CLR Jackson 400 Series, 450 Series, 451 series Installation Instructions Manual

INSTALLATION INSTRUCTIONS

CRL JACKSON OVERHEAD

CONCEALED DOOR CLOSER

CENTER HUNG AND OFFSET

crlaurence.com

HB

C

H

C

L

Phone: (800) 421-6144 • Fax: (800) 262-3299

crlaurence.com • usalum.com • crl-arch.com

11M0193

CRL JACKSON OVERHEAD CONCEALED DOOR CLOSER

PRODUCT DESCRIPTION

Jackson Overhead Concealed Door Closers (OHC) are available from C.R. Laurence as closer bodies only or as standard

packages for center hung and offset door installations. The standard packages include the closer mechanism,

mounting brackets, arms, and pivots. OHC's are divided into three groups:

Standard OHC's (Brown) are offered with four (4) xed spring sizes for doors from 2'6" to 4'0" wide (see chart on page 14).

Other options include 90 degree and 105 degree hold open and non-hold open versions.

Grade 1 OHC's (Black) have been tested to ANSI Grade 1 Standards (2 million cycles). They feature a valve

adjustable hydraulic backcheck and are available in 90 degree and 105 degree hold open and non-hold open

models.

Adjustable OHC's (Blue) allow the opening spring force to be adjusted from 4.5 lbs. to 15 lbs. Adjustability

is especially useful when attempting to balance between stack pressure and ADA requirements. The standard

factory adjusted spring pressure is set to the size "Light Duty" and is intended for a 7'0" x 3'0" door. To increase

the spring force by one size, turn the adjustment screw four (4) turns clockwise. Adjustable OHC's are also available

in 90 degree and 105 degree hold open and non-hold open models.

All Jackson OHC's are non-handed, double-acting, and work with center hung and offset applications. Additionally, the body

size and mounting holes of standard and adjustable OHC's are identical and interchangeable with one another.

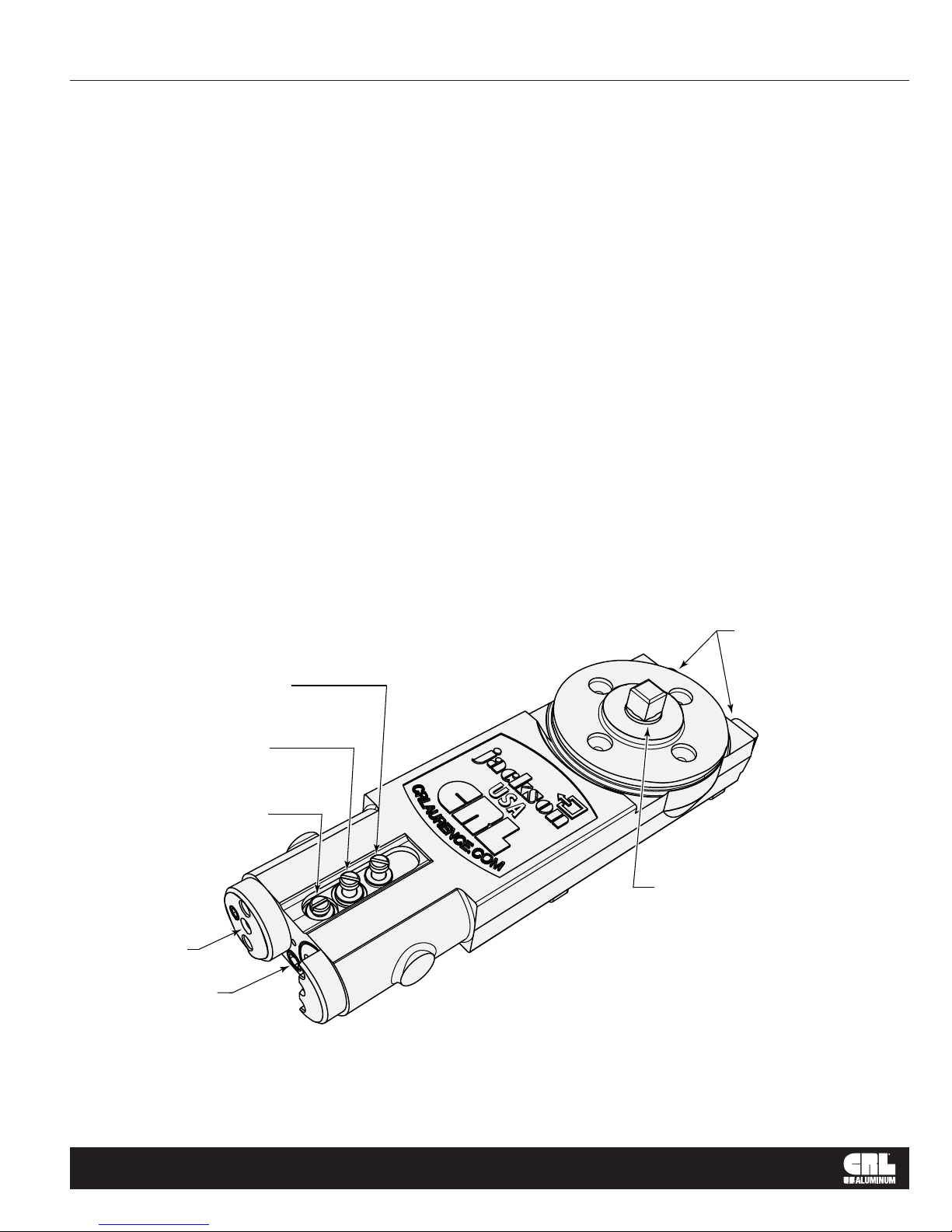

Optional Hydraulic

Backcheck Adjustment

(Black Models)

Closing Speed

Adjustment

(All Models)

Latching Speed

Adjustment

(All Models)

Bracket

Mounting Hole

Optional

Adjustable

Spring Power

(Blue Models)

Mounting Tabs

HB

C

H

C

L

Spindle

crlaurence.com | usalum.com

02

CRL JACKSON OVERHEAD CONCEALED DOOR CLOSER

CONTENTS

Jackson Overhead Concealed Door Closer ....................................... 04-06

Center Pivot Door Typical Installation Series 400, 450, and 451 ............................. 04

Instructions and Adjustments ..................................................... 05

Closer Located in Header ....................................................... 06

Frame Unit for Center-Hung Door with Overhead Concealed Door Closer ..........................07

Center Hung Installation, Door/Threshold Preparation .........................................08

Jackson Overhead Concealed Door Closer, Side Load Center Pivot Door ..........................09

Center-Hung Door Installation with a Side Load Top Arm ................................... 10 -11

Jackson Overhead Concealed Door Closer, End Load Center Pivot Door ...........................12

Center-Hung Installation ........................................................... 13-15

Top Arm Assemblies ............................................................... 13

Overhead Concealed Door Closers .................................................... 14

Pivots ...........................................................................15

Jackson Overhead Concealed Door Closer for Butt Hinge Door ......................................... 16

Jackson Overhead Concealed Door Closer for Offset Pivot Door, 90º Swing ........................ 17

Jackson Overhead Concealed Door Closer for Offset Pivot Door, 105º Swing .......................18

Offset Pivot Installation .............................................................. 19-20

Header for Jackson Overhead Concealed Door Closer With Offset Arm ...........................21

Jackson Overhead Concealed Door Closer for Offset Pivot Door .................................22

Offset Closer Arm Installation ......................................................... 23-24

Offset Arm/Channel Assemblies (Charts) ..................................................25

Center Pivot-Top Portion for Floor Mounted Closer ...........................................26

Frame Unit for Butt Hung Door with Surface Mounted Closer ................................ 27

crlaurence.com | usalum.com

03

CRL JACKSON OVERHEAD CONCEALED DOOR CLOSER

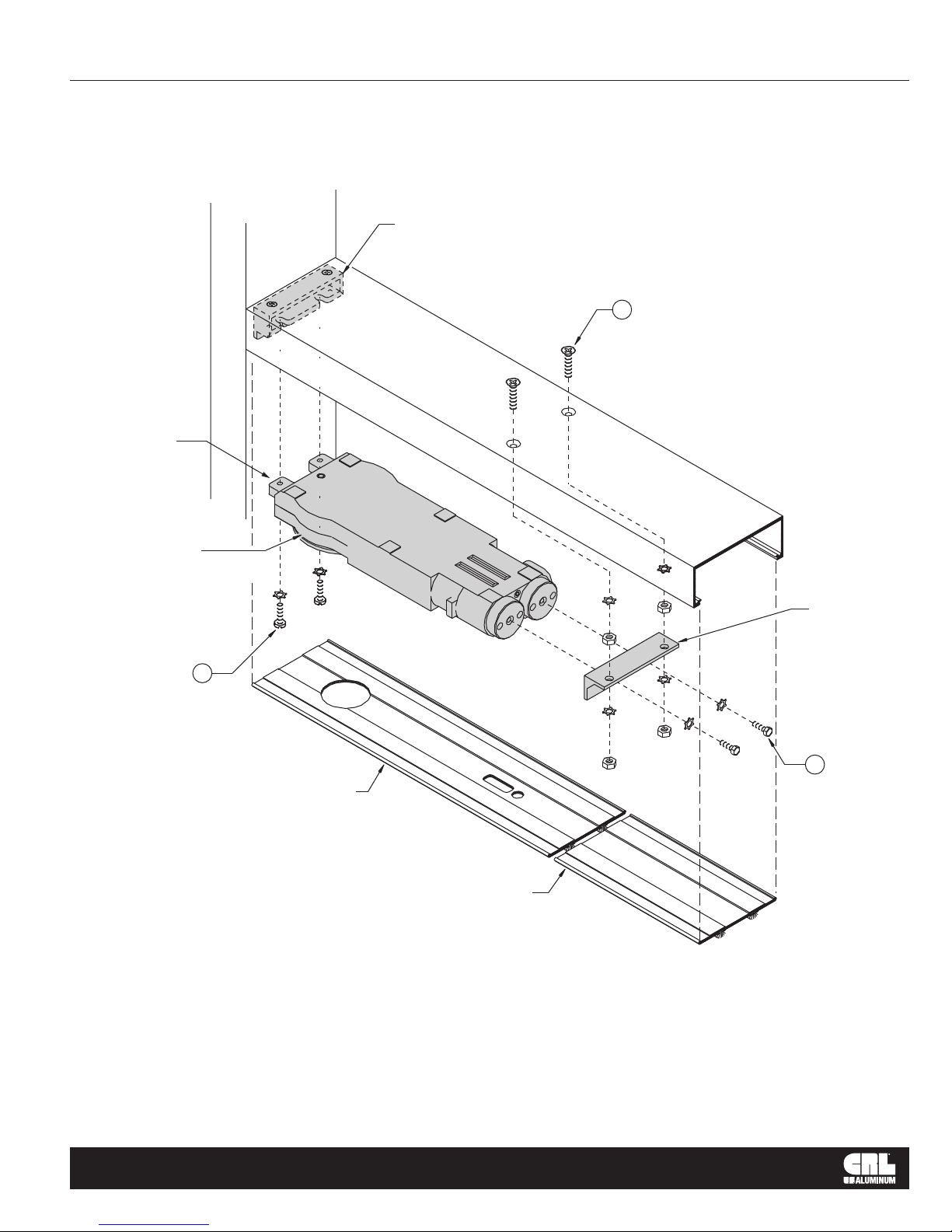

JACKSON OVERHEAD CONCEALED DOOR CLOSER

CENTER PIVOT DOOR TYPICAL INSTALLATION

SERIES 400, 450, AND 451 FABRICATED DOOR HEADER

Closer Mounting Bracket

(Bracket is also used as head to

jamb clip for frame fabrications)

*

3

(2) 1/4"-20 x 7/8" FH SMS

Mounting Lugs

Jackson Door Closer

See Page 5 for closer

adjustments

2

(2) 1/4"-20 x 5/8"

Round Head MS

Snap-In Cover Plate

(14" Long)

Snap-In Cover

Plate Extension

Closer mounting bracket is already installed (See FRAME UNITS installation instructions).

1. Mount angle bracket to door closer with (2) 1/4"-20 Hex Head Cap screw and (2) lock washers.

2. Install (2) 1/4"-20 x 5/8" Round Head MS into lugs of closer. Do not tighten screws.

3. Install (2) 1/4"-20 x 7/8" FH SMS* with (2) 1/4"-20 nuts and washers in header.

4. Insert closer lugs into mounting bracket slot at an angle and raise closer opposite end to align

mounting screws with angle bracket holes. Secure bracket to mounting screws using (2) nuts

and washers.

5. Tighten Round Head Screws.

6. Snap-In Cover Plate.

Angle Bracket

1

(2) 1/4"-20 x 1/2"

Hex Head Cap Screw

*For 2" x 4-1/2" header, longer screws are provided.

crlaurence.com | usalum.com

04

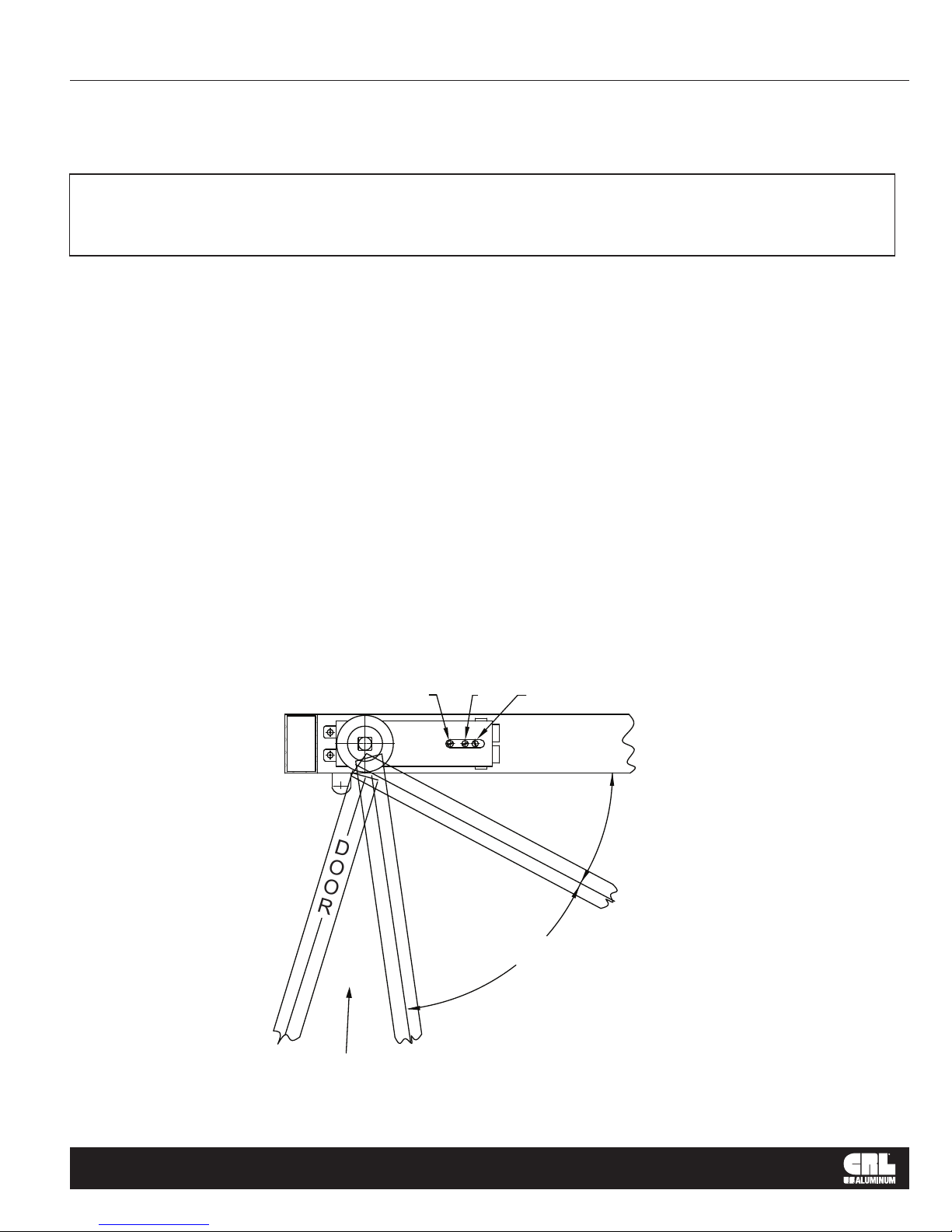

CRL JACKSON OVERHEAD CONCEALED DOOR CLOSER

JACKSON OVERHEAD CONCEALED DOOR CLOSER

INSTRUCTIONS AND ADJUSTMENTS

IMPORTANT: PLEASE READ BEFORE PROCEEDING. Observe all safety warnings. Always wear proper eye

protection and appropriate safety equipment. Always place a safety block between the door and the jamb to prevent the

door from closing while making adjustments. The closer contains springs compressed under high load and has no user

serviceable internal components. Do not attempt to remove the covers or otherwise open the closer in any manner.

The closer has been fully tested and adjusted at the factory. The closing and latching speeds have been pre-set to achieve a

6 to 8 second closing cycle. The optional hydraulic backcheck has not been factory pre-set. After installation, cycle the door

10 or more times from the maximum open position to the full closed position prior to making nal adjustments.

To increase either the closing or latching speeds, turn the appropriate adjustment valve counter-clockwise. To decrease either

the closing or latching speeds, turn the appropriate adjustment valve clockwise. Set the latching speed (Valve "L") rst, then

set the closing speed (Valve "C"). Check and readjust if necessary.

Hydraulic Backcheck (if so equipped) turn the adjustment valve clockwise to increase backcheck resistance which dampens

and slows the momentum of the door when opened with excessive force. Decrease resistance by turning the adjustment valve

counter-clockwise. The adjustment valve must not be adjusted so that the backcheck function is used as a rigid backstop.

Using the backcheck as a rigid backstop may cause damage to the closer or door.

Adjustable Spring Power (if so equipped) the adjustable spring power has been factory set to Size 2. To increase the

spring power, turn the adjuster clockwise. To decrease, turn the adjuster counter-clockwise. Typical door opening force adjusts

at the rate of approximately 1 pound of force (4.5 N) for each 3 to 4 revolutions of the adjuster.

IMPORTANT: Do not attempt to adjust the spring power with the door open beyond 20 degrees from fully closed.

WARNING: Neither the standard internal back stop nor the optional backcheck are to be used as the primary door stop.

An auxiliary oor or overhead door stop is always recommended to prevent structural interference and possible door and

closer damage.

C H"HBCH"

0°

DOOR

LATCHING AREA

"L" VALVE

80°

CLOSING AREA

"C" VALVE

HYDRAULIC BACKCHECK

VALVE AREA "HBCH"

crlaurence.com | usalum.com

05

CRL JACKSON OVERHEAD CONCEALED DOOR CLOSER

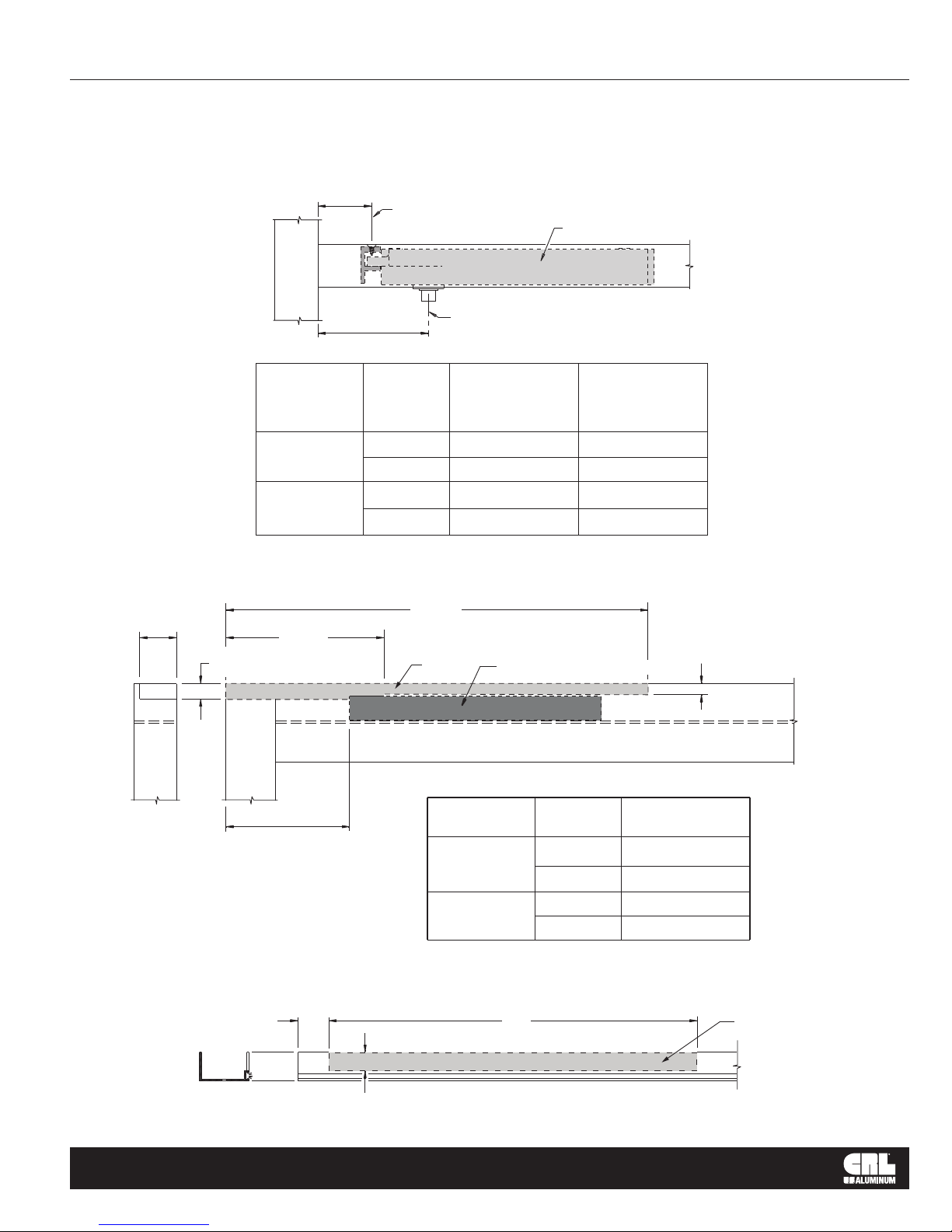

JACKSON OVERHEAD CONCEALED DOOR CLOSER

CLOSER LOCATED IN HEADER

1-1/2"

(38.1)

5/8"

(15.9)

"B"

DOOR TYPE

CENTER PIVOT

OFFSET PIVOT

(0P400)

BUTT HINGES

C of fasteners for closer mounting

L

VIEW OF HEADER AT CLOSER

C of Spindle

"A"

HOLD

OPEN

90º OR 105º

105º

90º

105º

90º

L

DIMENSION

"A"

2-3/4"

(69.9)

4-1/2"

(114.3)

3-3/4"

(95.3)

3-3/4"

(95.3)

2-7/8"

(73.0)

Jackson Closer

DIMENSION

(11.1)

2-3/16"

(55.6)

1-7/16"

(36.5)

1-7/16"

(36.5)

(14.3)

"B"

7/16"

9/16"

SLIDE CHANNEL LOCATION IN TOP DOOR RAIL FOR OFFSET ARM

17-3/16"

(436.6)

6-7/16"

(163.5)

Notch Out

Slide channel and spacer

(11.1)

7/16"

"C"

1-1/4"

(31.8)

DA201

crlaurence.com | usalum.com

TOP DOOR RAIL

DOOR VIEW FROM INSIDE

DOOR TYPE

OFFSET PIVOT

(0P400)

BUTT HINGES

HOLD

OPEN

90º

105º

90º

105º

OFFSET ARM COVER CHANNEL

RIGHT HAND SHOWN; LEFT HAND OPPOSITE

15"

(381.0)

3/4"

(19.1)

DIMENSION

"C"

4-15/16"

(125.4)

4-11/16"

(119.1)

4-1/16"

(103.2)

3-7/8"

(98.4)

Notch Out

NOT TO SCALE

06

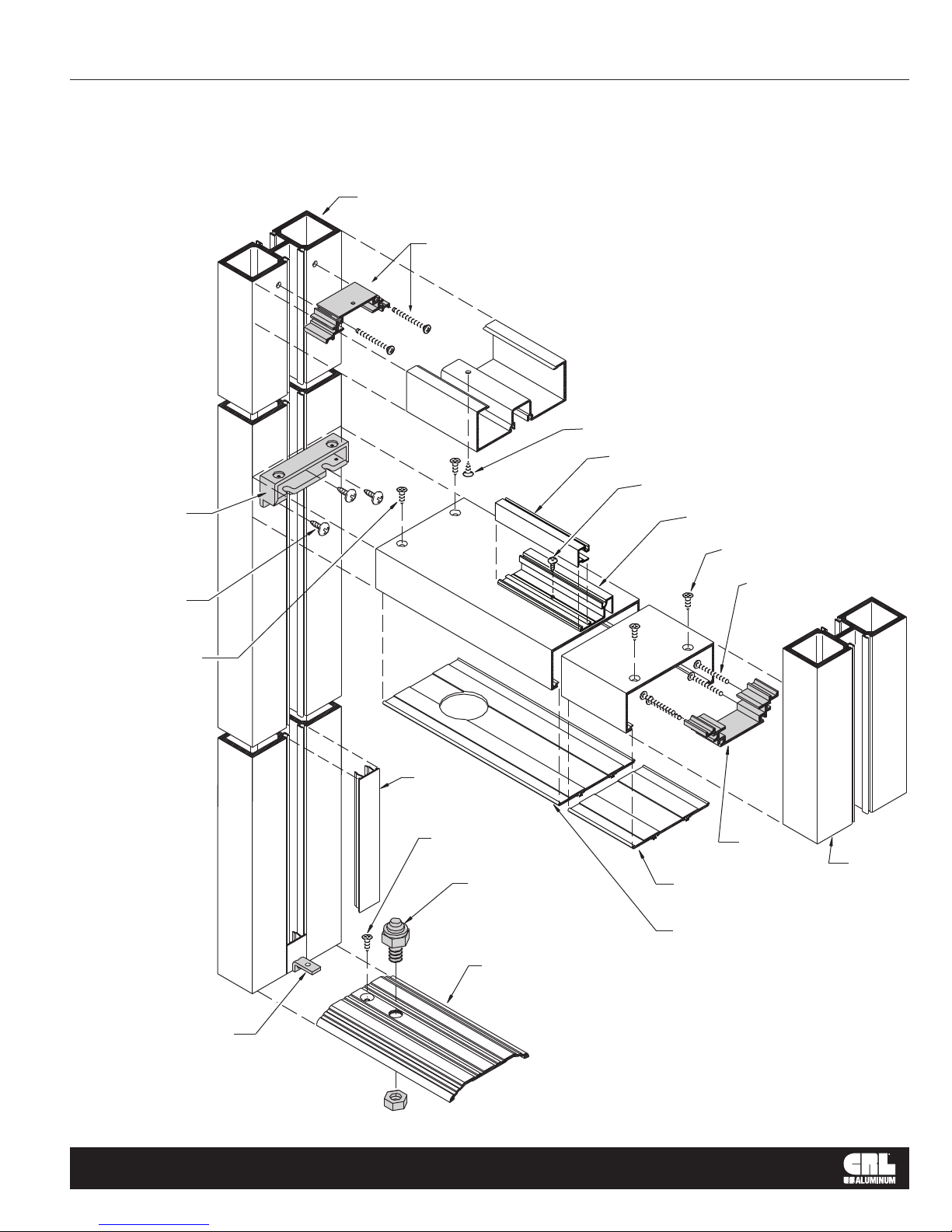

CRL JACKSON OVERHEAD CONCEALED DOOR CLOSER

FRAME UNIT FOR CENTER-HUNG DOOR

WITH OVERHEAD CONCEALED DOOR CLOSER

JH475

APK402

Anchor Clip

with (2) 10X2PHPSMS

(1) ST240

#10 x 1/2" FH

M123 Glazing Stop

#6 x 3/8" PH at app.

Header and closer

mounting brackets

(included in closer

package). Header

bracket shown. Closer

bracket not shown.

(3) #8-32 x 1/2" PH

(Included in closer

package)

18" (457.2) O.C.

122 Glazing Sash and Glass Stop

(Not shown at Jamb for clarity)

(2) ST240 #10 x 1/2" FH

(4) #10 x 2 PHPSMS

(included in closer package)

(2) #10 x 3/8" FH SMS

(Included in closer

package)

Threshold clip

attach to filler

with #6 x 3/8" PH

P050 Filler

runs continuous

from header to

finish floor

(1) ST240

#10 x 1/2" FH

Bottom Pivot

TH250

P427 Snap-In

Cover Plate

Snap-In

Cover Plate

APK402

Anchor Clip

JH475

crlaurence.com | usalum.com

NOT TO SCALE

07

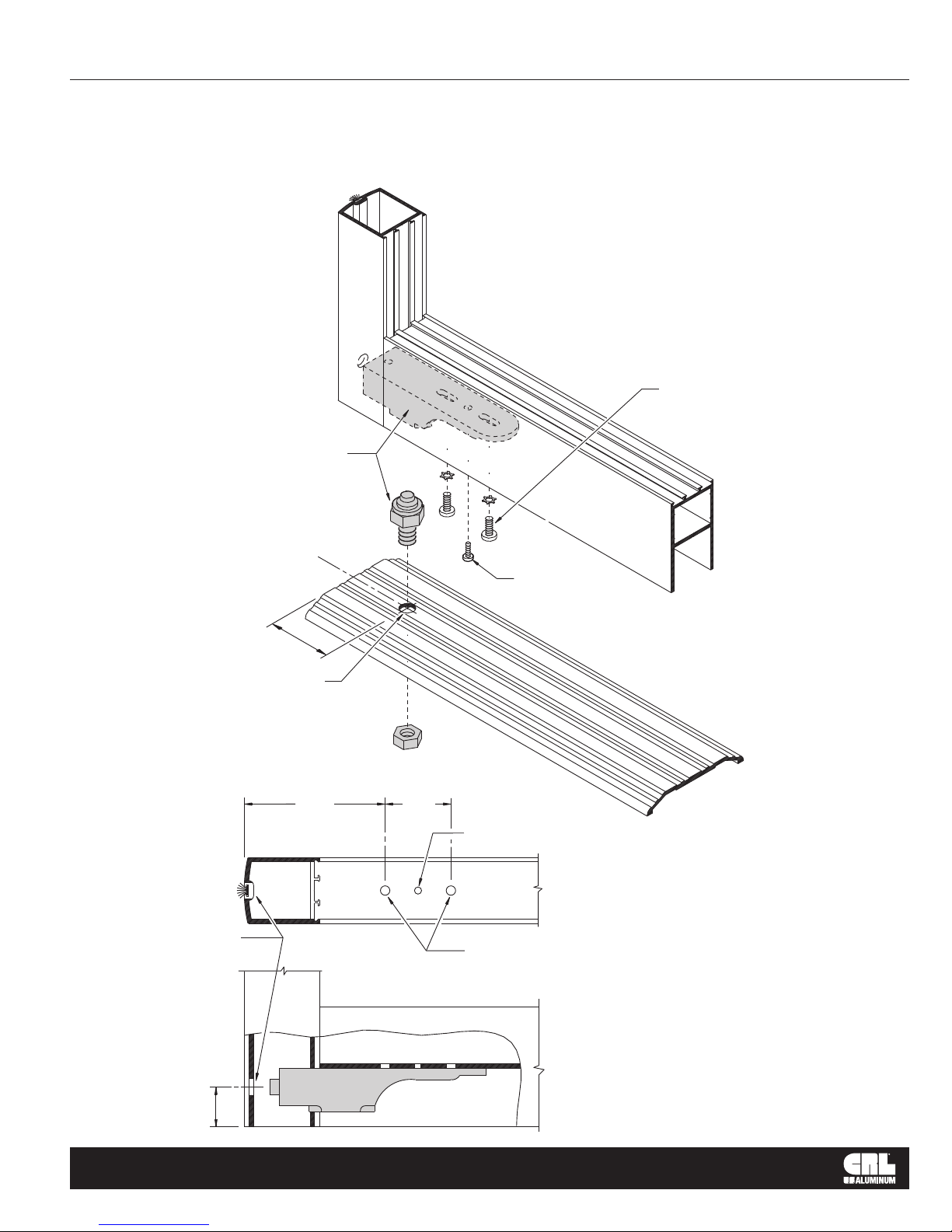

CRL JACKSON OVERHEAD CONCEALED DOOR CLOSER

CENTER-HUNG INSTALLATION

DOOR/THRESHOLD PREPARATION

Cat. No. 20944

Threshold Mount

Bottom Pivot Set

(2) 1/4"-20 PH SMS

(with lock washers)

1/2" (12.7) Dia. hole

7/16" (11.1)

Dia. hole for

adjusting screw

C

L

3-3/4"

(95.3)

1-3/4"

(44.5)

(1) #10-32 PHSMS

(Install after door pivot

has been adjusted)

(1) hole for #10-32 PH SMS

(Install after door pivot

has been adjusted)

BOTTOM DOOR VIEW

Drill and Tap

(2) holes for 1/4"-20 PH SMS

1-1/16"

(26.9)

crlaurence.com | usalum.com

FRONT DOOR VIEW

NOT TO SCALE

08

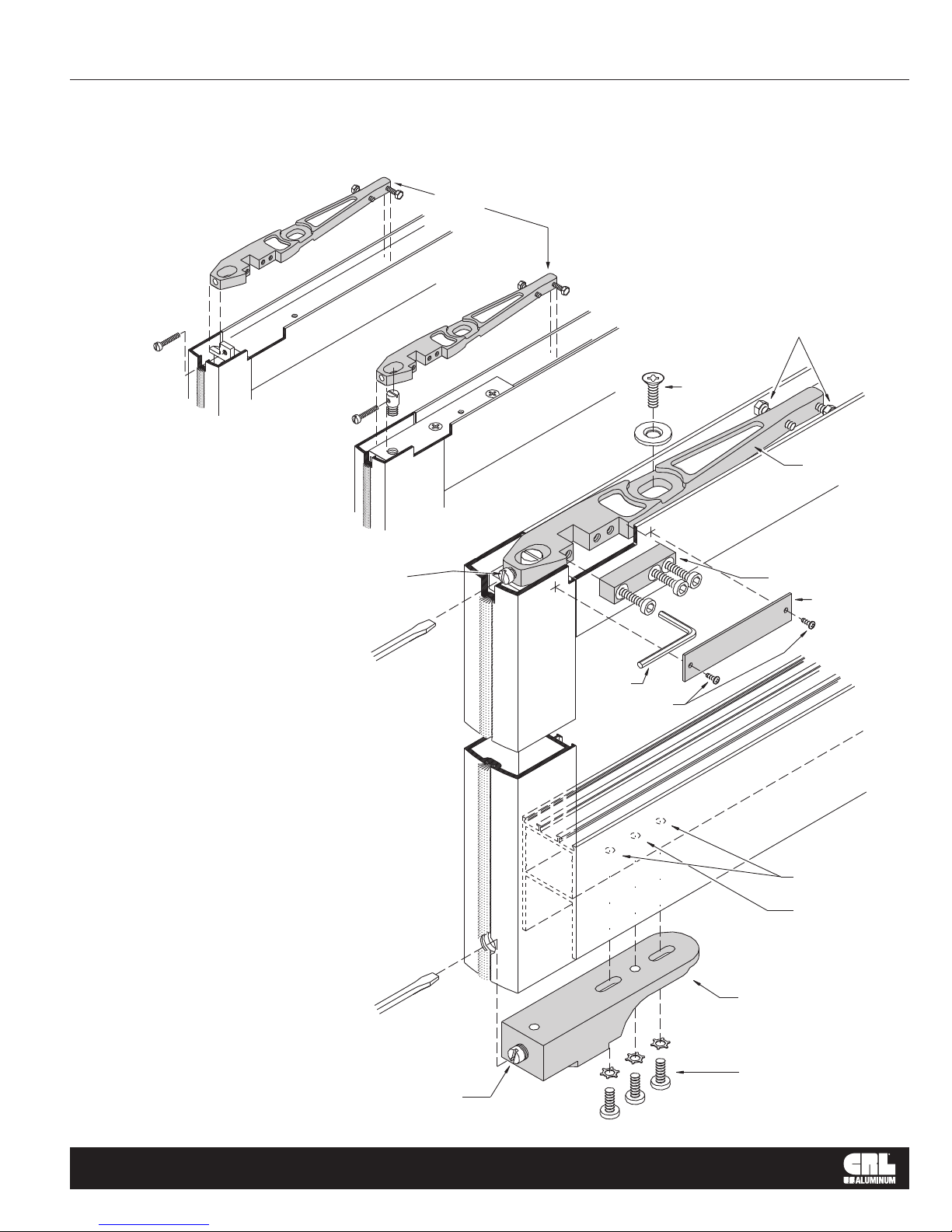

CRL JACKSON OVERHEAD CONCEALED DOOR CLOSER

JACKSON OVERHEAD CONCEALED DOOR CLOSER

SIDE LOAD CENTER PIVOT DOOR

Side Load

Top Arm

DETAIL A

Holding

Screw

NARROW STILE

Centering Screws

Side Load

Top Arm

MEDIUM AND WIDE STILE

Top Centering

Adjusting screw

(Horizontal Adjustment)

1. Install top arm and door portion of bottom pivot

as shown in DETAIL A.

2. Position door upright in closed position on the

outside of frame.

3. Lift onto oor pivot and tilt to vertical.

4. Adjust top arm as required to receive closer spindle.

5. Install top clamping block see DETAIL B.

6. Drill two holes in top of door to attach cover plate

see DETAIL C.

If vertical adjustment is required, loosen or

tighten Pivot Adjusting Screw at bottom pivot

(door portion).

7. Adjust top arm centering screws to center door

in frame.

DETAIL B

Clamping Block

Cover Plate

DETAIL C

Tool

Mounting

screws

Holes by

U.S. Aluminum

Pinning hole

by installer

Door portion of

bottom pivot

crlaurence.com | usalum.com

Pivot Adjusting Screw

(vertical adjustment)

(3) 1/4"-20 RH MS

(with lock washers)

NOT TO SCALE

09

Loading...

Loading...