Page 1

CXV225NA & CXV425NA

AMPLIFIERS

0

1

0

1

1

CXV425

4 CHANNEL 70V LINE AMPLIFIER

PROTECT

PEAK

SIGNAL

3

POWER

2

4

CXV225

500W STEREO 70V LINE AMPLIFIER

PROTECT

PEAK

SIGNAL

POWER

2

1

Installation and User Guide

Page 2

Page 3

Contents

Safety Information ........................................ 4

Safety Notes Regarding Installation ....................... 4

Conformities ............................................................... 4

Safety Considerations and Information ................4

General Description ...................................... 5

Applicable Models ......................................................5

Schematic Diagram ...................................... 5

Front Panel Description ............................... 6

Rear Panel Description ................................. 7

Installation ..................................................... 8

Mechanical ................................................................... 8

Ventilation .................................................................... 8

Connections and Adjustments ................................ 8

Inputs ............................................................................ 8

Sensitivity and Gain Control ................................ 8

Input Routing ........................................................... 8

Remote Control of Level ...................................... 9

Outputs ........................................................................ 9

Protection...............................................................10

High Pass Filters ....................................................10

VCA Cards (optional) ............................................. 10

Installation .............................................................10

Loudspeaker Equalisation Modules (optional) ..11

Installation ..............................................................11

General Notes ............................................. 11

EMC Considerations ...............................................11

Earthing ......................................................................11

Technical Specications .............................. 12

General Specications ................................ 12

Location of Internal Jumpers and

Connectors. .................................................. 13

CXV225NA connector and jumper details .......13

CXV425NA connector and jumper details .......14

CXV225NA & CXV425NA User Manual v1.0 3

Page 4

Safety Information

Safety Notes Regarding Installation

• Do not expose the unit to water or moisture.

• Do not expose the unit to naked ames.

• Do not block or restrict any air vent.

• Do not operate the unit in ambient temperatures above

35°C.

• Do not touch any part or terminal carrying the

hazardous live symbol ( ) while power is supplied to

the unit.

• Do not perform any internal adjustments unless you

are qualied to do so and fully understand the hazards

associated with mains-operated equipment.

• The unit has no user-serviceable parts. Refer servicing

to qualied service personnel.

Safety Considerations and Information

The unit must be earthed. Ensure that the mains power

supply provides an effective earth connection using a threewire termination.

When the mains switch is in the off ‘O’ position the live

and neutral conductors of the mains transformer are

disconnected.

Caution - High Voltages

Do not touch any part or terminal carrying the hazardous

live symbol ( ) while power is supplied to the unit.

Terminals to which the hazardous live symbol refers require

installation by a qualied person.

Caution - Mains Fuse

Replace the mains fuse only with the same type and rating as

marked on the rear panel.

The fuse body size is 20 mm x 5 mm.

• If the moulded plug is cut off the AC power lead for

any reason, the discarded plug is a potential hazard and

should be disposed of in a responsible manner.

Conformities

This product conforms to the following European EMC

Standards:

BS EN 55103-1:1997

BS EN 55103-2:1997

This product has been tested for use in commercial and

light industrial environments. If the unit is used in controlled

EMC environments, the urban outdoors, heavy industrial

environments or close to railways, transmitters, overhead

power lines, etc., the performance of the unit may be

degraded.

The product conforms to the following European electrical

safety standard:

BS EN 60065:2002

Caution - Servicing

The unit contains no user-serviceable parts. Refer servicing

to qualied service personnel. Do not perform servicing

unless you are qualied to do so.

Disconnect the power cable from the unit before removing

the top panel and do not make any internal adjustments with

the unit switched on.

Only reassemble the unit using bolts/screws identical to the

original parts.

The CXV Series was developed and manufactured with high

quality materials and components, which can be recycled

and/or reused.

CXV225NA & CXV425NA User Manual v1.04

Page 5

General Description

The Cloud CXV225NA and CXV425NA are high power

(250 W/ch), multi-channel audio ampliers intended for use

with high quality PA and background music systems in ofces,

hotels, factories, leisure facilities and other commercial and

industrial premises.

They are designed to drive 70 V-line speaker systems directly,

and have no low-impedance outputs. Low impedance

loudspeakers can only be connected to these ampliers

with the use of an intermediate 70 V-line transformer.

Loudspeakers designed for such ‘installed-sound’ applications

will normally include an integral transformer, typically with

selectable output power taps. If you have any doubt about

the suitability of this amplier for the speaker system it is to

be connected to, please verify that the speakers are of the

70 V-line type with the manufacturer.

Unlike traditional 70 V-line amplier designs, the CXV225NA

and CXV425NA do not employ an output transformer. This

produces a considerable saving in weight and a signicant

improvement in audio quality.

Applicable Models

This manual describes the installation and operation of the

following models:

• Cloud CXV225NA 2-channel amplier –

2 x 250 W, 2U 19” rack unit

• Cloud CXV425NA 4-channel amplier –

4 x 250 W, 3U 19” rack unit

Apart from the number of channels and the units’ physical

dimensions and power consumption gures, the two

models are otherwise identical for the practical purposes of

installation and operation.

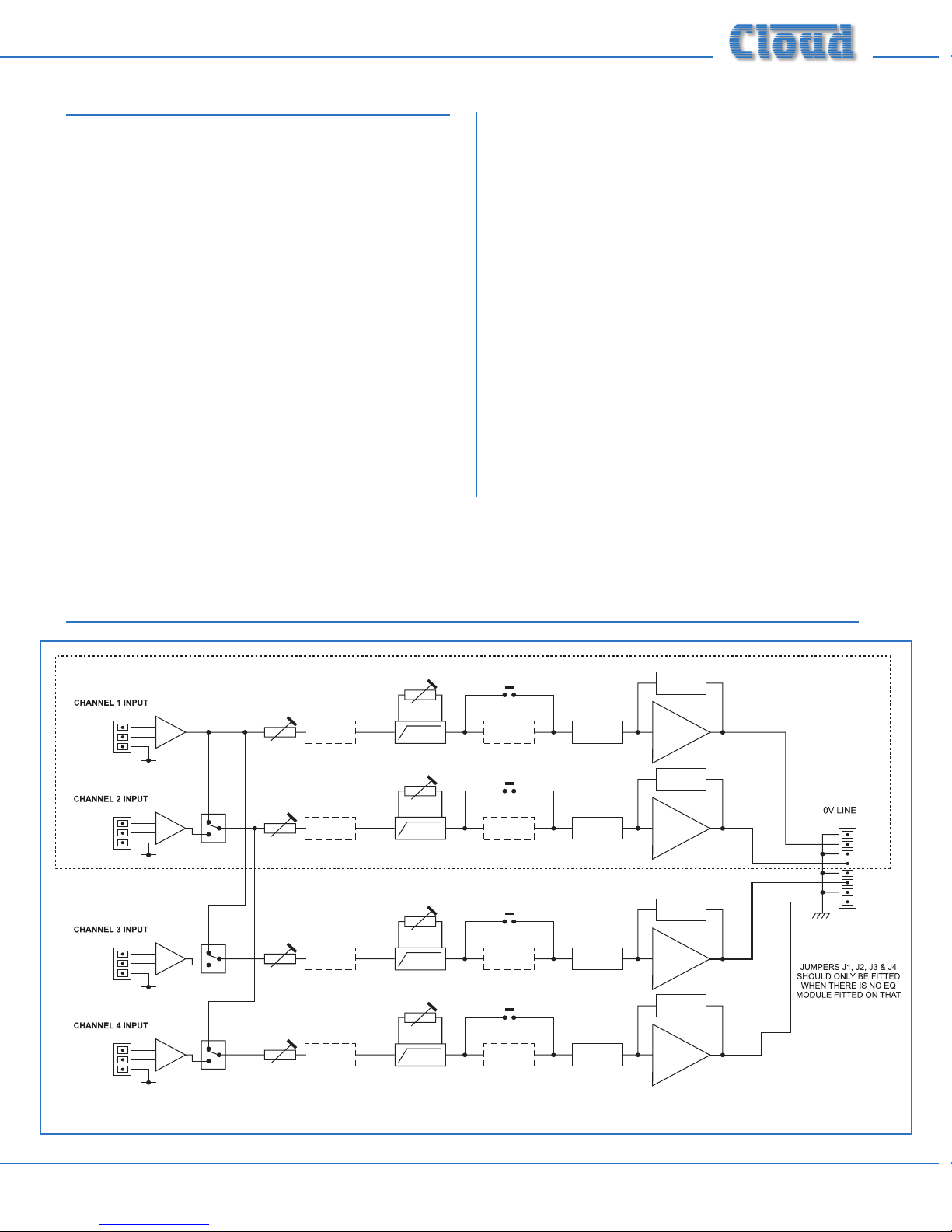

Schematic Diagram

CXV225NA

+

3

2

-

1

+

3

2

-

1

+

3

2

-

1

+

3

2

-

1

CXV425NA

fig.1: CXV Series schematic diagram

LEVEL

LEVEL

LEVEL

LEVEL

VCA

VCA

VCA

VCA

FREQ

FREQ

FREQ

FREQ

J1

SPEAKER

EQ

J2

SPEAKER

EQ

J3

SPEAKER

EQ

J4

SPEAKER

EQ

CLIP

LIMITER

CLIP

LIMITER

CLIP

LIMITER

CLIP

LIMITER

PROTECT

POWER

AMPLIFIER

PROTECT

POWER

AMPLIFIER

PROTECT

POWER

AMPLIFIER

PROTECT

POWER

AMPLIFIER

7

OUTPUTS

CHANNEL.

1

2

3

4

5

6

7

8

CXV225NA & CXV425NA User Manual v1.0 5

Page 6

4

3

6

fig.2: CXV425NA Front panel

4

0

1

0

1

1

2

CXV425

4 CHANNEL 70V LINE AMPLIFIER

PROTECT

PEAK

SIGNAL

3

POWER

2

6

4

1

5

CXV225

500W STEREO 70V LINE AMPLIFIER

3

PROTECT

PEAK

SIGNAL

POWER

2

1

fig.3: CXV225NA Front panel

Front Panel Description

1

SIGNAL LEDs (one per channel) – illuminate

when the output voltage exceeds approx. 12.5 V

(18 dB below maximum output)

2

PEAK LEDs (one per channel) – illuminate if

maximum output voltage is reached (70 V

3

PROTECT LEDs (one per channel) – indicate

fault conditions

rms

1

5

rms

4

AC POWER SWITCH

5

POWER LED

6

AIR INTAKE GRILLES

2

)

CXV225NA & CXV425NA User Manual v1.06

Page 7

5

OUTPUTS.

1

11 11

fig.4: CXV425NA Rear panel showing output terminal cover

2

3

4

6

9

10

8

5

1

2

fig.5: CXV225NA Rear panel showing output terminals

4

3

Rear Panel Description

1

INPUT CONNECTORS (one per channel)

2

INPUT LEVEL CONTROLS (one per channel)

3

HIGH PASS FILTER CONTROLS

(one per channel)

4

INPUT ROUTING SWITCHES –

1 for CXV225NA, 3 for CXV425NA

9

120VAC±5%

ONLY.

7

8

AC MAINS CONNECTOR

EARTH SAFETY TAG

9

MAINS FUSE

10

COOLING FANS AND AIR EXHAUST –

11

10

8

CXV425NA only

5

REMOTE VOLUME CONTROL CONNECTORS

– when remote control option is tted (one per

channel)

6

OUTPUT TERMINAL COVER

7

OUTPUT TERMINALS – accessible when Output

Terminal Cover (6) is removed

CXV225NA & CXV425NA User Manual v1.0 7

Page 8

Installation

Mechanical

The ampliers are designed to be mounted in a standard 19”

equipment rack. The front panels are tted with rackmount

ears for this purpose. The CXV225NA requires 2U of

vertical rack space, the CXV425NA requires 3U. See notes

below regarding spacing and ventilation.

Due to the units’ weight, the use of additional side supports

is recommended.

Ventilation

The CXV425NA is force cooled by two thermostaticallycontrolled fans mounted on the rear panel. The fan is

operative at all times, remaining at low speed at internal

temperatures below 50°C, then increasing in speed above

this temperature to a maximum speed at 70°C.

The CXV225NA has a single fan mounted internally to keep

noise to a minimum.

Always allow adequate space around the amplier(s) to

allow a free ow of air through the unit(s). Ensure that cable

bundles or other items do not obstruct any grilles.

In 19” rack applications we recommend leaving 1U of rack

space above and below each unit. Plain 1U blank panels,

not slotted ventilation panels should be used, as the latter

reduce the effect of forced-air cooling. The direction of

airow is from front-to-rear (CXV425NA) and front-to-

sides (CXV225NA); it is recommended not to mix these

ampliers with other equipment employing forced-air

cooling which acts in the opposite direction within the same

rack.

Connections and Adjustments

123

-

Amplifier input

pin 1: n/c

pin 2: cold

pin 3: hot

123

-

Amplifier input

pin 1: n/c

pin 2: cold

pin 3: hot

+

+

3

2

1

Balanced output

(typically XLR):

pin 1: ground

pin 2: hot

pin 3: cold

Unbalanced outputs

(e.g. phonos):

screen: ground

pin: hot

g.6: Input wiring

-

+

BALANCED CONNECTION

UNBALANCED CONNECTION

Sensitivity and Gain Control

Control of input level is provided by a preset rotary

control adjacent to each input connector. The control

should be adjusted using a trim tool or small screwdriver.

Full attenuation of the input signal – i.e., zero output – is

obtained with the control fully anti-clockwise. Maximum

sensitivity is with the control fully clockwise; at this setting

the maximum output level of 70 V

input signal level of 0.775 V

rms

will be produced for an

rms

(0 dBu).

We recommend that the level for each channel should

be adjusted after installation is complete to ensure that

adequate, but not excessive sound levels are achieved with

the programme material that will be used in practice.

Input Routing

To facilitate the use of the ampliers in multi-zone

applications, input selection switches are provided on all

channels except Ch1. This gives the installer an easy method

of paralleling channels from a single input.

Inputs

Each amplier channel has an electronically-balanced input

on a 3-pin 3.5 mm-pitch screw terminal connector. Twincore screened cable should be used when driving the

amplier inputs from a device with a balanced output. Single-

core screened cable can be used when connecting to an

unbalanced source.

CXV225NA & CXV425NA User Manual v1.08

The options are summarised in the table below:

CHANNEL

SOURCE

CXV225NA CXV425NA

Button position Out In Out In

Channel 2 Input 1 Input 2 Input 1 Input 2

Channel 3 Input 1 Input 3

Channel 4 Input 2* Input 4

* post Ch 2 switch

Refer also to the block diagram on page 5.

CXV225NA only: The CXV225NA’s single switch allows

Channel 2 to be operated in parallel with Channel 1, with

Input 1 acting as the common input connector.

Page 9

CXV425NA only: The three switches on the CXV425NA

allow a total of 8 routing possibilities, including 4-channel,

dual stereo and mono operation with 4 channels paralleled.

The table below claries the options:

BUTTON

POSITION

Ch 2 Ch 3 Ch 4 Input 1 Input 2 Input 3 Input 4

In In In

Out In In

In Out In

Out Out In

In In Out

Out In Out

In Out Out

Out Out Out

INPUT ROUTING: CHANNELS

FED BY EACH INPUT

Ch 1 Ch 2 Ch 3 Ch 4

Chs 1 & 2 Ch 3 Ch 4

Chs 1 & 3 Ch 2 Ch 4

Chs 1, 2 & 3 Ch 4

Ch 1 Chs 2 & 4 Ch 3

Chs 1, 2 & 4 Ch 3

Chs 1 & 3 Chs 2 & 4

Chs 1, 2, 3

& 4

Remote Control of Level

The CXV225NA and CXV425NA ampliers are compatible

with standard Cloud remote control plates type RL-1 Series,

allowing control of level from a remote position. In order

to use the ampliers with the RL-1, VCA cards must rst be

tted in the channels to be controlled remotely. See page 10

for details of VCA cards and tting. Once VCA cards have

been tted, RL-1s may be connected at the rear 3-pin 5 mm-

pitch screw terminal connectors (Remote Level), using the

wiring shown below.

RL-1

123

REMOTE LEVEL

CONNECTOR

123

Outputs

The 70 V-line speaker output terminals are behind the

removable output terminal cover (see page 7). The covers

are tted with a cable gland (one per channel); to use these,

slacken the rear nut by a few turns and feed the cable

through. The plug-in connectors are suitable for cable cores

up to 2.5 mm2.

Connect as shown below:

CXV425NA

1234

-+ -+ -+ -+

-+

CH 1CH 2

CXV225NA

1234

-+ -+

CH 1CH 2

g.8: Output wiring

After making the connections, replace the cover and tighten

the gland nuts. They only need to be rmly nger-tight; take

care not to over tighten, use only enough torque to give

reasonable cable retention. Do not use a wrench.

6785

CH 3 CH 4

USE TWO-CORE SCREENED CABLE

g.7: Remote level control wiring

Use two-core screened cable to connect the remote level

plate (maximum length 100 metres).

Caution: The amplier should never be operated without

the output terminal cover installed. Apart from exposing

the high voltage terminals, leaving the cover off also

compromises the amplier’s forced-air cooling.

The amplier’s transformerless output stage is designed

to drive up to 70 V

into an impedance of at least

rms

20 ohms (each channel). Check the input impedance of the

loudspeaker type in use and divide this gure by the number

of loudspeakers* to ensure that the total impedance is

greater than 20 ohms. Alternatively, add the wattages of all

the loudspeakers being driven by each channel (taking power

tappings into account); the total must be less than 250 W.

* Assumes all loudspeakers in the system are of the same type and have the

same tap setting.

CXV225NA & CXV425NA User Manual v1.0 9

Page 10

Protection

The ampliers include comprehensive protection circuitry

to prevent damage to loudspeakers, the output devices and

other components in the event of a fault condition.

speaker processor) or when the speaker manufacturer

explicitly states that they will operate correctly at such low

frequencies.

For speech-only

Thermal Protection

The output device heatsink temperatures are monitored and

the protection circuitry activated if any should exceed 90°C.

The red front panel PROTECT LED for the appropriate

channel illuminates to indicate the fault condition.

DC Protection

Crowbar protection is provided to safeguard the

loudspeakers in the event of DC being present at the output

terminals. This is an emergency protection feature that

will only operate in the event of the amplier developing a

fault. Its action is liable to blow internal DC rail fuses. The

amplier must be serviced before any attempt is made to

use it further.

Short-circuit protection

VI limiting is implemented in the ampliers to protect the

output stages from excessive dissipation caused by abnormal

loads; for example, a short-circuit.

Switch-on protection

Settings somewhere between 100 Hz (12 o’clock) and

200 Hz are appropriate. Start with the lter set to 100 Hz

and turn the control clockwise whilst listening to speech

through the system until you can hear a loss of bass in the

voice. Few voices contain any useful signal below 200 Hz,

so in many cases the lter can be set to 200 Hz without

any real loss of quality. Often a setting this high will actually

enhance the clarity of the speech, reduce microphone

handling noise and reduce breath blasts.

For music systems

The optimum lter setting will depend on the speakers

and their transformers. It should be recognised that many

70 V-line speakers have inferior LF performance compared to

low impedance speakers. If the manufacturer recommends

a minimum frequency of operation, set the lter to this.

Otherwise, settings between 70 Hz and 100 Hz should be

appropriate.

Test the system at full volume with a variety of music

containing high level, low bass notes and listen for any

distortion. If the transformers saturate, distortion will be

clearly audible. In this case, turn the control clockwise until

it disappears.

The protection circuitry is also activated immediately after

the amplier is switched on. This is to prevent any voltage

spikes due to start-up conditions from damaging the

loudspeakers. The protection circuitry automatically times

out after approx. 5 seconds. All PROTECT LEDs illuminate at

switch-on for the duration of the time-out period.

High Pass Filters

Most transformers tted to 70 V-line speakers exhibit

core saturation when fed with high-level signals at low

frequencies. Transformer saturation creates unpleasant

distortion and stresses the system. To counteract this, a

correctly congured high pass lter is an essential part of

any 70 V-line system. The CXV225NA and CXV425NA have

variable frequency high pass lters in each channel, accessible

at the rear panel (see page 7). These should be adjusted to

reject low frequencies, to suit both the speakers and the

application. When adjusting, bear in mind that the higher

the frequency setting, the less likely it is that the system will

suffer from saturation problems.

The minimum (20 Hz) setting should only be used when

the system has some other form of lter or protection

from high-level low frequency signals (e.g., a dedicated

VCA Cards (optional)

Cloud VCA-5 modules must be tted to the CXV225NA

and CXV425NA ampliers if remote control of audio level

is required. One VCA-5 module is required for each channel,

and as many as necessary may be tted. The VCA modules

use the industry-standard That’s 2181 VCA device, which

provides very low distortion and up to 90 dB attenuation at

cut-off.

The VCA module can also be used to provide muting by

using an auxiliary relay connected to a re alarm control

panel. Please contact our technical department for further

details.

Installation

• With the power turned off and the mains cable

removed, remove the top panel.

• Refer to the pcb layout diagrams on page 13. Locate the

VCA connector for the rst channel being tted, and

remove the jumper joining one pair of pins.

• Unscrew the blanking plate from the rear panel.

CXV225NA & CXV425NA User Manual v1.010

Page 11

• Remove and retain the M3 xing screw adjacent to the

connector, and t the 35mm M3 hex spacer supplied

with the VCA-5 in its place.

• Push the 10-way VCA plug onto the PCB connector,

aligned so the cable enters it from the rear of the

chassis. Check there is contact with all 10 pins.

• Locate the VCA module’s 3-pin socket in the rear panel

cut-out and secure using the M3 screw provided.

• Replace the top panel.

Once the VCA-5 modules have been installed, RL-1 remote

level control plate(s) may be connected to the REMOTE

LEVEL connector(s) on the rear panel.

General Notes

EMC Considerations

CXV Series ampliers have been designed with a range

of electromagnetic compatibility (EMC) measures and so

are technically well behaved. You should experience no

problems interfacing units to other items of equipment and

under normal circumstances, no special precautions need

to be taken. If the unit is to be used in close proximity to

potential sources of HF disturbance such as high power

communication transmitters, radar stations and the like, it is

suggested that input signal leads be kept as short as possible.

Always use balanced interconnections wherever possible.

Loudspeaker Equalisation Modules

(optional)

The CXV225NA and CXV425NA may be optimised for

use with certain popular installation speakers from various

manuafcturers; a single-channel equalisation module may be

tted to as many channels as necessary. Equalisation modules

for the following loudspeakers are available:

Bose®

• Panaray® MA12

• Panaray® 402-II, 502B and 502BEX

• Panaray® LT Series: Models 3302, 4402, 9402 and 9702

• Freespace® DS 16 range

• Freespace® Model 16

• Freespace® Model 32 range

Amina

• AIWX Series

• LFiT Series

Other modules are available; please enquire.

Installation

• With the power turned off and the mains cable

removed, remove the top panel.

• Refer to the pcb layout diagrams on page 13. The

modules plug into the white 12-pin connectors on the

PCB. Note the header connectors on the PCB have two

notches on one side only; these engage with lugs on

the equalisation module’s mating connector to ensure

correct orientation.

Earthing

When several mains powered units are connected together

via their signal cables, there is a risk of one or more earth

loops which may cause an audible hum on the system even

with the gain controls set to minimum.

The 0 V rail of a CXV Series amplier is directly coupled to

the chassis ground. No interconnection problems should be

encountered, but if there is any hum or other extraneous

noise when source equipment is connected, the situation can

generally be remedied by observing the following guidelines:

• Always connect sources using balanced connections

wherever possible, with the cable screen only connected

at the receiving end (amplier input).

• Use audio isolating transformers (readily available from

trade suppliers) at the inputs if necessary. These will

ensure that the amplier is electrically isolated from the

source equipment.

• The signal source units should be located as close as

possible to the ampliers and the metal housing of

the various units should not be electrically connected

together through the equipment rack. If this is a

problem, rack isolating kits are available from specialist

hardware suppliers. If the problem persists, try to

connect all interconnected units, including power

ampliers, to a common power source to ensure a

common ground is provided.

• After tting equalisation modules to any channel(s),

the corresponding module bypass jumper(s) must be

removed in order for the module to function. Refer to

the pcb layout diagrams for jumper locations.

• Replace the top cover with the original screws after

tting.

CXV225NA & CXV425NA User Manual v1.0 11

Page 12

Technical Specications

CXV225NA & CXV425NA

Outputs 70 V

; 250 W into 20 ohm min. load (per channel)

rms

Frequency Response 20 kHz -0.6 dB; LF response dependent on lter setting

High Pass Filter -3 dB @ 20 Hz – 200 Hz variable

Distortion <0.04% @ 1 kHz & 1 dB below limiting, 20 ohm load

Crosstalk -80 dB @ 10 kHz

Sensitivity 0.775 V

(0 dBu)

rms

Input Impedance 10 kohm balanced, 5 kohm unbalanced

Noise (rms) -96 dB, 22Hz - 22kHz, relative to 70 V

rms

Power Input 120 V ±5%

Fuse Rating 120 V, 8 A (CXV225NA)/10 A (CXV425NA)

Fuse Type T8A (CXV225NA)/ T10A (CXV425NA), 20 mm x 5 mm 120 V

General Specications

CXV225NA CXV425NA

Inputs Electronically balanced; 3-pin 2.5 mm-pitch plug-in screw terminal connectors

Outputs 2-pin 5 mm-pitch plug-in screw terminal connectors

Protection Clip Limiting, VI Limiting, DC Offset, Thermal & switch-on delay

Status Indicators LED indicators on each channel for Signal, Peak & Protect

Cooling Force cooled; internal variable speed

DC fan

Dimensions

(W x H x D)

482.6 x 88 (2U) x 300

19” x 3.46 (2U) x 11.81”

Weight 8.8 kg / 19.4 lbs net 21 kg / 47 lbs net

Force cooled; two rear-mounted

variable speed DC fans

482.6 x 132.5 (3U) x 332

19” x 5.22” (3U) x 13.07”

CXV225NA & CXV425NA User Manual v1.012

Page 13

Location of Internal Jumpers and Connectors.

CXV225NA connector and jumper details

CXV225NA: MAIN PCB LAYOUT.

TOP VIEW. ONLY PRIMARY

COMPONENTS SHOWN.

REAR OF AMPLIFIER

FAN ASSY.

OUTPUT

TERMINALS

CON3 CON1

EQ CARD

BYPASS JUMPERS

CON10

EQ CARD

SOCKETS

VCA CARD

SOCKETS

CON9

J1J2

g.9: Internal jumpers - CXV225NA

MODEL PCB REF Function Default Setting

CXV225NA

NOT TO SCALE

CON1 CH1 VC A CARD SET

CON3 CH2 VC A CARD SET

CON9 CH1 EQ CARD

CON10 CH2 EQ CARD

J1 CH 1 EQ CARD BYPASS SET

J2 CH 2 EQ CARD BYASS SET

CXV225NA & CXV425NA User Manual v1.0 13

Page 14

CXV425NA connector and jumper details

CXV425NA: MAIN PCB LAYOUT.

TOP VIEW. ONLY PRIMARY

COMPONENTS SHOWN.

OUTPUT

TERMINALS

REAR OF AMPLIFIER

(INPUTS 3 & 4 SUB BOARD)(OUTPUT SUB BOARD)

CON25CON12CON13CON24

J2

J4

EQ CARD

BYPASS JUMPERS

CON15

CON17

CON5

J1

J3

EQ CARD

SOCKETS

CON6

VCA CARD

SOCKETS

NOT TO SCALE

g.10: Internal jumpers - CXV425NA

MODEL PCB REF Function Default Setting

CON12 CH1 VCA C ARD SET

CON13 CH2 VCA C ARD SET

CON24 CH3 VCA C ARD SET

CON25 CH4 VCA C ARD SET

CXV425NA

CON5

CON6

CON15

CON17

J1

J2

J3

J4

CH1 EQ CARD

CH2 EQ CARD

CH3 EQ CARD

CH4 EQ CARD

CH 1 EQ CARD BYPASS SET

CH 2 EQ CARD BYPASS SET

CH 3 EQ CARD BYPASS SET

CH 4 EQ CARD BYPASS SET

CXV225NA & CXV425NA User Manual v1.014

Page 15

Bose® is a registered trademark of The Bose Corporation.

In the interest of continuing improvements Cloud Electronics Limited reserves

the right to alter specications without prior notice.

CXV225NA & CXV425NA User Manual v1.0 15

Page 16

Cloud Electronics Limited

140 Staniforth Road

Shefeld S9 3HF

England

Tel: +44 (0)114 244 7051

Fax: +44 (0)114 242 5462

E-mail: info@cloud.co.uk

Web: www.cloud.co.uk

Cloud Electronics USA

2065 Sidewinder Drive, Suite 200

Park City

Utah 84060

United States of America

Toll Free: 0855 810 0161

E-mail: sales@cloudusa.pro

Web: www.cloudusa.pro

Loading...

Loading...