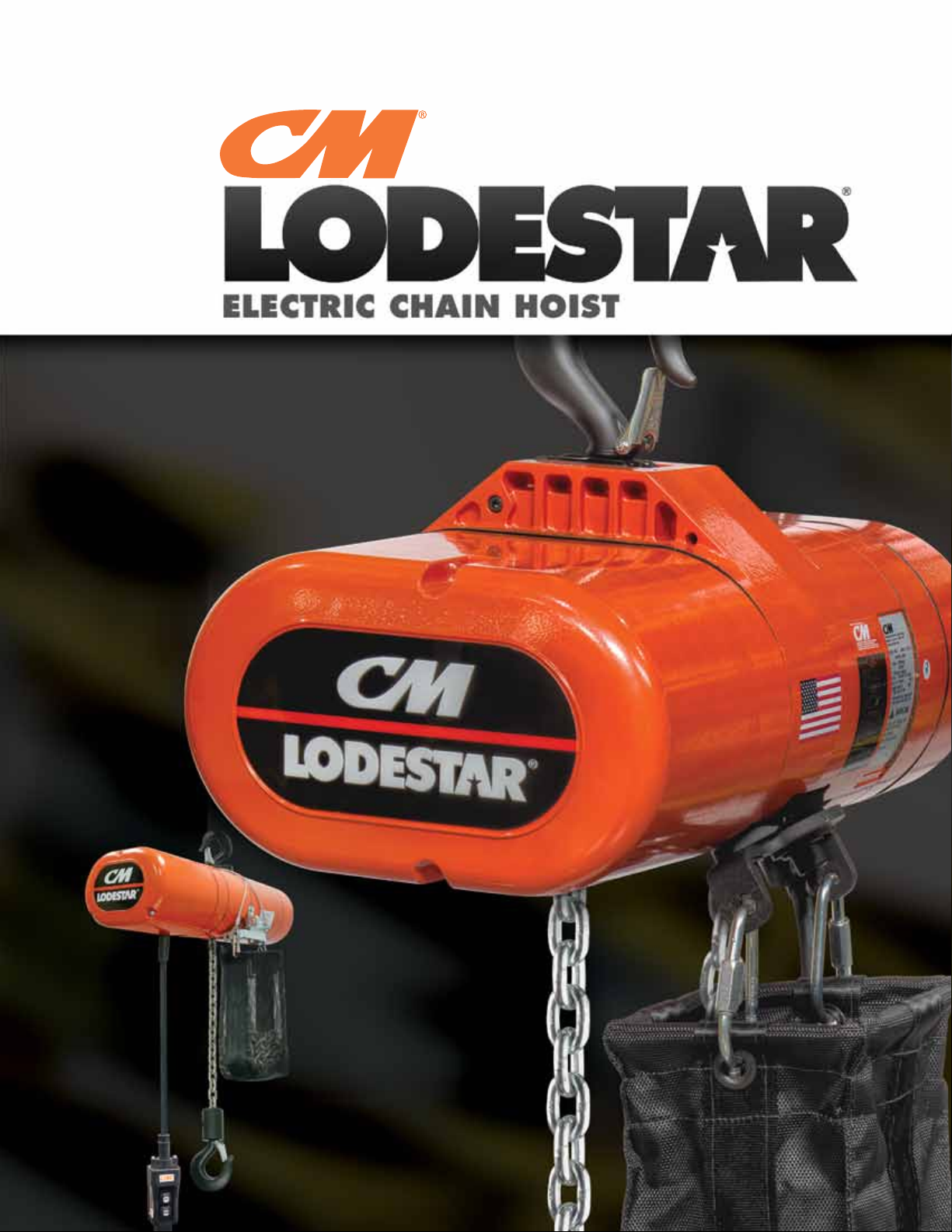

Page 1

COLUMBUS McKINNON CORPORATION

Page 2

First introduced in 1955, the CM® Lodestar® was engineered to be the best electric

chain hoist in the world. Developed through meticulous engineering and American

manufacturing know-how, we weren’t interested in building a hoist that merely

performed, we wanted to create something extraordinary.

Lodestar – iconic in name and legendary in performance – is recognized as the

standard in the overhead lifting industry. Generations of professional riggers

have come to rely on the CM Lodestar for the most demanding and challenging

applications. For this reason, we’ve never stopped reinventing and improving

it to satisfy the needs of every customer – that’s the cornerstone of how we do

business and part of our commitment to excellence.

Made in the USA, the Lodestar features quiet operation, an environmentally friendly

design, easy access to key components, high duty cycles, less maintenance

and enhanced safety features. Every Lodestar is designed, built and tested

to our exacting standards that not only meet, but surpass industry requirements.

Available as individual units, in hoist/trolley combinations, or as integral

components of complete lifting systems, the Lodestar takes lifting to

new heights for professionals in any industry.

With a history of unsurpassed performance and over a million units sold,

the next generation of Lodestar continues this legacy.

Page 3

®

ELECTRIC CHAIN HOIST

1/8 to 3 toN CAPACItIES

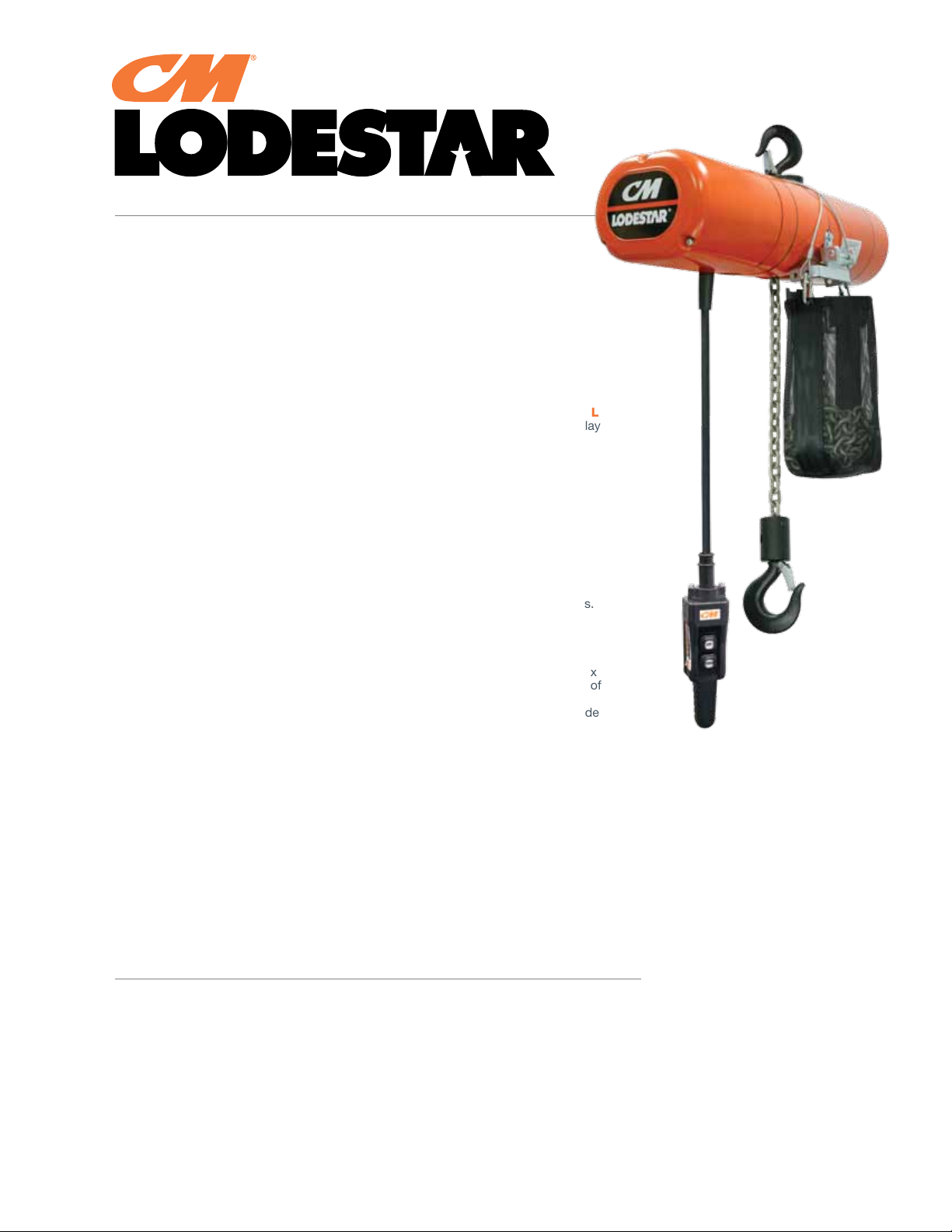

Legendary in performance, the CM® Lodestar® electric

chain hoist features quiet operation, an environmentally

friendly design, easy access to components, high duty

cycles, less maintenance and enhanced safety features.

BENEFITS & FEATURES

LESS MAINTENANCE

& EASIER INSPECTION

n

Brake location allows for quick access

and easy inspection.

n Lifetime grease-lubricated Gear Box means

no oil change out is required. Precision

gears provide better wear and longer life.

n

Clutch located outside the Gear Box

allows for easy access which eliminates

the need for complete disassembly and

reduces downtime.

IMPROVED SERVICEABILITY

Easy access to the Clutch, Motor, Electrical

Control Panel and Brake Assembly.

LONGER SERVICE LIFE

n

Heavy-duty DC brake is designed for

a long service life.

n

Lifetime grease-lubricated Gear Box

and helical gearing ensures better

wear and smooth operation.

n

Heavy-duty rated motor.

QUIETER OPERATION

80% reduction in sound pressure as

compared to the classic Lodestar.

IMPROVED LOAD SAFETY

Clutch is located outside the load path,

preventing slipping of the load in an overload

condition when the brake is not powered.

IMPROVED CHAIN LIFE

5-Pocket Lift Wheel provides better chain and

lift wheel engagement for smoother lifting and

reduced vibration, equating to less wear and

a longer chain life. Zinc plating protects chain

from environmental conditions.

EASY ACCESS CONTROL PANEL

Finger-safe wiring and plug-and-play

connectors on the Control Panel

allow for quick voltage change,

easy access to terminal strips and

simple fuse installation.

ZINC-PLATED LOAD CHAIN

Designed and manufactured in

the USA by Columbus McKinnon.

Zinc-plated Star Grade load chain

protects against corrosion.

EXCEEDS H4 REQUIREMENTS

Lodestar exceeds H4 requirements.

Engineered for high duty cycles

and the toughest applications.

ECO-FRIENDLY

Lifetime grease-lubricated Gear Box

means no changing and disposing of

hazardous oil. Documented RoHS

compliance. Shipped in boxes made

of recycled material.

METRIC RATED

CSA/US

National Recognized

Testing Laboratory (NRTL)

LIFETIME WARRANTY

The industry’s best warranty against

manufacturing and material defects.

FABRIC CHAIN CONTAINER

Standard up to 20 ft. lift.

RIGID HOOK SUSPENSION

OPTIONAL FEATURES

DOUBLE DC BRAKE

Two independent-acting DC Brakes

for redundant braking. Field Installation

Kit available.

AC ELECTRIC BRAKE

VARIABLE SPEED DRIVE (VFD) OR

TRADITIONAL 2-SPEED UNITS

AVAILABLE

PRIMARY & SECONDARY

TRANSFORMER FUSING

ROTATABLE LIMIT SWITCH

Designed for quick reset of limit position.

BLACK PHOSPHATE OR

STAINLESS STEEL LOAD CHAIN

METAL & STAINLESS STEEL

CHAIN CONTAINERS

Page 4

KEY COMPONENTS

Working together, these key components provide best-in-class

performance for any application in a wide variety of industries.

NOTE: Components shown do not represent 2-ton, single-reeved models.

LIFT WHEEL

The Lift Wheel’s 5 pockets increase

the engagement of the chain and lift

wheel to provide smooth lifting with

less vibration and reduced chain wear

when properly maintained – ultimately

extending the life of the chain.

MOTOR

Both heavy duty and efficient, the Motor is designed to

operate on power supplies worldwide. Standard Class F

insulation and thermal motor protection.

HOUSING

Cast aluminum, lightweight housing with acid-resistant,

powder-coated finish for superior durability and protection

against elements. Distinctive CM orange color allows

for easy recognition after installation. The sealed drive

shaft and standard weather-proofing gasket and

seals provide the hoist with a NEMA 3R rating —

suitable for outdoor use.

CONTROL PANEL

Easy access to plug & play connectors

allow for quick voltage change for dual

voltage motors. Effortless fuse installation

when required.

CLUTCH

Located outside the gear box for easy

access, the Clutch is designed to prevent

lifting loads greater than rated capacity.

Page 5

SUSPENSION

Rigid Upper Hook Suspension

is standard on every Lodestar.

Swivel hook optional. Push,

hand-geared and motorized

trolley suspension optional.

GEAR BOX

Precision helical gearing is grease

lubricated for quiet, smooth

operation and long service life.

BRAKE

Heavy-Duty DC Brake is standard.

AC Brake and Double DC Brake are

also available.

LOAD CHAIN & HOOK

Both the Hoistaloy

®

Load Chain and Forged Steel Hook are

manufactured in the USA by Columbus McKinnon. This ensures

full compatibility and the highest quality control standards

are met at all times. Load Chain is zinc plated for protection

against corrosion and is 100% proof tested.

FABRIC CHAIN CONTAINER

Standard on every Lodestar.

INTERNAL CHAIN GUIDE

The stamped steel Chain Guide,

coated for corrosion resistance

and quiet operation, keeps the

load chain and liftwheel aligned

during operation.

LIMIT SWITCH

Adjustable Screw Limit Switch that

automatically stops the hook at

any predetermined point when

either lifting or lowering. Limits are

field-configurable and can be

adjusted to the specific application.

Page 6

ELECTRIC CHAIN HOIST

2-toN, SINGLE-REEVED

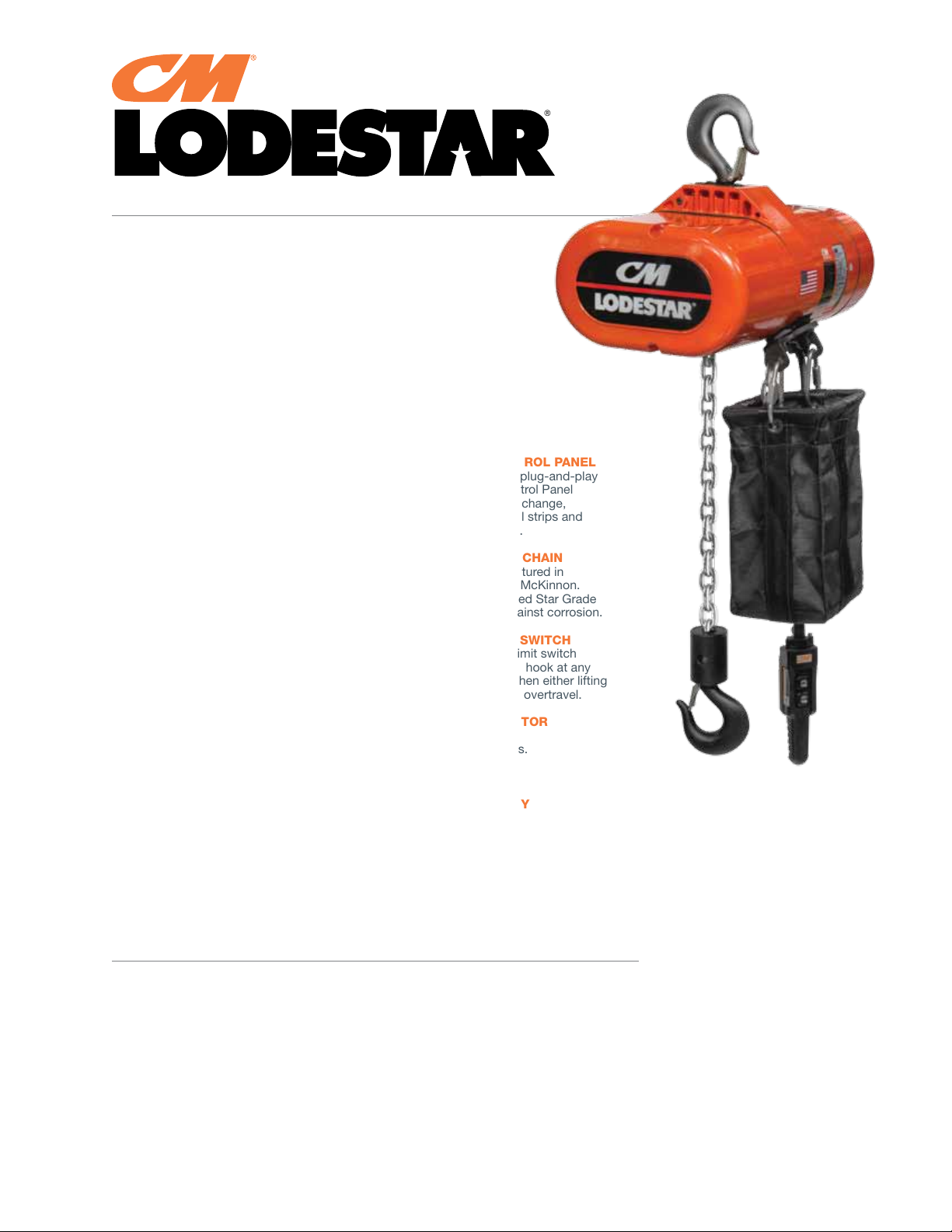

The CM® Lodestar® is now available as an

economical 2-ton, single-reeved unit that’s ideal

for a variety of industrial lifting applications.

And, because it’s a single-reeved unit,

the design prevents the lower hook block

from capsizing and damaging the hoist.

BENEFITS & FEATURES

®

LESS MAINTENANCE

& EASIER INSPECTION

n

Brake location allows for quick access

and easy inspection.

n Lifetime grease-lubricated Gear Box

means no oil change is required.

n

Clutch located outside the Gear Box

allows for easy access which eliminates

the need for complete disassembly and

reduces downtime.

IMPROVED SERVICEABILITY

Easy access to the Clutch, Motor, Electrical

Control Panel and Brake Assembly.

LONGER SERVICE LIFE

n

Heavy-duty DC brake is designed for

a long service life.

n

Lifetime grease-lubricated Gear Box

and helical gearing ensures better

wear and smooth operation.

n

Heavy-duty rated motors.

IMPROVED LOAD SAFETY

Clutch is located outside the load path,

preventing slipping of the load in an overload

condition when the brake is not powered.

IMPROVED CHAIN LIFE

5-Pocket Lift Wheel provides better chain

and lift wheel engagement for smoother lifting

and reduced vibration, equating to less wear

and a longer chain life. Zinc plating protects

chain from environmental conditions.

EASY ACCESS CONTROL PANEL

Finger-safe wiring and plug-and-play

connectors on the Control Panel

allow for quick voltage change,

easy access to terminal strips and

simple fuse installation.

ZINC-PLATED LOAD CHAIN

Designed and manufactured in

the USA by Columbus McKinnon.

10-millimeter, zinc-plated Star Grade

load chain protects against corrosion.

ADJUSTABLE LIMIT SWITCH

Easy-to-adjust screw limit switch

automatically stops the hook at any

predetermined point when either lifting

or lowering, preventing overtravel.

OVERLOAD PROTECTOR

Helps prevent lifting

of dangerous overloads.

METRIC RATED

LIFETIME WARRANTY

The industry’s best warranty against

manufacturing and material defects.

FABRIC CHAIN CONTAINER

Standard up to 20 ft lift.

RIGID HOOK SUSPENSION

OPTIONAL FEATURES

DOUBLE DC BRAKE

Two independent-acting DC Brakes

for redundant braking. Field installation

kit available.

VARIABLE SPEED DRIVE (VFD)

PRIMARY & SECONDARY

TRANSFORMER FUSING

ROTATABLE LIMIT SWITCH

Designed for quick reset of limit position.

METAL CHAIN CONTAINERS

Page 7

>>>

2-TON, SINGLE-REEVED MODEL

SHOWN WITH A CM

MOTORIZED TROLLEY

®

UNIVERSAL

Page 8

THE POWER OF INTELLIGENT LIFTING

Columbus McKinnon is one of the most respected and well-known

names in the material handling industry. We combine two different

yet complimentary areas of expertise – rigging products and hoists –

to develop complete floor-to-ceiling lifting systems for even the most

unique material handling applications.

Columbus McKinnon designs and manufactures a large portfolio of durable

and reliable products for a variety of industries. Our portfolio includes

powered and manual hoists, rigging products, below-the-hook attachments,

cranes, enclosed track systems and specially engineered products.

KNOW HOW. KNOW WHY. BE SAFE. GET TRAINED.

Not only is Columbus McKinnon a leader in material handling products, we are also a global leader

in providing expertise and training on the proper use and inspection of rigging and overhead lifting equipment.

With a range of comprehensive programs and seminars conducted at venues throughout North America,

including our hands-on training centers and private companies, our courses include:

Hoist Maintenance Crane & Hoist Inspection Crane Operator Training

Safe Hoisting Load Securement Rigging

Rigging Gear Inspection

One of our newest programs, CMCO University,

an intimate knowledge of our products, the information they’ll need to select

the right product for the application, and the tools to win in the marketplace.

Classes are available at our state-of-the-art, hands-on training centers,

including the Niagara Training Center and the Hoist & Rigging

Training Center of Excellence in the Center for Occupational

Health and Automobile Manufacturing (COHAM) lab at

The Ohio State University.

Rely on Columbus McKinnon for the products and expertise you need

to keep your workforce productive and safe.

™

is a three-day course designed to give attendees

For more information:

Phone: 800.888.0985 • 716.689.5400

Fax: 716.689.5644

www.cmworks.com

© 2015 Columbus McKinnon Corporation. All Rights Reserved. Stock # CMLSB-0715

07/15 1500 BB

Loading...

Loading...