for any damage, injury or loss arising out of the

use of the Goods or any Replacement Part if, prior to such damage, injury

or loss, such Goods or Replacement Parts are: (1) damaged or misused

following Seller’s delivery to the carrier; (2) not maintained, inspected, or

used in compliance with applicable law and Seller’s written instructions

and recommendations; or (3) installed, repaired, altered or modied (a) with

any part or accessory other than those supplied by Seller or (b) without

compliance with such laws, instructions or recommendations.

E. This warranty is limited and provided only to the original end user. Each

Good and Replacement Part must be registered within sixty (60)

days of receipt of each product to establish eligibility. Please register

at www.cmworks.com/hoist-warranty-registration or submit registration

card via US mail.

F. Any action against Seller for breach of warranty, negligence or otherwise

in connection with the electrical components of any Good must be

commenced by Buyer within one (1) year after: (a) the date any alleged

claim accrues; or (b) the date of delivery of the Goods to Buyer,

whichever is earlier. Any action against Seller for breach of warranty,

negligence or otherwise in connection with the brake discs on any

Good must be commenced by Buyer within three (3) years after: (y) the

date any alleged claim accrues; or (z) the date of delivery of the Goods

to Buyer, whichever is earlier. Any action against Seller for breach of

warranty, negligence or otherwise in connection with the mechanical

components of any Good (other than the brake discs on any Good)

must be commenced by Buyer within one (1) year after the date any

alleged claim accrues. Any action against Seller for breach of warranty,

negligence or otherwise in connection with any Replacement Part must

be commenced by Buyer within one (1) year after: (y) the date any alleged

claim accrues; or (z) the date of delivery of the Replacement Part to

Buyer, whichever is earlier.

G. This warranty is contingent upon Buyer’s proper maintenance and care

of the Goods and/or Replacement Part, and does not extend to normal

wear and tear. Seller reserves the right, at its option, to void this warranty

in the event of Buyer’s use with the Goods and/or Replacement Parts of

parts or accessories other than those supplied by Seller.

Alterations or modications of equipment and use of non-Seller

replacement parts can lead to dangerous operation and injury.

TO AVOID INJURY:

• Do not alter or modify equipment.

• Do use only replacement parts manufactured by seller.

1

(ENGLISH)

P/N: 192065084 Rev AA March 2020

Page 3

CM HOIST PARTS AND SERVICES ARE AVAILABLE

IN THE UNITED STATES AND IN CANADA

As a CM Hoist and Trolley user you are assured of reliable repair and parts services through a network of Master Parts Depots and Service Centers

that are strategically located in the United States and Canada. These facilities have been selected on the basis of their demonstrated ability to handle

all parts and repair requirements promptly and efciently. To quickly obtain the name of the Master Parts Depot or Service Center located nearest you,

go to www.cmworks.com, phone (800) 888-0985, Fax: (716) 689-5644.

LAS PIEZAS Y REPARACIONES DE LOS POLIPASTOS DE CM ESTÁN

ASEGURADAS EN ESTADOS UNIDOS Y CANADÁ

Como usuario de un polipasto y carro de CM le aseguramos cualquier reparación o la disponibilidad de cualquier pieza de repuesto a través de una

red de almacenes de piezas de repuesto y centros de servicio situados estratégicamente en Estados Unidos y Canadá. Estas instalaciones se han

seleccionado en base a su capacidad demostrada en la reparación de equipos y suminstro de piezas de repuesto de forma rápida y ecaz. Para obtener

la dirección del almacén de piezas de repuesto o del centro de servicio más cercano, vaya a www.cmworks.com, teléfono (800) 888-0985,

Fax: (716) 689-5644 (sólo en Estados Unidos y Canadá).

LE SERVICE DE RÉPARATION ET DE PIÈCES POUR PALANS CM EST

DISPONIBLE AUX ÉTATS-UNIS ET AU CANADA

Soyez assurés qu'en temps d'utilisateur de palan et treuil CM, d'un service de réparation et de pièces able par l'entremise d'un réseau de Centres de

service et de Dépôts de pièces maîtresses qui sont stratégiquement situés aux États-Unis et au Canada. Ces établissements ont été sélectionnés sur une

base de leur habileté démontrée à s'occuper promptement et efcacement des besoins de réparation de pièces. Aller à www.cmworks.com,

téléphone (800) 888-0985, Fax: (716) 689-5644 pour obtenir rapidement le nom du dépôt de pièces maîtresses ou du centre de service situé le plus près.

ENGLISH

2

(ENGLISH)

P/N: 192065084 Rev AA March 2020

Page 4

ENGLISH

Improper operation of a hoist can create a potentially hazardous

situation which, if not avoided, could result in death, or serious

injury. To avoid such a potentially hazardous situation, the

operator shall:

1. NOT operate a malfunctioning or unusually performing hoist.

2. NOT operate the hoist until you have thoroughly read and

understood this manual.

3. NOT operate a hoist which has been modied without the

manufacturer’s approval or certication to be in conformity

with applicable OSHA regulations.

4. NOT lift or pull more than rated load for the hoist.

5. NOT use damaged hoist or hoist that is not working properly.

6. NOT use hoist with twisted, kinked, damaged,

or worn load chain.

7. NOT operate with any lever extension (cheater bar).

8. NOT attempt to “free chain” the hoist while a load is applied.

9. NOT use the hoist to lift, support, or transport people.

10. NOT lift loads over people and make sure all personnel

remain clear of supported load.

11. NOT attempt to lengthen the load chain or repair damaged

load chain.

12. Protect the hoists load chain from weld splatter or other

damaging contaminants.

13. NOT operate a hoist when it is restricted from forming a

straight line from hook to hook in the direction of loading.

14. NOT use load chain as a sling or wrap load chain around load.

15. NOT apply the load to the tip of the hook or to the hook latch.

16. NOT apply load unless load chain is properly seated in the

chain wheel(s) or sprocket(s).

17. NOT apply load if bearing prevents equal loading on all load

supporting chains.

18. NOT operate beyond the limits of the load chain travel.

19. NOT leave load supported by the hoist unattended unless

specic precautions have been taken.

20. NOT allow the chain or hook to be used as an electrical

or welding ground.

21. NOT allow the chain or hook to be touched by

a live welding electrode.

22. NOT remove or obscure the warnings on the hoist.

23. NOT operate a hoist which has Not been securely attached

to a suitable support.

24. NOT operate a hoist unless load slings or other approved

single attachments are properly sized and seated

in the hook saddle.

25. NOT lift loads that are Not balanced and the holding action

is Not secure, taking up slack carefully.

26. NOT operate a hoist unless all persons are and remain clear

of the supported load.

27. Report malfunctions or unusual performances of a hoist,

after it has been shut down until repaired.

28. NOT operate a hoist on which the safety placards or decals

are missing or illegible.

29. Be familiar with operating controls, procedures and warnings.

Improper operation of a hoist can create a potentially hazardous

situation which, if not avoided, could result in minor or moderate

injury. To avoid such a potentially hazardous situation, the

operator shall:

1. Maintain a rm footing or be otherwise secured when

operating the hoist.

2. Check brake function by tensioning the hoist prior to each

lift or pulling operation.

3. Use hook latches. Latches are to retain slings, chains, etc.

under slack conditions only.

4. Make sure the hook latches are closed and not supporting

any parts of the load.

5. Make sure the load is free to move and will clear

all obstructions.

6. Avoid swinging the load or hook.

7. Avoid lever “y-back” by keeping a rm grip on the lever

until operating stroke is completed and lever is at rest.

8. Inspect the hoist regularly, replace damaged or worn parts,

and keep appropriate records of maintenance.

9. Use Columbus McKinnon parts when repairing the unit.

10. Lubricate load chain as recommended in this manual.

11. NOT operate except with manual power.

12. NOT permit more than one operator to pull on lever at

the same time. More than one operator is likely to cause

hoist overload.

13. NOT allow your attention to be diverted from operating

the hoist.

14. NOT allow the hoist to be subjected to sharp contact

with other hoists, structures, or objects through misuse.

15. NOT adjust or repair the hoist unless qualied to perform

such adjustments or repairs.

The hoists are intended for general industrial use

for moving loads within their load ratings. Prior

to installation and operation, the user should

review the application for abnormal environmental

or handling conditions.

GENERAL SAFETY INFORMATION

ADVERSE ENVIRONMENTAL CONDITIONS

Do not use the hoists in areas containing ammable vapors, liquids,

gasses or any combustible dust or bers. Do not use the hoist

in highly corrosive, abrasive, wet environments or in applications

involving exposure to temperatures below -10ºF or above 130ºF.

MOVING HAZARDOUS LOADS

The hoists are not recommended for lifting materials that could

cause widespread damage if dropped. The lifting or moving of

materials that could explode or cause chemical or radioactive

contamination requires fail-safe, redundant supporting devices

that are not incorporated into these hoists.

3

(ENGLISH)

P/N: 192065084 Rev AA March 2020

Page 5

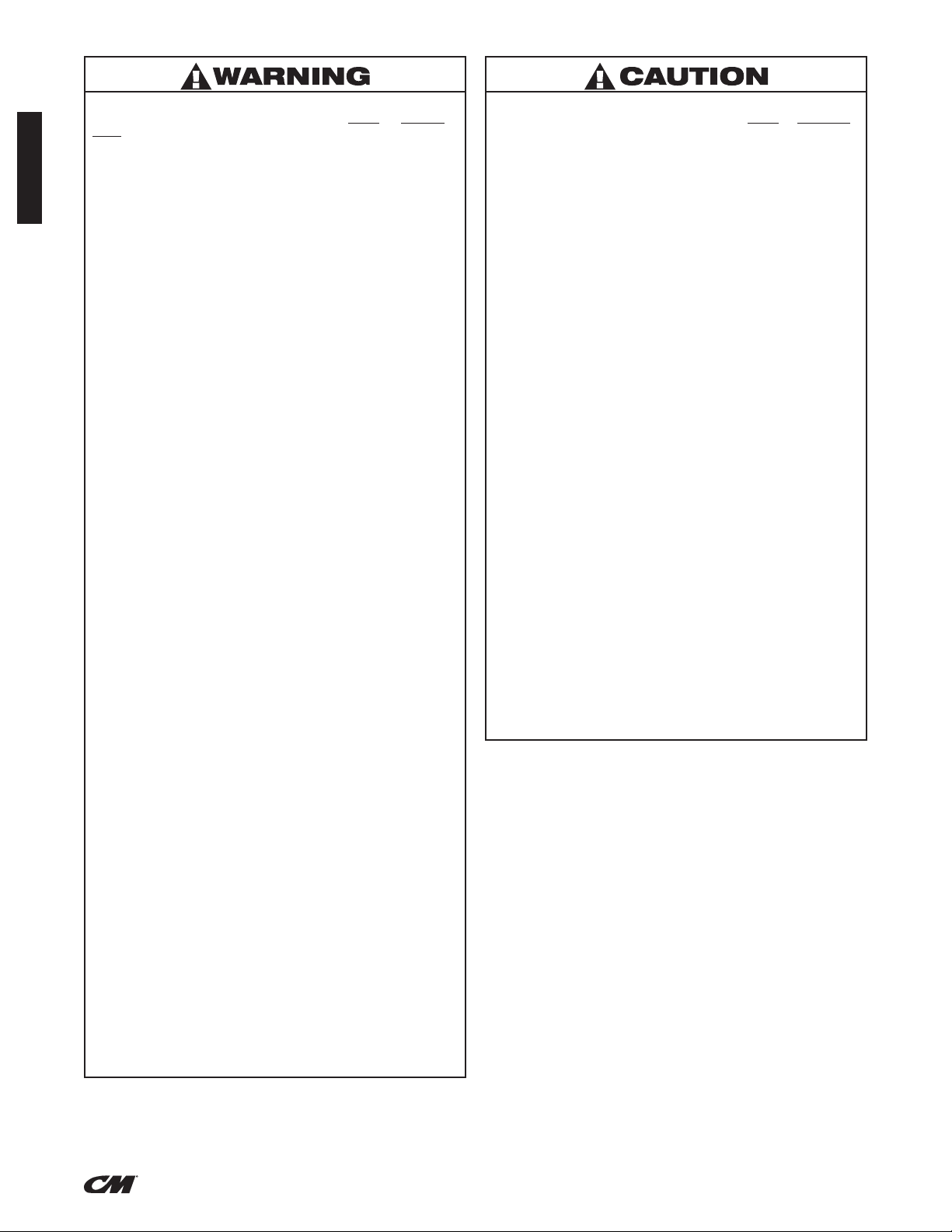

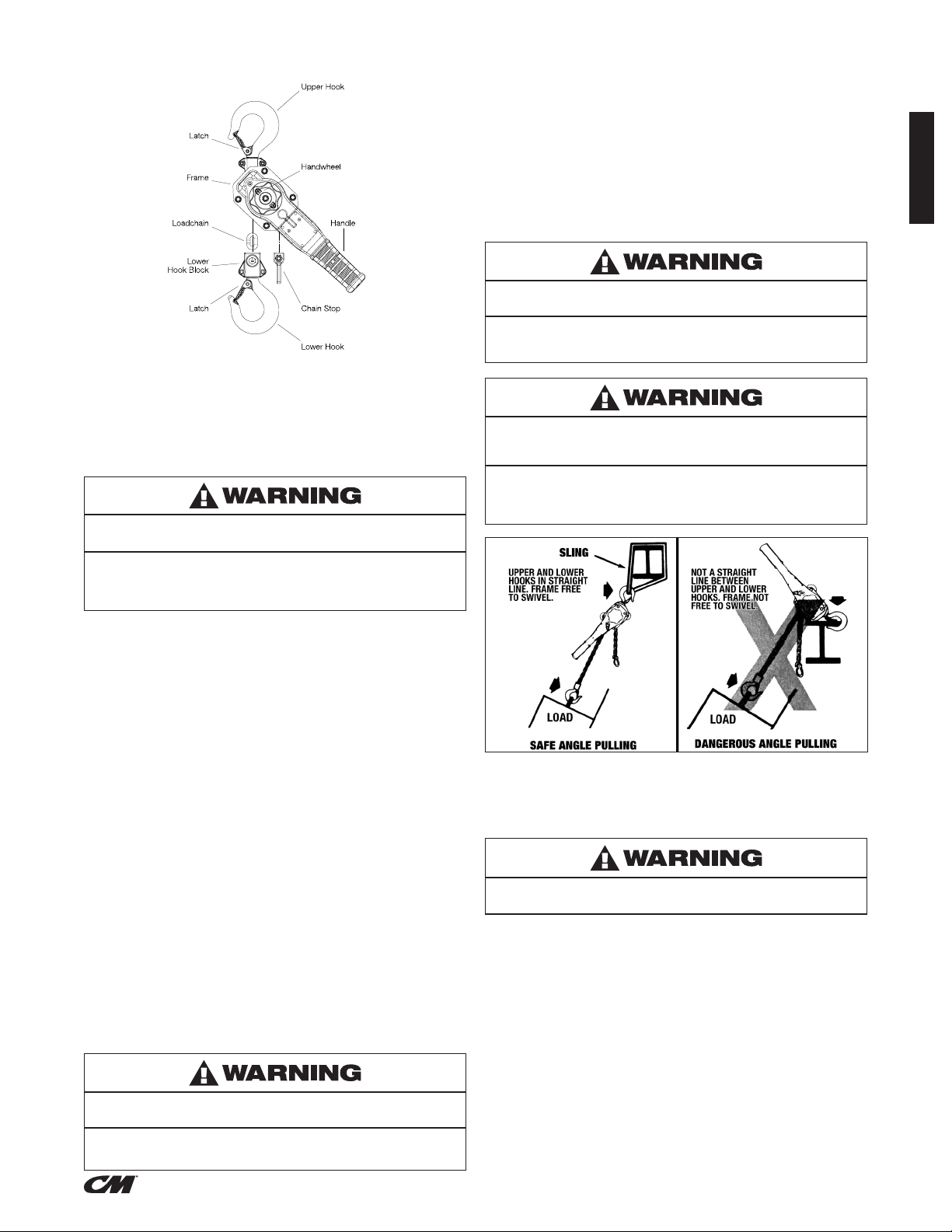

DESCRIPTION

Series 653-A Hand Operated Lever Hoists are highly versatile tools that can be used in any position to efciently pull, lift, drag or stretch.

The frame, covers and lever are made from steel stampings. The gears are heat treated steel, upper and lower hooks are forged steel

and

the chain is heat treated, welded link type.

Hoist with load ratings of 3/4, 1, 1½, 2, 3 and 6 ton are available and this manual applies to all of these units. The hoists are available

with 5, 10, 15 and 20 foot long chains.

Hooks with latches are standard on all units.

Series 653-A Hand Operated Lever Hoists are built in accordance with the specication contained herein and at the time of manufacture

complies with the applicable sections of the American Society of Mechanical Engineers (ASME) Standard B30.21: Manually Operated

Lever Hoists.

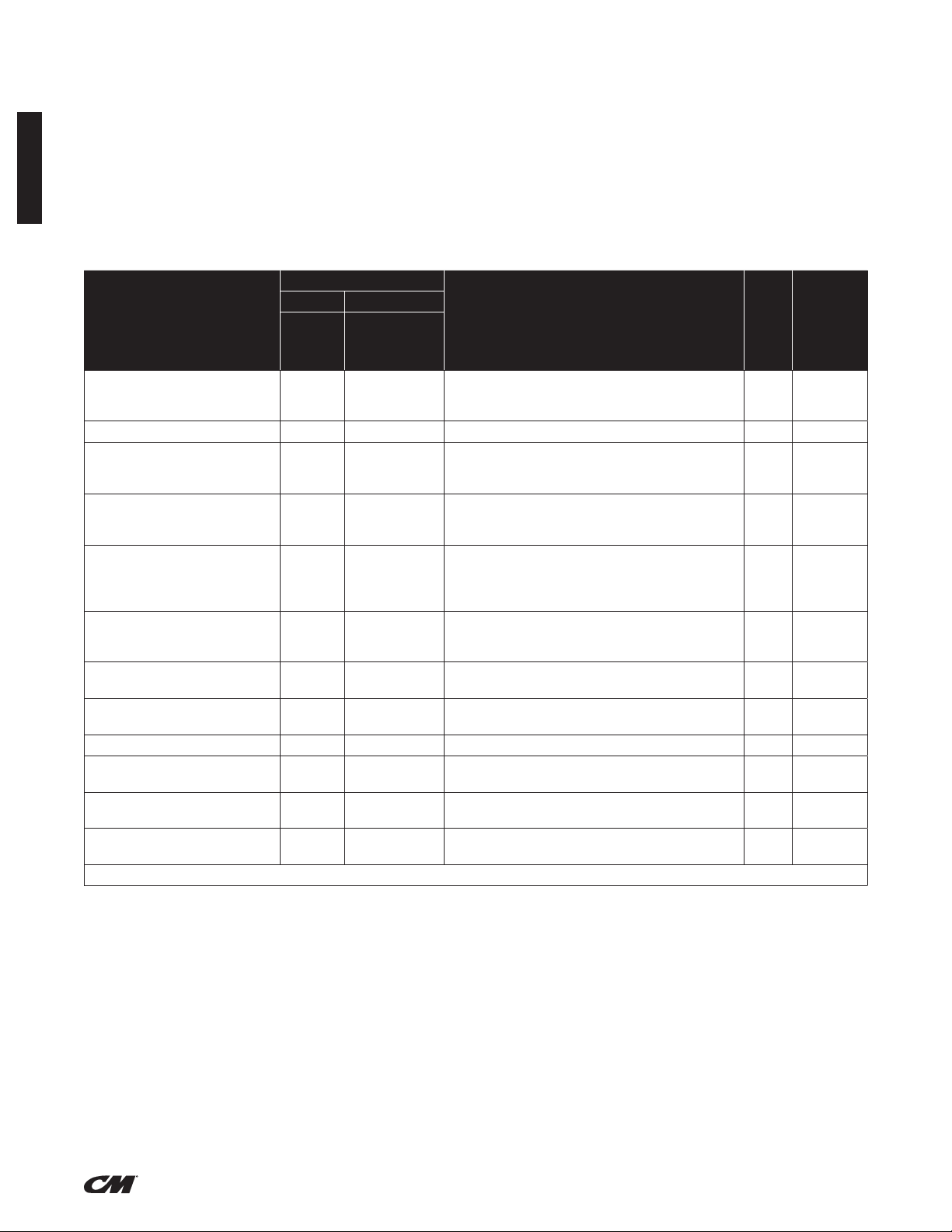

SPECIFICATIONS

F

G

H

BB

C

J

K

L

D

ENGLISH

A

C

Figure 2 – Specifications

Model

No.

5310A

5311A 10 (3) 16.05 (7.28)

5312A 15 (4.5) 18.3 (8.3)

5313A 20 (6) 20.55 (9.32)

5328A 1 5 (1.5) 51 19.84 (9)

5315A

5316A 10 (3) 23.61 (10.71)

5317A 15 (4.5) 27.12 (12.3)

5318A 20 (6) 30.62 (13.89)

5329A 2 5 (1.5) 58 35.27 (16)

5320A

5321A 10 (3) 44.29 (20.09)

5330A

5331A 10 (3) 77.18 (35.01)

5332A 15 (4.5) 91.4 (41.46)

5333A 20 (6) 105.62 (47.91)

Load Rating

(Tonnes)

3/4

1-1/2

3

6

Lift or

Reach

ft. (m)

5 (1.5)

5 (1.5)

5 (1.5)

5 (1.5)

Lever pull to Lift

Rated load (lbf)

51

77

87

92

Net Weight

lb (kg)

13.8 (6.26)

20.17 (9.15)

37.17 (16.86)

62.96 (28.56)

E

D

Dimensions in. (mm)

A (Min.) B C D E F G H J K L

11.78

0.78

1.05

0.7

10.41

4.72

1.56

(302)

13.50

(343)

14.63

(375)

16.10

(409)

17.52

(445)

22.17

(563)

(20)

0.87

(22)

1.01

(26)

1.18

(30)

1.64

(37)

1.77

(45)

(27)

1.14

(29)

1.21

(31)

1.38

(35)

1.57

(40)

1.73

(44)

(18)

0.75

(19)

0.82

(21)

0.87

(22)

1.10

(28)

1.38

(35)

(267)

10.51

(267)

10.51

(267)

14.80

(376)

14.80

(376)

14.80

(376)

(121)

5.47

(139)

5.69

(146)

6.81

(173)

7.09

(180)

9.13

(232)

(40)

1.69

(43)

1.99

(51)

1.97

(50)

2.24

(57)

2.80

(71)

3.16

(81)

3.78

(96)

3.71

(95)

4.84

(123)

4.84

(123)

6.34

(161)

5.62

(144)

6.46

(164)

6.46

(164)

7.60

(193)

7.60

(193)

7.60

(193)

2.07

(53)

2.68

(68)

2.68

(68)

3.27

(83)

3.27

(83)

3.27

(83)

3.55

(91)

3.78

(96)

3.78

(96)

4.33

(110)

4.33

(110)

4.33

(110)

4

(ENGLISH)

P/N: 192065084 Rev AA March 2020

Page 6

ENGLISH

UNPACKING

After unpacking the hoist, inspect carefully for any damage that may

have occurred during transit. Check for loose, missing or damaged

parts. Shipping damage claims must be led with carrier. The hoist

is supplied completely assembled and ready to use.

CM® REPAIR/REPLACEMENT POLICY

All Columbus McKinnon CM® Series 653-A hoists are inspected

and performance tested prior to shipment. If any properly maintained

hoist develops a performance problem, during the life of the Goods,

due to a material or workmanship defect, as veried by CM, repair

or replacement of the unit will be made to the original purchaser

without charge.

This repair/replacement policy applies only to CM Series 653-A hoists

installed, maintained and operated as outlined in this manual, and

specically excludes hoists subject to normal wear, abuse, improper

installation, improper or inadequate maintenance, hostile environmental

effects and unauthorized repairs/modications. We reserve the right

to change materials or design if, in our opinion, such changes will

improve our product. Abuse, repair by an unauthorized person,

or use of non-CM replacement parts voids the guarantee and could

lead to dangerous operation. For full Terms of Sale, see Sales Order

Acknowledgment. Also, refer to the Limitations of Warranties,

Remedies and Damages, and Indemnication and Safe Operation.

INSTALLATION

Before installing the hoist:

1. Estimate the weight of the load that is to be lifted or moved

and make sure it does not exceed the rated load of the hoist.

2. Make sure the support or sling to which the upper hook is

attached is strong enough to hold several times the weight of

the load to be lifted or moved. Be sure the hoist is solidly held

in the uppermost part of the upper hook and the latch is closed

and not in contact with the support or sling.

3. The area in which the hoist is installed must provide sufcient

room for:

a. The operator to operate the lever.

b. The operator and other personnel to stand clear

of the load at all times.

c. Firm footing for the operator.

d. Clearance between the hoist frame and any object.

The frame must be free to swivel on the upper hook.

OPERATION

If not used as directed, lever hoist may cause injury.

TO AVOID INJURY:

Use only as directed below. Read all instructions before operating

®

the CM

653-A Series hand operated lever hoist.

GENERAL

1. The hoist must be kept clean to assure proper operation.

Before use, check to be sure the load chain is clean, that there

is no foreign material in the liftwheel area and that the lever

operates freely.

2. Do not load beyond the rated capacity. Overload can cause

immediate failure or cause damage resulting in future failure,

even at less than rated capacity.

3. Do not use this hoist or any other material handling equipment

for lifting or moving people, or lifting loads over people.

4. Stand clear of all loads and warn other people of your intention

to move a load in their area.

5. Do not leave a load on the unit unattended.

6. Read warnings and instructions on the hoist before each use.

7. Do not hold the load chain while operating the hoist. Should the

hoist not operate properly, serious injury may occur.

8. Never operate the hoist when ammable materials or vapors

are present. Contact between metal parts may produce sparks

that can cause a re or explosion.

9. STAY ALERT! Watch what you are doing and use common

sense. Do not use the hoist when you are tired, distracted or

under the inuence of drugs, alcohol or medication causing

diminished control.

Malfunction of unit, rigging slip or loss of footing may cause user

to slip resulting in injury.

TO AVOID INJURY:

Always have a rm and secure footing when using the

®

CM

653-A Series hand operated lever hoist.

Attaching the hoist from an inadequate support may allow the

hoist and load to fall and cause injury and/or property damage.

TO AVOID INJURY:

Make sure the structure has sufcient strength to hold several

times the hoist weight and its rated load.

FREE CHAINING

In this mode of operation, the chain can be pulled through the hoist

in either direction by hand for quick attachment to the load.

To engage the free chaining feature, remove any load from the hoist

and move the directional lever to the (“N”) position.

5

(ENGLISH)

P/N: 192065084 Rev AA March 2020

Page 7

OPERATION (CONTINUED)

Do not take up the load chain to the point where the chain stop

or lower hook block becomes jammed against the frame.

ATTACHING THE LOAD

Attach the lower hook to the load so that it is seated in the bowl

of the hook and is not bearing against the tip of the hook or latch,

and the latch is tight against the hook tip.

Allowing the load to bear against the hook latch and/or hook tip

can result in loss of load.

TO AVOID INJURY:

Do not allow the load to bear against the hook latch and/or hook

tip. Apply load to hook bowl or saddle only.

Do not wrap the chain around the load and hook onto itself as a

choker chain sling or bring the load in contact with the hoist. Doing

this will result in the loss of the swivel effect of the hook which could

cause twisted chain and a jammed liftwheel. Also, the chain may be

damaged at the hook. Make sure the upper and lower hooks are in a

straight line and the frame is free to swivel on the upper hook.

Move directional lever to the unload position. Again, operate lever

in an up and down motion to increase the distance between hooks

and thus loosen or lower the load.

LOCKED BRAKE

If a hoist which is under load is suddenly relieved of the load by

lifting the load off of the lower hook by some other means or pulling

down walls, the brake will lock.

The brake will also lock if the lower hook block is pulled tightly

against the frame.

To unlock the brake, turn the directional lever to the unload position

and pull on the lever sharply.

Turning the Handwheel with a load attached will allow the load to

release and may cause injury.

TO AVOID INJURY:

Never turn the Handwheel when the lever hoist is under load.

If the unit is not rigged in a straight line hook to hook manner, and

if the frame is not free to swivel, lever pull may break frame and

cause physical injury and loss of load.

TO AVOID INJURY:

Rig the unit in a straight line hook to hook manner and keep frame

free to swivel (See Figure 4).

ENGLISH

TO PULL OR LIFT THE LOAD

Operate lever in up and down motion to shorten the distance

between hooks and thus pull or lift the load.

When pulling or lifting move the load only enough to slightly load

the unit, then check to be sure that the attachments to the hooks

and load are rmly seated. Continue movement only after you are

assured the load is free of all obstructions.

The hoist has been designed for hand powered operation only. Do

not use an extension on the lever. The following Lever pulls will result

in rated capacity on the unit:

3/4t: 51 lbf / 23 kgf

1t: 51 lbf / 23 kgf

1 1/2t: 77 lbf / 35 kgf

2t: 58 lbf / 26 kgf

3t: 87 lbf / 39 kgf

6t: 92 lbf / 42 kgf

Any greater pull is an indication of either an overload or an

incorrectly maintained unit

TO LOOSEN OR LOWER LOAD

Power operation may cause structural damage or premature wear

that in turn may cause a part to break and allow the load to fall.

TO AVOID INJURY:

Operate the CM® 653-A Series lever hoist using hand power only!

(ENGLISH)

Figure 4

INSPECT HOIST

Before each use and at specied intervals as directed in the

inspection section.

Use as directed above. Failure to do so may cause injury to you

or others.

1. DO NOT exceed capacity shown on nameplate.

2. DO NOT use to lift people or loads over people.

3. DO NOT use unless the hoist’s frame and chain form a straight

line between hooks.

4. DO NOT use if the frame is in contact with any object.

5. DO NOT use if the unit is damaged or malfunctions.

6. DO NOT use extension on lever. Use hand power only.

7. DO NOT use if chain is twisted, kinked or damaged.

6

P/N: 192065084 Rev AA March 2020

Page 8

ENGLISH

a

h

b

MAINTENANCE

INSPECTION

To maintain continuous and satisfactory operation, a regular

inspection procedure must be initiated so that worn or damaged

parts can be replaced before they become unsafe. The intervals

of inspection must be determined by the individual application and

are based upon the type of service to which the hoist is subjected.

The intervals indicated as follows are based on normal service.

The inspections are divided into two general classications

designated as “frequent” and “periodic”.

FREQUENT INSPECTIONS

These inspections are usually visual examinations by the operator.

Frequent inspections are to be performed daily or before each use

and they are to include:

1. Braking mechanism for evidence of slippage.

2. Operation of the directional lever for free movement.

3. Load chain for lubricant, wear, damaged links or foreign material.

4. Hooks for damage, cracks, twists, latch engagement

and latch operation.

PERIODIC INSPECTIONS

These are visual inspections of external and internal conditions

by a designated person making records to provide the basis for

continuing evaluation of the condition of the hoist. The frequency

of periodic inspections is based upon usage as dened in ASME

B30.21. Periodic inspections should include those items

as well as the following:

1. Chain for excessive wear or stretch (See Figures 6 and 7, page 8).

2. Worn, cracked or distorted parts such as lower hook block,

upper hook block, upper hook pin, chain guide, bushings,

lever, brake cover, handwheel, directional pawl, friction hub

and lever ratchet.

3. Inspect for wear on the tip of the pawls, teeth of the ratchet,

and pockets of the liftwheel.

4. Loose or missing bolts, nuts, pins or rivets.

5. Inspect the brake components for worn, glazed or contaminated

friction discs and scoring of the friction hub and ratchet. Replace

brake ratchet assembly if contaminated, glazed or if thickness

is less than 0.256 in. (6.5 mm) for 0.75 Tonne, 1 Tonne and 1.5

Tonne, 0.307 in. (7.8 mm) for 2 Tonne, 3 Tonne and 6 Tonne.

6. Corroded, stretched or broken pawl springs, directional lever

pawl spring and lever ratchet spring.

7. Hooks – Visual inspection based upon ASME B30.10

and ASME B30.21.

8. Nameplate and Warning Labels for legibility and retention.

9. Chain stop in place and properly secured.

Any deciency should be corrected before the hoist is returned

to service. Also, the external conditions may show the need

for more detailed inspection which, in turn, may require the use

of non-destructive type testing.

Any parts deemed unserviceable are to be replaced with new parts

before the hoist is returned to service. It is very important that the

unserviceable parts are destroyed and properly disposed of to

prevent their possible future use as a repair item.

When the unit is subjected to heavy usage or dusty, gritty, moist

or corrosive atmospheric conditions, shorter time periods must be

assigned. Inspection must be made of all parts for unusual wear,

corrosion or damage, in addition to those specically mentioned

in the schedule.

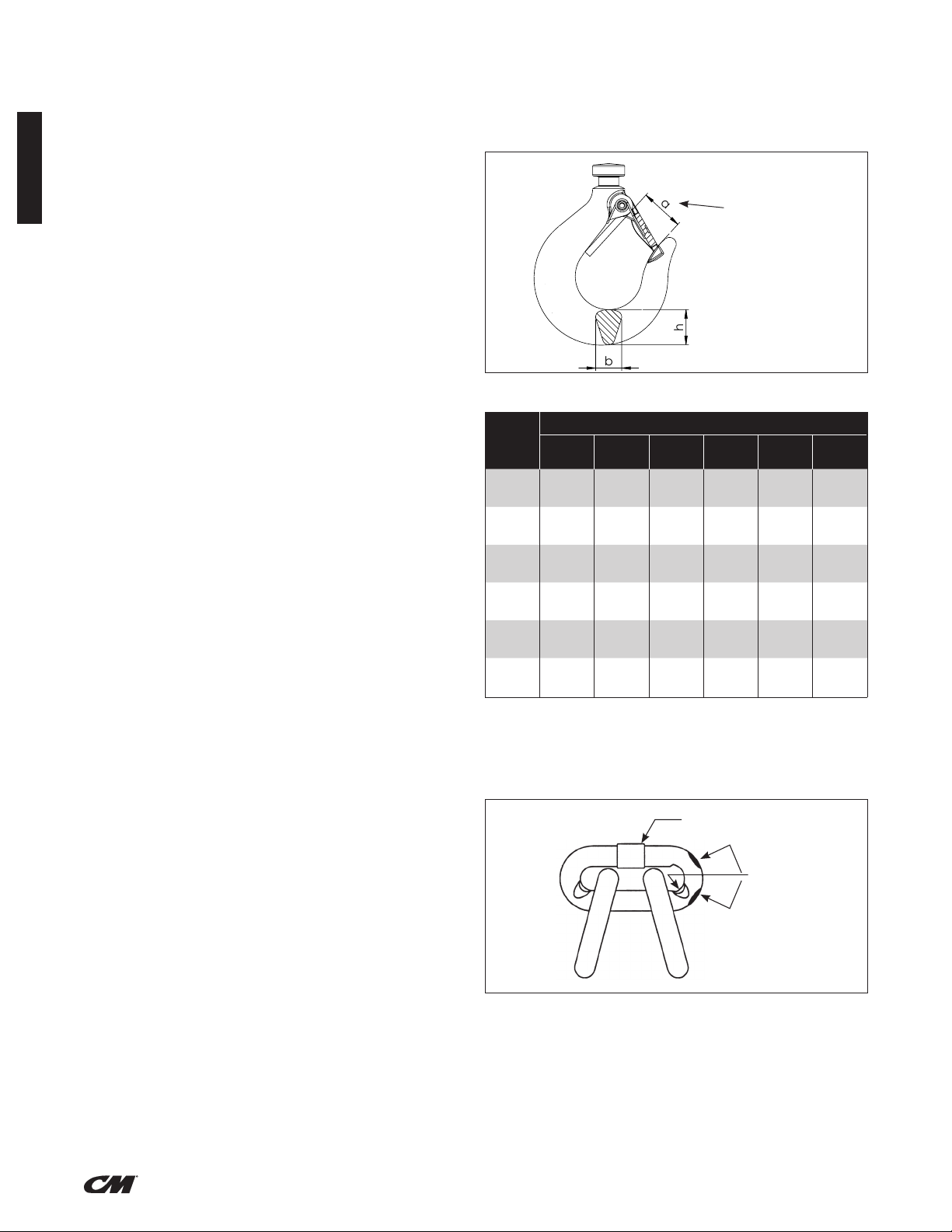

HOOK INSPECTION

Hooks damaged from chemicals, deformations or cracks, or that

have a twist from the plane of the unbent hook, excessive opening

or seat wear, must be replaced (see ASME B30.10). Also, hooks

that are opened to the extent that the latch does not engage the tip

must be replaced. Any hook that is twisted or has excessive throat

opening indicates abuse or overloading of the hoist. Other load

sustaining parts should be inspected for damage.

Check to assure the latch is not damaged or bent and that it operates

properly. It should have sufcient spring pressure to keep it tightly

against the tip of the hook and allow it to spring back to the tip when

released. If the latch does not operate properly, replace the latch.

The chart below should be used to determine when the hook must

be replaced.

Depress latch

to measure

throat opening

Figure 5 - Hook Inspection

"a"

Max.

1.17

1.25

1.38

1.51

1.73

(44)

1.90

Dimensions in. (mm)

"b" Std. "b" Min. "h" Std. "h" Min.

.59

(15)

.75

(19)

.77

(19.5)

.86

(22)

1.10

(28)

1.26

(32)

.56

(14.3)

.71

(18.1)

.73

(18.5)

.82

(20.9)

1.01

(26.6)

1.19

(30.4)

.79

(20)

.86

(22)

1.03

(26.2)

1.18

(30)

1.44

(36.6)

1.76

(44.8)

.75

(19)

.82

(20.9)

.98

(24.9)

1.12

(28.5)

1.37

(34.8)

1.68

(42.6)

Hoist

Capacity

(Tonnes)

0.75

1.0

1.5

2.0

3.0

6.0

"a" Std.

1.06

(27)

1.14

(29)

1.26

(32)

1.37

(35)

1.57

(40)

1.73

(44)

(29.7)

(31.9)

(35.2)

(38.5)

(48.4)

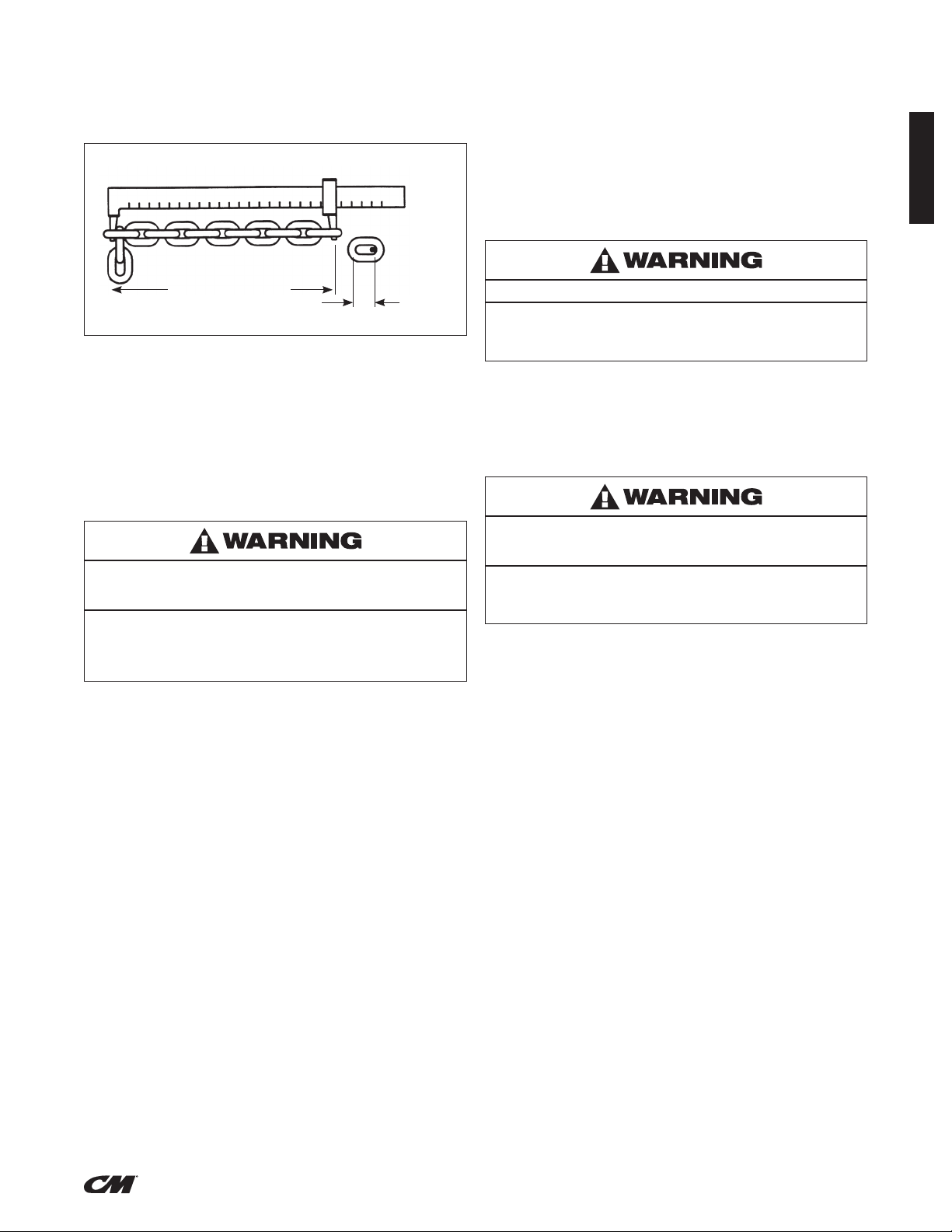

LOAD CHAIN

Chain should feed smoothly into and away from the hoist. If chain

binds, jumps or is noisy, rst clean and lubricate it (See Page 8).

If trouble persists, inspect chain and mating parts for wear,

distortion or other damage.

Weld

Wear In

These Areas

Figure 6 - Chain Inspection

CHAIN INSPECTION

First clean chain with a non-caustic/ nonacid type solvent

and make a link by link inspection for nicks, gouges, twisted links,

weld spatter, corrosion pits, striations (minute parallel lines),

cracks in weld areas, wear and stretching. Chain with any one

of these defects must be replaced.

Slack the portion of the chain that normally passes over the liftwheel.

Examine the interlink area for the point of maximum wear (polishing).

7

(ENGLISH)

P/N: 192065084 Rev AA March 2020

Page 9

Measure and record the stock diameter at this point of the link. Then

measure stock diameter in the same area on the link that does not

pass over the liftwheel (use the link adjacent to the chain stop for this

purpose). Compare these two measurements. If the stock diameter

of the worn link is 0.010 inches (0.254mm), or more, less than the stock

diameter of the unworn link, the chain must be replaced.

Vernier Caliper

IMPORTANT: Do not use replaced chain for other purposes such

as lifting or pulling. Load chain may break suddenly without visual

deformation. For this reason, cut replaced chain into short lengths to

prevent use after disposal.

CHAIN LUBRICATION

A small amount of lubricant will greatly increase the life of load chain.

Do not allow the chain to run dry. Keep it clean and lubricate at

regular intervals with Lubriplate

Rening Co.) or equal lubricant. Normally, weekly lubrication and

cleaning is satisfactory, but under hot and dirty conditions, it may

be necessary to clean the chain at least once a day and lubricate it

several times between cleanings.

®

Bar and Chain Oil 10-R (Fiske Bros.

ENGLISH

Measure 11 Pitches

One Pitch

Figure 7 - Chain Inspection

Also check chain for stretch using a vernier caliper as shown in

Figure 7. Select an unused, unstretched section of chain (usually

at the loose end) and measure and record the length over 11 chain

links (pitches). Measure and record the same length on a worn

section of chain.

If the result (amount of stretch and wear) is greater than 0.145 inch

(3.7 mm), the chain must be replaced.

Use only a “Knife-Edge” caliper to eliminate possibility of false

reading by not measuring full pitch length.

Using other than CM® 653-A SERIES supplied load chain may

cause the chain to jam in the hoist and/or allow the chain to break

and the load to drop.

TO AVOID INJURY:

Due to size requirements and physical properties, use only CM

653-A SERIES supplied load chain in the CM

®

653-A SERIES

®

lever hoist.

Note that worn chain can be an indication of worn hoist

components. For this reason, the hoist’s frame, stripper, and

liftwheel should be examined for wear and replaced as necessary

when replacing worn chain (See DISASSEMBLY and ASSEMBLY).

Also, the load chain is specially heat treated and hardened and

should never be repaired.

Used motor oils contain known carcinogenic materials.

TO AVOID INJURY:

Never use used motor oils as a chain lubricant. Only use Lubriplate

Bar and Chain Oil 10-R as a lubricant for the load chain.

When lubricating the chain, apply sufcient lubricant to obtain

natural run-off and full coverage, especially in the interlink area.

Hoist normally requires no additional lubrication except when it has

been disassembled for cleaning or repairs.

IMPORTANT: Brake is designed to operate dry. Do not use any

grease or lubricant on the braking surfaces.

Using any grease or lubricant on the braking surfaces will cause

brake slippage and loss of load control which may result in injury

and/or property damage.

TO AVOID INJURY:

Do not use any grease or lubricant on braking surfaces. The brake

is designed to operate dry.

When lubricating parts adjacent to the brake, do not use an

excessive amount of lubricant which could seep onto the brake

surfaces.

When the hoist is disassembled for cleaning or repairs, the following

locations should be lubricated with approximately 1 . oz. per hoist

of Molykote BR-2-S (Dow Corning), Molytex #2 (Texaco) or TopMoly

(Topsall) grease or equal lubricant: gears, liftwheel bushings, exterior

of pinion shaft, surfaces of frame bushings and surface of gear cover

bushings. Be sure to thoroughly clean the old grease from these

parts before re-lubricating.

IMPORTANT: To ensure long life and top performance, be sure to

lubricate the various parts of the hoist using the lubricants specied

above. If desired, these lubricants can be purchased from Columbus

McKinnon (See Figure 13, page 10).

®

8

(ENGLISH)

P/N: 192065084 Rev AA March 2020

Page 10

ENGLISH

Columbus McKinnon

Industrial Products GmbH

Yale-Allee 30

42329 Wuppertal / Germany

3

2

5

C

D

4

6

7

8

A

B

Edges According to

DIN 6784

Specified Tolerances

ISO 8015

Material No:

Standard:

Kettenverlauf

Chain installation

KON7

05/09/2019

Description:

mm

Dimensional Units

General Tolerances

ISO 2768-mk

Material:

Modeled:

First Angle Projection

MAINTENANCE (CONTINUED)

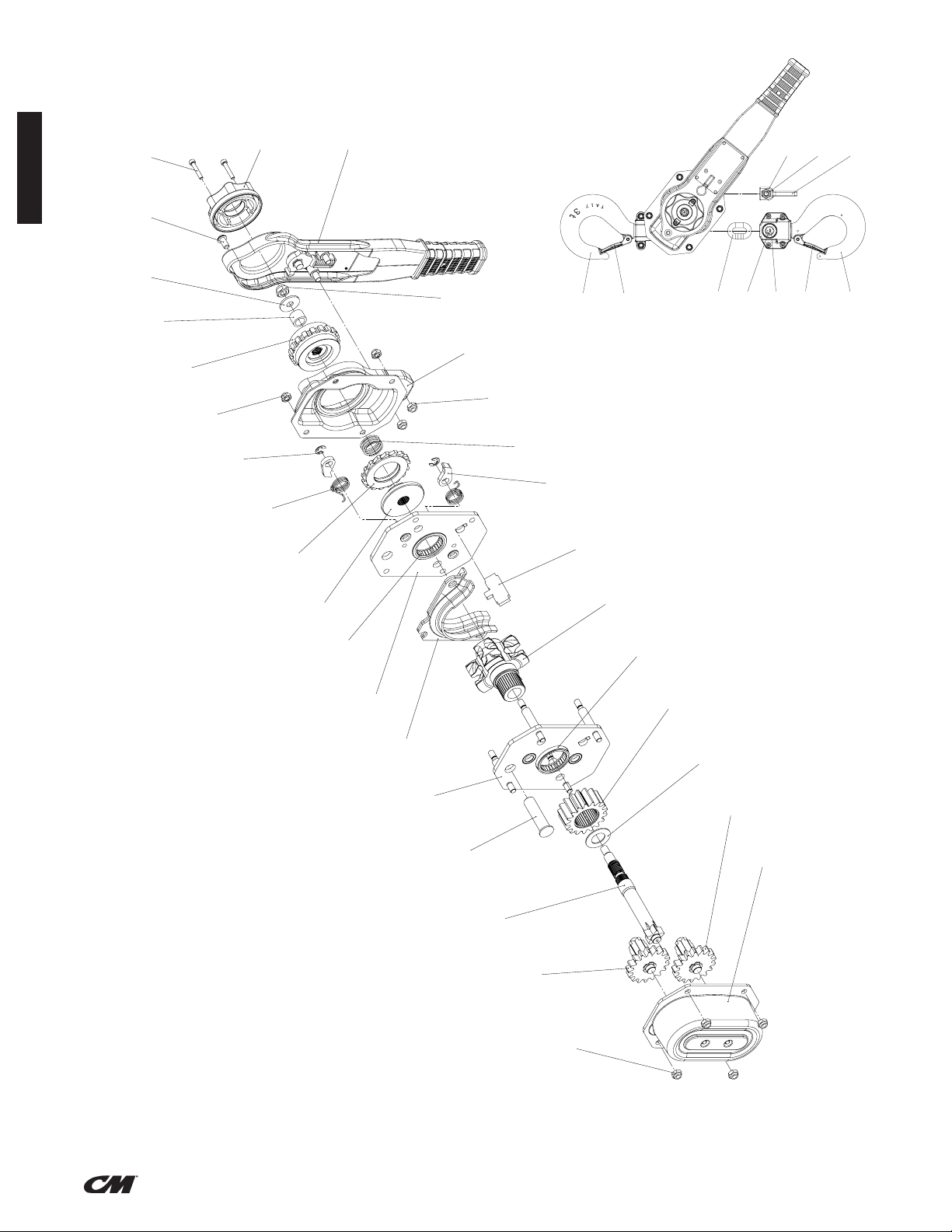

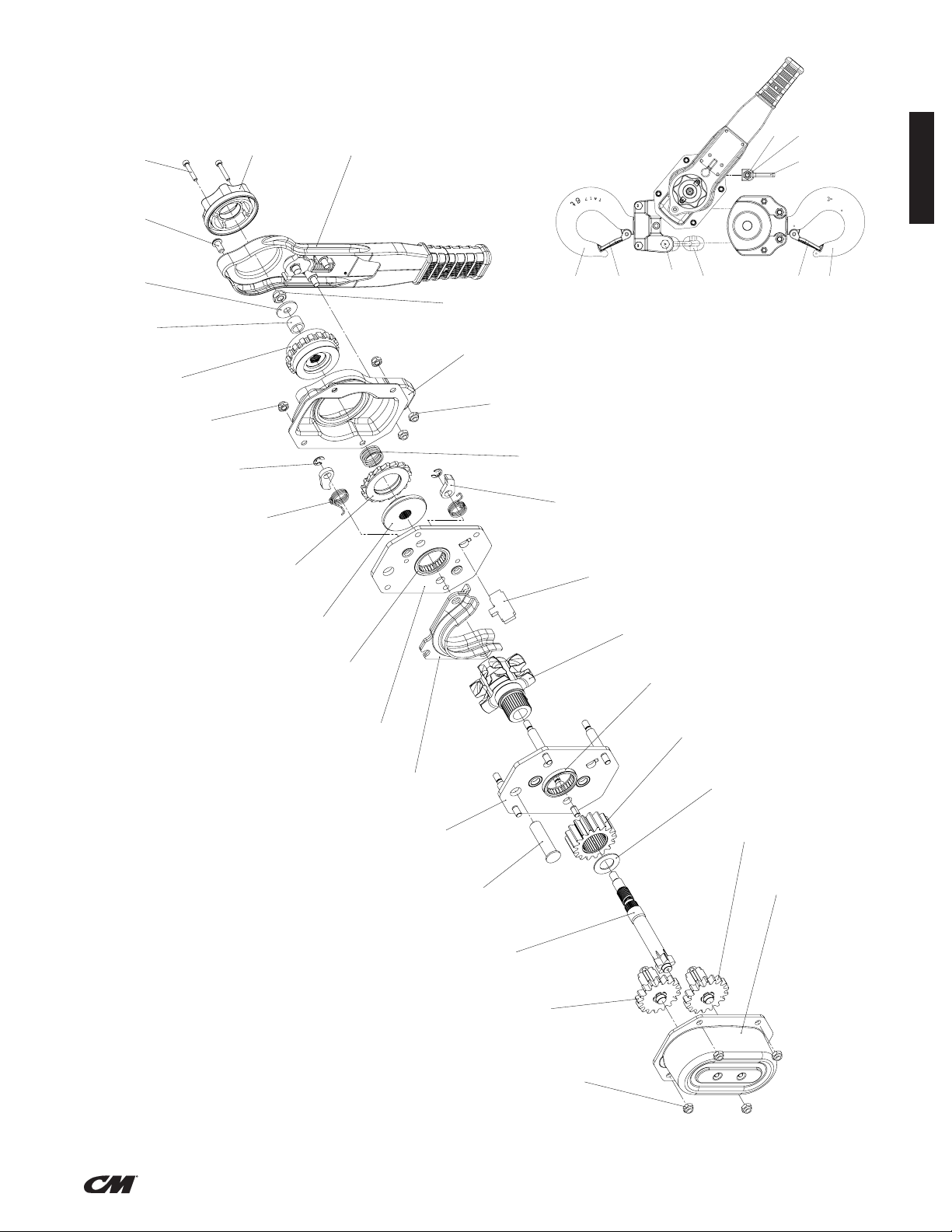

DISASSEMBLY AND ASSEMBLY

The parts illustration and list in the repair parts section show the

general arrangement and name of the parts of the CM® 653-A

SERIES lever hoist. These should be used when disassembling and

re-assembling the units so that all parts are properly installed.

DISASSEMBLY

To replace the liftwheel or stripper, completely disassemble the unit:

remove the chain (See REPLACING LOAD CHAIN, page 11) and then

remove the following: T2 Cylinder Screws M5x30, Handwheel, Lever

Handle Assembly (Button Head Screw and 2 Lock Nuts) Center Lock

Nut, Washer, Bushing, Ratchet Wheel (or Overload Assembly), Brake

Side Cover (4 Lock Nuts) Pressunre Spring, Ratchet Disc Assembly,

Disc Hub, Lever Side Plate Assembly, Chain Guide, Stripper.

On the gear side, remove the following: 4 Lock Nuts, Gear Case

Assembly, Spur Gear Assembly, Drive Shaft, Drive Shaft Washer,

Load Gear, Top Hook Shaft, Upper Hook Assembly, Gear Side Plate

Assembly

ASSEMBLY

Prior to re-assembly, check all parts for excessive wear, cracks and

distortion. Replace parts as necessary and then re-assemble the unit

in reverse to the order given above

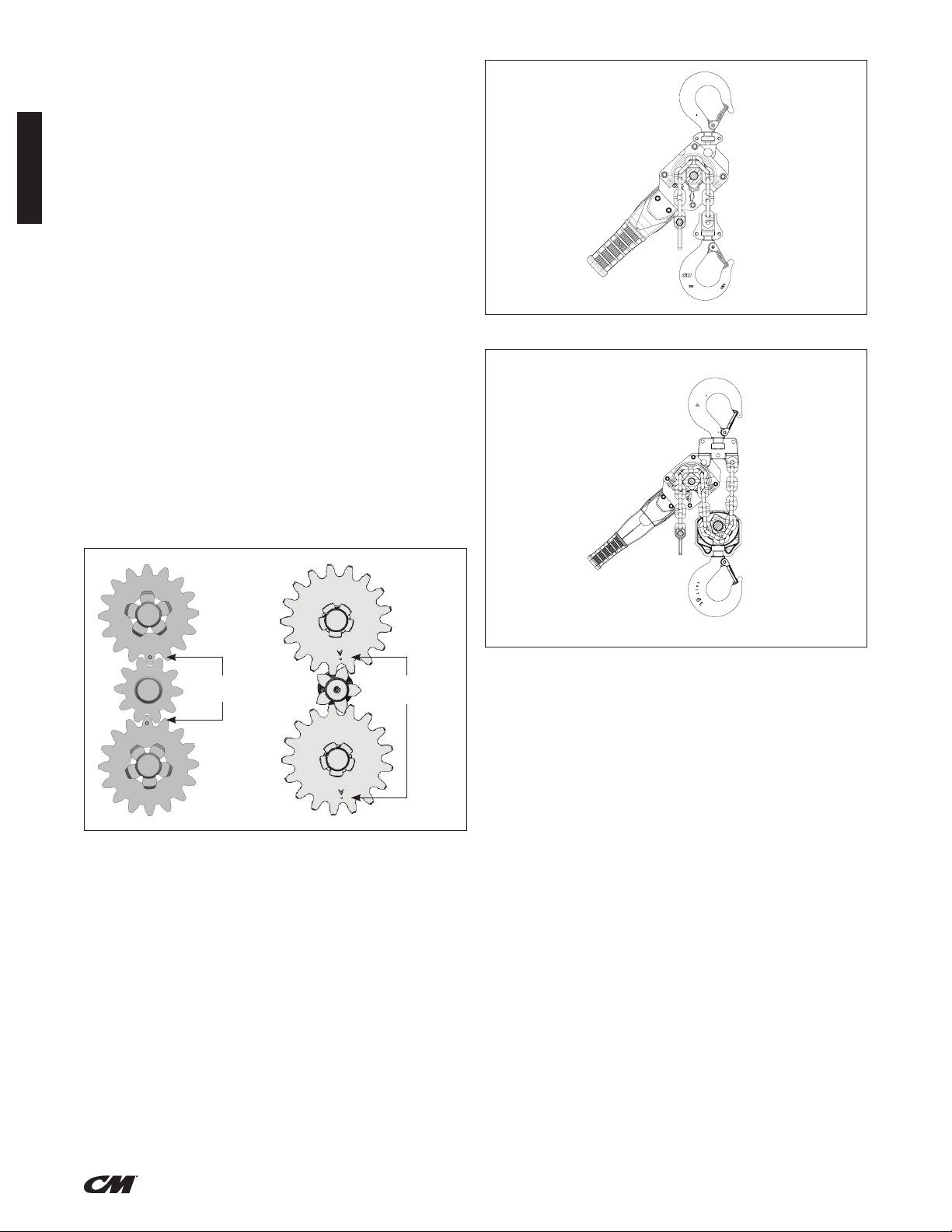

GEAR TIMING

When assembling gears, they must be orientated with the timing

marks orientated as shown. (use gure “Gear Timing”) Note: For 1t

+ 1.5t Tonne units, orientation of pinion/gear assemblies A and B are

not relevant providing the timing marks are orientated as shown and

one of each (A & B) assembly is present.

Chain Installation Single Reeved (0.75 – 3 Tonne)

Chain installation Double Reeved (6 Tonne)

Timing Marks Timing Marks

Figure 10 - Gear Timing

(0.75t + 1t + 1.5t)

Figure 11 - Gear Timing

(2t + 3t + 6t)

REPLACING LOAD CHAIN

To replace the load chain, remove the lower hook block and chain

stop from the chain. Move the directional lever to the neutral “N” and

pull the old chain out of the hoist. Feed a length of soft wire through

one side of the chain guide and over the liftwheel until it comes out

on the other side of the chain guide. Attach the wire to the end of the

new chain. Position the chain so that the rst link to enter the chain

guide will be an upstanding link and the welds on all upstanding

links will be away from the liftwheel. Pull on the wire until the chain

engages the liftwheel. Turn the handwheel while pulling on the wire,

until the chain comes out of the chain guide. Pull the chain through

and remove the wire. Attach the lower hook block to the chain that is

directly below the upper hook.

9

(ENGLISH)

P/N: 192065084 Rev AA March 2020

Page 11

RECOMMENDED SPARE PARTS

Ratchet Disc Assembly

Latch Kit

Upper & Lower Hook Assembly

Alterations or modications of equipment and use of any parts

other than CM

®

653-A Series lever hoist repair parts can lead to

dangerous operation and injury.

TO AVOID INJURY:

Do not alter or modify equipment. Do use only CM

®

653-A Series

provided replacement parts.

PREVENTATIVE MAINTENANCE

In addition to the inspection procedures, a preventative maintenance program should be established to prolong the useful life of the hoist

and maintain its dependability and continued safe use. The program should include the periodic inspections with particular attention being

paid to the lubrication of various components using the recommended lubricants (See Figure 13).

TESTING

Prior to initial use, all repaired or used hoists that have not been operated for the previous 12 months shall be tested by the user for proper

operation. Test the unit rst in the unloaded state and then with a light load of 100 pounds (45 kg.) times the number of load supporting parts

of load chain to be sure it operates properly and the brake holds the load when the lever is released; then test with a load of 125% of rated

capacity.

In addition, hoists in which load sustaining parts have been replaced must be tested with 125% of rated capacity by or under the direction of

a designated person and a written report prepared for record purposes.

NOTE: For additional information on Inspection and Testing refer to ASME B30.21 “Manually Lever Operated Hoists” obtainable from ASME

Order Department, 22 Law Drive, Box 2300, Faireld, NJ 07007-2300, U.S.A.

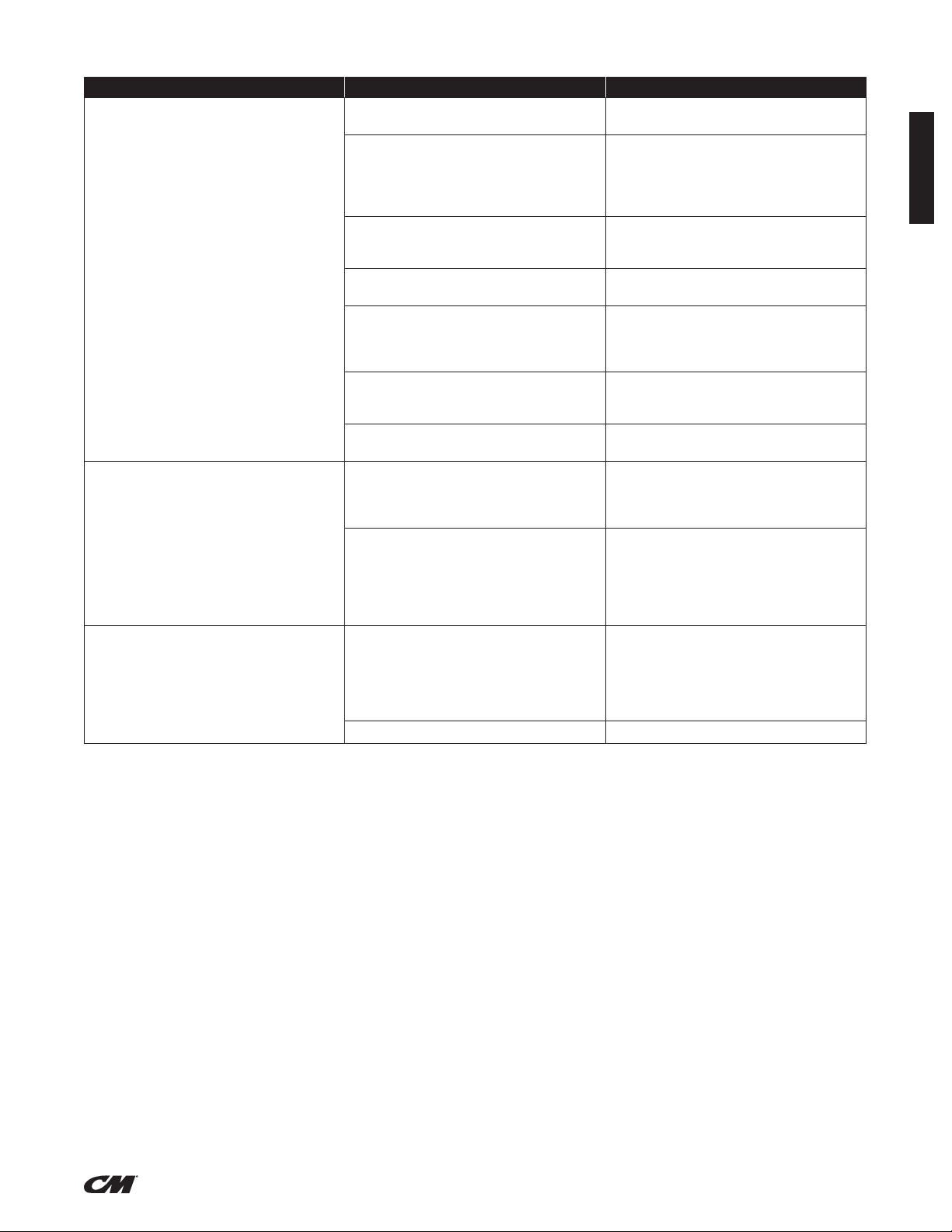

INSPECTOR’S REPORT

ITEM REMARKS (LIST DEFICIENCIES AND RECOMMENDED ACTION)

ENGLISH

Inspector’s

Signature

Date

Inspected Approved by Date

Figure 12 - Recommended Inspector’s Report

RECOMMENDED LUBRICATION SCHEDULE*

®

653-A SERIES HAND OPERATED LEVER HOISTS

CM

COMPONENT TYPE OF LUBRICANT ORDER PART NO. TYPE OF SERVICE AND FREQUENCY OF LUBRICATION

Load Chain Oil (See page 8) 28619 (1 gal. can)

Gears, Bushings, Liftwheel

bushings & Pinion shaft

(*) This lubrication schedule is based on a hoist operating in normal environment conditions. Hoists operating in adverse atmospheres containing excessive heat, corrosive fumes or vapors,

abrasive dust, etc., should be lubricated more frequently.

Grease (See page 8) 28618 (1 lb. can) When hoist is disassembled for cleaning or repairs

HEAVY NORMAL INFREQUENT

Daily Weekly Monthly

Figure 13 - Recommended Lubrication Schedule

10

(ENGLISH)

P/N: 192065084 Rev AA March 2020

Page 12

MAINTENANCE (CONTINUED)

ENGLISH

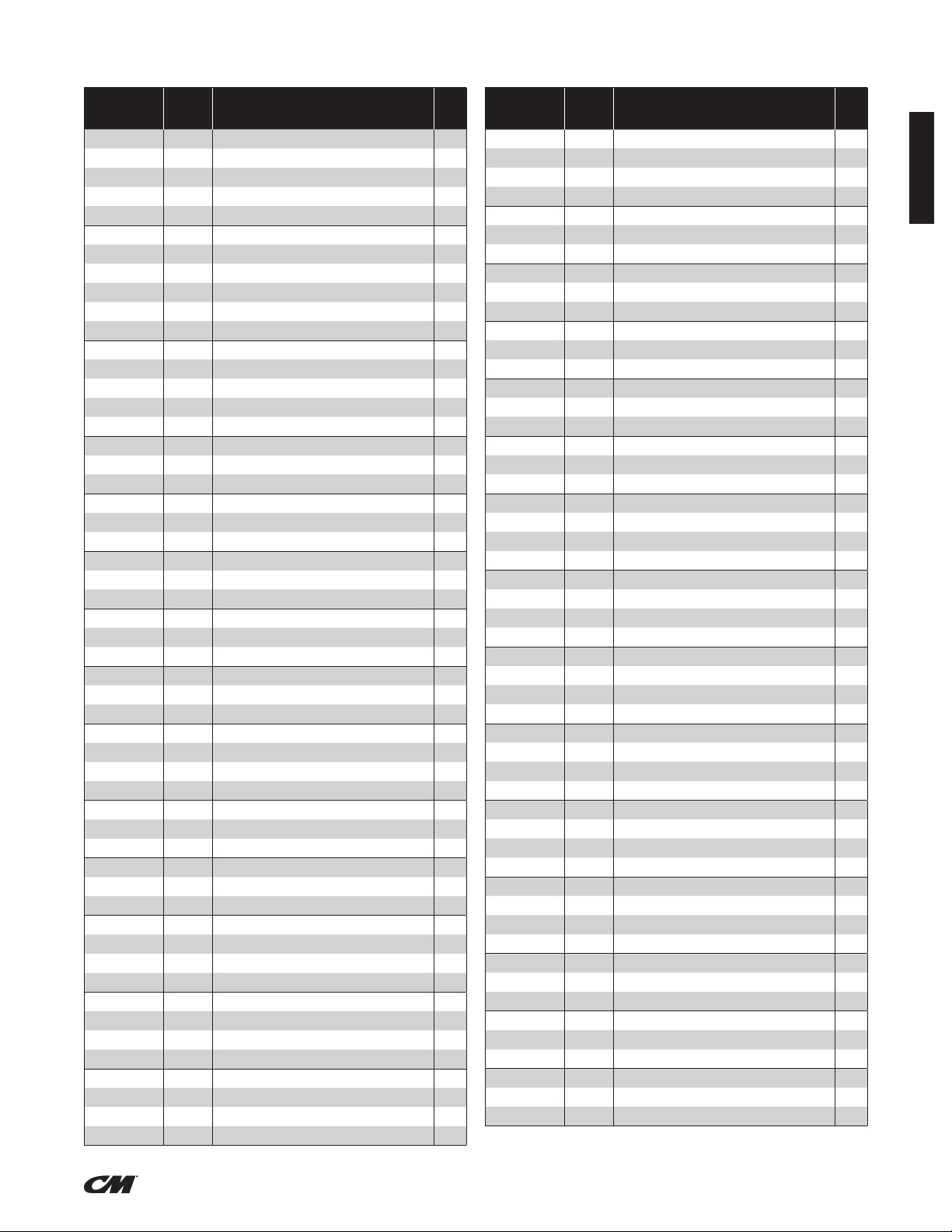

INSPECTION AND MAINTENANCE CHECK LIST

HAND OPERATED LEVER HOIST

Type of Hoist ________________________________________________ Capacity (Tons) ________________________________________________

Location ____________________________________________________ Original Installation Date _______________________________________

Manufacturer _________________________________________________ Manufacturer’s Serial No. _______________________________________

Frequency of Inspection

Frequent Periodic

Item

Daily

Brake Mechanism * * Slippage or excessive drift. Worn, glazed or contaminated

Directional Lever * * Binding and does not move freely.

Retractable Handle * * Possible Deficiencies: Binding and does not move freely.

Load Chain * * Inadequate lubrication, excessive wear or stretch, cracked

Hooks * * Excessive throat opening, twisted, damaged or non-operating

Lower Hook Block, Upper Hook Block,

Upper Hook Pin, Chain Guide, Bushings,

Gears, Pinion and Friction Hub

Tip of Pawls and Lever Pawl Teeth

of Ratchet and Lever Ratchet

Pockets of Liftwheel, Stripper

and Side Plates

Nuts, Bolts, Pins and Rivets * Cracks, bending, loose, stripped threads.

Pawl Springs, Directional Pawl Spring,

and Spring

Chain Stop * Missing, cracked, not secured to chain, not

Nameplate, Warning Labels

and Free Chaining

NOTE: Refer to Maintenance and Inspection Sections of this manual for further details.

Every 3 Months

to Annually as

defined per

ASME B30.21

friction discs. Thickness of brake ratchet assembly less

than 7mm

Cracks, distortion, excessive wear, corrosion or build-up

of foreign material.

damaged or twisted links, corroded or clogged with foreign

material.

hook latch, chemical damage. Cracks (Use dye penetrant,

magnetic or other suitable detection method at least once a

year).

* Cracks, distortion, excessive wear, corrosion or build-up

of foreign material.

* Cracks, distortion, excessive wear, corrosion or build-up

of foreign material.

* Cracks, distortion, excessive wear, corrosion or build-up

of foreign material.

* Corrosion, stretched or broken.

properly positioned.

* Missing, Damaged or illegible.

Possible Deficiencies OK

Action

Required

FREQUENCY OF INSPECTION

Frequent - Indicates items requiring inspection daily or before each use. These inspections may be performed by the operator

Periodic - Indicates items requiring inspection every three months. Inspections to be performed by or under the direction of a properly

NOTE: This inspection and maintenance check list is in accordance with our interpretation of the requirements of the Safety Standard

for Lever Hoists ASME B30.21. It is, however, the ultimate responsibility of the employer/user to interpret and adhere to the applicable

requirements of this safety standard.

Figure 14 — Recommended Inspection and Maintenance Check List

if properly designated.

designated person. The exact period of inspection will depend on frequency and type of usage. Determination of this period

will be based on the user’s experience. It is recommended that the user begin with a quarterly inspection and extend the

periods to semi-annually or annually based on the user’s quarterly experience.

11

(ENGLISH)

P/N: 192065084 Rev AA March 2020

Page 13

TROUBLESHOOTING CHART

Symptom Possible Cause(s) Corrective Action

Hoist is hard to operate in either direction. 1. Load chain worn long to gauge, thus binding

between liftwheel and chain guide.

2. Load chain rusty, corroded or clogged with

foreign matter such as cement or mud.

3. Bushings clogged with matter such as cement

or dust.

4. Lever binding. 4. Clean by removing any foreign matter which may

5. Brake parts corroded or clogged with

foreign matter.

6. Liftwheel pockets clogged with foreign matter or

worn excessively causing chain to bind between

liftwheel and chain guide.

7. Liftwheel twisted or bent - gear teeth bent. 7. Excessive overload had been applied.

Hoist is hard to operate in down direction. 1. Brake parts corroded or clogged with

foreign matter.

2. Chain binding. 2. Check chain, (See page 7) and replace if worn

Hoist is hard to operate in up direction. 1. Chain binding. 1. Check chain, (See page 7) and replace if worn

2. Overload. 2. Reduce load or use correct capacity unit.

1. Check chain, (See page 7) and replace

if worn excessively.

2. Clean chain by tumble polishing or using a

non-acid or non-caustic type solvent. Check

chain for gouges, damaged or bent links.

Lubricate with Lubriplate

®

Bar and Chain Oil

10-R (Fiske Bros. Refining Co.) or equal lubricant.

3. Disassemble and clean liftwheel bushings and

bushings in gear cover and side plate (gear side).

Any parts worn excessively should be replaced.

be between the lever and the brake cover.

5. Disassemble brake and clean thoroughly (by wiping

with a cloth - not by washing in a solvent). Replace

ratchet assembly if too gummy, worn or scored.

Keep brake surfaces clean and dry.

6. Clean out pockets and use if not worn excessively.

Replace liftwheel if pockets are worn.

Replace damaged parts.

1. Disassemble brake and clean thoroughly (by wiping

with a cloth - not by washing in a solvent). Replace

ratchet assembly if too gummy, worn or scored.

Keep brake surfaces clean and dry.

excessively. Clean chain by tumble polishing or using a non-acid or non-caustic type solvent. Check

chain for gouges, damaged or bent links. Lubricate

with Lubriplate

®

Bar and Chain Oil 10-R (Fiske

Bros. Refining Co.) or equal lubricant.

excessively. Clean chain by tumble polishing or using a non-acid or non-caustic type solvent. Check

chain for gouges, damaged or bent links. Lubricate

with Lubriplate

®

Bar and Chain Oil 10-R (Fiske

Bros. Refining Co.) or equal lubricant.

ENGLISH

12

(ENGLISH)

P/N: 192065084 Rev AA March 2020

Page 14

ENGLISH

REPAIR PARTS LIST

Using “Commercial” or other manufacturer’s parts to repair the

®

CM

653-A Series may cause load loss.

TO AVOID INJURY:

Use only CM supplied replacement parts. Parts may look alike but

CM parts are made of specic materials or processed to achieve

specic properties

ORDERING INSTRUCTIONS

The following information must accompany all correspondence

orders for replacement parts:

1. Hoist Model Number from identication plate.

2. Serial number of the hoist stamped below identication plate.

3. Length of lift.

4. Part number of part from parts list.

5. Number of parts required.

6. Part name from parts list.

NOTE: When ordering replacement parts, it is recommended

that consideration be given to the need for also ordering such

items as nuts, bolts, cotter pins, etc. These items may be

damaged or lost during disassembly or just unfit for future

use because of deterioration from age or service.

13

(ENGLISH)

P/N: 192065084 Rev AA March 2020

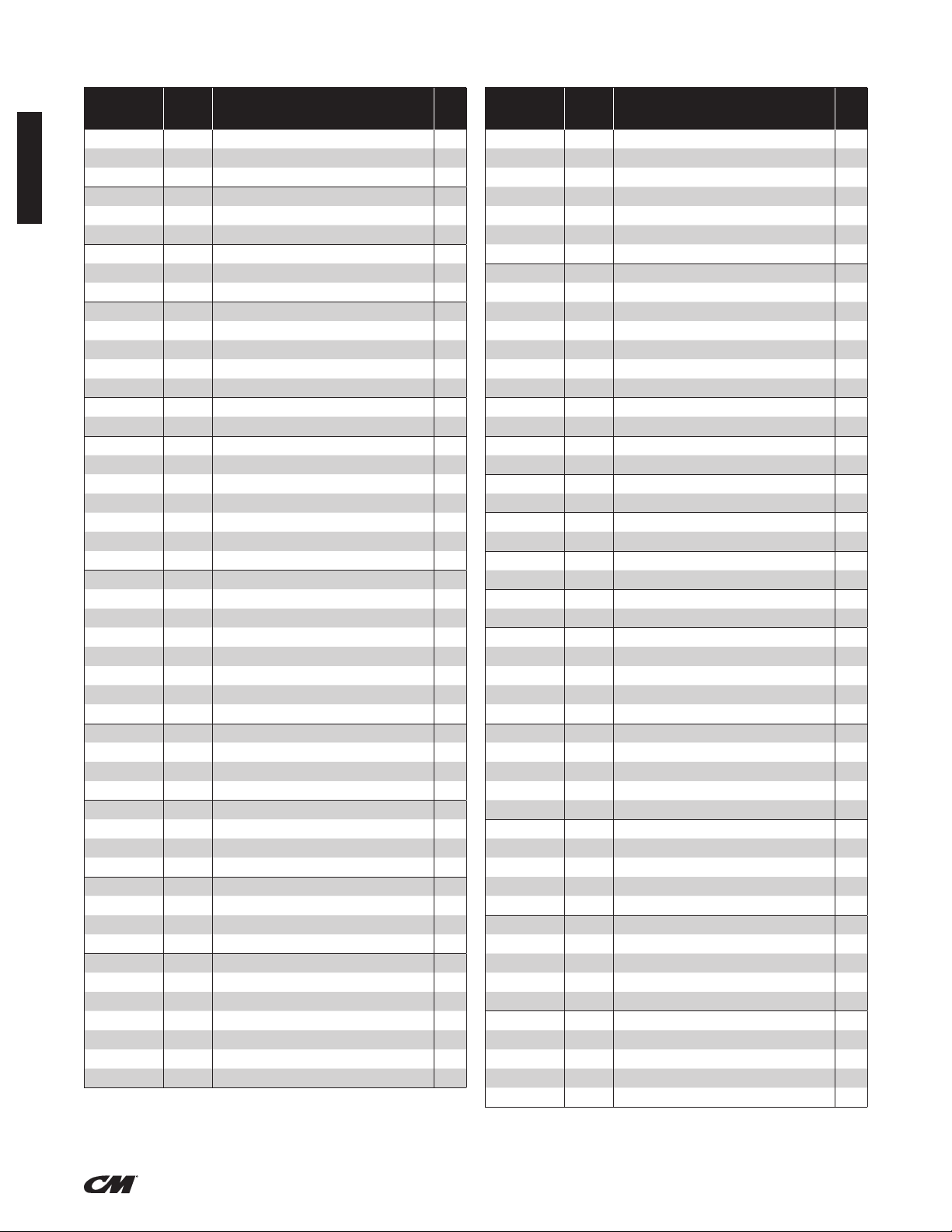

Page 15

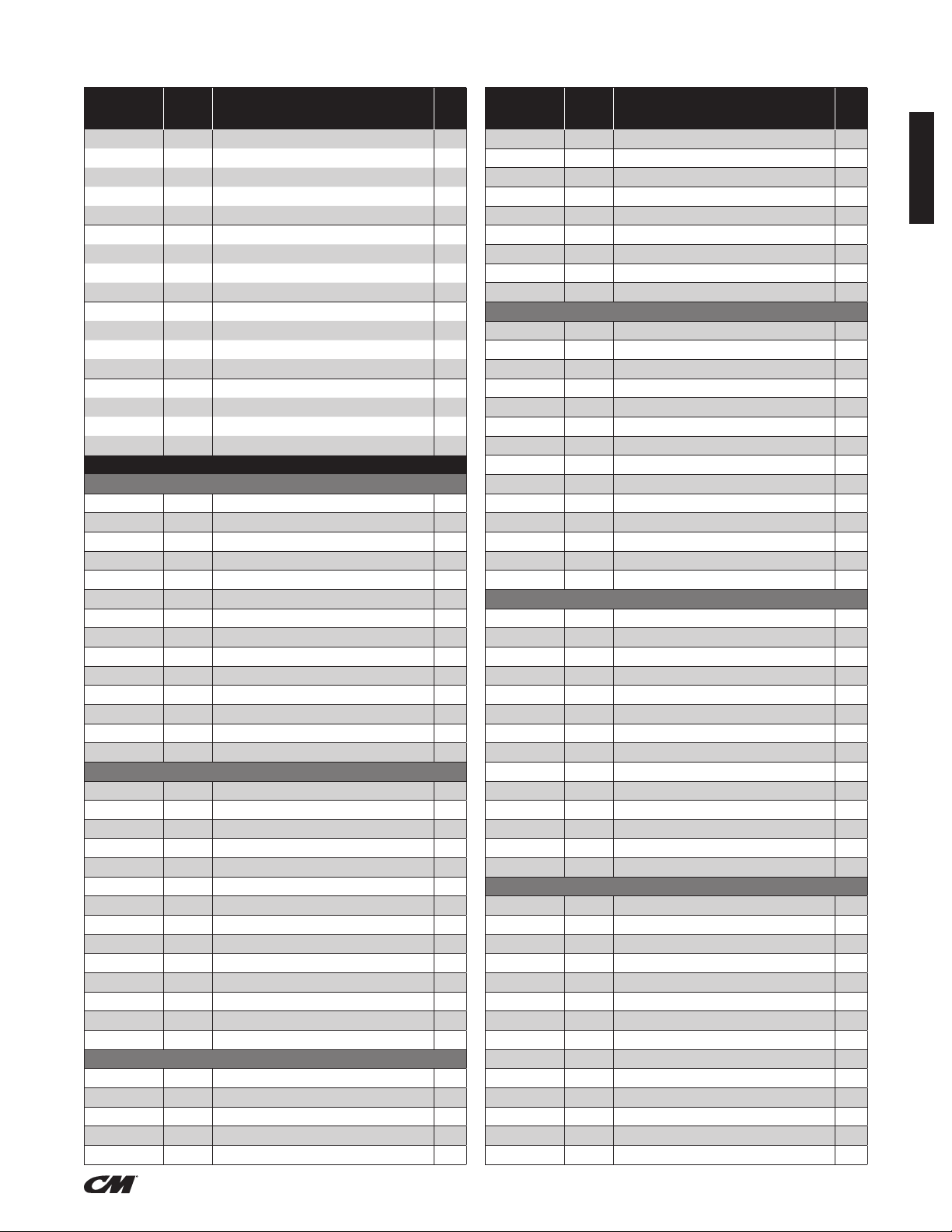

CM® 653-A SERIES HAND OPERATED LEVER HOIST

Part

Number

653A-0001 653-A Gear Kit 0.75T

- 15 LOAD GEAR 1

- 16 SPUR GEAR ASSEMBLY 2

- 17 DRIVE SHAFT WASHER 1

- 8 DRIVE SHAFT 1

653A-0002 653-A Gear Kit 1T & 1.5T

- 15 SPUR GEAR ASSEMBLY 'A' 1

- 16 SPUR GEAR ASSEMBLY 'B' 1

- 17 DRIVE SHAFT WASHER 1

- 19 LOAD GEAR 1

- 8 DRIVE SHAFT 1

653A-0003 653-A Gear Kit 2T, 3T & 6T

- 18 LOAD GEAR 1

- 16 SPUR GEAR ASSEMBLY 2

- 22 DRIVE SHAFT WASHER 1

- 8 DRIVE SHAFT 1

BAN-0010 LOAD SHEAVE KIT 0.75T

- 18 Load Sheave 1

- 17 Drive Shaft Washer 1

BAN-0011 LOAD SHEAVE KIT 1T & 1.5T

- 18 Load Sheave 1

- 17 Drive Shaft Washer 1

BAN-0012 LOAD SHEAVE KIT 2T, 3T & 6T

- 17 Load Sheave 1

- 20 Load Gear Bearing 2

653A-0020 653-A GEAR SIDE PLATE KIT 0.75T

- 1 GEAR SIDE PLATE; ASSY 1

- 22 BUTTON HEAD SCREW 1

653A-0021 653-A GEAR SIDE PLATE KIT 1T & 1.5T

- 1 GEAR SIDE PLATE, ASSY. 1

- 23 BUTTON HEAD SCREW 1

653A-0022 653-A GEAR SIDE PLATE KIT 2T, 3T & 6T

- 1 GEAR SIDE PLATE, ASSY. 1

- 23 BUTTON HEAD SCREW 1

- 20 LIFTWHEEL BEARING (OUTER RING + ROLLERS) 2

653A-0023 653-A LEVER SIDE PLATE KIT 0.75T

- 22 BUTTON HEAD SCREW 1

- 2 LEVER SIDE PLATE; ASSY. 1

653A-0024 653-A LEVER SIDE PLATE KIT 1T & 1.5T

- 23 BUTTON HEAD SCREW 1

- 2 LEVER SIDE PLATE, ASSY. 1

653A-0025 653-A LEVER SIDE PLATE KIT 2T, 3T & 6T

- 12 CYL. SCREW TO M8 - 13 x 22 4

- 23 BUTTON HEAD SCREW 1

- 20 LIFTWHEEL BEARING (OUTER RING + ROLLERS) 2

653A-0030 653-A STRIPPER KIT 0.75T

- 12 BUSHING 1

- 13 CHAIN GUIDE 1

- 14 STRIPPER 1

653A-0031 653-A STRIPPER KIT 1T & 1.5T

- 12 BUSHING 1

- 13 CHAIN GUIDE 1

- 14 STRIPPER 1

Manual

#

Description Qty.

Part

Number

653A-0032 653-A STRIPPER KIT 2T, 3T & 6T

- 12 BUSHING 1

- 13 CHAIN GUIDE 1

- 14 STRIPPER 1

653A-0040 653-A CHANGE GEAR KIT 0.75T

- 12 BUSHING 1

- 6 CHANGE OVER GEAR 1

653A-0041 653-A CHANGE GEAR KIT 1T & 1.5T

- 12 BUSHING 1

- 6 CHANGE OVER GEAR 1

653A-0042 653-A CHANGE GEAR KIT 2T, 3T & 6T

- 12 BUSHING 1

- 6 CHANGE OVER GEAR 1

653A-0050 653-A SPRING KIT 0.75T, 1T & 1.5T

- 11 PRESSURE SPRING 1

- 20 PAWL SPRING 2

653A-0051 653-A SPRING KIT 2T, 3T & 6T

- 11 PRESSURE SPRING 1

- 15 PAWL SPRING 2

TOR-0050 - 653-A CHAIN STOP KIT 0.75T

- 31 LOCK RING 1

- 34 LOCK RING SCREW 1

- 35 LOCK NUT M6 1

TOR-0051 653-A CHAIN STOP KIT 1T & 1.5T

- 38 LOCK RING 1

- 41 LOCK RING SCREW 1

- 42 M8 LOCK NUT 1

TOR-0052 653-A CHAIN STOP KIT 2T & 3T

- 32 LOCK RING 1

- 35 LOCK RING SCREW 1

- 36 LOCK NUT M10 2

TOR-0052 653-A CHAIN STOP KIT 6T

- 32 LOCK RING 1

- 35 LOCK RING SCREW 1

- 37 LOCK NUT M10 1

653A-0070 653-A RATCHET KIT 0.75T, 1T & 1.5T

- 9 DISC HUB 1

- 10 RATCHET DISC ASSEMBLY 1

- 11 PRESSURE SPRING 1

653A-0071 653-A RATCHET KIT 2T, 3T & 6T

- 9 DISC HUB 1

- 10 RATCHET DISC ASSEMBLY 1

- 11 PRESSURE SPRING 1

653A-0080 653-A BRAKE COVER KIT 0.75T

- 4 HOUSING COVER 1

- 24 LOCK NUT M8 4

653A-0081 653-A BRAKE COVER KIT 1T & 1.5T

- 4 HOUSING COVER 1

- 25 LOCK NUT M8 4

653A-0082 653-A BRAKE COVER KIT 2T, 3T & 6T

- 4 HOUSING COVER 1

- 26 LOCK NUT M8 4

Manual

#

Description Qty.

ENGLISH

14

(ENGLISH)

P/N: 192065084 Rev AA March 2020

Page 16

CM® 653-A SERIES HAND OPERATED LEVER HOIST

ENGLISH

Part

Number

653A-0083 653-A GEAR COVER KIT 0.75T

- 3 GEAR CASE ASSEMBLY 1

- 24 LOCK NUT M8 4

653A-0084 653-A GEAR COVER KIT 1T & 1.5T

- 3 GEAR CASE ASSEMBLY 1

- 25 LOCK NUT M8 4

653A-0085 653-A GEAR COVER KIT 2T, 3T & 6T

- 3 GEAR CASE ASSEMBLY 1

- 26 LOCK NUT M8 4

653A-0090 653-A HARDWARE KIT 0.75T

- 27 E-CLIP 2

- 25 LOCK NUT M6 2

- 23 CYLINDER SREW 2

- 24 LOCK NUT M8 9

- 26 WASHER 1

- 22 BUTTON HEAD SCREW 1

653A-0090 653-A HARDWARE KIT 1T & 1.5T

- 28 E-CLIP 2

- 26 LOCK NUT M6 2

- 24 CYLINDER SREW 2

- 25 LOCK NUT M8 9

- 27 WASHER 1

- 23 BUTTON HEAD SCREW 1

653A-0091 653-A HARDWARE KIT 2T, 3T & 6T

- 28 E-CLIP 2

- 25 LOCK NUT M10 1

- 24 CYLINDER SREW 2

- 26 LOCK NUT M8 10

- 27 WASHER 1

- 23 BUTTON HEAD SCREW 1

- 22 DRIVE SHAFT WASHER 1

653A-0100 653-A PAWL KIT 0.75T

- 20 PAWL SPRING 2

- 21 PAWL 2

- 27 E-CLIP 2

653A-0100 653-A PAWL KIT 1T & 1.5T

- 20 PAWL SPRING 2

- 21 PAWL 2

- 28 E-CLIP 2

653A-0101 653-A PAWL KIT 2T, 3T & 6T

- 15 PAWL SPRING 2

- 21 PAWL 2

- 28 E-CLIP 2

653A-0110 653-A HANDWHEEL KIT 0.75T

- 23 CYLINDER SREW 2

- 7 HAND WHEEL 1

- 12 BUSHING 1

- 26 WASHER 1

- 10 RATCHET DISC ASSEMBLY 1

- 24 LOCK NUT M8 1

Manual

#

Description Qty.

Part

Number

653A-0110 653-A HANDWHEEL KIT 1T & 1.5T

- 24 CYLINDER SREW 2

- 7 HAND WHEEL 1

- 12 BUSHING 1

- 27 WASHER 1

- 10 RATCHET DISC ASSEMBLY 1

- 25 LOCK NUT M8 1

653A-0111 653-A HANDWHEEL KIT 2T, 3T & 6T

- 24 CYLINDER SREW 2

- 7 HAND WHEEL 1

- 12 BUSHING 1

- 27 WASHER 1

- 10 RATCHET DISC ASSEMBLY 1

- 25 LOCK NUT M10 1

BAN-0120 653-A UPPER HOOK ASSEMBLY KIT 0.75T

- 28 Upper Hook Assembly 1

653A-0120 653-A UPPER HOOK ASSEMBLY KIT 1T

- 29 TOP HOOK ASSEMBLY 1

BAN-0121 653-A UPPER HOOK ASSEMBLY KIT 1.5T

- 29 TOP HOOK ASSEMBLY 1

653A-0121 653-A UPPER HOOK ASSEMBLY KIT 2T

- 29 TOP HOOK ASSEMBLY 1

BAN-0122 653-A UPPER HOOK ASSEMBLY KIT 3T

- 29 TOP HOOK ASSEMBLY 1

BAN-0123 653-A UPPER HOOK ASSEMBLY KIT 6T

- 29 TOP HOOK ASSEMBLY 1

BAN-0130 653-A LOWER HOOK ASSEMBLY KIT 0.75T

- 29 LOWER HOOK ASSEMBLY (incl. 30, 33 + 35) 1

- 33 LOWER HOOK CHAIN BOLT 1

- 30 LATCH KIT 2

- 35 LOCK NUT M6 2

653A-0130 653-A LOWER HOOK ASSEMBLY KIT 1T

- 30 LOWER HOOK ASSEMBLY (incl. 34 + 36) 1

- 34 LOWER HOOK CHAIN BOLT 1

- 31 LATCH KIT 2

- 36 LOCK NUT M8 2

BAN-0131 LOWER HOOK ASSEMBLY KIT 1.5 TONNE

- 30 LOWER HOOK ASSEMBLY (incl. 34 + 36) 1

- 34 LOWER HOOK CHAIN BOLT 1

- 31 LATCH KIT 2

- 36 LOCK NUT M8 2

653A-0130 653-A LOWER HOOK ASSEMBLY KIT 2T

- 30 LOWER HOOK ASSEMBLY (incl. 34 + 36) 1

- 34 LOWER HOOK CHAIN BOLT 1

- 31 LATCH KIT 2

- 36 LOCK NUT M10 2

653A-0130 653-A LOWER HOOK ASSEMBLY KIT 3T

- 30 LOWER HOOK ASSEMBLY (incl. 34 + 36) 1

- 34 LOWER HOOK CHAIN BOLT 1

- 31 LATCH KIT 2

- 36 LOCK NUT M10 2

Manual

#

Description Qty.

15

(ENGLISH)

P/N: 192065084 Rev AA March 2020

Page 17

CM® 653-A SERIES HAND OPERATED LEVER HOIST

Part

Number

BAN-0133 653-A LOWER HOOK ASSEMBLY KIT 6T

- 30 LOWER HOOK ASSEMBLY (incl. 34 + 36) 1

- 34 LOWER HOOK CHAIN BOLT 1

- 31 LATCH KIT 2

- 36 LOCK NUT M12 1

653A-0140 653-A HAND GRIP KIT 0.75T

- 5 RUBBER GRIP 1

- 6 GRIP FASTENER 1

- 7 GRIP FASTENER SCREW 1

653A-0141 653-A HAND GRIP KIT 1T & 1.5T

- 5 RUBBER GRIP 1

- 6 GRIP FASTENER 1

- 7 GRIP FASTENER SCREW 1

653A-0142 653-A HAND GRIP KIT 2T, 3T & 6T

- 5 RUBBER GRIP 1

- 6 GRIP FASTENER 1

- 7 GRIP FASTENER SCREW 1

192051361 5 LEVER HANDLE ASSEMBLY (incl. NAME PLATE) 1

00002034 19 TOP HOOK SHAFT 1

192035181 N/A SPLIT RING FOR WARNING TAG 1

192061167 N/A WARNING TAG 1

635121EN 32 5.6x17.1 mm LOAD CHAIN 192051362 8 NAME PLATE 1

89033012 9 ROUND HEAD GROOVED PIN 4

53820 30 LATCH KIT 2

N09108068 22 BUTTON HEAD SCREW 1

N09102257 23 CYLINDER SREW 2

89022036 24 LOCK NUT M8 9

89022032 25 LOCK NUT M6 2

N09121200 26 WASHER 1

N09123040 27 E-CLIP 2

192063669 5 LEVER HANDLE ASSEMBLY (incl. NAME PLATE) 1

00002137 20 TOP HOOK SHAFT 1

192035181 N/A SPLIT RING FOR WARNING TAG 1

192061167 N/A WARNING TAG 1

635128EN 33 7.1x21 mm LOAD CHAIN 192063670 8 NAME PLATE 1

89033012 9 ROUND HEAD GROOVED PIN 4

N00400450 31 LATCH KIT 2

N09108068 23 BUTTON HEAD SCREW 1

N09102257 24 CYLINDER SREW 2

89022036 25 LOCK NUT M8 9

89022032 26 LOCK NUT M6 2

N09121200 27 WASHER 1

N09123040 28 E-CLIP 2

192051309 5 LEVER HANDLE ASSEMBLY (incl. NAME PLATE) 1

00002137 20 TOP HOOK SHAFT 1

192035181 N/A SPLIT RING FOR WARNING TAG 1

192061167 N/A WARNING TAG 1

635128EN 33 7.1x21 mm LOAD CHAIN -

Manual

#

Description Qty.

Individual Parts

0.75 Ton

1 Ton

1.5 Ton

Part

Number

192051310 8 NAME PLATE 1

89033012 9 ROUND HEAD GROOVED PIN 4

53821 31 LATCH KIT 2

N09108068 23 BUTTON HEAD SCREW 1

N09102257 24 CYLINDER SREW 2

89022036 25 LOCK NUT M8 9

89022032 26 LOCK NUT M6 2

N09121200 27 WASHER 1

N09123040 28 E-CLIP 2

192051685 5 LEVER HANDLE ASSEMBLY (incl. NAME PLATE) 1

00002331 19 TOP HOOK SHAFT 1

192035181 N/A SPLIT RING FOR WARNING TAG 1

192061167 N/A WARNING TAG 1

85394L 33 10x28 mm LOAD CHAIN -

192063686 8 NAME PLATE 1

89033012 9 ROUND HEAD GROOVED PIN 4

N00400451 31 LATCH KIT 2

N09108069 23 BUTTON HEAD SCREW 1

N09102257 24 CYLINDER SREW 2

89022012 25 LOCK NUT M10 1

89022036 26 LOCK NUT M8 10

N09121045 27 WASHER 1

N09123046 28 E-CLIP 2

192051465 5 LEVER HANDLE ASSEMBLY (incl. NAME PLATE) 1

00002331 19 TOP HOOK SHAFT 1

192035181 N/A SPLIT RING FOR WARNING TAG 1

192061167 N/A WARNING TAG 1

85394L 33 10x28 mm LOAD CHAIN -

192051467 8 NAME PLATE 1

89033012 9 ROUND HEAD GROOVED PIN 4

53822 31 LATCH KIT 2

N09108069 23 BUTTON HEAD SCREW 1

N09102257 24 CYLINDER SREW 2

89022012 25 LOCK NUT M10 1

89022036 26 LOCK NUT M8 10

N09121045 27 WASHER 1

N09123046 28 E-CLIP 2

192051821 5 LEVER HANDLE ASSEMBLY (incl. NAME PLATE) 1

00002331 19 TOP HOOK SHAFT 1

192035181 N/A SPLIT RING FOR WARNING TAG 1

192061167 N/A WARNING TAG 1

85394L 33 10x28 mm LOAD CHAIN -

192051820 8 NAME PLATE 1

89033012 9 ROUND HEAD GROOVED PIN 4

53940 31 LATCH KIT 2

N09108069 23 BUTTON HEAD SCREW 1

N09102257 24 CYLINDER SREW 2

89022012 25 LOCK NUT M10 1

89022036 26 LOCK NUT M8 10

N09121045 27 WASHER 1

N09123046 28 E-CLIP 2

16

(ENGLISH)

Manual

#

Description Qty.

2 Ton

3 Ton

6 Ton

P/N: 192065084 Rev AA March 2020

ENGLISH

Page 18

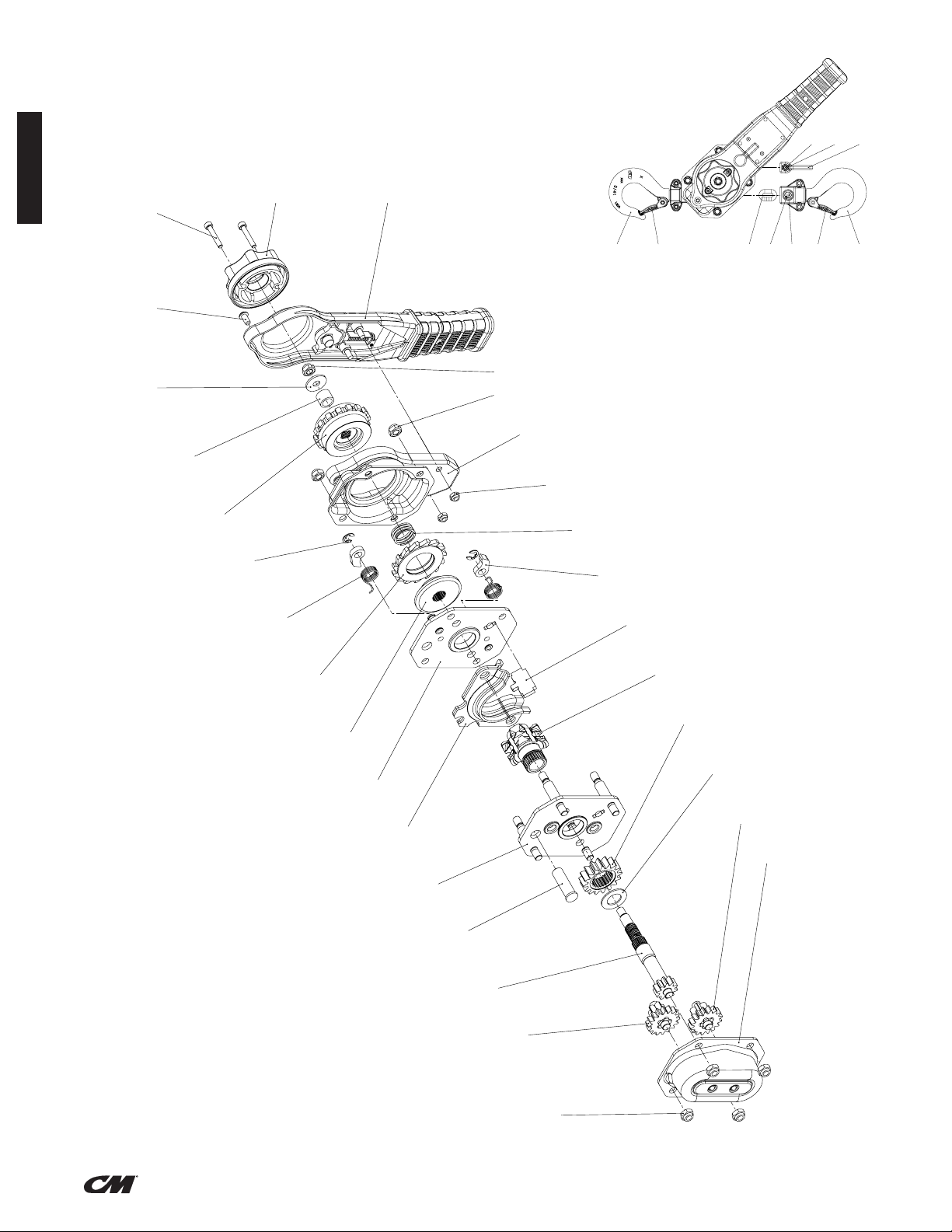

Columbus McKinnon

Industrial Products GmbH

Yale-Allee 30

42329 Wuppertal / Germany

24

16

16

8

17

15

19

18

14

13

2

9

27

10

21

25

4

12

5

24

7

23

3

2226

1

20

6

11

11111

1

1

1

1

1

1

1

2

1

1

1

2

2

1

2

9

2

1

2

9

3

4

5

6

7

8

10

11

By

Date

Description of change

ECN

Rev.

Edges According to

DIN 6784

Specified Tolerances

ISO 8015

Material No:

Standard:

09/13/2018

KON7

192051352

Handhebelzug, Grundgerät

Hand Lever Hoist, base unit

CM 653-A - 0,75t

KON7

KON7

Velbert

02/15/2018

02/15/2018

A1

Format

Number:

Description:

mm

Dimensional Units

General Tolerances

ISO 2768-mk

Material:

1:1

Original scale:

Original project:

Design Authority:

Approved:

Drawn:

Modeled:

First Angle Projection

Columbus McKinnon

Industrial Products GmbH

Yale-Allee 30

42329 Wuppertal / Germany

29 31

QTY.

1

1

2

1

1,8 m

1

1

2

E

B

C

D

F

5

6

7

G

ECN

Rev.

Description of change

Date

By

Modeled:

Drawn:

Approved:

Design Authority:

Original project:

Original scale:

1:1

Material:

General Tolerances

ISO 2768-mk

Dimensional Units

mm

Description:

Number:

Sheet

2

3

Format

A2

02/15/2018

02/15/2018

Velbert

KON7

KON7

653-A 0,75t

Lever Hoist w. 1,5m chain

Hebelzug m. 1,5m Kette

192051364

15.02.2018

Standard:

Material No:

Specified Tolerances

ISO 8015

Edges According to

DIN 6784

First Angle Projection

ENGLISH

PARTS DIAGRAM 0.75 TONNE

35

34

33

35

28

30

32

30

17

(ENGLISH)

P/N: 192065084 Rev AA March 2020

Page 19

Columbus McKinnon

Industrial Products GmbH

Yale-Allee 30

42329 Wuppertal / Germany

25

3

15

16

8

20

19

17

1

18

14

13

2

9

28

4

5

27

23 24

7

12

21

22

6

25

26

11

10

PART NUMBER

DESCRIPTION

QTY.

Getriebeseitenplatte, vormontiert

1

Hebelseitenplatte, komplett

1

Getriebehaube, kpl.

1

Bremshaube, kpl.

1

Hebel, kpl.

1

Sperrrad

1

Handrad

1

Antriebswelle

1

Druckscheibe

1

Sperrradscheibe, kpl.

1

Druckfeder, Freischaltung

1

Distanzbuchse

1

Kettenführung

1

Streiferblech

1

SPUR GEAR ASSEMBLY

1

00002105B

SPUR GEAR ASSEMBLY

1

DRIVE SHAFT WASHER

1

LOAD SHEAVE

1

LOAD GEAR

1

TOP HOOK SHAFT

1

PAWL SPRING

2

PAWL2Halbrundkopfschraube M6x12

1

Zylinderschraube ISO 4762 - M5x30 - 8.8

2

Sechskantmutter DIN EN ISO 10511 - M8 - 8

9

Sechskantmutter DIN EN ISO 10511 - M6 - 8

2

Scheibe ISO 7093-1 - 8,4 - Zn

1

Sicherungsscheibe DIN 6799 - 7 - FSt

2

9

2

3

4

5

6

7

8

10

11

By

Date

Description of change

ECN

Rev.

Edges According to

DIN 6784

Specified Tolerances

ISO 8015

Material No:

Standard:

19.03.2019

KON7

192063666

Handhebelzug, Grundgerät

Hand Lever Hoist, base unit

CM 653-A - 1t

KON7

KON7

Velbert

19.03.2019

19.03.2019

A1

Format

Number:

Description:

mm

Dimensional Units

General Tolerances

ISO 2768-mk

Material:

1:1

Original scale:

Original project:

Design Authority:

Approved:

Drawn:

Modeled:

First Angle Projection

Columbus McKinnon

Industrial Products GmbH

Yale-Allee 30

42329 Wuppertal / Germany

QTY.

1

1

2

1

1,8 m

1

1

2

E

B

C

D

F

6

7

G

ECN

Rev.

Description of change

Date

By

Modeled:

Drawn:

Approved:

Design Authority:

Original project:

Original scale:

1:1

Material:

General Tolerances

ISO 2768-mk

Dimensional Units

mm

Description:

Number:

Sheet

2

3

Format

A2

05.03.2019

05.03.2019

Velbert

KON7

KON7

CM 653-A - 1t

Lever Hoist

Hebelzug

192063671

KON7

05.03.2019

Standard:

Material No:

Specified Tolerances

ISO 8015

Edges According to

DIN 6784

First Angle Projection

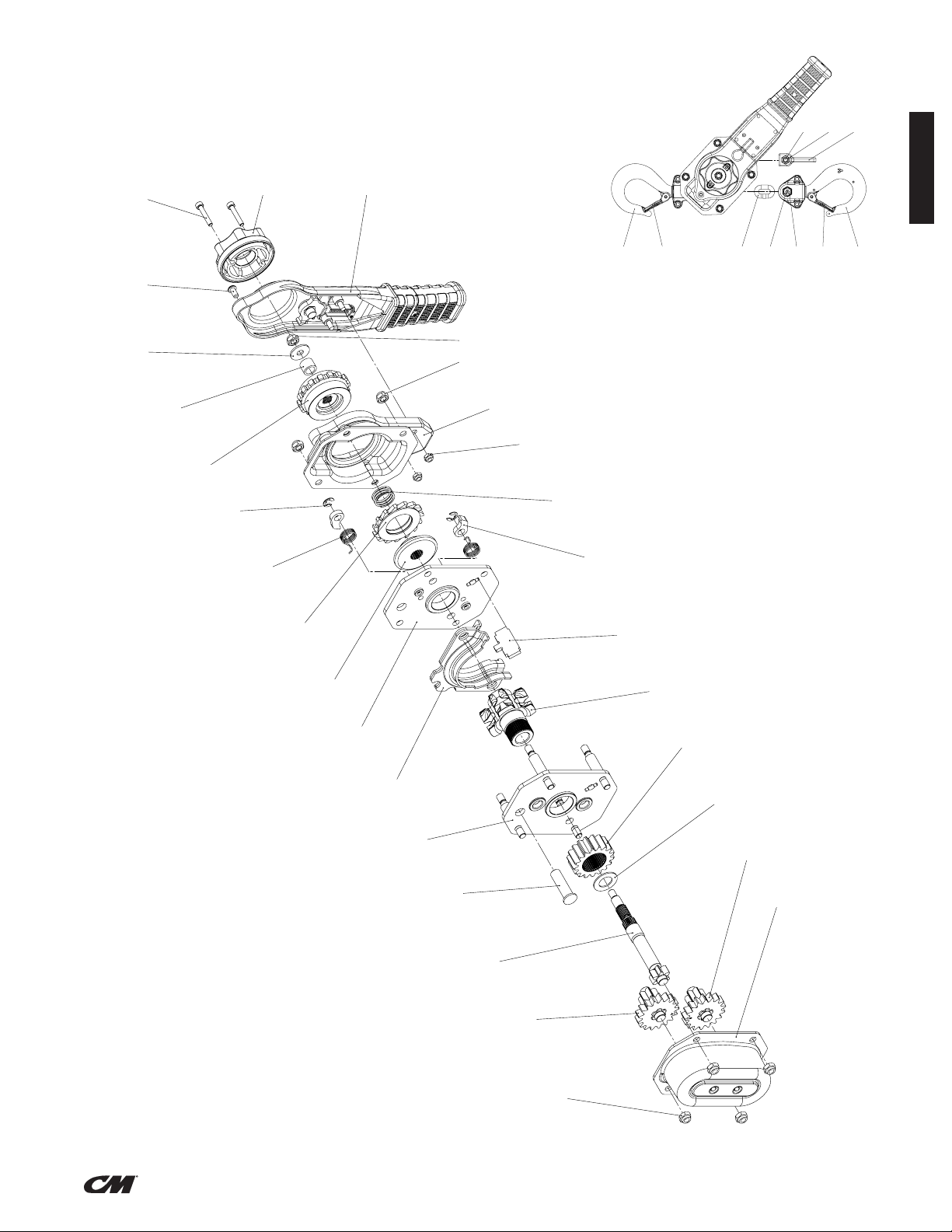

PARTS DIAGRAM 1 TONNE

32

30

ENGLISH

36

35

31

29

33

36

31

34

18

(ENGLISH)

P/N: 192065084 Rev AA March 2020

Page 20

Columbus McKinnon

Industrial Products GmbH

Yale-Allee 30

42329 Wuppertal / Germany

25

3

15

16

8

20

19

17

1

18

14

13

2

9

28

4

5

27 23 24

7

12

21

22

6

25

26

11

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

1 192021063

Getriebeseitenplatte, vormontiert

1

2 192021062

Hebelseitenplatte, komplett

1

3 192051308

Getriebehaube, kpl.

1

4 192051306

Bremshaube, kpl.

1

5 192051309

Hebel, kpl.

1

6 192054522

Sperrrad

1

7 192049848

Handrad

1

8 192044632

Antriebswelle

1

9 192049859

Druckscheibe

1

10 192061895

Sperrradscheibe, kpl.

1

11 192049856

Druckfeder, Freischaltung

1

12 192044633

Distanzbuchse

1

13 192049944

Kettenführung

1

14 192049946

Streiferblech

1

15

00002105A

SPUR GEAR ASSEMBLY

1

16

00002105B

SPUR GEAR ASSEMBLY

1

17 00002239

DRIVE SHAFT WASHER

1

18 00002117

LOAD SHEAVE

1

19 00002109

LOAD GEAR

1

20 00002137

TOP HOOK SHAFT

1

21 00002201

PAWL SPRING

2

22 00002202

PAWL

2

23 09108068

Halbrundkopfschraube M6x12

1

24 09102257

Zylinderschraube ISO 4762 - M5x30 - 8.8

2

25 09115098

Sechskantmutter DIN EN ISO 10511 - M8 - 8

9

26 09115135

Sechskantmutter DIN EN ISO 10511 - M6 - 8

2

27 09121200

Scheibe ISO 7093-1 - 8,4 - Zn

1

28 09123040

Sicherungsscheibe DIN 6799 - 7 - FSt

2

9

2

3

4

5

6

7

8

10

11

By

Date

Description of change

ECN

Rev.

Edges According to

DIN 6784

Specified Tolerances

ISO 8015

Material No:

Standard:

KON7

192051302

Handhebelzug, Grundgerät

Hand Lever Hoist, base unit

CM 653-A - 1,5t

KON7

KON7

Velbert

02/14/2018

02/14/2018

A1

Format

Number:

Description:

mm

Dimensional Units

General Tolerances

ISO 2768-mk

Material:

1:1

Original scale:

Original project:

Design Authority:

Approved:

Drawn:

Modeled:

First Angle Projection

Columbus McKinnon

Industrial Products GmbH

Yale-Allee 30

42329 Wuppertal / Germany

QTY.

1

1

2

1

1,8 m

1

1

2

E

B

C

D

F

5

6

7

G

ECN

Rev.

Description of change

Date

By

Modeled:

Drawn:

Approved:

Design Authority:

Original project:

Original scale:

1:1

Material:

General Tolerances

ISO 2768-mk

Dimensional Units

mm

Description:

Number:

Sheet

2

3

Format

A2

02/15/2018

02/15/2018

Velbert

KON7

KON7

653-A 1,5t

Lever Hoist

Hebelzug

192051313

KON7

09/13/2018

Standard:

Material No:

Specified Tolerances

ISO 8015

Edges According to

DIN 6784

First Angle Projection

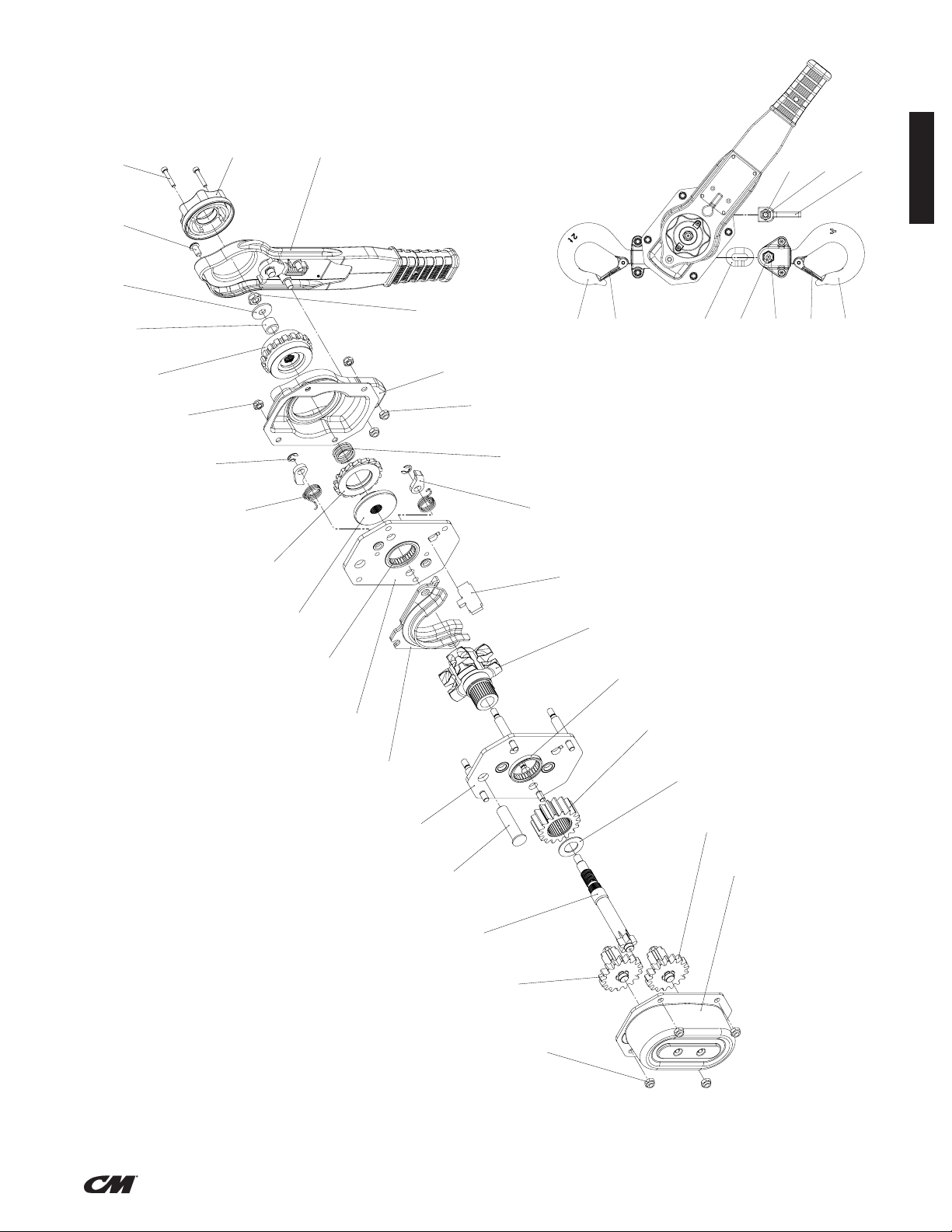

PARTS DIAGRAM 1.5 TONNE

ENGLISH

31

36

32

30

35

29

31

33

34

36

19

(ENGLISH)

P/N: 192065084 Rev AA March 2020

Page 21

Columbus McKinnon

Industrial Products GmbH

Yale-Allee 30

42329 Wuppertal / Germany

26

16

8

19

1

13

9

15

21

26

6

11

23 24

7

5

25

4

14

17

18

22

3

2

20

16

28

26

10

12

27

20

ITEM NO.

PART NUMBER

DESRIPTION

QTY.

1 00230506

Getriebeseitenplatte, vormontiert

1

2

00230507

Hebelseitenplatte, komplett

1

3

192051464

Getriebehaube, kpl.

1

4

192051462

Bremshaube, kpl.

1

5

192063685

Hebel, kpl.

1

6

192054524

Sperrrad

1

7

192050034

Handrad

1

8

192044676

Antriebswelle

1

9

192050037

Druckscheibe

1

10 192061897

Sperrradscheibe, kpl.

1

11 192050035

Druckfeder, Freischaltung

1

12 192044678

Buchse

1

13 192050029

Kettenführung

1

14 192050032

Streiferblech

1

15 192040786

Sperrhakenfeder

2

16 00002305

SPUR GEAR ASSEMBLY

2

17 00002374

LIFTWHEEL ASSEMBLY

1

18 00002309

LOAD GEAR

1

19 00002331

TOP HOOK SHAFT

1

20 00002312

LIFTWHEEL BEARING

2

21 00002336

PAWL

2

22 00002361

DRIVE SHAFT WASHER

1

23 09108069

Halbrundkopfschraube M8x16

1

24 09102257

Zylinderschraube ISO 4762 - M5x30 - 8.8

2

25 09115036