Page 1

Installation and Use Manual

®

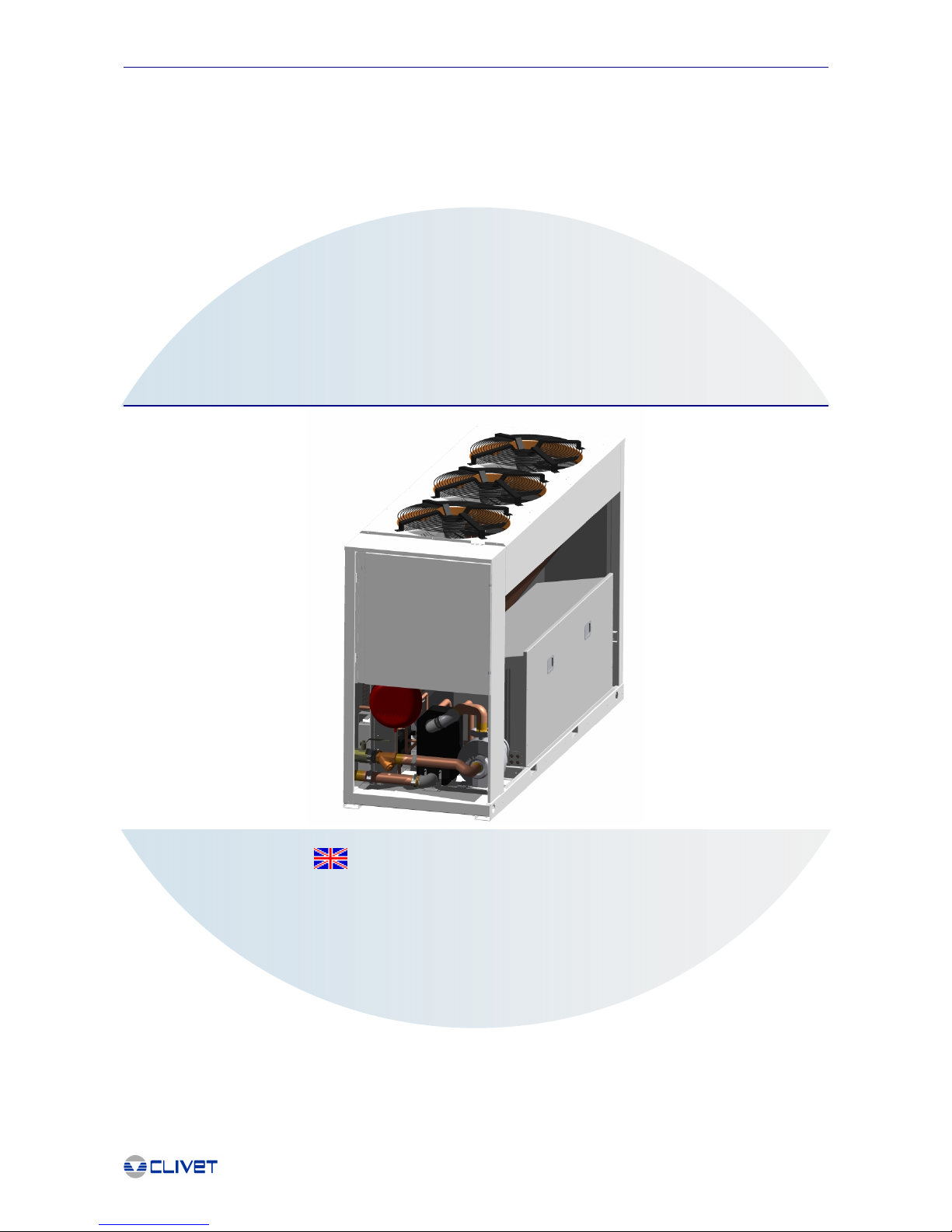

WSAT-2

302-323-404

464-524-564-614

AIR COOLED CHILLER WITH SCROLL COMPRESSORS (WITH PROPELLER FANS)

M91P44E5-05

(R-407C / R-22)

Page 2

Page 3

1

®

- CONTENTS -

GENERAL INFORMATION

GENERAL WARNINGS ............................................................................... 2

CORRECTION FACTORS ...........................................................................2

OPERATION LIMITS AND USE OF THE EXCHANGERS.......................... 2

GENERAL SPECIFICATIONS .....................................................................3

OPERATING LIMITS .................................................................................... 5

SETTING THE CUT-OUT DEVICES AND CONTROLS ............................. 5

SOUND LEVELS ..........................................................................................6

INTENDED USE........................................................................................... 6

ADDITIONAL SAFETY PRECAUTIONS...................................................... 6

REGULATIONS AND CERTIFICATIONS

UNI EN ISO 9001 CERTIFICATION ............................................................7

CE MARK ..................................................................................................... 7

EUROVENT CERTIFICATION ..................................................................... 7

RECEPTION/POSITIONING

INSPECTION UPON RECEPTION .............................................................. 8

STORAGE ....................................................................................................8

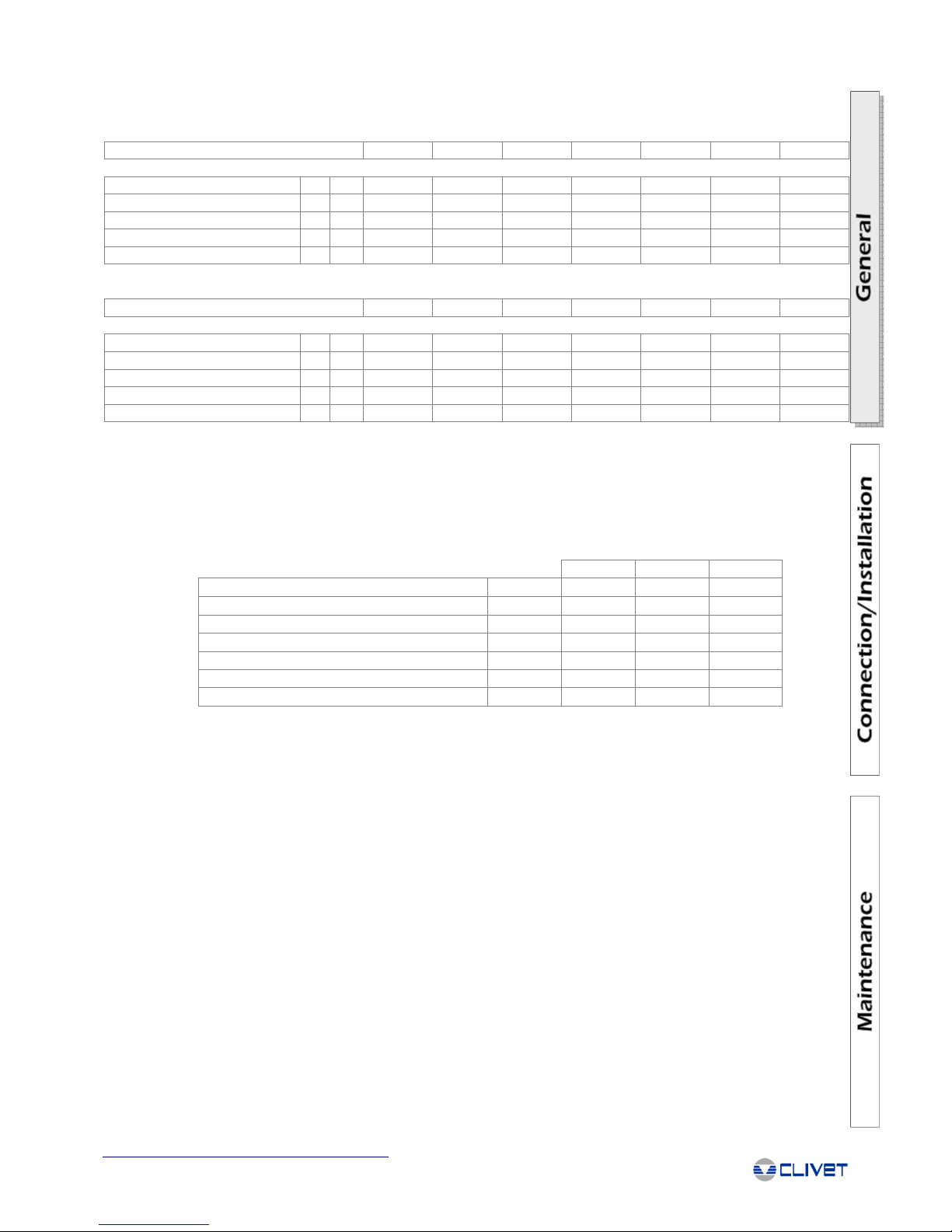

HANDLING USING A FORK LIFT OR SIMILAR ......................................... 8

HOISTING USING A CRANE OR SIMILAR................................................. 8

REMOVING THE PACKING ...................................................................... 10

FUNCTIONAL CLEARANCES ...................................................................10

INSTALLATION OF ANTIVIBRATION MOUNTS ......................................10

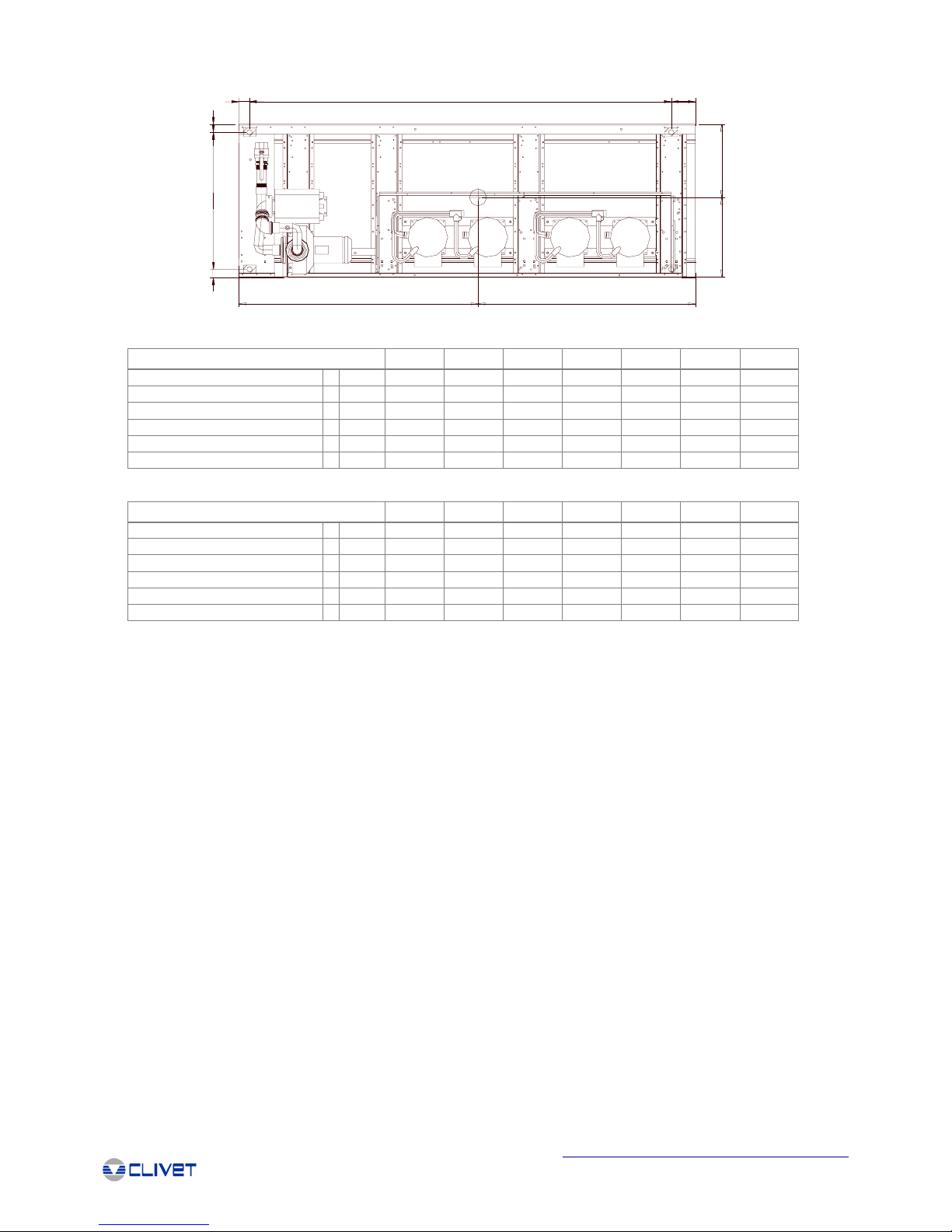

DIMENSIONS .............................................................................................11

WEIGHT DISTRIBUTION ...........................................................................12

POSITIONING ............................................................................................12

RESIDUAL RISKS

SAFETY INSTRUCTIONS.......................................................................... 13

DEFINITION OF DANGER AREA.............................................................. 13

SAFETY PRESCRIPTIONS ....................................................................... 13

WARNING!.................................................................................................. 13

DANGER!.................................................................................................... 14

PROHIBITIONS ..........................................................................................14

REFRIGERANT SAFETY CHARTS........................................................... 14

DECOMMISSIONING OF THE UNIT

DISCONNECTING THE UNIT .................................................................... 18

DISMANTLING AND DISPOSAL ............................................................... 18

CONTROL

MAIN CONTROL MODULE KE YPAD........................................................ 28

MEANING OF THE BUTTONS ..................................................................28

UNIT ON/OFF............................................................................................. 28

ALARM DISPLAY .......................................................................................28

ALARM RESET ..........................................................................................28

ALARMS ..................................................................................................... 29

ALARM LOG............................................................................................... 29

SELECTING THE OPERATING MODE..................................................... 30

SETTING THE WORKING SET POINT..................................................... 31

SETTING THE ANTIFREEZE SET POINT ................................................ 31

SETTING THE SECOND SET POINT FOR HEATING AND COOLING...32

SETTING THE MAINTENANCE SET POINT ............................................33

SETTING THE CLOCK .............................................................................. 34

SWITCHING ON AND OFF FROM TIME BANDS..................................... 35

CHANGING THE SET POINT FROM TIME BANDS ................................. 35

COUNTER DISPLAY.................................................................................. 37

LAYOUT OF THE MAIN MODULE ............................................................ 38

READING THE OPERATING STATUS .....................................................39

DIGITAL INPUTS ....................................................................................... 40

DIGITAL OUTPUTS ................................................................................... 40

DEMAND LIMIT .......................................................................................... 41

ANTIFREEZE THERMOREGULATOR...................................................... 41

ANTIFREEZE PRE-ALARM THERMOREGULATOR ............................... 42

HIGH PRESSURE ALARM PREVENTION ............................................... 42

FLUID THERMOREGULATOR .................................................................. 42

FLOW ALARM MANAGEMENT .................................................................42

CIRCULATING PUMP MANAGEMENT..................................................... 42

COIL FAN CONTROLLER ......................................................................... 42

COMPRESSOR ROTATION ......................................................................42

CONNECTING THE UNIT TO SUPERVISORY SYSTEMS ......................43

COMMUNICATION PROTOCOL ............................................................... 45

ROUTINE MAINTENANCE

GENERAL................................................................................................... 50

ROUTINE MAINTENANCE ........................................................................50

STRUCTURE.............................................................................................. 50

ELECTRICAL SYSTEM .............................................................................. 50

WATER SYSTEM .......................................................................................50

EXCHANGE COIL ......................................................................................50

WATER EXCHANGER ............................................................................... 50

REFRIGERANTS........................................................................................ 50

TROUBLESHOOTING

GENERAL................................................................................................... 53

FLOW ALARM ............................................................................................53

HIGH PRESSURE ALARM ........................................................................ 53

LOW PRESSURE ALARM ......................................................................... 53

ANTIFREEZE ALARM ................................................................................53

COMPRESSOR THERMAL OVERLOAD ALARM..................................... 53

FAN THERMAL OVERLOAD A LARM........................................................ 53

THE UNIT DOES NOT START .................................................................. 53

THE UNIT IS NOISY................................................................................... 54

WATER/AERAULIC CONNECTIONS

GENERAL................................................................................................... 19

EVAPORATOR PRESSURE DROPS (WATER SIDE) ............................. 20

EVAPORATOR ANTIFREEZE SOLUTIONS ............................................. 20

PUMP PERFORMANCE RELATED TO THE EFFECTIVE PLANT HEAD20

WATER FLOW LIMITS .............................................................................. 21

ELECTRICAL CONNECTIONS

GENERAL................................................................................................... 22

PRELIMINARY OPERATIONS .................................................................. 22

CONNECTING THE MACHINE TO THE MAINS POWER SUPPLY ... 22

FUNCTIONAL CONNECTIONS ................................................................. 22

ENABLING THE SECOND SET POINT FROM DIGITAL INPUT ............. 23

DEMAND LIMIT .......................................................................................... 23

ELECTRICAL DATA ................................................................................... 23

START-UP

GENERAL................................................................................................... 25

PRELIMINARY CHECKS ........................................................................... 25

PRELIMINARY CHECKS: ELECTRICAL SYSTEM .................................. 25

PRELIMINARY CHECKS: REFRIGERANT CIRCUIT ...............................25

PRELIMINARY CHECKS: WATER SYSTEM ............................................ 26

CHECKS ON SAFETY DEVICES, WATER SIDE (DIFFERENTIAL

PRESSURE SWITCH / FLOW SWITCH)............................................. 26

START-UP .................................................................................................. 26

ELECTRICAL CHECKS ............................................................................. 27

REFRIGERANT CIRCUIT CHECKS ..........................................................27

WATER SYSTEM CHECKS ....................................................................... 27

All technical specifications and images presented in this manual are not binding and subject to c hange without notice. Forbidden any

reproduction.

Page 4

2

®

F1 = Cooling capacity correction factors

FK1 = Compressors' input power correction factors

GENERAL WARNINGS

This manual has been designed to enable the unit to be installed, started up and maintained correctly, making it essential to observe

the following points:

- these instructions should be read carefully;

- the unit must be installed, tested and maintained by expert personal who meet the relevant legal requirements (Italian law No. 46 of

5/3/1990).

- The manufacturer declines all liability for any electrical and/or mechanical changes to the unit, which also invalid its guarantee. Any

operations whatsoever that have not been expressly authorised and do not respect the information in this manual shall invalidate the

guarantee.

- Observe the local safety regulations in force when installing the unit.

- Make sure the power supply conforms to the data on the unit’s rating plate, located inside the door of the main electrical panel.

- This manual and the unit’s wiring diagram should be carefully stored so that they are readily available to the operator when required.

- The packaging material (plastic bags, polystyrene foam, nails, etc.) is potentially dangerous and should therefore be kept away from

children and recycled in compliance with the local regulations in force.

- The unit must only be used for the specific purpose it was designed, as described in the paragraph GENERAL TECHNICAL

SPECIFICATIONS Any use other than that specified does not imply any commitment or constraint by the manufacturer in any way

whatsoever.

- Switch off the unit in the event of faults or poor operation.

- Only have repairs carried out by a service centre authorised by the manufacturer, and insist on the use of original spare parts only.

Failure to comply with the above may compromise the safety of the unit.

The manufacturer declines all liability for any damage that may be caused whether directly or indirectly to persons or things if these

instructions are not heeded.

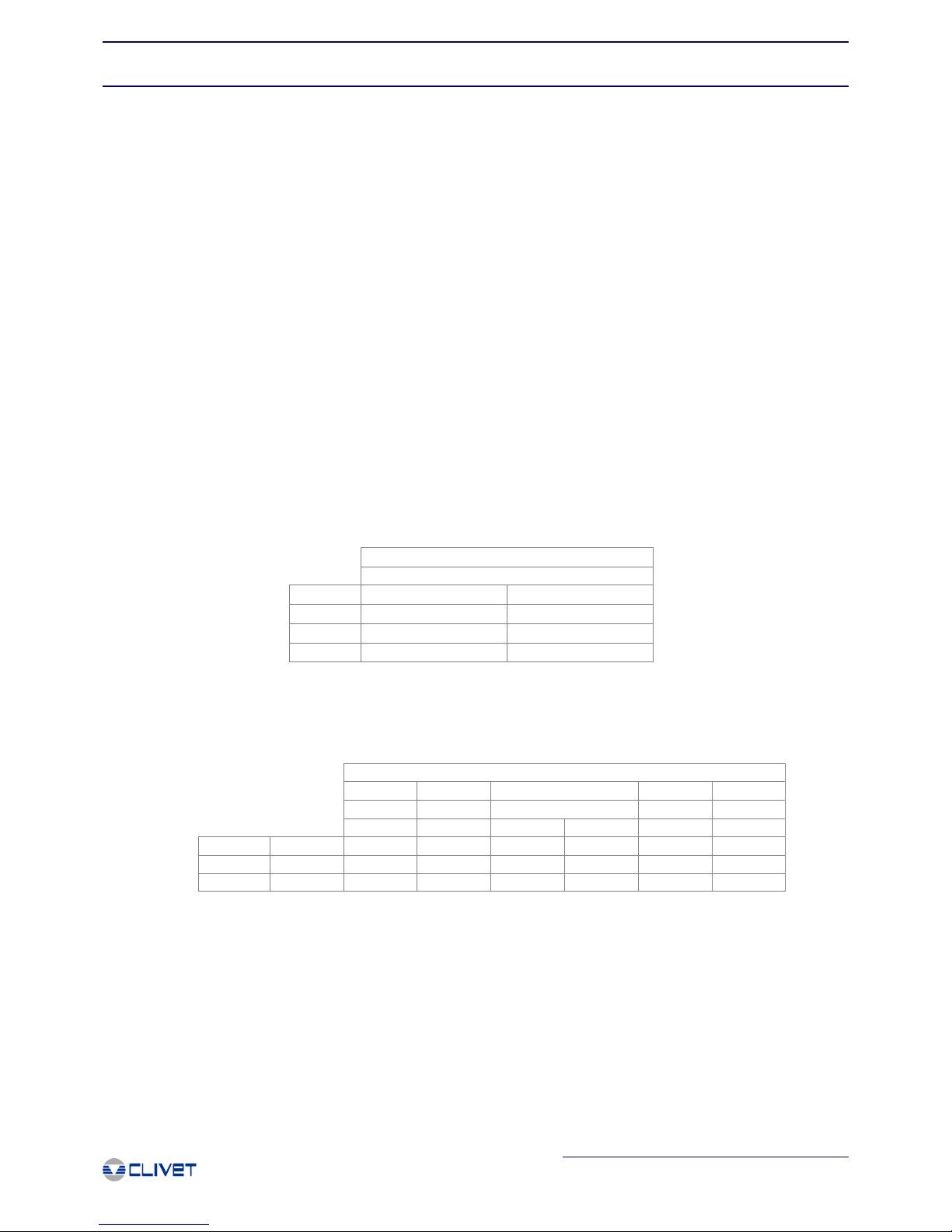

CORRECTION FACTORS

The performance data described in the general technical specifications is based on an evaporator fouling factor of 0.44x10-4 m2 x°C/

W and perfectly clean finned coils. For different value fouling factors, the performance data must be multiplied by the following

correction coefficients.

OPERATION LIMITS AND USE OF THE EXCHANGERS

- GENERAL INFORMATION-

General Information

CORRECTION FACTORS

m

2

°C / W

F1 FK1

0.44 x 10-4

1 1

0.88 x 10-4

0.97 0.99

1.76 x 10-4

0.94 0.98

Evaporator

Evaporator

DPr DPw Dteo Dtei

[kPa] [kPa] [°C]

S-B S B (*)

CLIVET C

3450 2500 6 -8 22

PED CE

3450 3450 6 -8 22

UDT U

- - 6 -8 22

[°C]

DT

[°C]

5

5

5

DPr = Maximum operating pressure at refrigerant side

DPw = Maximum operating pressure at water side

DTeo = Minimum water temperature at evaporator outlet

DTei = Maximum water temperature at evaporator inlet

DT = inlet / outlet temperature differential

S = Standard

B = Brine

(*) = Limit for 2 capacity steps unit

Page 5

3

®

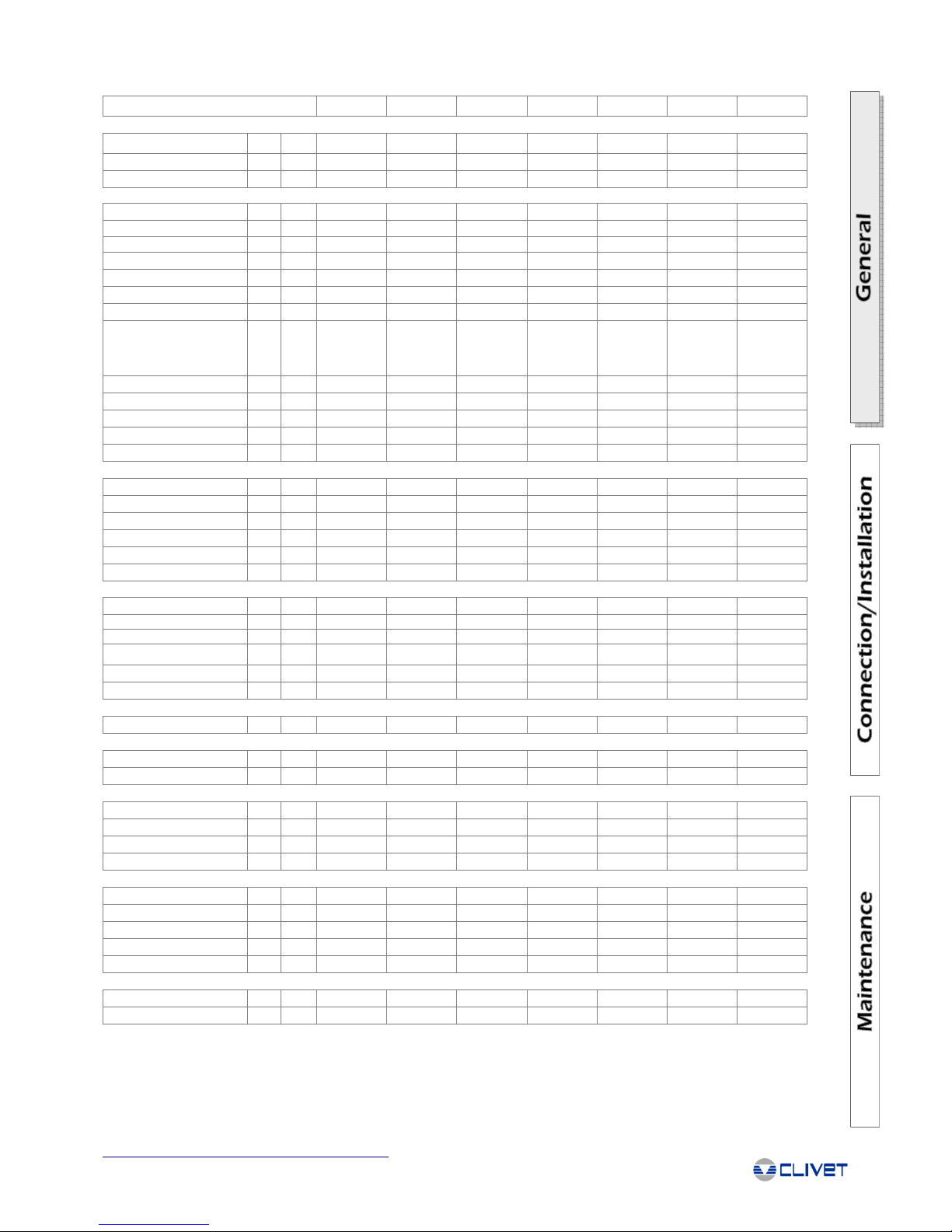

GENERAL SPECIFICATIONS

1. Data refer to the following conditions:

- Evaporator water = 12/7°C

- Ambient temperature = 35°C

Version S / Configuration ST

General Information

SIZE

302 323 404 464 524 564 614

Cooling

Cooling capacity (1) [kW] 81.4 93.5 101.5 119.1 134.3 144.0 159.5

Compr.input power (1) [kW] 26.3 28.6 33.1 37.3 42.0 46.7 54.5

Total input power (1) [kW] 30.2 32.5 37.1 43.0 47.7 52.4 60.2

COMPRESSORS

Compressors type scroll scroll scroll scroll scroll scroll scroll

Nr of compressors 2 3 4 4 4 4 4

Capacity control steps (ST) 2 3 4 4 4 4 4

Oil charge (C1) [l] 4.1 6.6 3.3 3.3 3.3 3.3 4.1

Oil charge (C2) [l] 4.1 3.3 3.3 3.3 3.3 3.3 4.1

Oil charge (C3) [l] 0 3.3 3.3 3.3 3.3 6.6 4.1

Oil charge (C4) [l] 0 0 3.3 3.3 3.3 6.6 4.1

Oil type (*)

Copeland

3MA (32 cSt)

Maneurop

160SZ

Polyolester

ISO32

Maneurop

160SZ

Polyolester

ISO32

Maneurop

160SZ

Polyolester

ISO32

Maneurop

160SZ

Polyolester

ISO32

Maneurop

160SZ

Polyolester

ISO32

Copeland

3MA (32 cSt)

Refrigerant charge (C1) [kg] 14.0 14.0 8.5 8.5 10.5 10.5 11.5

Refrigerant charge (C2) [kg] 14.0 8.5 8.5 8.5 10.5 10.5 11.5

Refrigerant charge (C3) [kg] 0 8.5 8.5 10.5 10.5 11.5 11.5

Refrigerant charge (C4) [kg] 0 0 8.5 10.5 10.5 11.5 11.5

Refrigerant circuits 2 2 2 2 2 2 2

EVAPORATORS

Evaporator type (2) PHE PHE PHE PHE PHE PHE PHE

Evaporator number [l/s] 1 1 1 1 1 1 1

Water flow [l/s] 3.9 4.5 4.8 5.7 6.4 6.9 7.6

Pressure drop [kPa] 29.7 23.8 27.7 27.6 34.6 30.9 37.6

Pump available head [kPa] 130 115 100 120 105 120 110

Water volume [l] 5.9 7.8 7.8 9.4 9.4 11.0 11.0

Outdoor Unit Fans

Evaporator type (3) AX AX AX AX AX AX AX

Evaporator number 2 2 2 3 3 3 3

Fan diametre [mm] 800 800 800 800 800 800 800

RPM [rpm] 870 870 870 870 870 870 870

Standard air flow [l/s] 9150 11650 11650 16650 16650 16650 16100

Single motor input [kW] 2.0 2.0 2.0 2.0 2.0 2.0 2.0

CONNECTIONS

Water connection ["] 2 " 1/2 2 " 1/2 2 " 1/2 2 " 1/2 2 " 1/2 2 " 1/2 2 " 1/2

STANDARD UNIT WEIGHT

Shipping weight [kg] 1347 1473 1548 1666 1695 1746 1789

Operating weight [kg] 1362 1490 1565 1685 1714 1766 1809

DIMENSIONS

Lenght [mm] 3250 3250 3250 3250 3250 3250 3250

Depth [mm] 1095 1095 1095 1095 1095 1095 1095

High [mm] 2030 2030 2030 2030 2030 2030 2030

Packing volume [m

3

] 7 7 7 7 7 7 7

EXPANSION / STORAGE TANK

Expans. tank capacity [l] 12 12 16 16 18 18 18

Max pressure water side [kPa] 800 800 800 800 800 800 800

Nitrogen buffer press. [kPa] 150 150 150 150 150 150 150

N° of expansion tanks 1 1 1 1 1 1 1

Storange tank cap. [l] 200 200 200 200 200 200 200

HYDRAULIC CIRCUIT

Water side max press. [kPa] 550 550 550 550 550 550 550

Safety valve setting [kPa] 600 600 600 600 600 600 600

* R-22 unit:

- Maneurop 160 P Mineral (sizes 323-404-464-524-564)

- SUNISO 3GS (sizes 302-614)

2. PHE = plates

3. AX = axial fan

Page 6

4

®

1. Data refer to the following conditions:

- Evaporator water = 12/7°C

- Ambient temperature = 35°C

Version S / Configuration LN

General Information

* R-22 unit:

- Maneurop 160 P Mineral (sizes 323-404-464-524-564)

- SUNISO 3GS (sizes 302-614)

2. PHE = plates

3. AX = axial fan

SIZE

302 323 404 464 524 564 614

Cooling

Cooling capacity (1) [kW] 79.2 89.6 98.4 115.9 129.1 137.4 153.3

Compr.input power (1) [kW] 27.6 29.8 34.9 39.1 44.1 49.4 57.6

Total input power (1) [kW] 30.1 32.2 37.4 42.6 47.8 52.9 61.2

COMPRESSORS

Compressors type scroll scroll scroll scroll scroll scroll scroll

Nr of compressors 2 3 4 4 4 4 4

Capacity control steps (ST) 2 3 4 4 4 4 4

Oil charge (C1) [l] 4.1 6.6 3.3 3.3 3.3 3.3 4.1

Oil charge (C2) [l] 4.1 3.3 3.3 3.3 3.3 3.3 4.1

Oil charge (C3) [l] 0 3.3 3.3 3.3 3.3 6.6 4.1

Oil charge (C4) [l] 0 0 3.3 3.3 3.3 6.6 4.1

Oil type (*)

Copeland

3MA (32 cSt)

Maneurop

160SZ

Polyolester

ISO32

Maneurop

160SZ

Polyolester

ISO32

Maneurop

160SZ

Polyolester

ISO32

Maneurop

160SZ

Polyolester

ISO32

Maneurop

160SZ

Polyolester

ISO32

Copeland

3MA (32 cSt)

Refrigerant charge (C1) [kg] 14.0 14.0 8.5 8.5 10.5 10.5 11.5

Refrigerant charge (C2) [kg] 14.0 8.5 8.5 8.5 10.5 10.5 11.5

Refrigerant charge (C3) [kg] 0 8.5 8.5 10.5 10.5 11.5 11.5

Refrigerant charge (C4) [kg] 0 0 8.5 10.5 10.5 11.5 11.5

Refrigerant circuits 2 2 2 2 2 2 2

EVAPORATORS

Evaporator type (2) PHE PHE PHE PHE PHE PHE PHE

Evaporator number [l/s] 1 1 1 1 1 1 1

Water flow [l/s] 3.8 4.3 4.7 5.5 6.2 6.6 7.3

Pressure drop [kPa] 28.2 22.0 26.1 26.2 32.1 28.3 34.8

Pump available head [kPa] 130 115 100 120 105 120 110

Water volume [l] 5.9 7.8 7.8 9.4 9.4 11.0 11.0

Outdoor Unit Fans

Evaporator type (3) AX AX AX AX AX AX AX

Evaporator number 2 2 2 3 3 3 3

Fan diametre [mm] 800 800 800 800 800 800 800

RPM [rpm] 870 870 870 870 870 870 870

Standard air flow [l/s] 7220 8890 8890 12770 12770 12770 12200

Single motor input [kW] 1.3 1.3 1.3 1.3 1.3 1.3 1.3

CONNECTIONS

Water connection ["] 2 " 1/2 2 " 1/2 2 " 1/2 2 " 1/2 2 " 1/2 2 " 1/2 2 " 1/2

STANDARD UNIT WEIGHT

Shipping weight [kg] 1378 1504 1579 1697 1726 1777 1820

Operating weight [kg] 1393 1521 1596 1716 1745 1797 1840

DIMENSIONS

Lenght [mm] 3250 3250 3250 3250 3250 3250 3250

Depth [mm] 1095 1095 1095 1095 1095 1095 1095

High [mm] 2030 2030 2030 2030 2030 2030 2030

Packing volume [m

3

] 7 7 7 7 7 7 7

EXPANSION / STORAGE TANK

Expans. tank capacity [l] 12 12 16 16 18 18 18

Max pressure water side [kPa] 800 800 800 800 800 800 800

Nitrogen buffer press. [kPa] 150 150 150 150 150 150 150

N° of expansion tanks 1 1 1 1 1 1 1

Storange tank cap. [l] 200 200 200 200 200 200 200

HYDRAULIC CIRCUIT

Water side max press. [kPa] 550 550 550 550 550 550 550

Safety valve setting [kPa] 600 600 600 600 600 600 600

Page 7

5

®

OPERATING LIMITS

The water flow-rate at the evaporator must be constant and fall within MIN-MAX limits shown in the diagram/diagrams under the

section on "Water/Aeraulic Connections".

Version S / Configuration ST

General Information

Version S / Configuration LN

SETTING THE CUT-OUT DEVICES AND CONTROLS

Opens Closes Value

High pressure switch [kPa] 2800 2000 -

Low pressure switch [kPa] 230 360 Antifreeze protection [°C] 4 6.5 -

High pressure safety valve [kPa] - - 3000

Low pressure safety valve [kPa] - - 1900

Max compressor starts per hour [n°] - - 10

Safety discharge thermostat [°C] - - 120

SIZE

302 323 404 464 524 564 614

Condenser

Max. air inlet temperature (1) [°C] 47.5 47.5 47.5 47 48.5 47 46

Max. air inlet temperature (2) [°C] 53.5 53.5 52.5 52 53 52.5 52

Min. air inlet temperature (3) [°C] -10 -10 -10 -10 -10 -10 -10

Min. air inlet temperature (4) [°C] 6 11 11 10 8 7 5

Min. air inlet temperature (5) [°C] 16 19.5 19.5 19 18 17.5 14.5

SIZE

302 323 404 464 524 564 614

Condenser

Max. air inlet temperature (1) [°C] 44.5 44.5 44.5 44.5 45.5 44 43

Max. air inlet temperature (2) [°C] 50 50 50 50 51 49.5 49

Min. air inlet temperature (3) [°C] -10 -10 -10 -10 -10 -10 -10

Min. air inlet temperature (4) [°C] 6 11 11 10 8 7 5

Min. air inlet temperature (5) [°C] 16 19.5 19.5 19 18 17.5 14.5

1) Unit at full load - Evaporator water = 12/7°C

2) Unit at partial load (automatic partialization)

3) With electronic low ambient temperature control (std), unit at full load and motionless external air

4) With electronic low ambient temperature control (std), unit at partial load and motionless external air

5) With electronic low ambient temperature control (std), unit at partial load with air speed 1m/s

Note: The electronic low ambient temperature control with inverter is recommended for temperatures lower than 5°C

Page 8

6

®

The sound levels refer to:

- units operating at full load

- rated test conditions

SOUND LEVELS

Version S / Configuration ST

Version S / Configuration LN

INTENDED USE

The unit is designed to cool water or a water and glycol mix for air-conditioning, within the limits defined in the technical bulletin and

this manual.

ADDITIONAL SAFETY PRECAUTIONS

This unit has been especially designed and manufactured so to prevent any risk to persons and health hazard.

For this reason, design solutions fit to eliminate (where possible) any cause of risk and sensibly reduce the probability of

danger have been adopted.

Please refer to the "Residual Risks" section of this manual and strictly observe the behaviour prescriptions listed there in order to

prevent any possible risk that hasn’t been possible to avoid in the design stage.

The sound pressure level is measured 1 metre from the surface of the unit operating in an open field.

General Information

Size SOUND POWER LEVEL (dB)

Sound

Pressure

Level

ST

Octave Band (Hz)

63 125 250 500 1000 2000 4000 8000 dB(A) dB(A)

302

90 91 91 88 86 82 75 68 72 91

323

92 94 93 90 88 84 76 70 74 93

404

93 95 94 91 89 85 77 71 75 93

464

95 96 95 93 90 86 78 73 77 95

524

95 96 95 93 91 87 79 73 77 95

564

95 96 95 93 91 87 80 73 77 95

614

95 96 95 93 90 87 80 73 77 95

Sound

Power Level

Size SOUND POWER LEVEL (dB)

Sound

Pressure

Level

LN

Octave Band (Hz)

63 125 250 500 1000 2000 4000 8000 dB(A) dB(A)

302

84 83 82 79 76 72 67 57 63 81

323

86 86 84 80 78 73 67 60 65 83

404

88 88 86 82 80 75 67 62 66 85

464

89 89 87 84 81 75 69 62 67 86

524

89 89 87 85 82 75 70 62 68 86

564

89 89 87 84 81 76 71 62 68 86

614

88 88 87 83 81 77 72 62 68 86

Sound

Power Level

Data calculated according to ISO 3744

Page 9

7

®

- REGULATIONS AND CERTIFICATIONS -

UNI EN ISO 9001 CERTIFICATION

Clivet S.p.A., in order to guarantee customer satisfaction, has chosen the ISO 9001 Quality

System as the reference for all its business activities. This is demonstrated by the

company’s commitment to ongoing improvements in the quality and reliability of its

products; its sales, design, purchasing, production and after-sales service activities are the

means used to reach such purpose.

CE MARK

Clivet products bear the CE mark, in compliance with the requirements of the following EC directives, including the

latest amendments, and with the corresponding national approximated legislation:

- 98/37/CE

- 89/336/CEE as modified by the directives 92/31/CEE and 93/68/CEE

- 73/23/CEE as modified by the directive 93/68/CEE

EUROVENT CERTIFICATION

Clivet is partecipating in the EUROVENT Certification Programme "Liquid Chilling Packages". Products are listed

in the EUROVENT Directory of Certified Products and in the site www.eurovent-certification.com. Eurovent Chillers Certification Programme covers air cooled packaged chillers up to 600 kW and water cooled packaged chillers

up to 1500 kW.

Regulations and Certifications

- 97/23/CE according to H module

CERTIFIED QUALITY SYSTEM

UNI EN ISO 9001:2000

Page 10

8

®

INSPECTION UPON RECEPTION

The units are shipped in special protective packaging. Check upon receipt that the unit has not been damaged during transport, and

that all the parts ordered are present. In the event of visible damage, immediately note the damage found on the shipping document,

writing: "ACCEPTED WITH RESERVATION DUE TO EVIDENT DAMAGE TO THE PACKAGING", as both freight-paid and freightcharged deliveries are covered by insurance in accordance with Italian law no. 450, 22/08/85, "limits of compensation".

IMPORTANT

ALL THE FOLLOWING OPERATIONS MUST BE CARRIED OUT IN COMPLIANCE WITH THE SAFETY STANDARDS IN FORCE,

RELATING TO BOTH THE EQUIPMENT AND THE METHODS USED.

CAUTION

BEFORE PERFORMING THE HANDLING OPERATIONS, CHECK THAT:

- THE HOISTING CAPACITY IS SUITABLY-RATED FOR THE WEIGHT OF THE UNIT IN QUESTION

- THE DISTRIBUTION OF THE WEIGHTS AND THE POSITION OF THE CENTRE OF GRAVITY MUST BE CAREFULLY

CONSIDERED

WARNINGS

FOLLOWING THE SUGGESTIONS INDICATED ON THE OUTSIDE OF THE PACKAGING WILL ENSURE THAT THE UNIT IS

PHYSICALLY INTACT AND FUNCTIONAL, TO THE BENEFIT OF THE END USER. THEREFORE, PLEASE HEED THE

FOLLOWING WARNINGS:

- HANDLE WITH CARE

- KEEP DRY

- AVOID STACKING OTHER OBJECTS ON THE UNIT AT ALL COSTS (UNLESS THIS FALLS WITHIN THE LIMITS OF STACKED

LEVELS SHOWN ON THE PACKAGING).

- AVOID POSITIONING THE UNITS WITH PROTECTIVE HEAT-SHRINK PACKAGING IN DIRECT SUNLIGHT, AS THE

PRESSURE IN THE CIRCUITS MAY REACH VALUES AT WHICH THE SAFETY VALVES ARE ACTIVATED.

STORAGE

- Shelter from: direct sunlight, rain, sand and wind

- Temperature: maximum 60°C minimum -10°C

- Maximum humidity: 90%

- RECEPTION/POSITIONING -

HOISTING USING A CRANE OR SIMILAR

Position the lifting pipes, supplied, in the holes on the base of the unit.

Position the ends of the pipes that protrude from the unit so that the safety pins (supplied) can be placed in the corresponding holes.

Fit the lifting belts over the pipes between the safety devices and the base of the unit (see drawing).

Gradually bring the lifting belts under tension, making sure they are positioned correctly. Make sure the unit is always in steady

equilibrium.

Start hoisting the unit.

Once the unit has been positioned, remove the lifting pipes. These must be kept in a safe place, where they cannot damage people or

property, for any future positioning of the unit.

HANDLING USING A FORK LIFT OR SIMILAR

Insert the forks in the long side of the base, in the corresponding slots.

Start hoisting the unit, making sure the load is in steady equilibrium.

Reception/Positioning

Page 11

9

®

!

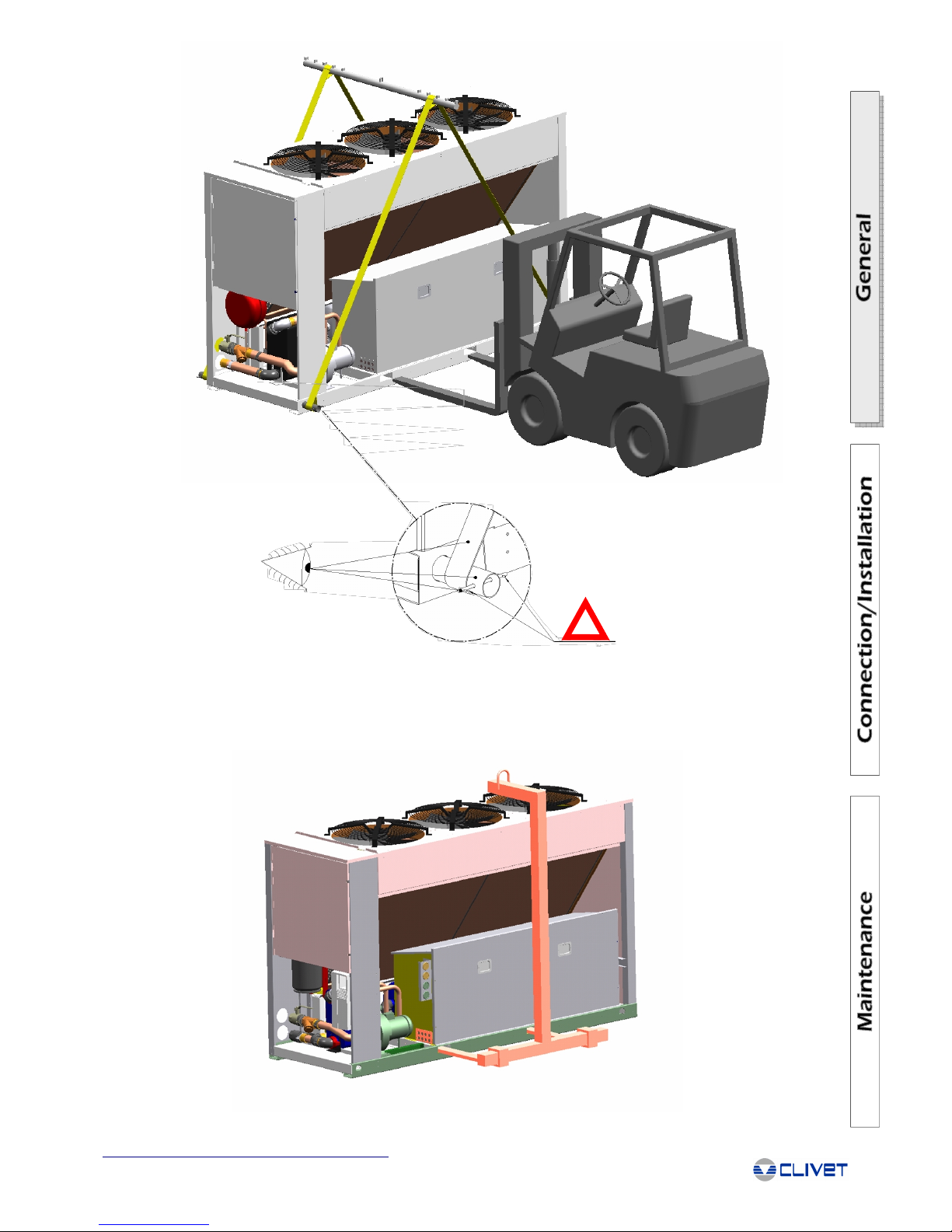

HOISTING USING A SELF-BALANCING FORK

Insert the self-balancing fork in the special slits of the unit. A rigid protective structure should be placed on the upper edge of the unit,

on the side facing the fork.

Start hoisting the unit, making sure the load is in steady equilibrium.

Reception/Positioning

Page 12

10

®

PLAN OF SPRING ANTIVIBRATION MOUNTS

1. n°4 holes Ø12

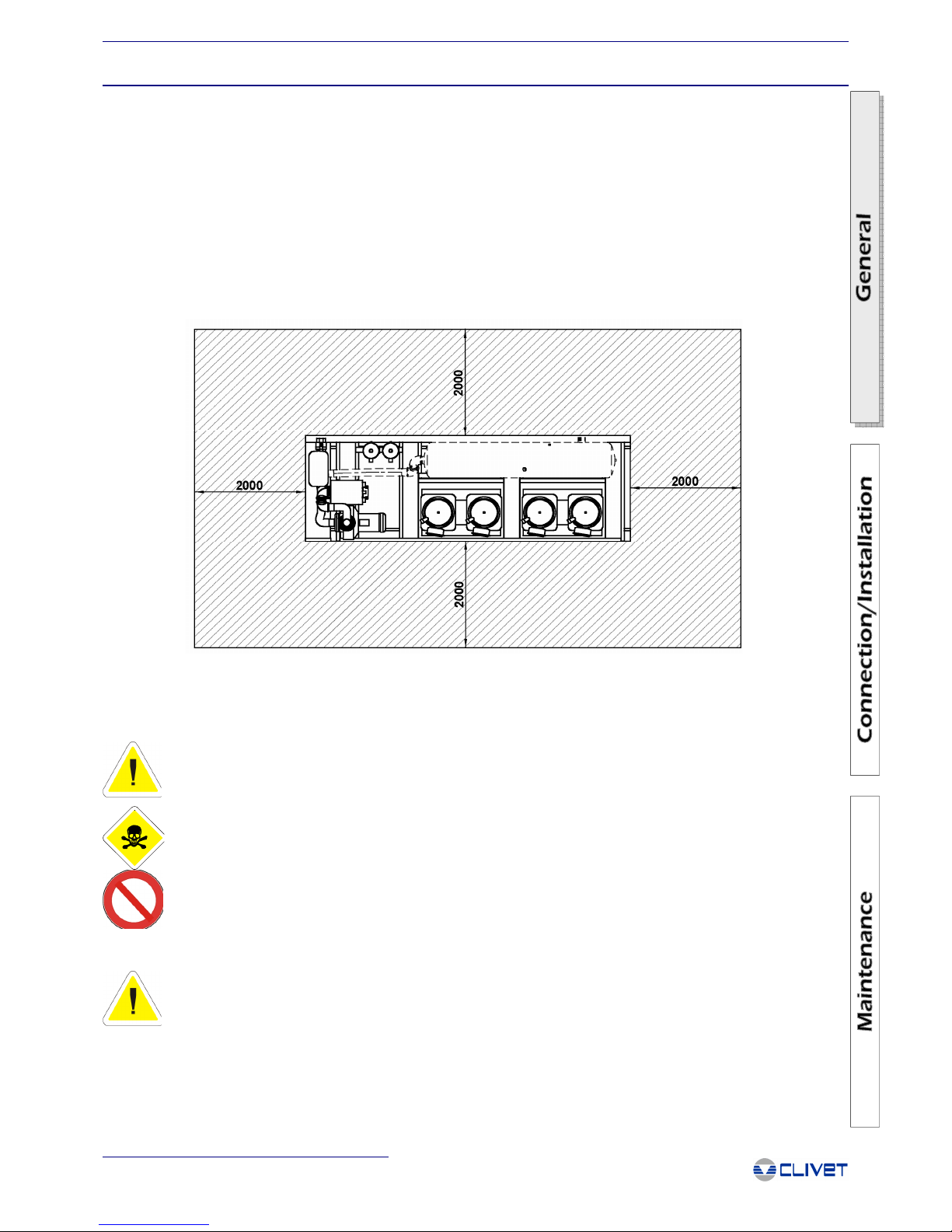

FUNCTIONAL CLEARANCES

IMPORTANT

WHEN PLACING THE UNIT, PLEASE MAKE SURE THAT THE FUNCTIONAL CLEARANCES ALLOW ALL MAINTENANCE

OPERATIONS TO BE PERFORMED. THIS IS REQUIRED FOR OPTIMUM UNIT OPERATION AND PARTICULARLY FOR THE

SAFETY OF AUTHORISED PERSONNEL AND EXPOSED PERSONS

The units require minimum clearances for operation and maintenance. In the event of multiple units, the functional clearances must be

doubled. The following sketches regard some types of installation; check on a case-by-case basis, considering the information

provided in this manual.

INSTALLATION OF ANTIVIBRATION MOUNTS

Spring or rubber (depending on the type of unit) antivibration mounts can be supplied upon request; in this case flexible joints (not

supplied by Clivet) are required for the hydraulic / aeraulic / refrigerant connections.

The tables and the drawings show the instructions for the installation of the antivibration mounts, with the part numbers of the

antivibration kits and their composition for correct installation.

The kits also include the assembly instructions.

INSTALLATION WITH JACK FOR UNIT LEVELLING

1. Minimum dimensions suggested

2. Jack

3. Plate

4. Clamps drowned in the concrete (not supplied)

5. Concrete foundation

* Unloaded height

INSTALLATION DIRECT-TO-FRAME

1. Minimum dimensions suggested

2. Clamps drowned in the concrete (not supplied)

3. Concrete foundation

* Unloaded height

Reception/Positioning

REMOVING THE PACKING

When removing the packaging the operator should, for personal safety, use suitable protective materials (gloves, glasses etc.)

Check for any visible damage.

Dispose of the packaging by taking it to specialist collection or recycling centres (in accordance with local regulations).

Remove the polystyrene packaging and the corresponding fasteners, making sure not to damage the unit.

1

5

0

0

1

5

0

0

1500

900

1

2

3

4

5

2

3

1

1

Page 13

11

®

The tables refer to standard units. For special units or versions R, D, etc., refer to the unit dimensional drawings.

Reception/Positioning

UNIT CODE POSITIONING

302 PE581072

W1 = cod. C6100080 K=21,2

W2 = cod. C6100080 K=21,2

W3 = cod. C6100080 K=21,2

W4 = cod. C6100080 K=21,2

323

404 W1 = cod. C6100080 K=21,2

464 W2 = cod. C6100082 K=25,6

524 W3 = cod. C6100080 K=21,2

564 W4 = cod. C6100082 K=25,6

614

PE581051

ANTIVIBRATION MOUNTS CODES

DIMENSIONS

W3

11 11

2

33

7

7

W1 W2

W4

10

MN

O

W3

W1 W2

W4

P

W3

W1 W2

W4

"G"

977

W

9

59

175299085

59

977

L

861

2990

9

8

160

85

11

4-5

12

148

6

2

4-5

148

6

200

350

175

59

4-5

8

H

59

4-5

10

KEY:

1. Compressor

2. Evaporator

3. Condenser

4. Unit mounts holes

5. Belt lifting holes

6. Fork lift lifting holes

7. Electrical panel

8. Power supply input

9. Sound proof enclosure

10. Centrifugal water Pump

11. Evaporator water inlet

12. Evaporator water outlet

Version S / Configuration ST

Version S / Configuration LN

SIZES 302 323 404 464 524 564 614

H

mm 2030 2030 2030 2030 2030 2030 2030

L

mm 3250 3250 3250 3250 3250 3250 3250

M

mm 1628 1675 1703 1701 1708 1722 1733

N

mm 1622 1575 1547 1549 1542 1528 1517

O

mm 523 544 554 557 559 564 568

P

mm 572 551 541 538 536 531 527

W

mm 1095 1095 1095 1095 1095 1095 1095

OD

“ 2" 1/2 2" 1/2 2" 1/2 2" 1/2 2" 1/2 2" 1/2 2" 1/2

SIZES 302 323 404 464 524 564 614

H

mm 2030 2030 2030 2030 2030 2030 2030

L

mm 3250 3250 3250 3250 3250 3250 3250

M

mm 1637 1682 1709 1707 1714 1727 1738

N

mm 1613 1568 1541 1543 1536 1523 1512

O

mm 529 548 558 561 563 568 572

P

mm 566 547 537 534 532 527 523

W

mm 1095 1095 1095 1095 1095 1095 1095

OD

“ 2" 1/2 2" 1/2 2" 1/2 2" 1/2 2" 1/2 2" 1/2 2" 1/2

Page 14

12

®

Version S / Configuration ST

Version S / Configuration LN

WEIGHT DISTRIBUTION

POSITIONING

The units have been designed for outdoor installation in a fixed position.

Check that the fastening/support points are in level and can bear the weight of the unit (see weights and weight distribution).

Avoid installation in areas that may be subject to flooding.

Installations below ground level or near very high walls must be carefully assessed.

Place a layer of rubber between the base of the unit and the support to prevent noise and vibrations. Depending on the place of

installation (balconies or roofs), the unit should be placed on special antivibration mounts (in this case, flexible joints are required for

the water/aeraulic connections - joints are not supplied by Clivet).

Fasten the unit to the ground.

The choice of the location of the unit is of fundamental importance for correct operation. Obstacles that block the flow of air, difficulty

in air circulation, leaves or other objects that may block the exchanger coils, winds that contrast or excessively assist the air flow,

phenomena of stratification or air re-circulation and nearby sources of heat, can cause operating anomalies (increases in condensing

pressure, and consequently decreases in performance) or the shut-down the machine (due to high pressure).

Reception/Positioning

W3

W1 W2

W4

MN

O

W3

W1 W2

W4

P

W3

W1 W2

W4

"G"

5

9

175299085

5

9

9

7

7

SIZES 302 323 404 464 524 564 614

W1 kg 346 352 355 380 383 386 389

W2 kg 369 399 418 447 454 467 477

W3 kg 313 346 364 395 401 413 423

W4 kg 333 392 428 463 476 499 519

Operating weight kg 1361 1489 1565 1685 1714 1765 1808

Shipping weight kg 1347 1473 1548 1666 1695 1746 1789

SIZES 302 323 404 464 524 564 614

W1 kg 348 354 357 382 384 388 391

W2 kg 375 405 424 453 460 473 483

W3 kg 322 355 373 403 410 422 432

W4 kg 348 407 443 478 491 514 534

Operating weight kg 1393 1521 1597 1716 1745 1797 1840

Shipping weight kg 1378 1504 1579 1697 1726 1777 1820

Page 15

13

®

Residual Risks

- RESIDUAL RISKS -

SAFETY INSTRUCTIONS

CAUTION

THIS BULLETIN DESCRIBES EVERY OPERATION THAT MAY CAUSE A SITUATION OF RISK, AS WELL AS THE

PRECAUTIONARY MEASURES TO BE HEEDED IN EACH CASE

The figure below highlights the area in which only authorised personnel may operate.

- External danger zone, identified by a precise area around the unit and its vertical projection on the ground in the case of

hanging unit.

- Internal danger zone, identified by the area that can be entered only after having intentionally removed the protecting panels or parts

of these.

DEFINITION OF DANGER AREA

- WARNING: if used improperly may lead to serious injury

To avoid injury to the user, third parties or the authorised personnel and damage to property, the following instructions MUST be

heeded; incorrect use due to these instructions being neglected may cause damage or injury, the seriousness of which is classified

according to the following symbols:

SAFETY PRESCRIPTIONS

- PROHIBITION: may damage the appliance and consequently the health of the user

- DANGER: may lead to serious injury, death, etc.

WARNING!

- Always contact authorised personnel for the maintenance and repair of this appliance. Contact a qualified installer for

the installation. This appliance has not been designed to be used by children or incapable people without supervision.

Keep out of the reach of the children and their games.

- Use only suitable components for the maintenance operations. The use of defective components may cause injuries or water leaks,

fires, electric shock, falls involving the unit and/or the appliance, …

- Use the specified wires for connecting the appliance to the electrical system and properly connect the cables to the connection

sections so that the stress from the wires not is applied to the sections. Incomplete or insecure connections may cause fires.

- Always contact authorised personnel for the maintenance and repair of this appliance. Contact a qualified installer for the installation.

This appliance has not been designed to be used by children or incapable people without supervision. Keep out of the reach of the

children and their games.

Page 16

14

®

- Installation must be performed following all the safety standards, with reference to the installation manual. Incomplete

or incorrect installation may cause serious personal injury, as the result of fire, electric shock, the falling of the unit or

water leaks.

- Avoid accidental contact with the compressors and outlet tubing, as this may cause burns and injuries. Always use protective gloves.

- Avoid entering the danger zone. Use appropriate clothing and glasses. The expelling of the refrigerant gas due to the activation of

the fuse plug or the safety valves may cause injuries and intoxication.

- Incorrect installation may cause water leaks, electric shocks or fires; contact an authorised reseller or specialised installer, keeping in

mind that faults caused by incorrect installation are not covered by warranty. The units must be installed in an easily accessible site:

any additional costs resulting from the hire of special equipment for the maintenance of the unit are completely at the customer’s

expense.

- Do not use the switch with wet hands. This may cause electric shocks.

- Never clean the appliance using water. This may penetrate into the unit and damage the insulation, and possibly cause electric

shocks.

- Do not insert objects in the air outlets or inlets. As the fan works at high speed, this may cause injuries or damage the unit.

- Securely fasten the cover of the unit’s electrical components. Failure to fasten the cover properly may lead to fires and electric

shock, due to dust, water, ...

- Use protective gloves to avoid injury due to contact with sharp edges.

- Never place a combustion appliance directly below the flow of air to the appliance. This may have negative affects on the

combustion process.

- Keep pets and plants away from the flow of air. They may be injured or damaged.

- Never touch the ventilation fins when the appliance is in operation. The blades may cause injuries.

- Carefully check that the unit is secured to the ground to avoid injury due to the unit tipping over.

DANGER!

- Never leave any compressor outlet and inlet valves closed when the machine is off. This may cause explosion due to an increase in

the room temperature (fires), with the consequent possibility of injuries, intoxication, serious burns, death.

- Securely install the appliance at a point that is able to support the entire weight of the appliance. Installation at points that are not

sufficiently secure may cause the appliance to fall and consequently cause possible injury and damage.

Residual Risks

R-407C

IDENTIFYING ELEMENTS FOR THE SUBSTANCE

- Product name: forane 407C N°SDS 01965/1

- Supplier: ELF ATOCHEM ITALIA, Via G.Murat 17, 20159 Milano tel. 02/668111

COMPOSITION

Chemical nature of the compound: mixture based on:

- Forane 32(difluoromethane) (N° CAS: 75-10-5)

- Forane 125 (pentafluoroethane) (N° CAS: 354-33-6)

- Forane 134a (1.1.1.2 tetrafluoroethane) (N° CAS: 811-97-2)

REFRIGERANT SAFETY CHARTS

- Avoid accidental contact with the exchanger coils, by always using protective gloves and applying the special protective grilles.

Contact may cause minor injuries.

- In the case of anomalies (burning smell, smoke) stop the appliance and turn off the automatic switch. Continuing to operate the unit

in abnormal conditions may cause fire, damage, etc. Contact the manufacturer’s authorised service centre.

- Check that there are no refrigerant gas leaks once installation has been completed.

- Do not install the appliance in sites where there are sporadic or possible leaks of flammable gas. If gas accumulates in

the area surrounding the unit, explosions may occur.

- Never turn the unit on or off using the mains switch. This may cause electric shock or fires due to the generation of heat.

- Make sure the main isolator switch is open and padlocked before removing guards, in that contact with the live parts that are

accessible after having removed the guards may cause death by electrocution or serious burns.

- Pay special attention when earthing the metal earth of the machine, making sure that the metal earth is not live and may thus cause

death by electrocution.

- No repairs may be performed by the customer. Carrying out such operations incorrectly may lead to fires, electric shock,

injuries from the unit falling, water leaks, etc. Contact the manufacturer’s authorised service centre.

- Pay special attention to the correct sizing of the cables and the protection devices on the mains power connection line, so as to avoid

possible fires due to short circuits or the overheating of the cables upstream of the machine’s isolator switch, which may cause death

by serious burns and intoxication.

PROHIBITIONS

Page 17

15

®

Residual Risks

IDENTIFICATION OF RISK

Greatest physical and chemical dangers:

- Thermal decomposition in toxic and corrosive products

FIRST-AID MEASURES

General information:

- Inhalation: Carry the victim into the open air. Resort to oxygen or artificial respiration if necessary.

- Contact with skin: Frostbite must be treated in the same way as burns.

- Contact with the eyes: Immediate rinsing in abundant water. If irritation should continue, consult an ophthalmologist.

- Medical instructions: Do not administer catecholamines (due to the cardiac sensitisation caused by the product).

FIRE PREVENTION MEASURES

- Specific dangers: Thermal decomposition into toxic and corrosive products. Hydrofluoric acid. Carbon monoxides.

- Specific means of intervention: Cool containers/cisterns with jets of water. Prevent any sparks or flames.

- Do NOT smoke.

- Special protection systems for fire-fighting squads: Carry breathing apparatus and wear protective clothing.

MEASURES TO TAKE IN CASE OF ACCIDENTAL SPILLAGE

- Individual precautions: Avoid contact with the skin, eyes and inhalation of vapours. Use personal protection devices.

- In an enclosed space: ventilate or use breathing apparatus (risk of suffocation). NO SMOKING ALLOWED.

- Precautions for environmental protection: Minimise the amount of waste deposited in the environment.

MANIPULATION AND STORAGE

- Technical measures/precautions: Form of storage and manipulation applicable to the products: PRESSURIZED GAS. Ensure

adequate ventilation and evacuation for the level of equipment.

- Advice for use: Prevent sparks and contact with hot surfaces. DO NOT SMOKE.

- Technical measures/Storage procedures: Store at room temperature in the original container. Keep away from flames, hot surfaces

and sparks. Store in a cool, well-ventilated place. Protect full containers from sources of heat to avoid excessive pressures.

- Recommended: Ordinary steel.

- Avoid: Alloy containing more than 2% magnesium. Plastics.

CONTROL OF INDIVIDUAL EXPOSURE/PROTECTION

- Precautionary measures to be taken: Ensure a sufficient exchange of air and/or suction in workplaces.

- Control parameters.

Exposure limits: There is no F-USA limit value

Forane 134a Elf recommended limit value: VME=1000ppm

Forane 32 Elf recommended limit value: VME=1000ppm

Forane 125 Elf recommended limit value: VME=1000ppm

- Protections:

Respiratory protection: In case of insufficient ventilation, carry suitable breathing apparatus.

Protection for the hands: Gloves

Protection for the eyes: Protective eyewear.

PHYSICAL AND CHEMICAL PROPERTIES

- Physical state (20°C): liquid gas

- Colour: colourless

- Smell: Slightly similar to ether; pH: not applicable.

- Boiling point/interval: -42,4 °C

- Melting point/interval: Not inflammable in test conditions

- Vapour pressure: (25°C): 1.13 Mpa (11,3 bar) a (50°C): 2.11 Mpa (21,1 bar) a (70°C): 3.26 Mpa (32,6 bar)

- Vapour density: At boiling point 4,54 kg/m3

- Density: (25°C) 1133 kg/m3 a (50°C) 1004 kg/m3 a (70°C) 861 kg/m3

STABILITY AND REACTIVITY

- Conditions to avoid: Avoid contact with flames and red-hot metal surfaces.

- Dangerous decomposition products: Thermal decomposition into toxic and corrosive products: Toxic fluorinates Hydrogen fluoride

(hydrofluoric acid) .

- Further information: Product stable in normal storage and handling conditions.

TOXICOLOGICAL INFORMATION

- Inhalation: Practically non-toxic in experiments conducted on animals Forane 134a, 32, 125. No rat mortality at 500000 ppm/4h. As

with other volatile aliphatic halogenated compounds, with the accumulation of vapours and/or the inhalation of large quantities, the

product can cause: loss of consciousness and heart problems aggravated by stress and lack of oxygen; risk of death.

- Contact with skin: Frostbite possible from splashes of liquefied gas.

- Chronic toxicity: Studies on extended inhalation in animals have not highlighted any sub-chronic toxic effect (rat/3 months/

Inhalation:50000ppm).

- Specific effects: Genotoxicity, according to experimental data available Forane 134a, 32, 125 NOT Genotoxic.

- Carcinogenic effect: Forane 134a experiments on animals have not demonstrated a clear cancerogenous effect (rat /oral inhalation)

- Toxicity for reproduction: Foetal development Forane 134a, 32, 125. according to available data there are no toxic effects for foetal

development. Fertility, according to available data for animals: Forane 134a no effect on fertility (mice/inhalation) .

ECOLOGICAL INFORMATION

Forane 32

- Durability/degradability: Not easily biodegradable in water: 5% after 28d

- Bioaccumulation: Practically non-absorbable by biological organisms log pow 0,21

Forane 125

- Mobility: Rapid evaporation t ½ life 3,2 h (estimated)

- Durability/degradability: Not easily biodegradable in water: 5% after 28 days. In the atmosphere degradation at rate of 1/2 life in 28,3

Page 18

16

®

y (estimated). . Potential for destruction of ozone ODP (R-11 = 1)=0. Potential greenhouse effect (GWP): (HGWP) = 0,58. Low

absorption in ground and sediments log Koc= 1,3-1,7

- Bioaccumulation: Practically non-absorbable by biological organisms log pow 1,48

Forane 134a

- Mobility: Rapid evaporation t ½ life 3 h (estimated)

- Durability/degradability: Not easily biodegradable in water: 3% after 28 days. In the atmosphere degradation at rate of 3% after 28

days (estimated). Potential for destruction of ozone ODP (R-11 = 1)=0. Potential greenhouse effect (GWP): (HGWP) = 0,26.

- Bioaccumulation: Practically non-absorbable by biological organisms log pow 1,06

NOTES CONCERNING DISPOSAL

Disposal of product: recycle or give to a centre specialized in disposal.

INFORMATION ON SHIPPING

Consult the ELF ATOCHEM safety service for supplementary information and updates

ONU number 3163. RID/ADR class 2 figure (and letter) 4° a

Regulations: No. danger/No. material 20/3163 label 2

IMDG class 2.2 ONU (IMDG) 3163

Regulations: 2.2 /2 label

IATA class 2.2 ONU (IATA) or No.ID 3163

Regulations: 2.2 /2 label

INFORMATION ON REGULATION

EEC directives

Security reports: D.91/155/CEE modified by D.93/112/CEE: Dangerous substances

Classification/CE mark

Dangerous manufactured compounds: Not classified as dangerous

Inventory: EINECS compliant

OTHER INFORMATION

Recommended uses: low-temperature coolant

Bibliographical references: Encyclopedie des gas (Air Liquide-ed.1976- ELSEVIER AMSTERDAM)

R-22

IDENTIFYING ELEMENTS FOR THE SUBSTANCE

- Product name: forane 22 N°SDS 0005/7

- Supplier: ELF ATOCHEM ITALIA, 4 cours Michelet Cedex 42, 92091 Paris, France. Tel: 00331 49.00.80.80

INFORMATION CONCERNING COMPOSITION OF COMPONENTS

Chemical nature of the compound: Mixture based on:

- Chlorodifluoromethane halogenated hydrocarbon N° CAS 75-45-6 EINECS 200-871-9

IDENTIFICATION OF RISK

- Effects on health: practically non-toxic

- Greatest physical and chemical dangers: Thermal decomposition in toxic and corrosive products

- Specific dangers/CEE: Dangerous for the ozone layer.

FIRST-AID MEASURES

General information:

- Inhalation: Carry the victim into the open air. Resort to oxygen or artificial respiration if necessary.

- Contact with skin: Frostbite must be treated in the same way as burns.

- Contact with the eyes: Immediate rinsing in abundant water. If irritation should continue, consult an ophthalmologist.

FIRE PREVENTION MEASURES

- Specific dangers: Thermal decomposition into toxic and corrosive products. Hydrofluoric acid. Hydrochloric acid in gaseous form.

Phosgene Carbon monoxides (CO).

- Specific means of intervention: Cool containers/cisterns with jets of water. Prevent any sparks or flames.

- Do NOT smoke.

- Special protection systems for fire-fighting squads: Carry breathing apparatus and wear protective clothing.

MEASURES TO TAKE IN CASE OF ACCIDENTAL SPILLAGE

- Individual precautions: Avoid contact with the skin, eyes and inhalation of vapours.

- In an enclosed space: ventilate or use breathing apparatus (risk of suffocation). NO SMOKING ALLOWED.

- Remove all risk of sparks or flames.

MANIPULATION AND STORAGE

- Technical measures/precautions:Form of storage and manipulation applicable to the products: PRESSURIZED GAS. Ensure

adequate ventilation and evacuation for the level of equipment.

- Advice for use: Prevent sparks and contact with hot surfaces. DO NOT SMOKE.

- Technical measures/Storage procedures: Store at room temperature in the original container. Keep away from flames, hot surfaces

and sparks. Store in a cool, well-ventilated place. Protect full containers from sources of heat to avoid excessive pressures.

- Recommended: Ordinary steel.

- Avoid: Alloy containing more than 2% magnesium. Plastics.

CONTROL OF INDIVIDUAL EXPOSURE/PROTECTION

- Precautionary measures to be taken: Ensure a sufficient exchange of air and/or suction in workplaces.

- Control parameters.

Exposure limits:

Residual Risks

Page 19

17

®

France 1989: VME = 1000

USA 1992: TWA = 1000 p.p.m. = 3500 mg/m3

- Individual protective equipment:

Respiratory protection: In case of insufficient ventilation, carry suitable breathing apparatus.

Protection for the hands: Gloves

Protection for the eyes: Protective eyewear.

- Specific hygiene measures: avoid contact with the skin, eyes and inhalation of the vapours.

PHYSICAL AND CHEMICAL PROPERTIES

- Physical state (20°C): liquid gas

- Colour: colourless

- Smell: Slightly similar to ether; pH: not applicable.

- Boiling point/interval: -40.8 °C

- Melting point/interval: -160 °C

- Decomposition temperature: 480 °C

- Vapour pressure: (20 °C) 0.91 Mpa (9.1 bar); at 50 °C: 1.91 Mpa (19.4 bar)

- Vapour density: (20° C) 3.57 kg/m3

- Solubility: water (25 °C) 3g/l - solvent soluble in hydrocarbons and chlorinated solvents, alcohols, ketones, esters.

- Solubility of water in the product at 30° C: 0.15% in weight.

STABILITY AND REACTIVITY

- Conditions to avoid: Avoid contact with flames and red-hot metal surfaces.

- Dangerous decomposition products: Thermal decomposition into toxic and corrosive products: hydrofluoric acid, hydrochloric acid in

gaseous form, phosgene, car-bon monoxide (CO)

TOXICOLOGICAL INFORMATION

- Inhalation: Practically non-toxic in experiments conducted on animals. No effect below 50,000 p.p.m.

- As with other volatile aliphatic halogenated compounds, with the accumulation of vapours and/or the inhalation of large quantities,

the product can cause: loss of con-sciousness and heart problems aggravated by stress and lack of oxygen; risk of death.

- Contact with skin: Frostbite possible from splashes of liquefied gas.

- Contact with the eyes: Temporary irritation.

ECOLOGICAL INFORMATION

- Mobility: Rapid evaporation: 1/2 life 2.7 h.

- Durability/degradability: Not easily biodegradable in water: 0% after 28 days. In the atmosphere degradation at rate of 1/2 life in 14

years. Potential for destruction of ozone ODP (R-11 = 1) = 0.055. Potential greenhouse effect (HGWP) - 0.36. Low absorption in

ground and sediments log Koc = 1.8.

- Bioaccumulation: Practically non-absorbable by biological organisms: log pow 1.08.

- Aquatic toxicity: Acute toxicity, level of toxicity for fish over 24 hours = 180 mg/l; for anaerobic bacteria, level of toxicity over 24 hours

> 400 mg/l.

NOTES CONCERNING DISPOSAL

Disposal of product: recycle or give to a centre specialized in disposal.

INFORMATION ON SHIPPING

ONU number 1018. RID/ADR class 2 figure (and letter) 3° a

Regulations: No. danger/No. material 20/1018 label 2

IMDG class 2.2 ONU (IMDG) 1018

Regulations: NON INFLAMMABLE GAS/2 label

IATA class 2.2 ONU (IATA) or No.ID1018

Regulations: NON INFLAMMABLE GAS/2 label

Product code: 00055/7

INFORMATION ON REGULATION

EEC directives

Security reports: D.91/155/CEE modified by D.93/112/CEE: Dangerous substances and manufactured compounds

Dangerous manufactured compounds: D.67/548/CEE modified by D.93/21/CEE: Guide to labelling (18th APT).

R59 Dangerous for the ozone layer S59 Consult producer/supplier for information concerning recovery and recycling.

S61 Do not dump. Consult specific instructions and safety information.

OTHER INFORMATION

Recommended uses: low-temperature coolant, Freezing agent, Air conditioning.

Bibliographical references: Encyclopédie des gas (Air liquide-ed. 1976 - ELSEVIER AMSTERDAM).

INRS toxicological report: No. 142 CHLOROFLUOROMETHANE

This document refers to the product as is, in accordance with the specifications supplied by ELF ATOCHEM.

If combinations or mixtures are made, check that there are no new dangers resulting from this action. The information provided in this

report has been provided in good faith and is based on our latest knowledge of the product in question as of the date of publication of

the same. The attention of users is drawn to the potential risks of employing the product for any use other than that for which it is

intended. This report must be used and reproduced solely for purposes of prevention and safety. The list of legislative, regulatory or

administrative texts must not be considered exhaustive. The user is obliged to refer to all the official texts concerning the use,

conservation and manipulation of the product for which he or she is solely responsible. The user of the product must also provide all

those who might come into contact with the product with the information necessary for their working safety and the protection of their

health and that of the environment, by giving them a copy of this safety chart.

Residual Risks

Page 20

18

®

DISCONNECTING THE UNIT

- DECOMMISSIONING OF THE UNIT -

- The units must be disconnected by authorised personnel, who before proceeding must first read the Residual Risks section in this

manual.

- Before disconnecting the unit, the following must be recovered, if present:

1. the refrigerant (if the circuits cannot be isolated): the refrigerant must be removed using suction devices operating in a closed

circuit, so as to ensure that none of the compound is released into the atmosphere.

2. the antifreeze in the circuits: when removing this fluid, make sure than none leaks or is released into the environment. The

antifreeze fluid must be stored in special containers.

IMPORTANT:

When recovering the substances present in the unit, all measures must be taken to avoid damaging persons and things and polluting

the surrounding area.

- Awaiting dismantling and disposal, the unit can also be stored outdoors, as bad weather and rapid changes in temperature will not

cause damage to the environment.

DISMANTLING AND DISPOSAL

- THE UNIT MUST ALWAYS BE SENT TO AUTHORISED CENTRES FOR DISMANTLING AND DISPOSAL.

- When dismantling the unit, the fan, the motor and the coil, if operating, may be recovered by the specialist centres for

reuse.

NOTE:

For further information on the decommissioning of the unit, contact the manufacturer.

Decommissioning of the unit

- All the materials must be recovered or disposed of in compliance with the corresponding national standards in force.

Page 21

19

®

GENERAL

- WAT ER /AERAULIC CONNECTIONS -

Install ON/OFF valves next to the parts that are subject to maintenance. This allows their replacement without having to empty the

system.

The pipework must be designed with the minimum possible difference in height. Install automatic or manual vents in the high points of

the piping to allow the outlet of the air in the circuit. The system can be kept at the right pressure by means of an expansion vessel or

of a combined pressure reduction-discharge valve.

All the water pipes must be insulated in order to prevent condensation and heat dispersions along the piping itself. Make sure that the

insulation is vapour seal type.

Check for any leaks in the piping before insulating it. Air-venting and draining connections must protrude outside of the insulation so

as to be accessible.

The weight of the water connections must be adequately supported by the outside of the unit. The fittings on the exchanger must not

be subject to stress.

For units with antivibration mounts, flexible joints must be used for the water connections.

It is suggested to install thermometers, pressure gauges and bleed valves at the inlet/outlet of the unit, as this will help in the routine

checking and maintenance of the unit.

ATTENTION:

The installation of a steel mesh strainer on the inlet of the exchangers must be scheduled in order to protect them from foreign

materials.

Danger of frost.

If the unit and its water connections are subject to temperatures lower than 0°C, specific actions must be taken to avoid frost on the

exchanger and in the corresponding water circuit.

If the unit is fitted with an antifreeze heater (standard oR optional, depending on the model) on the exchanger side, this must always

be powered together with the heaters in the water circuit.

An antifreeze solution can be used (e.g. Ethylene Glycol) in the required percentage (see the Technical bulletin).

The water circuit (including the exchanger) can be drained during for seasonal shut-down.

Carefully check that there are no leaks from the pipes when filling the system.

Water/Aeraulic Connections

If the flow switch is not installed on the unit, it must be fitted in the system.

For units operating in parallel with on-board hydronic assemblies, a non-return valve should be fitted, to prevent the circulation of

water.

UNIT = unit

EXT = exterior

VS = water side safety valve

SPM = water side minimum pressure switch

SF = air vent stop valve

SC = discharge stop valve

P = differential pressure switch

B = water side low temperature switch

VE = expansion tank

V = cock

VSA = automatic air vent

ST = water inlet and outlet probes

F = optional flow switch

PO = pump

A = water side high temperature switch

R = resistor

FI = water side filter

M = manometer

ACC = storage

GRA = filling valve

OPT = optional

SUGGESTED WATER CONNECTION DIAGRAM

Page 22

20

®

EVAPORATOR PRESSURE DROPS (WATER SIDE)

The unit is not available with pressure drops lower than 20kPa.

Water/Aeraulic Connections

EVAPORATOR ANTIFREEZE SOLUTIONS

The correction factors are referred to the water/glycol solution used in order to prevent ice forming in the heat exchanger (water side)

during the seasonal stop.

% ETHYLENE GLYCOL BY WEIGHT

10% 20% 30% 40%

Freezing point °C -3.9 -8.9 -15.6 -23.4

Safety temperature °C 1 -4 -10 -19

Cooling capacity - 0.990 0.981 0.974 0.968

Compr.input power - 0.993 0.988 0.984 0.981

Evaporator glycol solution flow - 1.010 1.033 1.072 1.124

Pressure drop - 1.060 1.118 1.182 1.243

PUMP PERFORMANCE RELATED TO THE EFFECTIVE PLANT HEAD

Pump Type FLA (A) LRA (A) FLI (KW)

PUMP 1 3,1 14.6 1,1

PUMP 2 3.8 19.0 1.5

PUMP 3 5.0 24.8 1.9

PUMP 4 4.9 33.8 2.2

PUMP 5 6.5 44.2 3.0

PUMP 6 8.5 63.8 4.0

If the unit is not supplied with a pumping station, follow what outlined in the picture for the passage of the water inlet and outlet tubes.

Page 23

21

®

WATER FLOW LIMITS

Water/Aeraulic Connections

SIZE

302 323 404 464 524 564 614

Min water flow l/s 3.2 4.1 4.1 4.9 4.9 5.6 5.6

Max water flow l/s 5.6 7.2 7.2 8.5 8.5 9.7 9.7

302 UNIT

Q = water flow

DP = pressure drop

323-404 UNIT

464-524 UNIT

80 kPa

100 kPa

120 kPa

140 kPa

160 kPa

180 kPa

200 kPa

220 kPa

240 kPa

260 kPa

280 kPa

300 kPa

320 kPa

340 kPa

3.0l/s 3.5l/s 4.0l/s 4.5l/s 5.0l/s 5.5l/s 6.0l/s

1 (std

)

2

3

5

6

Q

dP

80 kPa

100 kPa

120 kPa

140 kPa

160 kPa

180 kPa

200 kPa

220 kPa

240 kPa

260 kPa

280 kPa

300 kPa

320 kPa

340 kPa

3.5l/s 4.0l/s 4.5l/s 5.0l/s 5.5l/s 6.0l/s 6.5l/s 7.0l/s 7.5l/s

1 (std)

2

3

5

6

Q

dP

564-614 UNIT

80 kPa

100 kPa

120 kPa

140 kPa

160 kPa

180 kPa

200 kPa

220 kPa

240 kPa

260 kPa

280 kPa

300 kPa

320 kPa

340 kPa

4.5l/s 5.0l/s 5.5 l/s 6 .0l/s 6.5l/s 7.0l/s 7 .5l/s 8.0l/s 8.5l/s 9.0l/s

2 (std)

3

4

5

6

Q

dP

80 kPa

100 kPa

120 kPa

140 kPa

160 kPa

180 kPa

200 kPa

220 kPa

240 kPa

260 kPa

280 kPa

300 kPa

320 kPa

340 kPa

5.5l/s 6.0l/s 6.5l/s 7.0l/s 7.5l/s 8.0l/s 8.5l/s 9.0l/s 9.5l/s 10.0l/s

3 (std)

4

5

6

Q

dP

Page 24

22

®

- ELECTRICAL CONNECTIONS -

GENERAL

IMPORTANT

- BEFORE PERFORMING ANY OPERATIONS ON THE ELECTRICAL SYSTEM, MAKE SURE THAT THE POWER SUPPLY TO

THE UNIT IS ISOLATED AT THE SOURCE.

- FOR ALL OPERATIONS DESCRIBED IN THIS MANUAL, OR IN ANY CASE INVOLVING THE ELECTRICAL SYSTEM, REFER TO

THE WIRING DIAGRAM ENCLOSED WITH THE UNIT; THE CODE OF THE WIRING DIAGRAM IS SHOWN ON THE RATING

PLATE LOCATED IN OR NEXT TO THE ELECTRICAL PANEL.

- THE WIRING DIAGRAM, TOGETHER WITH THIS MANUAL, MUST BE KEPT WITH CARE AND MUST BE MADE AVAILABLE

FOR FUTURE OPERATIONS ON THE UNIT.

- ALL ELECTRICAL CONNECTIONS MUST BE PERFORMED BY PERSONNEL WITH THE NECESSARY LEGAL REQUISITES.

PRELIMINARY OPERATIONS

- Open the main isolator switch.

- If no main isolator switch is

present, check that the isolator device at the origin of the unit’s power supply line is open,

padlocked and fitted with a special sign.

- Check that the characteristics of the mains power conform to the data shown on the rating plate located inside the electrical panel.

CONNECTING THE MACHINE TO THE MAINS POWER SUPPLY

Identify, with the help of the machine’s wiring diagram, the power cable connection terminals L1 - L2 - L3 (N, where present) and the

earth cable connection terminal. (L-N in units with single-phase power supply).

Rate the electrical cut-out devices according to the rules of good practice prescriptions, based on the machine’s electrical data

contained in the technical bulletin, in this manual, and on the machine’s rating plate*.

Size the cross-section of the power cables and earth cable, according to the rules of good practice and the standards in force, based

on the characteristics of the cut-out devices used.

CAUTION:

- The correct sequence of the phases L1, L2, L3 must be followed. Failure to follow the correct sequence may lead, when the machine

is started, to serious malfunctions.

- Before powering the unit, check that all the cut-out devices removed during the electrical connection work have been replaced.

* The presence of any accessories not envisaged on the standard units may change, even slightly, the machine’s electrical data as

shown in the technical bulletin (this in fact refers to the standard unit). For this reason, in the event of discrepancies between the data

on the rating plate and the data provided in this manual or in the technical bulletin, the data on the rating plate must be considered.

FUNCTIONAL CONNECTIONS

IMPORTANT

Refer to the machine’s wiring diagram to identify the terminals and the function of the various connections.

- REMOTE ON/OFF CONTROL

The unit is fitted for connection to a remote device for switching the machine on or off, such as a switch, timer or the contact of a

device in a centralised supervisory system.

The contact must be suitable for the switching of low power loads and voltage free (free contact).

Electrical Connections

The unit’s supply line protection device must be able to cut-off power in the event of an assumed short-circuit, the value of which must

be determined by personnel authorised for design of electrical systems, in accordance with the characteristics of the system.

- CONNECTING THE WATER PUMP CONTROL

If the unit is ordered without an on-board pump, it is fitted for the control of the water pump contactor (free contact, max 24V 1A). This

power must be taken from a transformer with separate primary and secondary windings that complies with the standards in force. The

maximum rated current is 1.1A in Ac11.

The control module manages the operation of the pump with safety logic (different on/off times for the pump and compressor, and

management of the safety devices on the water side).

N.B.

For connection to a CLIVET pumping assembly, the water pump is controlled at 230V, therefore, in the event of

maintenance, isolate both electrical panels. This is an important warning for the safety of the operator.

- FLOW SWITCH/WATER DIFFERENTIAL PRESSURE SWITCH

This is a safety digital input that must be connected to the water flow control device/devices. The standard devices are:

a) A flow switch, fitted with an NO voltage-free contact (open when there is no water flow)

b) A water differential pressure switch, fitted with an NO voltage-free contact (open when there is no pressure difference between the

exchanger inlet/outlet)

If the unit is ordered without an on-board pump, these devices should be fitted in series with a NO contact on the water pump remote

control switch.

IMPORTANT: The installation and correct connection of the water flow control devices is fundamental for the operating safety of the

machine. These devices are necessary even if the unit is already fitted with an internal water differential pressure switch.

Page 25

23

®

- REMOTE MACHINE ALARM SIGNAL

The unit is fitted with a relay that is activated whenever a machine alarm condition arises. The contact of this relay, which is

normally open when no alarm is present, is connected to the two terminals for the remote signal. Refer to the machine’s wiring

diagram.

The voltage that can be applied to these terminals must not exceed 24V. This voltage must be taken from a transformer with separate

primary and secondary windings, in compliance with the legislation in force. The maximum current value is 1.1A at AC11.

Version S / Configuration ST

ELECTRICAL DATA

Electrical Connections

ENABLING THE SECOND SET POINT FROM DIGITAL INPUT

See the wiring diagram supplied with the unit to determine which terminals correspond to this function.

DEMAND LIMIT

See the wiring diagram supplied with the unit to determine which terminals correspond to this function.

SIZE 302 323 404 464 524 564 614

F.L.A. Full load current at max admissible conditions

Compressor 1 400/3/50 [A] 29.8 19.5 19.5 25.3 25.3 29.2 29.8

Compressor 2 400/3/50 [A] 29.8 29.2 19.5 19.5 25.3 25.3 29.8

Compressor 3 400/3/50 [A] - 19.5 19.5 25.3 25.3 29.2 29.8

Compressor 4 400/3/50 [A] - - 19.5 19.5 25.3 25.3 29.8

External fan 400/3/50 [A] 4 4 4 4 4 4 4

Nr. of fans - 2 2 2 3 3 3 3

Pump 400/3/50 [A] 3.1 3.1 3.1 3.8 3.8 5 5

Total 400/3/50 [A] 72.9 81.5 91.3 107.6 119.2 128.1 138.3

L.R.A. Locked rotor current

Compressor 1 400/3/50 [A] 198.0 130.0 130.0 175.0 175.0 175.0 198.0

Compressor 2 400/3/50 [A] 198.0 175.0 130.0 130.0 175.0 175.0 198.0

Compressor 3 400/3/50 [A] - 130.0 130.0 175.0 175.0 175.0 198.0

Compressor 4 400/3/50 [A] - - 130.0 130.0 175.0 175.0 198.0

External fan 400/3/50 [A] 14 14 14 14 14 14 14

Nr. of fans - 2 2 2 3 3 3 3

Pump 400/3/50 [A] 14.6 14.6 14.6 19.0 19.0 24.8 24.8

F.L.I. Full load power input at max admissible conditions

Compressor 1 400/3/50 [kW] 18.8 11.3 11.3 14.5 14.5 17.3 18.8

Compressor 2 400/3/50 [kW] 18.8 17.3 11.3 11.3 14.5 14.5 18.8

Compressor 3 400/3/50 [kW] - 11.3 11.3 14.5 14.5 17.3 18.8

Compressor 4 400/3/50 [kW] - - 11.3 11.3 14.5 14.5 18.8

External fan 400/3/50 [kW] 2.0 2.0 2.0 2.0 2.0 2.0 2.0

Nr. of fans - 2 2 2 3 3 3 3

Pump 400/3/50 [kW ] 1.1 1.1 1.1 1.5 1.5 1.9 1.9

Total 400/3/50 [kW] 43.4 45.7 51.0 59.8 66.2 72.1 83.7

Value 400/3/50 [A] 241.1 207.8 201.8 257.3 268.9 273.9 306.5

M.I.C. Max starting current

Page 26

24

®

Electrical Connections

Version S / Configuration LN

SIZE 302 323 404 464 524 564 614

F.L.A. Full load current at max admissible conditions

Compressor 1 400/3/50 [A] 29.8 19.5 19.5 25.3 25.3 29.2 29.8

Compressor 2 400/3/50 [A] 29.8 29.2 19.5 19.5 25.3 25.3 29.8

Compressor 3 400/3/50 [A] - 19.5 19.5 25.3 25.3 29.2 29.8

Compressor 4 400/3/50 [A] - - 19.5 19.5 25.3 25.3 29.8

External fan 400/3/50 [A] 2.3 2.3 2.3 2.3 2.3 2.3 2.3

Nr. of fans - 2 2 2 3 3 3 3

Pump 400/3/50 [A] 3.1 3.1 3.1 3.8 3.8 5.0 5.0

Total 400/3/50 [A] 69.5 78.1 87.9 102.5 114.1 123.0 133.2

L.R.A. Locked rotor current

Compressor 1 400/3/50 [A] 198.0 130.0 130.0 175.0 175.0 175.0 198.0

Compressor 2 400/3/50 [A] 198.0 175.0 130.0 130.0 175.0 175.0 198.0

Compressor 3 400/3/50 [A] - 130.0 130.0 175.0 175.0 175.0 198.0

Compressor 4 400/3/50 [A] - - 130.0 130.0 175.0 175.0 198.0

External fan 400/3/50 [A] 4.7 4.7 4.7 4.7 4.7 4.7 4.7

Nr. of fans - 2 2 2 3 3 3 3

Pump 400/3/50 [A] 14.6 14.6 14.6 19.0 19.0 24.8 24.8

F.L.I. Full load power input at max admissible conditions

Compressor 1 400/3/50 [kW] 18.8 11.3 11.3 14.5 14.5 17.3 18.8

Compressor 2 400/3/50 [kW] 18.8 17.3 11.3 11.3 14.5 14.5 18.8

Compressor 3 400/3/50 [kW] - 11.3 11.3 14.5 14.5 17.3 18.8

Compressor 4 400/3/50 [kW] - - 11.3 11.3 14.5 14.5 18.8

External fan 400/3/50 [kW] 1.25 1.25 1.25 1.25 1.25 1.25 1.25

Nr. of fans - 2 2 2 3 3 3 3

Pump 400/3/50 [kW ] 1.1 1.1 1.1 1.5 1.5 1.9 1.9

Total 400/3/50 [kW] 41.9 44.2 49.5 57.5 63.9 69.9 81.5

Value 400/3/50 [A] 237.7 204.4 198.4 252.2 263.8 268.8 301.4

M.I.C. Max starting current

Page 27

25

®

GENERAL

ALL THE EQUIPMENT MUST BE COMMISSIONED BY AUTHORISED SERVICE CENTRES.

THIS SERVICE IS LIMITED TO START-UP OF THE UNIT ONLY AND NOT THE CONNECTIONS OR INSTALLATION OF THE

SYSTEM

PRELIMINARY CHECKS

BEFORE PERFORMING ANY TYPES OF CHECKS, MAKE SURE THAT THE UNIT IS PROPERLY INSTALLED AND CONNECTED

PRELIMINARY CHECKS: ELECTRICAL SYSTEM

CAUTION: Before performing the checks described below, make sure that the unit’s electrical power line is disconnected at the

source. Check that the isolator device is padlocked or hat the handle has been applied with a special sign caution against operation.

Before performing the electrical connections, check that no voltage is present using a voltmeter or phase indicator.

CHECKS TO BE PERFORMED WITH ELECTRICAL POWER DISCONNECTED:

- Check that the cross-section of the electrical power cables is suitable for the load of the entire unit (see the section on electrical

connections in the manual).

- Check that the unit has been earthed (see the section on electrical connections in the manual).

-· Check that the screws that fasten the wires to the electrical components in the panel are tight, to ensure adequate electrical contact

(during handling and transport vibrations may have loosened the screws).

At this point, the unit can be electrically powered by closing the isolator device installed upstream of the power line. CAUTION: Before

performing this operation, check that all the cut-out devices on the unit have been reset.

- Place the handle of the unit’s mains isolator device / circuit-breaker in the on position.

- Check that the electronic board / display on the terminal turn on (after a few seconds)

- Check that the unit is off (see the section on "Control" in the manual)

CHECKS TO BE PERFORMED WITH ELECTRICAL POWER CONNECTED:

- Check the value of the mains voltage supplied to the unit, which must fall within the following limits:

230 +/- 6%, single-phase units

400 +/- 6%, three-phase units

-·Check the unbalance of the phases. This must be lower than a maximum value of 2% (see calculation example).

Calculation example:

L1 - L2 = 398

L2 - L3 = 405

L3 - L1 = 395

The average of the values measured is calculated as follows:

(398+405+395)/3=399.3

The maximum deviation from the average is thus:

405-395=10V

The unbalance is thus:

(10/399.3) x 100 = 2.5% (non acceptable)

If compressor crankcase heaters are present, when starting the unit for the first time and after each extended shut-down, the heaters

that heat the compressor crankcase oil should be operated for at least 8 hours before starting the compressor.

CAUTION: IF THE CRANKCASE HEATERS ARE PRESENT, DO NOT START THE COMPRESSOR WITH THE CRANKCASE OIL

BELOW OPERATING TEMPERATURE. (THE TEMPERATURE OF THE COMPRESSOR CASING ON THE LOWER SIDE MUST BE

AT LEAST 10°C HIGHER THAN THE OUTSIDE TEMPERATURE).

The units are activated according to the phases described below:

1 - Close the circuit breakers or the isolating switch on the unit.

2 - The unit will not start operating until the operating mode is selected on the keypad, therefore, as seen in the diagram, the

crankcase heater will be powered only for the time required to allow the compressor to reach the desired temperature.

Start-up

- START- UP -

PRELIMINARY CHECKS: REFRIGERANT CIRCUIT

- Visually check the refrigerant circuit. Any oil leaks may have been caused during transport.