Cloyes Hex-A-Just 9-3152A User Manual

Installation Instructions

9-3152A Hex-A-Just® Roller Timing Set

BEFORE YOU BEGIN: READ ALL OF THESE INSTRUCTIONS FIRST !!!

Note: The 9-3152A Hex-A-Just® timing set is not a direct bolt-on application. Machining is

required on the nose of the camshaft prior to installation. The following information explains

the modifications that must be made to the camshaft prior to assembly.

Camshaft Modification. The Viper production engine cam sprocket (OEM P/N 5245124) is

a single bolt installation design with a dowel pin for alignment. In order to apply the Cloyes

Hex-A-Just® system to the Viper engine, a 3-bolt pattern was incorporated into the design of

the high performance cam sprocket (S170DA). The camshaft modification requires three bolt

holes to be drilled and tapped into the nose of the camshaft. Below is a diagram illustrating

the dimensions and angular locations of the bolt holes.

CENTERLINE OF DOWEL PIN

DOWEL PIN

CAMSH AFT

60°15'

59°45'

120°15'

119°45'

FRONT VIEW OF

CAMS HAFT NOSE

60°15'

59°45'

BOLT CIRCLE

120°15'

119°45'

5/16-18 UNC BOL T HOLES

TYPICAL 3 PLACES

(MUST BE WITHIN .0050"

OF TRU E POSITION)

ORIGINAL BOLT HOLE

(NOT USE D)

Ø1.0310

As seen from the diagram, the position of the bolt holes is dependent upon the outer

diameter of the camshaft and the center of the dowel pin. They are centered around a

1.0310” bolt circle diameter and are equally spaced 120° apart. The angular location of the

bolt holes to the dowel pin is very important. Each bolt hole must be within .0050” of true

position, and they should be threaded at least .750” deep.

© Copyright 2007, Cloyes Gear Company. All rights reserved. 9-3152A 1

Note: The installation procedures which follow assume that the camshaft has been modified

appropriately and that the engine has been disassembled and cleaned as it would be for a

normal timing set change.

YOU WILL NEED:

TOOLS:

1/4" Hex Bit Socket or Hex Wrench

Torque Wrench

Hammer

Sleeve to fit over crankshaft for installing Crankshaft Sprocket

Degree Wheel (Optional, but Recommended)

SUPPLIES:

Assembly Lube or Camshaft Lube

Thread Locking Compound (LockTite7 #271 or equiv.)

1. Prepare the Engine. Loosen all rocker arms so that the camshaft can rotate freely.

2. Clean everything! Make sure that the engine mounting surfaces and timing set

components are as clean as possible. The life of the chain and sprockets depends on it.

3. Mount the Crankshaft Sprocket. Select the appropriate keyway for the camshaft timing

baseline desired. We recommend the Standard Timing position, which used the round

timing mark and round keyway mark. Carefully tap the sprocket onto the crankshaft using

a sleeve to protect the sprocket. Make sure that the sprocket is fully seated on the

crankshaft. Rotate the crankshaft until the appropriate crankshaft sprocket timing mark is

in the 12:00 position.

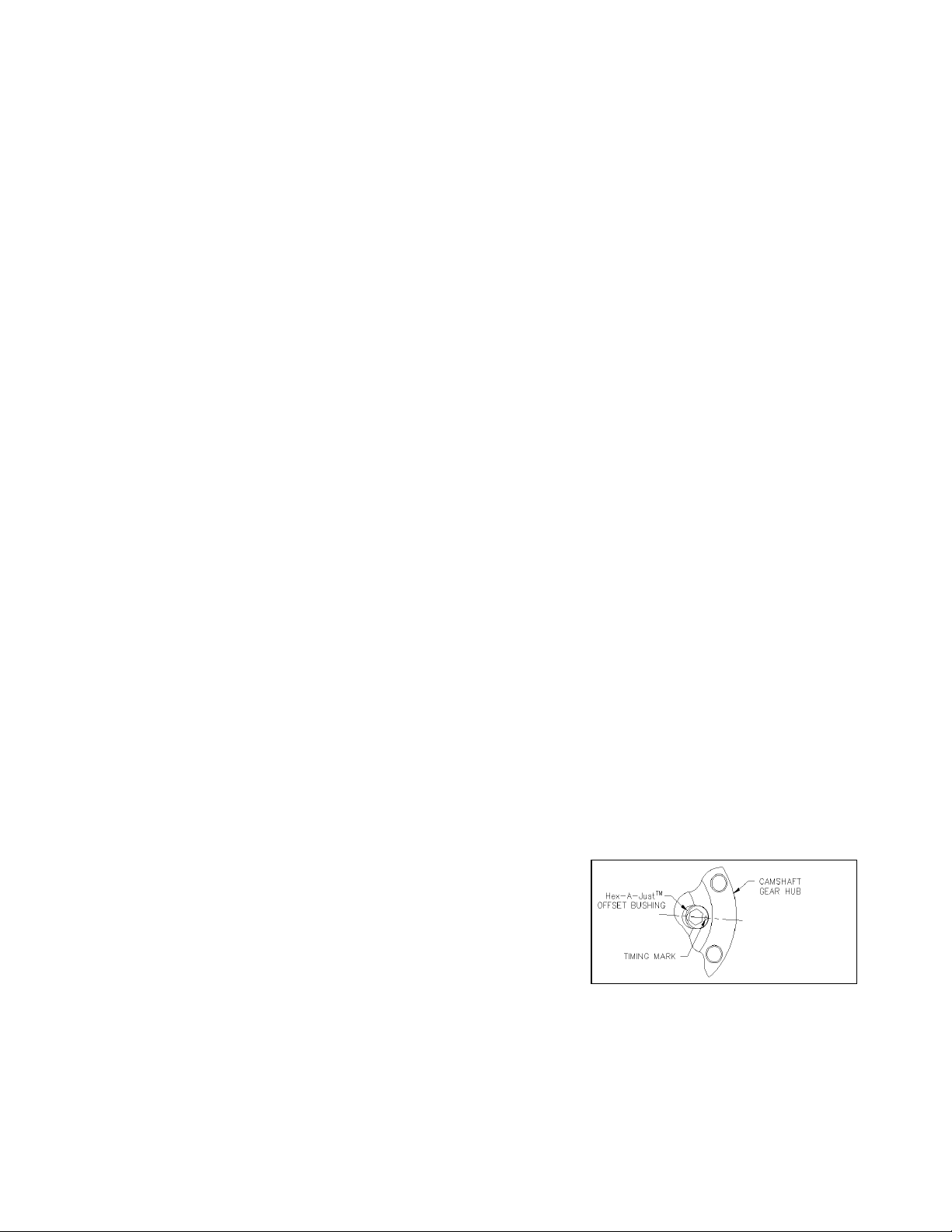

4. Insert the Hex-A-Just® Timing Bushing. Insert the offset bushing (with the Hex hole)

into the slot in the camshaft sprocket hub. Rotate it with a 1/4" Hex Wrench so that the

timing mark on the bushing points away from the center of the hub (Figure 1). The Hex-A-

Just® Adjustable Timing Bushing is infinitely

adjustable so you can fine adjust your engine's

CAMSHAFT TIMING to EXACTLY WHERE YOU

WANT IT.

5. Mount the Camshaft Sprocket. Loop the chain

over the camshaft sprocket. Align the camshaft and

crankshaft timing marks and loop the chain around

the crankshaft sprocket. Lift the camshaft sprocket

Inserting Offset Bushing

(Figure 1)

into place on the camshaft, with the Hex-A-Just®

Bushing in place. Be sure that the timing mark aligns

© Copyright 2007, Cloyes Gear Company. All rights reserved. 9-3152A 2

Loading...

Loading...